Page 1

© 04-08

Cole-Parmer Instrument Co.

625 East Bunker Court

Vernon Hills, Illinois U.S.A. 60061-1844

800-323-4340

fax: 847-247-2929

www.coleparmer.com

e-mail: techinfo@coleparmer.com

Cole-Parmer®Battery-Powered Digital Pressure Gauges

Accuracy

±0.25% of full scale ±1 least significant digit

Includes linearity, hysteresis, repeatability

Display

3 readings per second nominal display update rate

Ranges up to 1999: 31/2 digit LCD, 0.5" digit height

3000 psi, 5000 psi: 4

1

/2 digit LCD, 0.5" digit height,

lower alphanumeric display for engineering units

NEMA 4X models: Red LED backlight on whenever gauge is on

Controls

Ranges up to 1999

Front button turns gauge on/off

Front calibration potentiometers, non-interactive zero and span, ±10% range

3000 psi, 5000 psi ranges

Front button turns gauge on, starts auto shutoff timer, and provides zero function for gauge reference ranges

NEMA 4X models: Button activates backlighting for 1 minute while gauge is on

Internal calibration buttons, non-interactive zero and span, ±10% range

Batteries and Battery Life

Two AA alkaline

5 minute auto shutoff

Low battery symbol on display when batteries must be replaced

Standard models with ranges up to 1999: approx. 2500 hours

Standard models with 3000 psi, 5000 psi ranges: approx. 2000 hours

NEMA 4X models with backlit display and ranges up to 1999: approx. 180 hours

NEMA 4X models with backlit display, 3000 psi, 5000 psi ranges: approx. 150 to

1500 hours depending on backlight usage

Dimensions

Standard: 3.38" W x 2.88" H x 1.65" D housing

NEMA 4X: 3.5" W x 3.0" H x 2.0" D housing

Add approximately 0.75" to height for pressure fitting

Weight

Gauge: 9 ounces (approx)

Shipping weight: 1 pound (approx)

Material and Color

Standard: Extruded aluminum case, epoxy powder coated. Polycarbonate

cover, front and rear gaskets. Light gray body, light gray/blue front.

NEMA 4X: UV stabilized polycarbonate/ABS case, light gray color. Clear polycarbonate window to protect display. Gasketed rear cover, six captive stainless

steel screws.

Pressure/Vacuum Connection and Material

1

/4" NPT male, 316 stainless steel, compatible with most liquids and gases

Overpressure

3000 psig range and metric equivalents: 5000 psig

5000 psig range and metric equivalents: 7500 psig

3000 psi, 5000 psi: 112.5% out-of-range display

ii

– – – or ii–.–.–.–

All others 2 times rated pressure minimum

Burst Pressure

4 times rated pressure minimum or 10,000 psi, whichever is less

Environmental

Storage Temperature –40 to 203°F (–40 to 95°C)

Operating Temperature –4 to 185°F (–20 to 85°C)

Compensated Temperature 32 to 158°F (0 to 70°C)

68935-18

0 to 100.0 psig range

68935-32

0 to 5000 psig range

68936-95 Rubber Boot

Not for NEMA 4X models

Standard

Model no.

NEMA 4X

Model no.

Range Resolution

68935-00 68935-34 760 to 0 torr absolute 1 torr

68935-02 68935-36 0 to 30.0" Hg vacuum 0.1" Hg

68935-04 68935-38 0 to 3.00 psig 0.01 psig

68935-06 68935-40 0 to 5.00 psig 0.01 psig

68935-08 68935-42 –30.0" Hg vac. to 15.0 psig 0.1" Hg/0.1 psig

68935-10 68935-44 –15.0 to 15.0 psig 0.1 psig

68935-12 68935-46 0 to 15.00 psig 0.01 psig

68935-14 68935-48 0 to 30.0 psig 0.1 psig

68935-16 68935-50 –30.0" Hg vac. to 100.0 psig 0.1" Hg/0.1 psig

68935-18 68935-52 0 to 100.0 psig 0.1 psig

68935-20 68935-54 –30.0" Hg vac. to 199.9 psig 0.1" Hg/0.1 psig

68935-22 68935-56 0 to 199.9 psig 0.1 psig

68935-24 68935-58 0 to 300 psig 1 psig

68935-26 68935-60 0 to 500 psig 1 psig

68935-28 68935-62 0 to 1000 psig 1 psig

68935-30 68935-64 0 to 3000 psig 1 psig

68935-32 68935-66 0 to 5000 psig 1 psig

68935-36

0 to 30.0 inHg range, NEMA 4X

68935-66

0 to 5000 psig range, NEMA 4X

Certificate of Conformance

This product is manufactured according to applicable industry standards

and conforms to the manufacturer's engineering, production, calibration,

and quality standards.

This product conforms to the customer’s stated order requirements, including mechanical and electrical specifications, dimensions, physical item

identification (part number and serial number).

This product has been tested and calibrated to meet or exceed accuracy

specifications in effect at the time of manufacture using NIST traceable

standards maintained in accordance with ANSI/NCSL Z540-1 and ISO

10012.

This product is manufactured in the United States of America

Model

Serial Number

Date Purchased

Purchase Order

Page 2

Cole-Parmer Battery-Powered Digital Pressure Gauges

© 04-08

Installation and Precautions

Install or remove gauge using wrench on hex fitting only. Do not attempt to tighten by turning

housing or any other part of the gauge. Use fittings appropriate for the pressure range of the

gauge. Do not apply vacuum to gauges not designed for vacuum operation. Due to the hardness of 316 stainless steel, it is recommended that a thread sealant be used to ensure leakfree operation. NEVER insert objects into the gauge port or blow out with compressed air.

Permanent damage not covered by warranty will result to the sensor.

Operation – Ranges up to 1999

Press the round button on the front of the gauge to activate the display. The gauge will stay on

for approximately 5 minutes. The gauge can be shut off at any time by pressing the button

again. For models with display backlighting, the backlighting is on whenever the gauge is on.

Turn gauge off when not in use to conserve battery.

Operation – 3000 psi, 5000 psi Ranges

Press and hold the button for approximately 1 second. The full-scale range is indicated, display segments are tested, and the reading and units are displayed. The gauge will stay on for

5 minutes.

Power-Up with Zero (gauge reference models only)

1. Make absolutely certain no pressure is applied to the gauge. The gauge port should be

exposed to normal atmospheric pressure. Note that the zeroing function may only be activated at power-up and the stored zero correction is erased when the gauge is shut off.

2. Press and hold the button.

3. The full-scale range is indicated and the display segments are tested.

4. Continue to press the button until

o o o o

is displayed and then release the button. This indi-

cates that the gauge has been zeroed.

5. The actual pressure is displayed and the 5 minute auto shutoff timer starts.

Attempting to zero the gauge with pressure greater than approximately 3% of full-scale

applied will result in an error condition, and the display will alternately indicate

E r r 0

and the

actual measured pressure. The gauge must be powered down to reset the error condition.

Normal Operation

Following the start-up initialization, the display indicates the pressure reading and the engineering units. The 5 minute auto shutoff timer starts when the gauge is powered up or whenever the button is pushed.

If excessive vacuum is applied, the display will indicate

– E r r

until the vacuum is released.

Applying vacuum to a gauge designed for pressure may damage the sensor. If excessive pressure is applied (112.5% over range), an out-of-range indication of

I – – –

or

I –.–.–.–

will be

displayed depending on model.

Models with Display Backlighting

Display backlighting can be turned on by momentarily pressing the button whenever the gauge

is on. The backlighting will turn on for one minute and then automatically shut off. This also

restarts the auto shutoff timer.

Shut-Down

To shut off the gauge manually at any time, press and hold the button until the display indicates

O F F

(about 5 seconds) and then release.

The display indicates

O F F

five seconds prior to auto shutoff. The button can be pressed to

keep the gauge on. The auto shutoff and backlight timers are reset whenever the button is

pressed and released.

Calibration

All gauges are factory calibrated on NIST traceable calibration equipment. No calibration is

required before placing the gauge into service. Calibration equipment should be at least four

times more accurate than the gauge being calibrated. The calibration system must be able to

generate and measure pressure/vacuum over the full range of the gauge. A vacuum pump able

to produce a vacuum of 10 microns (0.01 torr or 10 millitorr) or lower is required for vacuum

and absolute gauges. It is good practice to install fresh batteries before calibrating batterypowered gauges. Allow the gauge to equalize to normal room temperature before calibration.

Calibration – Ranges up to 1999

Remove the calibration potentiometer covers on the front of the unit to access the zero and

span controls. Zero calibration must be done before span calibration.

Gauge reference Zero: The gauge port must be open to the ambient with no pressure or vacuum applied. Adjust the Zero control until the gauge reads zero with the minus (–) sign occasionally flashing. Gauges may be re-zeroed without affecting the span calibration.

Absolute reference Zero: Apply full vacuum to absolute reference gauges and adjust the Zero

control until the gauge reads zero with the minus (–) sign occasionally flashing. Gauges may

be re-zeroed without affecting the span calibration.

Span calibration: Apply pressure or vacuum depending on the type of gauge. Record readings

at three to five points over the range of gauge and adjust span control to minimize error and

meet specifications. Absolute reference gauges display atmospheric pressure when the gauge

port is open to the ambient and it is normal for the reading to fluctuate in response to normal

atmospheric pressure changes.

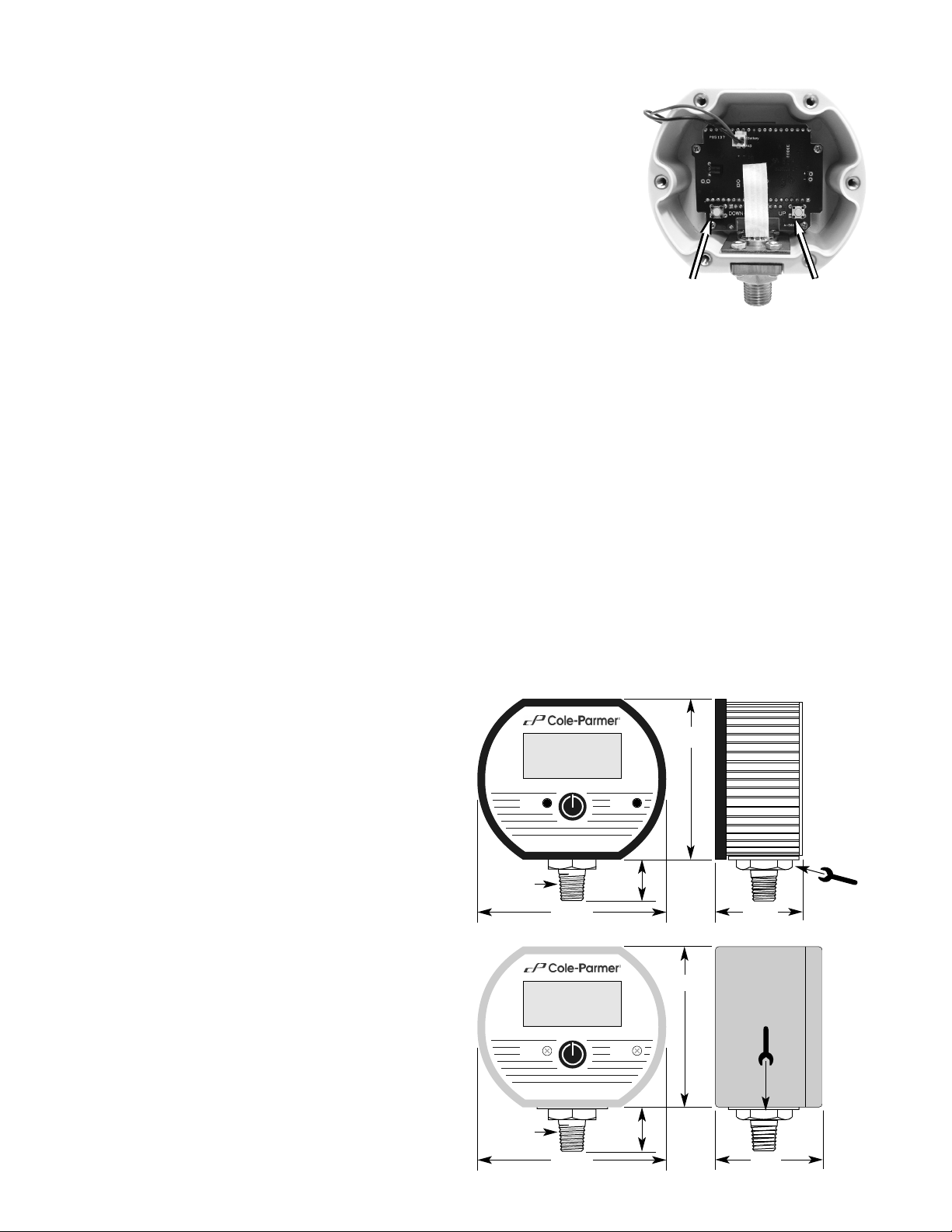

Calibration – 3000 psi, 5000 psi Ranges

Remove the screws on the back of the unit and remove cover and note the locations of the two

internal calibration buttons marked UP and DOWN. These buttons are disabled unless the

gauge is in calibration mode.

With the gauge off, press and hold the DOWN calibration button, and also press the front button to power up the gauge in calibration mode. The display first indicates the gauge’s full-scale

pressure range, tests all display segments, and then indicates

CAL

to indicate that the gauge

is in the calibration mode. Release all buttons.

The display will then indicate the current pressure reading. The gauge will remain in the calibration mode until powered down. While in the calibration mode the shutoff time, is disabled

and the calibration buttons are active.

Each press of the UP or DOWN button

makes a small correction, which may

not always be indicated on the digital

display. Press and hold the push button

for one second or longer to make larger

continuous corrections. The display of

the gauge being calibrated is adjusted to

match the calibrator’s setting or readout.

If the battery pack is unplugged during

calibration, calibration settings will not

be saved.

1. With the gauge port open to atmosphere, the character display will alternate between

ZERO

and

CAL

. Press the

UP and DOWN buttons to obtain a display

indication of zero.

2. Apply full-scale pressure. The character display will alternate between

+SPAN

and

CAL

.

Press the UP and DOWN buttons to obtain a display indication equal to full-scale pressure.

3. Apply 50% of full-scale pressure. The character display will alternate between

+MID

and

CAL

. Press the UP and DOWN buttons to obtain a display indication equal to 50% of full-scale

pressure.

4. Exit the calibration mode and save the calibration data by pressing and holding the front button until the display indicates

OFF

.

5. Verify pressure indications at 0%, 25%, 50%, 75%, and 100% of full scale.

6. Replace the rear cover and screws, taking care not to pinch the power leads between the

case and the rear cover.

Battery Replacement

A low battery indication will be shown in the upper left-hand corner of the display when the

battery voltage falls sufficiently. The battery should be replaced soon after the indicator comes

on or unreliable readings may result.

Remove the 6 Phillips head screws on the back of the unit.

Carefully remove batteries from the holders by lifting up the positive end of the battery (opposite the spring). Take care not to bend or distort the battery retention springs.

DO NOT discard the old battery into fire, any other sources of extreme heat, or in any other hazardous manner. Please consult local authorities if there is any question about proper disposal.

Always replace both batteries at the same time with high quality alkaline batteries. Observe

the polarity of the batteries when replacing them. The negative (flat) end of each battery should

be inserted first, and should face the spring in the battery holder.

Replace the back cover, including the rubber sealing gasket.

Dimensions

3000 psi and 5000 psi models use internal zero and span adjustments and do not have potentiometers.

1

/4 NPT

Cole-Parmer Instrument Co. / Made in USA

2.88"

3.38

"

0.75"

1.65

"

PSIG

Tur n

at hex

fitting

only

Span

Zero

31/2 digit or

4 digit display

1

/4 NPT

Cole-Parmer Instrument Co. / Made in USA

3.0"

3.5

"

0.75"

2.0

"

PSIG

Span

Zero

31/2 digit or

4 digit display

Tur n at

hex

fitting

only!

DOWN UP

NEMA 4X

Standard

Page 3

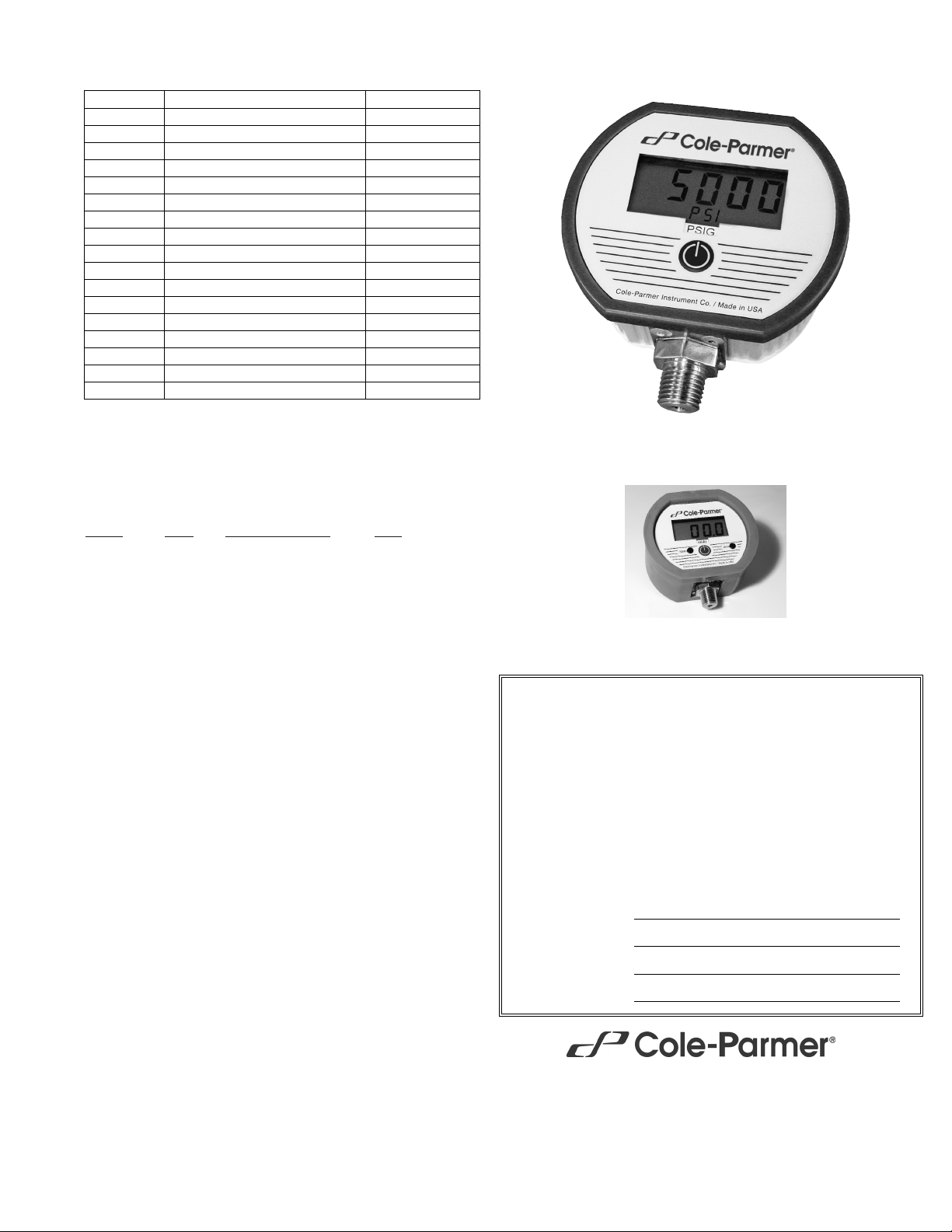

Cole-Parmer®Battery-Powered Gauges with Min/Max/Zero

68936-32

0 to 5000 psig range

Accuracy

Standard: ±0.25% of full scale ±1 least significant digit

Includes linearity, hysteresis, repeatability

Display

3 readings per second nominal display update rate

4 digit LCD, 0.5" H, 5 character 0.25" H alphanumeric lower display

Controls & Functions

Front button turns gauge on or off and cycles through functions

Calibration

Internal calibration buttons

Non-interactive zero, span, and linearity, ±10% range

Auto Shutoff

5 minutes

Batteries, Battery Life, Low Battery Indication

2 AA alkaline

Battery life approximately 2000 hours

Low battery symbol on display when batteries must be replaced

Dimensions

3.38" W x 2.88" H x 1.65" D housing

Add approximately 0.75" to height for pressure fitting

Weight

Gauge: 9 ounces (approx)

Shipping weight: 1 pound (approx)

Material & Color

Extruded aluminum case, light gray epoxy powder coated, ABS/ polycarbonate

bezel, front and rear gaskets, polycarbonate label

Pressure/Vacuum Connection Size & Material

1/4" NPT male

All wetted parts are 316 SS, compatible with most liquids and gases

Overpressure

3000 psig range and metric equivalents: 5000 psig

5000 psig range and metric equivalents: 7500 psig

All others: 2 x sensor pressure

112.5% out-of-range display: I – – – or I –.–.–.– depending on model

Burst Pressure

4 times sensor pressure rating, or 10,000 psi, whichever is less

Environmental

Storage Temperature –40 to 203°F (–40 to 95°C)

Operating Temperature –4 to 185°F (–20 to 85°C)

Compensated Temperature 32 to 158°F (0 to 70°C)

Model no. Range Resolution

68936-00 760.0 to 0 torr absolute 0.1 torr

68936-02 0 to 30.00" Hg vacuum 0.01" Hg

68936-04 0 to 3.000 psig 0.001 psig

68936-06 0 to 5.000 psig 0.001 psig

68936-08 –30.0" Hg vac. to 15.0 psig 0.1" Hg/0.1 psig

68936-10 –15.00 to 15.00 psig 0.01 psig

68936-12 0 to 15.00 psig 0.01 psig

68936-14 0 to 30.00 psig 0.01 psig

68936-16 –30.0" Hg vac. to 100.0 psig 0.1" Hg/0.1 psig

68936-18 0 to 100.0 psig 0.1 psig

68936-20 –30.0" Hg vac. to 200.0 psig 0.1" Hg/0.1 psig

68936-22 0 to 200.0 psig 0.1 psig

68936-24 0 to 300.0 psig 0.1 psig

68936-26 0 to 500.0 psig 0.1 psig

68936-28 0 to 1000 psig 1 psig

68936-30 0 to 3000 psig 1 psig

68936-32 0 to 5000 psig 1 psig

Function

Button Prompt

(Release Button)

Result

On Press 1 sec Gauge Range/Display Test Actual Pressure

One Touch Zero Press/hold

oooo

Zeroed Actual Pressure

Hi Reading Press/hold

HHII HHII

& max. reading

Lo Reading Press/hold

LLoo LLoo

& min. reading

Exit Hi/Lo Press/hold

AAPP

Actual Pressure

Clear Hi/Lo Press/hold

HHII/ LLOO/ AAPP ☞☞CCii

r

Actual Pressure

Clear Zero, Off Press/hold

HHII/ LLOO/ AAPP ☞☞CCiir☞☞ OOFFFF

Clear Zero, Gauge Off

© 04-08

Cole-Parmer Instrument Co.

625 East Bunker Court

Vernon Hills, Illinois U.S.A. 60061-1844

800-323-4340

fax: 847-247-2929

www.coleparmer.com

e-mail: techinfo@coleparmer.com

68936-95 Rubber Boot

Certificate of Conformance

This product is manufactured according to applicable industry standards

and conforms to the manufacturer's engineering, production, calibration,

and quality standards.

This product conforms to the customer’s stated order requirements, including mechanical and electrical specifications, dimensions, physical item

identification (part number and serial number).

This product has been tested and calibrated to meet or exceed accuracy

specifications in effect at the time of manufacture using NIST traceable

standards maintained in accordance with ANSI/NCSL Z540-1 and ISO

10012.

This product is manufactured in the United States of America

Model

Serial Number

Date Purchased

Purchase Order

Page 4

Installation and Precautions

Install or remove gauge using wrench on hex fitting only. Do not attempt to tighten by turning

housing or any other part of the gauge.

Use fittings appropriate for the pressure range of the gauge.

Do not apply vacuum to gauges not designed for vacuum operation.

Due to the hardness of 316 stainless steel, it is recommended that a thread sealant be used to

ensure leak-free operation.

NEVER insert objects into the gauge port or blow out with compressed air. Permanent damage

not covered by warranty will result to the sensor.

Power-Up

1. Press and hold the button for approximately 1 second.

2. The full-scale range is indicated and the display segments are tested.

3. The actual pressure and units are displayed.

Power-Up With Zero (gauge reference models only)

1. Be sure the gauge port is exposed to normal atmospheric pressure and no pressure is

applied. The zeroing function is only activated at each power-up and the stored zero correction

is erased when the gauge is shut off.

2. Press and hold the button.

3. The full-scale range is indicated and the display segments are tested.

4. Continue to press the button until

o o o o

is displayed and then release the button. This indi-

cates that the gauge has been zeroed.

5. The actual pressure is displayed.

Attempting to zero the gauge with pressure greater than approximately 3% of full-scale

applied will result in an error condition, and the display will alternately indicate

E r r 0

and the

actual measured pressure. The gauge must be powered down to reset the error condition.

Absolute reference gauges do not use the zero feature since they read atmospheric pressure

under normal conditions.

Normal Operation

Following the start-up initialization, the display indicates the pressure reading updated approximately 3 times per second. The auto shutoff timer starts when the gauge is powered up or

whenever the button is pushed.

If excessive vacuum is applied to a pressure-only gauge, the display will indicate

– E r r

until

the vacuum is released. Applying vacuum to a gauge designed for pressure may damage the

pressure sensor. If excessive pressure is applied (112.5% over range), an out-of-range indication of

I – – –

or

I –.–.–.–

will be displayed depending on model.

Minimum and Maximum Readings

Minimum and maximum readings are continuously stored and updated whenever gauge is on.

The stored readings can be manually cleared if desired. The high and low memory is also

cleared whenever the gauge is off.

Press and hold the button for about 1 second until HIis displayed. The maximum stored value

is displayed.

After

HI

is displayed, press and hold the button again for about 1 second until LOis displayed.

The minimum stored value is displayed.

After LOis displayed, press and hold the button again for about 1 second until AP(Applied

Pressure) is displayed. The high and low memory is not erased and the gauge returns to normal operation with the display indicating the current pressure.

Press and continue to hold the button until the display indicates

Clr Hi/Lo

(about 3 seconds

total) and then release the button. Both high and low values are cleared and the gauge returns

to the normal mode and displays the current pressure.

Shut-Down

To shut off the gauge manually at any time, press and hold the button until the display indicates

OFF

(about 5 seconds) and then release.

The display indicates

OFF

five seconds prior to auto shutoff. The button can be pressed to keep

the gauge on. The auto shutoff timers are reset whenever the button is pressed and released.

Turn gauge off when not in use to conserve battery life.

Calibration

All gauges are factory calibrated on NIST traceable calibration equipment. No calibration is

required before placing the gauge into service. Calibration equipment should be at least four

times more accurate than the gauge being calibrated. The calibration system must be able to

generate and measure pressure/vacuum over the full range of the gauge. A vacuum pump able

to produce a vacuum of 10 microns (0.01 torr or 10 millitorr) or lower is required for vacuum

and absolute gauges. It is good practice to install fresh batteries before calibrating batterypowered gauges. Allow the gauge to equalize to normal room temperature before calibration.

Remove the screws on the back of the unit and remove cover and note the locations of the two

internal calibration buttons marked UP and DOWN. These buttons are disabled unless the

gauge is in calibration mode.

With the gauge off, press and hold the DOWN calibration button, and also press the front button to power up the gauge in calibration mode. The display first indicates the gauge’s full-scale

pressure range, tests all display segments, and then indicates

CAL

to indicate that the gauge

is in the calibration mode. Release all buttons.

The display will then indicate the current pressure reading. The gauge will remain in the calibration mode until powered down. While in the calibration mode the shutoff timer is disabled.

Each press of the UP or DOWN button makes a small correction, which may not always be indicated on the digital display. Press and hold the push button for one second or longer to make

larger continuous corrections. The display of the gauge being calibrated is adjusted to match

the calibrator’s setting or readout.

If the battery pack is unplugged during calibration, calibration settings will not be saved.

Gauge Reference Gauges (3 Points)

1. With the gauge port open to atmosphere, the character display will alternate between

ZERO

and

CAL

. Press the UP and DOWN buttons to obtain a display indication of zero.

2. Apply full-scale pressure. The character display will alternate between

+SPAN

and

CAL

.

Press the UP and DOWN buttons to obtain a display indication equal to full-scale pressure.

3. Apply 50% of full-scale pressure. The character display will alternate between

+MID

and

CAL

. Press the UP and DOWN buttons to obtain a display indication equal to 50% of full-scale

pressure.

Absolute Reference Gauges (3 Points)

1. Apply full vacuum to the gauge. The character display will alternate between

ZERO

and

CAL

.

Press the UP and DOWN buttons to obtain a display indication of zero.

2. Apply full-scale pressure. The character display will alternate between

+SPAN

and

CAL

.

Press the UP and DOWN buttons to obtain a display indication equal to full-scale pressure.

3. Apply 50% of full-scale pressure. The character display will alternate between

+MID

and

CAL

. Press the UP and DOWN buttons to obtain a display indication equal to 50% of full-scale

pressure.

Bipolar (±) and –30inHg/15psig Compound Ranges (5 Points)

1. With the gauge port open to atmosphere, the character display will alternate between

ZERO

and

CAL

. Press the UP and DOWN buttons to obtain a display indication of zero.

2. Apply full-scale positive pressure. The character display will alternate between

+SPAN

and

CAL

. Press the UP and DOWN buttons to obtain a display indication equal to full-scale pressure.

3. Apply 50% of full-scale positive pressure. The character display will alternate between

+MID

and

CAL

. Press the UP and DOWN buttons to obtain a display indication equal to 50% of full-

scale pressure.

4. Apply full vacuum. The character display will alternate between

–SPAN

and

CAL

. Press the

UP and DOWN buttons to obtain a display indication equal to the full vacuum reading.

5. Apply 50% of the full-scale vacuum range (for example, –7.4 psi for a ±15 psi gauge). The

character display will alternate between

–MID

and

CAL

. Press the UP and DOWN buttons to

obtain a display indication equal to 50% of full-scale vacuum.

–30inHg/100psig and –30inHg/200psig Compound (4 Points)

1. With the gauge port open to atmosphere, the character display will alternate between

ZERO

and

CAL

. Press the UP and DOWN buttons to obtain a display indication of zero.

2. Apply full-scale positive pressure. The character display will alternate between

+SPAN

and

CAL

. Press the UP and DOWN buttons to obtain a display indication equal to full-scale pressure.

3. Apply 50% of full-scale positive pressure. The character display will alternate between

+MID

and

CAL

. Press the UP and DOWN buttons to obtain a display indication equal to 50% of full-

scale pressure.

4. Apply full vacuum. The character display will alternate between

–SPAN

and

CAL

. Press the

UP and DOWN buttons to obtain a display indication equal to the full vacuum reading.

Exit Calibration Mode and Verify Calibration

1. Exit the calibration mode and save the calibration data by pressing and holding the front button until the display indicates

OFF

.

2. Verify readings at 0%, 25%, 50%, 75%, and 100% of full scale.

3. Replace the rear cover and screws, taking care not to pinch the power leads between the

case and the rear cover.

Battery Replacement

A low battery indication will be shown in the upper left-hand corner of the display when the

battery voltage falls sufficiently. The battery should be replaced soon after the indicator comes

on or unreliable readings may result.

1. Remove the 6 Phillips head screws on the back of the unit.

2. Remove batteries by lifting up the positive end of the battery (opposite the spring) taking

care not to bend the battery holder spring.

3. Discard old batteries properly, DO NOT discard into fire, sources of extreme heat, or in any

other hazardous manner.

4. Always replace both batteries at the same time with high quality alkaline batteries. Install

batteries with correct orientation. The negative (flat) end of each battery should be inserted

first facing the battery holder spring.

5. Replace the back cover, including the rubber sealing gasket.

Dimensions

Cole-Parmer®Battery-Powered Gauges with Min/Max/Zero

1

/4 NPT

Cole-Parmer Instrument Co. / Made in USA

2.88"

3.38

"

0.75"

1.65

"

Tur n at

hex

fitting

only

XXXXX

8

8

8

8

8

2

© 04-08

Page 5

Applications

■■

Replace Mercury Manometers in Fume Hoods

■■

Monitor Vacuum Systems and Pumps

■■

Vacuum Packaging

Cole-Parmer®Absolute Reference Gauges, 760 Torr Absolute

Range and Resolution

760 to 0 torr absolute, 1 torr resolution

Display

31/2 digit LCD (3 digits are used for this range), 0.5" digit height

3 readings per second nominal display update rate

68936-82: Red LED display backlight on whenever gauge is on

Controls and Location

Front on/off button

Front-accessible multi-turn potentiometers for display zero/span

Non-interactive, ±10% range

Accuracy

±0.25% of full scale ±1 least significant digit

Includes linearity, hysteresis, repeatability

Power

Includes 115VAC/12VDC wall mount power supply

Gauge will operate on any DC source of 9 to 32 VDC or any AC source of

8 to 24 VAC 50/60 Hz

Reverse polarity protected

Power consumption approximately 5 mA

6 foot long, 2-conductor cable with female 3.5 mm socket

Power supply: 6 foot long, 2-conductor cable with male 3.5 mm plug

Dimensions

3.38" W x 2.88" H x 1.65" D housing

Add approximately 0.75" to height for pressure fitting and approximately 1" to

depth for wire strain relief

Weight

Gauge: 9 ounces (approx)

Shipping weight: 1 pound (approx)

Material

Extruded aluminum case, light gray epoxy powder coated, ABS/ polycarbonate

bezel, front and rear gaskets, polycarbonate label

Pressure/Vacuum Connection and Material

1

/4" NPT male, 316 stainless steel

Media Compatibility

All wetted parts are 316 SS, compatible with most liquids and gases

Overpressure

2 times rated pressure minimum

Burst Pressure

4 times rated pressure minimum

Environmental

Storage Temperature –40 to 203°F (–40 to 95°C)

Operating Temperature –4 to 185°F (–20 to 85°C)

Compensated Temperature 32 to 158°F (0 to 70°C)

Model Features

68936-80 Powered by 115 VAC/12 VDC adapter (included)

68936-82 Backlit display, powered by 115 VAC/12 VDC

adapter (included)

Externally Powered 760 Torr Absolute Gauge

Certificate of Conformance

This product is manufactured according to applicable industry standards

and conforms to the manufacturer's engineering, production, calibration,

and quality standards.

This product conforms to the customer’s stated order requirements, including mechanical and electrical specifications, dimensions, physical item

identification (part number and serial number).

This product has been tested and calibrated to meet or exceed accuracy

specifications in effect at the time of manufacture using NIST traceable

standards maintained in accordance with ANSI/NCSL Z540-1 and ISO

10012.

This product is manufactured in the United States of America

Model

Serial Number

Date Purchased

Purchase Order

Cole-Parmer Instrument Co.

625 East Bunker Court

Vernon Hills, Illinois U.S.A. 60061-1844

800-323-4340

fax: 847-247-2929

www.coleparmer.com

e-mail: techinfo@coleparmer.com

© 04-08

Page 6

Cole-Parmer®Absolute Reference Gauges, 760 Torr Absolute

Description

The externally powered 760 torr absolute models are designed for applications where a continuous display of vacuum is required. This makes it ideal for monitoring vacuum systems and

pumps such as in laboratory fume hoods.

Battery powered 760 torr absolute models are available for portable applications.

Absolute reference gauges read zero with full vacuum applied. They display atmospheric pressure when the gauge port is open to the ambient and it is normal for the reading to fluctuate

in response to normal atmospheric pressure changes.

Installation and Precautions

Install or remove gauge using a wrench on the hex fitting only. Do not attempt to tighten by

turning housing or any other part of the gauge.

Due to the hardness of 316 stainless steel, it is recommended that a thread sealant be used to

ensure leak-free operation.

NEVER insert objects into the gauge port or blow out with compressed air. Permanent damage

not covered by warranty will result to the sensor.

Electrical Connection

The externally powered 760 torr absolute models include 6 feet of cable with a female connector and a 115VAC/12VDC adapter with 6 feet of cable with plug. After the gauge is installed,

route the wires away from heat sources and moving equipment and connect the AC adapter’s

plug to the gauge cable connector. Lastly, plug the AC adapter into a 115 VAC outlet.

NEVER connect the gauge wires directly to 115 VAC or permanent damage not covered by warranty will result.

If the supplied AC adapter is not used, the externally powered 760 torr absolute models can

operate on any AC source of 8 to 24 VAC 50/60 Hz, or any DC source of 9 to 32 VDC. These models can be used with inexpensive unregulated low voltage AC or DC power sources. The type

and magnitude of the supply voltage have negligible effects on the gauge calibration as long

as it is within the voltage ranges stated above. No polarity needs to be observed when connecting a DC supply.

The only important consideration is to ensure that the gauge supply voltage does not fall below

8 VAC RMS if AC power is used, or 9 VDC if DC power is used. Operation with less than these

values may cause erratic or erroneous readings.

Operation

If the gauge display is off, press the center button to power up the gauge.

If the gauge was in the power-on state when the power was disconnected,the gauge will automatically turn on when power is reapplied.

If the gauge was turned off using the push button and then the power was turned off, the gauge

will not power up until the power is reapplied and the center button is pressed again.

Calibration

All gauges are calibrated using NIST traceable calibration equipment. No calibration is required

before placing the gauge into service.

An absolute reference gauge will display atmospheric pressure if the gauge port is open to the

ambient. It is normal for the reading to constantly change in response to atmospheric pressure

changes.

Absolute reference gauges require vacuum generation and atmospheric pressure measurement equipment for accurate calibration and thus are more difficult to calibrate in the field.

Calibration should only be attempted if the user has access to an absolute pressure reference

at least four times more accurate than the gauge being calibrated.

The calibration system must be able to generate and measure pressure/vacuum over the full

range of the gauge. A vacuum pump able to produce a vacuum of 10 microns (0.01 torr or 10

millitorr) or lower is required for vacuum and absolute gauges.

If recalibration is be required, remove the calibration covers from the front of the gauge to

access the individual zero and span controls. Allow the gauge to equalize to normal room temperature before calibration.

The gauge may be re-zeroed without affecting the span calibration. The gauge must be connected to a vacuum pump with the ability to maintain 0.1 torr absolute vacuum or less. Adjust

the Zero control until the gauge reads zero with the minus (–) sign occasionally flashing.

Span calibration should only be attempted if the user has access to an absolute pressure reference of known accuracy. Zero calibration must be done before span calibration. Record readings at three or more points over the range of the gauge and adjust span control to minimize

error over the range of the gauge.

Dimensions

1

/4 NPT

Cole-Parmer Instrument Co. / Made in USA

2.88"

3.38

"

0.75"

1.65

"

TORR

Tur n a t

hex

fitting

only

Span

Zero

Cable

length 6 ft

Cable

length 6 ft

Power supply

included with low

voltage powered

models

© 04-08

Page 7

Cole-Parmer®Loop-Powered Pressure Transmitters

Accuracy

±0.25% of full scale ±1 least significant digit

Includes linearity, hysteresis, repeatability

Display

3 readings per second nominal display update rate

31/2 digit LCD, 0.5" digit height

Controls

Non-interactive zero and span, ±10% range

Test calibration level: 0-100% range

Retransmission zero and span: Internal potentiometers

Loop Supply Voltage

Any DC supply/loop resistance that maintains 8 to 32 VDC at gauge terminals

Gauge is reverse polarity protected

3 ft long, 2-conductor 22 AWG cable

Output Characteristics

True analog output, 50 millisecond typical response time

If gauge terminal voltage falls below approx. 7.8 VDC erratic operation may

occur

Test Function

Front panel TEST button, when depressed sets loop current and display to test

calibration level, independent of pressure input, to allow testing of system operation.

Test level is set by multi-turn potentiometer to any value from 0 to 100% of full

scale output.

Dimensions

3.38" W x 2.88" H x 1.65" D housing

Add approximately 0.75" to height for pressure fitting

Add approximately 1" to depth for strain relief and wire clearance

Weight

Gauge: 9 ounces (approx)

Shipping weight: 1 pound (approx)

Material

Extruded aluminum case, light gray epoxy powder coated

ABS/ polycarbonate bezel

Front and rear gaskets

Polycarbonate label

Pressure/Vacuum Connection and Material

1

/4" NPT male, 316 stainless steel

Media Compatibility

All wetted parts are 316 SS

Compatible with most liquids and gases

Overpressure

2 times rated pressure minimum

Burst Pressure

4 times rated pressure minimum

Environmental

Storage Temperature –40 to 203°F (–40 to 95°C)

Operating Temperature –4 to 185°F (–20 to 85°C)

Compensated Temperature 32 to 158°F (0 to 70°C)

68936-36

30.0 inHg Vacuum

Certificate of Conformance

This product is manufactured according to applicable industry standards

and conforms to the manufacturer's engineering, production, calibration,

and quality standards.

This product conforms to the customer’s stated order requirements, including mechanical and electrical specifications, dimensions, physical item

identification (part number and serial number).

This product has been tested and calibrated to meet or exceed accuracy

specifications in effect at the time of manufacture using NIST traceable

standards maintained in accordance with ANSI/NCSL Z540-1 and ISO

10012.

This product is manufactured in the United States of America

Model

Serial Number

Date Purchased

Purchase Order

Model no. Range Resolution

68936-34 760 to 0 torr absolute 1 torr

68936-36 0 to 30.0" Hg vacuum 0.1" Hg

68936-38 0 to 3.00 psig 0.01 psig

68936-40 0 to 5.00 psig 0.01 psig

68936-42 –15.0 to 15.0 psig 0.1 psig

68936-44 0 to 15.00 psig 0.01 psig

68936-46 0 to 30.0 psig 0.1 psig

68936-48 0 to 100.0 psig 0.1 psig

68936-50 0 to 199.9 psig 0.1 psig

68936-52 0 to 300 psig 1 psig

68936-54 0 to 500 psig 1 psig

68936-56 0 to 1000 psig 1 psig

© 04-08

Cole-Parmer Instrument Co.

625 East Bunker Court

Vernon Hills, Illinois U.S.A. 60061-1844

800-323-4340

fax: 847-247-2929

www.coleparmer.com

e-mail: techinfo@coleparmer.com

Page 8

Description

All operating power is supplied by the 4-20 mA current loop. The 2-wire connection allows the

gauge to be used as a digital indicating transmitter in any 4-20 mA current loop application.

The output is a continuous analog signal based on the transducer output rather than the display. The output is filtered to improve noise immunity and has a response time of about 50 milliseconds.

The TEST button, when depressed,switches the display and output loop to a preset level determined by the setting of a Test potentiometer.

It is not required to utilize the 4-20 mA output. The gauge may be used as a low-voltage powered gauge by simply connecting it to a 8 to 32 VDC power supply. Current consumption will

be 4 mA at the low end of the scale and 20 mA at the high end of the scale. For this type of

application the TEST button does not provide functionality since the output is not being used.

Installation and Precautions

Install or remove gauge using wrench on hex fitting only.

Do not attempt to tighten by turning housing or any other part of the gauge.

Use fittings appropriate for the pressure range of the gauge.

Do not apply vacuum to gauges not designed for vacuum operation.

Due to the hardness of 316 stainless steel, it is recommended that a thread sealant be used to

ensure leak-free operation.

NEVER insert objects into the gauge port or blow out with compressed air. Permanent damage

not covered by warranty will result to the sensor.

Electrical Connection

Connection is made with the 2-wire cable at the gauge rear. Connect the loop (+) supply to the

RED lead and the loop (–) supply to the BLACK lead. Reversing the connections will not harm

the gauge but the transmitter will not operate with incorrect polarity.

Loop Voltage

Select a loop power supply voltage and total loop resistance so that when the loop current is

20 mA, the gauge will have at least 8 VDC at its terminals. For correct operation and to avoid

erratic or erroneous readings, the gauge terminal voltage must not fall below 8 VDC. Too large

a loop resistance will cause the gauge output to “limit” or saturate before reaching its full 20

mA output.

The minimum loop supply voltage may be calculated from the formula:

V

min

= 8V + (20mA x Total loop resistance)

If the terminal voltage of the gauge falls below about 7.8 VDC, erratic operation may occur. This

is an indication that the loop supply/resistance may not allow adequate headroom for reliable

operation. This should never occur in normal use. If it does, examine the loop supply and loop

resistance.

Operation

These models are designed for continuous operation. Warm-up time is negligible. The display

will show the system pressure or vacuum, and the loop current also will be proportional to the

system pressure/vacuum.

4 mA = Zero or low end

20 mA = Span, full-scale or high end

TEST Button

When the front-panel TEST button is held depressed, the display and loop current are switched,

independent of the system pressure, to a test level determined by the setting of the Test potentiometer. This test mode will allow setup and testing of the current loop by switching to this

test level whenever desired without having to alter the system pressure.

To set the test output level, see gauge label for location of Test potentiometer. Press and hold

the front-panel TEST button and adjust the Test potentiometer to set the display and loop current to the desired test level.

Calibration

The quality of the calibration is only as good as the accuracy of the calibration equipment and

ideally should be at least four times the gauge accuracy.

The calibration system must be able to generate and measure pressure/vacuum over the full

range of the gauge. A vacuum pump able to produce a vacuum of 10 microns (0.01 torr or 10

millitorr) or lower is required for vacuum and absolute gauges.

Connect to a 9-32 VDC power supply during the calibration procedure. The supply voltage has

negligible effects on the gauge calibration as long as it is within the stated voltage ranges.

Over voltage may result in damage.

Allow the gauge to equalize to normal room temperature before calibration.

Access the calibration potentiometers by removing the black plastic caps to expose the calibration potentiometers.

Gauges may be re-zeroed without affecting the span calibration.

Zero calibration must be done before span calibration. Span calibration should only be

attempted if the user has access to a pressure reference of known accuracy. Record readings

at three to five points over the range of gauge and adjust span control to minimize error and

meet specifications.

Internal Zero and Span potentiometers adjust the agreement between the display and the analog output. These normally do not need to be adjusted. If the output does need adjustment,

remove the rear cover to access the potentiomers. See photo below. Connect an accurate milliamp meter in series with the gauge and power supply to measure the milliamp output.

Zero for gauge reference pressure or vacuum gauges: With the gauge port open to atmosphere, adjust the Zero potentiometer until the gauge reads zero with the minus (–) sign occasionally flashing. Gauge output should be 4.0 milliamps.

Zero for absolute reference gauges: Apply full vacuum to the gauge. Adjust the Zero potentiometer until the gauge reads zero with the minus (–) sign occasionally flashing. Gauge output should be 4.0 milliamps.

Span for gauge reference pressure gauges and absolute reference gauges: Apply fullscale pressure and adjust the Span potentiometer for a display indication equal to full-scale

pressure. Gauge output should be 20.0 milliamps.

Span for gauge reference vacuum gauges: Apply full vacuum to the gauge. Adjust the Span

potentiometer for a display indication equal to full-scale vacuum. Gauge output should be 20.0

milliamps.

Verify pressure indications at 0%, 25%, 50%, 75%, and 100% of full scale and repeat calibration as needed to achieve best accuracy over desired operating range.

Replace the rear cover and screws, taking care not to pinch the power leads between the case

and the rear cover.

Dimensions

Cole-Parmer®Loop-Powered Transmitters

© 04-08

1400

1200

1000

800

600

400

200

0

Max Loop Resistance (Ohms)

8121620242832

Loop Supply Voltage (DC)

Voltage Compliance for

4-20 mA Current Loop

1

/

4 NPT

Cole-Parmer Instrument Co. / Made in USA

2.88"

3.38"

0.75"

0.75"

1.65"

Tur n

at hex

fitting

only

PSIG

Span

Zero

Test

TEST

3 ft long,

2-conductor

22 AWG cable

Loop

Zero

Loop

Span

Loading...

Loading...