Page 1

Mechanical Convection Ovens

Model No.

52100-00

52100-05

52100-10

52100-15

057-373-00 • 5/23/05

Page 2

Introduction ..................................................................................................................................................................3

Product Overview ..................................................................................................................................................3

Safety Information ........................................................................................................................................................4

Alert Signals ..........................................................................................................................................................4

Specifications ..............................................................................................................................................................5

Power Requirements ............................................................................................................................................5

Overall Dimensions................................................................................................................................................5

Chamber Dimensions ............................................................................................................................................5

Volume ..................................................................................................................................................................5

Shipping Weight ....................................................................................................................................................5

Performance Characteristics ................................................................................................................................5

Environmental Operating Conditions ....................................................................................................................5

Unpacking and Installation ..........................................................................................................................................6

Shipping Carton ....................................................................................................................................................6

Location ................................................................................................................................................................6

Leveling ................................................................................................................................................................6

Shelving ................................................................................................................................................................6

Electrical Requirements ........................................................................................................................................6

Operation......................................................................................................................................................................8

Te mperature Control (Thermostat) Operation ......................................................................................................8

Maintenance ..............................................................................................................................................................10

Cleaning ..............................................................................................................................................................10

Failure to Heat ....................................................................................................................................................10

Part Replacement Procedures ............................................................................................................................10

Replacing Thermostat ..................................................................................................................................10

Replacing Power Switch ..............................................................................................................................11

Replacing Status Lamp Bulb Assembly........................................................................................................12

Replacing Hi-Limit Thermostat ....................................................................................................................12

Replacing Heater ..........................................................................................................................................13

Replacing Blower Wheel; Servicing..............................................................................................................13

Replacing Blower Motor................................................................................................................................14

Temperature Readout Calibration........................................................................................................................15

Replacement Parts ....................................................................................................................................................17

Warranty ....................................................................................................................................................................20

2

Table of Contents

Page 3

Thank you for selecting Cole-Parmer instruments for your

equipment needs.

Product Overview

Cole-Parmer's Low Cost Gravity Convection Ovens are

designed for use in hospitals, industry, and school laboratories—wherever there is a need for low-cost, yet reliable ovens

for drying, sterilization, baking, evaporation or similar type

work.

A hydraulic thermostat provides reliable temperature control

with a range from slightly above ambient to 210°C. A

sheathed heater is positioned in the bottom of the chamber

along with a constant-speed fan that circulates heated air rapidly throughout the chamber. The metal cover shields the fan

and protects against splattering in the even that any material

is accidentally spilled in the area of the fan.

Chamber temperature is conveniently monitored via an LED

display on the control panel. To guard against overtemperature conditions, a factory-set hi-limit thermostat is an integral

part of the electrical system.

One-inch thick silica-based insulation in the double-walls of

the chamber helps retain chamber heat. The interior walls of

the chamber are stainless steel and the shelves are chromeplated steel for ease of maintenance and clean up.

These ovens also have a steel exterior finished in baked

enamel and are rigidly constructed for long, trouble-free service.

Introduction

3

Page 4

4

These instructions contain important operating and safety

information. The user must carefully read and understand

these instructions before using the unit. Your unit has

been designed to optimize function, reliability, safety and

ease of use. It is the user’s responsibility to install the

incubator in conformance with local electrical codes.

Safety Information

Warning

Warnings alert you to a possibility of

personal injury.

Caution

Cautions alert you to a possibility of

damage to the equipment.

Note

Notes alert you to pertinent facts and

conditions.

Hot Surface

Hot surfaces alert you to a possibility of

personal injury if you come in contact

with a surface during use or for a period

of time after use.

Alert Signals

Page 5

Power Requirements

52100-00: 120 Volts, 50/60 Hz, 12 Amps, 1100 Watts

52100-05: 240 Volts, 50/60 Hz, 6 Amps, 1100 Watts

52100-10: 120 Volts, 50/60 Hz, 15 Amps, 1100 Watts

52100-15: 240 Volts, 50/60 Hz, 8 Amps, 1100 Watts

Overall Dimensions

52100-00/52100-05: 18-7/16"W x 15-9/16"D x 25"H (47 x 39-1/2 x 63-1/2 cm)

52100-10/52100-15: 20-7/16"W x 17-11/16"D x 31"H (52 x 45 x 79 cm)

Chamber Dimensions

52100-00/52100-05: 16"W x 11-1/2"D x 16"H (40.6 x 29 x 40.6 cm)

52100-10/52100-15: 18"W x 13-1/2"D x 22"H (46 x 34 x 56 cm)

Volume

52100-00/52100-05: 1.7 cu. ft.

52100-10/52100-15: 3.1 cu. ft.

Shipping Weight

52100-00/52100-05: 34 lbs. (15.5 kg)

52100-10/52100-15: 47 lbs. (21.4 kg)

Performance Characteristics

Te mperature Range: All models slightly above ambient to 210°C

Thermostat, Control: ±5.0°C over entire range

Thermometer, Digital: ±2.0°C over entire range

Environmental Operating Conditions

Pollution Degree*: 2

Installation Category*: II

Altitude: 2000 Meters MSL (Mean Sea Level)

Humidity: 80% maximum, non-condensing

Electrical Supply: 120VAC or 240VAC

Voltage Tolerance: ±10% of normal rated line

Temperature: 15ºC to 40ºC

Product Usage: This product is intended for use indoors only

*Refer to IEC 664-1

5

Specifications

Page 6

6

Shipping Carton

The shipping carton should be inspected upon delivery.

When received, carefully examine for any shipping damage before unpacking. If damage is discovered, the delivering carrier should both specify and sign for the damage

on your copy of the delivery receipt.

Open the carton carefully making certain that all parts are

accounted for before packaging materials are discarded.

After unpacking, if damage is found promptly report it to

the carrier and request a damage inspection promptly.

IMPORTANT: Failure to request an inspection of damage

within a few days after receipt of shipment absolves the

carrier from any liability for damage. You must call for a

damage inspection promptly.

Location

The oven should be located in an area free from drafts

and sources of heat, as well as allowing for natural air

movement to dissipate heat from the oven.

Leveling

The oven should be on a level surface, in order to facilitate movement of materials into and out from the chamber.

Shelving

Slide shelves into place inside the oven and position

according to the height required for the items or materials

to be heated.

Electrical Requirements

The 120V unit is supplied with a 3-wire line cord with

molded plug. It should be plugged into an outlet designed

for 3-prong plugs. For an outlet designed to accept 2prong plugs (ungrounded), it is required that a qualified

electrician replace the outlet with a new grounded type.

Unpacking and Installation

Warning

Do not place oven on or near any

combustible surface to avoid the possibility of fire and resulting property

loss and injury or death to personnel.

Caution

Do not remove the rubber spacer feet.

Removal of the feet will prevent proper

air venting (air used to cool the electronics is discharged out the bottom)

of oven chamber that may cause

excessive heat buildup on electrical

components and erratic control of temperature.

Caution

Bottom shelf is fixed in place to guard

against access to heater area and

possibility of injury. Do not remove bottom shelf unless performing maintenance or repair.

Page 7

7

If a plug must be installed, use only the 3-prong grounded

type, rated for the unit load requirements and matching

the power outlet. Make sure the green ground wire is

secured to the plug ground terminal.

The unit must be connected to a power source that meets

the electrical requirements as specified on the unit’s

nameplate.

UNPACKING AND

INSTALLATION

Note

Where it becomes necessary to

make changes in electrical outlets,

wiring and other characteristics, it is

recommended that these be done by

a qualified or journeyman electrician.

This includes replacing 2-prong

plugs (ungrounded), for example,

with a 3-prong plug (grounded.) All

changes need to be made to match

the load requirements shown on the

nameplate of the unit. It is best to

leave the unit disconnected when

not in use.

Page 8

8

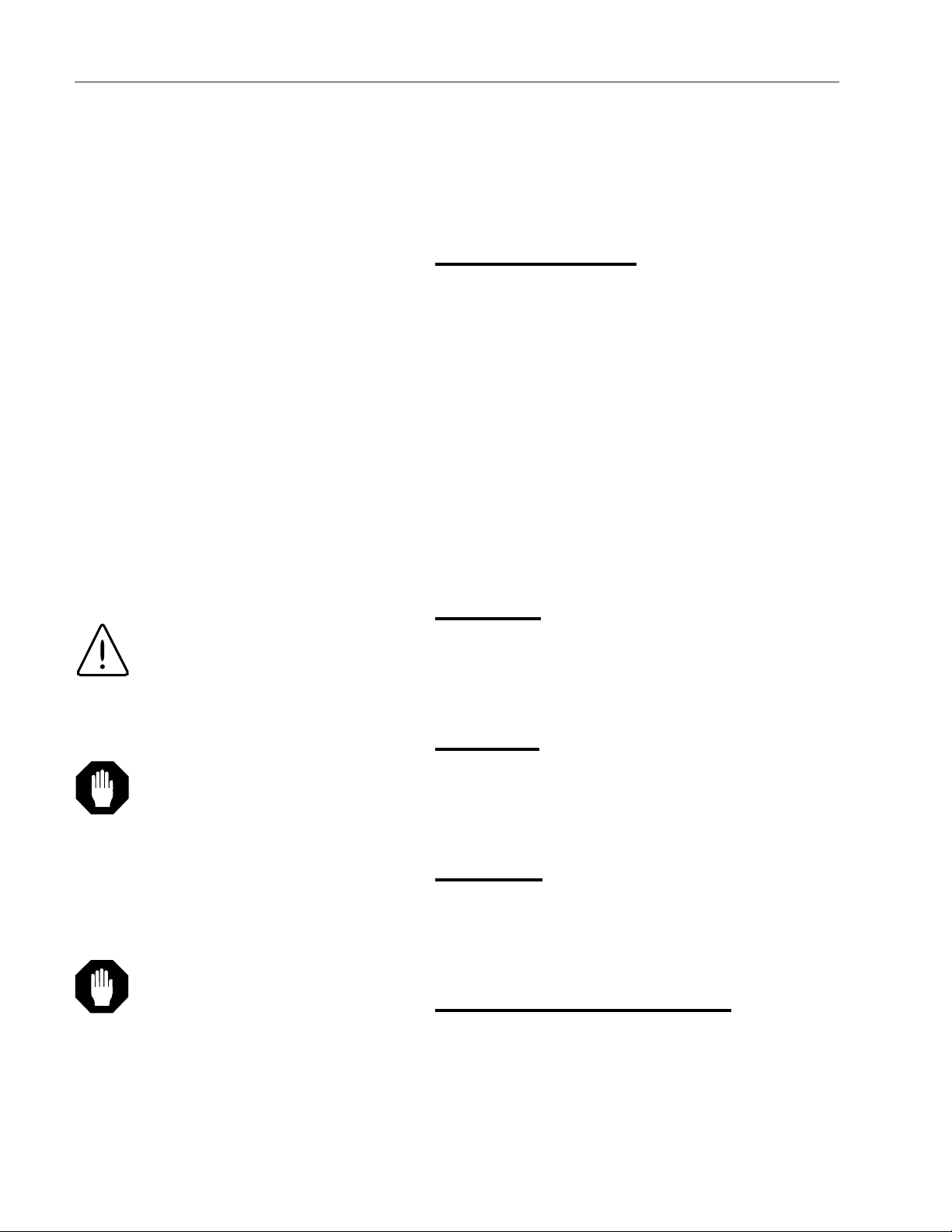

Operation

1. POWER SWITCH: Turns the unit ON (green status

lamp) and OFF.

2. HI-LIMIT RED STATUS LAMP: Lights when the hilimit thermostat is activated. It goes out when oven

reverts to a safe operating range.

3. CALIBRATION POTENTIOMETER: Utilizing a jeweler’s screwdriver, the temperature readout can be

adjusted.

4. LED DISPLAY: Displays current chamber temperatures.

5. TEMPERATURE CONTROL (THERMOSTAT):

Raises and lowers temperatures.

6. HEATERS AMBER STATUS LAMP: Lights when

heaters are energized.

Temperature Control (Thermostat)

Operation

1. With the temperature control thermostat (5) in the

extreme counterclockwise position, turn the power

rocker (1) to its ON position (switch’s green status

lamp will light).

2. Turn the temperature control thermostat in clockwise

direction to increase the temperature and counterclockwise to lower it. The amber status lamp (6)

above the thermostat goes on when the heaters are

energized. Wait for the chamber temperature to stabilize before advancing thermostat too rapidly to

reach target temperature. Note that dial setting to

Warning

Do not use in the presence of flammable or combustible materials or

explosive gases. Do not use in the

presence of pressurized or sealed

containers – fire or explosion may

result, causing death or severe

injury.

Caution

It is the user’s responsibility to

monitor oven action when setting

and maintaining operating temperature; oven failure may occur with

possible property damage and/or

injury to personnel.

Control Panel

ON

°COFST

OFF

1 2 3 4 5 6

HI-LIMIT

TEMPERATURE

TEMPERATURE

CONTROL

Page 9

obtain a specific temperature will need to be

approximated and can be affected by such factors as changes in line voltage, ambient conditions and types of materials being heated.

3. Read the LED display (4) for the chamber temperature produced by each setting of the temperature control thermostat. (As experience is

gained with the temperature control thermostat,

improved results will be obtained in setting it to

achieve specific target temperatures.)

4. Always allow time for the oven to reach target

temperature and to stabilize before making further adjustments of the temperature control thermostat.

5. A factory-set hi-limit thermostat cuts off power to

the heater in the event that the maximum operating range is exceeded. The red status lamp

(2) on the control panel indicates when the hilimit thermostat is controlling. It goes out when

oven reverts to a safe operating range.

9

Hot Surface

At the higher temperatures, the exterior of the oven and particularly the

thermometer vent ring on the top

become uncomfortably warm to the

touch. To avoid burns, do not touch

these surfaces.

Page 10

10

Maintenance

Cleaning

Because of their rugged, simple construction, these ovens

require very little maintenance. The bottom shelf that covers the heater can be removed for easy access to the

heater area.

Clean up any spills as soon as possible to prevent materials being baked on surfaces. When the oven is cool, use

a mild soap and water to clean surfaces. Rinse thoroughly and dry. It is best to avoid highly abrasive cleaners that

can damage the finish of the interior surfaces and

shelves.

Failure to Heat

If the oven fails to heat, there may be several possible

causes:

• Oven is not receiving electrical power.

• Heater is burned out.

• Thermostat is malfunctioning.

Have a qualified electrical technician determine the cause

of the problem and make the necessary repairs.

Part Replacement Procedures

The following should be performed only by authorized personnel. Unplug unit from power source. If oven has been

used recently, be certain that surfaces are safe to touch

before attempting to carry out any of the following procedures. Remove contents of oven and thermometer from

top of unit.

Replacing Thermostat

1. Lay unit on its side with door latch facing down.

2. Remove back by unscrewing Phillips screws.

Save.

3. Carefully remove insulation. Note how it is positioned, so that it can be easily reinstalled.

Note

Make no attempt to service or repair

a Cole-Parmer product under warranty before consulting Cole-Parmer.

After the warranty period, such consultation is still advised, especially

when the repair may be technically

sophisticated or difficult.

If assistance please call our

Customer Satisfaction Department at

800-323-4340 (outside Illinois) or at

847-549-7600 (inside Illinois). No

merchandise, however, should be

returned directly to Cole-Parmer without prior approval.

Warning

Disconnect from the power supply

prior to maintenance and servicing.

Warning

Disconnect oven from the power

source before cleaning or preforming

any maintenance or repair work.

Page 11

4. Remove bottom panel by unscrewing Phillips

screws. Save.

5. Remove control knob by unscrewing 2 Allenhead screws. Save.

6. Disconnect wires from thermostat. Note position

of wires for subsequent reattachment in same

sequence.

7. Knob removal allows access to 2 screws that

mount thermostat to panel. Remove the screws

and save.

8. Remove bottom shelf inside chamber. Loosen

screw on clamp that holds thermostat sensing

bulb to heater. Note position of temperature

sensing bulb, so that new one can be clamped

in same location.

9. Slide bulb toward exit hold at the back of unit.

10. Move to back of unit and pull temperature sensing bulb and tube through hole.

11. Next, pull bulb and tube through bottom hole.

12. Thermostat, sensing bulb, and tube assembly

can now be removed.

13. Reverse above procedure to install new thermostat.

14. Avoid making sharp bends in temperature sensing tube; otherwise, flow of temperature sensing

fluid will be impeded.

Replacing Power Switch

1. With unit on its side as in the preceding, remove

bottom plate and save screws.

2. Disconnect wires from switch. Note sequence of

pin numbers on the side of the switch and

attachment of wires. The replacement switch

must be oriented in the same manner and wires

11

MAINTENANCE

Page 12

attached in the same sequence.

3. Compress holding tabs on switch and push out.

4. Insert new switch from the front. When inserting,

follow same orientation of pin numbers as on

the switch just removed.

5. Attach wires in SAME SEQUENCE as originally

attached. To verify that correct sequence has

been followed, refer to wiring schematic.

6. Reverse remainder of procedure.

Replacing Status Lamp Bulb Assembly

1. With unit on its side as in the preceding, remove

bottom plate and save screws.

2. Note plastic lamp unit that houses bulb. Be alert

that lens will pop out in next step.

3. Grasp lamp unit and pull a fraction of an inch

toward the attached wires. Lens will pop out the

front. Save.

4. Cut wires and remove lamp unit. Discard.

5. To install new pilot lamp unit, splice the two

wires of the assembly to previously cut wires

using insulated crimp connectors.

6. Reinstall lens.

7. Reinstall bottom plate.

Replacing Hi-Limit Thermostat

1. Remove back panel and carefully remove insulation for subsequent reinstallation. Save.

2. Hi-limit thermostat is mounted on back of inner

chamber wall.

3. Unscrew 2 screws and nuts holding wires. Save.

12

M

AINTENANCE

Page 13

4. Remove screw securing thermostat to back of

inside wall.

5. Reverse preceding procedure to install a new hilimit thermostat.

Replacing Heater

1. Heater is located in bottom of chamber. Be sure

that unit has been turned off for a period of time,

so that there is no residual heat on any of the

surfaces.

2. Remove back panel by unscrewing Phillips

screws and save.

3. Carefully remove insulation and save. Note how

it is positioned, so that it can be easily reinstalled.

4. Remove two retaining clips that mount heater to

back of inside wall. Save.

5. Remove wires to heater by uncoupling the

quick-disconnects.

6. Remove bottom shelf inside chamber. Loosen

screw on clamp which holds thermostat sensing

bulb to heater. Note position of temperature

sensing bulb, so that new one can be clamped

in same location.

7. Install new heater and reverse the preceding

steps.

Replacing Blower Wheel; Servicing

1. Disconnect power cord.

2. Remove shelves. Note that bottom shelf is

retained by a clip at the back of the oven. Lift

shelf at the front edge until the back edge can

be withdrawn from the clip.

3. Remove Phillips screws holding shield that covers blower wheel.

13

MAINTENANCE

Page 14

4. Inspect blower wheel assembly for tightness and

any off-center operation. Inspect blower wheel

itself for damage to vanes or other deterioration.

If assembly is loose, tighten setscrew holding

wheel to motor shaft until wheel turns true. If

wheel is damaged, replace.

5. Replace the shield and shelves.

Replacing Blower Motor

1. Disconnect unit from power source. If previously

in use, let unit cool down.

2. Lay unit on side. Remove shelves, including the

bottom one.

3. Remove bottom cover, fan shield and blower

fan.

4. Accessing the unit from the bottom, remove

motor and bracket assembly. Disconnect wires.

5. Remove shaft extension, bottom fan and motor

bracket from old motor and reinstall on new,

replacement motor.

6. Reinstall motor assembly into unit in reverse

order of removal.

7. Reconnect wires.

8. Reinstall shelves. Make sure that bottom shelf is

securely in place to prevent access to the heater

area.

14

MAINTENANCE

Page 15

Temperature Readout

Calibration

A temperature readout calibration potentiometer (3) is

located in the upper left hand corner of the LED display

and is indicated by the word “OFST.”

• Use a jeweler’s screwdriver to make adjustments.

• Have a digital thermometer, known reliable thermocouple (Type-K or -T) and the jeweler’s

screwdriver on hand.

• Insert the thermocouple sensor through the outside top vent hold and position it in the center of

the oven chamber.

• Set oven temperature to a desired setpoint and

turn on the power.

• Allow temperature to stabilize for at least 2

hours before making any adjustments.

•Compare the chamber temperature on the digital thermometer to the temperature on the oven

readout.

• Insert jeweler’s screwdriver in calibration hole

and adjust the oven readout to match the thermometer reading. Turn potentiometer clockwise

to increase reading and counterclockwise to

decrease it.

15

MAINTENANCE

ON

Control Panel

°COFST

OFF

HI-LIMIT

TEMPERATURE

1 2 3 4 5 6

TEMPERATURE

CONTROL

Page 16

•Take two additional readings within an approximate 30 minute time span and make any necessary adjustments to the potentiometer. This

takes into account any temperature variations

that might exist within the oven and the time

delay in responding to such factors by the temperature sensors.

16

MAINTENANCE

Page 17

17

Replacement Parts

DESCRIPTION PART NUMBER

Cordset, (52100-00, 52100-10) 470-105-00

Cordset, (52100-05, 52100-15) 470-236-00

Door Catch 600-093-00

Door Latch 600-113-01

Fan, Axial (2) 160-136-00

Fan Shield 805-398-00

Feet, Rubber (4) 790-350-00

Fuse, 8 A, (52100-05, 52100-15) (2) 330-053-00

Fuse, 15 A (52100-00, 52100-10) 330-298-00

Fuse Holder (52100-00, 52100-10) 330-297-00

Fuse Holder (52100-05, 52100-15) (2) 330-237-00

Gasket (52100-00, 52100-05) 530-196-00

Gasket (52100-10, 52100-15) 530-197-00

Grommet (2) 790-247-00

Heaters:

52100-00, 52100-10 (120V, 1100W) 340-283-00

52100-05, 52100-15 (240V, 1100W) 340-296-00

Knob, Thermostat 560-223-00

Motor, (52100-00, 52100-10) 370-278-00

Motor, (52100-05, 52100-15) 370-279-00

Shelves:

52100-00, 52100-05 (3) 810-303-00

52100-10, 52100-15(3) 810-304-00

Status Lamp Base (52100-00, 52100-10) (2) 360-232-01

Status Lamp Base (52100-05, 52100-15) (2) 360-233-01

Status Lamp Lens, Amber 360-235-00

Status Lamp Lens, Red 360-234-00

Switch, Power (52100-00, 52100-10) 440-359-00

Switch, Power (52100-05, 52100-15) 440-292-00

Te mperature Sensor, RTD 410-654-00

Thermometer, Digital 910-126-00

Thermostat, Control 920-223-00

Thermostat, Hi-Limit 920-281-00

Transformer, Step-Down 460-266-00

Wiring Schematic (52100-00, 52100-10) 228-215-00

Wiring Schematic (52100-05, 52100-15) 228-234-00

Page 18

181920

Page 19

Page 20

Warranty

Cole-Parmer Instrument Company warrants this product to be free from significant deviations in material and

workmanship for a period of 15 months from date of purchase. If repair or adjustment is necessary and has

not been the result of abuse or misuse within the one year period, please return—freight pre-paid—and correction will be made without charge. Cole-Parmer alone will determine if the product problem is due to deviations or customer misuse.

Out of warranty products will be repaired on a charge basis.

RETURN OF ITEMS:

Authorization must be obtained from our Customer Service Department before returning items for any reason.

When applying for authorization, please include data regarding the reason the items are to be returned. For

your protection, items must be carefully packed to prevent damage in shipment and insured against possible

damage or loss. Cole-Parmer will not be responsible for damage resulting from careless or insufficient packing. A restocking charge will be made on all unauthorized returns.

NOTE: THE COLE-PARMER INSTRUMENT COMPANY RESERVES THE RIGHT TO MAKE IMPROVEMENTS IN DESIGN, CONSTRUCTION, AND APPEARANCE OF PRODUCTS WITHOUT NOTICE.

625 E. Bunker Court, Vernon Hills, IL 60061

Phone: 847-549-7600; Toll-free: 800-323-4340

Fax: 847-549-7676; Telex: 28-9405

Loading...

Loading...