Page 1

HORIZONTAL AIR FLOW

OVEN

MODEL: 05012-20, 05012-30

05012-40

INSTALLATION AND OPERATIONAL MANUAL

COLE-PARMER INSTRUMENT COMPANY_____________________________________________________________________

625 East Bunker Court, Vernon Hills, IL 60061 (847) 549-7600 • FAX (847) 549-7676

Page 2

TABLE OF CONTENTS

SECTION 1.0 RECEIVING AND INSPECTION

SECTION 2.0 GRAPHIC SYMBOLS

SECTION 3.0 INSTALLATION

SECTION 4.0 CONTROL OVERVIEW

SECTION 5.0 PRECAUTIONS

SECTION 6.0 CLEAN ROOM READY

INSTRUCTIONS, 05012-30,05012-40

SECTION 7.0 OPERATION

SECTION 8.0 MAINTENANCE

SECTION 9.0 TROUBLESHOOTING

SECTION 10.0 PARTS LIST

UNIT SPECIFICATIONS

SCHEMATICS

REV. 5/99

4861302

These units are for professional, industrial or educational use where the preparation or

testing of materials is done at approximately atmospheric pressure and no flammable,

volatile or combustible materials are being heated. These units are not intended for

hazardous or household locations or use.

22

22

Page 3

Section

1

RECEIVING AND INSPECTION

Your satisfaction and safety require a complete understanding of this unit. Read

the instructions thoroughly and be sure all operators are given adequate training

before attempting to put the unit in service. NOTE: This equipment must be used

only for its intended application; any alterations or modifications will void your

warranty.

1.1 Inspection: The carrier, when accepting shipment, also accepts responsibility

for safe delivery and is liable for loss or damage. On delivery, inspect for visible

exterior damage, note and describe on the freight bill any damage found, and

enter your claim on the form supplied by the carrier.

1.2 Inspect for concealed loss or damage on the unit itself, both interior and exterior.

If necessary, the carrier will arrange for official inspection to substantiate your

claim.

1.3 Return Shipment: Save the shipping crate until you are sure all is well. If for

any reason you must return the unit, first contact your customer representative

for authorization. Supply nameplate data, including model number and serial

number. Please see the manual cover for information on where to contact

customer service.

1.4 Accessories: Verify that all of the equipment indicated on the packing slip is

included with the unit. Carefully check all packaging before discarding. These

units are equipped with 2 shelves, 8 shelf clips, and 4 leveling feet.

33

33

Page 4

Section

2

GRAPHIC SYMBOLS

Your oven has been provided with a display of graphic symbols which should

help in identifying the use and function of the available user adjustable

components.

2.1 This symbol indicates that you should consult your

manual for further description or discussion of a

control or user item.

2.2 Indicates ÒAC PowerÓ

2.3 Indicates ÒManual ControlÓ

2.4 Indicates ÒTemperatureÓ

2.5 Indicates ÒOver Temperature SafetyÓ

2.6 Indicates ÒGroundÓ

2.7 Indicates ÒPotential Shock HazardÓ

44

44

Page 5

Section

3

INSTALLATION

Local city, county or other ordinances may govern the use of this equipment. If you

have any questions about local requirements, please contact the appropriate local

agency. Installation may be performed by the end user.

Under normal circumstances this unit is intended for use indoors, at room temperatures

between 5° and 40°C, at no greater than 80% Relative Humidity (at 25°C) and with a

supply voltage that does not vary by more than 10%. Customer service should be

contacted for operating conditions outside of these limits.

3.1 Power Source: The electrical supply circuit to the incubator must conform to all

national and local electrical codes. Consult the incubatorÕs serial data plate for

the voltage and ampere requirements before making connection. VOLTAGE

SHOULD NOT VARY MORE THAN 10% FROM THE DATA PLATE RATING.

This unit is intended for 50/60 Hz application. A separate circuit is recommended

to prevent possible loss of product due to overloading or failure of other

equipment on the same circuit. For installation of the units, the cord must be

plugged directly into a grounded outlet, without the use of an extension cord.

3. 2Lo ca tio n: In sele cting a locat ion , con sid er all cond it ion s which mig ht ef fect

pe rf orm ance, su ch as he at fr om rad ia tor s, ovens, a ut oclave s, et c. Avoid d ir ect su n,

fa st mo vin g air cu rr ent s, he ating/ co oling du cts an d hig h-t ra ffic are as. Allow a

minimum of 5cm bet we en the unit an d walls or pa rtitions wh ich migh t obstru ct fr ee

air flo w.

3.3 L if ti ng / Ha n dl in g: T he se un it s are hea vy an d car e sho uld be ta ken to use

a pp ro pr iat e lif ting de vices tha t are su ff icien tly rat ed fo r t he se lo ad s. Units sh ou ld

o nly be lift e d fr om th eir bot to m sur f aces. Do or s, ha nd les an d kn ob s are no t

a de qu at e for lift in g or sta bilizat io n . Th e unit sho uld be co m plet ely rest ra in ed fr om

t ip ping du rin g lift ing or tra nsp or t. All mo ving pa rt s, su ch as she lve s and tra ys

sho uld be re m oved an d do o rs nee d to be po sit ively locke d in the clo sed po sition

d ur in g tra nsf er t o pre ve n t sh if t in g and d am a ge .

3 .4 L ev el in g : T he unit must sit le ve l and solidly. Leveling fe et are su pp lie d an d must

b e in st a lled in the fo ur ho le s in th e bot to m cor n er s of th e unit. Wit h the fee t

insta lle d an d the un it st an ding up rig ht , ea ch fo o t ca n be ra ise d by tu rn ing it in a

cou nt er clo ckwise dir ectio n. Ad just the foo t at each co r ne r unt il th e un it st an d s

level an d so lid wit h ou t rocking . If th e un it mu st be mo ve d, tu rn th e le velin g fee t all

t he way clockwise t o p re ven t da m ag e while m o ving .

55

55

Page 6

3 .5 Adj us tme n ts : Whe n re m ovin g int er ior it em s fo r cle a ning or any ot he r rea so n ,

n ot e th a t yo u must, first rem ove the line r bot to m inser t bef o re rem o ving line r sid e

inser ts. Th is re qu ire s a 8 /3 2 nut d r iver t o r em o ve t he ca p nut s.

3.6 Cle an in g : The un it ch am be r sho uld be cle an ed an d disin fe cte d pr ior to use .

Rem ove all of the in te rio r pa rt s, if asse mb led , and cle a n th o ro ug hly, in clu ding all

cor ne rs usin g a suit ab le disinf e ct an t tha t is ap p ro pr ia t e to yo ur ap plica tion .

Reg ular pe rio dic cle an in g is re q uire d . Spe cia l car e sh o uld be ta ke n whe n cle an ing

a ro un d sen sin g he ad s to pre ve nt da ma g e. DO NOT USE chlorine-based

bleaches or abrasive cleaners as this will damage the stainless steel interior. DO

NOT USE spray cleaners that might leak through openings and cracks and get

on electrical parts or that may contain solvents that will harm the coatings. F or

M od els 050 12 - 30 a nd 05 01 2 -4 0 se e Sectio n 6 fo r f ur t he r in str uct io n.

Warning: Never clean the unit with alcohol or flammable cleaners with the unit

connected to the electrical supply. Always disconnect the unit from the electrical

service when cleaning and assure all volatile or flammable cleaners are

evaporated and dry before reattaching the unit to the power supply.

3 .7 Pla ce sh elve s in th e cha m be r as de sir ed .

66

66

Page 7

Section

4

CONTROL PANEL OVERVIEW

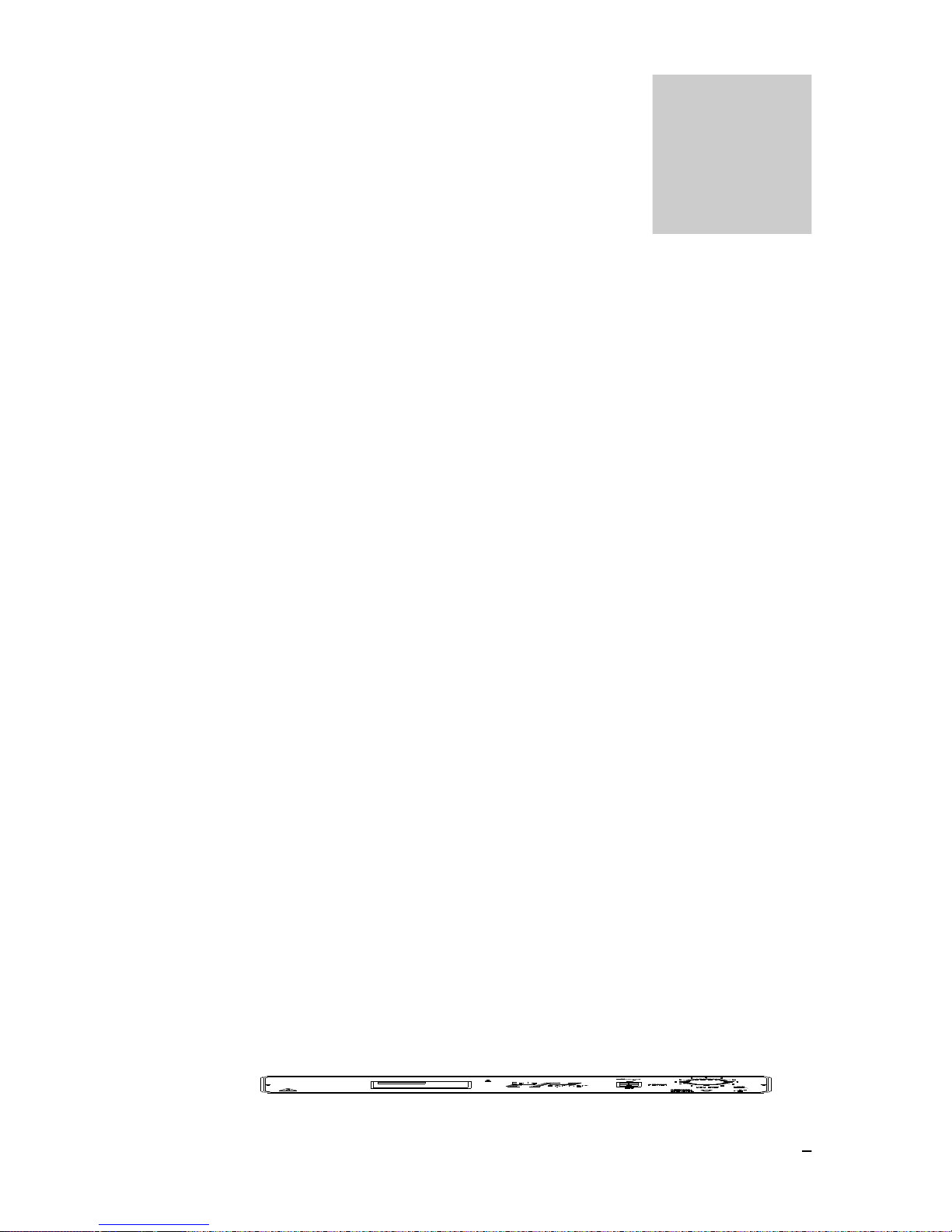

4.1 Power Switch: The main power I/O (on/off) switch controls all power to the unit

and must be in the I/ON position before any systems are operational.

4.2 High Limit Thermostat: This control is marked HIGH LIMIT and is equipped

with an adjustable knob and a graduated dial from 0-10. It is independent of the

Main Controller and guards against any failure which would allow the

temperature to rise past the Main Controllers set point. This allows continued

operation of the oven until the problem can be corrected or service can be

arranged. It is not recommended that the unit be operated for extended periods

of time using only the Overtemperature Safety as the controller as temperature

uniformity will suffer.

4.3 High Limit Activated: This pilot lamp will come on when the High Limit

Thermostat is activated and taken control of the heating element. Under normal

operating conditions this pilot lamp should never be on.

4.4 Main Temperature Controller: This is a microprocessor based temperature /

Time Control with ramp and soak capabilities ( Watlow model 981 ).

4.5 Fuse: Located at the back of the unit next to the power cord, the fuse provides

protection for the units electrical circuitry against power fluctuations. When

blown, the fuses must be replaced before the unit can continue operation.

4.6 Power Exhaust Outlet: Located at the back of the unit next to the power cord,

for easy installation of a power exhaust accessory. The 05012-30 does not come

equipped with this feature.

Figure One

77

77

Page 8

Section

5

PRECAUTIONS

5.1 This unit has been designed with vents from the chamber. In order to work

effectively and safely, some precautions will need to be taken by the operator.

a. In most applications, the exhaust damper will need to be open during

drying or degassing for best results.

b. THIS OVEN IS NOT DESIGNED TO HANDLE COMBUSTIBLE GASSES,

AND IS NOT AN EXPLOSION PROOF OVEN. DO NOT PLACE

EXPLOSIVE, COMBUSTIBLE OR FLAMMABLE MATERIALS INTO THE

CHAMBER.

c. Some of the out gassed byproducts may be hazardous or unpleasant to

operating personnel. If this is the case, the exhaust should be positively

ventilated to the outside and dealt with according to local regulations.

Contact your dealer about power exhausts.

5.2 Do not operate near noxious fumes.

5.3 Do not place sealed or filled containers in the oven chamber.

5.4 Do not cut or remove the ground prong from the power cord.

5.5 Do not use a 2-prong adapter plug.

5.6 Be sure that the power supply is as the same voltage as specified.

5.7 Disconnect the unit from its electrical source before proceeding to make any

electrical repairs or replacement.

5.8 If a mercury thermometer is used and breakage should occur, all spilled mercury

MUST be completely removed from the chamber before continuing operation.

5.9 This oven is NOT designed for the use in Class I, II, or III locations as defined by

the National electric Code.

5.10 This oven is not intended, nor can it be used, as a patient connected device.

88

88

Page 9

Section

6

CLEAN ROOM READY INSTRUCTIONS

The 05012-30 and 05012-40 have been designed to operate at class 100 standards. It

is not shipped clean room ready and the instructions below must be followed for proper

installation. See Figures Two and Three.

6.1 BURN-IN OF THE HEPA FILTER

Before using this oven, it is important that the filter be Òburnt-inÓ properly. During

burn-in, the Hepa filter will off gas. Because of this, the intake and exhaust port

must be open with the exhaust port being ducted outside. A material safety data

sheet is included with your operation literature for reference.

A. To burn in filter:

1. Set oven at: 175°C for 1 hour;

220°C for 4 hours;

225°C for 1 hour;

250°c for 1 hour.

2. If operating temperature is higher than 250°C, continue the cycle of

one (1) hour at 25° increments until the operating temperature is

achieved.

B. After burn-in, the interior must be disassembled and cleaned. Make sure

unit is unplugged before disassembly. This requires an 8/32 nut driver to

remove the cap nuts. Remove the bottom liner insert before removing the

liner side inserts.

6.2 CONTROL AREA EXHAUST

As part of this design the control compartment is sealed and requires a minimum

of 30 C.F.M. (Cubic Feet Per Minute) to be drawn from the control compartment

exhaust port. This is required to limit control compartment temperature and

maintain Class 100 integrity. If you are unable to exhaust the minimum 30

C.F.M. from the control compartment, then you must limit the maximum operating

temperature to 280°C. Operation of the unit above 280°C, without required 30

C.F.M. control compartment exhaust will result in control degradation and

99

99

Page 10

process failure. Not supplying the required 30 C.F.M. may also keep the unit

from operating at class 100 specifications by allowing particulars from the control

compartment to escape into the room.

Figure Two

05012-40 Intake/Exhaust

111100

00

Page 11

Figure 3

05012-30 Intake/Exhaust

111111

11

Page 12

Section

7

OPERATION

7.1 Power Supply: As mentioned is Section 3.1, be certain the power source

matches the requirements listed on the data plate.

7.2 Turn the power switch to the I/ON position and turn the High Limit Thermostat to

its maximum position, clockwise. This allows the setting of the Main

Temperature without interference of the High Limit..

7.3 Set Main Temperature Controller: This is explained in full detail in the enclosed

Watlow 982 users manual. A simplified 981 instruction sheet is included with the

manual for your convenience. Please refer to the users manual and instruction

sheet for operation and maintenance details.

7.4 Set High Limit Thermostat: Prior to setting the High Limit Control be certain the

Main Temperature Control has reached the input set point and has remained

stable for several hours. This will insure that the High Limit is set at the proper

temperature. As mentioned in step 7.2, the High Limit should be at maximum

position. Now turn the Thermostat counterclockwise until the High Limit

Activated indicator light comes on. Next, turn the Thermostat clockwise just until

the light turns off. Then turn the Thermostat two (2) of the smallest divisions on

its scale past the point where the indicator light went out. The High Limit should

now be set approximately 10° higher than the Main Temperature Controller.

Please note that the High Limit is a safety feature only. If the unit is allowed to

operate using only the High Limit Thermostat, the temperature stability will suffer.

7.5 Power Exhaust Outlet: The power exhaust outlet is controlled by the Main

temperature Controller. This is described in paragraphs 2 and 3 on the back

page of the 981 simplified instructions and in the Watlow 982 users Manual. The

05012-30 does not come equipped with this feature.

111122

22

Page 13

Section

8

MAINTENANCE

Note: Disconnect the power cord from the power source before performing any

service or maintenance on this unit.

8.1 Cleaning: Clean the oven interior and remove and clean shelves on a regular

basis. Use a disinfectant that is suitable for your application. DO NOT USE

chlorine based bleaches or abrasive cleaners as this will damage the stainless

steel interior. DO NOT USE spray cleaners that might leak through openings and

cracks and get on electrical parts or that may contain solvents that will harm the

coatings.

Warning: Never clean the unit with alcohol or flammable cleaners with the unit

connected to the electrical supply. Always disconnect the unit from the electrical

service when cleaning and assure all volatile or flammable cleaners are

evaporated and dry before reattaching the unit to the power supply.

8.2 Use care when cleaning the door gasket to prevent damage which could impair

the positive door seal.

8.3 Storage: To prepare the unit for storage, remove all shelves and shelf clips. Be

certain that the door is positively locked in the closed position. See Section 3.3,

Lifting/Handling, for proper transport procedures.

8.4 No maintenance is required on the electrical components. If the unit fails to

operate as specified, please see the Troubleshooting guide, Section 9.0 before

calling for service.

111133

33

Page 14

Section

9

TROUBLESHOOTING & SERVICE

FOR PERSONAL SAFETY, ALWAYS DISCONNECT THE POWER BEFORE

SERVICING. If the unit fails to operate as specified, review the following

troubleshooting suggestions prior to calling customer service.

TEMPERATURE

Temp-1Temperature too high

1/ controller set too high-see your Watlow users

manual

2/ controller failed on Ð call Customer Service

3/ wiring error Ð call Customer Service

Temp-2Chamber temp spikes

over set point and

then settles to set

point

Recalibrate Ð see Watlow users manual

Temp-3Temperature too low

1/ high limit set too low Ð see section 7.4

2/ controller set too low Ð see Watlow users manual

3/ unit not recovered from door opening Ð wait for

display to stop changing

4/ unit not recovered from power failure or being

turned off Ð ovens will need several hours to warm up

and stabilize

5/ element failure Ð call Customer Service

6/ controller failure Ð confirm with front panel lights

that controller is calling for heat

7/ high limit failure Ð confirm with front panel lights

that High Limit is operating correctly

8/ wiring problem Ð check all functions and compare

wiring to owners manual - especially around any areas

recently worked on

9/ loose connection Ð check shadow box for loose

connections

44

111144

Page 15

Temp-4Unit will not heat over

a temperature that is

below set point

Temp-5Unit will not heat up at

all

Temp-6Indicated chamber

temperature unstable

1/ confirm that blower motor is moving and that

amperage and voltage match data plate Ð check blower

motor motion in shadow box and feel for air movement

in chamber

2/ confirm that set point is set high enough Ðturn High

Limitcounter clockwise and see if High Limit light

comes on

3/ check connections to sensor

4/ check calibration Ð using independent reference

thermometer, follow instructions in Watlow users

manual

1/check amperage Ð amperage should be virtually at

maximum rated (data plate) amperage

2/ do all controller functions work?

3/ is the High Limit set high enough? Ð for diagnostics,

should be fully clockwise with the pilot light never on

4/ has the fuse/circuit breaker blown?

1/ ±0.1 may be normal

2/ is blower motor working? Ð remove top panel and

verify movement of blower motor in shadow box

3/ is ambient room temperature radically changing Ð

either door opening or room airflow from heaters or air

conditioning ? Ð stabilize ambient conditions

4/ it may happen if exhaust stack is 100% open or if

power exhaust is cycling Ð adjust stack to at least _

closed

5/ sensor miss-located, damaged or wires may be

damaged - check mounts for control and High Limit

sensors, then trace wires between sensors and

controls

6/ calibration sensitivity Ð call Customer Service

7/ high limit set too low Ð be sure that high limit is

more than 5 degrees over desired set point; check if

high limit pilot is on continuously; turn controller knob

completely clockwise to see if problem solved then

follow instructions in section 7.4 for correct setting

8/ electrical noise Ð remove nearby sources of RFI

including motors, arcing relays or radio transmitters

9/ bad connection on temperature sensor or faulty

sensor Ð check connectors for continuity and

mechanical soundness while watching display for

erratic behavior; check sensor and wiring for

mechanical damage

111155

55

Page 16

Temp-7Will not maintain set

point

Temp-8Display and actual

reference thermometer

donÕt match

Temp-9Can't adjust set points

or calibration

Temp-10Calibrated at one

temperature, but not at

another

10/ bad connections or faulty solid state relay Ð check

connectors for mechanical soundness and look for

corrosion around terminals or signs of arcing or other

visible deterioration

1/ ASSURE THAT SET POINT IS AT LEAST 5

DEGREES OVER AMBIENT ROOM TEMPERATURE

2/ see if ambient is fluctuating

1/ calibration error Ð see Watlow users manual

2/ temperature sensor failure Ð call Customer Service

3/ controller failure Ð call Customer Service

4/ allow at least two hours to stabilize

5/ verify that reference thermometer is certified

1/ turn entire unit off and on to reset

2/ if repeatedly happens, call Customer Service

This can be a normal condition when operating

temperature varies widely. For maximum accuracy,

calibration should be done at or as close to the set

point temperature.

111166

66

Page 17

Mech-1 Door not sealing

Mech-2 Motor doesn't move

Mech-3 Motor makes noise

MECHANICAL

1/ check physical condition of gasket

2/ assure that gasket is in original location

1/ if shaft spins freely: check connections to motor

and check voltage to motor;

2/ if shaft rubs or is frozen, relieve binding and retest

1/ If noise is from the motor, tap the top of motor shaft

with ball peen hammer.

2/ If the sound gets worse, tap the other end of the

shaft Ð avoiding touching the blower wheel.

3/ If there is no change, call Customer Service.

Other-1 Controller on at all

times - "locked-up"

Other-2 Controller timer resets

on its own

Other-3 Front panel displays

are off

Other-4 Unit or wall

fuse/circuit breaker is

blown

OTHER

1/ turn unit off and on to reset

2/ if cannot change any condition on the front panel,

call Customer Service

1/ confirm that power from wall is consistent and

within specs

2/ call Customer Service with serial number

1/ Check for wire damage.

1/ check wall power source

2/ compare current draw and compare to specs on

data plate

3/ see what other loads are on the wall circuit

111177

77

Page 18

Other-5 Unit will not turn on

Other-6 Unit is smoking Ðout

of box

OtherÐ7Contamination in

chamber

Other-8 Contamination in

sample

.

1/ check wall power source

2/ check fuse/circuit breaker on unit or in wall

3/ see if unit is on, e.g., fan or heater, and just

controller is off

4/ check all wiring connections, esp. around the on/off

switch

1/Put unit under vent and run at full power for one

hour.

2/Models 1601 and 1605 follow special burn in

procedures in section 6.0

1/ see cleaning procedure in operatorÕs manual

2/ develop and follow SOP for specific application;

include definition of cleaning technique and

maintenance schedule

1/ see ÒContamination in chamberÓ

2/ reduce air flow in chamber by dampening down inlet

restrictor; be sure to verify adequate temperature

uniformity at the reduced air flow

3/ protect open samples from areas of maximum air

current, e.g., inlet air ducts

If this product should require service, contact your service representative. For

information on where to reach customer service please see the front cover of this

manual. Should return of the product be necessary, a return authorization number must

be obtained and the product shipped, per instructions, to the indicated service center. If

a return authorization number is not obtained the product will be returned back to the

sender the same day it is received. To insure prompt handling, the return authorization

number should be placed on the outside of the package and a detailed explanation of

the return enclosed with the item.

111188

88

Page 19

Section

0

1

PARTS LIST

Description Part #

Adjustable Feet 200129

Blower Motor 4880512

Control Relay 102162

Convenience Outlet 101483

Cooling Fan 210001

EMI Filter - CE Complied Models 2800503

Fuse, 20 Amp ABC 101341

Heating Element Ð 05012-20, 05012-40 120073

Heating Element Ð 05012-30 200114

Hepa Filter Assembly Ð 05012-30 X1000577

Hepa Filter Assembly Ð 05012-40 9990503

High Limit Controller 1750571

High Limit Indicator Pilot Lamp 200020

On/Off Switch 103351

Power Cord 1800509

Power Relay 100064

Shelf Clips 200137

Temperature Probe 101827

Watlow 981 Main Temp. Controller 1750540

111199

99

Page 20

UNIT SPECIFICATIONS

Weight Shipping Net

05012-20 315 179

05012-30

05012-40 315 179

Call Customer

Service

135

Dimensions

05012-20 32X30.5X36.5 20X19X19

05012-30 28.5X25.5X29.25 16.5X13.75X15

05012-40 32X30.5X36.5 17X19X19

WxDxH (in.)

Exterior

Interior

WxDxH (in.)

Capacity Cubic Feet

05012-20 4.17

05012-30 1.96

05012-40 3.55

Temperature Range Sensitivity

05012-20

05012-30

05012-40

Amb. +5-200°C

Max 350°C

Amb. +5-200°C

Max 350°C

Amb. +5-200°C

Max 350°C

0.1

0.1

0.1

222200

00

Page 21

WIRE DIAGRAM

222211

11

Loading...

Loading...