Page 1

OPERATING MANUAL

ROTO-TORQUE®HEAVY DUTY ROTATORS

MODEL NOS. 07637-00 AND 07637-10

Cole-Parmer Instrument Company

625 East Bunker Court

Vernon Hills, Illinois U.S.A. 60061-1844

(847) 549-7600

(847) 247-2929 (Fax)

800-323-4340

www.coleparmer.com

e-mail: techinfo@coleparmer.com

A-1299-0029

Edition 09

SUPPLIER CERTIFIED

Page 2

DESCRIPTION

The COLE-PARMER ROTO-TORQUE Rotator consists of two units; the rotator assembly and the

Multipurpose disc. The rotator assembly is available in two models, wired for 115V AC 50/60 Hz (No.

07637-00) or 230V AC 50/60 Hz (No. 07637-10) input power. The rotator assembly contains a motor ,

speed control circuit, housing, base bracket and the rotor shaft adapter. The Multipurpose disc (No.

07637-01) includes small clips, large clips and mounting hardware.

The ROTO-TORQUE Rotator combines functional features with its attractive packaging. It can be

used for very low to moderate agitation. It has a stepless electronic speed control which can vary

the speed from about 3 to 80 rpm. Even with heavier loads on and around the rotating disc, the disc

will have a smooth rotation without cogging. The unit has an adjustable tilt housing that can be set

by an operator to the correct angle desired for a particular test.

The Multipurpose disc can accept different sizes of clips. They can hold test tubes, flasks and bottles. Clips around the periphery of the disc are placed at an angle. Any test tube placed in this clip

will move through a figure 8 motion causing a sloshing effect and mixing of its contents.

The unit is designed such that in most cases (when the disc is not heavily loaded), the center of

gravity of the system will act to tilt the disc upward. This safety device is provided in case the side

knob is left loose by mistake.

Trademarks bearing the ® symbol in this publication

are registered in the U.S. and in other countries.

Page 2

Page 3

ASSEMBLY AND GENERAL INFORMATION

Install the housing assembly on the base bracket using the top two slots in the sides of the base

bracket. It may be necessary to pull the sides of the base bracket outward for this installation.

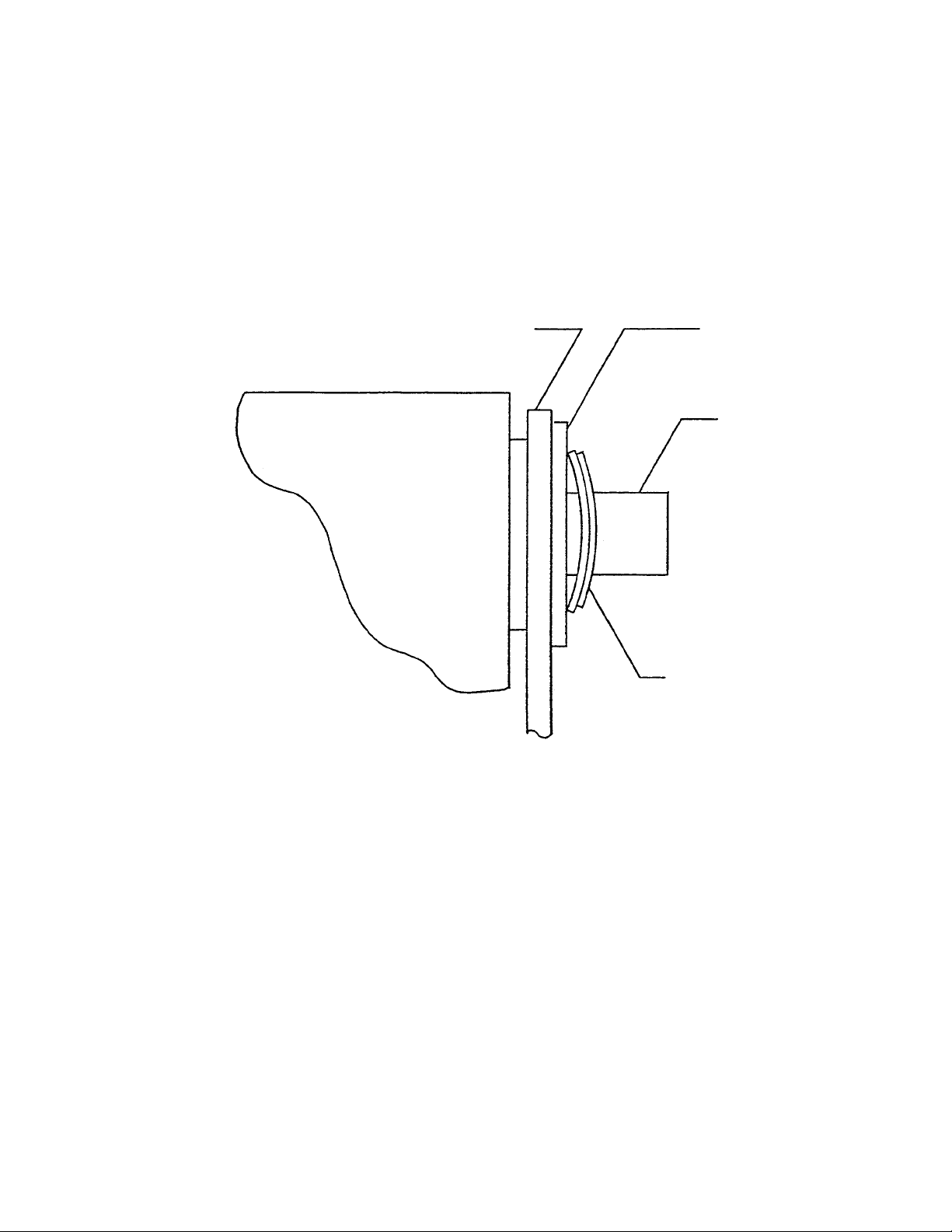

Place the fiber washer and two curved washers on the threaded shaft (side-axle) as shown in the

sketch. Use the side knob on the threaded shaft (axle) (it is the largest of the two knobs). Determine

the required tilt of the housing and tighten the side knob. The tilt angle of the housing can be

changed by loosening the side knob.

Slide the rotor shaft adapter onto the motor shaft. Tighten the set screws using the Allen wrench supplied with the unit. Line up the roll pin of the shaft adapter with the corresponding hole in the disc.

Attach the disc by tightening the adapter knob.

Two sizes of clips are supplied with the disc. They can grip diameters of 10 to 20 mm. The clamping diameters can be varied somewhat by slightly bending the clips. An extra large clip (20-25 mm)

and giant (25-40 mm) clip is also available as an accessory.

The clips can be attached on the periphery or the flat surface of the disc. Thirty mounting holes on

the periphery and sixteen holes on the front of the disc are provided for mounting the clips.

Page 3

BRACKET

CABINET

HOUSING

CURVED WASHERS

THREADED

SHAFT

FIBER

WASHER

Page 4

DIFFERENT APPLICATIONS

The Rotator can be used for:

Micro-Diffusion determinations

Semi-Micro extractions

Washing precipitates

Blood reconstruction

Dissolving of separations from Chromatography paper

Gas saturation of blood

Moderate agitation in tubes, flasks and bottles

OPERATING CHARACTERISTICS

The unit is equipped with a 6-foot three wire line cord and three prong plug. The third grounded wire

is connected to the chassis of the housing. Maximum current requirement is 0.3A at 115V AC for

Model 07637-00 and 0.15A at 230V AC for Model 07637-10. The units will work on 50-60 cycles.

Depending upon the position of the range switch, high or low speed range settings will be available

on the speed control reference dial. The low range is about 3 to 18 rpm. The high range is about 16

to 80 rpm. The high-low range switch has a center “off” position. This “off” position can be used to

turn the unit on and off without disturbing the speed setting.

The Rotator provides high torque even at low speeds. Yet, it is recommended that for best results,

balance the load as much as possible on the periphery of the disc.

The dial graduations on the speed control are for reference only; they are not calibrated as to rpm.

The 07637-10 model uses the same circuit and motor as the 07637-00 with the addition of a step

down autotransformer to reduce the 230V input to 115V. The on-off switch is in the 115V secondary.

With the switch off, some current still passes through the primary. Unplug the 07637-10 from the AC

receptacle when not in use.

Note

COLE-PARMER INSTRUMENT COMPANY reserves the right to make improvements in design,

construction and appearance of our products without notice.

Page 4

Page 5

W ARRANTY

The Manufacturer warrants this product to be free from significant deviations from published specifications. If repair or adjustment is necessary within the warranty period, the problem will be corrected at no charge if it is not due to misuse or abuse on your part as determined by the

Manufacturer. Repair costs outside the warranty period, or those resulting from product misuse or

abuse, may be invoiced to you.

The warranty period for this product is noted on the Warranty Card.

PRODUCT RETURN

To limit charges and delays, contact the seller or Manufacturer for authorization and shipping instructions before returning the product, either within or outside of the warranty period. When returning the

product, please state the reason for the return. For your protection, pack the product carefully and

insure it against possible damage or loss. Any damages resulting from improper packaging are your

responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the Manufacturer or authorized

seller.

Page 6

Page 6

REPLACEMENT PARTS LIST

Part Description Part No.

Gearmotor B-1952

Speed Control B-1496-2

Switch-Toggle B-1084-16

Side Knob B-1083-19

Adapter Knob B-1083-18

Small Knob B-1083-3

Bracket Assembly B-1786-1CR

Adapter Assembly A-1 141

Rubber Foot A-1390-1

Small Clip (10-15 mm) 07637-40

Large Clip (15-20 mm) 07637-50

Package of 50 screws and washers B-1238-31

for the clips

ACCESSORIES

Extra Large Clip (20-25 mm) 07637-60

Giant Clip (25-40 mm) 07637-70

Multipurpose Disc 07637-01

Test Tube Basket 07637-05

Serum Bottle Disc 07637-75

Page 5

Page 7

Page 7

07637-00

INPUT POWER

APPLIED AT B & D

07637-10

T1 IS ADDED:

INPUT POWER

APPLIED AT E & F

A & B AND C & D

ARE CONNECTED

ROTATOR SCHEMATIC

230V AC

115V AC

LAMP

HIGH

OFF

LOW

B-1496-2

R1

D3

D2

D1

Q1

F

C

R2

R3

R4

C1

C2

B

A

E

M

D4

D

T1

T2

Printed in U.S.A.

090700

Loading...

Loading...