Page 1

OPERATING MANUAL

SERVODYNE MIXER HEAD

MODEL NUMBERS

50003-10, 50003-15,50003-20, 50003-25

50003-30, 50003-35, 50003-40, 50003-45

AND

MIXER CONTROLLER

MODEL NUMBERS 50003-00, 50003-05

A heavy-duty modular mixing system, with a detachable

Precision Controller to accommodate a wide variety of small

batch mixing applications.

Cole-Parmer Instrument Company

625 East Bunker Court

Vernon Hills, Illinois U.S.A.60061-1844

(847) 549-7600

(847) 247-2929 (Fax)

800-323-4340

www.coleparmer.com

e-mail: techinfo@coleparmer.com

A-1299-0773

Edition 03

®

Page 2

Page 3

SAFETY PRECAUTIONS

DANGERS:

Highvoltagese xistandare accessible in theController.

Return the unit to your dealer for servicing.

Do not operate mixers where explosive v apors or

flammable materials exist. Death or serious injury

could result. Check NEC and local codes before

installing.

W ARNING:

Neverclean the Controller or MixerHeadwhile poweris

applied to the system.

W ARNINGS:

Use only those mixer shafts that are properly sized for

the Mixer Head being used. Refer to Mixer Head

specifications for the propershaft diameter or range to

be used. Sizes other than those specified can cause

injury to personnel or damage to equipment.

Disconnect the AC power input line cord before

connecting the Mixer Head cable.

Exercise extreme care when adjusting Mixer Height

and/or position to avoid personal injury. Never make

these adjustments while the mixer shaft is rotating.

Never insert or remove the mixer shaft/impeller while

the mixer shaft is rotating.

Check that all cords are clear of any moving parts and

not subject to splashes or spills.

Usecare when setting the operating speedofthemixer.

Operationat high speeds in small mixingvesselscould

result in hazardous splashing on the operator and

equipment.

When running at full speed and load at higher ambient

temperatures, the Mixer Head may get very hot to the

touch.

Use of mixing shafts and impellers larger than those

recommended could result in poor product

performance and shortened service life.

Mixer shafts must be inser ted into high speed

through-shaft mixers at least 3 in and the collet

hand-tightened firmly to insure adequate shaft

retention. Keep mixer shafts as short as possible to

reduce resonant vibrations caused by the shaft flexing

at higher speeds.

The Mixer Head is to be used only for mixing. It is not

intended for any other purpose.

JACOBS - Reg TM Power Tool Holders, Inc.

Trademarksbearing the ® symbol in this publication are registered in the U.S. and in other countries.

1

Page 4

INTRODUCTION

The heavy duty modular mixing system covered in this manual consists of four

different Mixer Heads and a Precision Controller in two different line voltages.

ThePrecision Controller isusedtoset the mixingspeedwithin±0.2% despite

changes in viscosity, temperature or power line voltage.The timer mode lets

you reproduce mixing runs of up to 100 minutes.

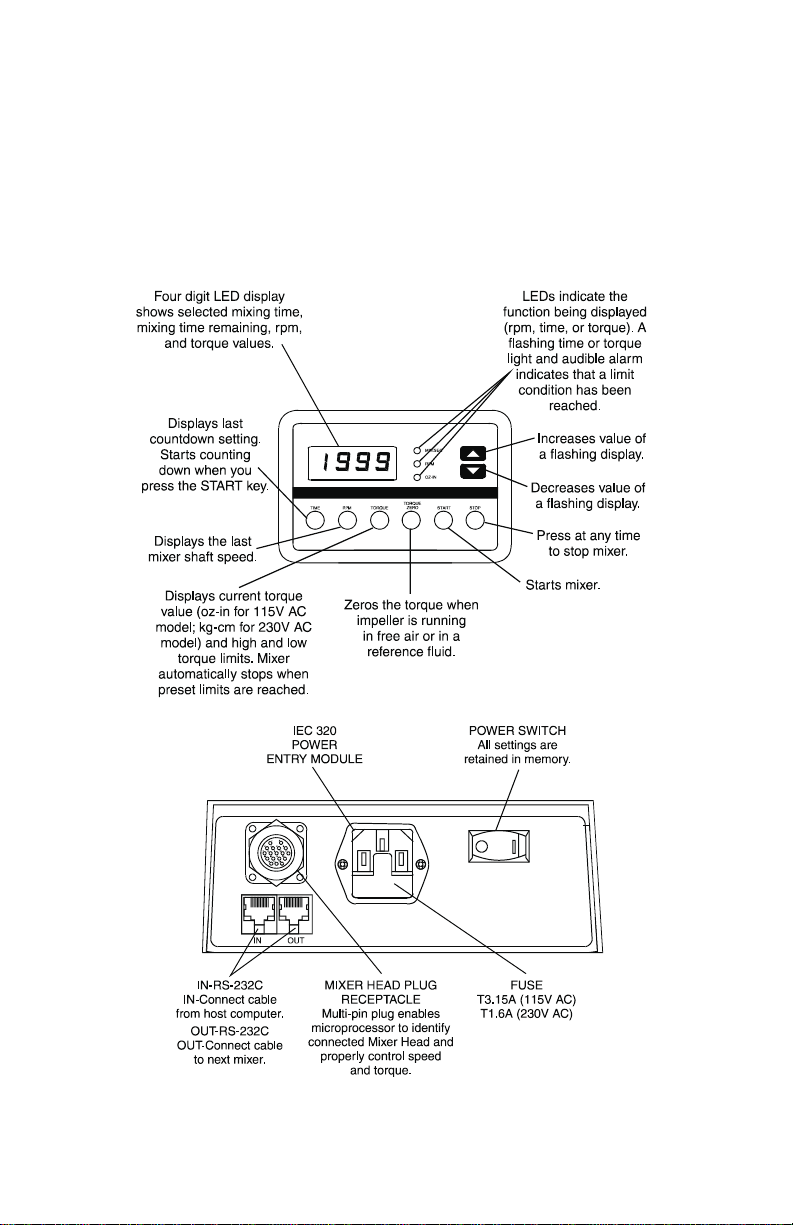

CONTROL/DISPLAY FUNCTIONS

Figure 1. Controller Rear Panel

2

Page 5

INSTALLATION AND SETUP PROCEDURE

The Mixer Heads are equipped with an adjustable-tilt Mounting Assembly.The

Mounting Assembly is designed to be attached to an optional mixer Support

Stand, or Tank Clamp. Components supplied as part of the mixer package

include the following:

Mixer Head with 6-ft cable

·

Precision Controller with 6-ft line cord

·

JACOBS

·

0.375 inch collet on high speed mixers

·

Adjustable-tilt Mounting Assembly with Support Rod

·

®

-type chuck on high torque mixers

Installation of Adjustable Tilt Mounting

W ARNING: Neverinsert orremovethe mixer shaft/impeller

while the mixer shaft is rotating.

Perform the following steps.

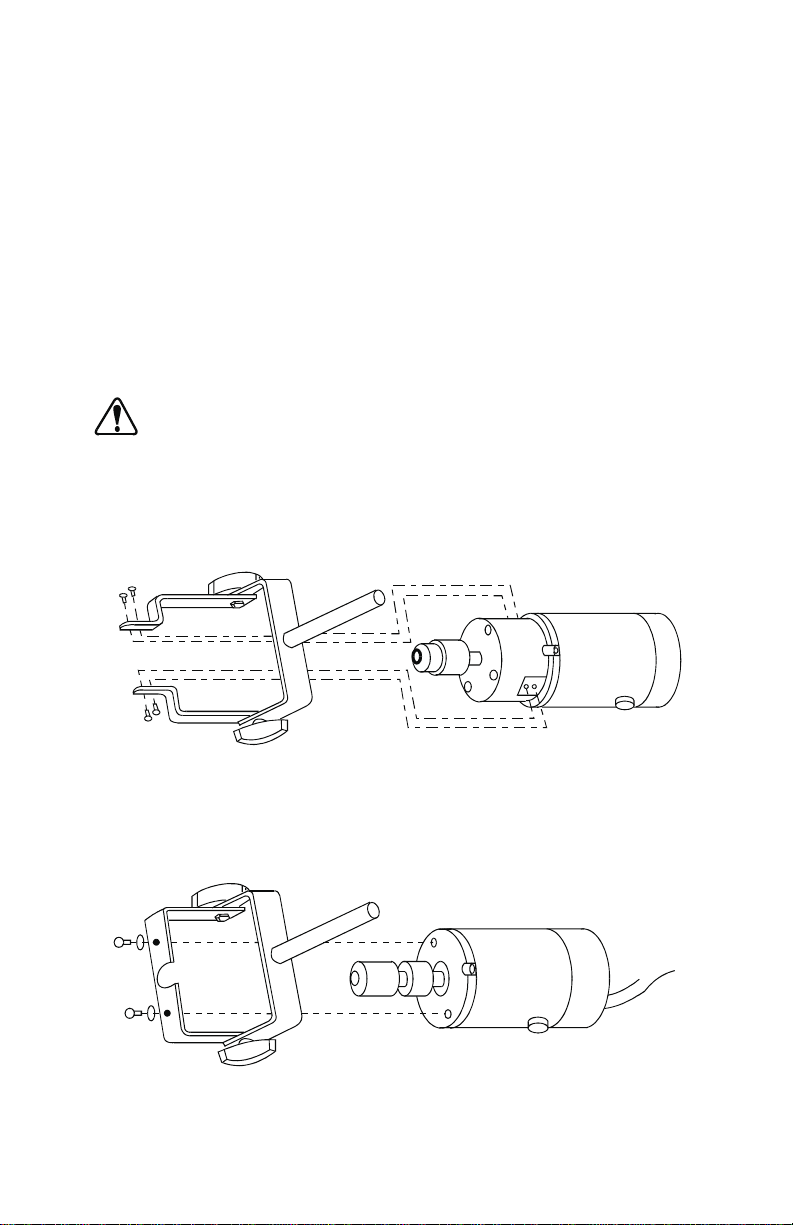

1. Attach Mixer Head to adjustable-tilt Mounting Assembly as follows:

a. For models 50003-10, 50003-15, 50003-20, and 50003-25 attach

Mounting Assembly with four screws and lockwashers.(See Figure 2.)

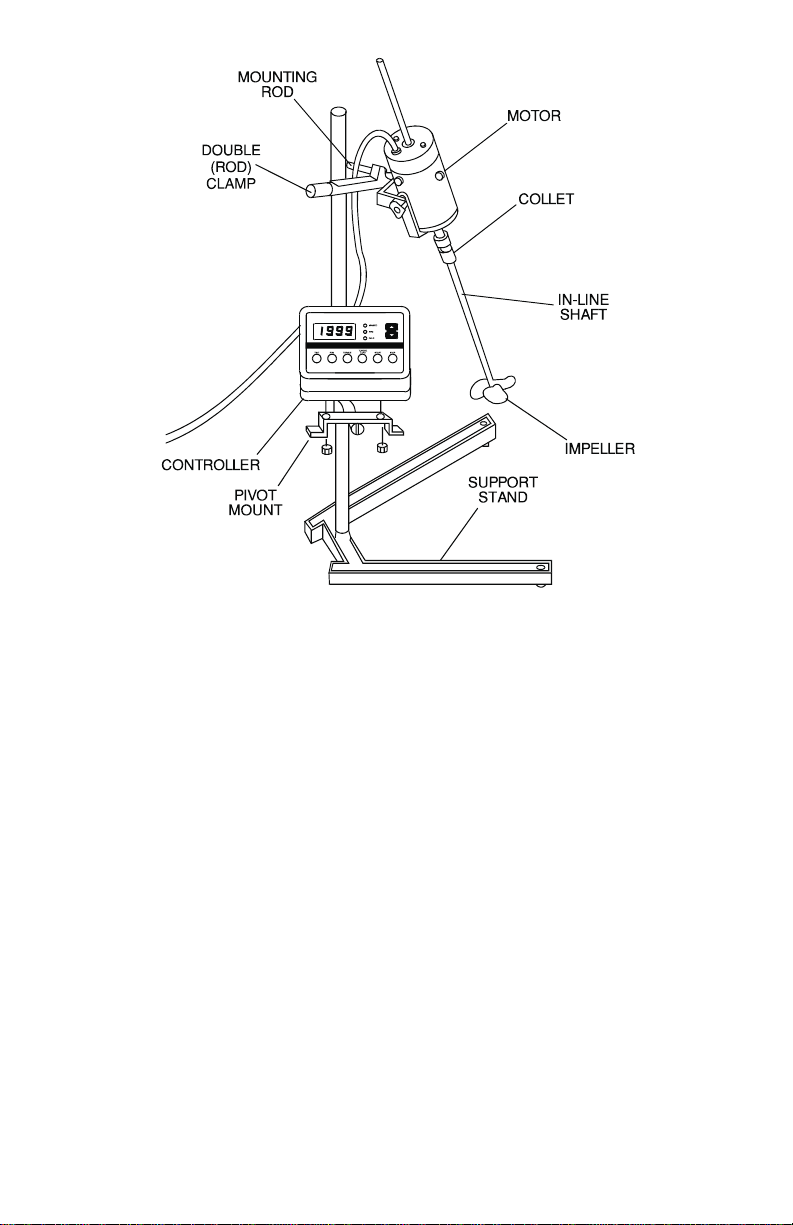

Figure 2. 50003-10, 50003-15, 50003-20, and 50003-25

Mixer Head Mounting

b. For models 50003-30, 50003-35, 50003-40, and 50003-45 attach

MountingAssemblywith twoscrewsandlockwashers.(SeeFigure3.)

Figure 3. 50003-30, 50003-35, 50003-40, and 50003-45

Mixer Head Mounting

3

Page 6

Note: The mixeris now ready to be attached toa SupportStand or to aTank

Clamp (not supplied). Recommended stands, T ank Clamps, and a

double (rod) clamp are available through your dealer. Part numbers

are listed in the ACCESSORIES section.

Installation Using a Support Stand

1. SetupSupportStandin accordancewith themanufacturer’sinstructions.

2. Attach a double (rod) clamp to the vertical rod on the Support Stand and

tighten clamp screw. (See Figure 4.)

3. Slide rod of adjustable-tilt Mounting Assembly into clamp and secure with

clamp screw.

4. Select an impeller and shaft for the required operation and install as

follows:

a. Place impeller on shaft and tighten set screw.

b. Forhigh-torque MixersHeads,slidetheshaft of the stirring device into

the JACOBS

c. For high-speed Mixer Heads, slide the shaft through the collet and

hand tighten collet.

5. Place SupportStand legs around vessel.Tilt angle is adjustablefrom 0 to

30 degrees.

®

-chuck and tighten chuck with key supplied.

W ARNINGS: Exercise extreme care when adjusting Mixer

Head height and/or position to avoid personal

injury.Nevermakethese adjustmentswhilethe

mixer shaft is rotating.

Mixer shafts must be inserted into high speed

through-shaftmixers at least 3 in and the collet

hand-tightened firmly to insure adequate shaft

retention. Keep mixer shafts as shor t as

possible to reduce resonant vibrations caused

by shaft flexing at higher speeds.

6. Position the height of the Mixer Head by moving the clamp up or down on

the Support Stand or on high-speed models by loosening the collet and

positioning the shaft.

4

Page 7

Figure 4. Typical Mixer Setup Using a Support Stand

Note: The Controller can be placed on any flat surface within 6 feet of the

MixerHead orcanbe mounted on a Support Platform (not supplied)or

a Pivot Mount (not supplied).Refer to the ACCESSORIES section for

part numbers.T oattach the Support Platform proceed with step 7.T o

attach the Pivot Mount proceed with step 8. If Controller is placed

elsewhere proceed with step 9.

7. To install the Support Platform proceed as follows:

a. Attachadouble (rod)clamp totheverticalSupportRodand positionso

that platform will be clear of Mixer Head.

b. Slide the mounting rod of the Support Platform into the double (rod)

clamp and tighten clamp.

c. Place Controller on platform and proceed to step 9.

8. To install the Pivot Mount proceed as follows:

a. Remove the two cap nuts from the mounting studs on bottom of

Controller.

5

Page 8

b. P ositionPivotMountbracketovertwostuds, re-installtwo capnuts and

tighten.

c. Attach a double (rod) clamp to the vertical Support Rod on the stand

and position so that Pivot Mount bracket will be clear of Mixer Head.

d. Slidethe mounting rod ofthe PivotMount bracketintothedouble(rod)

clamp and tighten clamp.

e. Adjust position of Controller by first loosening knob on Pivot Mount

bracket, adjust position and then retighten knob.

W ARNING: Check that all cords are clear of any moving

parts and not subject to splashes or spills.

9. Connect the 6-foot cable between the Mixer Head and the Controller rear

panel.

10. Check that the rear panel ON-OFF switch is in the OFF position.

11. Connect the 6-ft. line cord from the Controller to the appropriate 3-wire

grounded power source.

The mixer is now ready to operate.

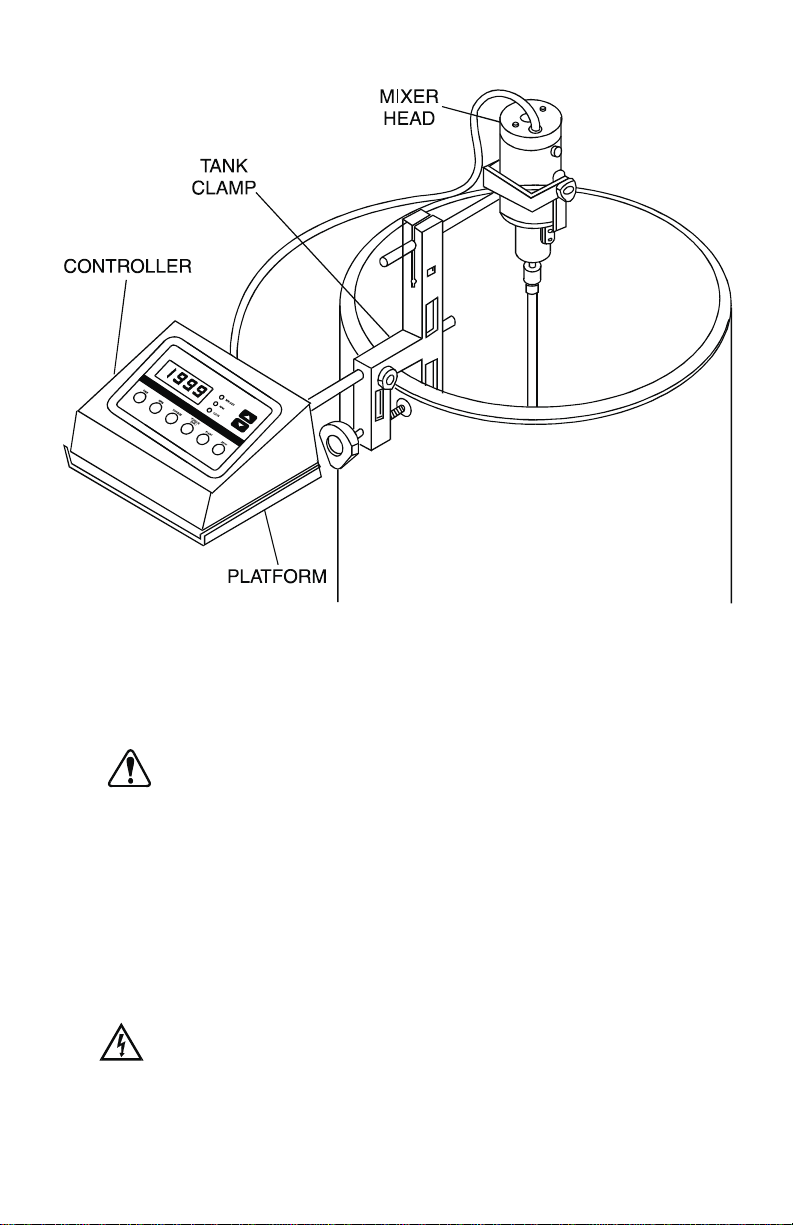

Installation Using a T ank Clamp

The TankClamp is attached to the side of a tank and supports both the Mixer

Head and the Controller.(See Figure 5.)

1. Position the Tank Clamp over the edge of the tank with large knob to the

outside of tank.

2. Allow clamp to rest on edge of tank for added stability and tighten knob.

3. Position Mixer Head over material to be mixed and insert mixer mounting

shaft into upper hole in Tank Clamp. Tighten locking knob securely.

4. Select an impeller and shaft for the required operation and install as

follows:

a. Place impeller on shaft and tighten set screw.

b. Forhigh-torqueMixer Heads,slide the 5/16inchto 3/8 inch shaftofthe

stirring device into the JACOBS-chuck and tighten chuck.

c. For high-speed Mixer Heads, slide the 0.375 inch mixer shaft through

the collet and tighten collet. Be sure only 0.375 (±0.0005) inch shafts

are used. See your dealer for obtaining the proper shaft size.Refer to

the ACCESSORIES section for the part numbers.

6

Page 9

Figure 5. Typical Mixer Setup Using a Tank Clamp

W ARNINGS: Exercise extreme care when adjusting Mixer

Head height and/or position to avoid personal

injury.Nevermake these adjustmentswhile the

mixer shaft is rotating.

Mixer shafts must be inserted into high speed

through-shaft mixers at least 3 inches and the

collethand-tightened firmlyto insure adequate

shaft retention. Keep mixer shafts as short as

possible to reduce resonant vibrations caused

by the shaft flexing at higher speeds.

DANGER: Do not operate mixers where explosive vapors

or flammable materials exist. Death or serious

injury couldresult.Check NECand local codes

before installing.

7

Page 10

5. Position the height of the Mixer Head on high-speed models by loosening

the collet and positioning the shaft.

Note: The Controller can be placed on any flat surface within 6 feet of the

MixerHead and can be mounted on a SupportPlatform (not supplied)

or a Pivot Mount (not supplied). Refer to ACCESSORIES for part

numbers.ToattachtheSupportPlatformproceedwith step 6.Toattach

the Pivot Mount proceed with step 7.If Controller is placed elsewhere

proceed with step 8.

6. To install the Support Platform proceed as follows:

a. Slide the mounting rod of the Support Platform into the lower hole on

the Tank Clamp and tighten clamp.

b. Place Controller on platform and proceed to step 8.

7. To install the Pivot Mount proceed as follows:

a. Remove the two cap nuts from the mounting studs on bottom of

Controller.

b. P ositionPivotMount bracketovertwo studs,re-installtwo cap nutsand

tighten.

c. Slide themountingrod of thePivotMount bracketinto thelowerholeon

the Tank Clamp and tighten clamp.

d. Adjust position of Controller by first loosening knob on Pivot Mount

bracket, adjusting position and then retighten knob.

8. Connect the 6-foot cable between the Mixer Head and the Controller rear

panel.

9. Check that the rear panel ON-OFF switch is in the OFF position.

10. Connect the 6-ft. line cord from the Controller to the appropriate power

source,either a 90-130V AC 50 or 60 Hz 3-wire grounded power source or

a 200-260V AC 50 or 60 Hz 3-wire grounded power source.

W ARNING: Check that all cords are clear of any moving

parts and not subject to splashes or spills.

The mixer is now ready to operate.

8

Page 11

OPERATION

W ARNINGS: Always wear appropriate eye protection when

mixing any kind of fluid.

Avoid wearing loose clothing that may be

caught by a rotating mixer shaft.

Use care when setting the operating speed of

the mixer. Operation at high speeds in small

mixing vessels could result in hazardous

splashing on the operator and equipment.

Power On

AnEEPROMpermitsstorage of all previously set parameters including speed,

torque,time andcalibration constant.Turning the rear panel mountedON/OFF

switchtothe“ON”positionenergizes thedisplaywithoutrunningthemotor.The

display will come up in the last mode operated.Depressing the START button

causes the mixer motor shaft to rotate at the previously programmed speed.

Depressingthe STOPbuttonstops the motor.ChangingDisplayModes(TIME,

RPM, TORQUE) is accomplished by pressing the desired mode button once.

Additional operation of the mode button advances operation to the set mode.

Set Run Time

The use of the TIME button in conjunction with the INC/DEC buttons permits

entry of a desired mixing time.Pressing the TIME buttononce when already in

the Time Display Mode causes the left (minutes) digit to flash, pressing the

TIME button once again causes the right two (seconds) digits to flash. During

this period the time can be set with the INC/DEC buttons. Pressing the TIME

button a third time starts the countdown provided the motor is running;

otherwise the display shows the set time. Maximum programmable time is 99

minutes 59 seconds. A “0” programmed time results in continuous motor

operation.

Set Motor Speed

Depressingthe RPM button when in theRPMmodecausesthe display to flash

and read set motor speed. Use of the INC/DEC buttons changes the desired

speed.

Set Motor Torque Limit

W ARNINGS: Neverinsertor removethemixer shaft/impeller

while the mixer shaft is rotating.

When running at full speed and load at higher

ambient temperatures,the Mixer Head may get

very hot to the touch.

9

Page 12

The TORQUE limit feature provides for the setting of both HI and LO torque

limits.Depressingthe TORQUEbuttonwhen in theTORQUEmodecauses the

first digit of thedisplayto read either on “H”or “L”(for High or Low limit) and the

last three digits to flash and read the set limit. Pressing the INC/DEC buttons

changes the set torque limit.

Pressing the T orquebutton once again while the digits areflashing causes the

H or L to flash while the set limit digits stop flashing. It is now that the High or

Lowlimitcan beselectedbypressing eithertheINC/DECbuttons.Pressingany

button other than INC/DEC buttons returns the display to actual torque. If the

motor is running while the torque limit is being modified the previously

programmed limit will be in effect until the torque limit mode is exited;then the

new limit will take over.

Regardlessof theset torquelimit,there isalwaysa maximumtorque limitcheck

toguard against motoroverheating.Ifthislimitis exceededthe motor stops,the

alarm sounds, the display flashes “HI” and the oz-in/kg-cm LED flashes.

Pressinganykeycausesthedisplayto return to what was previouslydisplayed

before the alarm. The error must be corrected or the over-limit warning will

sound again when the motor is restarted.

TheTORQUEZERO buttonis used to zerothe torque displayso that theactual

torque necessaryto mix something can be read directly on the display.T ouse

thisfeaturethe TORQUEZERO buttonispressedwhile the mixer head shaft is

running in free air; the display will zero .The mixer shaft is then placed into the

solution being mixed, the reading on the display will now indicate the torque

necessary to mix the solution. This number can now be used in helping

determinethepropershut off or torquelimitwhen mixing severalbatches tothe

same consistency.

When the TORQUE ZERO button is operated, the maximum torque limit that

can be set is adjusted so that the absolute torque does not exceed the

continuous torque of the mixer head being used.

Example:The operator has set a high torque limit of 50 oz-in for a motor rated

for 65. The motor is then running with an actual torque reading of 30 oz-in.

Whenthe TORQUEZERO button is pressed, the maximum torque that canbe

set would be 35 (65-30). Since the set limit of 50 is above this, it will

automaticallybe changed to35.Theoperator willseethis when thesetmode is

entered, which will prev ent a setting over 35.

An audible alarmwill sound and the LED that corresponds to the limit that has

been reached will flash when either the preset time or the torque limit is

reached. Both the LED and alarm will cycle on and off until turned off by

pressing any button other than the INC/DEC buttons.

Remote Operation Via Serial Port

Refer to APPENDIX A for computer controlled remote operation.

10

Page 13

MAINTENANCE AND TROUBLESHOOTING

Maintenance is limited to replacement of motor brushes on the Mixer Head,

replacingthefuse on the Controller,and cleaning theunits.If a faultis detected

when troubleshooting and cannot be corrected by the suggested remedy ,

contact your dealer for service.

Motor Brush Check/Replacement

Note: Brushes should be checked every 6 months or 1000 operating hours

or if erratic operation occurs.Erratic operationmayoccur immediately

after brush replacement. Allow motor to run up to an hour to allow

brushes to seat.

1. Place the rear panel ON-OFF switch in the OFF position.

2. Disconnect the AC line cord from the AC receptacle.

3. Disconnect the Mixer Head cable from the receptacle on the rear of the

Controller.

4. Carefully unscrew each brush holder cap. Withdraw the brush, and

examine it for wear.

Note: Replace both brushes if either brush is less than 0.300 inch (8 mm)

long. The replacement brushes (set of 2) part number is listed under

REPLACEMENT P ARTS.

5. Insert brushes into brushholder on each side of motor as shownin Figure

6 and screw in brush holder caps.

6. Reconnect Mixer Head to rear panel connector on Controller.

7. Reconnect Controller to primary power source.

Figure 6. Motor Brush Orientation

11

Page 14

Controller Fuse Replacement

1. Place the power switch in the OFF position.

2. Disconnect the AC power input line cord from the AC receptacle.

3. Remove and check the fuse and replace if defective.

4. Reconnect the AC power input line cord to the AC receptacle.

Cleaning

W ARNING: Never clean the Controller or Mixer Head while

power is applied to the system.

Keep the Mixer housing and Controller enclosure clean with mild detergents.

Never immerse nor use excessive fluid.

Replacement Parts

No user-serviceable partsare

dealer.

The following parts

Description Part Number

Fuse, T3.15A (model 50003-00) 77500-25

Fuse, T1.6A (model 50003-05) 77500-11

Motor Brushes (2) 07520-04

Brush Cap (1) A-2542-CR

JACOBS-ChuckAssembly (50003-10, 50003-15,

50003-20, and 50003-25) B-3094

Chuck Key (50003-10, 50003-15,

50003-20, and 50003-25) B-2809-2

Collet Nut (50003-30, 50003-35,

50003-40, and 50003-45) A-3535-0012

Pivot Assembly Knob (1) B-1083-39

Cordset–USA (115V units) 50001-68

Cordset–European (230V units) 50001-70

Cordset–British (230V units) 50001-72

Cordset–Swiss (230V units) 50001-74

Cordset–Italian (230V Units) 50001-76

Cordset–NEMA (230V units) 50001-78

Contact your dealer if you have service needs.

are

inside

of this instrument.Referservicingto your

user-replaceable:

12

Page 15

Troubleshooting

TheController microprocessordetectsand indicates systemfaults.Thedisplay

alternately shows the error number and a “Fail”message. The following table

summarizes the faults and suggested correctiveaction.The system cannot be

operated until the fault is corrected.

Error Code Fault Corrective Action

Err1 No Mixer Head

Connection

Err2 Invalid Mixer Head Bad motor cable—return Mixer

Err3 No encoder pulses Return Mixer Head and

Err4 Motor speed is

excessive

Err5 No torque information

display

Err6 Bad PROM check Return Controller for repair.

Err7 Motor overload Check mixer for obstructions.

Err8 Zero cross failure Return Controller for repair.

Err9 Bad EEPROM data or

WRITE/VERIFY error.

Plug Mixer Head into Controller.

Head for repair.

Controller for repair.

Return Mixer Head and

Controller for repair.

Return Controller for repair.

Unit must be turned off to clear

error.

Return Controller for repair.

“HI”Limit Message

Aflashing “HI”limitmessage willbe displayedandtheMixerHead willstopif the

maximumrated torque oftheMixerHead is exceededwhen the lowtorquelimit

mode is being used. To protect the Mixer Head motor from overheating, it

cannot be restarted until the fault is corrected.

Note: Before contacting your dealer for repair, try to determine whether the

fault is in the Controller or Mixer Head.The best way is to substitute a

known good unit, if available and recheck.

13

Page 16

ACCESSORIES

The accessories listed below, used for mounting the Mixer Head and

Controller, are available from your dealer. Many other accessories such as

shafts and impellers are also available.Contact your dealer for the full line of

available accessories.

Part Name Part Number

Tank Clamp 50001-80

Controller Support Platform 50001-90

Pivot Mount Controller Support 50001-82

Support Stand 50001-92

Double (Rod) Clamp 08047-20

Software 07550-72

Servodynes RS-232-C Interface Cable 07550-64

Satellite Cable 07550-66

Shaft, 12 inch 4553-52

Shaft, 18 inch 4553-57

Shaft, 24 inch 4537-10

Shaft, 30 inch 4538-10

SPECIFICATIONS

Mixer Head

Output:

Direction of Rotation: CCW (Impeller end)

Speed Range:

Models 50003-10 and 50003-15 3–180 rpm

Models 50003-20 and 50003-25 20–900 rpm

Models 50003-30 and 50003-35 60–2300 rpm

Models 50003-40 and 50003-45 150–6000 rpm

Torque Output, max.:

CONTINUOUS INTERMITTENT

Models 50003-10 and 50003-15 340 oz-in 510 oz-in

Models 50003-20 and 50003-25 70 oz-in 105 oz-in

Models 50003-30 and 50003-35 45 oz-in 65 oz-in

Models 50003-40 and 50003-45 17 oz-in 25 oz-in

14

Page 17

Specifications (Continued)

Mixer Shaft Interface:

Models 50003-10 and 50003-15 JACOBS-typechuckwith key accepts

Models 50003-20 and 50003-25 5/16 in to 3/8 in dia shaft

Models 50003-30 and 50003-35 Collet accepts 0.375 (±0.0005)

Models 50003-40 and 50003-45 in dia shaft

Input:

Voltage, max.:

50003-10, -20, -30, -40 90V DC

50003-15, -25, -35, -45 180V DC

Current, max.:

50003-30 and -40 2.3A

50003-35 and -45 1.2A

50003-10 and -20 1.5A

50003-15 and -25 0.8A

Installation Category: Installation Category I per IEC 664

(Signal lev el–parts of equipment)

Construction:

Dimensions (L x Dia): 11.5 in x 3.6 in (292 x 92 mm)

Weight: 8 lb (3.5 kg)

Enclosure Rating: IP 24 per IEC 34-5

Environment:

Temperature, Operating: 0° to 40°C (32° to 104°F)

Temperature, Storage: -45° to 65°C(-49° to 149°F)

Humidity (non-condensing): 10% to 90%

Altitude: Less than 2000 m

Pollution Degree: Pollution Degree 2 per IEC 664

(Indoor Usage–lab,office)

Chemical Resistance: Exposed material is painted

aluminum, plastic and vinyl

Compliance:

115V: UL508, CSA C22.2, No.14-M91

230V: EN61010-2-051: 1995

(EU Low Voltage Directive)

15

Page 18

SPECIFICATIONS

Controller

Output:

Voltage, max.:

50003-00 90V DC

50003-05 180V DC

Current, max.:

50003-00 2.3A

50003-05 1.2A

Speed regulation:

Line: ±0.25% F.S.

Load: ±0.25% F.S.

Drift: ±0.25% F.S.

Display: Four-digit, seven segment LED

Maximum settable

Countdown Time: 99 minutes, 59 seconds

Time Accuracy: ±1 second

Input:

Voltage, max.:

50003-00 90 to 130 Vrms @ 50/60 Hz

50003-05 200 to 260 Vrms @ 50 Hz

Current, max.:

50003-00 2.3A

50003-05 1.2A

Installation Category: Installation Category II per IEC 664

(Local lev el- appliances, portable

equipment, etc.)

Computer Control: RS-232-C (Full Duplex)

Construction:

Dimensions: (LxWxH) 7.8inx6.5inx3.5in

(197 x 165 x 89 mm)

Weight: 3 lb (1.4 kg)

Enclosure Rating: IP 22 per IEC 529

Environment:

Temperature, Operating: 0° to 40°C (32° to 104°F)

Temperature, Storage: -45° to 65°C(-49° to 149°F)

Humidity: (non-condensing) 10% to 90%

Altitude: Less than 2000 m

16

Page 19

Specifications (Continued)

Pollution Degree: Pollution Degree 2 per IEC 664

(Indoor Usage–lab,office)

Chemical Resistance: Exposed material is painted

aluminum, plastic and vinyl

Compliance:

115V: UL508, CSA C22.2, No.14-M91

230V: EN61010-2-051: 1995

(EU Low Voltage Directive)

17

Page 20

W ARRANTY

The Manufacturer warrants this product to be free from significant deviations

from published specifications. If repair or adjustment is necessary within the

warranty period, the problem will be corrected at no charge if it is not due to

misuseorabuseon your partas determinedbytheManufacturer.Repair costs

outside the warranty period, or those resulting from product misuse or abuse,

may be invoiced to you.

The warranty period for this product is noted on the Warranty Card.

PRODUCT RETURN

Tolimit charges and delays,contact the sellerorManufacturerforauthorization

and shipping instructions beforereturning the product, either within or outside

ofthe warrantyperiod.When returningthe product, please state the reasonfor

the return. For your protection, pack the product carefully and insure it against

possibledamage or loss.Any damages resulting fromimproper packagingare

your responsibility.

TECHNICAL ASSIST ANCE

If you have any questions about the use of this product, contact the

Manufacturer or authorized seller.

18

Page 21

APPENDIX A MIXER COMMUNICATION SPECIFICATION

1.0 – Linkable Instrument Network

The Linkable Instrument Network is a serialcommunication system consisting

of a control computer with one RS-232-C port and one or more mixer

controllers. This description descr ibes all the information needed to

communicate with a mixer controller.

All communications between the control computer and the mixer controller

units is based on a pseudo daisy-chain principle.The transmission line of the

computer will pass through the input and output buffers in each of the satellite

units. Each satellite unit has the ability to turn the buffers on and off to block

communications from other units below it in the daisy-chain. For

communications to work properly,AC power must be applied to all mixer units

connected to the daisy-chain.

The receive line of the control computer originates in the transmitter of the last

satellite in the chain. It is double buffered through each satellite so that each

output will only see one load.

Athirdline,theRequestT oSend(RTS)isasimilarly bufferedline.Eachsatellite

has the ability to activate this line to signal the computer its request to send.

The maximum number of satellites is limited to 25 by the Linkable Instrument

Networksoftware tominimizecommunicationtime.Howe ver,up to89satellites

could be controlled by a single RS-232-C port using custom software since

satellites can be assigned any number from 01 to 89.

1.1 – Serial Connections

The satellite units have two 4-wire, 6 position modular phone jacks labeled

“RS-232 IN” and “RS-232 OUT”. The control computer will have a standard

DB-25 plug as found on most RS-232-C connections. The DB-9 “AT” style

connector can also be used with a custom cable or DB-9 to DB-25 adapter

cable.

“RS-232 IN” JACK

Pin 1 — Receive signal from the computer

Pin 2 — Transmit signal to the computer

Pin 3 — Ground

Pin 4 — Request to send (RTS) to the computer

“RS-232 OUT”JACK

Pin 1 — Request to send (RTS) from the next mixer

Pin 2 — Ground

Pin 3 — Receive signal from the next mixer

Pin 4 — Transmit signal to the next mixer

19

Page 22

DB-25 PLUG ON CONTROL COMPUTER

Pin 2 — Transmitted data to mixer

Pin 3 — Received data from mixer

Pin 5 — Clear to send — RTS from mixer

Pin 7 — Ground

DB-9 PLUG “AT type” ON CONTROL COMPUTER

Pin 3 — Transmitted data to mixer

Pin 2 — Received data from mixer

Pin 8 — Clear to send — RTS from mixer

Pin 5 — Ground

Figure A-1. Serial Daisy-Chain Connections

Theseriallineand connectors are standard telephone4wire cables andRJ-11

connectors. In-line adapters are available to connect two cables together to

facilitate the interconnection of two cables if a mixer is removed.

1.2 – Serial Data Format

The serial data format is full duplex (simultaneously transmit and receive), 1

start bit, 7 data bits,oneodd paritybit,andonestop bit at 4800 bits per second.

All data transmitted consists of characters from the standard ASCII character

set.Note: Odd parity is defined such that the sum of the eight individual bits is

an odd number (1,3,5 or 7).

20

Page 23

1.3 – Serial Protocol

Alltransmissions originateorare requested bythe controlcomputer(master).It

may issue commands directly and it may request that the mixer report.When

asked to report, the mixer sends the data requested. Should a mixer require

communication with the computer, it has the ability to activate its request to

send (RTS) line. Upon detecting the RTS, the control computer would initiate

communications to determine why the RTS line is active (see section 1.11).

1.4 – Start Up Sequence

Normal start up consists of turning on all the mixer units first and then the

control computer.Each mixer unit enables its RS-232-C buffers and activates

itsRTSline.The control computer then sendstheenquire<ENQ>commandin

response to the active RTS line. Upon receiving the <ENQ> command, all

mixers with an active RTS line disable their receive and transmit buffers to the

mixersbelowthem inthe daisy-chain.Nextthemixerunit(s)wouldrespondwith

<STX>MMx<CR> indicating that it is a satellite mixer and it needs to be

numbered.The“x”isa characterfrom 0to9 orAto Findicatingthe typeofmixer

currentlyconnected.Thecontrol computeronlysees theresponse fromthe first

mixer in the chain since communications with the others is now blocked. The

control computer then sends back <STX>Mnn<CR> with nn being the desired

mixernumberstartingwith01forthefirst mixerandincrementingforeach mixer

up to 25 maximum.If the mixer unit receives the data withouterrors it performs

the following steps:

1. Deactivates its RTS line.

2. Sends an <ACK> to the control computer.

3. Enables the transmit and receives buffers for the next mixer.

4. Changes its display from “00” to number it received.

After the control computer receives the <ACK> it sees the RTS from the next

mixerand again issues the <ENQ> command.The above process is repeated

until all mixers are numbered.

If a mixer does not receive valid data from the control computer or detects a

transmission error (parity, framing, overrun), it sends a <NAK>. When the

controlcomputerreceives the <NAK> it resends the numberassignmentstring

tothe mixer.Section1.10onerrorhandling describes the maximum re-tries the

control computer performs.

If a mixer is turned on after all the other mixers have been numbered, it will be

numbered the same as described above with the next available number if no

commandshavebeen senttothe othermixers.If commands havebeenissued,

the mixer is assigned a temporary number starting with 89 and decrementing

for each subsequent mixer. This will cause the mixer to release its RTS so

normal communication can proceed. The operator will be alerted to the

conditionthat another mixer has come on-line and needs tobenumbered.The

operator will then be able to assign the new mixers a number so that they will

appear correctly in the system.

21

Page 24

If a mixer is requesting to be numbered and the control computer has already

issued25 mixernumbers,it willassignthe mixerthenumber89 as described in

the preceding paragraph and alert the operator to the situation.

If a mixer is powered down after it has been numbered, it will be treated as a

new unit as described above when it is powered up again.

1.5 – Remote / Local Operation

Once a mixer unit is assigned a number,it will keep the numberuntil thepower

switchis turnedoff.Itcanbereturned to local mode using the control computer

andthe“L”command.If the control computer program is no longer running, the

mixer can be powered off and then on to return it to local operation. If the “L”

command is used, the mixer will retain its assigned number and respond to

request commands from the control computer but ignore control commands.

1.6 – Command Format

Most commands from the control computer are preceded with the start of text

<STX> character (02 hex), a mixer identification letter (M for Mixer) and a two

digit mixer number (01 through 89). Numbers 00 and 90 through 99 are

reserved for special cases. Following the mixer number is the command

character and then the parameter field which varies in size from zero

charactersto20depending onthe command.Acarriagereturn<CR>, (0Dhex)

is used to indicate the end of a command string. The exceptions to this

command string format are the enquire, acknowledge, and negative

acknowledge(<ENQ>, <ACK>,and<NAK>).These three commands are sent

as a single character .

Five of the mixer unit commands can have a “99” for the mixer number to

indicate the command is for all mixer units.This allows units to simultaneously

be started, stopped, or for status checking.The specific commands to do this

are described in section (1.8).

<STX> M 01 S - 0130<CR>

Start of T ext (02 hex) Carriage Return (0D hex)

Mixer identification Parameterfield (0-20 char)

Mixer number Command character

22

Page 25

More than one command can be put in a command string as shown below:

<STX>M09S-500Q>20T90G<CR>

The above multiple command string example would set the speed at mixer

satellite 09 to 500 rpm, seta high torque limit of 20 oz-in,set the runtime to90

seconds,andturnthemotor on.Themaximum numberof charactersallowedin

a mixer command string is 24, including <STX>, Mnn and <CR>.

COMMAND CHARACTERS FROM CONTROL

COMPUTER TO MIXER

B Preset alarm output to specified state when G

command is executed 0=off, 1=on

F Request cumulative running time none

G Go(turn mixer on and alarm output if preset) none=timed run

H Halt (turn mixer off) none

I Request status data none

J Set torque zero reference none

K Request front panel switch pressed since last K

command none

L Enable Local operation none

NN Initialize units for status request none

O Controlalarm output 0=off, 1=on

Q Sethigh or low torque limit >xxx.xx or <xxx.xx

Q Requestactual torque none

R Enable Remote operation none

S Set motor direction and speed

NOTE: Units are not reversible

S Request motor direction and speed none

T Set time to go in seconds xxxx

T Request time to go none

U Change mixer number nn=new mixer

Z Zero time to go none

PARAMETER FIELD

0=continuous run

>=high, <=low limit

+xxxx.x, -xxxx.x

+=CW, -=CCW

number

Table 1. Control Computer to Mixer Commands

23

Page 26

CONTROL COMPUTER

COMMAND STRING

<STX>MnnBx<CR> x:0=off, 1=on <ACK>

<STX>MnnF<CR> <STX>Fxxxxxx<CR> xxxxxx =

cumulative run time (999,999

seconds max)

<STX>MnnG<CR> <ACK> or none if M99 or P99

<STX>MnnH<CR> <ACK> or none if M99 or P99

<STX>MnnI<CR> <STX>MnnIxx0xxx<CR>

(see section 1.8.1)

<STX>A99I<CR> <STX>MnnIxx0xxx<CR>

(see section 1.8.1)

<STX>MnnJ<CR> <ACK>

<STX>MnnK<CR> <STX>Kx<CR> (see section 1.12)

<STX>A99NN<CR> (see section 1.8)

<STX>MnnOx<CR> x:0=off, 1=on <ACK>

<STX>MnnQ>xxx.xx<CR> <ACK>

<STX>MnnQ<CR> <STX>Q016.00<CR>

<STX>MnnS-1000<CR> <ACK>

<STX>MnnS<CR> <STX>S-1000.0<CR>

<STX>MnnTxxxx<CR> <ACK>

<STX>MnnT<CR> <STX>T0069<CR>

<STX>MnnUnn<CR> nn=01 to 89 <ACK>

<STX>MnnZ<CR> <ACK>

MIXER RESPONSE

Table 2. Sample Mixer Commands and Responses

1.6.1 – Command Features

1. Initializing

Once a mixerunit has been assigned a number, it must first be sent a SPEED

and a TIME before the GO command can be sent. If the continuous run GO

command is used, onlya SPEED needs to be sent.Failureto do this will result

in a <NAK> from the mixer when it receives the GO command. The set torque

will default to the high limit equal to the maximum continuous torque rating for

the attached mixer head.

2. Setting Speed

The set speed command also includes a direction character,“+”for clockwise,

“-” for counter clockwise. The mixer is NOT reversib le, so the direction

24

Page 27

character must match the direction for the connected Mixer Head. An invalid

direction character in the set speed command will result in a <NAK> from the

mixer unit.

3. Setting Time

Whentimeto go is set with the T command, it isadded tothe currenttime togo

counter.The maximum this counter can be is 9999 seconds. If a time to go is

sent to the mixer which would cause the counter to overflow past 9999, the

mixerwill not add the valueto the counter and will send the control computer a

<NAK>. The time to go counter can be set to zero by using the Z command,

which will also cause the mixer to stop if it is running when the Z command is

received.Whenthetime togo counteriszero,themixercanonly bestarted with

the continuous run GO command.

4. Setting Torque Limit

The torque limit can be set to a high or low limit by preceding the torque limit

numberwitha “>”or“<”character.If thischaracter isomitted, thedefaultlimitwill

behigh.Whentheactual torqueexceedstheset torquelimit,the motorwillstop.

The control computer can determine the cause of the stop by requesting the

time to go (T command).If the time to go is greater than zero, then the torque

limitstoppedthemotor,otherwiseitwasbecause theruntime wascompleted.

1.7 – Control Computer Parameter Fields

The parameter field for each command is variable in length. The control

computer will have the option of using leading zeroes, leading spaces, or no

paddingat all.For example,if asetspeedof 200 rpmwasdesired, the following

list of parameters would all be accepted by the mixer as valid:

ssss-00200.00

(s = space) ssss-200.00

ssss-200.0

ssss-200

ssss-200.00

ssss-200.0

ssss-200

1.7.1 – Mixer Data Fields

Anydata thata mixersends to the controlcomputer willhavea fixed number of

characters which is determined by the command. For example, if the control

computer requested cumulative run time from the mixer, it would always

receive 6 characters representing the cumulative time (000000 to 999999).

1.8 – All Units Commands

Fiveof the mixerunit commands can be used with the special unit number 99,

which indicates the command is for all units. Each of these commands have

special conditions which apply to them as described below.The mixerunit will

ignore all other commands that are used with the 99 unit number.

(1) — <STX>M99G<CR> or <STX>P99G<CR>

25

Page 28

Eitherof thesecommandswill start all mixerunitsthathavebeen initializedwith

a speed and time.This command is not acknowledged by the mixer.

(2) — <STX> M99H<CR> or <STX>P99H<CR>

Either of these commands will stop all mixer units that are currently running.

This command is not acknowledged by the mixer.

(3) — <STX>M99Z<CR>

Thiscommand will zero the time togocounterinall mixer units.Ifamixer motor

isrunning whenthiscommand isreceived,themotor willstop.Thiscommandis

not acknowledged by the mixer.

(4) — <STX>A99NN<CR>

This command is the first part of atwostep command sequence.It instructsall

mixer units to disable their RS-232-C buffers and wait for the A99I command.

While waiting for the next step, the mixer unit will still respond to all other

commands, but only the first mixer unit in the daisy-chain will receive the

commands.The A99I command MUST be sent after the A99NN command to

restore normal communications.These two commands are used to determine

all the mixer units that are on-line. This is much more efficient than having to

send a command to all possible unit numbers and then checking which units

reply.

(5) — <STX>A99I<CR>

This command is the second partof a two-step sequence which is initiated by

the command previouslydescribed.If the mixer unit did not previously receive

theA99NN command, the A99I command will beignored. Otherwise the mixer

willrespond with the status informationasdescribedinsection1.8.1.When the

controlcomputer receivesthestatus information, it will send <ACK>Mnn<CR>

to the mixer with nn being the mixer unit number that replied.When the mixer

unit receives the <ACK> it will enable its RS-232-C buffers. The control

computerwouldthen repeat this sequence until no more units reply to the A99I

command, indicating all units have enabled their RS-232-C buffers.

26

Page 29

1.8.1 – Mixer Status Request

When the control computer requests status from the mixer (I command or

<ENQ>), the mixer will respond with the following status information:

<STX>MnnIxx0xxx<CR>

Operating status Mixer Head number (0-9, A-F)

(1=remote, 0=local)

Communications status

Alarm status 0=No error, 1=Parity error

(0=off, 1=on) 2=Framing error,

3=Overrun error

Not used in mixer, 4=Invalid command

always zero 5=Invalid data

6=Missing data

Unit status

1=Unit numbered,

waiting for instruction

2=Unit instructed, waiting to go

3=Unit running

4=Unit stopped by local stop

switch

5=No motor feedback

6=Incorrect motor feedback

7=Excessive motor feedback

8=Incorrect motor response—

no torque feedback

9=Max motor torque limit

exceeded

When the mixersends the status information, the communications status byte

willbe reset to zero whenthemixerreceives<ACK>Mnn<CR>from the control

computer.If the mixer receives the I command again before the <ACK>, it will

respond with the same status information.

1.9 – Mixer Response

When the mixer unit correctly receivesa controlcommand, it will sendback an

<ACK>(06 hex) if it was not an all units command (P99 or M99).If data has to

besent backto the masterinresponse tothecommand, itwillbe sent asshown

in table 2. If the mixer detected an error while receiving a command, it will

respond with a <NAK> and not process the command string.If the command

was for all units (P99 or M99) the mixer unit will not <NAK> but will activate its

RTS line and respond with the I command data when the control computer

sends the <ENQ> in response to the RTS.

27

Page 30

1.10 – Error Handling

Depending on the error code received from the mixer, the control computer

would have to take appropriate action to try to eliminate the error condition.

Communication errors of type 1,2 or 3 indicate a hardware type error: noisy

communicationlines,bad connection,glitches orcircuit failure.Communication

error codes 4, 5 or 6 could be hardware errorsas described aboveor software

errors caused by incorrect commands or data being sent by the control

computer.F orhardwaretype errors the control computer would trysendingthe

same command to see if the problem was only momentary.If an error code is

returnedfourtimesin arowor ifthere is noresponse atall,the controlcomputer

would aborttrying to send the command and notify the operator of the type of

error.

If a mixer does not respond at all, the control computer can assume one of the

following:

1. If allothermixersconnected after themixerin question also don’trespond,

the communication link is broken at that point or the mixer is defective.

2. If all other mixers respond, the un-responding mixer is either turned off,

removed from the loop, or defectiv e.

1.11 – Mixer Request to Send

When a mixer wants to communicate with the control computer, it will activate

its request to send(RTS)line and then waitforthe <ENQ> (enquire) character

(05 hex) from the control computer. The following list shows the possible

conditions that would cause the mixer to activate its RTS line.

1. Motor error

2. STOP key pressed at mixer while motor is on

3. Programmed run time completed

4. Torque limit exceeded

5. Power up

6. Error in all units command (M99 or P99)

Following is the sequence of events for when an RTS line is activated:

1. Mixer enables RTS line.

2. When control computer detects RTS, it will transmit the <ENQ> command

(05hex)after it completes any communicationsitmaybe in the process of

doing.

3. When the mixer that has its RTS line enabled receives the <ENQ> it will

disableits RS-232-C buffersto block the other mixersbelow it in the daisychain from communicating with the control computer.This would give the

mixerclosest to the control computer the highest priority if more than one

mixer enabled its RTS line at the same time.

28

Page 31

4. Next the mixer will send the response from the I command as shown in

section 1.8.1.

5. If the control computer received the mixer response without any errors

(parity, overrun, etc.) itwill send an acknowledge<ACK>Mnn<CR> which

will cause the mixer to release its RTS line and enable its RS-232-C

buffers. This will allow the mixers below it in the daisy-chain to

communicate. If the control computer detected any error during the

transmissionit would send the <ENQ>againwhichwouldcause the mixer

tore-send its response.Thecontrolcomputer will re-try a maximum offour

times before aborting and reporting the error to the operator.

6. If more than one mixer had its RTS line enabled, the control computer

wouldsee only the response from the mixer closest to it in the daisy-chain.

After the closest mixer sent its response and released the RTS line, the

controlcomputer wouldsee the RTSoftheother mixerand againissuethe

<ENQ> command which would allow the next mixer with RTS active to

respond.

7. If a mixerwas responding to an <ENQ> command and another mixerwith

higher priority also started to respond, cutting off the first responding

mixer, the control computer would receive invalid data and get some type

of error (parity or framing). This would cause the control computer to

resend the <ENQ>, but this time only the higher priority mixer would

respond since the communications with the lower mixers is blocked.

1.12 – Front Panel Switches

Thecontrolcomputercanreadthemixers front panel switchesbyissuing the K

command.The mixerwill respond with one characterindicating the last switch

pressed since the last K command was acknowledged. If more than one key

waspressed, only the lastone pressed is indicated.After the controlcomputer

receives the mixer unit switch status, it must send an <ACK>Mnn<CR> to

informthe mixeritcan reset the switch status to no key pressed.Table 3 shows

the character returned by the K command and the corresponding switch for

mixer units.

0 = No key pressed 5 = Torque

1 = Start 6 = T orqueZero

2 = Stop 7 = Up arrow

3 = Time 8 = Down arrow

4 = Speed

Table 3. K command key codes for mixer

29

Page 32

1.13 – ASCII Control Characters Used

FUNCTION

DECIMAL HEX

2 02 <STX> Start of Text (CTRL-B)

6 06 <ACK> Acknowledge (CTRL-F)

5 05 <ENQ> Enquire (CTRL-E)

13 0D <CR> Carriage Return (CTRL-M)(CR)

21 15 <NAK> Negative

24 18 <CAN> Cancel (CTRL-X)

CHARACTER

Acknowledge

CONTROL

KEY

(CTRL-U)

Table 4. ASCII Control Codes Used

30

Printed in U.S.A.

031000

Loading...

Loading...