Page 1

Model Nos.

Modèles n°

Modellnummern

Números de modelo

Modelli n°

75211-2075211-20

75211-20

75211-2075211-20

75211-2575211-25

75211-25

75211-2575211-25

OPERATING MANUAL

VV

ARIABLE-SPEED GEARARIABLE-SPEED GEAR

V

ARIABLE-SPEED GEAR

VV

ARIABLE-SPEED GEARARIABLE-SPEED GEAR

PUMP DRIVE SYSTEMPUMP DRIVE SYSTEM

PUMP DRIVE SYSTEM

PUMP DRIVE SYSTEMPUMP DRIVE SYSTEM

NOTICE D’UTILISATION

SYSTÈMESYSTÈME

SYSTÈME

SYSTÈMESYSTÈME

D’ENTRAÎNEMENT DED’ENTRAÎNEMENT DE

D’ENTRAÎNEMENT DE

D’ENTRAÎNEMENT DED’ENTRAÎNEMENT DE

POMPE À VITESSEPOMPE À VITESSE

POMPE À VITESSE

POMPE À VITESSEPOMPE À VITESSE

VV

ARIABLEARIABLE

V

ARIABLE

VV

ARIABLEARIABLE

BEDIENUNGSANLEITUNG

ZAHNRADPUMPENSYSTEMZAHNRADPUMPENSYSTEM

ZAHNRADPUMPENSYSTEM

ZAHNRADPUMPENSYSTEMZAHNRADPUMPENSYSTEM

MIT REGELANTRIEBMIT REGELANTRIEB

MIT REGELANTRIEB

MIT REGELANTRIEBMIT REGELANTRIEB

MANUAL DE OPERACIÓN

SISTEMA DE IMPULSIÓNSISTEMA DE IMPULSIÓN

SISTEMA DE IMPULSIÓN

SISTEMA DE IMPULSIÓNSISTEMA DE IMPULSIÓN

DE BOMBA DEDE BOMBA DE

DE BOMBA DE

DE BOMBA DEDE BOMBA DE

ENGRANAJES DEENGRANAJES DE

ENGRANAJES DE

ENGRANAJES DEENGRANAJES DE

VELOCIDAD VVELOCIDAD V

VELOCIDAD V

VELOCIDAD VVELOCIDAD V

MANUALE DI ISTRUZIONE

SISTEMA DISISTEMA DI

SISTEMA DI

SISTEMA DISISTEMA DI

AZIONAMENTO DELLAAZIONAMENTO DELLA

AZIONAMENTO DELLA

AZIONAMENTO DELLAAZIONAMENTO DELLA

ARIABLEARIABLE

ARIABLE

ARIABLEARIABLE

POMPPOMP

POMP

POMPPOMP

A VELOCITÀ VA VELOCITÀ V

A VELOCITÀ V

A VELOCITÀ VA VELOCITÀ V

1-800-MASTERFLEX (627-8373) (U.S. and Canada only) • 11 (847) 549-7600 (Outside U.S.)

(847) 549-7600 (Local) • www.masterflex.com • techinfo@coleparmer.com

Thermo Fisher Scientific

1-800-637-3739 (U.S. and Canada only) • 11 (847) 381-7050 (Outside U.S.)

(847) 381-7050 (Local) • www.thermoscientific.com • fluidhandling@thermoscientific.com

A A INGRANAGGIA A INGRANAGGI

A A INGRANAGGI

A A INGRANAGGIA A INGRANAGGI

ARIABILEARIABILE

ARIABILE

ARIABILEARIABILE

A-1299-0857

Edition 04

Page 2

Page 3

TABLE OF CONTENTS

Title Page

SAFETY PRECAUTIONS .................................................................................................................................. 2

INTRODUCTION................................................................................................................................................ 3

READOUTS AND CONTROLS.......................................................................................................................... 3

APPLICATIONS DATA ........................................................................................................................................ 4

DESCRIPTION................................................................................................................................................... 4

INSTALLATION/SETUP ..................................................................................................................................... 5

OPERATION ...................................................................................................................................................... 6

TROUBLESHOOTING AND MAINTENANCE ................................................................................................... 6

Troubleshooting .............................................................................................................................................. 6

Motor Brush Check/Replacement .................................................................................................................. 7

Fuse Replacement ......................................................................................................................................... 7

Cleaning the Drive/Controller System ............................................................................................................ 7

Replacement Parts ........................................................................................................................................ 8

SPECIFICATIONS ............................................................................................................................................. 8

WARRANTY....................................................................................................................................................... 9

PRODUCT RETURN .......................................................................................................................................... 9

TECHNICAL ASSISTANCE ............................................................................................................................... 9

MICROPUMP — Reg TM Micropump Inc., a division of Idex Corp.

RYTON — Reg TM Chevron Phillips Chemical Company, L.L.C.

VITON — Reg TM E.I. duPont DeNemours & Co.

Trademarks bearing the ® symbol in this publication are registered in the U.S. and in other countries.

1

Page 4

SAFETY PRECAUTIONS

DANGER: High voltages exist and are accessible in the Drive/Controller. Do not remove cover.

WARNINGS:Disconnect the AC power input line cord before connecting the drive motor cable.

No user-serviceable parts are inside of this instrument. Refer servicing to your dealer.

CAUTIONS: To prevent damage to pump, do not restrict pump inlet or run the pump dry.

Be sure available power matches unit requirements. Units are either 115V 50/60 Hz or 230V 50/60 Hz.

WARNING: PRODUCT USE LIMITATION

This product is not designed for, nor intended for use in, patient-connected applications, including, but not limited

to, medical and dental use and, accordingly, has not been submitted for FDA approval.

2

Page 5

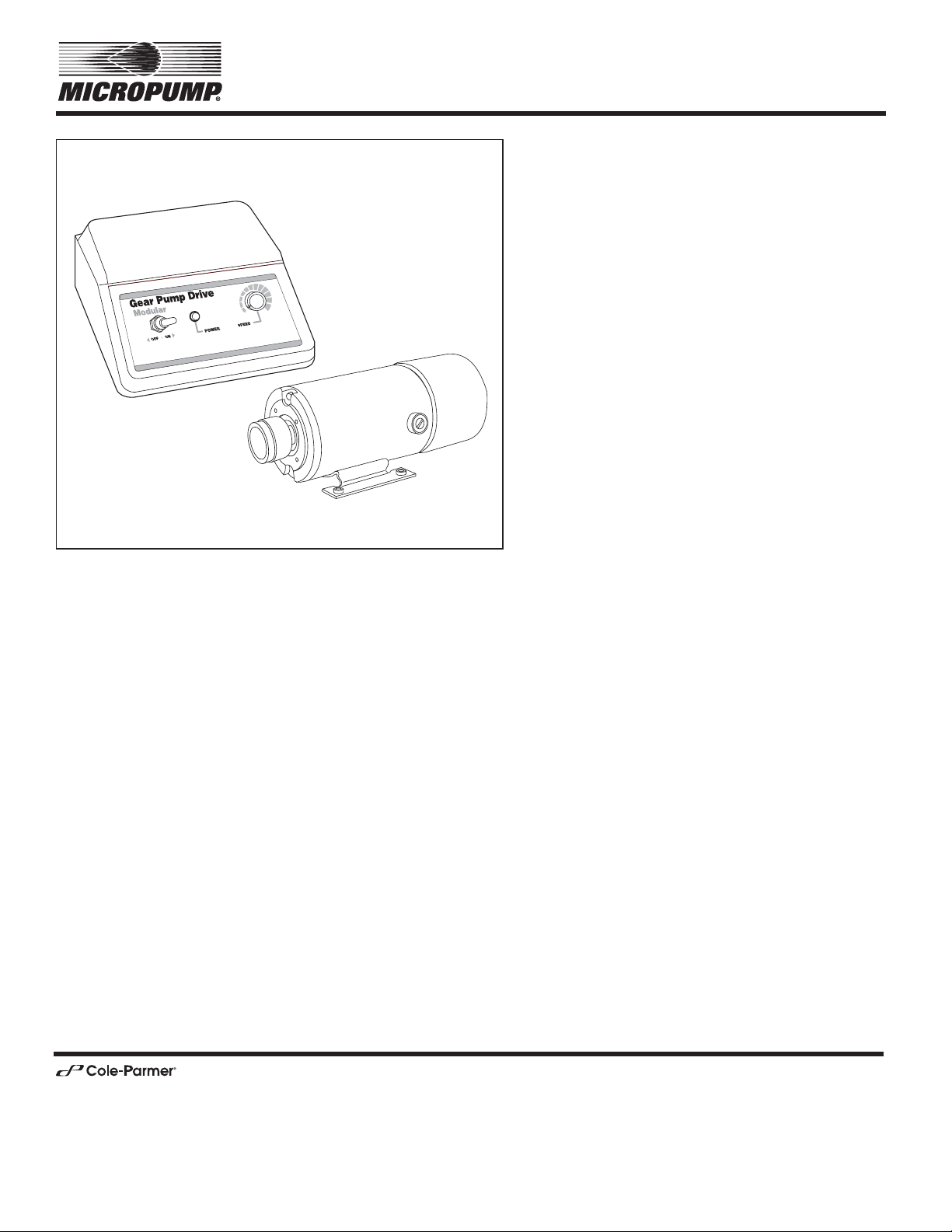

INTRODUCTION

Each of these Motor/Controller Systems incorporates a high-torque magnetic coupler and a

0.1 horsepower DC motor, designed for driving MICROPUMP® Pump Heads. The motor is extremely quiet in operation,

has long brush life, has increased torque at high speeds, is totally enclosed and permanently lubricated. The Motor/

Controller System automatically compensates for changes in load torque demands. Utilizing an electronic control

circuit, the Controller assures accurate, dependable motor speed (flow) control with “soft start” and smooth gradual

acceleration to the speed setting. Motor current limiting protects the system in case of a locked rotor condition and

assures magnetic lock over wide load variations. Output circuit protection protects against inadvertent output shorting.

Built-in motor current compensation minimizes no-load to full-load speed variation. Excellent speed regulation and

improved line noise immunity, even with line voltage and load variations, is designed into the electronic control.

Drive Catalog Power Requirement*

Number

75211-20 90 to 130V AC

75211-25 200 to 260V AC

*AC voltage can be either 50 or 60 Hz.

Included in this manual are Application, Description, Installation/Setup, Operation, Troubleshooting and Maintenance

and Specification Data.

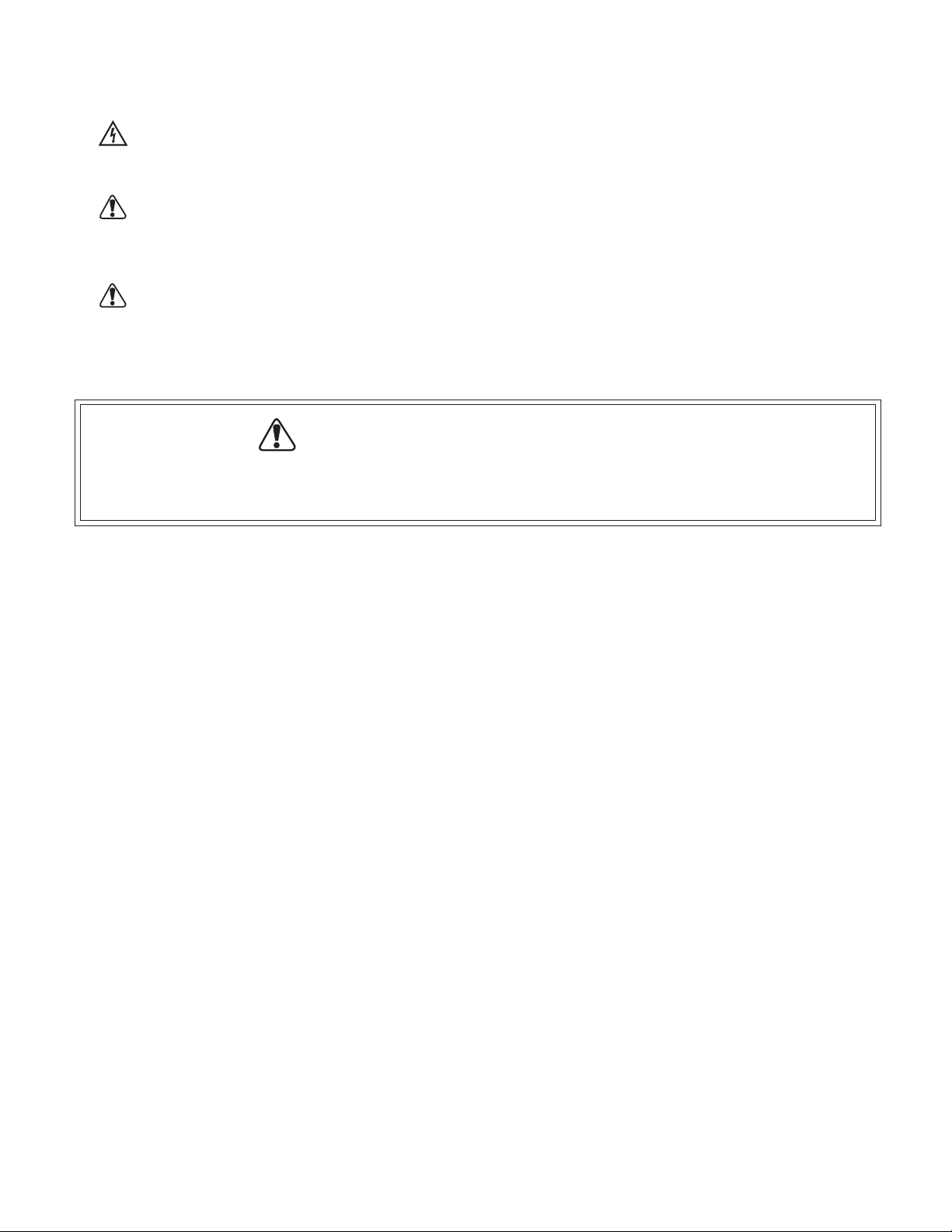

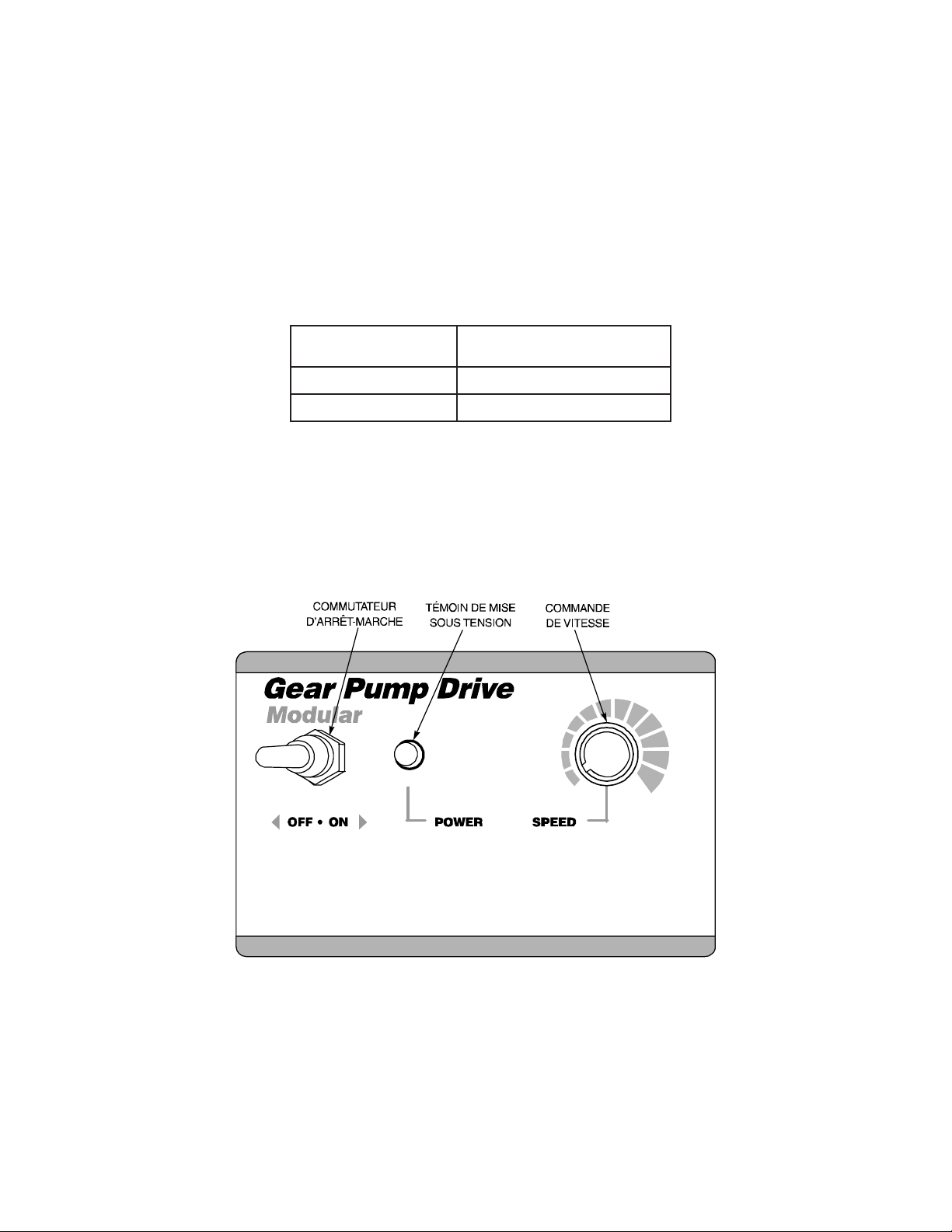

READOUTS AND CONTROLS

3

Page 6

Mfg. by Thermo Fisher Scientific

Mfg. by Thermo Fisher Scientific

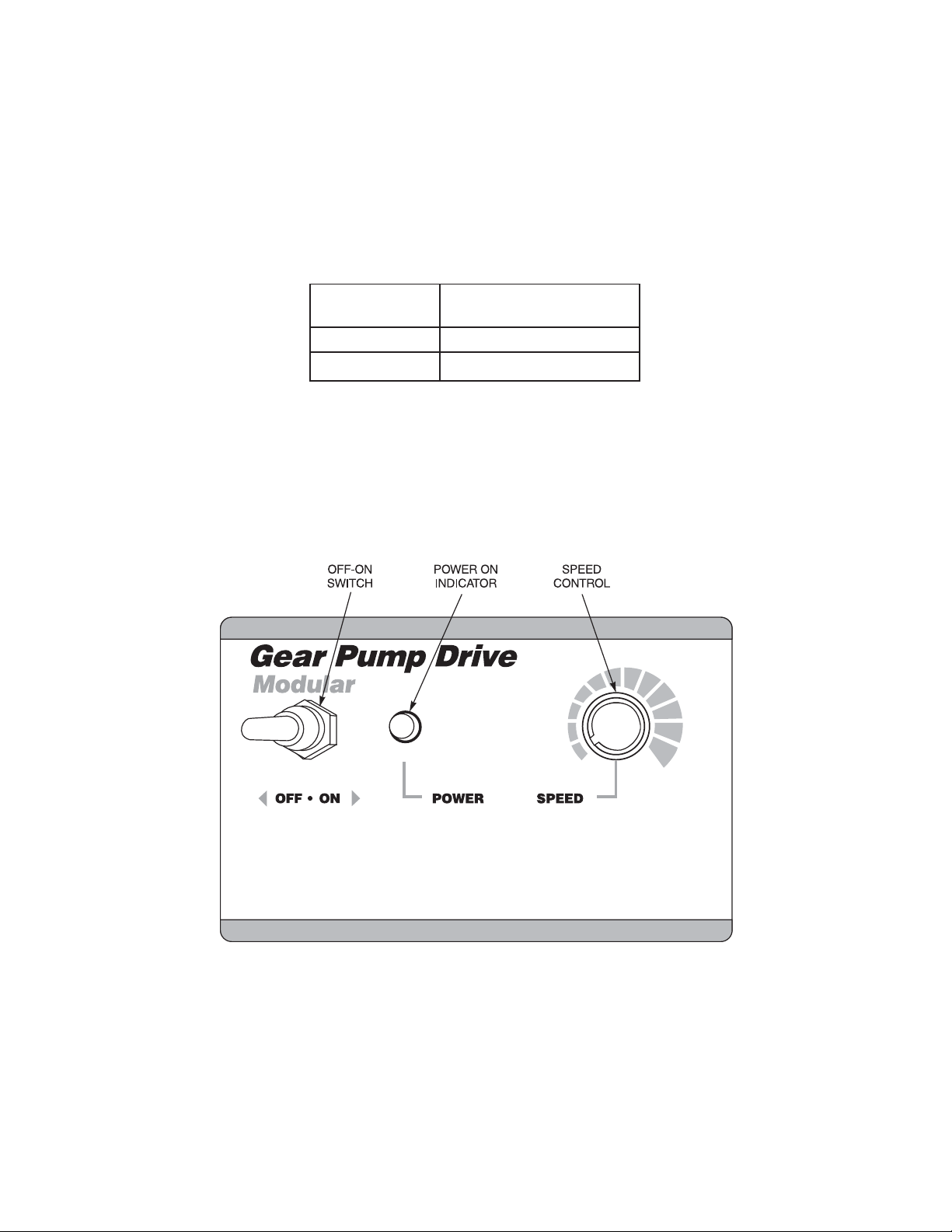

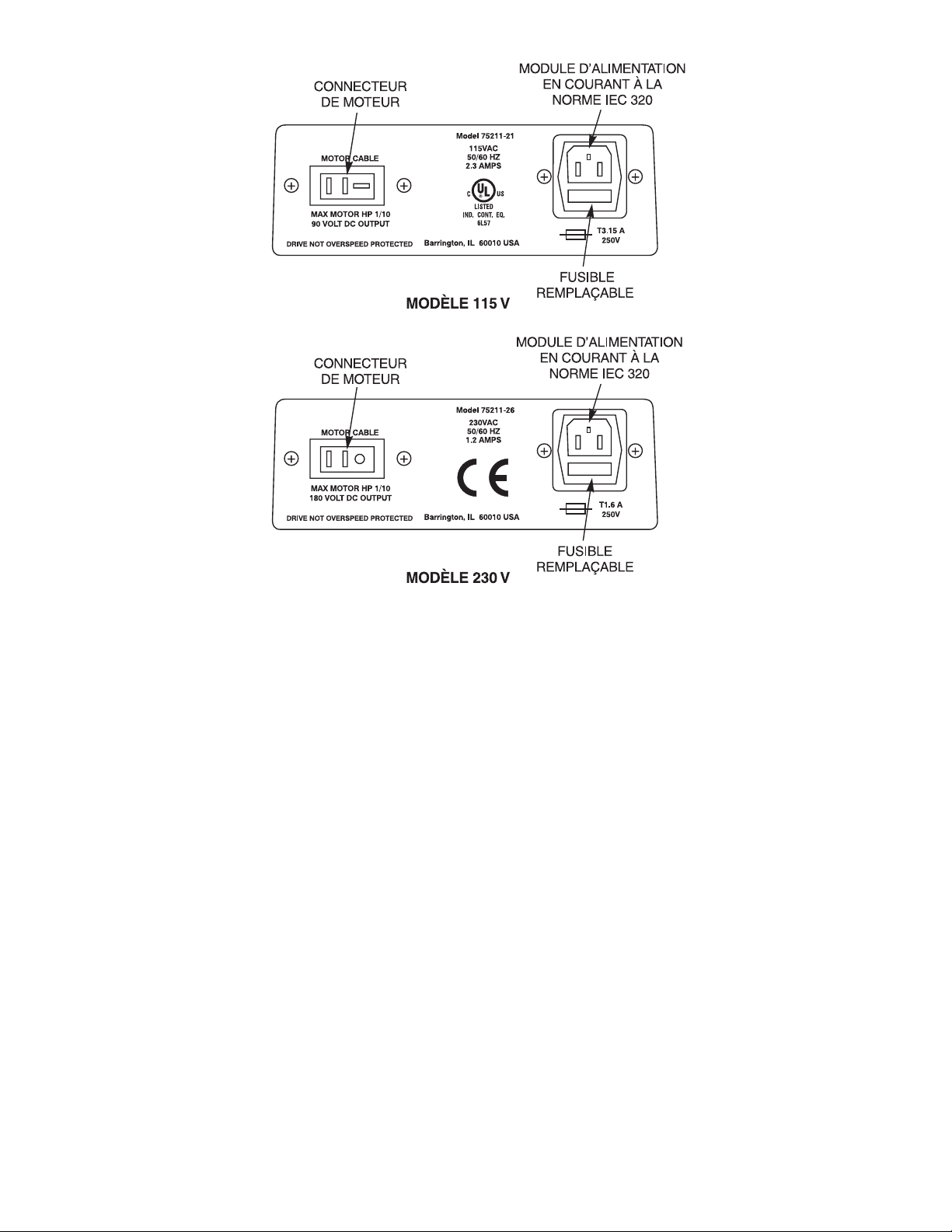

CONTROLLER REAR PANEL

APPLICATIONS DATA

Each of the Motor/Controller Systems incorporates a high-torque magnetic coupler and a

0.1 horsepower DC motor, designed for driving MICROPUMP Pump Heads.

DESCRIPTION

The Motor is designed for bench mounting, with a 6-foot, IEC-320 style cable for connection to the Controller unit. The

0.1 horsepower DC motor is totally enclosed and permanently lubricated.

The Controller enclosure, including top-mounted operator controls, is 7 inches long, 5 inches wide and 3-1/2 inches

high. The enclosure is a modular design, providing convenient control accessibility and easy motor cable connection.

The Controller has a detachable 6-foot, IEC-320 style line cord. The Controller incorporates an SCR-based power

amplifier that regulates motor speed based on operator settings.

4

Page 7

INSTALLATION/SETUP

The Motor includes a welded base for mounting or free-standing use. The Motor input signals are applied through a

3-wire cable with a keyed, 3-prong cinch connector. The motor cable must be connected to the rear of the controller

enclosure before power is applied through the controller.

The Controller is designed for installation on a bench and has a 6-foot, IEC-320 style line cord for connection to the

power line. The Controller comes with an IEC-320 power entry module and cordset. See REPLACEMENT PARTS for

other cordsets.

CAUTION: Be sure available power matches unit requirements. Units are either 115V 50/60 Hz or 230V 50/60 Hz.

1. Select pump head(s) using the following table.

sdaeHpmuP

se

ireS

A

B

C

D

E

golataC

rebmun

52-20070

62-20070

72-20070

41-20070

61-20070

71-20070

32-20070

08-10070

20-30070

40-30070

egnarwolF

)nim/Lm(

slairetamdetteW

ytudsuounitnoC

sevird

0006–400

0151–900

020

3–810

0363–120NOTYR

0311–060

0311–060

0032–121

0032–121EFTP&NOTYRisp06gisp003

0302–801

0014–612

®

EFTP&etihparGisp03gisp003

EFTP&isp03gisp003

EFTPisp54gisp003

®

NO

TIV&NOTYR

)remotsaleoroulf(

ffidxaM

erusserp

ytudsuounitnoC

sevird

isp06gisp003

mumixaM

metsys

erusserp

4–

erutarepmeT

egnar

)F°(C°

121ot64–

)052ot05–(

121ot64–

)052ot05–(

99ot6

)012ot05–(

121ot64–

)052ot05–(

121ot64–

)052ot05–(

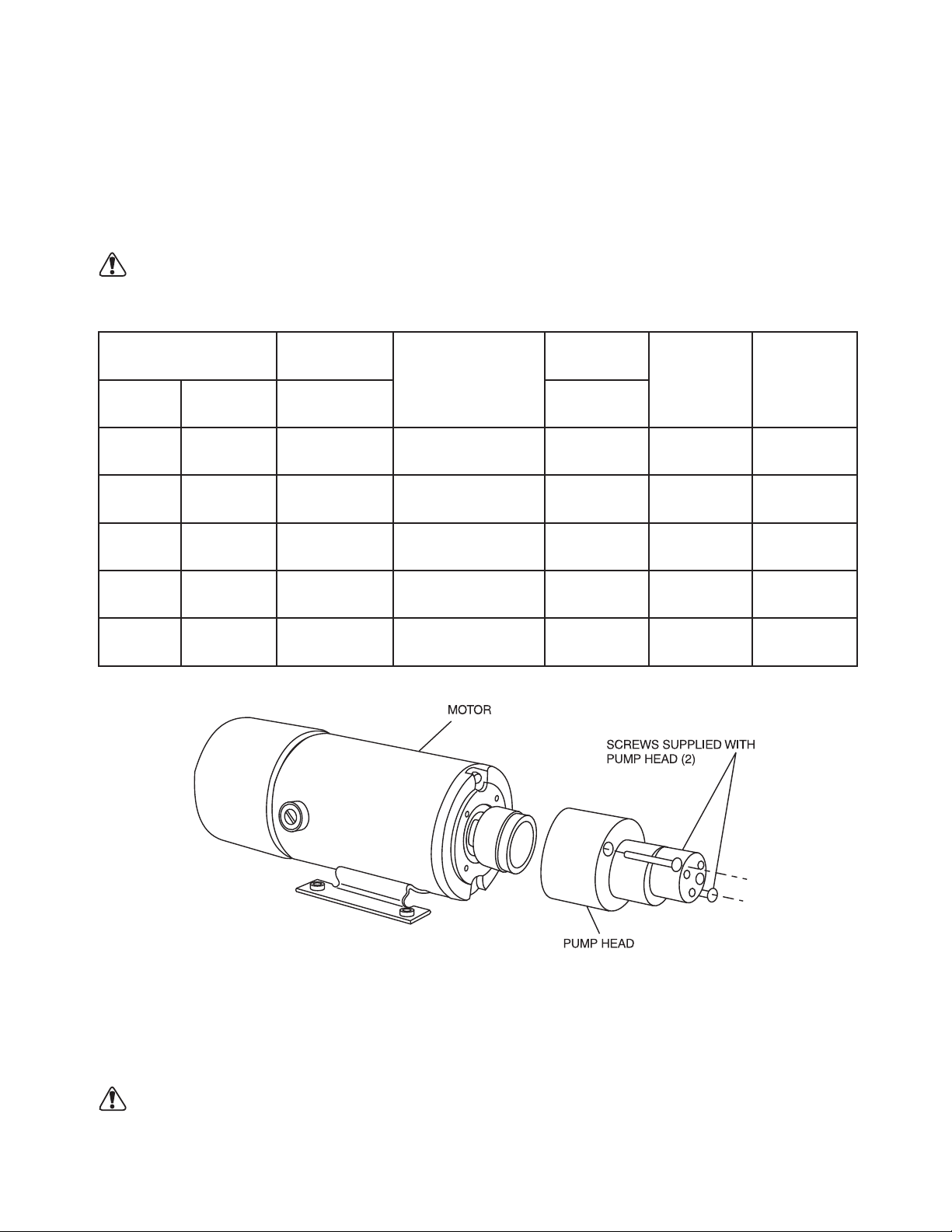

TYPICAL PUMP-TO-MOTOR CONFIGURATION

2. Check that the OFF-ON switch on the controller panel is in the OFF position.

WARNING: Disconnect the AC power input line cord before connecting the drive motor cable.

5

Page 8

3. Connect the drive motor cable to the receptacle on the rear side of the controller.

4. Connect the AC power input line cord to the AC receptacle.

5. Set speed control to full CCW.

6. This completes the basic connections.

OPERATION

After Installation/Setup is complete, the operator must position the OFF-ON switch to ON. The POWER indicator glows

green when the switch is in the ON position.

The operator must then turn the SPEED control clockwise to a setting that provides the desired flow rate.

TROUBLESHOOTING AND MAINTENANCE

Troubleshooting

SYMPTOM CAUSE REMEDY

Motor does not rotate when

switched to ON. POWER

Indicator does not glow.

Motor does not rotate when

switched to ON. Power Indicator

glows. SPEED control setting is

greater than full CCW.

Defective line cord or

fuse.

Defective Motor

or Controller.

1. Check that unit is plugged into a live line.

2. Check line cord for continuity and replace

if defective.

3. Check fuse and replace if defective.

1. Place the OFF-ON switch in the OFF

position.

2. Disconnect the AC line cord from the AC

receptacle.

3. Check the drive motor cable connector on

the rear of the controller and insert the

connector fully into the controller

receptacle.

4. If motor still does not rotate, disconnect

the AC line cord from the AC receptacle.

Disconnect the drive motor cable connector on the rear of the controller.

5. Replace motor with similar unit. Reconnect

the drive motor cable connector on the

rear of the controller. Reconnect the AC

line cord to the AC receptacle. Move the

OFF-ON switch to ON.

6. If motor still does not rotate, disconnect

the AC line cord from the AC receptacle.

Disconnect the drive motor cable

connector on the rear of the controller.

7. Replace controller with similar unit.

Reconnect the drive motor cable connector

on the rear of the controller. Reconnect the

AC line cord to the AC receptacle. Move

the OFF-ON switch to ON.

6

Page 9

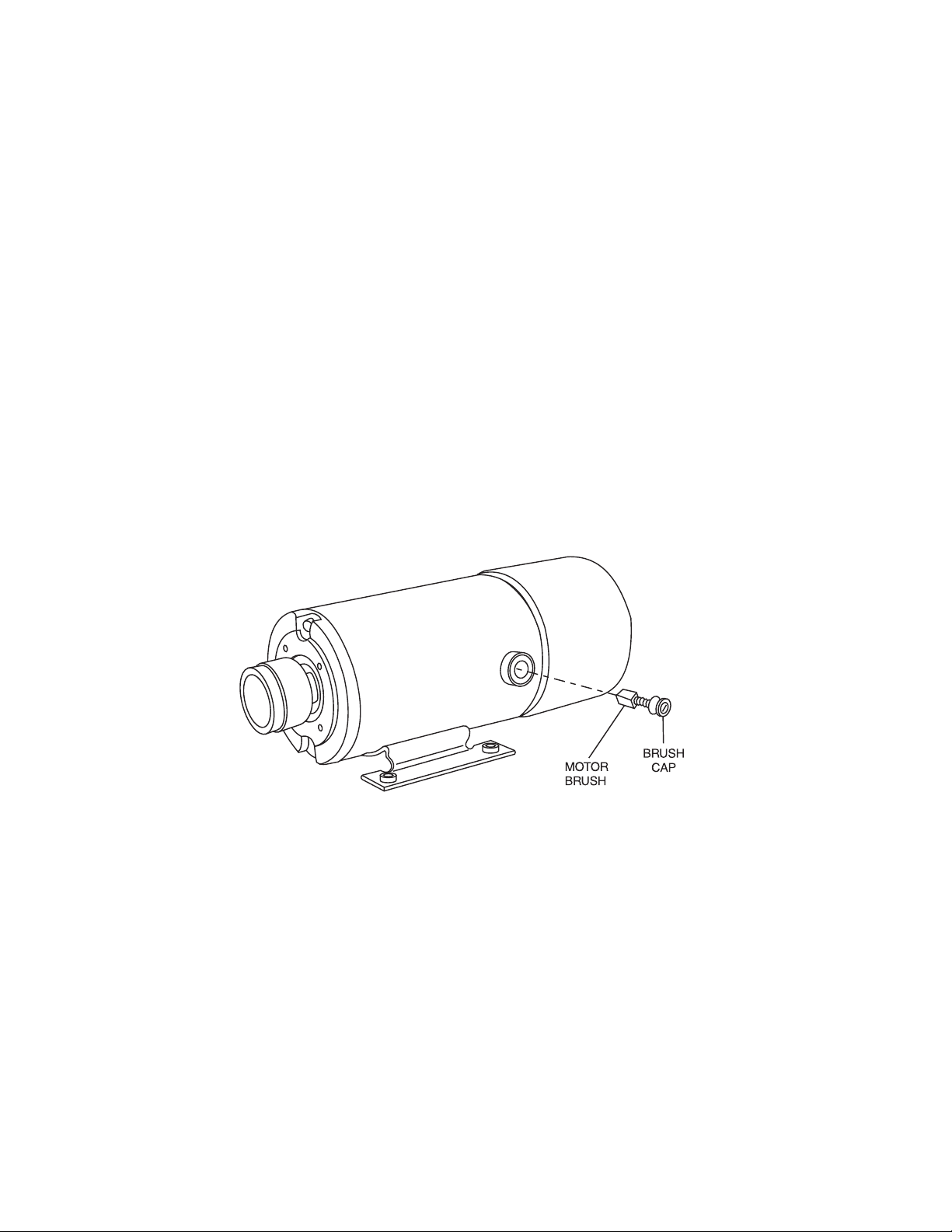

Motor Brush Check/Replacement

Note: Brushes should be checked every 6 months or 2000 operating hours.

1. Place the OFF-ON switch in the OFF position.

2. Disconnect the AC line cord from the AC receptacle.

3. Disconnect the drive motor cable from the receptacle on the rear of the controller.

4. Carefully unscrew each brush holder on opposite sides of the motor. Withdraw the brush, and examine it for wear.

Note: Replace both brushes if either is less than 0.300 in long from base to point. The replacement brushes

(set of 2) is P/N 07520-04.

5. Screw brushes into brush holder on each side of motor.

6. Connect motor to rear panel connector on controller.

7. Connect controller to primary power source.

Fuse Replacement

1. Place the OFF-ON switch in the OFF position.

2. Disconnect the AC line cord from the rear of the unit.

3. Remove and check the fuse located on the rear panel below the AC power connector and replace if defective.

4. Reconnect AC line cord.

TYPICAL PUMP-TO-MOTOR CONFIGURATION

Cleaning the Drive/Controller System

Keep the Drive Motor housing and the Controller enclosure clean by using a mild detergent. Avoid immersion and

excess fluid.

7

Page 10

Replacement Parts

The following parts are user replaceable.

Description Part Number

Brush Caps (set of 2) 07520-03

Motor Brushes (set of 2) 07520-04

Speed Control Knob B-1083-0062

Cordset—Australia (230V units) 50001-60

Cordset—Denmark (230V units) 50001-62

Cordset—India (230V units) 50001-64

Cordset—Israel (230V units) 50001-69

Cordset—USA/Japan (115V units) 50001-68

Cordset—European (230V units) 50001-70

Cordset—British (230V units) 50001-72

Cordset—Swiss (230V units) 50001-74

Cordset—Italian (230V units) 50001-76

Cordset—USA (NEMA) (230V units) 50001-78

Fuse – International T1.6A, 250V 5 × 20 mm (230V units) 77500-11

Fuse – International T3.15A, 250V 5 × 20 mm (115V units) 77500-25

Contact your dealer if you have service needs.

SPECIFICATIONS

Output:

Speed: 40 to 3600 rpm

Maximum torque output: 2.16 kg•cm (30 oz-in)

Speed Regulation: ± 1% Line Regulation

± 2% Load Regulation

± 10% Warm-Up Drift

Display: LED (green): Power indicator

Input:

Supply Voltage Limits:

115V AC 90V AC to 130V AC, 48 Hz to 63 Hz

230V AC 180V AC to 260V AC, 48 Hz to 63 Hz

Nominal Current:

115V AC 2.3 A

230V AC 1.2 A

Construction:

Controller dimensions:

115V AC and 230V AC 16.5 cm (6.5 in) wide

19.3 cm (7.6 in) deep

8.9 cm (3.5 in) high

Controller weight:

115V AC 1.0 kg (2.3 lbs)

230V AC 1.5 kg (3.2 lbs)

Controller Enclosure Rating: IP23 per IEC 529

8

Page 11

Specifications (Cont.)

Motor dimensions:

115V AC 8.6 cm (3.4 in) wide

18.0 cm (7.1 in) deep

9.9 cm (3.9 in) high

230V AC 8.6 cm (3.4 in) wide

23.9 cm (9.4 in) deep

9.9 cm (3.9 in) high

Motor Enclosure Rating: IP21 per IEC529

Motor weight:

115V AC 3.1 kg (6.8 lbs)

230V AC 3.2 kg (7.0 lbs)

Environment:

Operating Temperature: 0°C to 40°C (32°F to 104°F)

Storage Temperature: –25°C to 65°C (–13°F to 149°F)

Humidity (non-condensing): 10%–90%

Altitude: Less than 2000 m (6500 ft)

Pollution Degree: Pollution Degree 2 (Indoor use—lab, office)

Chemical Resistance: All materials withstand standard cleaning solvents.

Materials used in the construction are polyester labels,

and a combined aluminum chassis and plastic enclosure.

Compliance: 115V: UL508C, CSA C22.2, No. 14

230V (For CE Mark):

EN61010-1

(EU Low Voltage Directive) and

EN61326

(EU EMC Directive)

WARRANTY

The Manufacturer warrants this product to be free from significant deviations from published specifications. If repair or

adjustment is necessary within the warranty period, the problem will be corrected at no charge if it is not due to misuse

or abuse on your part, as determined by the Manufacturer. Repair costs outside the warranty period, or those resulting

from product misuse or abuse, may be invoiced to you.

The warranty period for this product is two (2) years from the date of purchase.

PRODUCT RETURN

To limit charges and delays, contact the seller or Manufacturer for authorization and shipping instructions before returning

the product, either within or outside of the warranty period. When returning the product, please state the reason for the

return. For your protection, pack the product carefully and insure it against possible damage or loss. Any damages

resulting from improper packaging are your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the Manufacturer or authorized seller.

9

Printed in U.S.A.

Page 12

TABLE DES MATIÈRES

Intitulé Page

MESURES DE SÉCURITÉ .............................................................................................................................. 11

INTRODUCTION.............................................................................................................................................. 12

TÉMOINS ET COMMANDES .......................................................................................................................... 12

APPLICATIONS ............................................................................................................................................... 13

DESCRIPTION................................................................................................................................................. 13

INSTALLATION ET CONFIGURATION ............................................................................................................ 14

FONCTIONNEMENT ....................................................................................................................................... 15

DÉPANNAGE ET ENTRETIEN ........................................................................................................................ 15

Dépannage................................................................................................................................................... 15

Contrôle et remplacement des balais de moteur.......................................................................................... 16

Remplacement du fusible............................................................................................................................. 16

Nettoyage de l’ensemble entraînement/contrôleur ....................................................................................... 16

Pièces de rechange ..................................................................................................................................... 17

CARACTÉRISTIQUES TECHNIQUES ............................................................................................................ 17

GARANTIE ....................................................................................................................................................... 18

RETOUR DE MARCHANDISES ......................................................................................................................18

ASSISTANCE TECHNIQUE ............................................................................................................................. 18

MICROPUMP — Marque déposée de Micropump Inc., une division de Idex Corp.

RYTON — Marque déposée de Chevron Phillips Chemical Company, L.L.C.

VITON — Marque déposée de E.I. duPont DeNemours & Co.

Les marques accompagnées du symbole ® citées dans cette publication sont déposées aux États-Unis et dans d’autres pays.

10

Page 13

MESURES DE SÉCURITÉ

DANGER : Des hautes tensions auxquelles on peut être exposé sont présentes dans l’ensemble

entraînement/contrôleur. Ne pas retirer le couvercle.

AVERTISSEMENTS : Débrancher le cordon d’alimentation avant de raccorder le câble du moteur

d’entraînement.

L’appareil ne comporte aucune pièce dont l’entretien peut être effectué par l’utilisateur.

Les faire entretenir par le revendeur.

FRANÇAIS

CONSEILS DE

PRUDENCE :

Ne pas obturer l’orifice d’entrée de la pompe ni faire tourner celle-ci à sec pour ne pas

risquer de l’endommager.

S’assurer que la tension du secteur correspond aux spécifications de l’appareil. Ces

appareils fonctionnent sur courant 115 V 50/60 Hz ou 230 V 50/60 Hz.

AVERTISSEMENT : LIMITATION D’UTILISATION DU PRODUIT

Ce produit n’est pas conçu ni supposé être utilisé dans les applications avec patients, y compris, entre autres, les

applications médicales et dentaires, et n’a par conséquent pas été soumis à l’agrément de la FDA.

11

Page 14

INTRODUCTION

Chacun de ces ensembles moteur/contrôleur se compose d’un accouplement magnétique à couple élevé et d’un

moteur de 74,6 W cv à courant continu conçus pour entraîner les têtes de pompes MICROPUMP®. Le moteur, dont le

fonctionnement est extrêmement silencieux, est équipé de balais à longue durée de service, offre un couple accru aux

vitesses élevées, est du type fermé et à graissage permanent. L’ensemble moteur/contrôleur compense automatiquement

les changements de couple nécessaires. Le contrôleur utilise un circuit électronique de commande pour assurer une

régulation précise et fiable de la vitesse du moteur (et par conséquent du débit) grâce à un

« démarrage en douceur » et à une accélération progressive et régulière jusqu’à la vitesse sélectionnée. Le limiteur de

courant du moteur protège le système en cas de blocage du rotor et assure un verrouillage magnétique dans une vaste

plage de variations de charge. Le circuit de sortie est protégé contre une sortie involontaire en court-circuit. La

compensation du courant incorporée au moteur minimise la variation entre les vitesses à vide et à pleine charge. La

commande électronique se caractérise par une excellente régulation de la vitesse et par une immunité améliorée

contre le bruit de circuit, même lors des variations de tension du secteur et de charge.

Numéro catalogue

de l’entraînement Spécification de tension*

75211-20 90 à 130 V c.a.

75211-25 200 à 260 V c.a.

* L’intensité du courant alternatif peut être de 50 ou 60 Hz.

Cette notice traite des applications, de la description, de l’installation et de la configuration, du fonctionnement, du

dépannage et de l’entretien, et indique les caractéristiques techniques.

TÉMOINS ET COMMANDES

12

Page 15

Mfg. by Thermo Fisher Scientific

Mfg. by Thermo Fisher Scientific

PANNEAU ARRIÉRE DU CONTRÔLEUR

APPLICATIONS

Chacun des ensembles moteur/contrôleur se compose d’un accouplement magnétique à couple élevé et d’un moteur

de 74,6 W à courant continu conçus pour entraîner les têtes de pompes MICROPUMP.

DESCRIPTION

Le moteur est conçu pour un montage sur table et est équipé d’un câble de 1,80 m à la norme IEC 320 permettant de

le raccorder au contrôleur. Ce moteur de 74,6 W à courant continu est fermé et à graissage permanent.

Le boîtier du contrôleur, y compris les commandes qui se trouvent sur le dessus, est long de 17,8 cm, large de 12,7 cm

et haut de 8,9 cm. Il est de conception modulaire, ce qui facilite l’accès aux commandes et le raccordement du câble du

moteur. Le contrôleur est pourvu d’un cordon d’alimentation débranchable de 1,80 m à la norme IEC 320 et équipé d’un

amplificateur de puissance à thyristor qui assure la régulation de la vitesse du moteur en fonction des paramètres

établis par l’opérateur.

13

Page 16

INSTALLATION ET CONFIGURATION

Le moteur comporte un socle soudé permettant son montage ou un fonctionnement autonome. Ses signaux d’entrée

sont transmis par l’intermédiaire d’un câble à 3 fils à connecteur Cinch à 3 broches. Le câble du moteur doit être

raccordé à l’arrière du boîtier du contrôleur avant la mise sous tension de ce dernier.

Le contrôleur est conçu pour être installé sur une table et raccordé au secteur au moyen d’un cordon d’alimentation de

1,80 m à la norme IEC 320. Il est fourni avec un module et un cordon d’alimentation à cette même norme. Voir la

rubrique PIÈCES DE RECHANGE pour d’autres cordons.

ATTENTION : S’assurer que la tension du secteur correspond aux spécifications de l’appareil. Ces

appareils fonctionnent sur courant 115 V 50/60 Hz ou 230 V 50/60 Hz.

1. Sélectionner la ou les têtes de pompes à l’aide du tableau suivant.

sepmopedsetêT

eiréS

A

B

C

D

E

orémuN

eugolatac

52-20

070

62-20070

72-20070

41-20070

61-20070

71-20070

32-20070

08-10070

20-30070

40-30070

00 4– 06 00

00 9– 151 0

0 81– 203 0

0

12– 363 0

0 06– 0311

0 06– 0311

121– 0032

121– 0032

801– 0302

612– 0014

tibédedegalP

)nm/lm(

àstnemenîartnE

ecivres

upmorretnini

lfartétylopsrab1,3srab7,0299à64–

OTYR

seélliuomserèitaM

teetihparG

enèlyhtéoroulfartétylop

®

te

NOTYR

enèlyhtéoroulfartétylop

enèlyhtéorou

N

te

enèlyhtéoroulfartétylop

®

NOTIVteNOTYR

)erèmotsaléoroulf(

noisserP

.xam.ffid

àstnemenîartnE

ecivres

upmorretnini

srab1,2srab7,02

srab1,2srab7,02

srab1,4srab7,02121à64–

srab1,4srab7,02121à64–

noisserP

udmumixam

emètsys

edegalP

erut

arépmet

C°

121à64–

121à64–

CONFIGURATION TYPE D’ACCOUPLEMENT DE LA POMPE AU MOTEUR

2. Vérifier que le commutateur d’arrêt-marche du panneau du contrôleur est dans la position OFF (Arrêt).

AVERTISSEMENT : Débrancher le cordon d’alimentation avant de raccorder le câble du moteur

d’entraînement.

14

Page 17

3. Raccorder le câble du moteur d’entraînement à la prise qui se trouve à l’arrière du contrôleur.

4. Raccorder le cordon d’alimentation au secteur.

5. Tourner la commande de vitesse à fond dans le sens antihoraire.

6. Les connexions de base sont alors terminées.

FONCTIONNEMENT

Une fois l’installation et la configuration terminées, l’opérateur doit positionner le commutateur de marche-arrêt sur ON

(Marche). Le témoin d’alimentation s’allume en vert lorsque le commutateur est dans la position ON.

L’opérateur doit ensuite tourner la commande de vitesse (SPEED) dans le sens horaire jusqu’à la position permettant

d’obtenir le débit désiré.

DÉPANNAGE ET ENTRETIEN

Dépannage

SYMPTÔME CAUSE MESURES CORRECTRICES

Le moteur ne tourne pas lorsque

le commutateur d’arrêt-marche

est placé en position ON

(Marche). Le témoin

d’alimentation (POWER) est

éteint.

Le moteur ne tourne pas lorsque

le commutateur d’arrêt-marche

est placé en position ON

(Marche). Le témoin

d’alimentation (POWER) est

allumé. La vitesse (SPEED) est

supérieure à celle qui correspond

à la position de rotation maximum

dans le sens antihoraire de la

commande.

Cordon d’alimentation ou

fusible défectueux.

Moteur ou

contrôleur

défectueux.

1. Vérifier que l’appareil est branché dans

une prise sous tension.

2. Vérifier la continuité du cordon et le

remplacer s’il est défectueux.

3. Vérifier le fusible et le remplacer s’il est

défectueux.

1. Placer le commutateur d’arrêt-marche en

position OFF (Arrêt).

2. Débrancher le cordon d’alimentation de la

prise de courant.

3. Vérifier le connecteur du câble du moteur

d’entraînement à l’arrière du contrôleur et

l’enfoncer à fond dans la prise de ce dernier.

4. Si le moteur ne tourne toujours pas,

débrancher le cordon d’alimentation de la

prise de courant, ainsi que le connecteur

du câble du moteur d’entraînement qui se

trouve à l’arrière du contrôleur.

5. Remplacer le moteur par un moteur

semblable. Rebrancher le connecteur du

câble du moteur d’entraînement à l’arrière

du contrôleur. Rebrancher le cordon

d’alimentation à la prise de courant. Placer

le commutateur d’arrêt-marche à la

position ON (Marche).

6. Si le moteur ne tourne toujours pas,

débrancher le cordon d’alimentation de la

prise de courant, ainsi que le connecteur

du câble du moteur d’entraînement qui se

trouve à l’arrière du contrôleur.

7. Remplacer le moteur par un moteur

semblable. Rebrancher le connecteur du

câble du moteur d’entraînement à l’arrière

du contrôleur. Rebrancher le cordon

d’alimentation à la prise de courant. Placer

le commutateur d’arrêt-marche à la

position ON (Marche).

15

Page 18

Contrôle et remplacement des balais de moteur

Remarque : Les balais doivent être contrôlés tous les 6 mois ou toutes les 2000 heures de fonctionnement.

1. Placer le commutateur d’arrêt-marche sur la position OFF (Arrêt).

2. Débrancher le cordon d’alimentation de la prise de courant.

3. Débrancher le câble de moteur d’entraînement de la prise qui se trouve à l’arrière du contrôleur.

4. Dévisser avec précaution chaque porte-balais sur les côtés opposés du moteur. Retirer chaque balai et l’examiner

pour voir s’il est usé.

Remarque : Remplacer les deux balais si l’un d‘eux est long de moins de 7,6 mm de la base à la pointe. Le numéro

de pièce des balais de rechange (jeu de 2) est 07520-04.

5. Visser les balais dans le porte-balais de chaque côté du moteur.

6. Raccorder le moteur au connecteur qui se trouve sur le panneau arrière du contrôleur.

7. Raccorder le contrôleur au secteur.

Remplacement du fusible

1. Placer le commutateur d’arrêt-marche à la position OFF (Arrêt).

2. Débrancher le cordon d’alimentation de l’arrière de l’appareil.

3. Retirer et vérifier le fusible qui se trouve sur le panneau arrière en dessous du connecteur d’alimentation et le

remplacer s’il est défectueux.

4. Rebrancher le cordon d’alimentation.

CONFIGURATION TYPE D’ACCOUPLEMENT DE LA POMPE AU MOTEUR

Nettoyage de l’ensemble entraînement/contrôleur

Utiliser un détergent peu agressif lors du nettoyage du carter du moteur et du boîtier du contrôleur. Ne jamais les

plonger dans du liquide ni utiliser trop de solution de nettoyage.

16

Page 19

Pièces de rechange

Les pièces suivantes peuvent être remplacées par l’utilisateur.

Description Numéros de pièce

Capuchons de balais (jeu de 2) 07520-03

Balais de moteur (jeu de 2) 07520-04

Bouton de réglage de vitesse B-1083-0062

Cordon d’alimentation—Australie (modèles 230 V) 50001-60

Cordon d’alimentation—Danemark (modèles 230 V) 50001-62

Cordon d’alimentation—Inde (modèles 230 V) 50001-64

Cordon d’alimentation—Israël (modèles 230 V) 50001-69

Cordon d’alimentation—États-Unis/Japon (modèles 115 V) 50001-68

Cordon d’alimentation—Europe (modèles 230 V) 50001-70

Cordon d’alimentation—Grand-Bretagne (modèles 230 V) 50001-72

Cordon d’alimentation—Suisse (modèles 230 V) 50001-74

Cordon d’alimentation—Italie (modèles 230 V) 50001-76

Cordon d’alimentation—États-Unis (NEMA) (modèles 230 V) 50001-78

Fusible – International T1,6A, 250 V 5 × 20 mm (modèles 230 V) 77500-11

Fusible – International T3,15A, 250 V 5 × 20 mm (modèles 115 V) 77500-25

Contacter le revendeur si un entretien s’avère nécessaire.

CARACTÉRISTIQUES TECHNIQUES

Sortie :

Vitesse : 40 à 3600 tr/mn

Couple maximum de sortie : 2,16 kg•cm

Régulation de vitesse : ± 1 % de régulation de ligne

± 2 % de régulation de charge

± 10 % de dérive au réchauffage

Indication : DÉL (verte) : témoin de mise sous tension

Entrée :

Limites de tension d’alimentation :

115 V c.a. 90 à 130 V c.a., 48 à 63 Hz

230 V c.a. 180 à 260 V c.a., 48 à 63 Hz

Intensité nominale :

115 V c.a. 2,3 A

230 V c.a. 1,2 A

Fabrication :

Dimensions du contrôleur :

115 et 230 V c.a. 16,5 cm de large

19,3 cm de profondeur

8,9 cm de haut

Poids du contrôleur :

115 V c.a. 1,0 kg

230 V c.a. 1,5 kg

Homologation du boîtier du contrôleur : IP23 (IEC529)

17

Page 20

Caractéristiques techniques (suite)

Dimensions du moteur :

115 V c.a. 8,6 cm de large

18,0 cm de profondeur

9,9 cm de haut

230 V c.a. 8,6 cm de large

23,9 cm de profondeur

9,9 cm de haut

Homologation du carter du moteur : IP21 (IEC529)

Poids du moteur :

115 V c.a. 3,1 kg

230 V c.a. 3,2 kg

Conditions d’utilisation :

Température de fonctionnement : 0 à 40 °C

Température d’entreposage : –25 à 65 °C

Humidité (sans condensation) : 10 à 90 %

Altitude : Inférieure à 2000 m

Degré de pollution : Degré 2 (utilisation intérieure—laboratoire, bureau)

Résistance aux attaques chimiques : Toutes les matières résistent aux solvants de nettoyage

standard. Les matières utilisées dans la fabrication sont le

polyester pour les étiquettes, l’aluminium pour le châssis et

le plastique pour le boîtier.

Conformités : 115 V : UL508C, ACNOR C22.2, n° 14

230 V (pour estampillage CE) :

EN61010-1

(directive européenne concernant les basses tensions) et

EN61326

(directive européenne concernant la compatibilité

électromagnétique)

GARANTIE

Nous garantissons que ce produit est conforme aux descriptifs. Si une réparation ou un réglage s’avère nécessaire

durant la période de garantie, le problème sera corrigé gratuitement s’il n’est pas dû à une utilisation par le client dont

nous avons déterminé qu’elle est incorrecte ou abusive. Les réparations effectuées en dehors de la période de garantie

ou rendues nécessaires par une utilisation incorrecte ou abusive seront à la charge du client.

La durée de garantie de ce produit est de deux (2) ans à compter de la date d’achat.

RETOUR DE MARCHANDISES

Pour limiter les frais et délais, le produit ne peut être retourné sans notre autorisation préalable et nos instructions

d’expédition ou celle du revendeur. Lors du renvoi du produit, bien vouloir en indiquer la raison. Pour se protéger, nous

recommandons au client d’emballer soigneusement le produit et de le garantir contre les risques de dommages ou de

perte. Nous ne serons pas responsable des dommages résultant d’un emballage incorrect.

ASSISTANCE TECHNIQUE

Pour toute question concernant l’utilisation de ce produit, prendre contact avec nous ou avec le revendeur agréé.

Imprimé aux États-Unis

18

Page 21

INHALTSVERZEICHNIS

Titel Seite

SICHERHEITSMASSNAHMEN ....................................................................................................................... 20

EINFÜHRUNG ................................................................................................................................................. 21

ANZEIGEN UND BEDIENELEMENTE ............................................................................................................ 21

ANWENDUNGSDATEN ................................................................................................................................... 22

BESCHREIBUNG ............................................................................................................................................ 22

INSTALLATION/EINRICHTUNG ...................................................................................................................... 23

BETRIEB .......................................................................................................................................................... 24

STÖRUNGSBESEITIGUNG UND WARTUNG ................................................................................................ 24

Störungsbeseitigung .................................................................................................................................... 24

Überprüfen und Auswechseln der Kohlebürsten .......................................................................................... 25

Auswechseln der Sicherung .........................................................................................................................25

Reinigen des Antriebs-/Steuerungssystems ................................................................................................ 25

Ersatzteile .................................................................................................................................................... 26

TECHNISCHE DATEN ..................................................................................................................................... 26

GARANTIE ....................................................................................................................................................... 27

WARENRÜCKSENDUNGEN ........................................................................................................................... 27

TECHNISCHE BERATUNG ............................................................................................................................. 27

DEUTSCH

MICROPUMP — eingetragene Marke von Micropump Inc., Division der Idex Corp.

RYTON — eingetragene Marke der Ch evron Phillips Chemical Company, L.L.C.

VITON — eingetragene Marke von E.I. duPont DeNemours & Co.

Marken mit dem Symbol ® in dieser Veröffentlichung sind in den USA und in anderen Ländern eingetragen.

19

Page 22

SICHERHEITSMASSNAHMEN

VORSICHT, Im Antrieb und in der Steuerung herrscht Hochspannung, die zugänglich ist. Die

LEBENSGEFAHR: Abdeckung nicht abnehmen.

VORSICHT: Vor Anschließen des Antriebsmotorkabels das Netzkabel ziehen.

Das Geräteinnere enthält keine vom Benutzer zu wartenden Teile. Das Gerät vom

Fachhändler warten lassen.

ACHTUNG: Um eine Beschädigung der Pumpe zu vermeiden, den Pumpeneingang nicht verengen

und die Pumpe nicht ohne Flüssigkeit betreiben.

Sicherstellen, dass die vorhandene Versorgungsspannung den Geräteanforderungen

entspricht. Die Einheiten werden entweder mit 115V 50/60 Hz oder 230V 50/60 Hz geliefert.

VORSICHT: ANWENDUNGSEINSCHRÄNKUNGEN

Dieses Gerät ist nicht für den Einsatz am Patienten vorgesehen und auch nicht für diesen Zweck bestimmt (z.B.

medizinischen oder zahnmedizinischen Bereich) und entspricht demgemäß auch keinen FDA (Food & Drug

Administration) Normen.

20

Page 23

EINFÜHRUNG

Jedes Motor-/Steuerungssystem enthält eine magnetische Hochmomentkupplung und einen 74,6 W Gleichstrommotor,

der für den Antrieb von MICROPUMP®-Pumpenköpfen ausgelegt ist. Der Motor läuft extrem ruhig, hat äußerst haltbare

Kohlebürsten, ein bei hohen Drehzahlen erhöhtes Drehmoment und ist vollständig gekapselt und permanent geschmiert.

Das Motor-/Steuerungssystem gleicht Änderungen in der erforderlichen Lastdrehzahl automatisch aus. Mit Hilfe einer

elektronischen Steuerschaltung sorgt das Steuerungsgerät für eine präzise, zuverlässige Steuerung der Motordrehzahl

(Fördermenge) mit „Sanftanlauf“ und stetiger Beschleunigung bis zur eingestellten Drehzahl. Die Strombegrenzung

des Motors schützt das System, falls der Rotor blockiert, und sorgt über einen weiten Belastungsbereich für eine

magnetische Sperrung. Ein Ausgangsschaltungsschutz schützt vor versehentlichem Kurzschließen des Ausgangs.

Eine integrierte Motorstromkorrektur minimiert Drehzahlvariationen zwischen einem belastungsfreien Zustand und

maximaler Belastung. Weiterhin verfügt die elektronische Steuerung über eine hervorragende Drehzahlregelung und

bietet selbst bei Schwankungen der Netzspannung und Belastung eine verbesserte Leitungsstörfestigkeit.

Artikelnr. Antrieb Stromanforderung*

75211-20 90 bis 130 V

75211-25 200 bis 260 V∼

*Die Netzspannung kann entweder 50 oder 60 Hz sein.

Dieses Handbuch enthält eine Beschreibung, Angaben zur Anwendung, Installation/Einrichtung, Bedienung,

Störungsbeseitung und Wartung sowie die technischen Daten.

∼

ANZEIGEN UND BEDIENELEMENTE

21

Page 24

Mfg. by Thermo Fisher Scientific

Mfg. by Thermo Fisher Scientific

RÜCKWAND DER STEUERUNG

ANWENDUNGSDATEN

Jedes Motor-/Steuerungssystem enthält eine magnetische Hochmomentkupplung und einen 74,6 W Gleichstrommotor,

der für den Antrieb von MICROPUMP®-Pumpenköpfen ausgelegt ist.

BESCHREIBUNG

Der Motor ist als Tischgerät ausgelegt und mit einem 1,8 m Kabel nach IEC-320 für den Anschluss an das Steuerungsgerät

ausgelegt. Der 74,6 W Gleichstrommotor ist vollständig gekapselt und permanent geschmiert.

Das Gehäuse der Steuerung einschließlich der oben montierten Bedienelemente ist 17,8 cm lang, 12,7 cm breit und

8,9 cm hoch. Das Gehäuse ist modular konstruiert, so dass die Bedienelemente leicht erreichbar sind und das Motorkabel

mühelos angeschlossen werden kann. Das Steuerungsgerät hat ein abnehmbares 1,8 m langes Netzkabel nach IEC 320.

Die Steuerung umfasst einen Thyristor-basierten Leistungsverstärker, der die Motordrehzahl entsprechend den

Bedienereinstellungen regelt.

22

Page 25

INSTALLATION/EINRICHTUNG

Im Lieferumfang des Motors ist eine verschweißte Grundplatte enthalten, so dass der Motor montiert oder freistehend

verwendet werden kann. Die Motoreingangssignale werden über ein dreiadriges Kabel mit einem verpolsicheren,

dreipoligen Cinch-Stecker angelegt. Bevor der Strom über die Steuerung eingespeist wird, muss das Motorkabel an die

Rückwand des Steuerungsgehäuses angeschlossen werden.

Das Steuerungsgerät ist für die Tischmontage ausgelegt und verfügt über ein 1,8 m Netzkabel nach IEC 320 für den

Anschluss ans Netz. Das Steuerungsgerät wird mit einem Netzanschluss nach IEC 320 und einem Geräteanschlusskabel

geliefert. Für weitere Geräteanschlusskabel siehe ERSATZTEILE.

ACHTUNG: Sicherstellen, dass die vorhandene Versorgungsspannung den Geräteanforderungen entspricht.

Die Einheiten werden entweder mit 115V 50/60 Hz oder 230V 50/60 Hz geliefert.

1. Wählen Sie einen oder mehrere Pumpenköpfe aus der folgenden Tabelle aus.

-negnem-redröF

efpöknepmuP

eireS

A

B

C

D

E

-lekitrA

remmun

52-20070

62-20070

72-20070

41-20070

61-20070

71-20070

32-20070

08-10070

20-30070

40-30070

hciereb

)nim/lm(

timebeirtnA

beirteb-reuaD

00 4– 06

00 9– 151 0

0 81– 203 0

0 12– 363 0 NOTYR

0 06– 0311

0 06– 0311

21– 0032EFTPdnuNOTYRrab1,4rab7,02121sib64–

00

®

121– 0032

1

801– 0302

612– 0014

lairetamssaN

EFTPdnutihparGrab1,2rab7,02121sib64–

EFTPdnurab1,2rab7,02121sib64–

EFTPrab1,3rab7,0299sib64–

®

NOTIVdnuNOTYR

)remotsaleroulF(

-znereffiDxaM

kcurd

timebeirtnA

beirteb-reuaD

rab1,4rab7,02121sib64–

-metsyS.xaM

kcurd

-rutarepmeT

C°hc

iereb

TYPISCHE KONFIGURATION PUMPE-ZU-MOTOR

2. Sicherstellen, dass der AUS-EIN-Schalter an der Frontplatte der Steuerung auf AUS steht.

VORSICHT: Vor Anschließen des Antriebsmotorkabels das Netzkabel ziehen.

23

Page 26

3. Das Antriebsmotorkabel an die Steckdose an der Rückwand der Steuerung anschließen.

4. Das Netzkabel in die Netzsteckbuchse einstecken.

5. Den Drehzahlregler so weit wie möglich entgegen dem Uhrzeigersinn drehen.

6. Damit sind die Hauptverbindungen hergestellt.

BETRIEB

Nach Abschluss der Installation und Einrichtung muss der Bediener den AUS-EIN-Schalter auf EIN (ON) stellen. Wenn

der Schalter auf EIN steht, leuchtet die Betriebsanzeige (POWER) grün.

Dann muss der Bediener den Drehzahlregler (SPEED) so weit Uhrzeigersinn drehen, bis die gewünschte Fördermenge

erreicht ist.

STÖRUNGSBESEITIGUNG UND WARTUNG

Störungsbeseitigung

SYMPTOM URSACHE VORGEHENSWEISE

Eingeschalteter Motor dreht sich

nicht. Netzanzeige (POWER)

leuchtet nicht.

Eingeschalteter Motor dreht sich

nicht. Netzanzeige (POWER)

leuchtet. Drehzahlreglereinstellung

(SPEED) ist nicht so weit wie

möglich entgegen dem

Uhrzeigersinn gedreht.

Netzkabel oder

Sicherung

Motor oder

Steuerung defekt.

1. Sicherstellen, dass das Gerät an eine

stromführende Leitung angeschlossen ist.

2. Netzkabel auf Durchgang prüfen und

auswechseln, falls defekt.

3. Sicherung prüfen und auswechseln, falls

defekt.

1. AUS-EIN-Schalter auf AUS (OFF) stellen.

2. Netzkabel aus der Netzsteckdose ziehen.

3. Den Anschluss für das

Antriebsmotorkabel an der Rückwand der

Steuerung prüfen und den Steckverbinder

fest in die Steckdose der Steuerung

einstecken.

4. Wenn sich der Motor nach wie vor nicht

dreht, das Netzkabel aus der

Netzsteckdose ziehen. Den

Steckverbinder des Antriebsmotorkabels

aus der Rückwand der Steuerung ziehen.

5. Den Motor gegen eine gleichwertige

Einheit auswechseln. Den Steckverbinder

des Antriebsmotorkabels wieder an der

Rückwand der Steuerung anschließen.

Das Netzkabel wieder an die

Netzsteckdose anschließen. Den AUSEIN-Schalter auf EIN (ON) stellen.

6. Wenn sich der Motor nach wie vor nicht

dreht, das Netzkabel aus der

Netzsteckdose ziehen. Den

Steckverbinder des Antriebsmotorkabels

aus der Rückwand der Steuerung ziehen.

7. Das Steuergerät gegen eine gleichwertige

Einheit auswechseln. Den Steckverbinder

des Antriebsmotorkabels wieder an der

Rückwand der Steuerung anschließen.

Das Netzkabel wieder an die

Netzsteckdose anschließen. Den AUSEIN-Schalter auf EIN stellen.

24

Page 27

Überprüfen und Auswechseln der Kohlebürsten

Hinweis: Die Bürsten müssen alle 6 Monate oder nach jeweils 2000 Betriebsstunden geprüft werden.

1. AUS-EIN-Schalter auf AUS (OFF) stellen.

2. Das Netzkabel aus der Netzsteckdose ziehen.

3. Das Antriebsmotorkabel aus der Steckdose an der Rückwand der Steuerung ziehen.

4. Die Bürstenhalterungen auf den gegenüberliegenden Seiten des Motors vorsichtig abschrauben. Die Bürsten

herausnehmen und auf Abnutzungserscheinungen prüfen.

Hinweis: Beide Bürsten auswechseln, wenn eine Bürste bis auf weniger als 7,6 mm abgenutzt ist. Artikelnummer

für die Ersatzkohlebürsten (je zwei) ist 07520-04.

5. Die Bürsten wieder in die Bürstenhalterung auf beiden Seiten des Motors einschrauben.

6. Den Motor an den Anschluss an der Rückwand der Steuerung anschließen.

7. Die Steuerung an die Hauptstromquelle anschließen.

Auswechseln der Sicherung

1. AUS-EIN-Schalter auf AUS (OFF) stellen.

2. Das Netzkabel aus der Rückwand des Geräts ziehen.

3. Die Sicherung an der Rückwand unter der Netzsteckdose herausnehmen und prüfen. Auswechseln, falls defekt.

4. Das Netzkabel wieder anschließen.

TYPISCHE KONFIGURATION PUMPE-ZU-MOTOR

Reinigen des Antriebs-/Steuerungssystems

Das Gehäuse des Antriebsmotors und der Steuerung mit einem milden Reinigungsmittel reinigen. Nicht eintauchen

oder zu viel Flüssigkeit verwenden.

25

Page 28

Ersatzteile

Die folgenden Teile können vom Benutzer ausgewechselt werden:

Beschreibung Artikelnummer

Abdeckkappen der Kohlebürsten (je 2) 07520-03

Kohlebürsten (je 2) 07520-04

Drehzahlreglerknopf B-1083-0062

Geräteanschlusskabel—Australien (230V-Einheiten) 50001-60

Geräteanschlusskabel—Dänemark (230V-Einheiten) 50001-62

Geräteanschlusskabel—Indien (230V-Einheiten) 50001-64

Geräteanschlusskabel—Israel (230V-Einheiten) 50001-69

Geräteanschlusskabel—USA/Japan (115V-Einheiten) 50001-68

Geräteanschlusskabel—Europa (230V-Einheiten) 50001-70

Geräteanschlusskabel—Großbritannien (230V-Einheiten) 50001-72

Geräteanschlusskabel—Schweiz (230V-Einheiten) 50001-74

Geräteanschlusskabel—Italien (230V-Einheiten) 50001-76

Geräteanschlusskabel—USA (NEMA) (230V-Einheiten) 50001-78

Sicherung – International T1,6A, 250 V 5 × 20 mm (230V-Einheiten) 77500-11

Sicherung – International T3,15A, 250 V 5 × 20 mm (115V-Einheiten) 77500-25

Bei evtl. notwendigen Reparaturen wenden Sie sich bitte an Ihren Fachhändler.

TECHNISCHE DATEN

Ausgangsleistung:

Drehzahl: 40 bis 3600 U/min

Maximales Drehmoment: 2,16 kg•cm

Drehzahlregelung: ± 1 % ohne Last

± 2 % mit Last

± 10 % Warmlaufabweichung

Anzeige: LED (grün): Betriebsanzeige

Eingangsleistung:

Versorgungsspannungsbereich:

115 V∼ 90 V∼ bis 130 V∼, 48 Hz bis 63 Hz

230 V∼ 180 V∼ bis 260 V∼, 48 Hz bis 63 Hz

Nennstromstärke:

115 V∼ 2,3 A

230 V∼ 1,2 A

Bauweise:

Abmessungen Steuerungsgerät:

115 V∼ und 230 V∼ 16,5 cm breit

19,3 cm tief

8,9 cm hoch

Gewicht Steuerungsgerät:

115 V∼ 1,0 kg

230 V∼ 1,5 kg

Schutzart Steuerungsgehäuse: IP 23 nach IEC529

26

Page 29

Technische Daten (Fortsetzung)

Abmessungen Motor:

115 V∼ 8,6 cm breit

18,0 cm tief

9,9 cm hoch

230 V∼ 8,6 cm breit

23,9 cm tief

9,9 cm hoch

Schutzart Motorgehäuse: IP 21 nach IEC529

Motorgewicht:

115 V∼ 3,1 kg

230 V∼ 3,2 kg

Umweltbedingungen:

Betriebstemperatur: 0 bis 40 °C

Lagertemperatur: –25 bis 65 °C

Luftfeuchtigkeit (nicht kondensierend): 10 bis 90 %

Höhe ü. M.: Unter 2000 m

Verschmutzungsgrad: Verschmutzungsgrad 2 (Innengebrauch —Labor,

Büroräume)

Chemische Beständigkeit: Alle Materialien sind gegen Standardreinigungslösungen

beständig. In der Konstruktion wurden folgende Materialien

verwendet: Schilder aus Polyester, Grundrahmen aus

Aluminium und Gehäuse aus Kunststoff.

Entspricht den Normen: 115 V: UL 508C, CSA C22.2, Nr. 14

230 V (für CE-Kennzeichen):

EN61010-1

(Niederspannungsrichtlinie der EU) und

EN61326

(EMV-Richtlinie der EU)

GARANTIE

Der Hersteller garantiert, dass dieses Produkt keine nennenswerten Abweichungen von den veröffentlichten

Spezifikationen aufweist. Falls während der Garantiezeit eine Reparatur oder Nachbesserung erforderlich werden sollte,

wird dies kostenlos vorgenommen, vorausgesetzt, es liegt kein vom Hersteller feststellbarer fehlerhafter oder

unsachgemäßer Einsatz seitens des Kunden vor. Reparaturkosten außerhalb der Garantiezeit oder aufgrund von

fehlerhaftem oder unsachgemäßem Gebrauch des Produktes werden Ihnen in Rechnung gestellt.

Die Garantie gilt für einen Zeitraum von zwei (2) Jahren nach dem Kaufdatum.

WARENRÜCKSENDUNGEN

Um Kosten und Verzögerungen so gering wie möglich zu halten, lassen Sie sich in jedem Fall von Ihrem Fachhändler oder

dem Hersteller eine Rücksendegenehmigung und die Versandanweisungen geben, bevor Sie Ware zurückschicken. Geben

Sie bitte den Rücksendegrund mit an. Verpacken Sie die Ware sorgfältig und versichern Sie die Sendung gegen Beschädigung

bzw. Verlust. Für Transportschäden aufgrund unsachgemäßer Verpackung haften Sie.

TECHNISCHE BERATUNG

Wenn Sie Fragen zur Anwendung diese Produktes haben, wenden Sie sich bitte an den Hersteller oder autorisierten

Fachhändler.

Printed in U.S.A.

27

Page 30

ÍNDICE GENERAL

Título Página

PRECAUCIONES DE SEGURIDAD ................................................................................................................ 29

INTRODUCCIÓN ............................................................................................................................................. 30

LECTURAS Y CONTROLES............................................................................................................................ 30

DATOS DE APLICACIONES ............................................................................................................................ 31

DESCRIPCIÓN ................................................................................................................................................ 31

INSTALACIÓN/CONFIGURACIÓN .................................................................................................................. 32

OPERACIÓN .................................................................................................................................................... 33

LOCALIZACIÓN Y RESOLUCIÓN DE PROBLEMAS Y MANTENIMIENTO ................................................... 33

Localización y resolución de problemas ....................................................................................................... 33

Comprobación/Reemplazo de escobillas de motor ...................................................................................... 34

Reemplazo de fusibles ................................................................................................................................. 34

Limpieza del sistema de impulsión/controlador ............................................................................................ 34

Piezas de repuesto ...................................................................................................................................... 35

ESPECIFICACIONES ...................................................................................................................................... 35

GARANTÍA ....................................................................................................................................................... 36

DEVOLUCIÓN DEL PRODUCTO .................................................................................................................... 36

ASISTENCIA TÉCNICA ................................................................................................................................... 36

MICROPUMP — Marca comercial registrada de Micropump Inc., una división of Idex Corp.

RYTON — Marca comercial registrada de Chevr on Phillips Chemical Company, L.L.C.

VITON — Marca comercial registrada de E.I. duPont DeNemours & Co.

Las marcas comerciales con el símbolo ® de esta publicación están registradas en EE.UU. y otros países.

28

Page 31

PRECAUCIONES DE SEGURIDAD

PELIGRO: Existen altos voltajes y son accesibles en el mando/controlador. No quite la tapa.

ADVERTENCIAS: Desconecte el cordón de la línea de entrada de CA que conecta el cable del motor de

impulsión.

En el interior de este instrumento no hay piezas reemplazables. Consulte el servicio con su

distribuidor.

PRECAUCIONES: Para impedir daños en la bomba, no limite la entrada de la bomba ni la haga funcionar en

seco.

Asegúrese de que la corriente disponible corresponda a los requisitos de la unidad. Las

unidades son de 115 V 50/60 Hz o 230 v 50/60 Hz.

ADVERTENCIA: LIMITACIÓN DE USO DEL PRODUCTO

Este producto no está diseñado, ni ha sido destinado para usarse en aplicaciones conectadas al paciente, incluidas

aplicaciones médicas y dentales, pero sin limitarse a las mismas, y por lo tanto no se ha enviado a la FDA para su

aprobación.

ESPAÑOL

29

Page 32

INTRODUCCIÓN

Cada uno de estos sistema de motor/controlador dispone de un acoplador magnético de alto par y un motor de CC de

74,6 W, diseñado para impulsar las cabezas de bomba MICROPUMP®. El motor tiene una operación extremadamente

silenciosa, escobillas de larga duración, mayor par a altas velocidades, está totalmente cerrado y permanentemente

lubricado. El motor/sistema de controlador compensa automáticamente los cambios de demanda del par de carga.

Utilizando un circuito de control electrónico, el controlador asegura un control exacto de la velocidad (caudal) del motor

y fiable con un arranque suave y una aceleración gradual suave hasta la velocidad fijada. La limitación de corriente del

motor protege el sistema en caso de que el rotor esté bloqueado y asegura un bloqueo magnético para amplias

variaciones de carga. El protector del circuito de salida protege contra el cortocircuitado inadvertido de la salida. La

compensación integrada de la corriente del motor disminuye al mínimo la variación de velocidad sin carga a velocidad

a plena carga. El control electrónico está diseñado con una regulación de velocidad excelente y una mayor inmunidad

contra el ruido de la línea, incluso con variaciones de voltaje de línea y carga.

Especificación Número de catálogo

de corriente* del mando

75211-20 90 a 130 VCA

75211-25 200 a 260 VCA

*El voltaje de CA puede ser 50 ó 60 Hz.

En este manual se incluyen Aplicación, Descripción, Instalación/Configuración, Operación, Localización y resolución

de problemas y Mantenimiento y Datos de las especificaciones.

LECTURAS Y CONTROLES

30

Page 33

Mfg. by Thermo Fisher Scientific

Mfg. by Thermo Fisher Scientific

PANEL TRASERO DEL CONTROLADOR

DATOS DE APLICACIONES

Cada uno de estos sistemas de motor/controlador dispone de un acoplador magnético de alto par y un motor de CC de

74,6 W, diseñado para impulsar las cabezas de bomba MICROPUMP.

DESCRIPCIÓN

El motor está diseñado para montarse en un banco, con un cable estilo IEC 320 de 1,8 m de largo para conectarlo a la

unidad del controlador. El motor de CC de 74,6 W está totalmente cerrado y permanentemente lubricado.

El recinto del controlador, incluidos los controles del operador montados en la parte superior, miden 17,8 cm de largo,

12,7 cm de ancho y 8,9 cm de alto. El recinto tiene un diseño modular que proporciona una accesibilidad de control

conveniente y una conexión sencilla del cable del motor. El controlador tiene un cordón de línea desmontable estilo

IEC 320 de 1,8 m de largo. El controlador dispone de un amplificador de corriente basado en SCR que regular la

velocidad del motor basándose en los ajustes del operador.

31

Page 34

INSTALACIÓN/CONFIGURACIÓN

El motor incluye una base soldada para montaje o uso autónomo. La señales de entrada del motor se aplican a través

de un cable trifilar con un conector enchavetado de 3 clavijas. El cable del motor debe conectarse a la parte trasera del

recinto del controlador antes de aplicar corriente a través del controlador.

El controlador está diseñado para instalarse en un banco y tiene un cordón de línea estilo IEC 320 de 1,8 m de largo

para conectarlo a la línea de alimentación. El controlador dispone de un módulo de entrada de alimentación IEC 320 y

un juego de cordón. Vea PIEZAS DE REPUESTO para otros juegos de cordón.

PRECAUCIÓN: Asegúrese de que la corriente disponible corresponda a los requisitos de la unidad. Las

unidades son de 115 V 50/60 Hz o 230 v 50/60 Hz.

1. Escoja las cabezas de bomba usando la tabla siguiente.

abmobedsazebaC

eireS

A

B

C

D

E

0

edoremúN

ogolátac

52-20070

62-20070

72-20

070

41-20070

61-20070

71-20070

32-20070

08-1007

20-30070

40-30070

00 4– 06 00

00 9– 151 0

0 81– 203 0

0 12– 363 0

0 06– 0311

0 06– 0311

121– 0032

121– 0032EFTPyNOTYRserab1,4serab7,02121a64–

801– 0302

612– 0014

laduacedamaG

)nim/lm(

sodajomselairetaM

oicivresedsodnaM

ounitnoc

EFTPootifarGserab1,2serab7,02121a64–

®

NOTYR

EFTPy

EFTPserab1,3serab7,0299a64

®

NOTIVyNOTYR

)oremótsaleoroulf(

ed.fid.xáM

nóiserp

edsodnaM

ounitnocoicivres

serab1,2serab7,02121a64–

serab1,4serab7,02121a64–

amixámnóiserP

ametsisled

edamaG

C°sa

rutarepmet

CONFIGURACIÓN TÍPICA DE BOMBA A MOTOR

2. Compruebe que el interruptor de encendido/apagado del tablero del controlador esté en la posición de apagado.

ADVERTENCIA: Desconecte el cordón de la línea de entrada de CA antes de conectar el cable del motor de

impulsión.

32

Page 35

3. Conecte el cable del motor del mando al receptáculo en la parte trasera del controlador.

4. Conecte el cordón de la línea de entrada de CA al receptáculo de CA.

5. Fije el control de velocidad a giro máximo a la izquierda.

6. Esto completa las conexiones básicas.

OPERACIÓN

Después de completar la instalación/configuración, el operador debe poner el interruptor de encendido/apagado en la

posición de encendido. Se enciende de color verde del indicador de corriente (POWER) cuando el interruptor está en

la posición de encendido.

A continuación, el operador debe girar el control de velocidad (SPEED) a la derecha hasta un ajuste que proporcione

el caudal deseado.

LOCALIZACIÓN Y RESOLUCIÓN DE PROBLEMAS Y MANTENIMIENTO

Localización y resolución de problemas

SÍNTOMA CAUSA SOLUCIÓN

El motor no gira cuando se

enciende (ON). El indicador de

corriente (POWER) no se

enciende.

Cordón de línea o fusible

defectuoso.

1. Compruebe que la unidad esté enchufada

a una línea con corriente.

2. Compruebe la continuidad del cordón de

la línea y reemplácelo si es defectuoso.

3. Compruebe el fusible y reemplácelo si es

defectuoso.

El motor no gira cuando se

enciende (ON), Se enciende el

indicador de corriente (POWER). El

ajuste de control de velocidad

(SPEED) es mayor que giro

máximo a la izquierda.

Motor o

controlador

defectuoso.

1. Ponga el interruptor de encendido/apagado

(ON/OFF) en la posición de apagado (OFF).

2. Desconecte el cordón de la línea de CA

del receptáculo de CA.

3. Compruebe el conector del cable del motor

de impulsión de la parte trasera del

controlador e inserte completamente el

conector en el receptáculo del controlador.

4. Si el motor sigue sin girar, desconecte el

cordón de la línea de CA del receptáculo

de CA. Desconecte el conector del cable

del motor del mando en la parte trasera

del controlador.

5. Reemplace el motor por una unidad similar.

Vuelva a conectar el conector del cable del

motor del mando en la parte trasera del

controlador. Vuelva a conectar el cordón de

la línea de CA del receptáculo de CA. Ponga

el interruptor de encendido/apagado (OFF/

ON) en la posición de encendido (ON).

6. Si el motor sigue sin girar, desconecte el

cordón de la línea de CA del receptáculo

de CA. Desconecte el conector del cable

del motor del mando en la parte trasera

del controlador.

7. Reemplace el controlador por una unidad

similar. Vuelva a conectar el conector del

cable del motor del mando en la parte trasera

del controlador. Vuelva a conectar el cordón

de la línea de CA del receptáculo de CA.

Ponga el interruptor de encendido/apagado

(OFF/ON) en la posición de encendido (ON).

33

Page 36

Comprobación/Reemplazo de escobillas de motor

Nota: Se deben inspeccionar las escobillas cada 6 meses o 2000 horas de operación.

1. Ponga el interruptor de encendido/apagado en la posición de apagado.

2. Desconecte el cordón de la línea de CA del receptáculo de CA.

3. Desconecte el cable del motor del mando del receptáculo de la parte trasera del controlador.

4. Desatornille cuidadosamente cada portaescobillas en los lados opuestos del motor. Retire la escobilla, y examínela

si está desgastada.

Nota: Reemplace ambas escobillas si cualquiera de ellas mide menos de 7,6 mm de largo de la base a la punta. El

número de pieza de las escobillas de repuesto (juego de 2) es 07520-04.

5. Atornille las escobillas en el portador de escobillas de cada lado del motor.

6. Conecte el motor al conector del panel trasero del controlador.

7. Conecte el controlador a la fuente de alimentación primaria.

Reemplazo de fusibles

1. Ponga el interruptor de encendido/apagado en la posición de apagado.

2. Desconecte el cordón de la línea de CA de la parte trasera de la unidad.

3. Quite y compruebe el fusible ubicado en el panel trasero debajo del conector de CA y reemplácelo si es defectuoso.

4. Vuelva a conectar el cordón de la línea de CA.

CONFIGURACIÓN TÍPICA DE BOMBA A MOTOR

Limpieza del sistema de impulsión/controlador

Mantenga limpios la caja del motor del mando y el recinto del controlador usando un detergente suave. Evite la

inmersión y el exceso de fluido.

34

Page 37

Piezas de repuesto

Las piezas siguientes pueden ser reemplazadas por el usuario.

Descripción Número de pieza

Tapas de escobilla (juego de 2) 07520-03

Escobillas de motor (juego de 2) 07520-04

Perilla de control de velocidad B-1083-0062

Juego de cordón—Australia (Unidades de 230 V) 50001-60

Juego de cordón—Dinamarca (Unidades de 230 V) 50001-62

Juego de cordón—India (Unidades de 230 V) 50001-64

Juego de cordón—Israel (Unidades de 230 V) 50001-69

Juego de cordón—EE.UU./Japón (Unidades de 115 V) 50001-68

Juego de cordón—Europeo (Unidades de 230 V) 50001-70

Juego de cordón—Británico (Unidades de 230 V) 50001-72

Juego de cordón—Suizo (Unidades de 230 V) 50001-74

Juego de cordón—Italiano (Unidades de 230 V) 50001-76

Juego de cordón—EE.UU. (NEMA) (Unidades de 230 V) 50001-78

Fusible – Internacional T1,6A, 250 V 5 × 20 mm (Unidades de 230 V) 77500-11

Fusible – Internacional T3,15A, 250 V 5 × 20 mm (Unidades de 115 V) 77500-25

Póngase en contacto con su distribuidor si tiene necesidades de servicio.

ESPECIFICACIONES

Salida:

Velocidad: 40 a 3600 rpm

Salida de par máximo 2,16 kg•cm

Regulación de velocidad: Regulación de la línea de ± 1%

Regulación de carga de ± 2%

Desviación de calentamiento de ± 10%

Pantalla: LED (verde): Indicador de corriente

Entrada:

Límites de voltaje de suministro:

115 VCA 90 a 130 VCA, 48 a 63 Hz

230 VCA 180 a 260 VCA, 48 a 63 Hz

Corriente nominal:

115 VCA 2,3 A

230 VCA 1,2 A

Construcción:

Dimensiones del controlador:

115 y 230 VCA 16,5 cm de ancho

19,3 cm de profundidad

8,9 cm de alto

Peso del controlador:

115 VCA 1,0 kg

230 VCA 1,5 kg

Clasificación del recinto del controlador: IP23 según IEC529

35

Page 38

Especificaciones (cont.)

Dimensiones del motor:

115 VCA 8,6 cm de ancho

18,0 cm de profundidad

9,9 cm de alto

230 VCA 8,6 cm de ancho

23,9 cm de profundidad

9,9 cm de alto

Clasificación del recinto del motor: IP21 según IEC529

Peso del motor:

115 VCA 3,1 kg

230 VCA 3,2 kg

Ambiente:

Temperatura de operación: 0°C a 40°C

Temperatura de almacenamiento: –25°C a 65°C

Humedad (sin condensado): 10% a 90%

Altitud: Menos de 2000 m

Grado de contaminación: Grado de contaminación 2 (Uso interior—laboratorio,

oficina)

Resistencia química: Todos los materiales resisten los disolventes de limpieza

estándar. Los materiales usados en la construcción son

etiquetas de poliéster, y un chasis de aluminio y recinto de

plástico combinados.

Cumplimiento: 115 V: UL508C, CSA C22.2, No. 14

230 V (para la marca CE):

EN61010-1

(Directiva de bajo voltaje de la UE) y

EN61326

(Directiva EMC de la UE)

GARANTÍA

El Fabricante garantiza que este producto no se desvía significativamente de las especificaciones publicadas. Si es

necesario efectuar reparaciones o ajustes en el período de garantía, el problema se corregirá de forma gratuita si no se

debe al uso indebido o abuso por su parte según lo determine el Fabricante. Es posible que le facturemos los costos de

reparación fuera del período de garantía, o los costos que sean consecuencia del uso indebido o abuso del producto.

El período de garantía de este producto es dos (2) años a partir de la fecha de compra.

DEVOLUCIÓN DEL PRODUCTO

Para limitar los cargos y demoras, póngase en contacto con el vendedor o Fabricante para obtener autorización e

instrucciones de envío antes de devolver el producto, ya sea en el período de garantía o fuera del mismo. Al devolver

el producto, indique el motivo de su devolución. Para su protección, empaque cuidadosamente el producto y asegúrelo

contra posibles daños o pérdidas. Usted es responsable de cualquier daño debido a un empacado indebido.

ASISTENCIA TÉCNICA

Si tiene dudas sobre el uso de este producto, póngase en contacto con el Fabricante o vendedor autorizado.

Impreso en EE.UU.

36

Page 39

INDICE

Titolo Pagina

MISURE DI SICUREZZA ................................................................................................................................. 38

INTRODUZIONE .............................................................................................................................................. 39

INDICATORI E COMANDI ............................................................................................................................... 39

DATI SULLE APPLICAZIONI ........................................................................................................................... 40

DESCRIZIONE................................................................................................................................................. 40

MONTAGGIO/MESSA A PUNTO..................................................................................................................... 41

FUNZIONAMENTO .......................................................................................................................................... 42

INDIVIDUAZIONE E RISOLUZIONE DI PROBLEMI E MANUTENZIONE ...................................................... 42

Individuazione e risoluzione di problemi .......................................................................................................42

Ispezione/sostituzione delle spazzole motore .............................................................................................. 43

Sostituzione dei fusibili ................................................................................................................................. 43

Pulizia del sistema azionamento/controller .................................................................................................. 43

Ricambi ........................................................................................................................................................ 44

SPECIFICHE TECNICHE ................................................................................................................................ 44

GARANZIA ....................................................................................................................................................... 45

RESTITUZIONE DEL PRODOTTO.................................................................................................................. 45

ASSISTENZA TECNICA .................................................................................................................................. 45

MICROPUMP — Marchio depositato della Micropump Inc., una divisione della Idex Corp.

RYTON — Marchio depositato della Chevro n Phillips Chemical Company, L.L.C.

VITON — Marchio depositato della E.I. duPont DeNemours & Co.

In questa pubblicazione il simbolo

®®

® indica che i marchi di fabbrica sono marchi depositati negli Stati Uniti e in altri paesi.

®®

ITALIANO

37

Page 40

MISURE DI SICUREZZA

PERICOLO: internamente all’azionamento/controller si trovano componenti ad alta tensione accessibili;

non rimuovere il coperchio.

ATTENZIONE: prima di collegare il cavo del motore dell’azionamento, disinnestare il cavo elettrico in c.a;

all’interno di questo strumento si trovano elementi su cui l’utente non può effettuare interventi,

ma deve rivolgersi al distributore per la manutenzione.

USARE per evitare di danneggiare la pompa, non ostruirne l’orificio di ammissione e non azionarla

CAUTELA: a secco;

accertarsi che l’alimentazione disponibile corrisponda ai requisiti dell’unità; le unità sono o a

115 V 50/60 Hz o a 230V 50/60 Hz.

ATTENZIONE: RESTRIZIONI SULL’USO DEL PRODOTTO

Questo prodotto non è progettato per apparecchiature che agiscono direttamente sul paziente e non è inteso, tra

gli altri, per usi medici e odontoiatrici. Di conseguenza non è stato sottoposto all’approvazione della FDA, l’ente

statunitense per gli alimenti e i farmaci.

38

Page 41

INTRODUZIONE

Tutti questi sistemi motore/controller includono un accoppiatore magnetico a coppia elevata ed un motore da 74,6 W a

corrente diretta, progettato per azionare le teste pompanti MICROPUMP®. Il motore è estremamente silenzioso, le

spazzole sono di lunga duratura, ha una coppia più elevata ad alte velocità, è completamente chiuso ed è lubrificato

permanentemente. Il sistema motore/controller compensa automaticamente le variazioni dei requisiti di coppia-carico.

Utilizzando un circuito di comando elettronico, il controller rende il controllo della velocità (flusso) del motore affidabile

con un “avvio dolce” ed un’accelerazione graduale omogenea fino al raggiungimento della velocità prestabilita. I limiti di

corrente del motore proteggono il sistema in caso di rotore bloccato e garantisce il blocco magnetico in una vasta

gamma di variazioni di carico. La protezione del circuito di uscita protegge contro i cortocircuiti involontari. La

compensazione di corrente incorporata del motore minimizza le variazioni di velocità da zero a pieno carico. L’eccellente

regolazione della velocità e la maggiore immunità al rumore di linea, anche con le variazioni della tensione di linea e del

carico sono parte integrale della progettazione del comando elettronico.

Codice Requisiti di

azionamento alimentazione*

75211-20 Da 90 a 130 V c.a.

75211-25 Da 200 a 260 V c.a.

* La tensione in c.a. può essere o a 50 o a 60 Hz.

Questo manuale contiene dati sull’applicazione, la descrizione, il montaggio/la messa a punto, il funzionamento,

l’individuazione e la risoluzione di problemi, la manutenzione e le specifiche tecniche.

INDICATORI E COMANDI

39

Page 42

Mfg. by Thermo Fisher Scientific

Mfg. by Thermo Fisher Scientific

PANNELLO POSTERIORE DEL CONTROLLER

DATI SULLE APPLICAZIONI

Tutti i sistemi motore/controller sono dotati di accoppiatore magnetico a coppia elevata e motore a corrente diretta da

74,6 W progettato per azionare le teste pompanti MICROPUMP.

DESCRIZIONE

Il motore è progettato per essere montato su banco con un cavo, lungo 1,8 m, a norma UE CEI 320, per il collegamento

al Controller. Il motore da 74,6 W a corrente diretta è completamente chiuso e lubrificato permanentemente.

La custodia del controller, inclusi i comandi dell’operatore montati sul lato superiore, è lunga 17,8 cm, larga 12,7 cm e

alta 8,9 cm. È di design modulare e rende l’accesso ai comandi comodo e il collegamento del cavo del motore facile. Il

controller ha un cavo elettrico staccabile lungo 1,8 m conforme a norma UE CEI 320. Il controller include un amplificatore

di potenza basato su raddrizzatore controllato al silicio (SCR) che regola la velocità del motore a seconda delle

impostazioni prestabilite dall’operatore.

40

Page 43

MONTAGGIO/MESSA A PUNTO

Il motore include una base saldata per il montaggio o per l’uso come unità autonoma. I segnali di ingresso del motore