Page 1

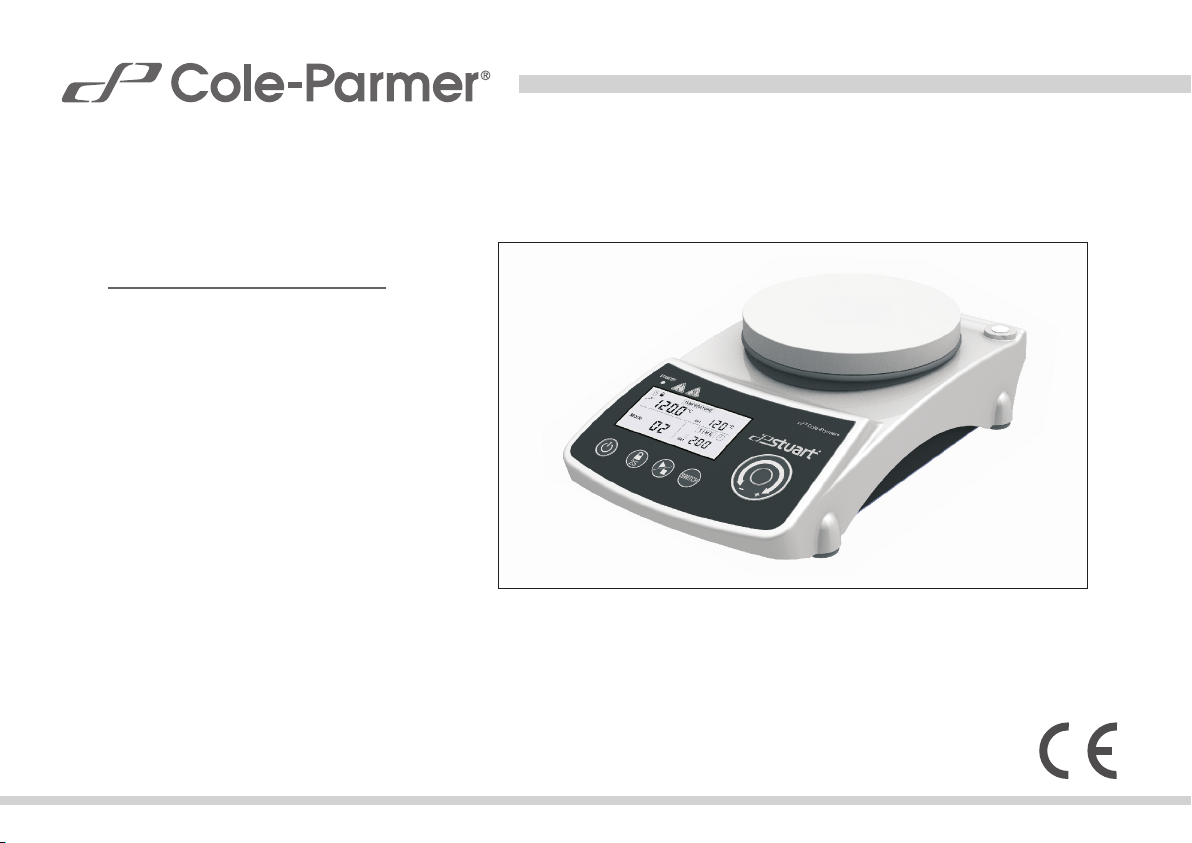

User manual

Hot plate

04661- 23

04661- 24

Page 2

Page 3

Contents

Safety instruct ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance and c leaning . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Support rod i nstallation

Switching on . . ... . . . . . . . . ... . . . . . . . . ... . . . . . . . . ... . . . .

Plate overview ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting safety te mperature . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting heating tempera ture . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locking functio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch off and data savin g . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting g uide ..... . . . . . . . . . . . . . . . . . . . . . . . . .

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard accessories

User man ual

Hot plate

04661-23

04661-24

1 23

3

4

5

6

7

8

9 1112

12

13 1415

User manual ×1

Power

line ×1

Page 4

Safety instructions

·When operating the magnetic stirrer, please follow the safety instructions, the accident prevention regulations, and pay attention to your

occupational health.

· Notice: Effects of magnetic field should be taken into account(e.g.data storage, cardiac pacemakers...)

· Risk of burns! The heating plate can reach a high temperature of 280 °C when the stirrer is working. Please exercise caution when

touching the outer housing and the heating plate. Pay attention to the residual heat even after the instrument is shut down.

!!

· Ensure that the power cord does not make contact with the heating plate.

· Wear appropriate protective equipments when operating.

!!

Otherwise there may have risks from:

- Splashing of medium

- Release of toxic or flammable gases

·Place the instrument on a stable, clean, anti-slip, dry and fireproof surface.

·Ensure the base of instrument is clean and intact.

· Beware of hazards due to:

!!

- Flammable materials

- Low-boiling flammable medium

- Improper container size

- - Overflows of the medium

The container is in an unsafe condition

• The instrument may be heated up under normal use.

• Process pathogenic materials only in airtight container within a suitable fume hood.

•

Do not operate the instrument in explosive atmospheres, with hazardous substances or under water.

!!

• Only use medium that will not react dangerously with the energy generated through processing or through other ways e.g. Light.

• Safe operation is only guaranteed with the accessories described in the ‘Optional accessories’ section.

• Please use the accessories listed on the manual in accordance with the operating instructions.

• Accessories must be securely installed and firmly attached to the instrument and the centre of gravity of the assembly must lie within the

surface on which it is set up.

21211

Page 5

Safety instructions

• Always disconnect power before installing accessories.

• The instrument can only be disconnected from the power supply by pulling out the power plug.

• Caution: Do not spill corrosive liquids on the instrument!

!!

• Caution: High voltage!The appliance should be opened only by professionally trained maintenance and repair personnel.

!!

• The mains voltage must be in accordance with the voltage marked on the nameplate.

• Unplug the instrument from the electric outlet if it will be unused for a long period of time.

• Do not cover the device with cloth or plastic film, or the instrument will be overheat.

• Keep the instrument and accessories from pressing and colliding.

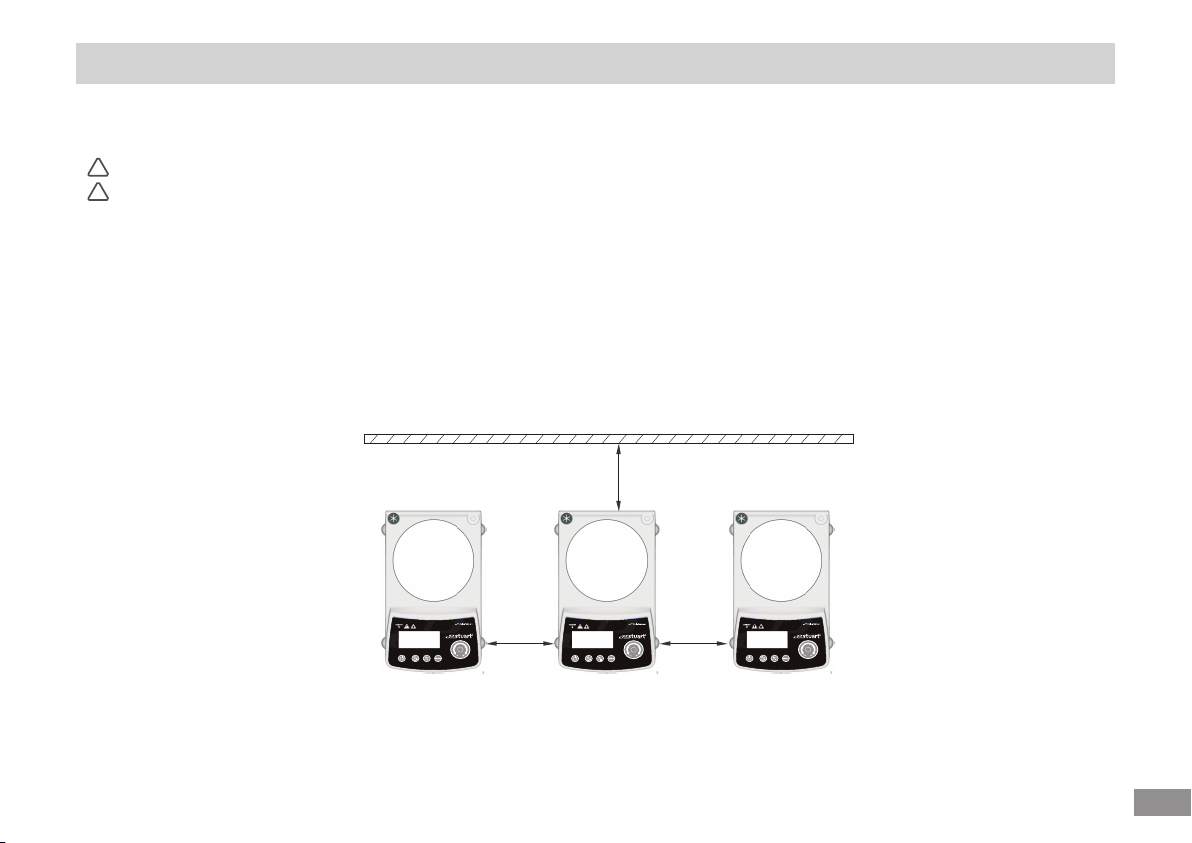

• The minimum distance between the instrument and above should be 800mm.

• Ensure the distance between the instruments and the distances between the instrument and the surrounding walls is at lease 100mm.

>10 0m m

>10 0m m >10 0m m

2

Page 6

Maintenance and cleaning

• Keep the surface of the plate clean and intact.

• Unplug the power line before cleaning.

• Minimize exposure to moisture when cleaning instrument.

• Wear protective gloves when cleaning.

• We only recommend using the cleaning methods listed below, using alternate cleaning methods may cause damage to the instrument.

Suggested cleaning methods:

Dyes------------------------Isopropyl alcohol

Construction materials------Water containing active agent / isopropyl alcohol

Cosmetics-------------------Water containing active agent / isopropyl alcohol

Foodstuffs ------------------Water containing active agent

Fuels------------------------Water containing active agent

Warranty

• This instrument is warranted for a period of 24 months from the date of invoice. For claims under the warranty please contact Cole Parmer . After receiving confirmation from our warranty department, you will be liable for freight costs.

• The warranty does not cover normal wear and tear of parts or accessories, nor does it apply to improper use, abnormal operation or

insufficient maintenance which is not in accordance with the instructions in this user manual.

• Make sure the instrument is clean and free from any materials that may harm people before sending for repair.

• Please send the instrument back to Cole-Parmer in its original packaging. If you couldn’t find the original packaging, ensure to use

suitable packaging to protect the instrument during transportation.

21213

Page 7

Support rod installation

If using external temperature sensor to measure temperature of the medium, please install support rod, horizontal head

clamp, horizontal holding rod and external temperature sensor.

1

Remove the white protective cap of the tapped hole

2

Remove the protective cap from support rod

3

Screw the support rod into the tapped hole, until the end stop is reached

4

Using a wrench to tighten the nut on the support rod

Install horizontal head clamp and horizontal holding rod as illustrated

5

Install external temperature sensor

6

Support rod

Screw nut

Support rod

Pt100 0s S lotted ho le

Horizontal

holding rod

Horizontal head clamp

Senso r in terf ace

Attenti on !

When pl ug i n the senso r, make

sure th e arrow p oint upwa rd.

Pt1000s temperature sensor

4

Page 8

Switching on

Preparation before start up

C

heck that the power voltage is in accordance with the voltage marked on the nameplate and the electric outlet is well grounded.

1

The instrument may be damaged and there may be security problem if someone does not strictly follow the above instruction. The

instrument should be operated under appropriate temperature and humidity according to the technical parameters in this manual.

Set the power switch on the back of the device to the “O” (Power off) position.

2

3

Connect the power line.

21215

Mode

Power voltage

Power frequency

Powersocket

Switching on

1

Set the power switch to the “ | ” (Power on) position and the “Standby” indicator will be lit and the system enters into standby status.

2

Press (Power on / off) to activate the instrument, and then the standby indicator will go off.

Powerswitch

04661-23

115V±10%

04661-24

220V±10%

~50/60Hz

Page 9

Plate overview

Hot warning

indicator

LCD display

Power on/off

Lock key

Start/Stop

Switch

显示 屏

To uc h wh ee l

Rod tapped

hole

Heating plate

5 1

6

7

8

34

9

2

10

Item Designation

1

Setti ng t emperat ure

2

Plate s af ety tempe rature ic on

3

Real- ti me temper ature

4

Key -l ock icon

5

Heati ng i con(Dyn amical)

6

Exter na l sensor ic on

7

Heati ng p late icon

8

Mode ic on

9

Mode di sp lay

10

Heati ng t iming /Co nstant te mp erature timing i con

11

Timer s et ting time / Timer rem ainin g ti me

12

Timin g ic on(Dyna mical)

1211

6

Page 10

Setting safety temperature

Notice! If using an external temperature sensor (Pt1000s) to measure the temperature of the liquid medium, user must connect the

!!

external temperature sensor and probe into the liquid medium before activating the heating function. Do not remove the external

temperature sensor during the heating, otherwise the internal components will be damaged.

Do not set the safety temperature higher than the ignition point of the medium used. The safety temperature should be set at least

!!

25 degrees lower than the ignition point of the medium.

1

Press (Power on/off) until standby indicator goes off and the system enters into setting operation status. The LCD screen will be

lightened and (Plate safety temperature icon) will flash showing that the system is now in the setting area of plate safety

temperature;

2

When the safety temperature setting is switched on, then touch and move your

finger around the “Touch wheel” (clockwise+ / counterclockwise-) to adjust the

setting data of safety heating temperature with the adjustable increment of 1°C,

and total adjustable range is . After setting the safety temperature,

the heated top plate temperature will not exceed the setting safety temperature

to keep the liquid medium from damage;

3

After the safety temperature is finished, press (Start/Stop) or “Switch” key to record and save the safety temperature

setting and system will automatically switch to heating temperature setting area;

50°C ~360°C

If the safety temperature is not been set in 15 second, the indicator on the LCD screen will be deemed to be the safety heating

temperature and the system will automatically switch to heating temperature setting area;

The safety temperature can only be set right after pressing button, and cannot be set again during operation. Once the safety

heating temperature is set, it cannot be adjusted again until next start up.

Notice

The setting of plate safety temperature is to make sure the sample liquid will not be damaged. However if the initial plate

temperature is too low, it will slow down the heating speed, therefore, if the plate temperature, considering the sample liquid ,

is allowed to be set higher than the safety temperature, please set the plate to the highest safety temperature 360°C, it will

help to accelerate the heating speed.

21217

!!

Page 11

Setting heating temperature

Start heating

Press “Switch” key until the “Set” indicator on the temperature setting section flashes and the system will enter into heating

1

temperature setting status;

When the heating temperature setting is switched on, then touch and move your finger around the “Touch wheel”

2

(clockwise+ / counterclockwise-) to adjust the heating temperature with the adjustable increment of 1°C;

Plate temperature setting range

Sensor temperature setting range

3

Press (Start/Stop) to start stirring after temperature setting, and the heating indicator will be shown on. When the

temperature of the hotplate is higher than 50°C, the hot top alter indicator will be on;

Notice: 1. When setting the heating temperature, the “heating temperature” must be 10°C less than the “Plate safety temperature”

2. When (Start/Stop) is pressed and the set temperature is lower than the temperature

the system will not perform the heating operation.

3. Do not heating the hotplate without Liquid in the container.

4

During the heating, user can repeat the above 1, 2 steps to alter the temperature setting.

Stop heating

To stop heating, press “Switch” key until the “Set” indicator on the heating setting section flashes and the system entering into stirring

speed setting status, then press (Start/Stop) to stop heating and the heating indicator will disappear.

temperature sensor,

Risk of burns!

°

the “Hot warning indicator” will not stop flashing until the temperature of the hotplate is lower than 50 C

When the temperature of the hotplate is higher than 50 C even after the device is shut down,

Room temperature - 340°C

Room temperature - 320°C

!!

actual measured by the

°

8

Page 12

21219

Setting the timer

Choosing timer mode

There are two timer modes as for 01 and 02

Mode 01: Heating timer mode.

The timer will start countdown instantly after activated. Heating function will be turned off when the countdown ends.

Mode 02: Constant temperature timing mode.

The timer will not start countdown until the heated liquid medium's temperature reaches the preset heating temperature.

Heating function will be turned off when the countdown ends.

Notice: The mode cannot be changed once the timer starts working

Setting the timer

Enable mode 01

Press“Switch” button until the “Mode” icon flashes, touch and move your finger around the “Touch wheel” (clockwise+ /

1

counterclockwise-) to choose mode 01 and press“Switch” button to confirm your choice. The “Set” icon will flash afterwards and the

system is set to timer timing setting status; (if the“Switch” button is not pressed within 15 seconds, the system will automatically

choose mode 01 as current mode.

2

When the timer function is on, touch and move your finger around the “Touch wheel” (clockwise+ / counterclockwise-) to adjust the

timer setting with the adjustable increment of 5 minutes and the setting time range 0 - 9 hours.

3

If the heating function is off:

When finished setting, press (Start/Stop) to start countdown and

heating function simultaneously. The “heating timer icon” and the

“timer icon” will be lit up simultaneously.

If the heating function is on:

After setting the timer's timing, press“Switch” button to confirm the

setting and start the countdown, the “heating timer icon” and the

“timer icon” will be lit up simultaneously. If the “Switch” button is

not pressed within 15 seconds, the system will automatically start the

timer function.

4

When the timer starts working, user can press ”Switch” button until the timing setting zone's “Set” icon flashes, then readjust the

timing setting through the “Touch wheel”.

Instant heating

timer mode

Timer icon

Page 13

Setting the timer

Enable mode 02

1

Press“Switch” button until the “Mode” icon flashes, touch and move your finger around the “Touch wheel” (clockwise+ /

counterclockwise-) to choose mode 02 and press“Switch” button to confirm your choice. The “Set” icon will flash afterwards and

the system is set to timer timing setting status; (if the“Switch” button is not pressed within 15 seconds, the system will automatically

choose mode 01 as current mode.

2

When the timer function is on, touch and move your finger around the “Touch wheel” (clockwise+ / counterclockwise-) to adjust the

timer setting with the adjustable increment of 5 minutes and the setting time range 5 minutes~9 hours.

3

If the heating function is off:

When finished setting, press (Start/Stop) to start heating function

and the “constant temperature timer icon” is lit up, the countdown

will not start until the heated liquid medium's temperature reaches the

preset heating temperature. When the countdown starts,

the “timer icon” will be lit up simultaneously.

If the heating function is on:

After setting the timer's timing, press “Switch” button to confirm the

setting, and the “constant temperature timing icon” is lit up,

the countdown will not start until the heated liquid medium's

temperature reaches the preset heating temperature. When the

Instant heating

timer mode

countdown starts, the “timer icon” will be lit up simultaneously.

If the “Switch” button is not pressed within 15 seconds,

the “constant temperature timing icon” will be automatically lit up.

4

When the timer starts working, user can press ”Switch” button until the timing setting zone's “Set” icon flashes, then readjust the

timing setting through the “Touch wheel”.

Timer icon

10

Page 14

Setting the timer

Disable the timer

When the mode 01 is on, if the user wants to disable the timer, he should press “Switch” button until the timing setting zone's “Set” icon

flashes and the system will enter into timing function setting status; then readjust the timing setting through the “Touch wheel” to 0:00,

press “Switch” button to confirm the operation and wait for 15 seconds until the timer is disabled and the “heating timer icon” and

the “timer icon” will go off simultaneously.

212111

Page 15

Locking function

Activate

Press (Function key) for more than 2 seconds in operation status, as a result,

all the keys on the operation panel will be locked, and the “Lock indicator” will be

shown on the LCD while all keys stop working.

Inactivate

Press (Function key) for more than 2 seconds when the lock function is on,

as a result, the lock function will be off, and the “Lock indicator” will disappear

while all keys start working again.

Switch off and data saving

Power off

1

2

Set the power switch on the back of the device to the “ ” position, the “Standby” indicator will go out and the device will be turn off.

Notice:Unplug the instrument from the electric outlet before being left unused for a long period of time。

Auto save function

When using to turn off the instrument, will be saved automatically and the system will automatically restore

the previous settings next time when user restarts the instrument.

2S

2S

Model:

04661-23

Press (Power on/off) then the device will go on standby and the “Standby” indicator will lit.

O

Risk of burns!

°

Notice: Unplug the instrument from the electric outlet before left it unused for a long period of time。

When the temperature of the hotplate is higher than 50 C even after the device is shut down, the “Hot warning indicator”

will not stop flashing until the temperature of the hotplate is lower than 50 C

!!

°

the related parameters

04661-24

12

Page 16

Troubleshooting guide

Before contacting your supplier in case of issue, please check below for troubleshooting some common issues.

Problem

Instruments does not on

Figures on LCD flash for no reason

or operation key does not function

Error Code

Error code display on the LCD screen when a malfunction occurs during operation

212113

Code

E 0.0

E 2.1

E 2.2

E 8.0

E16.1

Cause Solution

Temperature inside

device too high

Heating parts malfunction

Heating circuit malfunction

Safety temperature

circuit malfunction

Temperature control sensor

malfunction

Possible causes

The power line and the power outlet

is disconnected

The power socket is in poor electrical

contact condition or un-powered

The power voltage is lower

Effect

Heating function shutdown

Heating function shutdown

Heating function shutdown

Heating function shutdown

Solutions

Make sure the power line correctly

connected with the power socket

Replace the power outlet with the one in

good electrical contact condition

Turn off other high power instrument or add

another A.C.stabilized voltage power supply

Turn off the device and wait for it to cool down

Turn off the device

Warning! Only an authorized maintenance

and repair personnel can carry out an internal

checking on the heating part -s

Turn off the device

-Warning! Only an authorized maintenance and

repair personnel can carry out an internal checking

on the safety temperature circuit

Turn off the device

Warning! Only an authorized maintenance

-

and repair personnel can carry out an internal

checking on the temperature sensor

Page 17

Troubleshooting guide

Code

E16.2

E16.3

E16.4

E32.1

E32.2

E64.0

Example of LCD screen displays Error code

Cause

Temperature safety

sensor malfunction

Difference between temperature of

safety sensor and temperature of

control sensor is larger than 20 C

when not heated

Difference between temperature of

safety sensor and temperature of

control sensor is larger than 20 C

when heated

External temperature sensor is

plugged out during heating process

External temperature sensor

malfunction

Surface temperature of the base

plate is higher than the set safe

temperature

°

°

Effect

Heating function shutdown

Heating function shutdown

Heating function shutdown

Heating function shutdown

Solution

Turn off the device

-Warning! Only an authorized maintenance and

repair personnel can carry out an internal checking

on the temperature sensor

Turn off the device and restart it

Replace the malfunctioned Pt1000 Temperature

sensor or the external contact temperature sensor

Switch off device until the surface temperature of the

base plate is lower than the selected safe temperature

limit

14

Page 18

Technical data

Model

Heating power output

Heating temperature increases speed(1L H2O)

Safety temperature setting range

Plate temperature setting range

Sensor temperature setting range

Plate temperature control accuracy

External temperature sensor(Pt1000) accuracy

Timer

Display

Heating Plate Material

Heating Plate Size

Dimensions (W x D x H)

Weight

Power input

Permissible ambient temperature

Permissible relative moisture

Storage temperature

IP protection class (DIN EN 60529)

04661-23

600W

6.5°C/min

50 - 360°C

Room temperature - 340°C

Room temperature - 320°C

Aluminum alloy ceramic coating

5 - 40 (In operation)

±5°C

±1°C

0 - 9huors

LCD

Diameter 13

175 x 270 x 76mm

°C

80%

-10 - 70

IP42

2.1kg

620W

5mm

°C

04661-24

212115

Page 19

Page 20

Toll-Free: 1-800-323-4340

Phone: 1-847-549-7600

Fax: 1-847-247-2929

Coleparmer . com

Loading...

Loading...