Page 1

OPERATING MANUAL

High Capacity

Vacuum/Pressure Pump

Vacuum/Pressure Station

Barnant Company

28W092 Commercial Avenue

Barrington, Illinois U.S.A.60010-2392

(847) 381-7050

(847) 381-7053 (Fax)

800-637-3739

www.barnant.com

A-1299-0380

Edition 05

115V AC Models

Pump Only 475-3010

Vacuum/Pressure Station 470-5942

SPECIAL APPLICATIONS

Technical information and advice concerning the use of this product in specific applications may be obtained from our Engineering Department. If volume justifies, modifications can be made to adapt the unit to special customer applications. OEM inquiries are welcome and encouraged.

NOTE: The BARNANT COMPANY reserves the right to make improvements in design, construction, and appearance of our products without

notice.

W ARRANTY

The Manufacturer warrants this product to be free from significant

deviations from published specifications. If repair or adjustment is

necessary within the warranty period, the problem will be corrected at

no charge if it is not due to misuse or abuse on your part as determined

by the Manufacturer. Repair costs outside the warranty period, or those

resulting from product misuse or abuse, may be invoiced to you.

The warranty period for this product is noted on the Warranty Card.

PRODUCT RETURN

To limit charges and delays, contact the seller or Manufacturer for

authorization and shipping instructions before returning the product, either

within or outside of the warranty period.When returning the product, please

state the reason for the return. For your protection, pack the

product carefully and insure it against possible damage or loss. Any damages resulting from improper packaging are your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the

Manufacturer or authorized seller.

Printed in U.S.A.

040599

18

Page 2

17

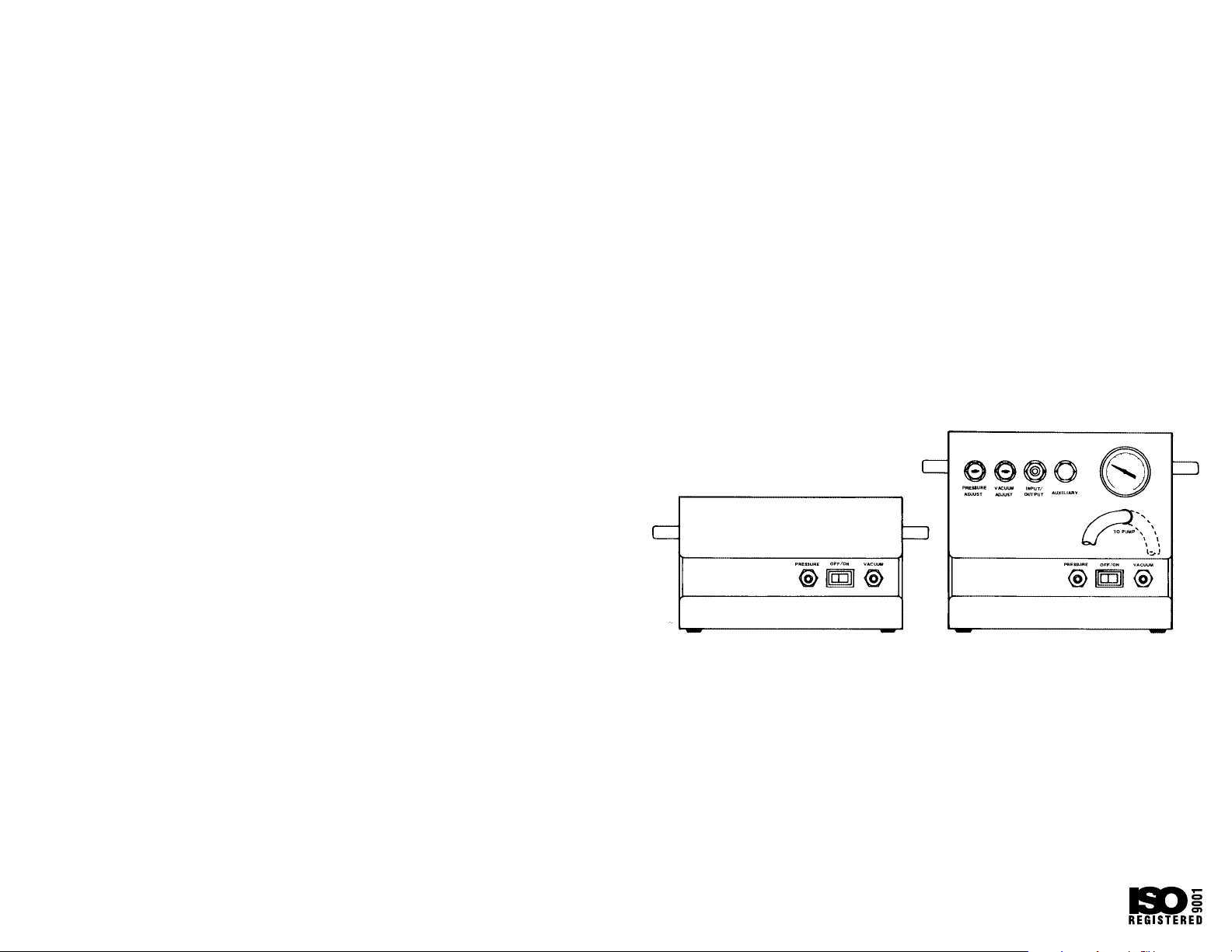

475-3010

The Pump is a chemically resistant, diaphragm operated, variable flow unit

designed for efficient vacuum, pressure, or gas circulating applications. An

integral fan keeps the pump head cool; the temperature of your service

should remain stable.

470-5942

The Pump is teamed up with a Vacuum/Pressure Control Station to provide

easy, convenient regulation of vacuum or pressure .These adjustments can

be made while the pump is running. The system is portable enough for

benchtop laboratory use, plus many commercial applications where reliability and optimum chemical resistance are required.

FLUOREL - Reg TM Minnesota Mining and Manufacturing Co.

NORPRENE - Reg TM Norton Co.

NORYL,VALOX - Reg TM General Electric Co.

VITON - Reg TM DuPont Dow Elastomers L.L.C.

Trademarks bearing the ® symbol in this publication

are registered in the U.S. and in other countries.

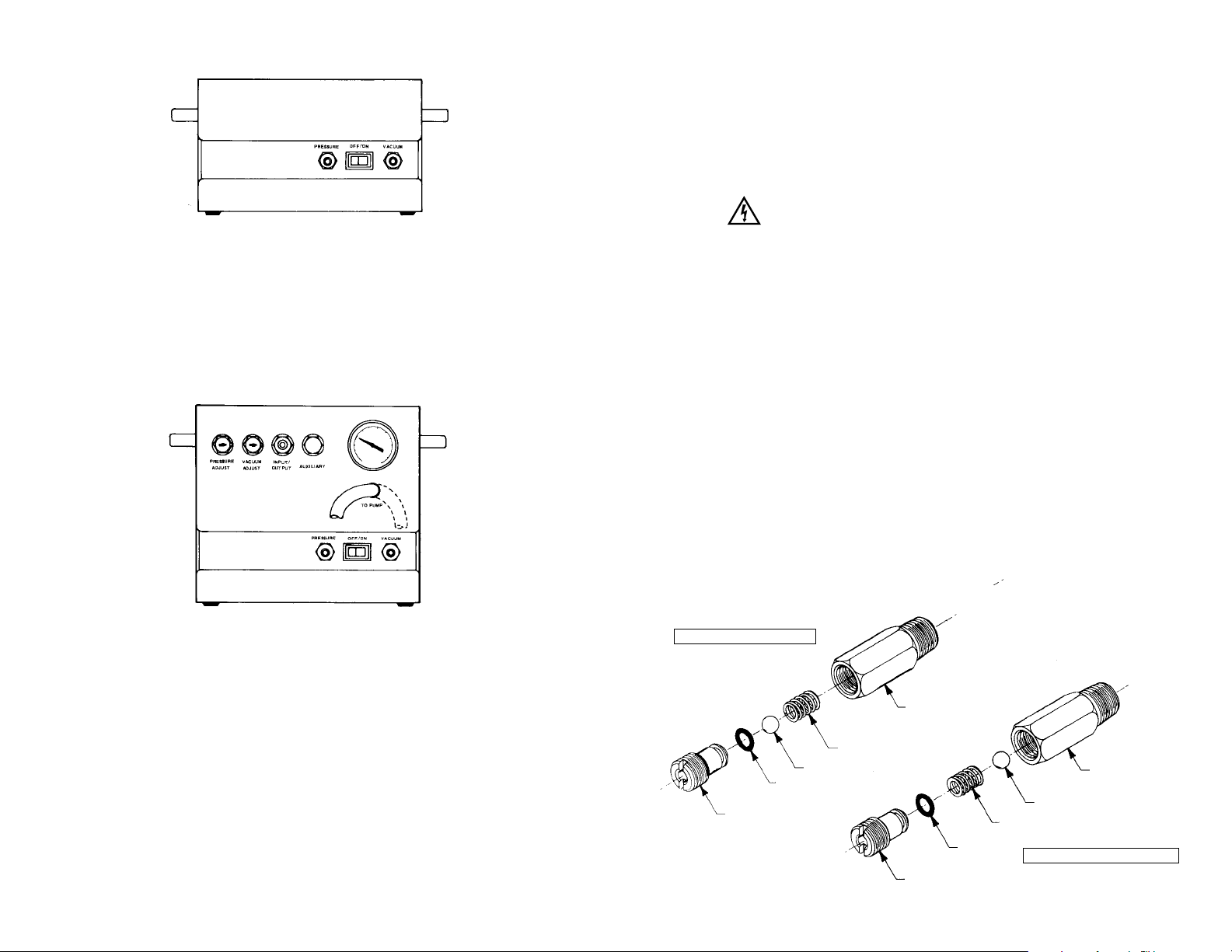

VALVE BODY

BALL

SPRING

O-RING

ADJUSTMENT SCREW

PRESSURE REGULATION VALVE

VACUUM REGULATION VALVE

VALVE BODY

BALL

SPRING

O-RING

ADJUSTMENT SCREW

(3) Storage Procedure

If the system will not be in service for any appreciable length of time,

store it in a clean, dry space. Cover any open ports to prevent entry of

dust.Wipe the pow er cord with a dry cloth and inspect for crac ks in the

insulation. Repair any defects or replace the cord before reusing the

pump.

WARNING: Do not modify the plug. And do not connect the grounding

wire to either of the flat blade terminals. (Grounding wire

is green, sometimes with yellow stripes.)

REPLACEMENT PARTS

Service Kit (7530-09)

Composed of: 1 FLUOREL Diaphragm Assembly

1 Pump Head Assembly

(Consisting of 2 valves and 2 valve retainers installed in a

pump head)

Regulation Valve Components

Item Part No

O-RING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1169-11

BALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3988

SPRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3789

VACUUM REGULATION VALVE ASSEMBLY . . . . . . . . . .B-2067

PRESSURE REGULATION VALVE ASSEMBLY . . . . . . .B-2066

Page 3

TABLE OF CONTENTS

Title Page

PANEL CONTROLS/CONNECTIONS . . . . . . . . . . . . .See Foldout Page

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pressure vs.Vacuum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1. Plug in the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2. Connect Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3. Optional Filter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

SETUP PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Material Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1 Setup for VACUUM Operation . . . . . . . . . . . . . . . . . . . . . . . . . .8

2. Setup for PRESSURE Operation . . . . . . . . . . . . . . . . . . . . . .10

3. Setup for TWO-LINE Operation . . . . . . . . . . . . . . . . . . . . . . .11

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Maximum Vacuum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Maximum Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

FLOW VS. PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Performance Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

MAINTENANCE PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

To Remove the Pump Head . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

To Replace the Diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

To Install the Diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

To Replace the Pump Head . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

1. How to Clean the Regulation Valves . . . . . . . . . . . . . . . . . . .16

2. Motor Overload Protection . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3. Storage Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

SPECIAL APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

PRODUCT RETURN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

TECHNICAL ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

1

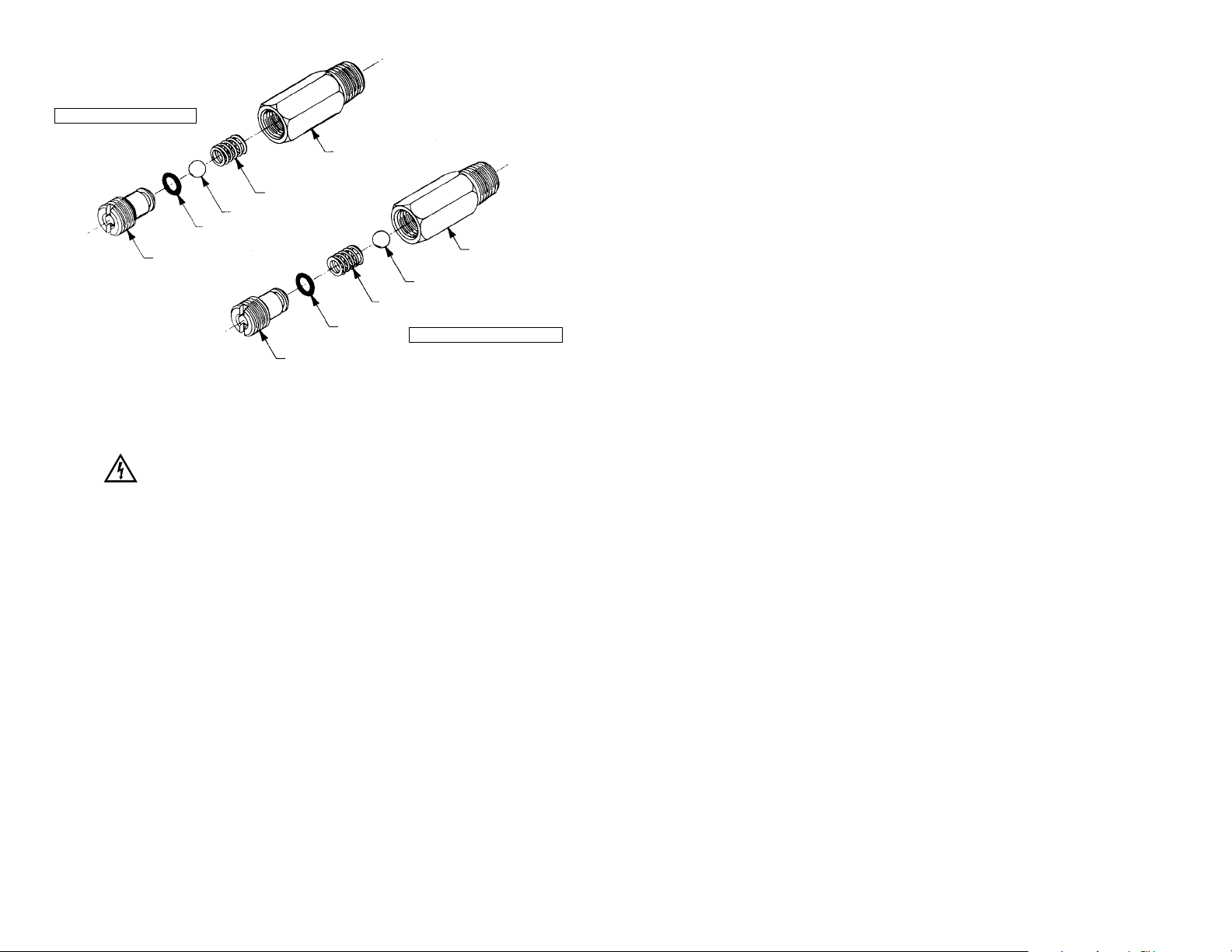

(1) How to Clean Regulation Valves

DANGER: Unplug power cord before any cleaning operation is started.

The PRESSURE ADJUST and VACUUM ADJUST valves should be

occasionally inspected and cleaned.

• Remove the valve elements by turning the adjustment screws CCW.

Use a cotton swab or clean cloth to clean out dirt or grit around the

venting holes.

• Remove BALL and SPRING. Clean the areas around valve seating

surfaces in the VALVE BODY and elements.

• Reassemble VACUUM ADJUST and PRESSURE ADJUST valves.

IMPORTANT: Note that in the VACUUM valve, the SPRING must

go back in first, followed by the BALL. In the PRESSURE valve, the

BALL must go back in before the SPRING.

(2) Motor Overload Protection

The pump motor has an internal thermal overload switch which may

trip if abnormal operation occurs. If the motor stops, check the pump.

If you find no defect, allow the motor to cool for approximately 30 minutes, then restart. If the overload trips again—and no external source

causing the overload can be identified—return the complete unit to

your dealer for repair. (Refer to PRODUCT RETURN section at the

end of the manual.)

16

VALVE BODY

VALVE BODY

BALL

BALL

SPRING

SPRING

O-RING

O-RING

ADJUSTMENT SCREW

ADJUSTMENT SCREW

PRESSURE REGULATION VALVE

VACUUM REGULATION VALVE

Page 4

To Remove the Pump Head

Remove the eight (8) screws holding the pump head to the pump housing.

Do not discard.With the ‘old’head off, examine the diaphr agm f or cr ac ks or

loose particles. Deep cracks would suggest that the diaphragm should be

replaced. Nor mal operation will cause some par ticles to be worn from the

diaphragm. Wipe the diaphragm clean with a dr y cloth or one dampened

with alcohol.If not removed, these particles could affect the perf ormance of

the valves.

To Replace the Diaphragm

Remove the eight (8) screws holding the pump head to the housing. Do

not discard.Slide the diaphragm away from the motor and then lift upward.

Unscrew the bearing collar assembly from the diaphragm. Examine the

bearing; check that the “needles” rotate freely. Install the new diaphragm

onto the bearing collar. Hold the diaphragm center plate, not the rubber

portion of the diaphragm, while the assembly is tightened. Rotate the

eccentric (attached to the motor shaft) by hand while applying grease to the

dowel pin. Use a wooden toothpick or something similar.Don’t scratch the

pin by using a metal object.

To Install the Diaphragm

Rotate the eccentric so that the dowel pin is “upward.” Slide the diaphragm

toward the motor, while gently pushing downward. Align the diaphragm

bead with the groove in the pump housing. It is recommended that a new

pump head be installed whenever a diaphragm is replaced.Excessive wear

particles from the old diaphragm may have entered the valves and

decreased their performance.

To Replace the Pump Head

Position the new pump head so that the flat edge is located toward the

motor.Care should be taken to align the diaphragm bead to the recess in

the pump head before the screws are tightened.Use the original screws to

attach the head onto the housing. IMPORTANT: tighten the screws alter-

nately, at opposite sides of the head, so that it will seat evenly. Use two

steps—first, tighten all to approximately 50 oz-in, then tighten to 100 to 110

oz-in.

CAUTION: Do not disassemble the pump housing from the motor. Proper

assembly (factory adjusted) is critical to proper pump performance.

15

SAFETY PRECAUTIONS

DANGERS: Unplug power cord before any cleaning operation is started.

Improper use of grounding plug can result in a risk of electric

shock.

WARNING: Gas under pressure should not be used for supply as a haz-

ardous bursting condition could develop in the pump head.

Use only gases contained at atmospheric pressure.

CAUTION: Do not operate pump when pressure ports of both heads are

in a blocked condition.

2

WARNING: PRODUCT USE LIMITATION

These products are not designed for, nor intended for use in patient

connected applications; including, but not limited to medical and dental

use and accordingly, have not been submitted for FDA approval.

Page 5

INTRODUCTION

The introductions in this manual are task-oriented.You can go directly to a

particular section and quickly find the answers. The step-by-step installation and setup instructions are easy to follow. Also, functions for all the tubing connections and adjustment valves are defined at the front of the manual for easy reference.

Pressure vs. Vacuum

In relation to atmospheric air, pressure can be positive or negative in a

closed space. In positive pressure applications, the pump compresses

atmospheric air to perform work, usually expressed as pounds per square

inch (psi). In negative pressure applications, the pump reduces the pressure of the atmospheric air to create a vacuum (or suction) to perform work,

usually expressed as inches of mercury (in Hg).

Although the way these pressure differentials are generated and used in a

closed space is exactly opposite, the same equipment can be used by simply changing tubing connections.

Description

The Pump is a chemically resistant, diaphragm operated, variable flow unit

designed for efficient vacuum, pressure, or gas circulating applications. An

integral fan keeps the pump head cool—the temperature of your service

should remain stable.

The Pump is teamed up with a Vacuum/Pressure Station to provide easy,

convenient regulation of vacuum or pressure. These adjustments can be

made while the pump is running.The system is portable enough for benchtop laboratory use, plus many commercial applications where reliability and

optimum chemical resistance are required.

3

MAINTENANCE PROCEDURES

The Vacuum/Pressure Station can be serviced without removal of the

pump.

Service Kit 7530-09 contains a pump head assembly, a diaphragm assembly, and grease. The pump head consists of two valves and two valve

retainers installed in the pump head.The diaphragm assembly consists of

a set screw installed in the diaphragm center plate to a calibrated height.

The grease is needed whenever a diaphragm is replaced.

Cleaning

DANGER: Unplug power cord before any cleaning operation is started.

Keep the pump enclosure clean by using a mild detergent solution.Never

immerse nor use excessive fluid when cleaning the pump.

14

Bearing

Collar

Assy.

Diaphragm

Pump Head

Pump Head

Screws (8)

Valve Retainer

Valve

Valve

Valve Retainer

475-3010

470-5942

Page 6

FLOW vs. PRESSURE

High Capacity

Performance Characteristics

The graph shows typical flow characteristics.

in Hg PSIG

Construction

Rugged, epoxy painted metal housing protects the all-plastic, corrosion

resistant pump. The diaphragm and head cavity provide extended life by

minimizing stress, wear and heat buildup—while optimizing pressure and

vacuum characteristics.

Permanent split-capacitor motor is fan cooled, thermally protected, and has

sealed ball bearings.

Regulation valves are 303 stainless steel.The gauge is bronze and brass.

13

The Vacuum/Pressure Station per mits independent regulation of vacuum

and pressure using an easy reading, dual function gauge. It eliminates the

need for separate systems and elaborate plumbing networks.The horizontal position of regulation valves protects against dirt or dust. Also, pump

vibrations won’t alter your valve settings.

To change from pressure to vacuum, or vice versa, simply switch the VACUUM/PRESSURE TUBING from one port to the other. An auxiliary

input/output port is also provided on the Vacuum/Pressure Station to draw

a vacuum or pressurize a system on tw

o lines simultaneously.

Contamination-free operation is provided via these corrosion-resistant

pump materials:

VALOX

®

Pump Head—Thermoplastic polyester resin assures excel-

lent resistance to a wide range of chemicals, including aliphatic hydrocarbons, oil vapors, dilute acids and bases.

FLUOREL®Fluoroelastomer Diaphragm—Provides exceptional

chemical resistance.

NORPRENE

®

Valves—Provides resistance to most hydrocarbons,

acids and alkalies

NORYL®Retainers—Corrosion resistant glass filled valve retainers.

Contact our Applications Department regarding compatibility with specific services.

4

Page 7

Application Data

The 475-3010 Pump can handle a broad range of vacuum or pressure

applications—especially those where contamination-free operation is

important. It’s ideal for filtration jobs, but there are virtually no limits within

its capacity range. For pressure output, use ambient air or other gas as a

supply source.

WARNING: Gas under pressure should not be used for supply. A haz-

ardous bursting condition could develop in the pump head.

Use gases contained at atmospheric pressure only.

Following is just a partial list of high capacity vacuum/pressure applications

which the system can handle.

• Pressure/Vacuum Filtration

• Air/Gas Sampling

• Lab Science Stations

• Gas Analyzers

• Power Burners

• Precious Metal Recovery

• Computer Peripherals

• Analysis Instr uments

• Flame Photometry

• Environmental Air Testing

• Photographic Enlargement

Tables

5

SPECIFICATIONS

Free-air Capacity Maximum Maximum Dimens.

System Model cfm (L/min) Vacuum Pressure Power (Housing)

VACUUM/

1.1 20 in Hg init. 18 psig initial

115 ±10% V AC 15 in W x

PRESSURE 475-3010

(31.1) 18 in Hg cont. 16 psig cont.

60 Hz 7-1/2 in D x

PUMP (1.3A) 6-1/2 in H

VACUUM/

0.9 20 in Hg init. 17 psig initial

115 ±10% V AC 15 in W x

PRESSURE 470-5942

(25.5) 18 in Hg cont. 15 psig cont.

60 Hz 7-1/2 in D x

STATION (1.3A) 9-1/2 in H

Temperature range:

+ 40°F to 100°F (+ 4°C to 38°C)

NOTE: Motor ther mal cutout at 135°C, ± 5°C.

Motor:

1/12 hp @ 1550 rpm. Starting torque - 54 oz/in; can star t against 5

psig backpressure at outlet.

Operating Temperature Range: 0°C to 40°C (32°F to 104°F)

Humidity Range: 10% to 90% non-condensing

Altitude: Less than 2000 m

Pollution Degree: Pollution Degree 2 per

IEC 664 (Indoor usage -

lab, office)

Enclosure Rating: IP 20 per IEC 529

Weight: 7.7 kg (17 lbs)

Installation Category: Installation category II per

IEC 664

(Local level, appliances, por table

equipment, etc...)

12

• Automotive Emission

Testing

• Pneumatic Controls

• Suction Units

• Process Control

• Nebulizers

• Circulating/Aerating

Equipment

• Optical Equipment

• Inhalation Apparatus

• PC Board Flux Foamers

Page 8

(3) Setup for TWO-LINE Operation

The system can evacuate or pressurize two de vices sim ultaneously by

using the AUXILIARY port, as shown below.The illustration shows the

system connected for vacuumoperation.For a two-line pressureoperation, the VACUUM/PRESSURE TUBING would be connected to the

PRESSURE port (as denoted by the broken lines).

Required tubing connections are shown for 2-line VACUUM operation.

(Broken lines denote connection for 2-line PRESSURE operation.)

• Remove the plastic pipe plug from the AUX port.

• Inser t into the AUX port any tube fitting with a standard 1/4 NPT

male pipe thread on one end. Use a pipe thread tape or sealant on

the male thread to insure leakfree fit.

• Connect the VACUUM/PRESSURE TUBING to the desired port.

• Press the ON switch to star t the pump.

• Regulate performance be turning the corresponding regulation

valve (with a screwdriver). Watch the GAUGE.Stop the adjustment

when it sho

ws the desired value.

116

USER

TUBING

VACUUM/PRESSURE

TUBING

Typical VACUUM application

Typical TWO-LINE application

Typical PRESSURE application

Page 9

INSTALLATION PROCEDURES

The Pump and Station are furnished ready to install. Follow this procedure:

(1) Plug In The System

A 6-ft. long 3-wire cord with grounded plug is furnished.

• Insert plug with grounding pin into a properly grounded receptacle.

DANGER: Improper use of grounding plug can result in a risk of

electrical shock.Also, if an adapter is used with a 2-pole

receptacle, be sure to ground the adapter to the outlet

box or similar permanent ground.

EXTENSION CORDS: If necessary, use only a 3-wire extension

cord, in good condition and capable of carrying the current drawn

by the product (3 A). No. 18 AWG conductor is recommended.

CAUTION: An undersized extension cord will cause a drop in line

voltage, resulting in loss of power and overheating.

(2) Connect Tubing

(See SET-UP PROCEDURES following.)

(3) Optional Filter Installation

If air or gas being pumped is relatively dirty , dust and particles can collect at valve seats.This can interfere with proper valve action, resulting in decreased or erratic pressure and vacuum characteristics.Filter

Kit #7396-00 is available with necessary hardware.

• Install filter on inlet side, as close to pump as possible. The filter

should be capable of withstanding 1.3 cfm and 20 psig internal

pressures.

7

(2) Setup for PRESSURE Operation

(Station Model 470-5942)

• Connect user’s 3/8 in I.D. OUTLET TUBING at INPUT/OUTPUT

port, as shown.

• Connect other end of 3/8 in I.D. OUTLET TUBING at device to be

pressurized.

• Connect the VACUUM/PRESSURE TUBING to the PRESSURE

port.This tubing has a quick-connect/disconnect feature—just push

the female coupling over the male connector, and it will snap into

place.(To disconnect, press latch on the coupler, and it will release.)

• Press the ON switch to star t pump.

• Regulate the pressure by tur ning the PRESSURE ADJUST valve

(with a screwdriver).Watch the GAUGE. Stop the adjustment when

it reads the desired vacuum value.

10

VACUUM/PRESSURE

TUBING

(FOR PRESSURE)

USER SERVICE

TUBING

Required tubing connections are shown

for regulated pressure

operation.

Page 10

• Connect user’s 3/8 in I.D.INLET TUBING at INPUT/OUTPUT port,

as shown.

• Connect other end of 3/8 in I.D. INLET TUBING at closed container.

• Connect the VACUUM/PRESSURE TUBING to the VACUUM port.

This tubing has a quick-connect/disconnect feature—just push the

female coupling ov er the male connector, and it will snap into place.

(To disconnect, press latch on the coupler, and it will release.)

• Press the ON switch to star t pump.

• Regulate the vacuum by turning the VACUUM ADJUST valve (with

a screwdriver). Watch the GAUGE. Stop the adjustment when it

reads the desired vacuum value.

NOTE: No vacuum oil is required.

9

SET-UP PROCEDURES

Material Compatibility

In some applications it is important to consider material compatibility before

running any service through the pump.Follo wing are pump materials which

service will contact:

Pump Head:

VALOX (polybutylene terephthalate)

FLUOREL (fluorocarbon elastomer)

NORPRENE (thermoplastic olefin)

NORYL (glass filled)

Manifold Chamber & Fittings:

PVC

Acetal

Linear polyethylene

303 stainless steel

VITON®(fluoroelastomer)

Pressure/Vacuum Gauge:

Bronze tubing

Brass socket

IMPORTANT: Any sudden changes in diameter of tubing and fittings, plus

bends or other obstructions, will increase system pressure, thus decreasing flow characteristics.

CAUTION: Do not operate pump when pressure ports of both heads are in

a blocked condition.

(1) Setup for VACUUM Operation

(470-5942)

IMPORTANT: If the Station previously was used for pressure delivery,

be sure all pressures are relieved bef ore disconnecting tubing from the

PRESSURE and/or the INPUT/OUTPUT ports. Stop the pump and

turn the PRESSURE ADJUST screw CCW until the GAUGE reads

zero.

8

VACUUM/PRESSURE

TUBING

(FOR VACUUM)

USER SERVICE

TUBING

Required tubing connections are shown

for regulated v

acuum operation.

Page 11

To regulate vacuum, turn with screwdriver

until GAUGE shows desired value.

Port for either pressure or vacuum application.

Connect inlet tubing to this port. Polyethylene

fitting accepts 3/16 to 3/8 in I.D. flexible tubing.

Auxiliary input/output port for drawing a vacuum or pressurizing with 2 lines simultaneously.

Accommodates any tube fitting with standard

1/4 in (M) NPT pipe thread.

Dual-function gauge reads either vacuum (to 30

in Hg) or pressure (to 30 psig).

VACUUM/PRESSURE TUBING (9 in long) is permanently connected to pump. Other end has

Quick-Connect/Disconnect Coupler for changing to either VACUUM inlet or PRESSURE outlet

port.

Squeeze Quick-Connect/Disconnect Coupler to

attach or detach the VACUUM/PRESSURE TUBING for vacuum operation.

Squeeze Quick-Connect/Disconnect Coupler

to attach or detach the VACUUM/PRESSURE

TUBING for pressure operation.

Use Quick-Connect/Disconnect Coupler to

attach your service to either the VACUUM or

PRESSURE port.

To regulate pressure, turn with screwdriver

until GAUGE shows desired value.

Press to

start or

stop pump.

Press to

start or

stop pump.

PRESSURE

ADJUST

PRESSURE VACUUMOFF/ON

VACUUM

ADJUST

INPUT/

OUTPUT AUXILIARY

TO PUMP

470-5942

475-3010

PRESSURE OFF/ON VACUUM

Loading...

Loading...