Page 1

1

Page 2

Operating Manual

USB-based

Analog and Digital I/O Module

MODEL NO. 18200-00

The 18200-00 is a USB 1.1 low-speed device. It is designed for USB 1.1 ports, and was tested for full

compatibility with both USB 1.1 and USB 2.0 ports.

The 18200-00 features eight analog inputs, two 10-bit analog outputs, 16 digital I/O connections, and one

32-bit external event counter. The 18200-00 is powered by the +5 volt USB supply from your computer.

No external power is required.

The 18200-00 analog inputs are software configurable for either eight 11-bit single-ended inputs, or four

12-bit differential inputs. An on-board industry standard 82C55 programmable peripheral interface chip

provides the 16 digital I/O lines in two 8-bit ports. You can configure each digital port independently for

either input or output.

Cole-Parmer Instrument Company

625 East Bunker Court

Vernon Hills, Illinois 60061-1844

(847) 549-7600

(847) 247-2929 (Fax)

800-323-4340

www.coleparmer.com

e-mail: techinfo@coleparmer.com

Document Revision 1, May, 2006

© Copyright 2006 Measurement Computing Corporation, 1208LSR1

2

Page 3

Table of Contents

Preface

About this Operating Manual...............................................................................................................5

What you will learn from this manual ................................................................................................................5

Conventions in this manual ................................................................................................................................5

Where to find more information.........................................................................................................................5

Chapter 1

Introducing the 18200-00......................................................................................................................6

18200-00 block diagram.....................................................................................................................................7

Software features................................................................................................................................................7

Connecting a 18200-00 to your computer is easy...............................................................................................8

Chapter 2

Installing the 18200-00..........................................................................................................................9

What comes with your 18200-00 shipment? ......................................................................................................9

Hardware .......................................................................................................................................................................... 9

Additional documentation................................................................................................................................................. 9

Unpacking the 18200-00 ....................................................................................................................................9

Installing the software ......................................................................................................................................10

Installing the hardware .....................................................................................................................................10

Chapter 3

Functional Details ...............................................................................................................................11

Theory of operation - analog input acquisition modes .....................................................................................11

Software paced mode.......................................................................................................................................................11

Continuous scan mode .....................................................................................................................................................11

Burst scan mode...............................................................................................................................................................11

External components ........................................................................................................................................12

USB connector.................................................................................................................................................................12

LED .................................................................................................................................................................................12

Screw terminal wiring......................................................................................................................................................12

Main connector and pin out .............................................................................................................................................13

Analog input terminals (CH0 IN - CH7 IN).....................................................................................................................14

Digital I/O terminals (Port A0 to A7, and Port B0 to B7)................................................................................................17

Power terminals ...............................................................................................................................................................17

Ground terminals .............................................................................................................................................................18

Calibration terminal .........................................................................................................................................................18

Trigger terminal...............................................................................................................................................................18

Counter terminal ..............................................................................................................................................................18

Accuracy...........................................................................................................................................................18

18200-00 channel gain queue feature...............................................................................................................21

Chapter 4

Specifications......................................................................................................................................22

Analog input section......................................................................................... Error! Bookmark not defined.

Analog output section....................................................................................... Error! Bookmark not defined.

Digital input/output........................................................................................... Error! Bookmark not defined.

External trigger................................................................................................. Error! Bookmark not defined.

Counter section................................................................................................. Error! Bookmark not defined.

Non-volatile memory........................................................................................ Error! Bookmark not defined.

Power................................................................................................................ Error! Bookmark not defined.

General ............................................................................................................. Error! Bookmark not defined.

3

Page 4

18200-00 Operating Manual

Environmental .................................................................................................. Error! Bookmark not defined.

Mechanical ....................................................................................................... Error! Bookmark not defined.

Main connector and pin out.............................................................................. Error! Bookmark not defined.

4-channel differential mode ............................................................................................. Error! Bookmark not defined.

8-channel single-ended mode........................................................................................... Error! Bookmark not defined.

4

Page 5

Preface

About this Operating Manual

What you will learn from this manual

This manual explains how to install, configure, and use the 18200-00 so that you get the most out of its

temperature measurement and data logging features.

This manual also refers you to related documents available on our web site, and to technical support resources.

Conventions in this manual

For more information on …

Text presented in a box signifies additional information and helpful hints related to the subject matter you are

reading.

Caution! Shaded caution statements present information to help you avoid injuring yourself and others,

damaging your hardware, or losing your data.

<#:#> Angle brackets that enclose numbers separated by a colon signify a range of numbers, such as those assigned

to registers, bit settings, etc.

bold text Bold text is used for the names of objects on the screen, such as buttons, text boxes, and check boxes. For

example:

1. Insert the disk or CD and click the OK button.

italic text Italic text is used for the names of manuals and help topic titles, and to emphasize a word or phrase. For

example:

The InstaCal® installation procedure is explained in the Quick Start Guide.

Never touch the exposed pins or circuit connections on the board

Where to find more information

The following electronic documents provide helpful information relevant to the operation of the 18200-00.

Cole-Parmer's Specifications: 18200-00 (the PDF version of the Electrical Specification Chapter in this

guide) is available on our web site at www.coleparmer.com/catalog/MoreInfo/18200-00-spec.pdf

Cole-Parmer's Quick Start Guide is available on our web site at

www.coleparmer.com/catalog/MoreInfo/CP-Quick-Start.pdf

Cole-Parmer's Guide to Signal Connections is available on our web site at

www.coleparmer.com/catalog/MoreInfo/CPsignals.pdf

Cole-Parmer's Universal Library User's Guide is available on our web site at

www.coleparmer.com/catalog/MoreInfo/sm-ul-user-guide.pdf

Cole-Parmer's Universal Library Function Reference is available on our web site at

www.coleparmer.com/catalog/MoreInfo/sm-ul-functions.pdf

Cole-Parmer's Universal Library for LabVIEW

www.coleparmer.com/catalog/MoreInfo/SM-UL-LabVIEW.pdf

™

User’s Guide is available on our web site at

.

.

.

.

.

.

18200-00 Operating Manual (this document) is also available on our web site at

www.coleparmer.com/cpusbdaq1/18200-00.pdf

.

5

Page 6

Chapter 1

Introducing the 18200-00

This manual contains all of the information you need to connect the 18200-00 to your computer and to the

signals you want to measure. The 18200-00 is part of the Cole-Parmer brand of USB-based data acquisition

products.

The 18200-00 is a USB 1.1 low-speed device supported under popular Microsoft

systems. It is designed for USB 1.1 ports, and was tested for full compatibility with both USB 1.1 and USB 2.0

ports.

Refer to the "Be sure you are using the latest system software

make sure you are using the latest USB drivers.

The 18200-00 features eight analog inputs, two 10-bit analog outputs, 16 digital I/O connections, and one 32-bit

external event counter. The 18200-00 is powered by the +5 volt USB supply from your computer. No external

power is required.

The 18200-00 analog inputs are software configurable for either eight 11-bit single-ended inputs, or four 12-bit

differential inputs. An on-board industry standard 82C55 programmable peripheral interface chip provides the

16 digital I/O lines in two 8-bit ports. You can configure each digital port independently for either input or

output.

The 18200-00 is shown in Figure 1-1. I/O connections are made to the screw terminals located along each side

of the 18200-00.

" note in Chapter 2, "Installing the 18200-00," to

®

Windows® operating

Figure 1-1. 18200-00

6

Page 7

18200-00 Operating Manual Introducing the 18200-00

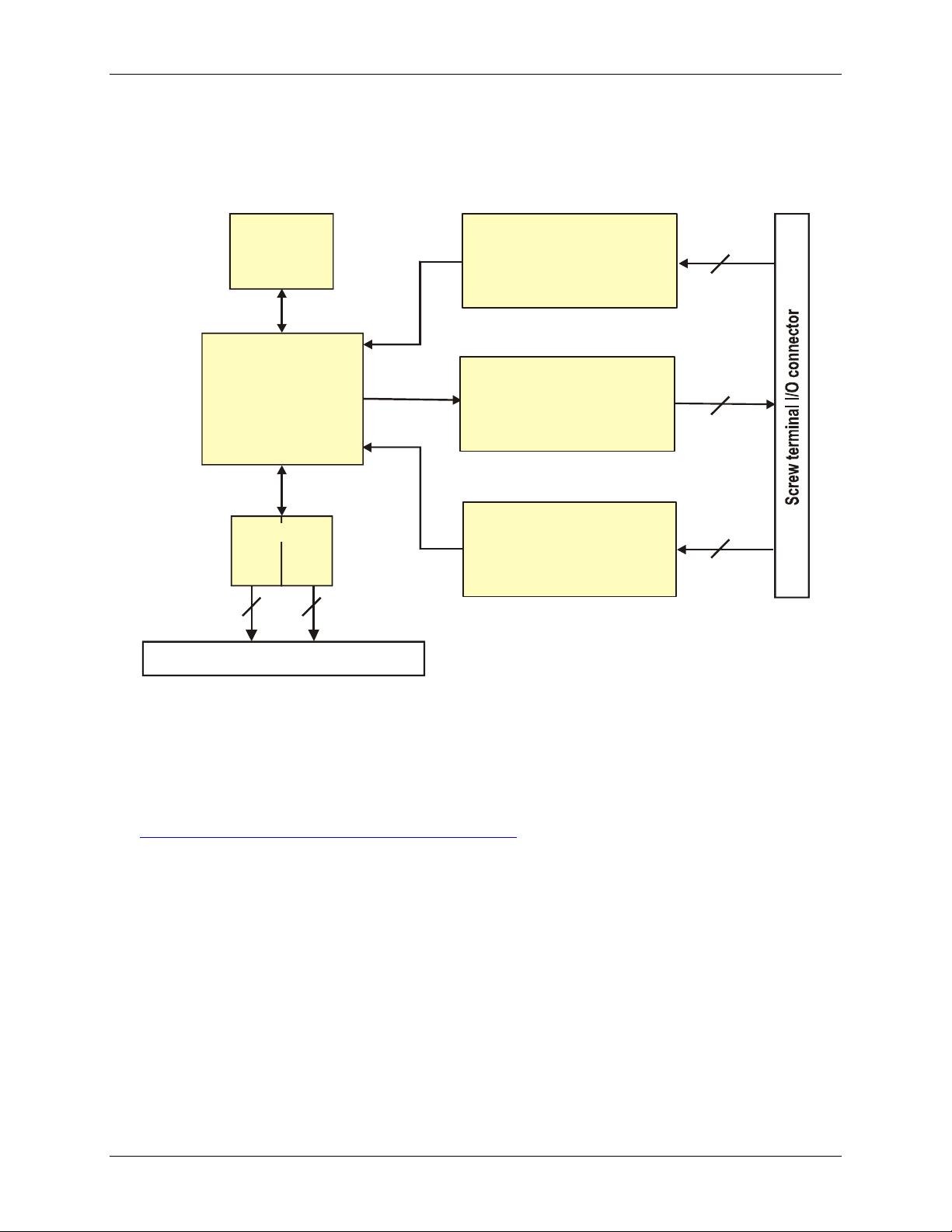

18200-00 block diagram

18200-00 functions are illustrated in the block diagram shown here.

USB1.1

Compliant

Interface

USB

Microcontroller

82C55 DIO

PortAPort

B

8 8

Screw terminal I/O connector

Analog Input

8 SE (

4 Diff. (

11-bit ) channels

12-bit ) channels

Analog Output

10-bit

2 channels

32-bit

Event Counter

1 channel

or

8

2

1

Figure 1-2. 18200-00 functional block diagram

Software features

For information on the features of InstaCal and the other software included with your 18200-00, refer to the

Quick Start Guide that shipped with your device. The Quick Start Guide is also available in PDF at

www.coleparmer.com/catalog/MoreInfo/CP-Quick-Start.pdf

.

7

Page 8

18200-00 Operating Manual Introducing the 18200-00

Connecting a 18200-00 to your computer is easy

Installing a data acquisition device has never been easier.

The 18200-00 relies upon the Microsoft Human Interface Device (HID) class drivers. The HID class

drivers ship with every copy of Windows that is designed to work with USB ports. We use the Microsoft

HID because it is a standard, and its performance delivers full control and maximizes data transfer rates for

your 18200-00. No third-party device driver is required.

The 18200-00 is plug-and-play. There are no jumpers to position, DIP switches to set, or interrupts to

configure.

You can connect the 18200-00 before or after you install the software, and without powering down your

computer first. When you connect an HID to your system, your computer automatically detects it and

configures the necessary software. You can connect and power multiple HID peripherals to your system

using a USB hub.

You can connect your system to various devices using a standard four-wire cable. The USB connector

replaces the serial and parallel port connectors with one standardized plug and port combination.

You do not need a separate power supply module. The USB automatically delivers the electrical power

required by each peripheral connected to your system.

Data can flow two ways between a computer and peripheral over USB connections.

8

Page 9

Installing the 18200-00

What comes with your 18200-00 shipment?

As you unpack your 18200-00, verify that the following components are included.

Hardware

18200-00

Chapter 2

USB cable (2 meter length)

Additional documentation

In addition to this hardware manual, you should also receive the Quick Start Guide (available in PDF at

www.coleparmer.com/catalog/MoreInfo/CP-Quick-Start.pdf

software you received with your 18200-80 and information regarding installation of that software. Please read

this booklet completely before installing any software or hardware.

.). This booklet supplies a brief description of the

Unpacking the 18200-00

As with any electronic device, you should take care while handling to avoid damage from static

electricity. Before removing the 18200-00 from its packaging, ground yourself using a wrist strap or by simply

touching the computer chassis or other grounded object to eliminate any stored static charge.

If your 18200-00 is damaged, notify Cole-Parmer immediately by phone, fax, or email:

Phone: 800-323-4340.

Fax: 847-247-2929

Email: techinfo@coleparmer.com

9

Page 10

18200-00 Operating Manual Installing the 18200-00

Installing the software

Refer to the Quick Start Guide for instructions on installing the software on the C-P Data Acquisition Software

CD. This booklet is available in PDF at www.coleparmer.com/catalog/MoreInfo/CP-Quick-Start.pdf.

Installing the hardware

Be sure you are using the latest system software

Before you connect the 18200-00, make sure that you are using the latest versions of the USB drivers.

Before installing the 18200-00, download and install the latest Microsoft Windows updates. In particular, when

using Windows XP, make sure you have XP Hotfix KB822603 installed. This update is intended to address a

serious error in Usbport.sys when you operate a USB device. You can run Windows Update or download the

update from www.microsoft.com/downloads/details.aspx?familyid=733dd867-56a0-4956-b7fe-

e85b688b7f86&displaylang=en. For more information, refer to the Microsoft Knowledge Base article

"Availability of the Windows XP SP1 USB 1.1 and 2.0 update." This article is available at

support.microsoft.com/?kbid=822603.

To connect the 18200-00 to your system, turn your computer on, and connect the USB cable to a USB port on

your computer or to an external USB hub that is connected to your computer. The USB cable provides power

and communication to the 18200-00.

When you connect the 18200-00 for the first time, a Found New Hardware popup balloon (Windows XP) or

dialog (other Windows versions) opens as the 18200-00 is detected by your computer.

Another

USB Human Interface Device.

When this balloon or dialog closes, the installation is complete. The LED on the 18200-00 should flash and then

remain lit. This indicates that communication is established between the 18200-00 and your computer.

Caution! Do not disconnect any device from the USB bus while the computer is communicating with the

If the LED turns off

If the LED is illuminated but then turns off, the computer has lost communication with the 18200-00. To restore

communication, disconnect the USB cable from the computer, and then reconnect it. This should restore

communication, and the LED should turn back on.

Found New Hardware balloon or dialog opens after the first closes that identifies the 18200-00 as a

18200-00, or you may lose data and/or your ability to communicate with the 18200-00.

10

Page 11

Chapter 3

Functional Details

Theory of operation - analog input acquisition modes

The 18200-00 can acquire analog input data in three different modes – software paced, continuous scan, and

burst scan.

Software paced mode

In software paced mode, you can acquire one analog sample at a time. You initiate the A/D conversion by

calling a software command. The analog value is converted to digital and returned to the computer. You can

repeat this procedure until you have the total number of samples that you want from one channel.

Software pacing is limited by the 20 mS round-trip requirement of a USB interrupt-type endpoint operation.

The maximum throughput sample rate in software paced mode is 50 S/s.

Continuous scan mode

In continuous scan mode, you can acquire data from up to eight channels. The analog data is continuously

acquired, converted to digital values, and written to an on-board FIFO buffer until you stop the scan. The FIFO

buffer is serviced in blocks as the data is transferred from the 18200-00 to the memory buffer on your computer.

The maximum continuous scan rate of 1.2 kS/s is an aggregate rate. The total acquisition rate for all channels

cannot exceed 1.2 kS/s. You can acquire data from one channel at 1.2 kS/s, two channels at 600 S/s and four

channels at 300 S/s. You can start a continuous scan with either a software command or with an external

hardware trigger event.

Burst scan mode

In burst scan mode, you can acquire data using the full capacity of the 18200-00 4 k sample FIFO. You can

initiate a single acquisition sequence of up to 4096 samples channels by either a software command or an

external hardware trigger. The captured data is then read from the FIFO and transferred to a user buffer in the

host PC.

Burst scans are limited to the depth of the on-board memory, as the data is acquired at a rate faster than it can be

transferred to the computer. The maximum sampling rate is an aggregate rate. The maximum rates that you can

acquire data using burst scan mode is 8 kS/s divided by the number of channels in the scan.

11

Page 12

18200-00 Operating Manual Functional Details

External components

The 18200-00 has the following external components, as shown in Figure 3-1.

USB connector

LED

Screw terminal banks (2)

Screw terminals

Pins 1-20

LED

Screw terminals

Pins 21-40

USB connector/cable

Figure 3-1. 18200-00 external components

USB connector

The USB connector is on the right side of the 18200-00 housing. This connector provides +5V power and

communication. The voltage supplied through the USB connector is system-dependent, and may be less than

5V. No external power supply is required.

LED

The LED on the front of the housing indicates the communication status of the 18200-00. It uses up to 5 mA of

current and cannot be disabled. Table 3-1 defines the function of the 18200-00 LED.

Table 3-1. LED illumination

When the LED is… It indicates…

Steady green The 18200-00 is connected to a computer or external USB hub.

Blinks continuously Data is being transferred.

Blinks three times Initial communication is established between the 18200-00 and the computer.

Blinks at a slow rate

The analog input is configured for external trigger. The LED stops blinking and illuminates

steady green when the trigger is received.

Screw terminal wiring

The 18200-00 has two rows of screw terminals—one row on the top edge of the housing, and one row on the

bottom edge. Each row has 20 connections. Pin numbers are identified in Figure 3-2.

12

Page 13

18200-00 Operating Manual Functional Details

Figure 3-2. 18200-00 Screw terminal pin numbers

Screw terminal – pins 1-20

The screw terminals on the top edge of the 18200-00 (pins 1 to 20) provide the following connections:

Eight analog input connections (

CH0 IN to CH7 IN)

Two analog output connections (D/A OUT 0 to D/A OUT 1)

One external trigger source (TRIG_IN)

One external event counter connection (

CTR)

Seven GND connections (GND)

One calibration terminal (CAL)

Screw terminal – pins 21-40

The screw terminals on the bottom edge of the (pins 21 to 40) provide the following connections:

16 digital I/O connections (

PortA0 to Port A7, and Port B0 to Port B7)

One power connection (PC+5 V)

Three ground connections (GND)

Main connector and pin out

Connector type Screw terminal

Wire gauge range 16 AWG to 30 AWG

13

Page 14

18200-00 Operating Manual Functional Details

CH7 IN

CH6 IN

CH3 IN LO

CH3 IN HI

CH2 IN LO

20 CTR

19 GND

18 TRIG_IN

17 GND

16 CAL

15 GND

14 D/A OUT 1

13 D/A OUT 0

12 GND1110

9GND

8

7CH2 IN HI

6GND

5CH1 IN LO

4CH1 IN HI

3GND

2CH0 IN LO

1CH0 IN HI

20 CTR

19 GND

18 TRIG_IN

17 GND

16 CAL

15 GND

14 D/A OUT 1

13 D/A OUT 0

12 GND1110

9GND

CH5 IN

8

7CH4 IN

6GND

5CH3 IN

4CH2 IN

3GND

2CH1 IN

1CH0 IN

GND 40

Port B7 39

Port B6 38

Port B5 37

Port B4 36

GND 31

PC+5V 30

GND 29

Port B3 35

Port B2 34

Port B1 33

Port A7 28

Port B0 32

Port A6 27

Port A5 26

Port A4 25

Port A3 24

Port A2 23

4-channel differential mode pin out

GND 40

Port B7 39

Port B6 38

Port B5 37

Port A1 22

Port A0 21

Port B4 36

8-channel single-ended mode pin out

GND 31

PC+5V 30

GND 29

Port B3 35

Port B2 34

Port B1 33

Port A7 28

Port B0 32

Port A6 27

Port A5 26

Port A4 25

Port A3 24

Port A2 23

Port A1 22

Port A0 21

Analog input terminals (CH0 IN - CH7 IN)

You can connect up to eight analog input connections to the screw terminal containing pins 1 to 20 (CH0 IN

through CH7 IN). Refer to the pinout diagrams

You can configure the analog input channels as eight single-ended channels or four differential channels. When

configured for differential mode, each analog input has 12-bit resolution. When configured for single-ended

mode, each analog input has 11-bit resolution, due to restrictions imposed by the A/D converter.

Single-ended configuration

When all of the analog input channels are configured for single-ended input mode, eight analog channels are

available. The input signal is referenced to signal ground (GND), and delivered through two wires:

The wire carrying the signal to be measured connects to CH# IN.

The second wire connects to GND.

The input range for single-ended mode is ±10V. No other ranges are supported in single-ended mode. Figure

3-3 illustrates a typical single-ended measurement connection.

above for the location of these pins.

Figure 3-3. Single-ended measurement connection

14

Page 15

18200-00 Operating Manual Functional Details

Single-ended measurements using differential channels

To perform a single-ended measurement using differential channels, connect the signal to "CHn IN HI" input,

and ground the associated "CHn IN LO" input.

Differential configuration

When all of the analog input channels are configured for differential input mode, four analog channels are

available. In differential mode, the input signal is measured with respect to the low input.

The input signal is delivered through three wires:

The wire carrying the signal to be measured connects to CH0 IN HI, CH1 IN HI, CH2 IN HI, or

CH3 IN HI.

The wire carrying the reference signal connects to CH0 IN LO, CH1 IN LO, CH2 IN LO, or CH3 IN LO.

The third wire connects to GND.

A low-noise precision programmable gain amplifier (PGA) is available on differential channels to provide gains

of up to 20 and a dynamic range of up to 12-bits. Differential mode input voltage ranges are ±20 V, ±10 V,

±5 V, ±4 V, ±2.5 V, ±2.0 V, 1.25 V, and ±1.0 V.

In differential mode, the following two requirements must be met for linear operation:

Any analog input must remain in the −10V to +20V range with respect to ground at all times.

The maximum differential voltage on any given analog input pair must remain within the selected voltage

range.

The input [common-mode voltage + signal] of the differential channel must be in the

−10 V to +20 V range in order to yield a useful result. For example, you input a 4 V pp sine wave to CHHI, and

apply the same sine wave 180° out of phase to CHLO. The common mode voltage is 0 V. The differential input

voltage swings from 4 V-(-4 V) = 8 V to -4 V-4 V = -8V. Both inputs satisfy the -10 V to +20 V input range

requirement, and the differential voltage is suited for the ±10 V input range (see Figure 3-4).

+4V

CHHI

CHLO

0V

-4V

8V Differential

+4V

-4V

Figure 3-4. Differential Voltage Example: Common Mode Voltage of 0 V

+/-8V

Measured Signal

If you increase the common mode voltage to 11 V, the differential remains at ±8 V. Although the [commonmode voltage + signal] on each input now has a range of +7 V to +15 V, both inputs still satisfy the -10 V to

+20 V input requirement (see Figure 3-5).

15

Page 16

18200-00 Operating Manual Functional Details

+15V

CHHI

+11V

Measured Signal

+/-8V

CHLO

8V Differential

+11V

+7V

Figure 3-5. Differential Voltage Example: Common Mode Voltage of 11V

If you decrease the common-mode voltage to -7 V, the differential stays at ±8 V. However, the solution now

violates the input range condition of -10 V to +20 V. The voltage on each analog input now swings from -3V to

-11V. Voltages between -10 V and -3 V are resolved, but those below -10 V are clipped (see Figure 3-6).

CHHI

CHLO

-3V

-7V

-11V

-3V

-7V

-11V

3V

8V Differential

+/-7V

Figure 3-6. Differential Voltage Example: Common Mode Voltage of -7 V

Measured Signal

Since the analog inputs are restricted to a −10 V to +20 V signal swing with respect to ground, all ranges except

±20V can realize a linear output for any differential signal with zero common mode voltage and full scale signal

inputs. The ±20 V range is the exception. You cannot put −20 V on CHHI and 0 V on CHLO since this violates

the input range criteria.

Table 3-2 shows some possible inputs and the expected results.

Table 3-2. Sample Inputs and Differential Results

CHHI CHLO Result

-20 V 0 V Invalid

-15 V +5 V Invalid

-10 V 0 V -10 V

-10 V +10 V -20 V

0 V +10 V -10 V

0 V +20 V -20 V

+10 V -10 V +20 V

+10 V 0 V +10 V

+15 V -5 V +20 V

+20 V 0 +20 V

For more information on analog signal connections

For more information on single-ended and differential inputs, refer to the Guide to Signal Connections (this

document is available on our web site at www.coleparmer.com/catalog/MoreInfo/CPsignals.pdf.)

16

Page 17

18200-00 Operating Manual Functional Details

Digital I/O terminals (Port A0 to A7, and Port B0 to B7)

You can connect up to 16 digital I/O lines to the screw terminal containing pins 21 to 40 (Port A0 to Port A7,

and Port B0 to Port B7.) Refer to the pinout diagrams on page 14 for the location of these pins. You can

configure each digital port for either input or output.

When you configure the digital bits for input, you can use the digital I/O terminals to detect the state of any

TTL level input. Refer to the switch shown in Figure 3-7 and the schematic shown in Figure 3-8. If the switch is

set to the +5 V input, Port A0 reads TRUE (1). If you move the switch to GND, Port A0 reads FALSE.

Figure 3-7. Digital connection Port A0 detecting the state of a switch

Port A0

+5V+GND

Figure 3-8. Schematic showing switch detection by digital channel Port A0

For more information on digital signal connections

For more information on digital signal connections and digital I/O techniques, refer to the Guide to Signal

Connections (available on our web site at www.coleparmer.com/catalog/MoreInfo/CPsignals.pdf.)

Power terminals

The PC +5 V connection (pin 30) is on the bottom screw terminal of the 18200-00. Refer to the pinout diagrams

on page 14 for the location of this pin. This terminal draws power from the USB connector. The +5 V screw

terminal is a 5 volt output that is supplied by the host computer.

Caution! The +5V terminal is an output. Do not connect to an external power supply or you may damage

the 18200-00 and possibly the computer.

The maximum total output current that can be drawn from all 18200-00 connections (power, analog and digital

outputs) is 500 mA. This maximum applies to most personal computers and self-powered USB hubs.

Bus-powered hubs and notebook computers may limit the maximum available output current to 100 mA.

Just connecting the 18200-00 to your computer draws 20 mA of current from the USB +5 V supply. Once you

start running applications with the 18200-00, each DIO bit can draw up to 2.5 mA, and each analog output can

17

Page 18

18200-00 Operating Manual Functional Details

draw 30 mA. The maximum amount of +5 V current available for experimental use, over and above that

required by the 18200-00, is the difference between the total current requirement of the USB device (based on

the application), and the allowed current draw of the PC platform (500 mA for desktop PCs and self-powered

hubs, or 100 mA for bus-powered hubs and notebook computers).

With all outputs at their maximum output current, you can calculate the total current requirement of the 1820000 USB +5 V as follows:

(18200-00 @ 20 mA) + (16 DIO @ 2.5 mA ea) + (2 AO @ 30 mA ea ) = 120 mA

For an application running on a PC or powered hub, the maximum available excess current is 500 mA−120 mA

= 380 mA. This number is the total maximum available current at the PC+5V screw terminals. Measurement

Computing highly recommends that you figure in a safety factor of 20% below this maximum current loading

for your applications. A conservative, safe user maximum in this case would be in the 300-320 mA range.

Since laptop computers typically allow up to 100 mA, the 18200-00 in a fully-loaded configuration may be

above that allowed by the computer. In this case, you must determine the per-pin loading in the application to

ensure that the maximum loading criteria is met. The per-pin loading is calculated by simply dividing the +5 V

by the load impedance of the pin in question.

Ground terminals

The 10 ground connections (GND) are identical, and provide a common ground for all 18200-00 functions.

Refer to the pinout diagrams on page 14 for the location of the GND terminal pins.

Calibration terminal

The CAL connection (pin 16) is an output you should use only to calibrate the 18200-00. Refer to the pinout

diagrams on page 14 for the location of this pin. Calibration of the 18200-00 is software-controlled via InstaCal.

Trigger terminal

The TRIG_IN connection (pin 18) is an external digital trigger input. You can configure this terminal with

software for either trigger high or trigger low.

Counter terminal

The CTR connection (Pin 20) is input to the 32-bit external event. Refer to the pinout diagrams on page 14 for

the location of this pin. The internal counter increments when the TTL levels transition from low to high. The

counter can count frequencies of up to 1 MHz.

Accuracy

The overall accuracy of any instrument is limited by the error components within the system. Quite often,

resolution is incorrectly used to quantify the performance of a measurement product. While "12-bits" or "1 part

in 4096" does indicate what can be resolved, it provides little insight into the quality of an absolute

measurement. Accuracy specifications describe the actual results that can be realized with a measurement

device.

There are three types of errors which affect the accuracy of a measurement system:

offset

gain

nonlinearity.

18

Page 19

18200-00 Operating Manual Functional Details

The primary error sources in the 18200-00 are offset and gain. Nonlinearity is small in the 18200-00, and is not

significant as an error source with respect to offset and gain.

Figure 3-9 shows an ideal, error-free, 18200-00 transfer function. The typical calibrated accuracy of the 1820000 is range-dependent, as explained in the "Specifications

" chapter of this document. We use a ±10 V range

here as an example of what you can expect when performing a measurement in this range.

Inp ut Vo lta ge

+FS

Output Code

0

2048

4095

-FS

Figure 3-9. Ideal ADC transfer function

The 18200-00 offset error is measured at mid-scale. Ideally, a zero volt input should produce an output code of

2048. Any deviation from this is an offset error. Figure 3-10 shows the 18200-00 transfer function with an

offset error. The typical offset error specification on the ±10 V range is ±9.77 mV. Offset error affects all codes

equally by shifting the entire transfer function up or down along the input voltage axis.

The accuracy plots in Figure 3-10 are drawn for clarity and are not drawn to scale.

Inp ut Vo lta ge

+FS

Ideal

2

2048

9.77mV

Output Code

4095

0

Ac t ua l

Offset= 9.77m V

-FS

Figure 3-10. ADC transfer function with offset error

19

Page 20

18200-00 Operating Manual Functional Details

V

V

V

Gain error is a change in the slope of the transfer function from the ideal, and is typically expressed as a

percentage of full-scale. Figure 3-11 shows the 18200-00 transfer function with gain error. Gain error is easily

converted to voltage by multiplying the full-scale (FS) input by the error.

The accuracy plots in Figure 3-11 are drawn for clarity and are not drawn to scale.

Inp ut Volta g e

+FS

Id ea l

Gain error=+0.2%, or +20 m

Gain e rror= -0.2%, or -20 m V

Ac t ua l

Output Code

0

2048

4095

-FS

Figure 3-11. ADC Transfer function with gain error

For example, the 18200-00 exhibits a typical calibrated gain error of ±0.2% on all ranges. For the ±10 V range,

this would yield 10 V × ±0.002 = ±20 mV. This means that at full scale, neglecting the effect of offset for the

moment, the measurement would be within 20 mV of the actual value. Note that gain error is expressed as a

ratio. Values near ±FS are more affected from an absolute voltage standpoint than are values near mid-scale,

which see little or no voltage error.

Combining these two error sources in Figure 3-12, we have a plot of the error band of the 18200-00 for the

±10 V range. This is a graphical version of the typical accuracy specification of the product.

The accuracy plots in Figure 3-12 are drawn for clarity and are not drawn to scale

Ideal + 9.77mV + 20 m V

Ide al

Idea l -(9.77m V + 20 mV)

Inp u t Volta ge

+FS

9.77mV

0

-FS

Figure 3-12. Error band plot

2048

Ideal + 9.77m V + 20 m

Ideal + 9.77m V + 20 m

Ide al

Ide a l -(9.7 7m V + 20 m V)

Output Code

4095

20

Page 21

18200-00 Operating Manual Functional Details

18200-00 channel gain queue feature

The 18200-00's channel gain queue feature allows you to set up a scan sequence with a unique per-channel gain

setting and channel sequence.

The channel gain queue feature removes the restriction of using an ascending channel sequence at a fixed gain.

This feature creates a channel list which is written to local memory on the 18200-00. The channel list is made

up of a channel number and range setting. An example of a four-element list is shown in Table 3-3.

Table 3-3. Sample channel gain queue list

Element Channel Range

0 CH0 BIP10V

1 CH0 BIP5V

2 CH7 BIP10V

3 CH2 BIP1V

When a scan begins with the gain queue enabled, the 18200-00 reads the first element, sets the appropriate

channel number and range, and then acquires a sample. The properties of the next element are then retrieved,

and another sample is acquired. This sequence continues until all elements in the gain queue have been selected.

When the end of the channel list is detected, the sequence returns to the first element in the list.

This sequence repeats until the specified number of samples is gathered. You must carefully match the gain to

the expected voltage range on the associated channel—otherwise, an over range condition can occur. Although

this condition does not damage the 18200-00, it does produce a useless full-scale reading. It can also introduce a

long recovery time from saturation, which can affect the next measurement in the queue.

21

Page 22

Chapter 4

Specifications

Typical for 25°C unless otherwise specified.

Specifications in italic text are guaranteed by design.

Analog input

Parameter Conditions Specification

A/D converter type Successive approximation type

Input voltage range for linear operation,

single-ended mode

Input common-mode voltage range for linear

operation, differential mode

Absolute maximum input voltage CHx to GND ±40V max

Input current (Note 1)

Input impedance 122K Ohms

Number of channels

Input ranges, single-ended mode ±10V, G=2

Input ranges, differential mode ±20V, G=1

Throughput

Channel gain queue Up to 8 elements

CAL accuracy CAL = 2.5V ±0.05% typ, ±0.25% max

Integral linearity error ±1 LSB typ

Differential linearity error ±0.5 LSB typ

Repeatability ±1 LSB typ

Trigger Source Software selectable External digital: TRIG_IN

Note 1: Input current is a function of applied voltage on the analog input channels. For a given input

voltage, Vin, the input leakage is approximately equal to (8.181*Vin-12) µA.

CHx to GND ±10 V max

CHx to GND -10 V min, +20 V max

Vin = +10 V 70µA typ

Vin = 0V -12µA typ

Vin = -10 V -94µA typ

8 single ended / 4 differential, software

selectable

±10V, G=2

±5V, G=4

±4V, G=5

±2.5V, G=8

±2.0V, G=10

±1.25V, G=16

±1.0V, G=20

Software selectable

Software paced 50 S/s

Continuous scan 1.2 kS/s

Burst scan to 4 K sample

FIFO

Differential 12 bits, no missing codes Resolution (Note 2)

Single ended 11 bits

Source 5 mA max CAL current

Sink 20 µA min, 200 nA typ

8 kS/s

Software configurable channel, range, and

gain.

Note 2: The AD7870 converter only returns 11-bits (0-2047 codes) in single-ended mode.

22

Page 23

18200-00 Operating Manual Specifications

Table 1. Accuracy, differential mode

Range Accuracy (LSB)

±20 V 5.1

±10 V 6.1

±5 V 8.1

±4 V 9.1

±2.5 V 12.1

±2 V 14.1

±1.25 V 20.1

±1 V 24.1

Table 2. Accuracy, single-ended mode

Range Accuracy (LSB)

±10 V 4.0

Table 3. Accuracy components, differential mode - all values are (±)

Range % of Reading Gain Error at FS

(mV)

±20 V 0.2 40 9.766 49.766

±10 V 0.2 20 9.766 29.766

±5 V 0.2 10 9.766 19.766

±4 V 0.2 8 9.766 17.766

±2.5 V 0.2 5 9.766 14.766

±2 V 0.2 4 9.766 13.766

±1.25 V 0.2 2.5 9.766 12.266

±1 V 0.2 2 9.766 11.766

Table 4. Accuracy components, single-ended mode - all values are (±)

Range % of Reading Gain Error at FS

(mV)

±10 V 0.2 20 19.531 39.531

Offset (mV) Accuracy at FS (mV)

Offset (mV) Accuracy at FS (mV)

Analog output

Parameter Conditions Specification

D/A converter type PWM

Resolution 10-bits, 1 in 1024

Maximum output range 0 -5 Volts

Number of channels 2 voltage output

Throughput Software paced 100 S/s single channel mode

50 S/s dual channel mode

Power on and reset voltage Initializes to 000h code

Maximum voltage (Note 3)

Output drive Each D/A OUT 30 mA

Slew rate 0.14 V/mS typ

Note 3: Vs is the USB bus +5V power. The maximum analog output voltage is equal to Vs at no-load.

V is system dependent and may be less than 5 volts.

No load Vs

1 mA load 0.99 * Vs

5 mA load 0.98 * Vs

23

Page 24

18200-00 Operating Manual Specifications

Digital input/output

Digital type 82C55

Number of I/O 16 (Port A0 through A7, Port B0 through B7

Configuration 2 banks of 8

Pull up/pull-down configuration

Input high voltage 2.0 V min, 5.5 V absolute max

Input low voltage 0.8 V max, –0.5 V absolute min

Output high voltage (IOH = -2.5 mA) 3.0 V min

Output low voltage (IOL = 2.5 mA) 0.4 V max

All pins pulled up to Vs via 47K resistors (default). Positions

available for pull down to ground. Hardware selectable via zero ohm

resistors as a factory option.

External trigger

Parameter Conditions Specification

Trigger source (Note 4) External digital TRIG_IN

Trigger mode Software selectable

Trigger latency Burst 25 µs min, 50 µs max

Trigger pulse width Burst 40 µs min

Input high voltage 3.0 V min, 15.0 V absolute max

Input low voltage 0.8 V max

Input leakage current ±1.0 µA

Note 4: TRIG_IN is protected with a 1.5KOhm series resistor.

Level sensitive: user configurable for

TTL level high or low input.

Counter

Counter type Event counter

Number of channels 1

Input source CTR screw terminal

Input type TTL, rising edge triggered

Resolution 32 bits

Schmidt trigger hysteresis 20 mV to 100 mV

Input leakage current ±1 µA

Maximum input frequency 1 MHz

High pulse width 500 ns min

Low pulse width 500 ns min

Input low voltage 0 V min, 1.0 V max

Input high voltage 4.0 V min, 15.0 V max

Non-volatile memory

Memory size 8192 bytes

Memory configuration

Address Range Access Description

0x0000 – 0x17FF Read/Write A/D data (4K samples)

0x1800 – 0x1EFF Read/Write User data area

0x1F00 – 0x1FEF Read/Write Calibration data

0x1FF0 – 0x1FFF Read/Write System data

24

Page 25

18200-00 Operating Manual Specifications

Power

Parameter Conditions Specification

Supply current (Note 5) 20 mA

Connected to Self-Powered Hub 4.5 V min, 5.25 V max +5V USB power available (Note 6)

Connected to Bus-Powered Hub 4.1 V min, 5.25 V max

Connected to Self-Powered Hub 450 mA min, 500 mA max Output current (Note 7)

Connected to Bus-Powered Hub 50 mA min, 100 mA max

Note 5: This is the total current requirement for the 18200-00 which includes up to 5mA for the status

LED.

Note 6: Self-powered refers to USB hubs and hosts with a power supply. Bus-powered refers to USB

hubs and hosts without their own power supply.

Note 7: This refers to the total amount of current that can be sourced from the USB +5V, analog outputs

and digital outputs.

General

Parameter Conditions Specification

25 °C ±30 ppm max USB controller clock error

0 to 70 °C ±50 ppm max

Device type USB 1.1 low-speed

Device compatibility USB 1.1, USB 2.0

Environmental

Operating temperature range -0 to 70 °C

Storage temperature range -40 to 70 °C

Humidity 0 to 90% non-condensing

Mechanical

Dimensions 79 mm (L) x 82 mm (W) x 25 mm (H)

USB cable length 3 Meters max

User connection length 3 Meters max

Main connector and pin out

Connector type Screw terminal

Wire gauge range 16 AWG to 30 AWG

25

Page 26

18200-00 Operating Manual Specifications

4-channel differential mode

Pin Signal Name Pin Signal Name

1 CH0 IN HI 21 Port A0

2 CH0 IN LO 22 Port A1

3 GND 23 Port A2

4 CH1 IN HI 24 Port A3

5 CH1 IN LO 25 Port A4

6 GND 26 Port A5

7 CH2 IN HI 27 Port A6

8 CH2 IN LO 28 Port A7

9 GND 29 GND

10 CH3 IN HI 30 PC+5V

11 CH3 IN LO 31 GND

12 GND 32 Port B0

13 D/A OUT 0 33 Port B1

14 D/A OUT 1 34 Port B2

15 GND 35 Port B3

16 CAL 36 Port B4

17 GND 37 Port B5

18 TRIG_IN 38 Port B6

19 GND 39 Port B7

20 CTR 40 GND

8-channel single-ended mode

Pin Signal Name Pin Signal Name

1 CH0 IN 21 Port A0

2 CH1 IN 22 Port A1

3 GND 23 Port A2

4 CH2 IN 24 Port A3

5 CH3 IN 25 Port A4

6 GND 26 Port A5

7 CH4 IN 27 Port A6

8 CH5 IN 28 Port A7

9 GND 29 GND

10 CH6 IN 30 PC+5V

11 CH7 IN 31 GND

12 GND 32 Port B0

13 D/A OUT 0 33 Port B1

14 D/A OUT 1 34 Port B2

15 GND 35 Port B3

16 CAL 36 Port B4

17 GND 37 Port B5

18 TRIG_IN 38 Port B6

19 GND 39 Port B7

20 CTR 40 GND

26

Page 27

Declaration of Conformity

Manufacturer: Measurement Computing Corporation

Address: 16 Commerce Boulevard

Middleboro, MA 02346

USA

Category: Electrical equipment for measurement, control and laboratory use.

Measurement Computing Corporation declares under sole responsibility that the product

18200-00

to which this declaration relates is in conformity with the relevant provisions of the following standards or other

documents:

EU EMC Directive 89/336/EEC: Electromagnetic Compatibility, EN 61326 (1997) Amendment 1 (1998)

Emissions: Group 1, Class B

EN 55011 (1990)/CISPR 11: Radiated and Conducted emissions.

Immunity: EN61326, Annex A

IEC 1000-4-2 (1995): Electrostatic Discharge immunity, Criteria A.

IEC 1000-4-3 (1995): Radiated Electromagnetic Field immunity Criteria A.

IEC 1000-4-8 (1994): Power Frequency Magnetic Field immunity Criteria A.

Declaration of Conformity based on tests conducted by Chomerics Test Services, Woburn, MA 01801, USA in

May, 2004. Test records are outlined in Chomerics Test Report #EMI3733.04.

We hereby declare that the equipment specified conforms to the above Directives and Standards.

Carl Haapaoja, Director of Quality Assurance

Page 28

HM 18200-00.doc

Cole-Parmer Instrument Company

625 East Bunker Court

Vernon Hills, Illinois 60061-1844

(847) 549-7600

Fax: (847) 247-2929 (Fax)

800-323-4340

www.coleparmer.com

E-mail: techinfo@coleparmer.com

Loading...

Loading...