Page 1

Stable Temp

®

Model 282A

Vacuum Oven

105714 • Rev. 2

Page 2

Cole-Parmer

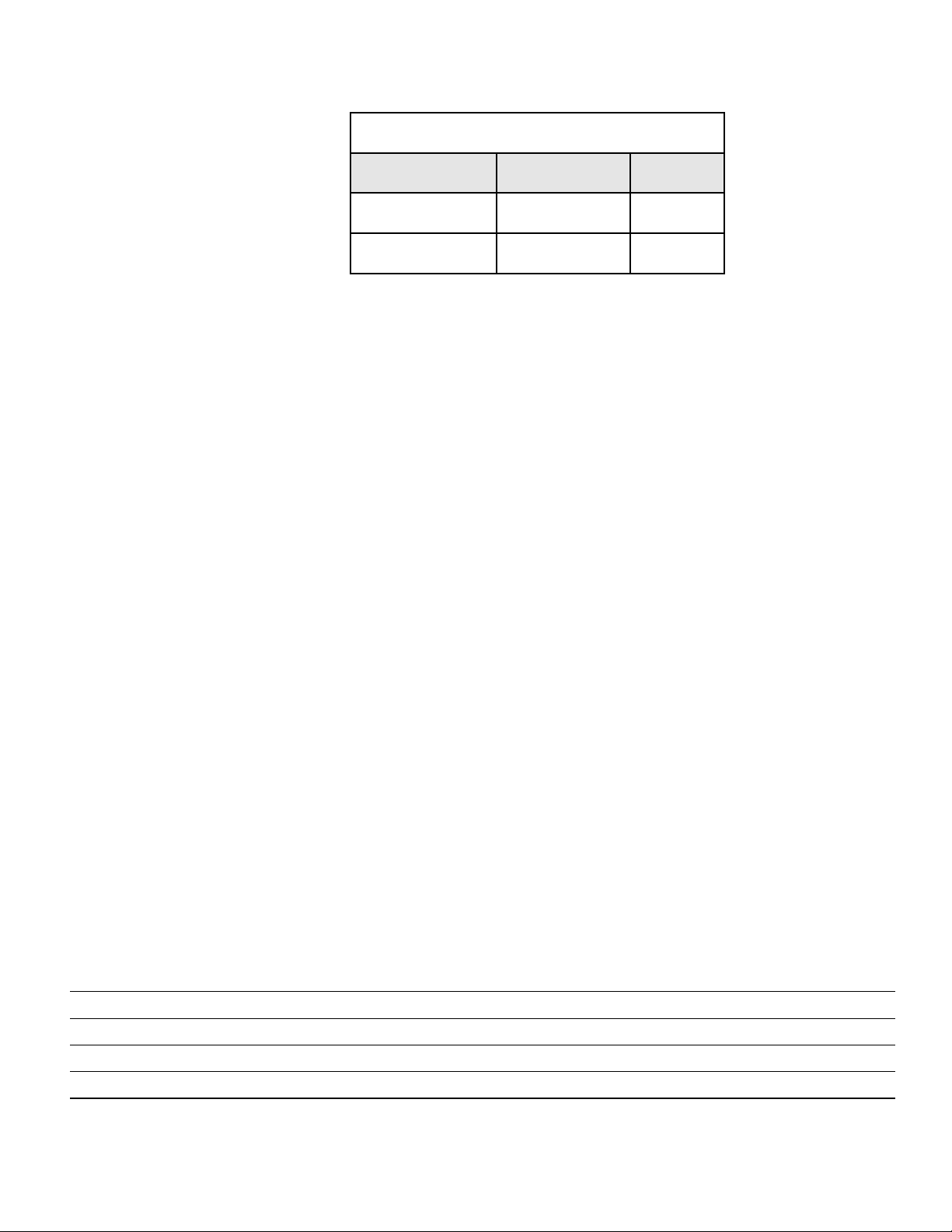

MANUAL NUMBER 105714 (7006281)

2 26741/SI-10360 11/9/10 Updated TCCB to comply with in-house test procedure QT049 (pg 6-13) ccs

1 26565/SI-10360 11/1/10 Repl readout thermocouple w/ 255036 ccs

0 -- 3/31/10 Transfer to Marietta (was 105714 2/6/09) ccs

REV ECR/ECN DATE DESCRIPTION By

Preface

Vacuum Oven i

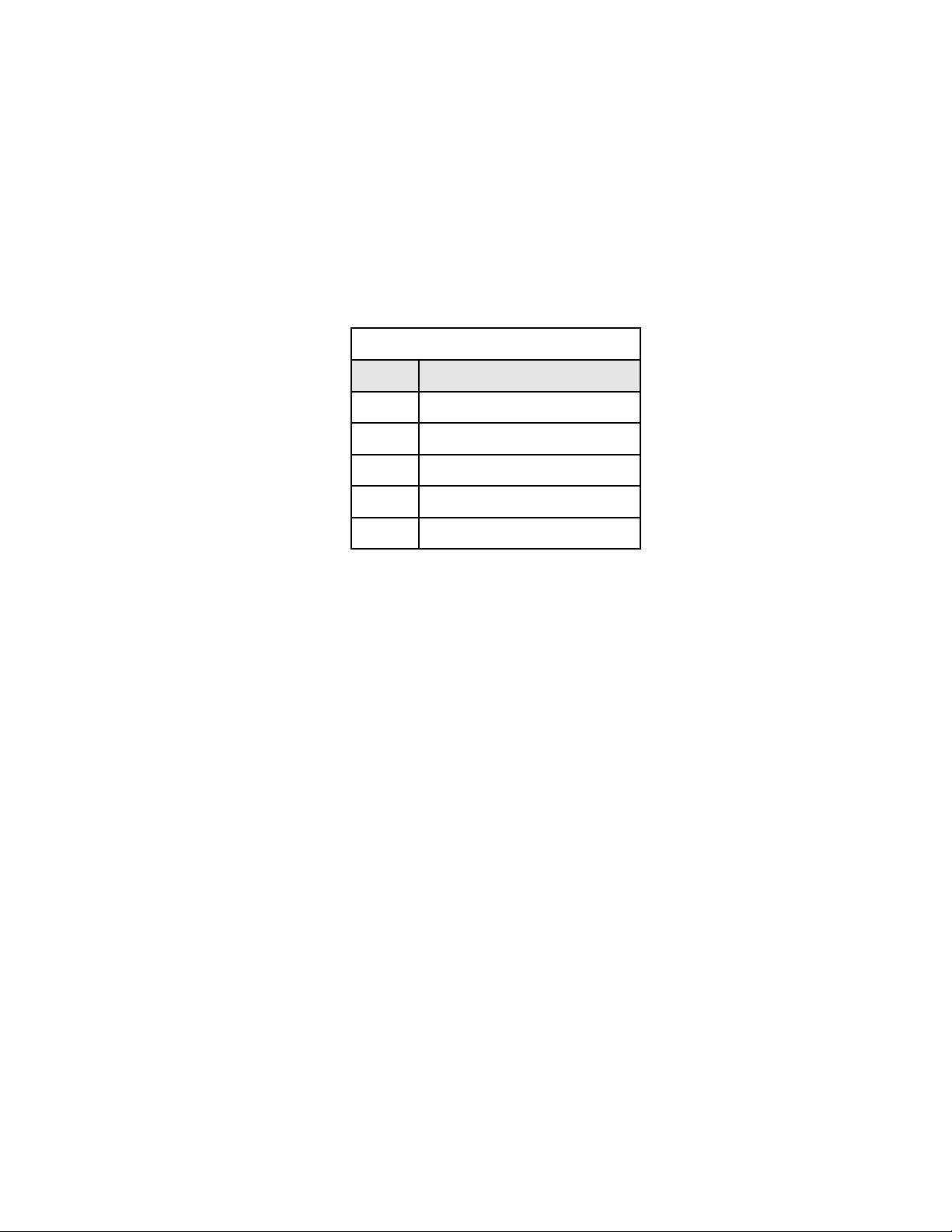

Models covered in this manual

Catalog number Model number Voltage

05017-10 6281 115V

05017-15 6282 230V

Page 3

Cole-Parmerii Vacuum Oven

Preface

Important Read this instruction manual. Failure to read, understand and follow the instructions in this manual

may result in damage to the unit, injury to operating personnel, and poor equipment performance.

s

Caution All internal adjustments and maintenance must be performed by qualified service personnel. s

Material in this manual is for information purposes only. The contents and the product it describes are subject to

change without notice. Cole-Parmer makes no representations or warranties with respect to this manual. In no

event shall Cole-Parmer be held liable for any damages, direct or incidental, arising out of or related to the use of

this manual.

©2010 Cole-Parmer. All rights reserved.

Page 4

Cole-Parmer Vacuum Oven iii

Preface

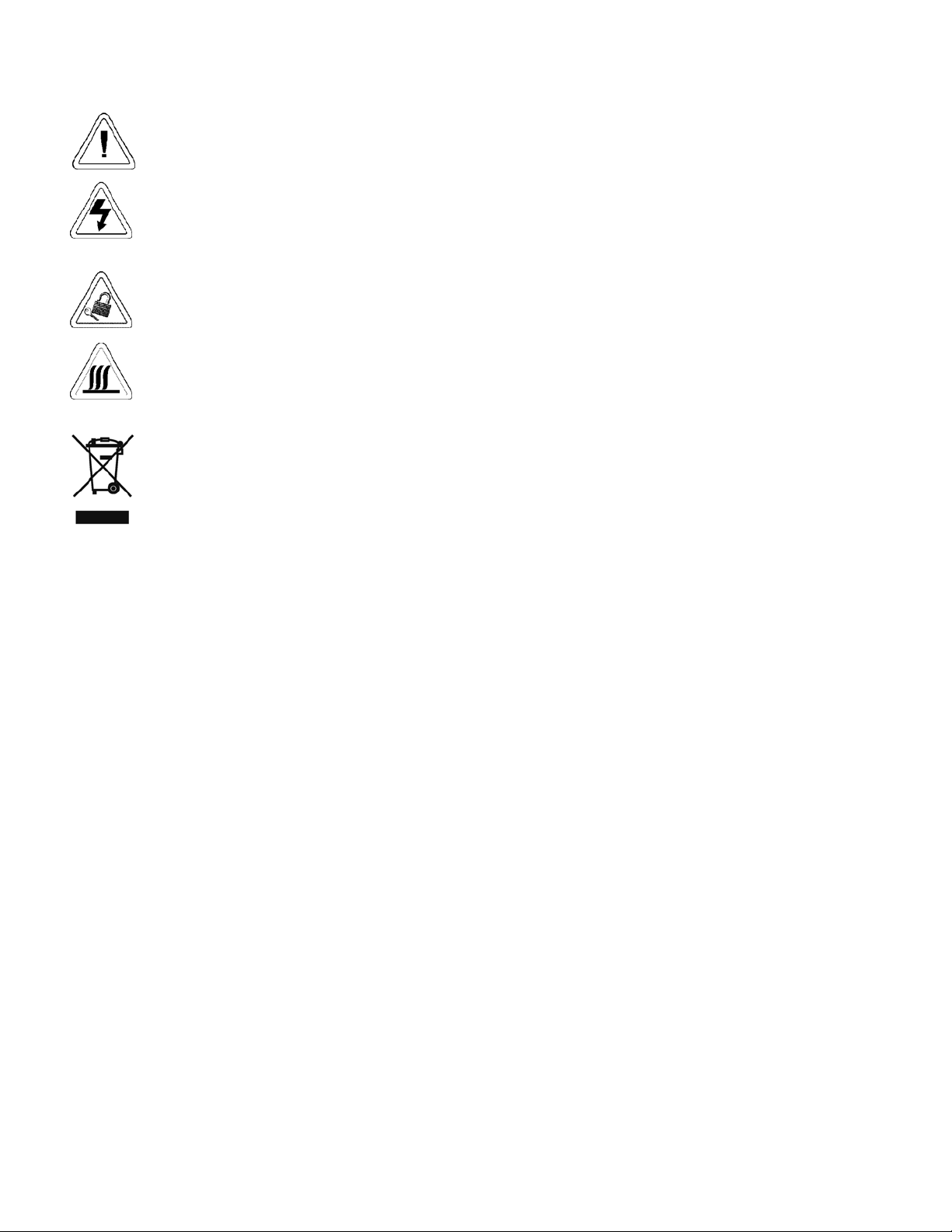

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Potential electrical hazards. Only qualified persons should perform procedures associated with this

symbol.

Equipment being maintained or serviced must be turned off and locked off to prevent possible injury.

Hot surface(s) present which may cause burns to unprotected skin, or to materials which may be

damaged by elevated temperatures.

Marking of electrical and electronic equipment, which applies to electrical and electronic equipment

falling under the Directive 2002/96/EC (WEEE) and the equipment that has been put on the market

after 13 August 2005.

This product is required to comply with the European Union’s Waste Electrical & Electronic

Equipment (WEEE) Directive 2002/96/EC. It is marked with the WEEE symbol. Cole-Parmer has

contracted with one or more recycling/disposal companies in each EU Member State European

Country, and this product should be disposed of or recycled through them. Further information on

Cole-Parmer’s compliance with this directive, the recyclers in your country and information on ColeParmer products will be available at www.coleparmer.com.

4 Always use the proper protective equipment (clothing, gloves, goggles, etc.)

4 Always dissipate extreme cold or heat and wear protective clothing.

4 Always follow good hygiene practices.

4 Each individual is responsible for his or her own safety.

Page 5

Cole-Parmeriv Vacuum Oven

Preface

Do You Need Information or Assistance

on Cole-Parmer Equipment?

The Cole-Parmer Instruments Sales Group can provide information on pricing and give you

quotations. We can take your order and provide delivery information on major equipment items or

make arrangements to have your local sales representative contact you.

1-800-323-4340 Cole-Parmer, Toll Free, US

Cole-Parmer Instruments Product Service Support can supply technical information about

proper setup, operation or troubleshooting of your equipment. We can fill your needs for

replacement parts or provide you with on-site service. We can also provide you with a quotation on

our Extended Maintenance Program for our products.

Whatever products you need or use, we will be happy to discuss your applications. If you are

experiencing technical problems, working together, we will help you locate the problem and, chances

are, correct it yourself...over the telephone without a service call.

When more extensive service is necessary, we will assist you with direct factory trained

technicians or a qualified service organization for on-the-spot repair. If your service need is covered

by the Cole-Parmer Instruments Products warranty, we will arrange for the unit to be repaired at our

expense and to your satisfaction.

Regardless of your needs, professional service technicians are available by telephone to assist

you concerning our products Monday through Friday from 8:00 a.m. to 6:00 p.m. Eastern Time.

Please call or fax us at:

1-800-323-4340 Toll Free U.S. and Canada

1-847-549-7600 Direct

1-847-549-7676 Fax

International customers, please contact your local Cole-Parmer Instruments distributor.

Page 6

Vacuum Oven vCole-Parmer

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Performance and Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Control, Indicators and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Self-Diagnostic Safety Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Installation and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Main Controller Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Establishing Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Auxiliary Pump Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Setting the Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Operation in a Static Environment . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Operation in a Controlled Environment . . . . . . . . . . . . . . . . . . . . .6-6

Operation in a Vacuum Environment . . . . . . . . . . . . . . . . . . . . . . .6-6

Setting the Time and Day . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Temperature/Pressure Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Programming the Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Program Execution - Enabling/Disabling . . . . . . . . . . . . . . . . . . . .6-9

Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Door Alignment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Section 1

Section 2

Section 3

Section 4

Section 5

Section 6

Section 8

Section 7

Section 9

Page 7

Page 8

Vacuum Oven 1-1Cole-Parmer

Section 1 Introduction

Before operation, always observe the following safety precautions:

• This unit is not explosion proof.

• Do not use in the presence of flammable or combustible materials; fire

or explosion may result. Unit contains components that may ignite

such materials.

• Do not place volatile items in the chamber.

• Fumes and spillage from acidic solutions cause corrosion of the

stainless steel chamber.

• Care should be taken to maintain neutral pH at all times.

Page 9

Page 10

Vacuum Oven 2-1Cole-Parmer

Section 2 Performance and Physical

Data

Temperature

Temperature Range . . . . Ambient to 280°C, continuously adjustable

with 1°C resolution

Heat Rise Time . .Ambient to 100°C in <30 minutes,

. . . . . . . . . . . . . . . . . . . .with temp set to 200°C

Average Set-Point Accuracy . . . . . . . . . . . . . . . .±2°C

Cool-Down Time . . . . . .280 to 100°C in ~2.5 hours

Temperature Set-Point Reproducibility . . . . . .±0.1°C

Temperature Control Band . . . . . . . . . . . . . . .±0.2°C

Long-Term (12 hours) Temp. Stability . . . . .±0.03°C

Temperature Display . . . . . 3 digit LED display to nearest to nearest 1°C

Average Temperature Uniformity . . . . ±5°C (in vacuum), based upon

measuring points at the geometric center and each corner of oven chamber at 100°C

Vacuum

Average Leak Rate . . . . . . . . . .< 1” Hg per 24 hours

Vacuum Display Accuracy . . . Average error 0.2 inch Hg between ambient

and complete vacuum

Atmosphere Control . . . . Use with non-corrosive, non-flammable gases

such as nitrogen and CO2

Environmental

Operating Temperature . . . . . . . . . . . . .60° to 100°F

Storage Temperature . . . . . . . . . . . . . . .32° to 120°F

Humidity . . . . . . 20 to 80% relative humidity, non-condensing

Recorder Outputs

Temperature, Pins P3-1, P3-2 . . . . . . . . .10 mv / °C

Chamber Pressure, Pins P3-3, P3-4 . .100 mv / in Hg

Connector Type: . . . . . . . . . . . . . . . .AMP 640456-4

Page 11

2-2 Vacuum Oven Cole-Parmer

Section 2

Performance and Physical Data

Physical Characteristics

External Dimensions . . . . . . . .26”W x 23”D x 22”H

Chamber Size . . . . . . . . . . . . .12”W x 18”D x 12”H

Chamber Volume . . . . . . . . . . . . . . . . . . . . .1.5 cu ft

Page 12

Vacuum Oven 3-1Cole-Parmer

Section 3 Unpacking

Refer to the packing list below and be certain that all listed items are

present. If any are missing, notify Cole-Parmer. Also, be certain to

complete and return the included warranty card.

Note If any shipping damage has occurred, retain the unit intact, including

all packing materials, and file claim with the final carrier promptly.

Usually, the firm will send an investigator to ascertain liability.

s

Unpacking Checklist

Qty Description

1 Oven

2 Shelves (shipped in chamber)

2 Hose Connectors

1 Instruction Manual

1 Warranty Card

Page 13

Page 14

Vacuum Oven 4-1Cole-Parmer

Section 4 Control, Indicators and

Connectors

Before putting the Oven into operation, the user should become

thoroughly familiar with the location and function of all controls,

indicators, and connectors. Most are clearly labeled and located on or

below the front panel, with the exception of the two (PURGE and

VACUUM) hose connectors, which are located on the lower right side of

the oven. A set of vacuum pump auxiliary contacts and the

temperature/vacuum recorder output connectors are located on the rear

side of the control board. See Auxiliary Pump Contacts for instructions on

accessing these connectors.

The control panel consists of two 14-segment alphanumeric displays, six

indicator LEDs, four keypads, and an ON/OFF toggle. The VACUUM

and PURGE valves are located just beneath the control panel. The list

below gives a more detailed explanation of each.

Day/Time Display

A four character alphanumeric readout that alternately displays the day

of the week and time of day in 5-second intervals.

Temp/Vacuum Display

A four character alphanumeric readout that alternately displays the temperature (°C) and chamber pressure (in Hg) in 5-second intervals.

Page 15

4-2 Vacuum Oven Cole-Parmer

Section 4

Controls, Indicators and Connectors

LED Indicators

AM: Indicates first 12-hour time is being displayed/programmed in the

upper display window. Flashes when in Calibration mode.

°C: Indicates chamber temperature (°C) is being

displayed/programmed in the lower display window.

in Hg: Indicates chamber absolute pressure is being displayed in the

lower display window. Also illuminated during vacuum pump

program step.

Heater: Indicates heater activation.

Pump: Indicates closed vacuum pump contact condition.

Program: Indicates 7-day program setup or operation.

Keypads

Menu: Allows operator to cycle through main menu and calibration

menu.

Set: Selects one of six main menu parameters and one of five

calibration menu parameters.

Increase: Increments values to be selected for each parameter.

Decrease: Decrements values to be selected for each parameter.

Connectors and Valves

Power Switch: A rocker type switch that controls all power to the

Vacuum Oven.

Vacuum Control Valve: A forged body, shut-off valve used to open and

close the connection to an auxiliary vacuum pump. Valve port

accepts a supplied serrated fitting to ease in connecting a 1/4-inch

(Inside diameter) hose.

Purge Control Valve: A forged body, shut-off valve used to open and close

the connection to an auxiliary gas source. Valve port accepts a supplied

serrated fitting for ease in connecting a 1/4-inch (inside diameter) hose.

Page 16

Vacuum Oven 4-3Cole-Parmer

Section 4

Controls, Indicators, and Connectors

Vacuum Inlet Port: A serrated hose fitting used to connect an auxiliary

vacuum pump to the oven. Fitting accepts a 1/4-inch (inside diameter)

hose.

Purge Inlet Port: A serrated hose fitting used to connect an auxiliary gas

source to the vacuum oven. Fitting accepts a 1/4-inch (inside diameter)

hose.

Vacuum Pump Auxiliary Contacts: Normally open contacts located at the

bottom of the rear side of the control board (Tabs 3 & 4). The contacts

close when either the pump is manually activated at the keypad, or by

running a program step that calls for pump activation.

Temperature and Vacuum Recorder Outputs: Four pins located on the

top, right of the rear side of the control board (P3) which provide a voltage readout corresponding to chamber temperature and/or pressure.

Calibration Jumper Pin (JP4): Group of four pins located in the center of

the rear of the control board. The lower two pins when jumped enable

calibration mode. See illustration below for control board rear view.

Battery module

Calibration Jumper P4

(shown in Calibration mode)

Recorder

outputs - P3

Page 17

A group of five messages alert the operator to heater and control

malfunctions. The OTC (open thermocouple) and OVR (over

temperature) errors alternately display in the TEMP/VACUUM display.

The PWRF (power failure), BATT LOW (low battery) and CRC

(calibration data corruption) are displayed in the DAY/TIME display

window. All messages and their meanings are as follows:

OTC (Open Thermocouple): The TEMP/VACUUM display alternates

between OTC and current chamber pressure at 5 second intervals, where

OTC replaces the normal process temperature display field. The heaters

and vacuum pump (if connected to auxiliary contacts) are forced OFF.

Program execution is halted.

OVR (Over Temperature): Activates if oven temperature exceeds the set-

point +20°C.

PWRF (Power Failure): Power failure only detected during program mode.

The failure must be longer than 2 minutes. Time display alternates

between PWRF, HH:MM and DAY(n) at 5 second intervals.

BATT LOW (Low Battery): Indicates it is time to replace the 6-year bat-

tery module. Module is in a socket on the back of the control board. See

control board illustration on previous page.

CRC (Calibration Data Corrupted): Indicates an error in the stored cali-

bration data. The heater and pump relay are forced off. Unit must be calibrated to clear.

4-4 Vacuum Oven Cole-Parmer

Section 4

Controls, Indicators and Connectors

Self-Diagnostic

Safety Monitors

Page 18

Vacuum Oven 5-1Cole-Parmer

Section 5 Installation and Assembly

The oven is shipped assembled and ready for operation. However, before

installing the oven, the operating site should be prepared to meet necessary

requirements. Additionally, a few assembly procedures must be performed

before the oven can be safely and properly operated.

The standard plug configurations are shown in the illustration below. The

115VAC model is supplied with a 20 amp plug (NEMA 5-20P). The

230VAC model is supplied with a 15 amp plug (NEMA 6-15P). Verify

that the appropriate receptacle is at the location the oven will be used.

Warning To avoid the risk of electrical shock, verify that the source plug is

properly grounded.

s

The supporting bench or table must be capable of holding in excess of 200

pounds. The bench should be sufficient to accommodate sample-handling

processes. The oven itself is 26-inches wide and 23-inches deep; therefore,

the bench surface should be approximately 48-inches wide and 30-inches

deep to allow for ventilation clearance at the rear of the oven.

Warning To avoid the risk of fire, provide 6 inches of clearance for the top,

back and sides of the oven. Do not set or lean any objects against or on top

of the oven while hot.

s

For installations that may use a tank atmosphere, check that site facilities

and tank equipment are in compliance with OSHA requirements for

handling compressed gas. Responsible personnel must also be thoroughly

knowledgeable in the use, storage, and handling of compressed gases.

Site Requirements

5-20P 6-15P

Page 19

5-2 Vacuum Oven Cole-Parmer

Section 5

Installation and Assembly

When using a tank atmosphere, a 1/4” tube to 1/4” pipe adapter is

required for the regulator outlet of the tank. This adapter is not supplied.

A Swagelok B-400-7-4 adapter, or equivalent, may be used. Also, 9/16”,

and 1-1/8” open-end or, preferably, flare-nut wrenches are required.

After verifying all site and safety requirements, the following steps should

be completed to prepare the vacuum oven for operation:

1. Verify that all-packing items and securing materials have been removed

from the oven.

2. Move the oven to the desired location as specified above.

3. Locate the two serrated hose fittings, packed in the INSTRUCTIONS

envelope accompanying each oven.

4. Install the hose fittings on the VACUUM and PURGE ports located

on the lower right-side panel. Hose fittings should be installed by

turning the fitting nut clockwise until finger-tight then, using a 9/16”

wrench, turn the nut an additional 1/4-turn while holding the fitting

stationary with a 3/8” wrench.

5. Close both the PURGE and VACUUM valves by turning the control

knob clockwise as far as possible.

6. Connect a vacuum pumping system, including a suitable trap, to the

serrated fitting labeled VACUUM. Use 1/4-inch I.D. heavy-walled

vacuum tubing and secure the connection with a hose clamp.

7. If desired, connect a purge gas supply to the serrated fitting labeled

PURGE using a suitable length of 1/4” I.D. tubing. Use a two-stage

gas flow regulator if gas is to be supplied by a pressurized cylinder.

8. After installing connecting tubing, check that the PURGE CONTROL

valve on the Oven is closed (full clockwise position) then open the

regulator flow control valve to pressurize the line. At this point, check

all connections for leaks using an ordinary soapy water solution.

9. Check data plate and plug line cord into a suitable power receptacle.

Site Requirements

(continued)

Installation

Page 20

Section 6 Operation

Energize the oven by switching the ON/OFF toggle to the ON position.

The upper display will show VER while the lower display will show 1.0,

indicating the current software version. Next, the DAY/TIME display will

begin alternating between the day of week and the time of day. At the

same time, the TEMP/VACUUM display will alternate between chamber

temperature (°C) and chamber pressure (in Hg). Press the MENU key to

scroll through menus 1-6, then press SET to enter a menu. If there is no

keypad activity for 5 seconds, the unit returns to Menu 1 automatically.

The following table lists the main menus and their functions. The tables

that follow list the subcategories of the controller main menu and describe

the function of each.

Vacuum Oven 6-1Cole-Parmer

Table 2: Default Menu (Menu 1)

Step Key Entry Action Display

1 Press SET

Unit enters Temperature Setpoint mode with the current

setpoint displayed. Use the UP/DOWN keys to adjust the

setpoint.

SP: 280

2 Press SET 2nd Time

The temperature setpoint is updated and the vacuum pump

ON/OFF option is displayed. Use the UP key to switch the

pump on, and the DOWN key to switch the pump off.

PUMP OFF

3 Press SET or wait 2 seconds Unit returns to the default menu. MON 280

Table 1: Main Menu

Menu Prompt Display Functions Setup Functions

1 (Default) Top Display – Day of week, Time of day Adjust temperature control setpoint

Bottom Display – Temp (°C), Pressure (in Hg) Turn vacuum pump contacts ON/OFF

2 ADJT Display temperature offset value Adjust temperature control offset

3 ADJP Displays pressure offset value Adjust for barometric pressure variations

4 TSET Displays flashing day or time value Set clock and day of the week

5 PRGM Displays program mode Start / Stop program mode

6 PSET Displays day, step and setpoint Program 7 – Day event timer

Page 21

6-2 Vacuum Oven Cole-Parmer

Section 6

Operation

Main Controller

Menus

Table 3: Adjust Temperature Offset (Menu 2)

Step Key Entry Action Display

1

Press MENU until ADJT is

displayed, then press SET

Use the UP/DOWN keys to adjust the

temperature offset. (Range ±30 °C)

ADJT 00

2 Press SET or wait 2 seconds Unit returns to the default menu. MON 280

Table 6: Program Mode ON/OFF (Menu 5)

Step Key Entry Action Display

1

Press MENU until PRGM is

displayed, then press SET

Use the UP/DOWN keys to switch the

program on or off.

PRGM OFF

2 Press SET or wait 2 seconds Unit returns to the default menu. MON 280

Table 4: Adjust Barometric Pressure Offset (Menu 3)

Step Key Entry Action Display

1

Press MENU until ADJT is

displayed, then press SET

Use the UP/DOWN keys to adjust the

pressure offset. (Range ±8.0 in Hg)

ADJP 0.0

2 Press SET or wait 2 seconds Unit returns to the default menu. MON 280

Table 5: Set Time and Day (Menu 4)

Step Key Entry Action Display

1

Press MENU until TSET is

displayed, then press SET

Unit enters set time and day mode and

the current hour and minute is displayed.

Hours digits are flashing. Use the

UP/DOWN keys to adjust the hour.

08:00 AM •

2 Press SET

Minutes digits are flashing. Use the

UP/DOWN keys to adjust minutes.

08:00 AM •

3 Press SET

Day of the week is displayed (flashing).

Use the UP/DOWN keys to adjust the day

of the week.

MON

4 Wait 2 seconds Unit returns to default menu. MON 280

Page 22

Vacuum Oven 6-3Cole-Parmer

Section 6

Operation

Establishing

Operating Conditions

Table 7: Program Edit Mode (Menu 6)

Step Key Entry Action Display

1

Press MENU until PSET is dis-

played, then press SET

Unit enters the program edit

mode and points to MONday,

step 1. Use the UP/DOWN keys

to select the day and step.

MON1

2 Press UP or DOWN,

Unit displays the program time

then press SET. for the current

step. Hour digits are flashing. Use

the UP/DOWN keys to adjust hour.

08:00

AM •

3 Press SET

Minutes digits are flashing. Use

the UP/DOWN keys to adjust

minutes.

08:00

AM •

4 Press SET

Step time and temperature setpoint is displayed. Setpoint is

flashing. Use the UP/DOWN keys

to adjust setpoint.

08:00

280

5 Press SET

Program step time & pump status

is displayed. Pump ON or OFF is

flashing. Use the UP/ DOWN keys

to switch pump ON or OFF.

08:00

OFF

6 Press SET

Unit displays the program day,

step and ʻN ?ʼ prompt. Use the

UP/DOWN keys to adjust prompt

to Y to accept or N not accept.

08:00

N ?

7

Press SET, then MENU to exit

or SET again to continue

Unit displays the next program

step. To exit the edit session press

MENU, or press SET to view or

edit another step.

MON2

8 Press MENU to exit

Unit displays COPY/NO. This

option will copy 8 steps forward

to each day through the end of

the week. Use the UP/DOWN

keys to adjust prompt to Y or N.

NO

Establishing the operating conditions consists of setting the desired

temperature program and establishing the desired environmental

conditions, e.g., vacuum, inert gas atmosphere, or both. Instructions

pertaining to connecting a vacuum pump and/or gas supply to the oven

are given under the INSTALLATION AND ASSEMBLY section of this

manual. Before establishing conditions, be certain that all steps given

under the aforementioned section have been completed.

Main Controller

Menus (continued)

Page 23

The following procedure describes the proper method used for operating a

vacuum pump using the auxiliary contacts supplied on the control board

(Tabs 3 and 4).

Note Vacuum pump operation can be performed independently as well.

s

Warning High voltages are present when the side panel is removed. Only

trained personnel should conduct this procedure.

s

1. Remove power cord from the supply outlet.

2. To access the auxiliary contacts, remove six screws holding the right

side panel in place.

3. Pull the back edge of the side panel away from the oven and slide the

front edge out the front panel slot.

4. Remove the hole-plug located just to the right of the VACUUM port.

The keyed hole is properly sized to support a UL/CSA type SR 7W-2

strain relief bushing to be used with 18/2, 18/3, 16/2, 16/3 type S or

ST cable. Verify the cable is long enough to reach the pump contacts,

then fasten the cable in the keyed hole with a strain relief bushing.

5. Crimp two 1/4” push-on connectors to the two cable wires. Connect

one wire to Tab 3 and the other to Tab 4. The pump circuit should be

connected as shown in illustration below.

6-4 Vacuum Oven Cole-Parmer

Section 6

Operation

Auxiliary Pump

Contacts

Pump Contacts

Page 24

6. Reattach the side panel using the six side panel screws.

7. Connect the vacuum hose to the Vacuum Inlet Port on the side of the

oven and open the Vacuum valve. Close the door and the Purge Inlet

Port by turning Purge valve clockwise completely.

8. Plug the oven in and switch the ON/OFF toggle to the ON position.

The top and bottom displays will alternately flash between time of

day/day of the week and chamber temperature/pressure, respectively.

Caution The maximum allowable current in auxiliary circuit is 6 amps. See

Performance Characteristics for contact ratings before applying power.

s

9. Press the SET key until PUMP is displayed in the upper display

window. Press the UP arrow key. The lower display window should

show ON. Press the SET key again or leave as is for two seconds. The

contacts will close and the pump should turn on. Control will then

revert to the default mode after five seconds.

10. While the pump evacuates the chamber, the chamber pressure should

begin to drop as indicated by the lower display. The bottom display

alternately shows chamber pressure (in Hg) and chamber temperature

(°C).

11. To turn off the pump, press the SET key until PUMP is displayed in

the upper display window. Press the DOWN ARROW key. OFF

should then be displayed in the lower display window. Press SET or

leave as is for two seconds. The auxiliary pump contacts will open and

the pump should turn off.

As noted above, the vacuum pump can be controlled as described or

manually using an external switch.

To set the oven temperature, begin by pressing the SET key. The upper

display will show SP while the lower display indicates the last set

temperature or OFF, indicating the heaters are turned off. Next use the

UP/DOWN arrow keys to toggle through temperature values. When the

desired temperature is displayed, press the SET key to enter the value.

Return to the default mode by continuously pressing MENU or leave as is

for two seconds and control will revert to the default mode automatically.

Note If fast warm up is desired, the temperature must be set at

approximately 25°C higher than the final temperature, then set back to the

final temperature when the oven reaches a temperature within 10°C of the

final temperature.

s

Vacuum Oven 6-5Cole-Parmer

Section 6

Operation

Auxiliary Pump

Contacts (continued)

Setting the

Temperature

Page 25

Static environment is defined as operation at atmospheric pressure and

with air - as it is present. In this case, the operator would simply place the

sample in the oven chamber and set the desired temperature.

Controlled environment is defined as operation with the samples in an

inert gas. To accomplish this, perform the following:

1. Place samples in the oven chamber, then close and lock the chamber

door.

2. Close the PURGE CONTROL valve (full clockwise rotation).

3. Open the VACUUM CONTROL valve (full counterclockwise

rotation) then turn on the vacuum pumping system to remove any air

remaining in the oven.

4. Close the VACUUM CONTROL valve and open the PURGE

CONTROL valve slowly to bleed in an inert gas.

5. Close the PURGE CONTROL valve, then set the desired temperature

and process time.

To operate the oven in a vacuum environment, perform the following:

1. Place samples in the oven then close and lock the oven door. Verify

that gasket seal has been coated with high temperature vacuum grease.

Caution Do not use silicone vacuum grease. It will damage the door seal

and has restrictions for some types of materials placed in the oven.

s

2. Close both the PURGE CONTROL and VACUUM CONTROL

valves.

3. Turn on the vacuum pumping system then open the VACUUM

CONTROL valve (full counterclockwise rotation).

4. The vacuum, in inches-of-mercury, can be read on the

TEMP/VACUUM Display.

6-6 Vacuum Oven Cole-Parmer

Section 6

Operation

Operation in a Static

Environment

Operation in a Controlled

Environment

Operation in a Vacuum

Environment

Page 26

When the oven reaches a stable operating condition, the display

temperature should indicate the actual center chamber temperature

(±2.0°C). In the event a more accurate display reading is needed, the offset

parameter, located in the MAIN MENU, can compensate for the error.

To enter an offset value, press the MENU key until the upper display

window shows ADJT (adjust temperature) then press UP/DOWN arrow

keys to enter an offset for the display temperature. Press the MENU key 5

times to return to the default display, or wait for 2 seconds and control

will shift automatically.

EXAMPLE: The oven is temperature is set for 200°C. After it has reached

a stable state (usually 2-1/2 hours for 200°C) the actual temperature of the

oven center, as read by a certified thermometer, is 203°C. The oven display

shows 200°C. Entering a +3 for the ADJT parameter will move the display

to agree with the actual oven temperature.

Note Adjusting the offset only changes the display temperature. It does not

alter the controller operation.

s

The vacuum display can be adjusted in the same way. In the event the

displayed chamber pressure is not accurate, press the MENU key until the

upper display window shows ADJP (adjust pressure). Use the UP/DOWN

keys to enter the desired offset. Press the MENU key four and control will

shift automatically. The displayed chamber pressure will be updated with

the offset value.

To set the time and day press the MENU key until the upper display

shows TSET (time set). Press the SET key and use the UP/DOWN arrow

keys to adjust the hour of the day. When the current hour is displayed

enter it by pressing the SET key again. Use the UP/DOWN arrow keys to

adjust the minutes. When the correct minutes are displayed, press the SET

key. Finally, days of the week can also be adjusted by pressing the

UP/DOWN arrow keys. Press the SET key again to enter the day of the

week.

Vacuum Oven 6-7Cole-Parmer

Section 6

Operation

Temperature/Pressure

Offsets

Setting the Time and Day

Page 27

The oven controller is capable of handling 8 instructions per day, 7 days a

week. Programming the controller is not difficult. Table 7, listed as MENU

6 - Program Edit Mode, provides step by step instructions for setting the

control temperature and/or vacuum pump operation at any given time of

day or day of the week. Use Table 7 in conjunction with the following

description when programming the oven controller.

To enter the Program Edit Mode, press the MENU key until the upper

display shows PSET. The upper display will then show MON1, indicating

the first step in Monday. Use the UP/DOWN arrow keys to step through

to the current day of the week. When the desired step is reached, press

SET. Use the UP/DOWN arrow keys to adjust the starting hour of the

current step, press SET to select the desired hour. Repeat for minutes,

temperature and vacuum pump operation. The next prompt (N ?) asks the

user to copy the current step to the remaining steps in the day.

Use the UP arrow key to select Y (yes), or leave as is and select no by

pressing the SET key. The upper display will then shift to the next step,

MON2 (if MON1 was the previous step). Repeat this procedure for

entering new steps. If a step was copied to the end of the day, that same

day can also be copied to the end of the week. To do this, press the MENU

key when the next step appears in the upper display window. At that point,

press the MENU key.

The upper display will show COPY, while the lower display shows NO.

Use the UP arrow key to change the NO to YES. Press the SET key and

the previous dayʼs program is copied to the end of the week.

Note The program week begins on Monday and ends on Sunday.

Sample Program:

Monday:

1. Evacuate chamber and operate at 100°C for 5 hours starting at 8AM.

Maintain less than 5 in Hg during the 5 hours.

2. Increase temperature to 150°C and operate for 2 hours. Maintain same

chamber pressure.

3. Shut down oven for remainder of day.

6-8 Vacuum Oven Cole-Parmer

Section 6

Operation

Programming the Oven

Page 28

Tuesday:

Repeat steps from Monday except Step 2. Have oven shut down after

100°C operation.

Wednesday:

Repeat Tuesday.

Thursday:

Repeat Monday.

Friday:

Repeat Monday.

Using the information in MENU 6 (Table 7: Program Edit Mode), the

program could be set up as shown in the Sample Program Array on the

following page.

The default settings for any step are: TEMP- OFF, PUMP- OFF, and

TIME- 12:00 AM. The outlined areas in the Sample Program Array chart

indicate actual program editing. Notice the final step programmed for each

day is copied through to the end of that day. This was accomplished by

selecting Y (yes) at the ‘?’ menu (see MENU6, Step 6).

To execute a program, press the MENU key until the upper display shows

PGRM. Press the UP key to display ON, then press SET or wait 2 seconds

and control will return to the default mode automatically. The program

will then search for the current day and begin execution at the most recent

step.

To stop program execution, press the MENU key until the upper display

again shows PRGM. Press the DOWN arrow key to display OFF, then

press SET or wait 2 seconds for the program to stop automatically.

Vacuum Oven 6-9Cole-Parmer

Section 6

Operation

Programming the Oven

(continued)

Program Execution -

Enabling/Disabling

Page 29

The Vacuum Oven is carefully calibrated before leaving the factory.

However, re-calibration will be necessary when component parts are

repaired or replaced. This is especially true regarding the vacuum readout

system. In fact, it may be necessary to re-calibrate this system if critical

vacuum levels are required to meet particular applications due primarily to

altitude and atmospheric conditions.

6-10 Vacuum Oven Cole-Parmer

Section 6

Operation

Calibration Procedure

SAMPLE PROGRAM ARRAY

STEPS MONDAY TUESDAY WEDNESDAY THURSDAY FRIDAY SATURDAY SUNDAY

1 Temp: 100°C Temp: 100°C Temp: 100°C Temp: 100°C Temp: 100°C Temp: OFF Temp: OFF

Time: 8:00 AM Time: 8:00 AM Time: 8:00 AM Time: 8:00 AM Time: 8:00 AM Time: 12:00 AM Time: 12:00 AM

2 Temp: 100°C Temp: 100°C Temp: 100°C Temp: 100°C Temp: 100°C Temp: OFF Temp: OFF

Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: ON Pump: ON

Time: 8:10 AM Time: 8:10 AM Time: 8:10 AM Time: 8:10 AM Time: 8:10 AM Time: 12:00 AM Time: 12:00 AM

3 Temp: 150°C Temp: OFF Temp: OFF Temp: 150°C Temp: 150°C Temp: OFF Temp: OFF

Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: ON Pump: ON

Time: 1:00 PM Time: 1:00 PM Time: 1:00 PM Time: 1:00 PM Time: 1:00 PM Time: 12:00 AM Time: 12:00 AM

4 Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF

Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: ON Pump: ON

Time: 3:00 PM Time: 1:00 PM Time: 1:00 PM Time: 3:00 PM Time: 3:00 PM Time: 12:00 AM Time: 12:00 AM

5 Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF

Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: ON Pump: ON

Time: 3:00 PM Time: 1:00 PM Time: 1:00 PM Time: 3:00 PM Time: 3:00 PM Time: 12:00 AM Time: 12:00 AM

Pump: ON Pump: ON Pump: ON Pump: ON Pump: ON Pump: ON Pump: ON

6 Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF

Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: ON Pump: ON

Time: 3:00 PM Time: 1:00 PM Time: 1:00 PM Time: 3:00 PM Time: 3:00 PM Time: 12:00 AM Time: 12:00 AM

7 Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF

Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: ON Pump: ON

Time: 3:00 PM Time: 1:00 PM Time: 1:00 PM Time: 3:00 PM Time: 3:00 PM Time: 12:00 AM Time: 12:00 AM

8 Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF Temp: OFF

Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: OFF Pump: ON Pump: ON

Time: 3:00 PM Time: 1:00 PM Time: 1:00 PM Time: 3:00 PM Time: 3:00 PM Time: 12:00 AM Time: 12:00 AM

Page 30

Follow the instructions below to access the calibration mode:

1. Set the POWER switch to the OFF position.

2. Remove the right side panel.

Note Refer to instructions for removing the side panel in Auxiliary Pump

Contacts before proceeding.

s

3. Locate two sets of jumpers on the back of the control board labeled

JP4. To enter the calibration mode, remove the bottom jumper and

place it across the bottom pins as shown in the control board

illustration below.

4. Set the power switch to the ON position. The upper display will show

INIT, which is the first calibration menu. By pressing the MENU key

repeatedly, all calibration menus can be viewed in the upper display.

Table 8 summarizes the calibration menus.

Note Any part of the calibration can be conducted individually without

altering data from the others.

s

5. To abort a calibration and return to the control mode, simply set the

power switch to the OFF position and remove JP4 before completing a

calibration. The previous calibration data will not be affected.

Vacuum Oven 6-11Cole-Parmer

Section 6

Operation

Calibration Mode

Battery module

Calibration Jumper P4

(shown in Calibration mode)

Recorder

outputs - P3

Page 31

INIT-Initialize Memory

The INIT menu allows the operator to selectively clear data stored for

program, calibration and/or clock functions. To select one of the functions,

simply press the SET key when the upper display shows the INIT menu.

Next, use the UP/Down arrow keys to select which data to clear. The

choices are as follows:

1. VAR Miscellaneous Variables

2. PRG Program Data

3. TIM Time Data

4. CBR Calibration Data

Finally, with the desired data type displayed in the lower display, press the

SET key again to reset the data to the factory set values. The lower display

will show CLR indicating the data has been cleared.

6-12 Vacuum Oven Cole-Parmer

Section 6

Operation

Table 8: Calibration Menus

Prompt Calibration Routine Comments

INIT Initialize data memory.

Four options. Selectively clears data

variables, program and clock. Resets all

calibration data to defaults.

TCCB

Measure and Control thermocouple

calibration.

Requires two temperature points (T2 -T1)

>100°C temperature control loop is on

during calibration.

VCMC Pressure sensor.

Requires two pressures, ambient plus

second point near 0 in Hg.

D/AC

Temperature and vacuum recorder

outputs

Adjust full scale. Temperature, vacuum

inputs not required.

CJCD Cold junction compensation temp.

Display for verification only. No adjustment

Page 32

TCCB-Thermocouple Calibration

Before beginning the temperature calibration, place a NIST calibrated

thermometer in the center of the vacuum oven chamber and close the

door. Press the MENU key until the upper display shows TCCB, then

press the SET key. The unit enters the thermocouple calibration mode and

displays the first temperature set-point (flashing). Allow the unit ample

time to reach each set point. A 50°C calibration point will take

approximately 2 hours to stabilize. When the chamber temperature has

completely stabilized, record the temperature of the thermometer in the

chamber center. Using that value as the reference, use the UP/DOWN

keys to match the oven display temperature to the reference temperature.

Press the SET key. The controller will WAIT and SAMPLE values for the

low end calibration, then displays the second temperature set-point

(flashing). Use the UP/DOWN arrow keys to adjust the desired second

set-point. Press the SET key to enter the second set-point. Allow the unit

time to heat and stabilize at the second set-point. When the unit is stable,

record the temperature of the reference thermometer. Adjust the display to

match the reference thermometer using the UP/DOWN arrow keys. Press

the SET key. The controller will then SAMPLE this data. When the

controller is finished, the next menu will appear (VCMC).

VCMC-Vacuum Calibration

Before calibrating the vacuum readout system, it is necessary that the

barometric or atmospheric pressure be known. One way of doing this is to

contact the U.S. Weather Bureau in the installation area. The bureau will

provide the barometric pressure corrected to sea level, this pressure must

then be corrected to the altitude where the calibration will be performed.

This can be done by interpolating the data from Table 9. Once a pressure

for the calibration altitude is obtained, the value is subtracted from the sea

level value on Table 9 to obtain the correction factor. The correction factor

will then be subtracted from the value obtained from the bureau.

Obviously, the corrected value obtained will be only as accurate as the

accuracy to which the exact elevation is known.

Example:

The barometric pressure corrected to sea level, as reported by the

U.S. Weather Bureau on June 13, 1983, was 30.19 In. of Hg, in

Pittsburgh, PA. The elevation at the calibration site, also in Pittsburgh, is

850 ft. above sea level. Interpolating the data from Table 9, the pressure at

850 ft. is 29.02 In. of Hg; subtracting this value from 29.92 (sea level

pressure) gives a correction factor of 0.9. The actual pressure at the

calibration site is: 30.19 - 0.9 = 29.29 In of Hg.

Vacuum Oven 6-13Cole-Parmer

Section 6

Operation

Page 33

VCMC-Vacuum Calibration (continued)

Another method is to read the pressure directly from a temperature

compensated barometer that can be adjusted for altitude. This method will

give the pressure at the elevation of the calibration site without the need

for any additional calculations or corrections. Generally, the pressure value

measured should fall within the 29 to 30 inches-of-mercury range. In fact,

measurements outside this range should be suspect.

Slight variations will exist usually because of pressure variations due to

weather conditions. Therefore, the most accurate way to calibrate the

Model 282A vacuum readout system is to first obtain the atmospheric

pressure using one of the methods previously listed.

Note The procedure below for calibrating the vacuum display assumes the

vacuum pump is being controlled by the Auxiliary Contacts, Tabs 3 & 4.

The vacuum display can be calibrated with manual pump operation, as

well.

s

To calibrate the vacuum display, perform the following:

1. While in the VCMC calibration mode, open the vacuum (full-CCW)

valve to expose the chamber to atmospheric pressure.

2. Connect a suitable vacuum pump to the PURGE port along with a

vacuum gauge as shown in the illustration below.

3. Press the SET key to enable vacuum calibration. The upper display will

show PRSR with the AM LED flashing. The lower display will indicate

29.0 in Hg.

4. Use the UP/DOWN arrow keys to set the displayed pressure to match

the atmospheric pressure.

6-14 Vacuum Oven Cole-Parmer

Section 6

Operation

Vacuum Pump Hookup

Page 34

VCMC-Vacuum Calibration (continued)

5. Press the SET key again to enter the value. The controller will sample

the pressure and adjust the display to it.

Note The controller will sample the vacuum data, then it will

automatically close the auxiliary vacuum pump contacts for the secondpoint calibration.

s

6. Rotate the PURGE valve about two turns counterclockwise from the

closed position

7. Rotate the VACUUM valve to the full clockwise (closed) position.

8. Allow time to for the pump to evacuate the oven chamber as much as

possible (about 10 minutes).

9. After vacuum equilibrates, read the vacuum gauge (McLeod) and

convert the reading from millimeters to inches-of-mercury (divide by

25.4 mm/inches).

10. Using the UP/DOWN arrow keys, adjust the vacuum display to match

the reading converted from the reference gauge (in Hg).

11. Press the SET key. The controller will sample the vacuum data, then

indicate when it is done.

12. If it is desired, check for chamber leakage by rotating the PURGE

valve to the full clockwise position. Leakage should be less than 0.5

inch-of- mercury in one hour.

13. Open the VACUUM valve (rotate counterclockwise) and allow air to

bleed into the chamber.

14. Verify the atmospheric pressure is shown in the lower display. Repeat

the procedure if necessary by pressing the MENU key until the upper

display again reads VCMC.

Vacuum Oven 6-15Cole-Parmer

Section 6

Operation

Page 35

Table 9. Pressure at Atmosphere; Source U.S. Standard Atmosphere,

P.62 (NASA)

D/AC-Temperature/Vacuum Recorder Outputs

Connector pin P3 is the Temperature/Pressure Recorder Output interface.

Output pins P3-1 and P3-2 provide an output voltage proportional to the

chamber temperature, while the pins P3-3 and P3-4 provide a similar

voltage proportional to the chamber pressure. To begin calibrating the

Recorder Outputs, press the menu key until the upper display shows

D/AC, then press the SET key. The lower display will show CAL and then

enter the temperature D/A calibration (D/AT). Connect a voltmeter across

output pins P3-1 (+) and P3-2 (-). The upper display will show a number

that corresponds to the temperature output voltage. Use the UP/DOWN

arrow keys to adjust the corresponding display value to increase or decrease

the temperature output voltage then press the SET key to enter the new

value. The output voltage will be updated.

6-16 Vacuum Oven Cole-Parmer

Section 6

Operation

Pressure

Altitude (ft.) Inches of Hg Torr(mm of Hg) PSI

-1000 31.02 787.87 15.25

-500 30.47 773.83 14.94

Sea Level (0) 29.92 760.00 14.70

500 29.38 746.37 14.43

1000 28.86 732.93 14.18

1500 28.33 719.70 13.90

2000 27.82 706.66 13.67

2500 27.31 693.81 13.41

3000 26.81 681.15 13.19

3500 26.32 668.69 12.92

4000 25.84 656.40 12.70

4500 25.36 644.30 12.45

5000 24.89 632.38 12.23

5500 24.43 620.65 12.00

6000 23.98 609.09 11.77

6500 23.53 597.70 11.56

7000 23.09 586.49 11.34

7500 22.65 575.45 11.12

8000 22.23 564.58 10.90

8500 21.81 553.88 10.70

9000 21.38 543.34 10.50

9500 20.98 532.97 10.30

10000 20.58 522.75 10.10

Page 36

D/AC-Temperature/Vacuum Recorder Outputs

Repeat the process until the voltmeter indicates +3.00VDC. Press the

MENU key to accept the new calibration data and enter the vacuum

pressure recorder calibration, indicated by D/AV in the upper display.

To begin calibrating the vacuum pressure recorder output, move the

voltmeter leads to output pins P3-3 (+) and P3-4 (-). The lower display

again indicates a number corresponding to the vacuum recorder voltage.

Use the UP/DOWN arrow keys to increase or decrease the vacuum output

voltage then press the SET key to enter the new value. The output voltage

will be updated. Repeat the process until the vacuum output voltage is

+3.00VDC. When complete, press the MENU key to accept the data The

calibration is complete when both displays indicate DONE CAL.

CJCD-Cold Junction Compensation Temperature Display

The cold junction calibration is a self-calibrating procedure. To initialize

the CJCD process, press the SET key when the upper display shows

CJCD. The upper display will then indicate CJC with the lower display

showing the cold junction temperature. There is no adjustment to be

made, simply press the SET key again to conclude the calibration. The

next menu to appear in the upper display is the INIT menu. Remove the

jumper at JP4 to return to normal operating mode (see step #5 under

Calibration Mode).

Vacuum Oven 6-17Cole-Parmer

Section 6

Operation

Page 37

Page 38

Section 7 Maintenance

The Model 282A is constructed and finished with materials that provide

long maintenance-free service. All that is normally required is a routine

cleaning of the exterior surfaces, oven shelf, and oven floor. Use a mild

detergent for this purpose. Additionally, all external line connections for

inert atmospheres should be checked for tightness on a weekly basis. The

oven door seal should also be visually checked for deterioration such as

cracks or loss of flexibility. A good seal is necessary to ensure proper

operation of the instrument.

Warning Secured access panels, covers, etc., should never be removed from

this equipment by anyone other than experienced service personnel.

Hazardous line voltages are present at various internally exposed points. A

separate manual section is included for qualified service personnel.

s

To replace the oven seal, remove the old seal and perform the following:

1. Clean the edge of the chamber with Xylene or similar.

2. Apply a thin bead of Dow Corning RTV-736 red silicone rubber

adhesive to the edge of the chamber.

3. Install gasket and close door.

4. Keep door closed for a minimum of 16 hours with 1-2 inches of

vacuum before using.

Vacuum Oven 7-1Cole-Parmer

Seal Replacement

Page 39

7-2 Vacuum Oven Cole-Parmer

Section 7

Maintenance

Door Alignment

Procedure

A good seal around the door is critical, particularly when operating the

oven with a vacuum environment. Therefore, the following procedure

should be performed carefully. Refer to the illustrations below and perform

the following.

1. Loosen, but do not remove, the four (two in both the top and bottom

hinge) screws securing the door hinges.

2. Loosen the three door bracket screws (located next to the control

panel) that hold the bracket to the cabinet.

3. Slide the bracket all the way to the right. Securely tighten the three

screws.

4. Loosen the two slide-adjust nuts on the bracket and slide the catch

outward.

5. Align the top door edge parallel to the top surface of the chassis to

within 1/16 inch.

Page 40

Vacuum Oven 7-3Cole-Parmer

Section 7

Maintenance

Door Alignment

Procedure (cont.)

6. Draw a vacuum by pressing on both left and right sides of the door

using your hands. Close vacuum valve at 25 inches of Hg.

7. Tighten the two bolts for each hinge while lightly pressing each corner

of the door in the area of the hinge being tightened.

8. Slide the cam assembly to engage the catch, and then turn the handle

down so that the flat on the cam is vertical. Push gently on the catch

until it touches the flat on the cam.

9. Insert a 1/32-inch thick shim (not supplied) between the catch and flat

side of cam, and securely tighten the two nuts on the catch while

applying vacuum.

10. Remove the shim. Then release vacuum and open door.

11. Try cam mechanism for clearance of both door edge and cam. If there

is a clearance of more than 1/16 inch between the end of the cam and

catch projection, adjust spacing by loosening the three catch screws

and readjust catch.

12. Secure the three screws and check clearance of Step 11. Check that

oven door positively seals after completion of this procedure.

Page 41

Page 42

Section 8 Service

Caution Only trained personnel should perform service on this oven. s

Correcting a malfunction in the Oven primarily involves replacing the

defective component. Components that can be replaced are listed under

Table 11 in Replacement Parts. Most components can be accessed by

removing the right side panel. There are six screws that hold the panel to

the oven chassis.

Heater replacement is a much larger task, requiring near complete

disassembly of the oven by two persons. Therefore it is recommended that

when required, heaters be replaced by returning the oven to a service

center. It should be noted that, because of the very low watt density of the

heater elements, an almost indefinite life is expected.

Because the Oven is equipped with self-diagnostic features, the service

recommendations here are limited to the Trouble Analysis Chart shown

below which incorporates these features. To use this chart effectively, select

the Symptom category(s) that best describes the observable malfunction, in

particular the error codes. Proceed to inspect the Probable Cause

description(s) and take the necessary Corrective Action.

Vacuum Oven 8-1Cole-Parmer

Page 43

8-2 Vacuum Oven Cole-Parmer

Section 8

Service

Table 10: Trouble Analysis Chart

Symptom Probable Cause Corrective Action

Oven does not heat. CRC error. Error found in calibration data. Recalibrate unit.

Oven does not heat. OTC error. Open Control Thermocouple Check T.C. continuity; replace if open.

Oven does not heat. Open triac Check triac located on large heatsink.

Oven heaters

Check resistance of each heating element. Resistance should be

between 14.00 and 17.12 Ohms. Replace if defective.

Heater power turned off during

program execution.

Enter Program Edit Mode. Check current step for heater operation.

Oven does not heat. OVR error. Open safety sentinel

Push RESET button on sentinel. Replace sentinel if unable to reset.

Sentinel is preset to trigger when heater temperature exceeds

approximately 300°C.

Pressure readout indicates wrong

pressure

Calibration incorrect. Perform Calibration procedure in this manual.

Offset value incorrect. Change offset so display value matches actual chamber pressure.

Temperature readout indicates

wrong temperaature

Calibration incorrect. Perform Calibration procedure in this manual

Offset value incorrect. Change offset so display value matches actual temperature.

Vacuum readout indicates atmospheric pressure with vacuum being

drawn on the oven.

PURGE valve open. Close PURGE valve.

VACUUM valve closed. Open VACUUM valve.

Faulty door seal. Regrease or replace seal.

Internal tygon tubing between

inlet port and vacuum sensor

disconnected.

Reconnect tubing.

Door improperly aligned. Realign door following instruction given in this manual.

Page 44

The replacement part descriptions and their corresponding numbers are

provided below. Note that parts information is only valid at the

publication date (see front cover of this manual), and subsequent revisions

may have occurred after publication.

Vacuum Oven 8-3Cole-Parmer

Section 8

Section title

Replacement Parts

Description Part Number

Control P.C. Board (115/230V)

CP103305

Power Switch (S1)

CP102627

Heater (HTR1, HTR2) CP50098

Triac (Q1) CP52563

Thermostat

CP52018

Control Thermocouple (TC1)

CP52025

Readout Thermocouple (TC2)

255036

Seal Replacement Kit

CP70435

Shelf

CP52002

Valve (Vacuum or Purge)

CP44342

Handle

CP44342

Cam CP02371

Hose Connector

CP52062

Page 45

Page 46

Vacuum Oven 9-1Cole-Parmer

115V Schematic

230V Schematic

Page 47

Page 48

Cole-Parmer

625 East Bunker Court

Vernon Hills, IL 60061-9872

1-800-323-4340

1-847-549-7600

www.coleparmer.com

Loading...

Loading...