Page 1

Aluminum

Heating Mantles

User Guide

ON/OFF

HOT

Version 1.3

Page 2

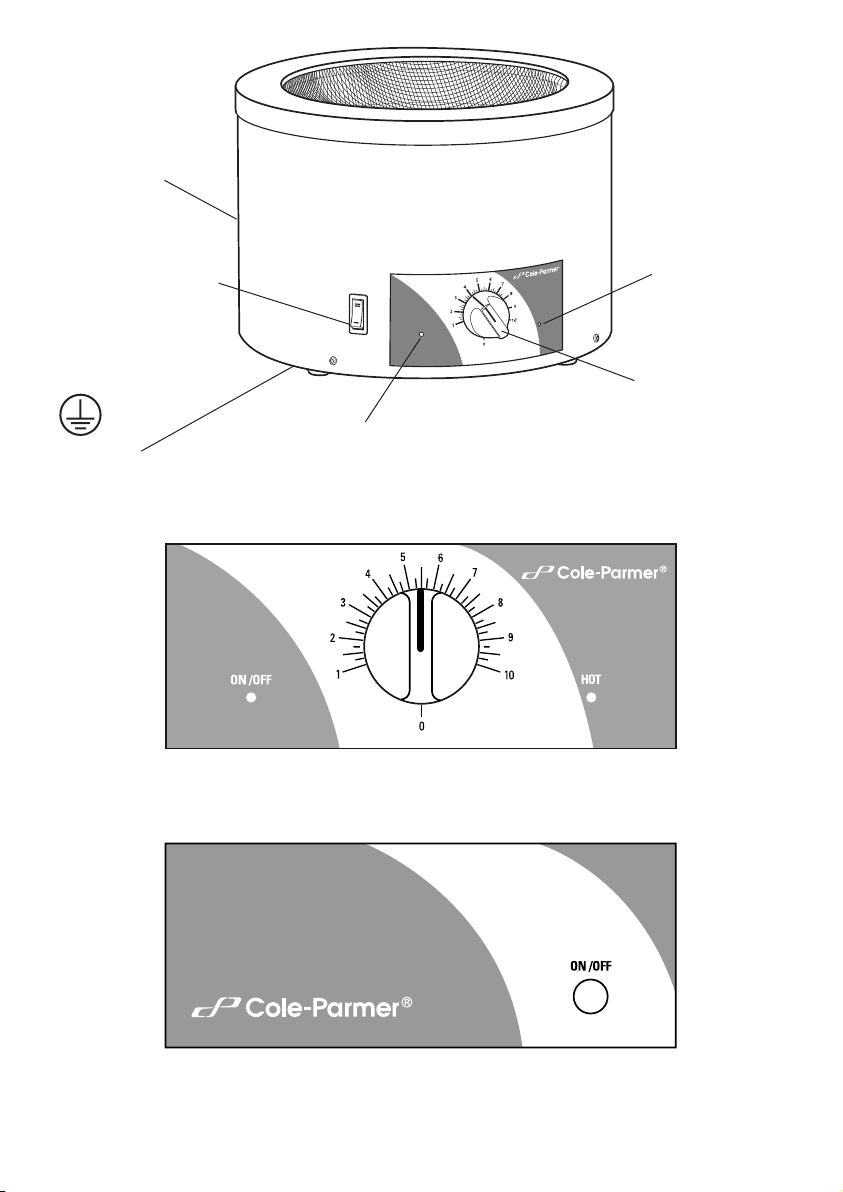

IEC power

inlet socket

Power supply switch

(large-volume models).

Power to either the

lower part of the

element or the upper

and lower parts.

Protective

conductor terminal

(Do not loosen or

disconnect).

ON/OFF

HOT

Power ON LED light

Figure 1: Front view

Figure 2: Controlled Mantle Models

Heating LED light

Power on/off and

heating control dial

Figure 3: Uncontrolled Mantle Models

2

Page 3

Aluminum Heating Mantles

Introduction

Thank you for purchasing this Cole-Parmer product. To get the best performance from the

equipment, and for your own safety, please read these instructions carefully before use.

Before discarding the packaging check that all parts are present and correct.

This equipment is designed to operate under the following conditions:

❖ For indoor use only

❖ Use in a well ventilated area

❖ Ambient temperature range +5°C to +40°C (+41°F to +104°F)

❖ Altitude to 2000 m (6500 ft)

❖ Relative humidity not exceeding 80%

❖ Power supply fluctuations not exceeding 10% of nominal

❖ Overvoltage category II IEC60364-4-443

❖ Pollution degree 2 IEC664

❖ Use with a minimum distance all round of 300 mm (12 in.) from walls or other items

If the equipment is not used in the manner described in this manual and with accessories other than

those recommended by the manufacturer, the protection provided may be impaired.

Electrical Installation

THIS EQUIPMENT MUST BE GROUNDED

Before connection please ensure that the line supply corresponds to that shown on the

rating plate located on the back of the unit.

Power requirements:

120 V Models Watt Fuse 230 V Models Watt Fuse

37013-00 75 1 A 37013-02 75 500 mA

37013-01 75 1 A 37013-03 75 500 mA

37013-04 100 1.25 A 37013-06 100 0.5 A

37013-05 100 1.25 A 37013-07 100 0.5 A

37013-08 200 2.5 A 37013-10 200 1.25 A

37013-09 200 2.5 A 37013-11 200 1.25 A

37013-12 280 3.15 A 37013-14 280 2.5 A

37013-13 280 3.15 A 37013-15 280 2.5 A

37013-16 380 5 A 37013-18 380 2.5 A

37013-17 380 5 A 37013-19 380 2.5 A

37013-20 500 5 A 37013-21 500 2.5 A

37013-22 800 10 A 37013-23 800 5 A

The 120 V Models are provided with a NEMA 5-15 plug. The 230 V Models are provided with a UK

3-pin and a “Schuko” 2-pin plug.

Should the cable not be suitable for connecting to the power supply, replace the plug with a suitable

alternative.

3

Page 4

THIS OPERATION SHOULD ONLY BE UNDERTAKEN BY A QUALIFIED ELECTRICIAN.

NOTE: Refer to the equipment rating plate to ensure that the plug and fusing are suitable for the

voltage and wattage stated.

The wires in the power cable (120 V) are colored as follows:

BLACK - HOT/LIVE

WHITE - NEUTRAL

GREEN - EARTH

The wires in the power cable (230 V) are colored as follows:

BROWN - HOT/LIVE

BLUE - NEUTRAL

GREEN/YELLOW - EARTH

IF IN DOUBT CONSULT A QUALIFIED ELECTRICIAN

Should the power cable need replacing, a cable of 1 mm2 of harmonized code H05W-F connected to

an IEC320 plug should be used.

The appropriate power cable should be connected BEFORE connection to the power supply.

General Description

Cole-Parmer Heating Mantles are ideal instruments for heating fluids in round-bottomed flasks in the

modern laboratory. The controlled mantles contain a built-in control dial and energy regulator. The

uncontrolled mantles require the use of an external temperature controller. All mantles are constructed

of a powder coated aluminum case to provide excellent chemical resistance. All units combine the

traditional heating element with a built-in earth screen and, depending on the size, can support up to

three lab support rod positions.

The following tables identify the different sizes and groups within the Heating Mantle range:

Controlled Mantles Uncontrolled Mantles

Flask Capacity 120 V 230 V 120 V 230 V

50 ML 37013-00 37013-02 37013-01 37013-03

100 ML 37013-04 37013-06 37013-05 37013-07

250 ML 37013-08 37013-10 37013-09 37013-11

500 ML 37013-12 37013-14 37013-13 37013-15

1000 ML 37013-16 37013-18 37013-17 37013-19

2000 ML - - 37013-20 37013-21

5000 ML - - 37013-22 37013-23

Available separately are multiple types of external controllers, glassware, and lab support rods to

support various laboratory applications. Please visit the Cole-Parmer website www.coleparmer.com

for further information.

*

*Large volume mantles contain a switch to alternate the power supply between the upper and lower

parts of the heating element, or lower parts only (for when heating smaller volumes).

4

Page 5

Safety Advice

❖ HIGH TEMPERATURES ARE DANGEROUS as they can cause serious burns to operators and

ignite combustible material. Users should be aware of the following safety advice:

❖ USE CARE AND WEAR PROTECTIVE GLOVES TO PROTECT HANDS.

❖ DO NOT use combustible substances near hot objects.

❖ NEVER lift or carry the instrument until it has been switched off and allowed to cool for at least

30 minutes. The hot warning light will give guidance.

❖ The unit should be carried using both hands with the fingers under the side edges.

❖ NEVER move or carry the unit with containers on the top or while still connected to the power

supply.

❖ DO NOT mix combustible liquids or use the equipment in hazardous atmospheres.

❖ NEVER place a cold glass vessel into a mantle which is already hot.

❖ When a lab support rod is installed with apparatus attached, or with swivelling support rods, take

care that there is sufficient weight on the plate to prevent the whole unit tipping over.

❖ DO NOT position the unit such that it is difficult to disconnect it from the power by removing the

power cable from the socket at the back.

❖ DO NOT position the unit such that the ventilation slots are blocked or otherwise obstructed.

❖ DO NOT leave equipment switched on without a charged flask and it is not recommended to

leave any heating apparatus unattended during operation.

❖ AVOID SPILLAGES: Always fill the glassware / vessel away from the heating mantle. Only

introduce a pre-filled, clean, wiped-dry flask into the heating mantle. If spillage does occur,

disconnect unit from the power supply and follow instructions in the Servicing and Repair section.

❖ DO NOT operate or handle any part of the product with wet hands or use on surfaces that may

become flooded.

❖ NEVER connect uncontrolled mantles directly to the mains supply, these are designed for use with

an external controller.

Before Use

Position the mantle on a firm level surface but DO NOT connect to the power supply yet.

Please refer to the installation instructions for any accessories before applying power and ensure

there is sufficient room for the unit to operate and that the ventilation slots are not blocked or

otherwise obstructed.

NOTE: This product should be connected to a mains supply source which incorporates an RCD or

GFCI device that has a tripping current of 30mA or less.

5

Page 6

Controlled Mantle Models

Connect the power cable attached IEC socket of the mantle as illustrated in Figure 4 and connect

directly to the power supply.

Uncontrolled Mantle Models

Connect the power cable attached to external temperature controller to the IEC socket of the mantle

as illustrated in Figure 5 and connect to the power supply. This product requires an external controller

to operate. Please note, the illustration of controller may be different depending on the model. Please

visit the Cole-Parmer website www.coleparmer.com for further information.

Protective

conductor terminal

(Do not loosen or

disconnect).

Figure 4

Figure 5

Operation

Place a pre-filled, clean, wiped-dry glass vessel of the appropriate size into the mantle. Wherever

possible the glass vessel should be supported by means of the lab support rod and clamp (available

separately). Switch the unit ON and adjust the controller regulator or control dial on the front of the

unit to the desired setting. To switch the unit OFF, adjust the controller regulator or control dial to the

OFF position and disconnect the power supply.

NOTE: Glassware should always be supported to maintain a vertical position.

WARNING: The top surface of the instrument and the glass vessel will be HOT. Use protective

equipment to prevent burns and protect from cuts that may be caused by breakage of glass

vessels. Handle any hot vessel with care.

WARNING: The mantle may still be HOT beyond 30 minutes, even though the "HOT" warning

light has gone out.

WARNING: Do not leave heaters switched on when not in use or unattended.

6

Page 7

Cleaning and Care

Before Attempting Cleaning:

Ensure that the unit is cool, and disconnect from the power supply.

WARNING: Ensure the unit is disconnected from the power supply before attempting

maintenance or servicing.

Metal Casework:

The unit should be cleaned using a damp cloth and a mild detergent solution. Cleaning is made easier

if spillages are attended to promptly. In any case, spillages of acids and alkalies MUST be removed

immediately as these chemicals can attack and damage the casework finish. Ensure that the

appropriate safety precautions are observed.

NOTE: Do not use solvents for cleaning any parts of this equipment.

Servicing and Repair

This product range does not require any routine servicing, but in the case of damage or an open

circuit, the unit has replaceable fuses and heater cartridge. In case of accidental spillage, instructions

for cleaning and decontamination are also included in this section.

In the event of product failure it is recommended that any repair is only undertaken by suitably

qualified personnel. For advice, please contact Cole-Parmer quoting the model and serial number.

Only spare parts supplied by the manufacturer or its agent should be used. Fitting of non-approved

parts may affect the performance of the safety features of the instrument.

If in doubt, please contact Cole-Parmer.

Fuse Replacement

The mains fuse holder is located at rear the unit next to the power inlet. Refer to the Power

Requirements section (on page 3) for correct fuse type and rating for your model. To replace the

fuses, ensure the unit is OFF and disconnected it from the power supply. Open the drawer of the IEC

electrical input socket and remove the installed fuses. Ensure the fuses are of the correct rate and

type before reinstalling the drawer into the unit.

NOTE: Periodic electrical safety

testing is recommended on a

yearly schedule or after any

servicing to ensure safe

operation.

7

Page 8

Heater Cartridge Replacement

WARNING: Contains Rockwool mineral insulation which can cause irritation. When handling the

cartridge, a suitable face mask which bears the CE mark or BS/EN 149 should be used. Gloves

should be worn to prevent skin irritation, but if experienced it can be lessened by rinsing hands

under cold running water before washing.

Replacement Procedure for Controlled Mantle Models

Remove the glassware from the mantle and disconnect the power supply after allowing it to cool. Turn

the mantle upside down onto a clean dry surface. Remove the cross-head screws from around the

base of the mantle and if necessary, remove the cross-head screws retaining the rod support clamp

to the case and remove the clamp. Remove the M3 nuts retaining the heater cartridge and, with the

exception of the 5-liter mantle, disconnect the two sleeved wires from the IEC socket. On the 5-liter

mantle, disconnect cartridge wires from the switch, IEC socket and inline connector. Lift the heater

cartridge clear of the case and disconnect the earth wire attached to the heater assembly.

WARNING: DO NOT DISCONNECT ANY OTHER EARTH WIRE.

Reconnect the earth wire to the earth terminal on the replacement heater cartridge. Insert the heater

cartridge into the case and fasten it to the rim using the clips provided, which locate on the fixing

studs. Reconnect the heater wires and case ensuring correct alignment of fixing studs, cartridge and

cartridge wires to IEC socket. Fasten the base to the case using the screws previously removed.

NOTE: Periodic electrical safety testing is recommended on a yearly schedule or immediately after

any servicing to ensure safe operation.

Replacement Procedure for Uncontrolled Mantle Models

Remove the glassware from the mantle and disconnect the power supply after allowing it to cool. Turn

the mantle upside down onto a clean dry surface. Remove the cross-head screws from around the

base of the mantle and hinge the base to one side. Remove the M3 nuts retaining the heater cartridge

and disconnect the heater wires. Lift the heater cartridge clear of the case and disconnect the earth

wire attached to the heater assembly.

WARNING: DO NOT DISCONNECT ANY OTHER EARTH WIRE.

Reconnect the earth wire to the earth terminal on the replacement heater cartridge. Insert the heater

cartridge into the case and fasten it to the rim using the M3 nut previously removed. Reconnect the

heater wires and fasten the base to the case using the screws previously removed.

NOTE: Periodic electrical safety testing is recommended on a yearly schedule or immediately after

any servicing to ensure safe operation.

In Case of Accidental Spillage

8

Page 9

Please note, the equipment cannot be assumed to meet all the safety requirements of

EN 61010-2-010 until the drying out process has been fully completed.

WARNING: DO NOT TOUCH THE MANTLE IF A SPILLAGE/BREAKAGE HAS

OCCURRED. DISCONNECT THE POWER DIRECTLY AT THE POWER SUPPLY

SOURCE.

Drying Out Procedure

In the event of spillage or glassware fracture, disconnect the power supply and allow the unit to cool.

Wearing suitable hand protection to prevent burns and cuts from heated glassware, carefully remove

any pieces of broken glassware. If decontamination is necessary, see section below. If not, wipe off all

excess liquid from the mantle and surrounding area using an absorbent soft cloth and drain off any

residual fluid retained in the mantle. In the case of excessive spillage or flask fracture, invert the mantle

and allow it to drain for minimum of one hour. To complete the drying process, place the entire mantle

in the correct orientation inside a heated oven at 50°C (122°F) for a minimum period of 40 hours. If

required, replacement heater cartridges are available on the Cole-Parmer website.

NOTE: Periodic electrical safety testing is recommended on a yearly schedule or immediately after

any servicing to ensure safe operation.

In Case of Contamination

WARNING: THE BELOW PROCEDURE IS INTENDED AS A GUIDE. SHOULD SPILLAGE OF A

TOXIC OR HAZARDOUS FLUID OCCUR, THEN ADDITIONAL SPECIAL PRECAUTIONS MAY

BE NECESSARY.

Decontamination Procedure

If the equipment has been exposed to contamination, the Responsible Body is responsible for

carrying out appropriate decontamination. If hazardous material has been spilt on or inside the

equipment, decontamination should only be undertaken under the control of the Responsible Body

with due recognition of possible hazards. Before using any cleaning or decontamination method, the

Responsible Body should check with the manufacturer that the proposed method will not damage the

equipment. Prior to further use, the Responsible Body shall check the electrical safety of the unit. Only

if all safety requirements are met can the unit be used again.

NOTE: In the event of this equipment or any part of the unit becoming damaged or requiring service,

the item(s) should be returned to the manufacturer for repair accompanied by a decontamination

certificate. Copies of the Certificate are available from the manufacturer or can be extracted from this

user guide (see pages 13-14). At the end of its service life, the product must be accompanied by a

Decontamination Certificate.

9

Page 10

Warranty

Cole-Parmer warrants this equipment to be free from defects in material and workmanship, when

used under normal laboratory conditions, for a period of one (1) year. In the event of a justified

claim, Cole-Parmer will replace any defective component or replace the unit free of charge.

This warranty does NOT apply if:

❖ Any repair has been made or attempted other than by the manufacturer or its agent.

❖ Any minor coating chips or scratches occur during normal use (i.e., wear and tear).

❖ Damage is caused by fire, accident, misuse, neglect, incorrect adjustment or repair, damage

caused by installation, adaptation, modification or fitting of non-approved parts.

10

Page 11

Technical Specification

Flask capacity 50 to 250 ml 500 to 1000 ml 2000 to 5000 ml

Case material Powder-coated Powder-coated Powder-coated

aluminum aluminum aluminum

Thermal insulation Rockwool mineral Rockwool mineral Rockwool mineral

Max element 450°C (842°F) 450°C (842°F) 450°C (842°F)

temperature

Internal dimensions 50 ml: 52 x 31 mm 500 ml: 106 x 61 mm 2000 ml: 168 x 94 mm

(w x d) (2 x 1.2 in.) (4.1 x 2.4 in.) (6.6 x 3.7 in.)

100 ml: 67 x 39 mm 1000 ml: 136 x 78 mm 5000 ml: 224 x 190 mm

(2.6 x 1.5 in.) (5.3 x 3 in.) (8.8 x 7.4 in.)

250 ml: 86 x 48 mm

(3.3 x 1.8 in.)

Dimensions 175 x 175 x 150 mm 220 x 220 x 170 mm 320 x 320 x 220 mm

(w x d x h) (6.8 x 6.8 x 5.9 in.) (8.6 x 8.6 x 6.7 in.) (12.6 x 12.6 x 7.5 in.)

Net weight 0.75 kg (1.7 lb) 1.5 kg (3.3 lb) 2.75 kg (6.1 lb)

Electrical supply

Fuse rating

See Electrical Supply Section under Power Requirements on page 3.

11

Page 12

This page intentionally left blank

Page 13

DECONTAMINATION CLEARANCE CERTIFICATE

For the Inspection, Repair or Return of Medical, Laboratory or Industrial Equipment.

Prior to a Service Engineer working on equipment that has been in an environment where substances

hazardous to health may have been used, you are requested to provide the following information:

Company: Address:

Department:

Contact Name:

Tel Number:

Fax Number:

Model Number: Serial Number:

Please answer all questions by indicating YES/NO as applicable and by providing details below:

1. Has the equipment been exposed to any of the following;

A. Blood, body fluids, pathological specimens YES/NO Provide details if YES

B. Biodegradable material that could become a hazard YES/NO Provide details if YES

C. Other biohazard YES/NO Provide details if YES

D. Chemical or substances hazardous to health YES/NO Provide details if YES

E. Radioactive substances. State name(s) and quantities YES/NO Provide details if YES

of isotopes and checks made for residual activity

F. Other hazards YES/NO Provide details if YES

2. Please provide details of any hazard present as indicated above. Include details of names and

quantities of agents as appropriate:

3. Your method of decontamination (please describe):

4. Are there likely to be any areas of residual contamination (please specify):

I declare that the above information is true and complete to the best of my knowledge and belief.

Authorized signature: Name (please print):

Title/Position:

For and behalf of: Date:

Use reverse side if additional space is needed.

13

Page 14

Page 15

These products meet the relevant EC

harmonized standards for radio frequency

interference and may be expected not to

interfere with, or be affected by, other equipment with

similar qualifications. We cannot be sure that other

equipment used in their vicinity will meet these standards

and we cannot guarantee that interference will not occur

in practice. Where there is a possibility that injury,

damage or loss might occur if equipment malfunctions

due to radio frequency interference, or for general advice

before use, please contact the manufacturer.

Declaration of Conformity

Catalog Number: Description:

37013-00 ALUMINUM HEATING MANTLE, CONTROLLED, 50 ML, 120 V

37013-01 ALUMINUM HEATING MANTLE, UNCONTROLLED, 50 ML, 120 V

37013-02 ALUMINUM HEATING MANTLE, CONTROLLED, 50 ML, 230 V

37013-03 ALUMINUM HEATING MANTLE, UNCONTROLLED, 50 ML, 230 V

37013-04 ALUMINUM HEATING MANTLE, CONTROLLED, 100 ML, 120 V

37013-05 ALUMINUM HEATING MANTLE, UNCONTROLLED, 100 ML, 120 V

37013-06 ALUMINUM HEATING MANTLE, CONTROLLED, 100 ML, 230 V

37013-07 ALUMINUM HEATING MANTLE, UNCONTROLLED, 100 ML, 230 V

37013-08 ALUMINUM HEATING MANTLE, CONTROLLED, 250 ML, 120 V

37013-09 ALUMINUM HEATING MANTLE, UNCONTROLLED, 250 ML, 120 V

37013-10 ALUMINUM HEATING MANTLE, CONTROLLED, 250 ML, 230 V

37013-11 ALUMINUM HEATING MANTLE, UNCONTROLLED, 250 ML, 230 V

37013-12 ALUMINUM HEATING MANTLE, CONTROLLED, 500 ML, 120 V

37013-13 ALUMINUM HEATING MANTLE, UNCONTROLLED, 500 ML, 120 V

37013-14 ALUMINUM HEATING MANTLE, CONTROLLED, 500 ML, 230 V

37013-15 ALUMINUM HEATING MANTLE, UNCONTROLLED, 500 ML, 230 V

37013-16 ALUMINUM HEATING MANTLE, CONTROLLED, 1000 ML, 120 V

37013-17 ALUMINUM HEATING MANTLE, UNCONTROLLED, 1000 ML, 120 V

37013-18 ALUMINUM HEATING MANTLE, CONTROLLED, 1000 ML, 230 V

37013-19 ALUMINUM HEATING MANTLE, UNCONTROLLED, 1000 ML, 230 V

37013-20 ALUMINUM HEATING MANTLE, UNCONTROLLED, 2000 ML, 120 V

37013-21 ALUMINUM HEATING MANTLE, UNCONTROLLED, 2000 ML, 230 V

37013-22 ALUMINUM HEATING MANTLE, UNCONTROLLED, 5000 ML, 120 V

37013-23 ALUMINUM HEATING MANTLE, UNCONTROLLED, 5000 ML, 230 V

This product complies with the requirements of the EU Directives listed below:

2004/108/EC EMC Directive

2006/95/EC Low Voltage Directive (LVD)

2011/65/EC RoHs Directive

Page 16

For technical, sales or

servicing information,

contact:

Cole-Parmer

625 East Bunker Court

Vernon Hills, IL 60061-1844

Toll-Free: 800-323-4340

Phone: 847-549-7600

Fax: 847-247-2929

www.coleparmer.com

M7153CP

Loading...

Loading...