Page 1

Model 02655-10

And

Model 02655-15

Flame Photometer

Operator Manual

Cole-Parmer Instrument Company

625 East Bunker Court

Vernon Hills

IL 60061

USA

425 91 002 Issue 9, 6th August 2008 ECN 527

G:\DOCUMENT CONTROL\Manuals\Flame\425\42591002 Cole Parmer M420 & M425 Operator Manual Issue 9.doc

Page 2

Model 02655-10 & 02655-15 Flame Photometer

Short Form Instructions Model 02655-10/15 Flame Photometer

The Default mode for the Model 02655-10/15 that will appear when the instrument is

switched on is: Dual channel Sodium and Potassium with Peak detection and Reference mode

selected. These instructions are to be used in the default mode.

NB In Reference Mode the Blank solution as well as the Calibration Standard

and Sample must contain 100ppm Li (Use the Blank solution to dilute the

Standards and Samples).

Operation: -

Set Up and Ignition

1. Ensure that the ‘U’ tube is full of deionised water.

2. Connect the gas supply (maximum 30psi Propane or Butane) via a Primary

regulator.

3. Switch on the compressor and regulate the air pressure to 11psi on the gauge

at the rear of the instrument.

4. Switch on the instrument with the “1/O” switch.

5. If the flame ignites then an auto sequence will test various circuits and end with

the ‘000’ flashing in both channel displays.

6. If the flame does not ignite, switch off, wait 15 - 20 seconds and repeat step 4.

It may take 3 or 4 attempts if the instrument has not been used for some time.

Blanking (Zeroing)

7. With the ‘000’ flashing aspirate the blank solution and press the ‘Blank’ button

once.

8. The instrument will then zero to the blank values; this will take at least 30

seconds; Remove the blank when complete.

Calibration

9. When the blanking procedure is complete, the previous calibration values that

were used will appear in the displays and the ‘Cal’ indicators will flash. If you

wish to calibrate to these values go to 11.

10. If you wish to change the values use the ‘+ and –’ keys before aspirating the

standard solution.

11. Then press the Sodium ‘Set’ button, then start aspirating the standard and

press the Potassium ‘Set’ button within a few seconds.

12. Once the instrument has calibrated itself then the ‘Cal’ lights will flash; remove

the standard and press ‘Set’ on both channels again.

Measuring a Sample

13. After 5 seconds both displays will flash and the “Measure” light will illuminate,

the first sample can now be measured.

14. Aspirate the sample and then immediately press the ‘Print/Measure’ button.

15. The instrument will measure the sample until the peak algorithm captures the

value and the measure light shows continuously. Remove the sample.

16. After 5 seconds the displays will flash and the next measurement can be made.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 2 -

Page 3

Model 02655-10 & 02655-15 Flame Photometer

Table of Contents

Page

Short Form Instructions Model 02655-10/15 Flame Photometer .................................................. 2

Operation: - ................................................................................................................................. 2

1 INTRODUCTION ........................................................................................................... 6

1.1 Contacting Cole-Parmer ...................................................................................... 6

1.2 Using this manual ............................................................................................... 6

1.3 Safety Precautions ............................................................................................... 7

1.4 Reagents ............................................................................................................. 8

Reference/Lithium Standard ................................................................................ 8

Blank Storage...................................................................................................... 8

Purification ......................................................................................................... 8

1.5 Dilutions ............................................................................................................. 8

Dilution Ratio ..................................................................................................... 9

Urine Samples ..................................................................................................... 9

2 INSTALLATION .......................................................................................................... 10

2.1 Location ............................................................................................................ 10

2.2 Services Required .............................................................................................. 10

Electrical Supply ............................................................................................... 10

Fuel ................................................................................................................... 10

Air .................................................................................................................... 10

Waste Container ................................................................................................ 10

2.3 Unpacking......................................................................................................... 11

Accessory List ................................................................................................... 11

2.4 Assembly .......................................................................................................... 12

2.5 Connecting Peripheral Devices .......................................................................... 16

Printer ............................................................................................................... 16

Computer .......................................................................................................... 16

Analogue Devices.............................................................................................. 16

Auto-sampler .................................................................................................... 16

2.6 Setting Date and Time....................................................................................... 17

2.7 Setting Filter Factors ......................................................................................... 18

2.8 Setting Units ..................................................................................................... 18

2.9 Setting Sample Delay (in Peak mode) ................................................................ 19

2.10 Setting the Output Voltage ................................................................................ 19

2.11 Setting the analogue damping coefficient. ......................................................... 19

3 PRINCIPLES OF OPERATION ..................................................................................... 20

3.1 Application of Flame Photometry ...................................................................... 20

3.2 Principles of Flame Photometery ....................................................................... 20

3.3 The Internal Standard Mode .............................................................................. 21

4 PERFORMANCE CHARACTERISTICS & SPECIFICATIONS ................................... 22

4.1 Readout ............................................................................................................. 22

4.2 Measurement Ranges ........................................................................................ 22

4.3 Specificity ......................................................................................................... 23

4.4 Accuracy ........................................................................................................... 23

Linearity ........................................................................................................... 23

Drift .................................................................................................................. 23

Reproducibility (using Peak mode) .................................................................... 23

Using Peak with Ref (Internal Standard) Mode.................................................. 23

4.5 Warm Up .......................................................................................................... 24

4.6 Sample Requirements ........................................................................................ 24

Type .................................................................................................................. 24

Method of Presentation...................................................................................... 24

Volume ............................................................................................................. 24

4.7 Chart Recorder Output ...................................................................................... 25

425 91 002 Issue 9, 6th August 2008 ECN 527

- 3 -

Page 4

Model 02655-10 & 02655-15 Flame Photometer

Page

4.8 Environmental Conditions................................................................................. 25

Temperature ...................................................................................................... 25

Humidity ........................................................................................................... 25

4.9 Power Requirements .......................................................................................... 25

Voltage ............................................................................................................. 25

Power ................................................................................................................ 25

4.10 Fuel ................................................................................................................... 25

4.11 Air .................................................................................................................... 26

4.12 Size ................................................................................................................... 26

4.13 Weight .............................................................................................................. 26

5 DESCRIPTION OF INSTRUMENT .............................................................................. 27

5.1 Front Panel Controls and Indicators .................................................................. 27

Primary Function .............................................................................................. 27

Secondary Function ........................................................................................... 27

Tertiary Function .............................................................................................. 27

Quaternary Function ......................................................................................... 27

Blank ................................................................................................................ 27

Channel selector ................................................................................................ 27

Mode Selector ................................................................................................... 27

Measure/Print.................................................................................................... 27

Channel 1 Set .................................................................................................... 27

Channel 2 Set .................................................................................................... 27

5.1.1 Controls ............................................................................................................ 27

‘-’ ‘Set’ ‘+’ ..................................................................................................... 27

(Feedback beep confirms the action) .................................................................. 27

Blank ................................................................................................................ 28

Single/Dual and Element Selection ................................................................... 28

Peak/Ref/Cont ................................................................................................... 28

Measure ............................................................................................................ 29

5.1.2 Description of Indicators ................................................................................... 29

Cal (Ch1 & Ch2) ............................................................................................... 29

Single................................................................................................................ 29

Dual .................................................................................................................. 29

Peak .................................................................................................................. 29

Ref .................................................................................................................... 29

Cont .................................................................................................................. 30

Measure ............................................................................................................ 30

Flame On .......................................................................................................... 30

Power On .......................................................................................................... 30

5.2 Rear Panel Controls and Connections ................................................................ 30

Channel 1 & 2 Data Outputs ............................................................................. 31

RS232/Printer Output ........................................................................................ 31

External Device Output ..................................................................................... 31

Power ................................................................................................................ 31

Gas ................................................................................................................... 31

Air .................................................................................................................... 31

Air Regulator .................................................................................................... 31

5.3 Operating Modes ............................................................................................... 32

5.3.1 Single/Dual Mode ............................................................................................. 32

Single................................................................................................................ 32

Dual .................................................................................................................. 32

Blanking ........................................................................................................... 32

Calibration ........................................................................................................ 32

5.3.2 Peak/Cont ......................................................................................................... 33

Peak .................................................................................................................. 33

The Peak Cycle ................................................................................................. 33

425 91 002 Issue 9, 6th August 2008 ECN 527

- 4 -

Page 5

Model 02655-10 & 02655-15 Flame Photometer

5.3.3 Ref Mode .......................................................................................................... 34

Cont .................................................................................................................. 34

5.3.4 Blank ................................................................................................................ 34

6 OPERATING THE INSTRUMENT .............................................................................. 35

6.1 Start Up ............................................................................................................ 35

6.1.1 Compressor Start Up ......................................................................................... 35

6.1.2 Switch On ......................................................................................................... 35

6.1.3 Ignition Successful ............................................................................................ 35

6.2.1 Required Blanking ............................................................................................ 35

6.2.2 Required Calibration ......................................................................................... 36

6.3 Sample Measuring ............................................................................................ 37

6.3.1 Measuring in Peak mode ................................................................................... 37

6.3.2 Measuring in Continuous mode ......................................................................... 37

6.4 Automatic operation .......................................................................................... 37

6.5 Sample Numbering ........................................................................................... 38

6.5.1 Reset of sample number..................................................................................... 38

6.5.2 Repeat sample ................................................................................................... 38

6.5.3 QC sample ........................................................................................................ 38

6.6 Shutdown Procedure.......................................................................................... 38

7 OPERATING HINTS, PRECAUTIONS & LIMITATIONS ........................................... 39

7.1 Hints ................................................................................................................. 39

7.2 Operational Precautions and Limitations ........................................................... 39

7.3 Hazards ............................................................................................................. 40

7.4 Measuring Calcium ........................................................................................... 40

8 CLEANING AND MAINTENANCE PROCEDURES ................................................... 41

8.1 General ............................................................................................................. 41

8.2 Daily Maintenance ............................................................................................ 41

8.3 Weekly Maintenance ......................................................................................... 41

8.4 Monthly Maintenance ....................................................................................... 41

8.5 Six Monthly Maintenance ................................................................................. 42

8.6 Nebuliser ........................................................................................................... 42

8.6.1 Operational Check ............................................................................................ 42

8.6.2 Cleaning the Nebuliser ...................................................................................... 43

8.7 Cleaning the Mixing Chamber, Burner and Drain ............................................. 43

8.7 Cleaning the Mixing Chamber, Burner and Drain continued ............................. 44

8.8 Cleaning the Glass Chimney ............................................................................. 44

8.10 Deproteinising or Disinfecting Procedure .......................................................... 45

9 ACCESSORIES, CONSUMABLES & SPARE PARTS ................................................. 46

9.1 Ordering Information ........................................................................................ 46

9.2 Spares and Accessories ...................................................................................... 46

9.3 Reagents ........................................................................................................... 47

APPENDIX A ........................................................................................................................... 48

BIBLIOGRAPHY ...................................................................................................................... 48

APPENDIX B ........................................................................................................................... 49

APPENDIX C ........................................................................................................................... 51

Cole Parmer Instruments Warranty Statement ........................................................................... 52

425 91 002 Issue 9, 6th August 2008 ECN 527

- 5 -

Page 6

Model 02655-10 & 02655-15 Flame Photometer

1 Introduction

1.1 Contacting Cole-Parmer

Postal address for letters and orders:

Cole-Parmer Instrument Company

625 East Bunker Court

Vernon Hills

IL 60061

USA

Telephone 847 549 7600

Toll Free 800 323 4340

Fax 847 247 2929

For Certificates of Analysis and Material Safety Data Sheet downloads, contacting Distributors and

Technical and Application information on our products go to our website

www.coleparmer.com

The following section must be carefully read before unpacking, installing, using, maintaining or

repairing the instrument and/or its accessories.

1.2 Using this manual

This manual is structured to allow both quick access to a measurement from the

default position of the Instrument (refer to Section entitled Short Form

Instructions on page 2) and an in depth understanding of the Set-up, Operation

and Maintenance of these two advanced Flame Photometers.

The information contained in this manual was correct at the time of going to print. However, Cole-Parmers’

policy is one of continuous product improvement and the right to change specifications, equipment and

maintenance procedures at any time, without notice, are reserved.

This manual is copyrighted, and all rights are reserved. No part of this manual may be reproduced by any means

or in any form without prior consent in writing.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 6 -

Page 7

Model 02655-10 & 02655-15 Flame Photometer

Introduction

continued

1.3 Safety Precautions

The Model 02655-10 and 02655-15 are intended for use by persons knowledgeable in

safe laboratory practices. If the instruments are not used in accordance with these

“Instructions for use”, the protection provided by the equipment may be impaired.

WARNING The Model 02655-10/15 are designed to be earthed (grounded) through

the power supply lead (line cord) for safe operation. For the safety of operating

personnel and optimum performance make sure that the instrument is only

connected to a 3-pin socket (outlet) that has an effective earth connection. If you

are in any doubt about the safety of your electrical supply system consult a

competent, qualified electrician.

There are no user replaceable parts within the instrument. Do not remove the rear

cover from the instrument.

Cole-Parmer Instrument Company and its authorised Distributors consider themselves responsible for the effects

of safety, reliability and performance of the Model 02655-10 and 02655-15 only if: ** Assembly operations, extensions, re-adjustments, modifications or repairs are only carried out by

persons authorised by them.

** The electrical installation of the relevant room complies with IEC requirements or the local regulatory

code.

** The equipment is used in accordance with the instructions for use.

PLEASE NOTE that no cables neither for power-in nor for signals-out to the printer, computer via

RS232 output nor analogue to a chart recorder, nor signal cables from an Autosampler nor any other

device should exceed 2.5 metres in length.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 7 -

Page 8

Model 02655-10 & 02655-15 Flame Photometer

Introduction

continued

1.4 Reagents

Cole-Parmer supply a wide range of reagents, including standards, diluent and

maintenance solutions, for use with the Model 02655-10 and 02655-15 Flame

Photometers. Please refer to Section 9.3 for a complete list of the reagents available.

Reference/Lithium Standard

The full benefit of the technology incorporated in the Model 0655-10/15 is utilised in

the default mode of operation. This mode, ‘Peak’ and ‘Reference’, requires that the

blank, standards and samples contain Lithium at the concentration of approximately

100ppm in the final solution that is aspirated. This is best achieved if the diluent

contains 100ppm Lithium. That is 100ml of the 1000ppm Li standard solution supplied

with the instrument (Part No. 001 56 622) diluted to 1 litre with the diluent described

in the following paragraph.

Blank Storage

All solutions should be stored away from direct sunlight, in a cool place (below

25°C/77°F), in an airtight container to prevent evaporation and discolouration. Glass

containers should not be used, as they can affect Na concentration levels. Prolonged

exposure to the atmosphere must be avoided to prevent evaporation of standard

solutions.

Purification

No purification is required for Cole-Parmer standard solutions.

1.5 Dilutions

Samples and standards should be diluted with the same batch of diluent, made up of 1

part Diluent Concentrate (Part # 001 56 181) to 999 parts good quality distilled water.

The same batch of diluent should be used to zero the Model 02655-10 and Model

02655-15 and to prepare dilutions of standards and samples. This will prevent

variations in water purity affecting the measurements.

Great care should be taken so that contamination does not occur when preparing the

samples and standards. Remember that the accuracy of the instrument is dependent on

the accuracy and purity of the Standards and Blank used for calibration.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 8 -

Page 9

Model 02655-10 & 02655-15 Flame Photometer

Introduction

continued

Dilution Ratio

The Model 02655-10/15 are optimised for the following Dilution Ratios: -

In Clinical Mode

Na & K both Serum and Urine: - 1:200 with diluent described above

(including Li if used in Reference Mode).

Li (Measurement) Dilution Ratio: - 1:50.

In Non Clinical Mode

The user should ascertain from his sample what is appropriate by reference to

the input concentrations listed in the specification in Section 4 pp 19/20.

To aid the dilution of clinical samples Cole-Parmer produce a Dilutor, the Model 805,

which automates the process and gives extremely reproducible dilution ratios and

therefore precise results.

Urine Samples

The Potassium content of urine samples is some 20 times that of plasma or serum. In

the past it has been necessary to pre-dilute urine samples prior to following a normal

dilution procedure with e.g. Model 805. The design of the Model 02655-10/15

however, minimises the need for this pre-dilution and urine samples with a Potassium

concentration of 120mmol/l or less can be treated in exactly the same way as plasma

and serum samples provided that the appropriate standard is used to calibrate the

instrument for the high Potassium value. Samples with a Potassium level greater than

120mmol/l should be pre-diluted 1 part in 5 prior to the normal dilution 1 part in 200.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 9 -

Page 10

Model 02655-10 & 02655-15 Flame Photometer

2 Installation

2.1 Location

WARNING Under no circumstances install the Model 02655-10/15 beneath

overhanging cupboards. There must be at least 1 metre of clear space

above the chimney.

For optimum performance, this instrument should be installed in

accordance with the following conditions: -

2.1.1 The environment must be clean and free from dust.

2.1.2 The instrument must be placed on a strong, level worktop, free from

vibration. The Model 02655-10/15 requires approximately 500mm x

500mm of bench space, which includes an area in front for solutions

and clearance at the rear for fuel and air tubing, with clear access to the

mains supply switch.

2.1.3. Avoid sites that expose the instrument to direct sunlight or draughts.

2.1.4. To meet the specification the ambient temperature must be within the

range +10°C to +35°C and the maximum relative humidity must not be

more than 85%, non-condensing.

2.2 Services Required

Electrical Supply

An A.C. supply between 90V and 240V ±10%, at 50Hz or 60Hz, is required for the

Model 02655-10 and 02655-15. The instrument is powered from an external power

supply, which will accommodate these voltages without any need to adjust the

instrument.

Fuel

A supply of Propane, Butane or Propane/Butane mixture regulated at the cylinder to

2.1kg/cm2 (30psi), flow rate at least 0.4 litres per minute.

(NB. Propane only, gives the best results for Ca on the Model 02655-15).

Primary regulators to fit cylinders are available from Cole-Parmer, regulators are

available as optional accessories, refer to Section 9.2.

Air

A supply of clean, dry, oil-free air at 1kg/cm2 (11psi), flow rate 6 litres per minute. A

suitable air compressor is listed in Section 9.2.

Waste Container

A sink or waste container sited to the right of the instrument will ensure the minimum

length of waste tubing. Do not use a waste container with high sides, as this will cause

the drain tube to be lifted above the level of the constant head drain.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 10 -

Page 11

Model 02655-10 & 02655-15 Flame Photometer

Installation

continued

2.3 Unpacking

1. Unpack the instrument and accessories.

NOTE The Model 02655-10/15 weighs 9.5kg; follow safe lifting techniques.

2. Check all items for damage.

3. Check that all the items on the Accessory List have been delivered. Contact

your Sherwood Scientific distributor if you have any problems.

4. The Model 02655-10/15 is shipped with the following items: -

Accessory List

CAT. NO. DESCRIPTION QUANTITY

001 72 043 Air tubing, nylon reinforced 2 metres

001 72 114 Fuel tubing 2 metres

400 22 002 Drain tube, 200 mm, and spare tube 200mm 1 pack

001 53 420 Universal external power supply 1

100 99 010 Nebuliser cleaning wire, pack of 3 1 pack

001 31 076 'O' ring, spare for mixing chamber 1

420 08 102 Nebuliser 1

400 22 003 Nebuliser inlet tube, polythene, 150 mm 1

425 91 002 Operators manual

926 09 052 RS232 Output Cable 1

001 08 718 'Unex' tubing clamp 4

001 56 100 Standard Solution containing l40.0mmol/l Na,

5.00mmol/l K and 1.5mmol/l Li

001 56 622 Lithium 1000ppm Standard, 6 x 100ml 1 pack

001 56 620 Sodium 1000ppm Standard, 6 x 100ml 1 pack **

001 56 621 Potassium 1000ppm Standard, 6 x 100ml 1 pack **

001 56 623 Calcium 1000ppm Standard , 6 x 100 ml 1 pack ***

410 92 001 CDROM, Flame Training Guide 1

* supplied with Clinical instruments.

** supplied with Industrial instruments.

*** supplied with Model 02655-15.

1

1 x 100 ml*

425 91 002 Issue 9, 6th August 2008 ECN 527

- 11 -

Page 12

Model 02655-10 & 02655-15 Flame Photometer

Installation

continued

2.4 Assembly

EQUIPMENT REQUIRED: 'Pozidriv' (cross head) screwdriver 1PT

Flat blade screwdriver.

To assemble the instrument, proceed as follows: -

1. Lift off the chimney cap from the chimney assembly and lift out the glass

chimney. Remove any packing material from inside, making sure that there are

no small pieces left within the chimney.

2. Replace the glass chimney with the clear strip at the bottom and refit the

chimney cap on top of the chimney.

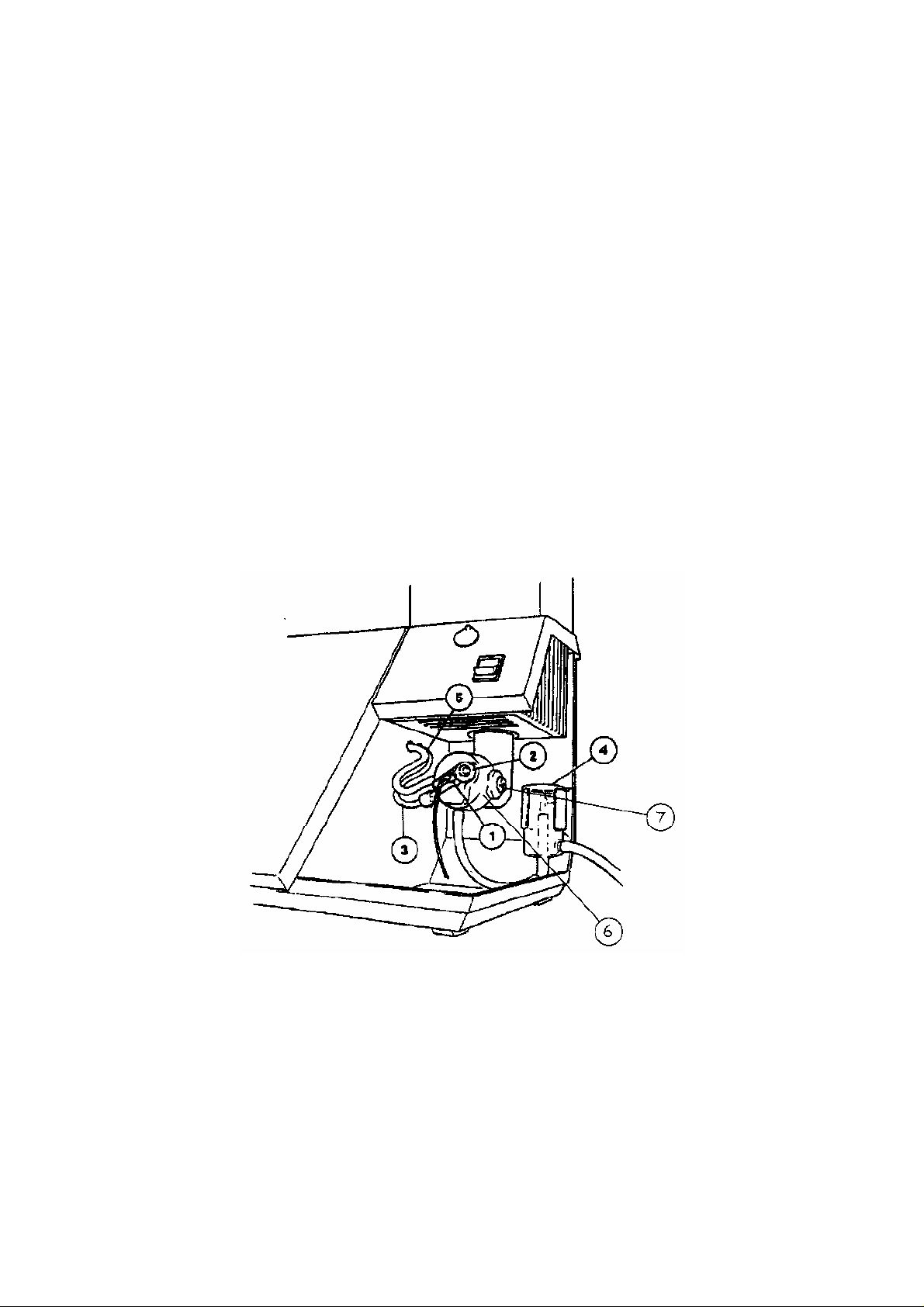

3. Remove the Nebuliser (420 08 102) from its box and push the barbed

connector in to the end of the air tubing (item 3, figure 2.1). Fit the Nebuliser

(item 1, figure 2.1) to the mixing chamber and position the retainer (item 2,

figure 2.1) to lock it into position. Locate the Nebuliser inlet tubing (400 22

003) and fit over the narrow tube in the front of the Nebuliser.

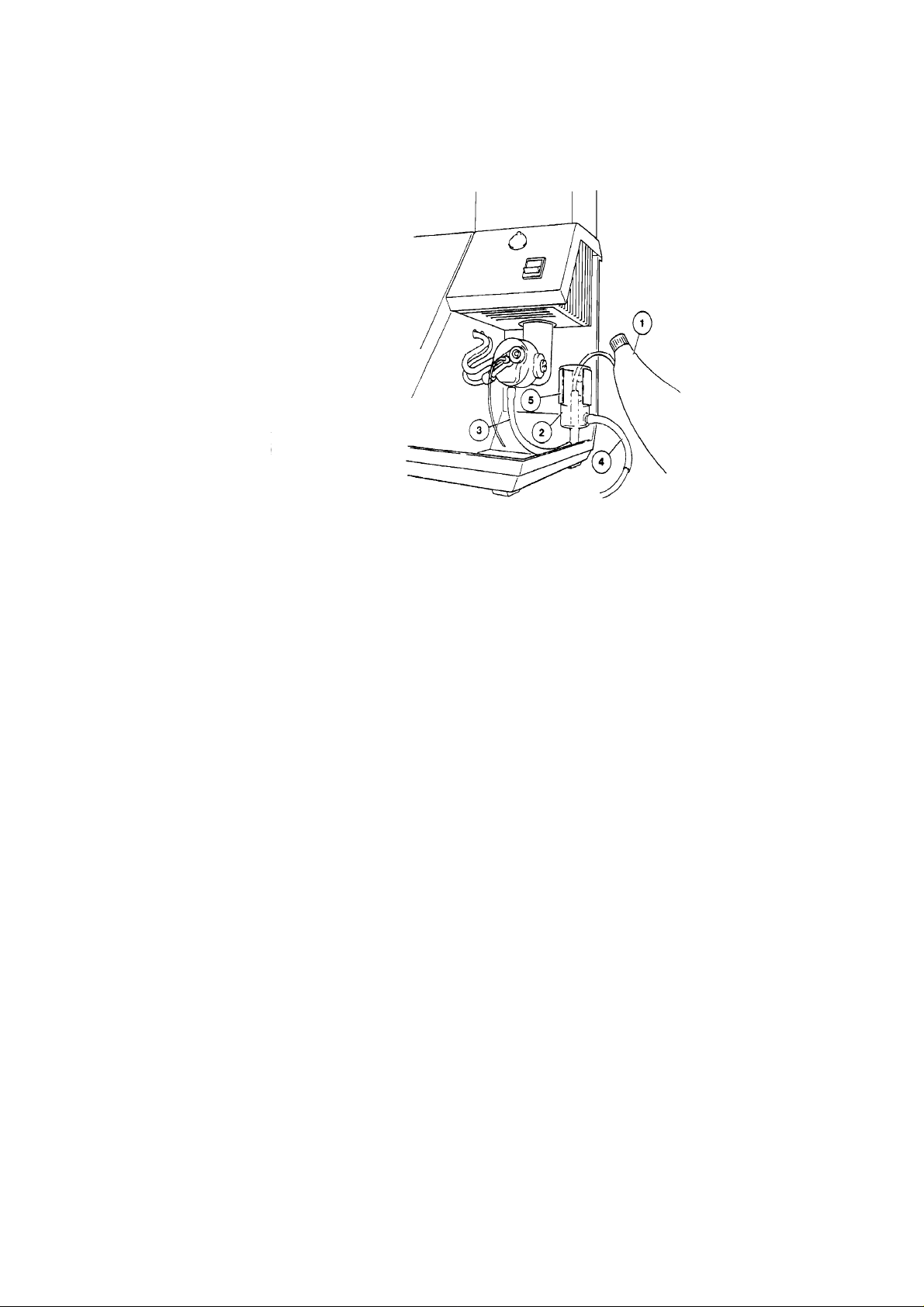

Figure 2.1 Mixing Chamber

1. Nebuliser, 2. Nebuliser retainer, 3. Air tubing, 4. Constant head & drain, 5. Fuel tubing.

6. End Cap, 7. Securing Screw.

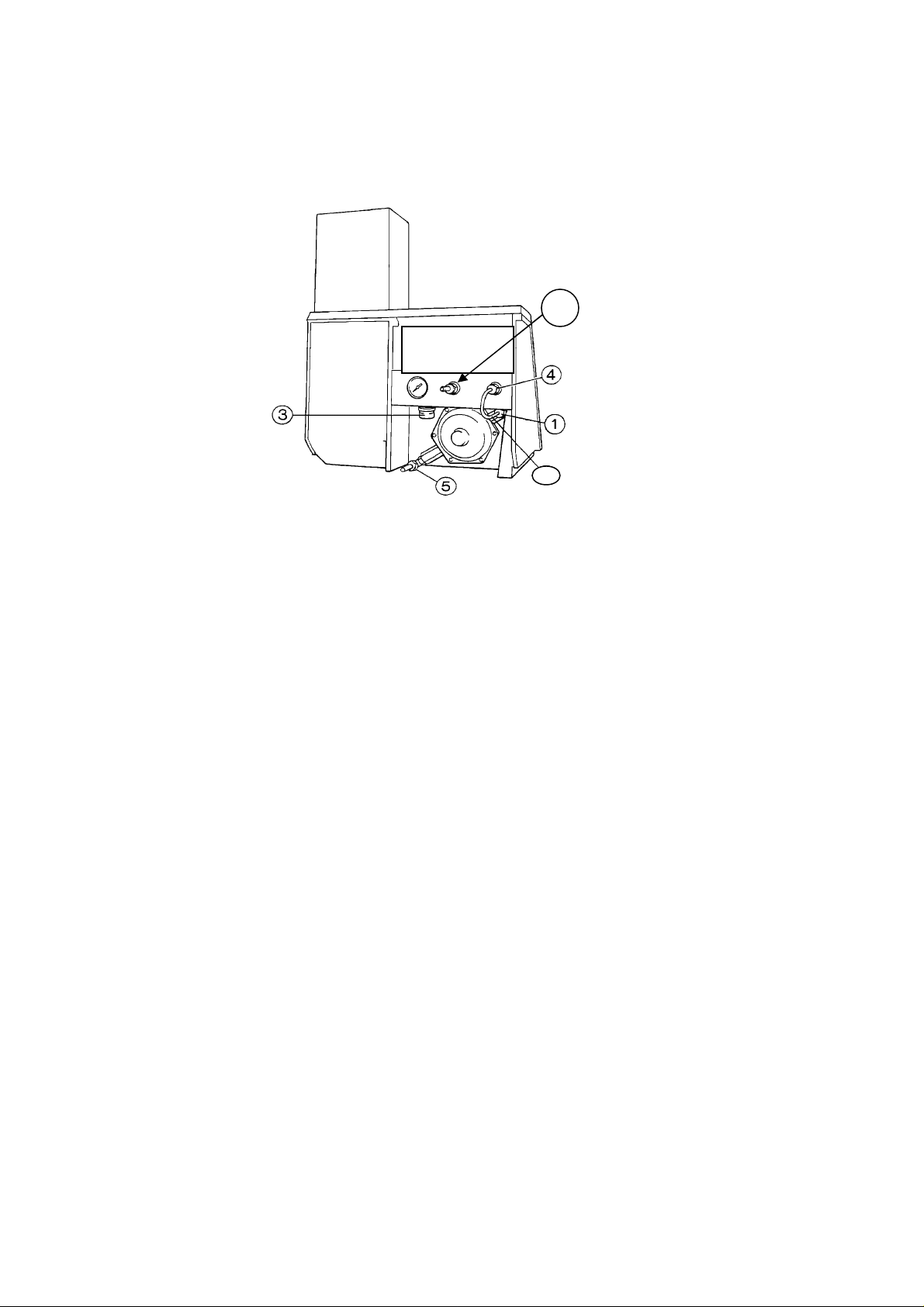

4. Connect the length of rubberised fuel tubing (001 72 114) between the inlet

connector on the internal regulator, (item 5, figure 2.2) and the regulator at the

cylinder outlet connector. Secure with 'Unex' tubing clamps (001 08 718).

425 91 002 Issue 9, 6th August 2008 ECN 527

- 12 -

Page 13

Model 02655-10 & 02655-15 Flame Photometer

2

Installation

Continued

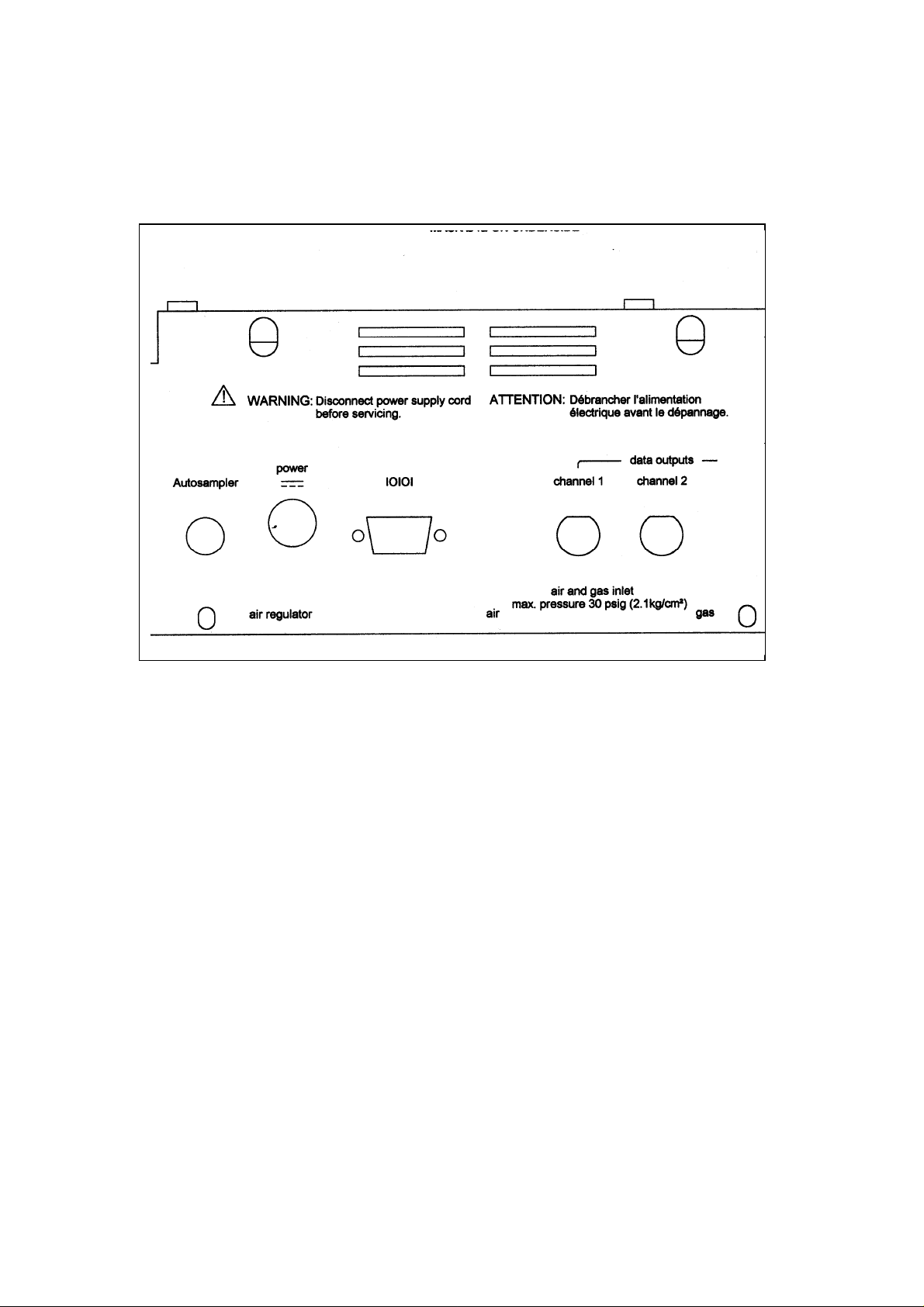

Figure 2.2 Rear Connections for Services

1. Regulator outlet connector, 2. Air inlet, 3. Air regulator adjuster,

4. Gas inlet connector, 5. Gas Regulator inlet connector.

5. Turn on the fuel supply and check all connectors for leaks, using soap solution.

Do not use the instrument until you are satisfied that the installation is leak

proof.

6. Connect the air compressor to a suitable mains supply.

7 Connect the length of reinforced hose (001 72 043) between the air compressor

outlet and the air inlet connector on the rear panel (item 2, figure 2.2). Secure

both ends with 'Unex' tubing clamps (001 08 718).

425 91 002 Issue 9, 6th August 2008 ECN 527

- 13 -

Page 14

Model 02655-10 & 02655-15 Flame Photometer

Installation

continued

Figure 2.4 Filling the’U’ tube

Wash bottle, 2. Constant head & drain, 3. ‘U’ tube, 4. Drain tube, 5. Spring Clip

8 Fit one of the 200mm lengths of drain tubing (item 4, figure 2.4) to the outlet

on the constant head and drain. If necessary connect a suitable length of tubing

(not supplied), to extend the drain tubing to carry waste to a sink or other drain

receptacle. The downward flow of waste must not be restricted. The second

length of tubing supplied is a spare for either the 'U' tube or drain tube.

9 Make sure that the constant head and drain is positioned so clip that the lip at

the top is resting on the spring clip. Use a wash bottle (item 1, figure 2.4) to fill

the 'U' tube with deionised water. Sufficient water should be used to purge the

tube of air. Allow excess water to flow back into the drain.

IMPORTANT Do not continue until you are satisfied that the 'U' tube has been

completely filled with water, and is purged of air.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 14 -

Page 15

Model 02655-10 & 02655-15 Flame Photometer

10. Plug in the external Power supply to the inlet shown on Fig 2.3.

Installation

continued

11. Fit a suitable a.c. supply lead to the External Power supply.

CAUTION Ensure that the green/yellow earth connector in the a.c. supply lead

is connected to a properly grounded earth point, the brown lead is connected to the

Line terminal (L) and blue lead is connected to the Neutral terminal (N).

12. If necessary, set the “1/0" power switch (below the chimney) to the 0 position.

and connect the plug to a convenient supply socket.

13. If no printer/computer or chart recorder interfacing is required proceed to

Chapter 6 of this manual.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 15 -

Page 16

Model 02655-10 & 02655-15 Flame Photometer

Installation

continued

2.5 Connecting Peripheral Devices

Printer

Cole-Parmer can supply a serial printer set up to operate with the Model 02655-10 &

Model 02655-15 (Part # 473 56 903. This should be connected to the cable supplied

with the instrument, the other end of which is connected to the rear panel in the RS232

socket as shown in Fig 2.3.

Computer

The same serial outlet and cable can be connected to a computer, which, through the

“terminal” function, will display a .txt file identical to the printer display.

Sherwood Scientific now supply an Excel spreadsheet program which can take the

output from the Model 02655-10 or Model 02655-15 directly into a spreadsheet for

further manipulation

Analogue Devices

The Model 02655-10/15 have one set of analogue outputs corresponding to each

channel.

The left hand coaxial socket takes the output from Channel 1 and the right hand socket

from Channel 2. The appropriate voltages are set as described in Section 2.10.

Auto-sampler

The Model 02655-10/15 can be augmented with an Auto-sampling device to form a

fully automatic analytical system. The Model 860 Autosampler has 40 positions for

serum and other clinical samples and is used in conjunction with the Model 805

Automatic Diluter.

The Autosampler is supplied with a signal cable which is plugged in to the Rear panel

as shown in Fig 2.3.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 16 -

Page 17

Model 02655-10 & 02655-15 Flame Photometer

Installation

continued

2.6 Setting Date and Time

Press and hold ‘Print’ during the start up sequence to put the instrument into Date and

Time Mode, which will be operative as soon as the flame has lit. Ch1 displays the date

format "day month year".

Display day as ‘d 10’.

Adjust with ‘- or +’.

Press 'Set' to confirm and move on.

Display month as ‘n 05’.

Adjust with ‘- or +'.

Press 'Set' to confirm and move on.

Display year as ‘y 98’.

Adjust with ‘- or +’.

Press 'Set' to confirm and move on.

Display hour as ‘h 13’.

Adjust with ‘- or +'.

Press 'Set' to confirm and move on.

Display minutes as ‘n 40’.

Adjust with ‘- or +’.

Press 'Set' to confirm and move on.

Automatically sends output as in format: day = 10 month = 05 year = 98 hours = 13 minutes = 40

The instrument now reverts back to the point in the operating sequence waiting for the

first blank.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 17 -

Page 18

Model 02655-10 & 02655-15 Flame Photometer

Installation

continued

2.7 Setting Filter Factors

The Model 02655-10 uses three detectors permanently connected; one each for

Sodium, Potassium and Lithium. (NB The Model 02655-15 has four detectors with the

extra Calcium channel).

Each detector has an interference filter of the appropriate wavelength fitted in front it.

The filters have a unique transmittance factor, which is measured during construction

and entered into the software. These values are held in a battery-backed memory. If the

battery fails, shown by Error Code ‘E62’, it is necessary to re-introduce the factors by

the following procedure. The correct Filter Factors can be obtained from Cole-Parmer

by reference to the Serial number.

1. Press then hold down the ‘Set’ key, the ‘Blank’ key and the ‘Print/Measure’

key together and wait for the ‘beep’. After a few seconds the top display will

show 1000 and the lower display will show F1.

2. Adjust the top display using the ‘+ and –’ controls to the value for the Sodium

(Na) filter. Press ‘Set’ in the top display to fix the value. This will then reveal

1000 in the top display and F2 in the lower display.

3. Repeat step 2 for F2 Potassium (K) value.

4 Repeat step 2 for F3 Lithium (Li) value.

5. Repeat step 2 for F4 Calcium (Ca) value

2.8 Setting Units

The default mode for the Model 02655-10 and Model 02655-15 is to print results as

well as blank and calibration values in mmol/l units. It is possible to change this option

so that no units are printed.

1. After switch on or at any time press and hold down the ‘Blank’ key until ‘101’

is displayed in Channel 1.

2. To remove the units change the display to 100 using the “-” button.

3. Press ‘Set’ to accept the new value.

4. The display will now show 200 in Channel 1, which allows sample delay see

Section 2.9 (below).

425 91 002 Issue 9, 6th August 2008 ECN 527

- 18 -

Page 19

Model 02655-10 & 02655-15 Flame Photometer

Installation

continued

2.9 Setting Sample Delay (in Peak mode)

In Peak mode, the instruments have a default delay of 19 seconds after pressing ‘Cal’

or ‘Print’ before the Peak-seeking algorithm initiates; this allows the calibrant/sample

to stabilise in the flame. This time delay can be adjusted by the user to accommodate,

for example, a diluter where there is a considerable delay before such stabilisation can

take place. (The length of this delay can be ascertained by running the instrument in

continuous mode and observing the exact time between introducing the sample and the

stabilisation of the display).

1. Following the setting or acceptance of the units as described in Section 2.8

(above) the display reads ‘200’ in Channel 1.

2. Press ‘+’ in Channel 1 to display the delay value in Channel 2.

3. If the default delay of 19 seconds is acceptable press ‘Set’.

4. If not, adjust the value in Channel 2 by pressing the ‘+’ key until the value is

correct and then press ‘Set’ on Channel 1.

5. The display will now show ‘300’ in Channel 1. Which allows the output voltage

to be adjusted, see Section 2.10 (below).

NB It is essential while operating in Peak Mode to aspirate the standard or

sample before pressing “Cal” or “Print” to take advantage of this facility.

2.10 Setting the Output Voltage

The output voltage is the maximum voltage measured when at full scale. This can be

set from 0.05 to 7.5.

1. Following the setting or acceptance of the sample delay as described in Section 2.9,

Channel 1 display reads ‘300’, and Channel 2 ‘1.0’ (default).

2. Adjust the output voltage in Channel 2 using the ‘+ or -’ buttons.

3. Accept the required output voltage by pressing ‘Set’ in Channel 1.

(NB The Model 02655-15 has an additional feature, which allows the analogue outputs

to be set for blank and “span” by passing the normal calibration protocol. This feature

can be invoked by adjusting the 300 to 301 by the ‘+’ key before pressing “SET” as

above).

Setting the analogue damping coefficient.

1 After adjusting the voltage level in section 2.10 above, the instrument shows

“400” in the Channel 1 display.

2 To adjust the level of damping in the analogue output adjust the channel 2 display

from 1 (No damping) to 20 (Maximum Damping) by use of the ‘+ & –‘ keys. Press

”SET”.

The displays will return to flashing ‘000’ and the blanking and calibration procedures

can begin again.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 19 -

Page 20

Model 02655-10 & 02655-15 Flame Photometer

3 Principles of Operation

3.1 Application of Flame Photometry

Prior to the advent of flame photometry, Sodium and Potassium were typically

determined gravimetrically after the precipitation of relatively insoluble salts such as

Sodium Uranyl Zinc Acetate (Ref. 1) and Potassium Chloroplatinate (Ref. 2). As with

all chemical methods for these two elements there were cross interferences and also

interference from other ions such as NH4+. Many analytical steps such as protein

precipitation or ashing of the sample were involved with all the attendant losses and

inaccuracies and the complete procedures required many hours.

In many applications, particularly in clinical situations, rapid availability of results is of

prime importance. By flame photometry both Sodium and Potassium results on a single

sample can be available in less than 5 minutes of the sample reaching the laboratory.

With the availability of the Li Reference Mode accurate results can be achieved while

the instrument is still warming up. A simple dilution step is all that is required;

therefore sample handling, losses and inaccuracies are at a minimum (Ref. 3 to 10).

3.2 Principles of Flame Photometery

When a solution is aspirated into a low temperature flame, in an aerosol, each droplet

of water evaporates leaving a solid core of the residue of evaporation. The core further

breaks down to the molecular level, and provided the molecules are not too refractory,

progress to form atomic species. The atom then is excited by the flame and its electron

temporarily moves to a higher energy state.

When the electrons return to the ground state, they lose the excitation energy and a

discrete wavelength of visible light is emitted, characteristic of the atom. The emitted

light can be isolated from other light wavelengths by an optical filter. The amount of

light being emitted is proportional to the number of atoms in the flame, and it follows,

the concentration of that atom in the original solution. The amount of light emitted can

be measured by a suitable photodetector.

The photodetector generates an electrical signal which is amplified and displayed on a

digital readout.

The Cole-Parmer Model 02655-10 Flame Photometer is a Dual Channel low

temperature Flame Photometer designed to be used for the simultaneous determination

of Sodium (Na), and Potassium (K) in Clinical and Industrial samples. The Model

02655-10 also has the benefit of an Internal Standard using a Lithium (Li) signal to

eliminate interferences due to variation in dilution ratios (where a continuous Diluter is

used) as well as variability in the characteristics of the flame photometer itself.

The Model 02655-10 can also function as a Single Channel instrument for the

determination of Na and K including reference mode and Li without reference mode.

The Model 02655-15 is a Four element Flame Photometer where the user can choose

to display any two of the following elements Na, K, Li and Ca. (or two from Na, K, Ca

with Li Internal Standard.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 20 -

Page 21

Model 02655-10 & 02655-15 Flame Photometer

Principles of Operation

continued

3.3 The Internal Standard Mode

When the Internal Standard is invoked with the ‘Ref’ mode, this uses the signal from

the Li detector to scale the readings from the other detector(s) to allow for external

effects such as drift, flame disturbances, changes in dilution, nebuliser uptake rate, etc.

It works by adding a known concentration, (Co), of Li to the Blank, and the diluent of

the Standard solutions and the Sample. The Li signal is constant at Co if all the

external effects are constant. If the Li signal changes it does so because of flame and

instrument variables. By introducing a factor based on the reference Li measurement,

we can remove many of these variables from the analysis of Sodium and Potassium.

The Li reference factor is assigned a value of 1.000 at the time of calibration. This

factor is shown on the print-out each time an analysis is performed, which indicates the

amount of change due to drift, aspiration rate etc., since the calibration was made. The

limit of ±20% can be corrected for and if the factor exceeds this limit an error is

indicated which tells the operator to clean the aspirator and recalibrate.

To use this mode the blank, calibration standard, and samples will have to be in a

solution that contains Lithium of a constant concentration, Co, in the diluent. See

Section 1.3.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 21 -

Page 22

Model 02655-10 & 02655-15 Flame Photometer

4 Performance Characteristics &

Specifications

The Model 02655-10 can be ordered in two versions: the Model 02655-10 Clinical and

the Model 02655-10 Industrial. The following specification applies to the Clinical

version. The Model 02655-15 is offered in the non-clinical mode although clinical

standards can be supplied separately see Section 9.

The specification of the Industrial version is included as an appendix to this manual.

4.1 Readout

Dual three-digit light emitting diode (LED) display, 12.5 mm high.

Display ranges 0 to 199.9.

NOTE If negative values are displayed the instrument is operating outside of the

recommended measurement range or it is in between samples in continuous reference

Mode as the Lithium reference is absent.

4.2 Measurement Ranges

Model Model 02655-10 Model 02655-15

Elements analysed Na, K (with Li Int Std)

Li

Sample concentration Na 0.5 to 40ppm

K 0.5 to 20ppm

Li 0.0 to 0.6ppm

Measurement ranges ppm All 1.00-

9.99,10.0-199.9

mmol/l as above except

Li only 1.00-5.00

Readout No Units or mmol/l No Units or mmol/l

Sensitivity for 100

displayed

Reproducibility <± 1.0% <± 1.0%

Reading Stabilisation Variable software

Recorder output 2 outputs 50mV-7.5V

Air Supply (required) 6 liters/min @ 11 psi oil

Na and K= 0.5ppm,

Li = 2 ppm

command

via software command

and moisture free

Na, K& Ca (with Li Int

Std) Li

Na 0.5 to 40ppm

K 0.5 to 20ppm

Li 0.0 to 0.6ppm

Ca 5 to 100ppm

ppm All 1.00-

9.99,10.0-199.9

mmol/l as above except

Li only 1.00-5.00

Na and K= 0.5ppm,

Li = 2 ppm

Ca = 5ppm

Variable software

command

2 outputs 50mV-7.5V

via software command

6 liters/min @ 11 psi oil

and moisture free

425 91 002 Issue 9, 6th August 2008 ECN 527

- 22 -

Page 23

Model 02655-10 & 02655-15 Flame Photometer

Performance Characteristics and Specification

continued

4.3 Specificity

For Na, K and Li measurements, interference will be less than 0.5% from a

concentration of Na, K, and Li, equal to the concentration of the element under test.

For calcium there is a significant background interference from Sodium :

The emission of a 100ppm Calcium solution will be increased by approximately 20% in

the presence of a 100ppm Sodium solution. This will be reduced to 13% if a Lithium

internal standard reference is used. The effect is linear so a correction factor can be

used if a mixture of Calcium and sodium is to be analysed.

4.4 Accuracy

Linearity

Better than 1% measured at mid-range, when standardized at the following

concentrations: - 140.0mmol/, Na; 5.0mmol/l K; 1.5mmol/l Li.

Drift

NOTE A minimum 15 minutes warm up must be allowed to meet the drift

specification, refer to Section 4.5.

Na < 2mmol/l in 10 minutes at all ranges

K & Li < 0.1mmol/l in 10 minutes at 5.00mmol/l

NB In Reference Mode this drift is greatly reduced.

Reproducibility (using Peak mode)

< 2.0% CV for 20 consecutive readings of the same bulk sample, aspirating sample for

20 seconds then 10 seconds of air.

Using Peak with Ref (Internal Standard) Mode

< 1.0% CV for 20 consecutive readings of the same bulk sample, aspirating sample for

20 seconds then 10 seconds of air. With a delay of 30 seconds see section 2.9

425 91 002 Issue 9, 6th August 2008 ECN 527

- 23 -

Page 24

Model 02655-10 & 02655-15 Flame Photometer

Performance Characteristics and Specification

continued

4.5 Warm Up

To achieve the stated specification the flame must be alight for a minimum of 15

minutes, with diluent being aspirated.

4.6 Sample Requirements

Sample Types

Serum Na 0 to 199.9mmol/l

(Model 02655-10 and Model 0655-15 incorporate Linearisation in the

software to correct for Na self absorption)

K 1.00 to 9.99mmol/l

Li: 1.0 to 9.9mmol/l

Urine Na 0.0 to 199.9mmol/l

K 40.0 to 120.0mmol/l

These are original sample concentrations before dilution.

Dilution Ratios Na/K 1:200 Serum and Urine

Li 1:50

Type

Is dependent on application. However, samples should not be highly viscous or nonhomogeneous.

Method of Presentation

The diluted sample is presented to the nebuliser from a sample cup, test-tube, or other

suitable container.

Alternatively a continuous flow diluter, Model 805, can be used and the undiluted

sample can be presented to the Dilutor

The Model 02655-10 and Model 02655-15 can now be used with the Model 860

Auto-Sampler and Model 805 Diluter giving a fully automatic Clinical System for Na

and K analysis.

Volume

The maximum diluted sample volume required for 20 seconds aspiration is 2ml, which

gives the minimum sample volume as 10µl. 50µl for the Model 805 and 0.2ml for the

Model 860 system.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 24 -

Page 25

Model 02655-10 & 02655-15 Flame Photometer

Performance Characteristics and Specification

continued

4.7 Chart Recorder Output

Can be adjusted for 100.0 display from 0.05V to 5.0V.

4.8 Environmental Conditions

Temperature

Operating +10°C to +35°C

Transportation –10°C to +45°C

The instrument specification will be unaffected by an ambient temperature change of

4°C (or less) per hour, within the range +10°C to +35°C, with a maximum of 7°C shift

during 8 hours.

Humidity

Operating: - 85% maximum at +35°C

Transportation: - 95% maximum at +45°C (non condensing).

For use in these conditions use the Compressor Model 855 with a water-cooled trap.

4.9 Power Requirements

Voltage

90V to 132V or 198V to 264V, 50/60 Hz

Power

20 VA.

4.10 Fuel

Propane, Butane or Propane/Butane mixture. (Not Natural Gas, as the Model 0265510/15 features a fully automatic ignition system which requires a constant pressure gas

supply). All fuels to be free of heavy hydrocarbon deposits and regulated at the

cylinder to approximately 2.1kg/cm2 (30psi). NB for the Model 02655-15 Calcium

requires Propane/Air flame.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 25 -

Page 26

Model 02655-10 & 02655-15 Flame Photometer

Performance Characteristics and Specification

continued

4.11 Air

A supply of clean air at a pressure of 0.9kg/cm2 (11psi) at 6 litres/minute, as supplied

by a Model 851 Air Compressor.

The stability of the readings from the Model 02655-10 and Model 02655-15, especially

at high gain, depends on a smooth aspiration of the sample; this can be disturbed by

droplets of condensation coming from the air compressor where the

compression/expansion causes significant condensation in humid atmospheres. If

condensation problems arise a Model 855 Air Compressor should be used, which has a

water separator fitted.

Air Compressors are listed in Section 9.2.

4.12 Size

Overall, including chimney and rear panel connectors: -

510mm high

390mm wide

345mm deep.

4.13 Weight

9.5kg, instrument only.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 26 -

Page 27

Model 02655-10 & 02655-15 Flame Photometer

5 Description of Instrument

5.1 Front Panel Controls and Indicators

Model

02655-10/15

Controls

Blank

Channel

selector

Mode Selector

Measure/Print

Channel 1 Set

Channel 2 Set

5.1.1 Controls

Primary Function Secondary

Function

Reset all channels to

zero

Selects single and dual

channels for display and

printing

Selects Peak, Lithium

Reference and

Continuous in various

combinations

Initiates Measure cycle

in Peak Mode

Initiates Calibration

procedure

Initiates Calibration

procedure

Reset

instrument to

default mode

Initiates Print

in Continuous

Mode

Confirms

Calibration

Value

Confirms

Calibration

Value

Tertiary

Function

Enter set-up mode

for Units, Delay,

Voltage

Enter set-up mode

for Date and Time

Confirms Set-up

choices

Enter Set-up

Mode for Filter

Factor

Quaternary

Function

Enter set-up

Mode for Filter

factor

Enter set-up

Mode for Filter

factor

Software

version

‘-’ ‘Set’ ‘+’

(Feedback beep confirms the action)

Primarily used in the calibration process.

Secondary functions include: -

date and time setting

Filter Factors and other settings

When Pressed during a measurement session the instrument will automatically interrupt

the measurement and require ‘Blanking’ and ‘Calibration’.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 27 -

Page 28

Model 02655-10 & 02655-15 Flame Photometer

Description of Instrument

continued

Blank

(A feedback beep confirms the action).

Forces the instrument to zero all channels.

Must be used at start-up and after change of ‘Peak/Cont’, ‘Single/Dual’ or element

selection.

A short press may be used at any time during a measurement session to reset the blank

while aspirating the blank solution.

A long press at any time will reset to default settings and put the instrument into startup blanking mode and into Set-up mode.

Single/Dual and Element Selection

Used at start-up to choose ‘Single’ or ‘Dual’ channel operation.

Used to select particular elements by “toggling” through sequence: -

The Model 02655-10 The Model 02655-15

“Na & K” “Na & K”

“Na & Li” “Na & Ca”

“Na” “Na & Li”

“K” “Ca & K”

‘Li’. “Ca & Li”

“Na”

“Ca”

‘K’

“Li”

When in “Ref” Mode with Li Internal Standard, Li cannot be measured and will not

be selectable.

Peak/Ref/Cont

Used at start-up to choose the measurement mode, must be chosen before Blanking.

‘Peak’ has the instrument sense when a steady reading has been achieved and freeze

that reading.

‘Ref’ uses signals from the Lithium channel as an internal reference. Can be used with

‘Peak’ or ‘Cont’.

‘Cont’ displays readings in real-time.

Sequence is: “Peak & Ref” (Default Mode), “Cont”, “Cont & Ref”, “Peak”.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 28 -

Page 29

Model 02655-10 & 02655-15 Flame Photometer

Description of Instrument

continued

Measure

(A feedback beep confirms the action).

Used to initiate the measurement and will send an output to the RS232 serial port

(connected to a printer, computer or data logger) at the end of the measurement

process in “Peak” mode. In ‘Cont’ mode it sends an instantaneous value to the Printer.

The sample must be introduced before 'Print' is pressed. Short, long or double presses

produce different sample identification in output format (see Section 6.5).

5.1.2 Description of Indicators

All of the front panel indicators are LED’s mounted behind a flexible plastic overlay

which provides protection from the laboratory environment. Some windows are plain

rectangles others are text legends.

Cal (Ch1 & Ch2)

‘Cal’ on a given channel is illuminated when the instrument automatically goes into

calibrate mode after a successful blanking.

“Cal” Starts flashing after the Calibration sequence has been initiated ‘Cal’ changes

from flashing to steady when either: -

In ‘Cont’ mode.

'Set' is pressed for the second time in the calibration process (see Section 7.2).

In ‘Peak’ mode.

The internal part of the calibration process is complete.

Single

Is steadily illuminated when in ‘Single’ (Ch1) or ‘Single’ (Ch2) modes.

Dual

Is steadily illuminated only when in ‘Dual’ mode.

Peak

Indicates that ‘Peak’ mode has been selected.

Ref

Indicates that the ‘Reference’ mode has been selected.

‘Peak’ and ‘Ref’ can both be steadily illuminated at the same time.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 29 -

Page 30

Model 02655-10 & 02655-15 Flame Photometer

Description of Instrument

continued

Cont

Indicates that ‘Continuous’ measurement mode has been selected.

‘Cont’ and ‘Ref’ can both be steadily illuminated at the same time.

Measure

Indicates that the instrument is in ‘Measurement’ mode.

“Measure” flashes during “Peak” measurement process before completion.

Flame On

Indicates that an internal sensor has detected the presence of the flame, absence of

illumination after the ignition process will be accompanied by the error message

‘E61’on the measurement displays.

Power On

Indicates that the instrument is on and connected to the proper electricity supply.

5.2 Rear Panel Controls and Connections

Fig: 2.3

425 91 002 Issue 9, 6th August 2008 ECN 527

- 30 -

Page 31

Model 02655-10 & 02655-15 Flame Photometer

Description of Instrument

continued

Channel 1 & 2 Data Outputs

Both these outputs carry a variable voltage signal (set as indicated in Section 2.10 and

2.11) equivalent to a reading of 199.9 on the two channel displays.

When either instrument is the Clinical Mode and when the display is in the lower range

for Potassium and Lithium where the display is indicating x.xx the output is equivalent

to 19.9.

The outputs can be connected to an Analogue/Chart recorder using coaxial plugs (not

supplied).

RS232/Printer Output

This is a standard 9way output and the printer output cable (supplied) should be

connected here. The other end of the cable is a 9 pin standard RS232 connector for

serial printers and other data logging devices.

External Device Output

This is another 8-pin DIN connector, which enables the instrument to be connected to

the Model 860 Autosampler.

Power

The instrument is supplied with a Universal External Power supply which can

accommodate 90-240V AC input.

Gas

¼-inch fuel inlet connector to the instrument, permanently connected to the in-built

regulator inlet (item 5, figure 2.2). The instrument will operate satisfactorily on

Propane and Butane.

Air

5/16-inch connector for the air inlet tubing to the instrument (item 2, figure 2.2), from

the air compressor outlet. See Section 4.11 for pressure and flow rate specifications.

Air Regulator

Control to adjust the pressure of the air supply (item 3, figure 2.2). The air pressure

gauge provides a visual indication of the air pressure.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 31 -

Page 32

Model 02655-10 & 02655-15 Flame Photometer

Description of Instrument

continued

5.3 Operating Modes

Operating Modes for Model 02655-15 are additional and in italics.

5.3.1 Single/Dual Mode

Refer to Section 5.1.1 for the function of the 'Single/Dual' button and to Section 5.1.2

for its status indicators ‘Single’, ‘Dual’.

Single

The Model 02655-10 has 3 detectors one each for Na, K and Li, permanently

producing signals from the light of the flame. The option of running in single channel

mode has been provided and is selected by use of the 'Single/Dual' button mentioned

above. This allows the user to choose not only between ‘Single’ or ‘Dual’ operation

but also between Ch1 and Ch2. to access K or Li.

For the Model 02655-15 there are 4 detectors the additional detector is for Calcium,

which can be selected as a single element.

Dual

This mode allows the user to simultaneously measure two elements in the same sample.

For clinical use this guarantees better than a 100% time saving compared with the

Model 02655-00 single channel instrument.

Ch1 will display Na.

Ch2 can be either K or Li unless in Ref. mode when Li is used as the reference element

and cannot also be displayed.

Calcium in combination with Na will be shown on the lower display. When in

combination with K (or Li when not in “ref” mode) it is in the upper display.

Blanking

Affects all channels so it will operate in the same way regardless of which of these

modes has been selected.

Calibration

If operated in Dual mode, both channels must be calibrated before measurements can

begin, but it does not matter which channel is calibrated first.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 32 -

Page 33

Model 02655-10 & 02655-15 Flame Photometer

Description of Instrument

continued

5.3 Operating Modes continued

5.3.2 Peak/Cont

Refer to Section 5.1.1 for the function of the ‘Peak/Cont’ button and to Section 5.1.2

for its status indicators ‘Peak/Ref/Cont’.

Peak

This mode is intended to give the user a frozen measurement value on the instrument

display. This not only removes subjectivity form the user but also offers a much greater

advantage by enabling automation of sample delivery and collection of results.

The Peak Cycle

The full sequence of the peak process is as follows: The cycle commences with the introduction of a new sample, quickly followed by

pressing 'Measure'.

The instrument starts a built-in delay (which can be varied see Section 2.9) as soon as a

press of 'Measure' has been registered, (whether a short, long or double press does not

matter); readings are displayed on all operative channels. When the values satisfy the

peak detection algorithm the display(s) freeze and the "Measure" indicator will become

steady. A single beep will sound and a valid measurement value will be output to the

RS232 serial port.

The cycle cannot re-commence until the previous values flash and the measure indicator

is steady.

Then a new sample can be aspirated and “Measure” is pressed.

If the cycle has timed out for the previous sample before the algorithm was successful

on all operative channels, "measure" will flash and "E22" will be showing on at least

one display.

(NB a full list of all codes is printed as Appendix B).

425 91 002 Issue 9, 6th August 2008 ECN 527

- 33 -

Page 34

Model 02655-10 & 02655-15 Flame Photometer

Description of Instrument

continued

5.3 Operating Modes continued

5.3.3 Ref Mode

Ref. stands for internal reference. This mode uses the signal from the Li detector to

scale the readings from the other detector(s) to allow for external effects such as flame

disturbances, changes in dilution, nebuliser uptake rate, etc.

For full explanation see Section 3.3.

To use ‘Ref’ mode make sure Li is not selected and the calibration and measure

samples will have to be in a solution with the known concentration (we recommend

100ppm Li), C0, of Li in the diluent. Make sure that calibration and measurement

samples contain the same concentration of Li.

Cont

‘Cont.’ is short for continuous. Readings are continually updated. There are no timeouts or delays. This mode can be used in various combinations with Single, Dual and

Ref.

There is one major difference from the Peak mode, a press of 'Print' causes output of

the current displayed reading to whatever is connected to the RS232 connector, e.g.

printer, computer, data logger.

5.3.4 Blank

Blanking can be initiated at any time during a measurement session by pressing 'Blank',

having already introduced a blank sample. There are 5 circumstances where it is

initiated automatically by the instrument as part of the start-up sequence: On initial Switch on after Diagnostic sequence

immediately after use of 'Peak./Cont'

immediately after use of 'Single/Dual'

immediately after any element selection process

immediately after 'Set' is pressed during a measurement session

NB It may be that more than one of the above buttons is pressed as the user selects

a new operating mode. "000" flashing in the measurement displays will indicate that the

instrument is waiting for the user to press 'Blank' and the blanking process will not

commence until it is pressed.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 34 -

Page 35

Model 02655-10 & 02655-15 Flame Photometer

6 Operating the

Instrument

6.1 Start Up

After completing the assembly of the instrument as described in Chapter 2

(remembering to fill the ’U’ tube with water and to allow the waste water to fall to a

reservoir) the instrument is ready to be started.

6.1.1 Compressor Start Up

Switch on the compressor and adjust the air regulator assembly (see Section 5.2) to

read 11psi on the gauge.

6.1.2 Switch On

The Model 02655-10 and Model 02655-15 automatically select a high gas /air ratio to

ignite the flame. If the instrument has been switched off recently then the flame should

ignite at the first operation of the 1/0 switch. If not then two or even three operations

might be necessary to fill the gas tube up-stream of the instrument.

6.1.3 Ignition Successful

The instrument automatically selects a reduced gas/air mixture, which optimises the

flame for highest sensitivity.

The Flame detector operates and the “flame on” light illuminates.

6.2.1 Required Blanking

When the instrument has just been switched on it automatically goes into blanking

mode as soon as the flame has lit (although this may be temporarily interrupted by the

date and time setting and other processes described in Section 2.7 to 2.9).

At this point: "Measure" and "Cal" are off, the display(s) flash "000"and the instrument

waits for the user to introduce the blank sample before pressing 'Blank'.

‘Blank’ affects all channels simultaneously, even Li whether being used for reference or

not. The instrument brings the readings of all channels to zero, a steady display of "0.0"

on all enabled channels.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 35 -

Page 36

Model 02655-10 & 02655-15 Flame Photometer

Operating the Instrument

continued

6.2.2 Required Calibration

(NB Li must be in diluent if operating in Ref).

On initial start up the instrument requires a Calibration step after the Blanking process.

The instrument goes into calibrate mode with the "Cal"(s) flashing, "Measure" off, and

the most recent calibration values on the display.

The ‘Single’ and ‘Dual’ mode of operations both Calibrate in the same manner.

The preparation and presentation of standards in “Dual” are different for “Cont” and

“Peak”.

Continuous Mode.

(In Dual Mode standards can be

presented as individual elements and each

channel separately calibrated). The

channel(s) should be adjusted to desired

value(s) using '-' or '+'. When desired

value(s) are flashing introduce the

standard and then press 'Set' in any order

within 2 seconds of each other. The user

waits for readings to reach what the user

judges to be steady plateau values and

presses 'Set' on each channel at the

appropriate time to confirm the values. As

these presses of 'Set' are registered the

displayed readings are adjusted to

calibration values, output is sent and the

instrument goes into measure mode with

"Measure" on and "Cal" off.

Peak Mode (With Reference is

Default Mode).

(In Dual Mode both Sodium and Potassium

standards must be mixed and presented as

one solution as there is no operator

involvement in the calibration sequence).

Each channel should be adjusted to desired

value using '-' or '+'. When desired value is

achieved press “Set” on that channel and

then modify the other channel if necessary

and introduce the calibration sample

IMMEDIATELY BEFORE pressing 'Set'

on the second channel.

The “Peak” process starts on both channels

and readings are displayed. Once the Peak

algorithm has accepted the values, and the

displays on both channels change to the

calibrated values, the user presses 'Set' on

both channels and the output is sent. The

displays start flashing, "Cal" goes out,

"Measure" comes on and the instrument is

ready to measure.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 36 -

Page 37

Model 02655-10 & 02655-15 Flame Photometer

Operating the Instrument

continued

6.3 Sample Measuring

6.3.1 Measuring in Peak mode

The cycle commences with the introduction of a new sample, quickly followed by

pressing 'Measure'. The instrument starts the built-in delay (which can be varied see

Section 2.9) as soon as a press of 'Measure' has been registered (whether a short, long

or double press does not matter).

Readings are displayed on all operative channels and ‘measure’ is flashing.

Once the peak mode algorithm is satisfied, the values will “freeze”, the signals are

corrected to the reference signal, “measure” will become steady and a valid

measurement value will be output to the RS232 serial port.

After 5 seconds the Display(s) will flash prompting the user to remove the sample,

introduce a new sample and press 'Measure' to start the cycle again.

6.3.2 Measuring in Continuous mode

In Continuous Mode, after introducing the sample, the user will decide when the

displayed results have stabilised and the reading can be taken and/or sent to the

printer/output. When he/she is so satisfied then a simple press of the ‘Measure/Print’

button will send the currently displayed/measured value to the output port. A new

sample can be presented at any time and the user again can take the result when it is

judged ready.

6.4 Automatic operation

Both the Model 02655-10 and Model 02655-15 can be easily used in a partial or fully

automatic system using the Model 805 Continuous Flow Diluter and the Sherwood

Model 860 Autosampler.

The Model 805 diluter is specifically designed to work with either system for Clinical

samples, especially when used in “Ref” Mode where the Lithium Internal standard is

diluted using the Model 805, will give excellent drift free reproducibility.

The Model 860 Autosampler is used as a slave to the Flame Photometers and operates

the Blank and Calibration and Measure cycle under the commands already described in

Sections 6.2 and 6.3 above.

425 91 002 Issue 9, 6th August 2008 ECN 527

- 37 -

Page 38

Model 02655-10 & 02655-15 Flame Photometer

Operating the Instrument

continued

6.5 Sample Numbering

The Sample number is set at 001 when the initial calibration is successful and the

“measure” light is illuminated. The sample number is then incremented at each single

press of the ‘Measure’ button both in “Cont” and “Peak” modes.

6.5.1 Reset of sample number

The sample number is reset to 001 when a calibration is carried out or if both “+” s are

pressed simultaneously.

6.5.2 Repeat sample

If it is necessary to repeat a sample so that the new value is listed against the same

sample number then the “Measure’ button is pushed twice; the output is RRR instead

of the next sample number.

6.5.3 QC sample

A Quality Control sample can be identified by a long push on the print button: the