Colenta Mediphot 900E Service manual

SERVICE MANUAL

for

MEDIPHOT 900E

X-Ray-Filmprocessor

Warnung: Diese Anleitung ist nur für qualifizierte Service Techniker bestimmt.

Warning: For the use of qualified service personnel only.

Avertissement: Réservé au personnel de service qualifié.

MMP89 V2.4 and up

02/2006 FR

MEDIPHOT 900E

X-Ray-Filmprocessor

Technical Specifications

Processing applications: Cut sheets of all commonly used X-Ray films

incl. Mammography

Film thickness: min. 0,10 mm

Material width: min. 10 cm (4") - max. 36 cm (14")

Material length: min. 10 cm (4")

Time in Developer: min.15 sec max. 84 sec

Intake Speed: 76cm/min (31inch/min) 14cm/min (14inch/min)

Cycle Time: 82 sec 459 sec

(see the table on one of the next page)

MP 900 E

Tank capacity - Developer 2,6 L

Fixer: 2,5 L

Wash water: 3 L

Solution heating(Fix and DEV): variable in a range of 18°C - 43°C

(350W Inline Heater)

Dryer: warm air

Replenishment: fully automatic.

replenishment is microprocessor controlled and

calculated from information received from sensors

measuring the width and length of material entering the

processor. Replenishment cycles are variable.

power supply: 1 / N / PE~ 230V (+6% / -10%), 50Hz, 13A, 1.7KW

(alternatives are avaliable on request)

water supply: 2-way magnetic valve, with 3/4" hose connection by using a

DVGW-approved system-separating device or pipe-separating

device.

Wash water flow rate: 1,5 ltr/min when film is in process

Wash water supply pressure: 3 - 10 bar

Wash water supply: filtered at a temperature of 10°C - 15°C

MP 900E

Weight: Empty 58 kg

With solution 66 kg

Technical specification subject to change without notice.

FR 02/2006

MEDIPHOT 900E

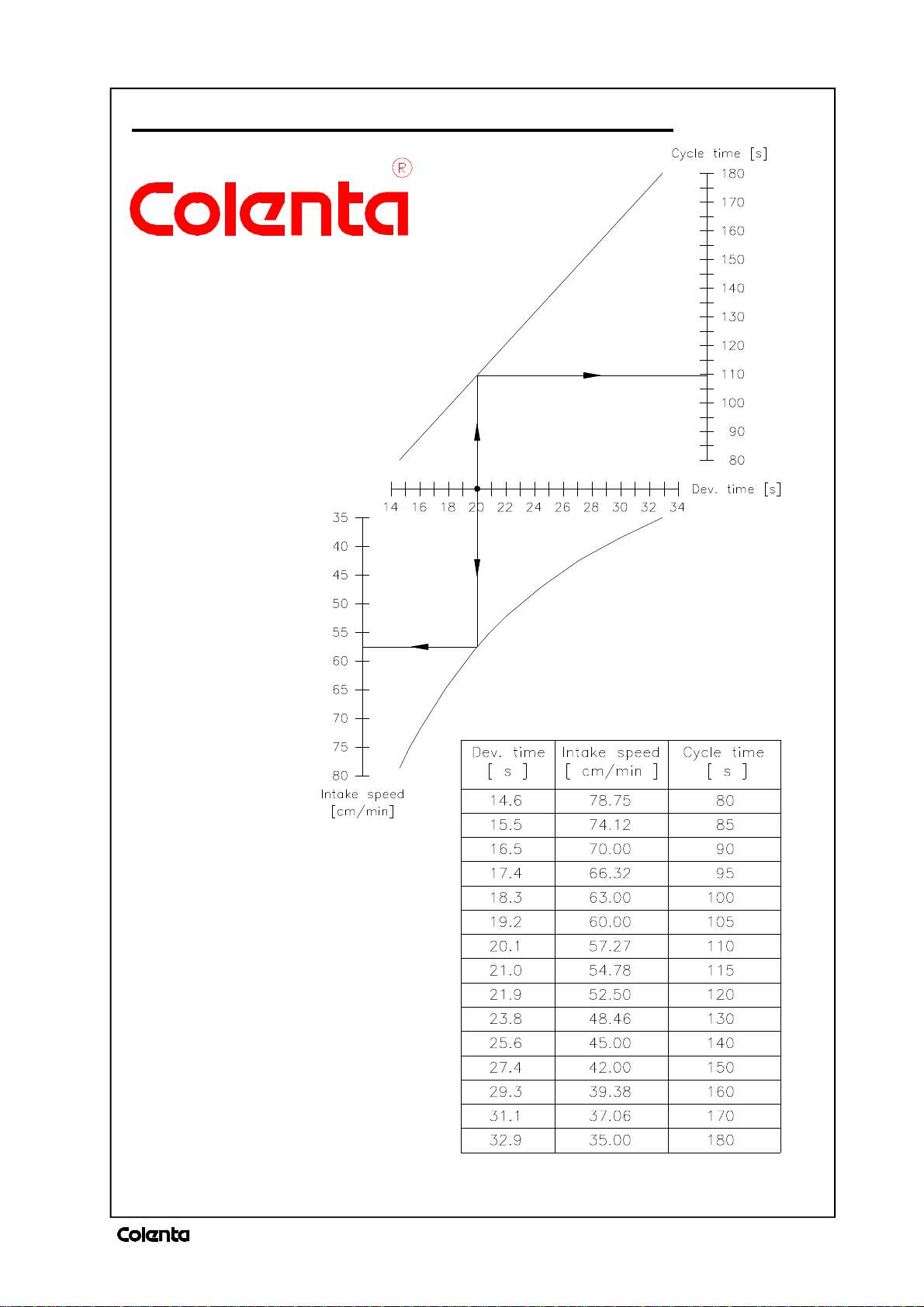

INPUT SPEED / DEV-TIME / CYCLE-TIME:

MEDIPHOT

900E

FR 02/2006

MEDIPHOT 900E

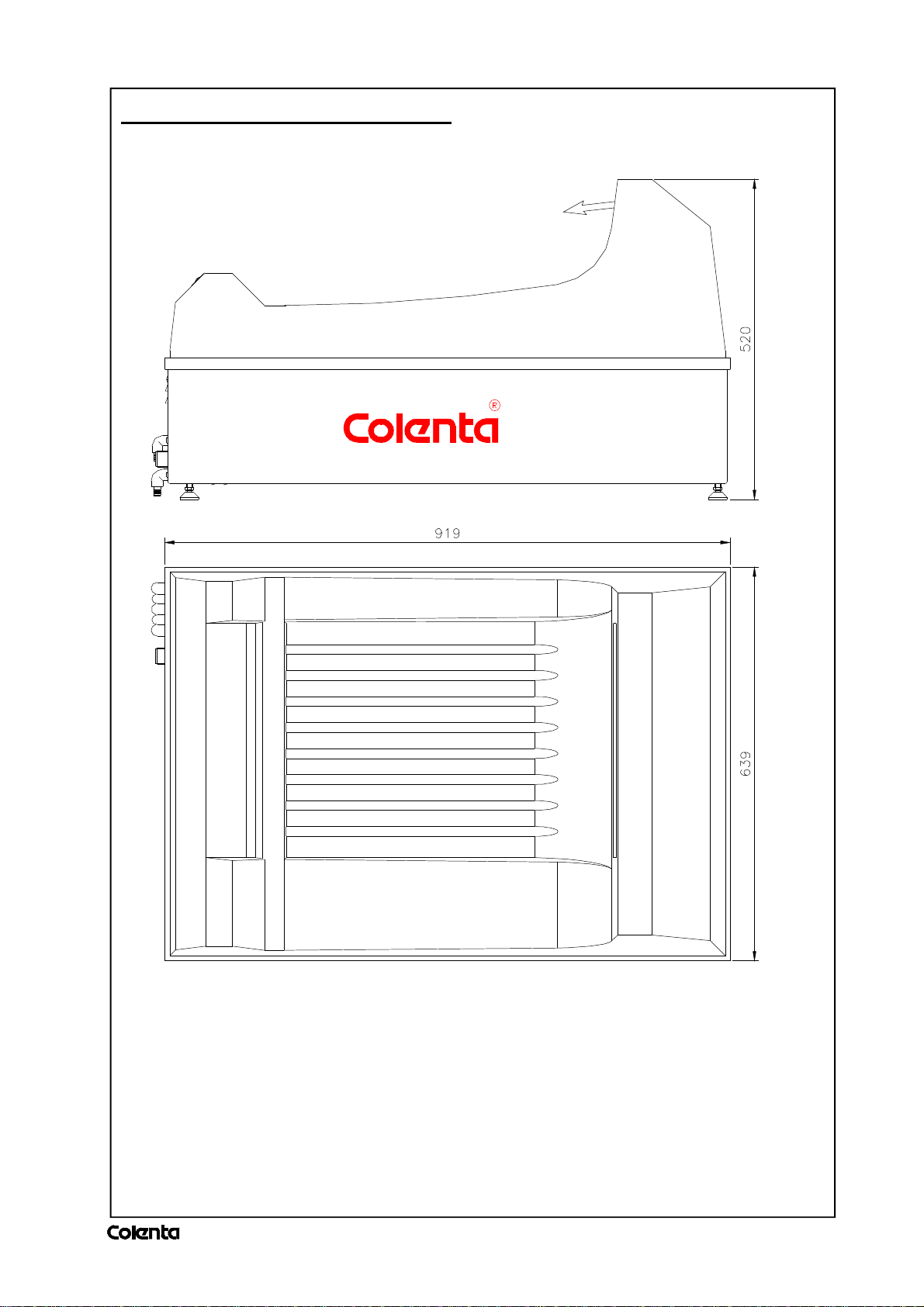

Dimensions of MEDIPHOT 900E:

FR 02/2006

MEDIPHOT 900E

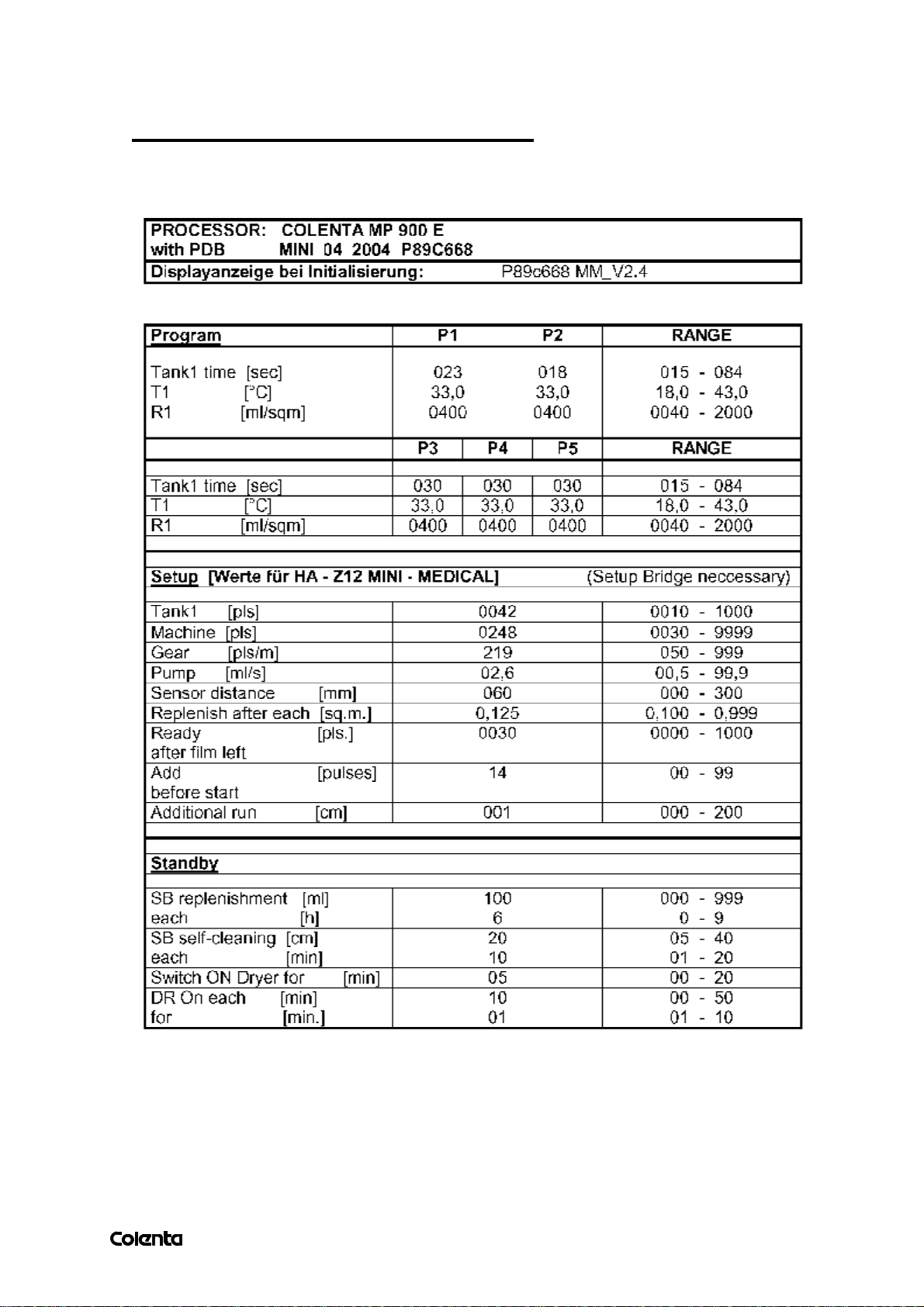

FACTORY SETTINGS: MP900E

FR 02/2006

MEDIPHOT 900E

FR 02/2006

MEDIPHOT 900E

INDEX

1. INTRODUCTION 1

2. GENERAL SAFETY INSTRUCTIONS 2-6

3. PREINSTALLATION 7

4. CHEMISTRY- and WATERCIRCUTS 8,9

5. REPLENISHMENT 10

6. CHEMISTRY DRAINS / WATER DRAINS 11,12

7. INSERT THE TRANSPORT RACKS 13-15

8. THE FIRST STEPS 16

9. WORKING WITH THE FILMPROCESSOR 17,18

10. THE DISPLAY 19 - 25

11. MAINTENANCE 26

12. RECOM. MAINTENANCE EVERY 2-4 MOUNTH 27

13. SERVICE OF THE PROCESSOR 28-44

14.SOFTWARE UPDATE 45-46

FR 02/2006

Service Manual for MEDIPHOT 900E

1.INTRODUCTION

Congratulations upon your decision to buy a

COLENTA X-RAY FILMPROCESSOR.

Your purchase has been designed to meet the highest technical standards.

Some outstanding design features are:

*) compact, space-saving design

*) full automatic processing cycle

*) smooth roller transport system

*) low tank volumes

*) electronically controlled temperature system

*) automatic replenishment

*) low energy consumption

This manual is an instruction for routine use of your:

COLENTA X-RAY FILMPROCESSOR.

MEDIPHOT 900E

FR 02/2006 page

1

Service Manual for MEDIPHOT 900E

2.GENERAL SAFETY INSTRUCTIONS

*) Staff in charge of maintenance of the processor need to be thoroughly familiar with the

equipment.

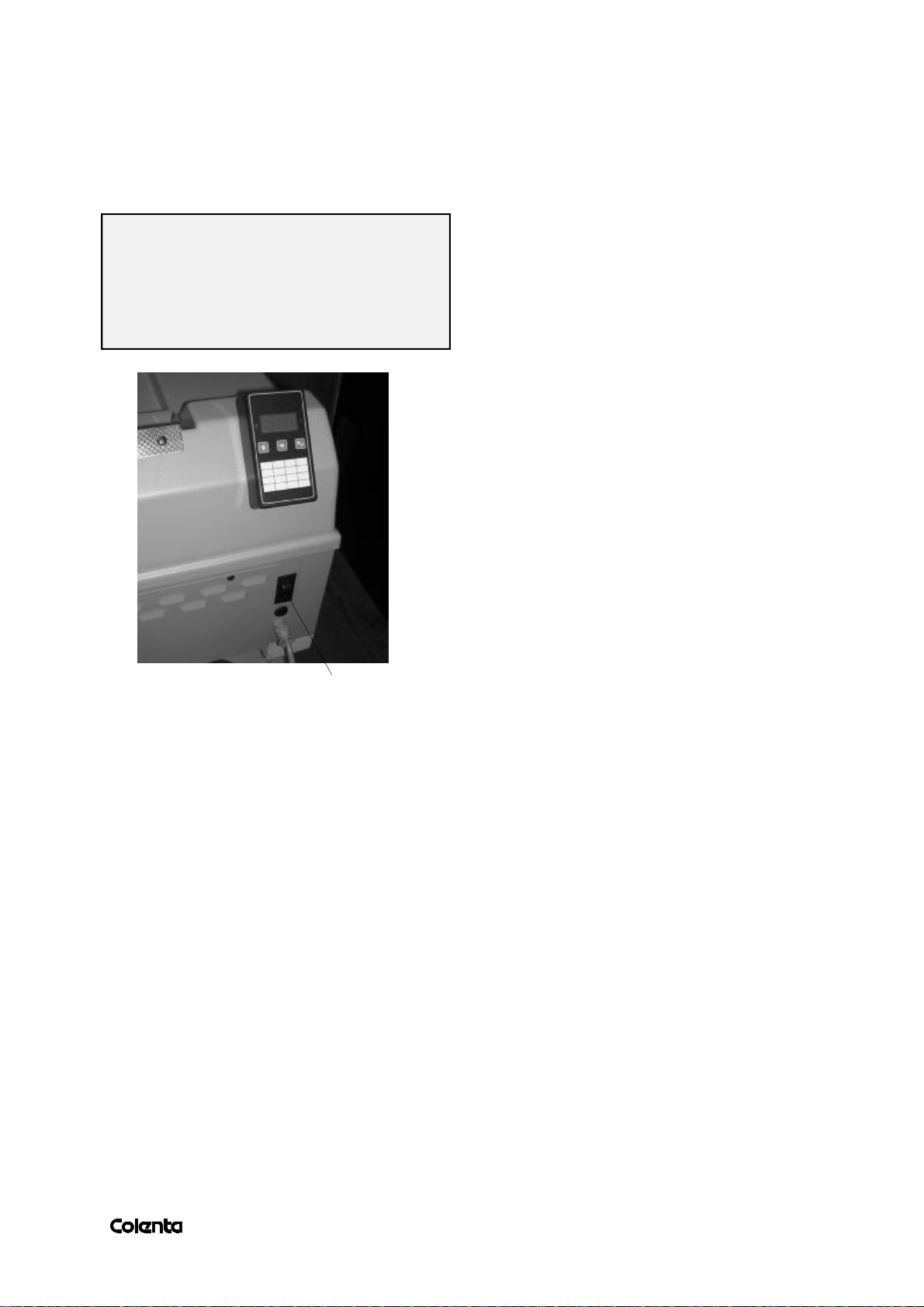

*) Only the Top Cover of the Filmprocessor may be removed by the operator (see picture

below)

.

*) The film processor must be separated from mains prior to carrying out any maintenance. To

do so, switch the mains switch of the machine to „0“ position. Always wear safety goggles

and protective clothing when handling chemicals.

Top cover

Main switch of

*) The filmprocesor may not be in operation without supervision.

*) Make sure that clothing or other objects cannot get entrapped in gear drives or similar of the

film processor.

*) The installation, service, repair as well as the initial operation of the machine may be carried

out by qualified and trained service personnel only.

*) Built-in safety devices may not be eluded or made inoperative. Use only original COLENTA

spare parts when exchanging failed electrical components.

*) Do not wear any loose necklaces or bracelets!

the film processor

2.1 CHEMICAL HANDLING

*) Observe all safety technical regulations of the chemical manufacturer.

*) Wear safety goggles and protective clothing when handling chemicals.

*) Ensure proper ventilation of the room in which the chemicals are prepared.

*) Spillage or overflow of chemicals has to be removed instantly.

*) In case of contact with the eyes flush with plenty of cold water for approximately fifteen

minutes and consult an physician.

*) Chemical disposal has to be in accordance with the local environmental codes. Contact your

local water treatment and sewer district authorities for more information.

FR 02/2006 page

2

Service Manual for MEDIPHOT 900E

2.2 IMPORTANT WARNING AND SAFETY INSTRUCTIONS

(Please read these instructions carefully.)

Processor Operation

Make sure that no long hair, loose clothing or

jewellry can get entrapped in the gear drives

or in the media transport area.

The „Service Manual for Colenta Film

Processor" is for the use of qualified

service personnel only.

The racks must be cleaned with running

water outside the Film Processor.

Do not clean the processor with running

water.

Electrical and Mechanical Hazards

Observe all safety warnings to minimize the risk of

electrical shock,burns or equipment damage.

Photographic Film Processors are complex

machines with many electrical and mechanical

parts as well

as with a considerable amount of chemicals.

2).When handling chemicals wear protective

clothing, safety goggles and rubber gloves .

3).Label storage containers properly.Avoid

storing hazardous chemicals on high

shelves or in unprotected glass containers.

Keep chemicals away from children.Do

not store chemicals in a refrigerator used

for food because they may contaminate

food or be mistaken for edibles.

4).Ensure proper ventilation in the area where

chemicals are used or stored.

5).Observe the manufacturer’s recommendations for using and mixing chemicals.

Overexposure to photographic

chemistry may cause skin irritation to

certain individuals.

PHOTOGRAPHIC CHEMICAL EMERGENCIES

AND FIRST AID PROCEDURES:

Fire Prevention

The area around the processor must be kept

clean at all times. Keep dust ,wood shavings,

scrap paper or other inflamable materials out

of the dryer compartment.

Fire extinguishers must be available in the

room where the processor is installed.

Chemical Handling and Accident Prevention

Misuse of almost any chemical may create

a hazard of some type.Generally photo chemicals

are not any more dangerous as most of the regular

cleaning agents. However, there is always a residual

risk. When handling chemicals observe the procedures

below.

1).Never sniff a container or open bottle to

determine its contents. A cautious sniff of

the cap or lid is safer.

• SKIN - Rinse thoroughly with water.

• EYES -Rinse thoroughly with water and

consult a physician.

• INGESTION -Consult a physician imme-

diately.

FR 02/2006 page

3

Service Manual for MEDIPHOT 900E

Chemical Disposal

Waste from photographic processing normally

contains diluted chemicals. These chemicals

should be collected and disposed in accordance

with local environmental codes.Dumping

chemicals into a drain system could lead to a

pollution problem.Contact your local water

treatment and sewer district authorities before

disposing chemicals.

All plumbing must comply with local and

national codes.The DRAIN must be made of

chemical resistant and non-corrosive material.

Use PVC or equivalent

Exhaust,Temperature and Humidity

It is necessary to ensure proper ventilation

in order to receive good processing results.

Make sure that the exhaust hose of the

built-in exhaust fan is properly connected

to the exhaust air socket (Picture 1).

The built-in exhaust fan exhausts the

fumes from the filmprocessor.

These chemical fumes are corrosive. The top

cover of the filmprocessor should be removed over

night.

· High voltage may cause electric shocks,

burns or even death.

· Hands or fingers may be pinched or

injured by moving parts or when handling

heavy parts.

· Dryer compartment heat may ignite

combustible materials and cause fires.

· Eyes,skin and lungs may be irritated

by photo chemicals.Before using photo

processing chemicals always read the

Material Safety Data Sheets (MSDSs)

for information about the hazards of

the particular chemicals and how to use

them safely.

· Do not operate the film processor after

consuming alcohol or taking strong

medication.

· Do not wear jewellery or loose clothing

when operating the processor.

Room temperatures between 18-26 °C

(65-80 °F)with a relative humidity between 35%

and 75%are ideal for photographic processing

and working.

The filmprocessor is a complex

machine with moving parts such as the gear

train and media transfer components.It uses

photo processing chemicals which are irritating

to eyes,lungs and skin.High voltage is used to

power the filmprocessor.

The dryer compartment produces heat.

Electronical and Electrical Hazards

HAZARDOUS VOLTAGE CAN CAUSE

ELECTRIC SHOCK,BURNS OR EVEN

DEATH ·

Qualified service personnel must verify during

installation that the processor is permanently

and reliable grounded according to

standards in the National Electrical Code.

FR 02/2006 page

4

Service Manual for MEDIPHOT 900E

Carry out the following steps prior removal

of the top cover:

1.Train operators of the filmprocessor.

2.Switch off the main power switch

(„0“-position) and secure against

restart by locking with a padlock

(see picture below).

Burn Hazard

DRYER COMPARTMENT PRODUCES

HEAT -DRYER PANELS AND GUARDS

GET HOT

· Therefore do not touch dryer panels or guards

when dryer in operation

Corrosive Liquids

CHEMICALS MAY IRRITATE EYES,

LUNGS, SKIN AND DIGESTIVE TRACT

# Wear safety goggles,protective gloves and

chemical aprons as indicated on Material

Safety Data Sheets (MSDSs)when handling

chemistry.

# Drain tanks carefully,avoid splashing.

Always drain the system thoroughly before

working on any of the external hose systems.

# Read the MSDSs for more information

regarding the proper safety procedures for

working with photo processing chemicals.

Main switch of

Fire Hazards

DRYER COMPARTMENT PRODUCES

HEAT -PAPER OR OTHER COMBUSTIBLES CAN BE IGNITED

· Keep the area within 10 feet of the processor

clean.Do not store combustible materials,

including paper, close to the filmprocessor.

· Verify that a functional 10 lb.ABC fire

extinguisher is located closed to the processor.

the film processor

# Do not allow untrained personnel to handle

photo processing chemicals or to operate

the filmprocessor.

# To avoid hazardous situations,keep floors

and floor coverings around the processor and

associated drains clean and dry at all times.

Any accumulation of fluids outside the film

processor, should be cleaned up

immediately

FR 02/2006 page

5

Service Manual for MEDIPHOT 900E

In the event of an accumulation

of liquid due to backup,overflow or other

malfunctions of the drain associated with the

filmprocessor call a plumber or other contractor

to correct the problem with the drain.

Colenta assume any responsibility or liability

whatsoever for the service ability of any

drain connected to the filmprocessor.

Such drains are the sole responsibility

of the customer.

DRAINS must be made of chemically

resistant and non-corrosive material.

Chemical Hazards

Chemicals can be the source for errors,

contaminate the waste water, irritate skin

or eyes.

Spills must be cleaned up immediately as

follows:

1.Prevent the spilled chemicals from entering

a waste water drain.

Corrosive Vapours

CHEMICAL VAPOURS MAY IRRITATE

EYES,LUNGS AND SKIN IF ALLOWED TO

ACCUMULATE IN WORK AREA

Assure an adequate supply of fresh

outdoor air through natural or mechanical

ventilation.

· Make sure that qualified service personnel

is checking the external exhaust system at

regular intervals.

· Read the Material Safety Data Sheets

(MSDSs)for more information regarding

the proper safety procedures for working

with photo processing chemicals.

2.Clean up the spill with a moist mop or rag.

CAUTION!

When handling chemicals, especially fixer,

wear protcctive clothing, safety goggles

and rubber gloves.

If filmprocessor chemicals make contact with the

eyes,rinse them thoroughly with lots

of water.If irritation persists,consult a physician.

3.Dispose cleaning materials and collected waste

water from the clean up according to

environmental regulations and locals codes.

4.Avoid any inhalation of chemicals as

this is dangerous to health.

5.Observe all environmental regulations for

storage and disposal of waste chemicals.

6.Use this manual together with the

instructions for chemicals.

When handlingchemicals wear

protective clothing, safety goggles and rubber gloves,

FR 02/2006 page

6

Service Manual for MEDIPHOT 900E

3.PRE- INSTALLATION

*) Site preparation, e.g., water supply, drainage electrical supply must be completed prior

installation.

3.1.LOCATION

*) Processor can be installed "through-the-wall" or completely in the darkroom.

Required measurements can be taken from the processor specification sheet.

For "through-the-wall", a purpose built panel is required (optional accessory).

3.2 ELECTRICAL SUPPLY

*) All electrical connections must meet national safety requirements. Correct fuses and

electrical requirement can be taken from the processor specification sheet.

Main switch of

the film processor

Power cord

3.3 WATER SUPPLY

*) The processor must be connected to the local water supply by using a DVGW-approved

system separating device or pipe separating device.

*) The cold water supply pipe must have a stopcock fitted connection to the processor and

should be done by using the 3/4" hose connector, supplied. Easy access to the stopcock

should be provided as it has to be opened and closed daily.

*) A built in magnetic valve reduces water consumption to a maximum of 2,5 ltr./minute using

pressure and quantity control.

*) It is recommended to run a second cold water supply with

2.5 meters of hosing to facilitate easy cleaning of the racks

and tanks (water supply kit - optional accessory).

Water connection und

drains in front of the

processor.

FR 02/2006 page

7

Service Manual for MEDIPHOT 900E

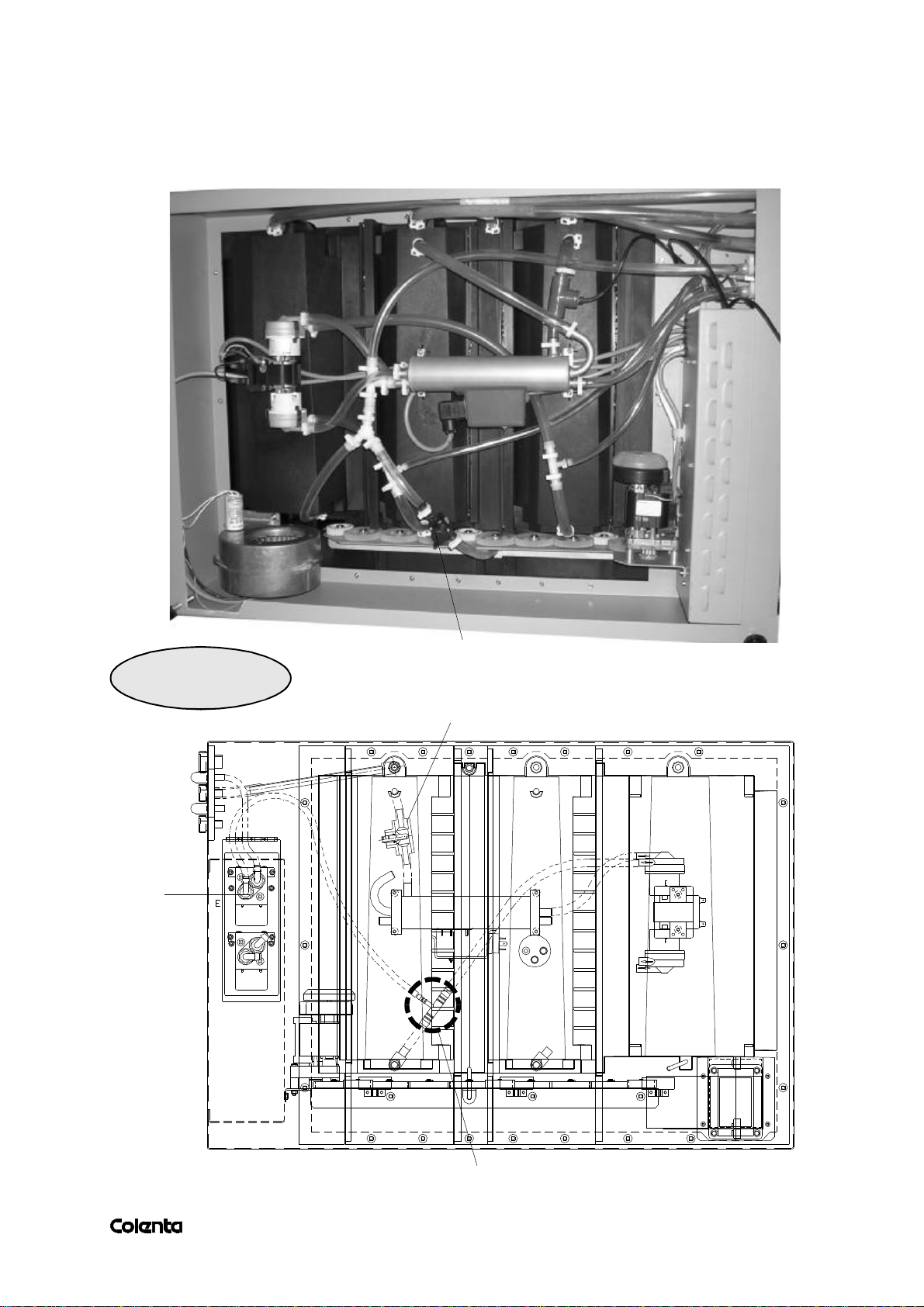

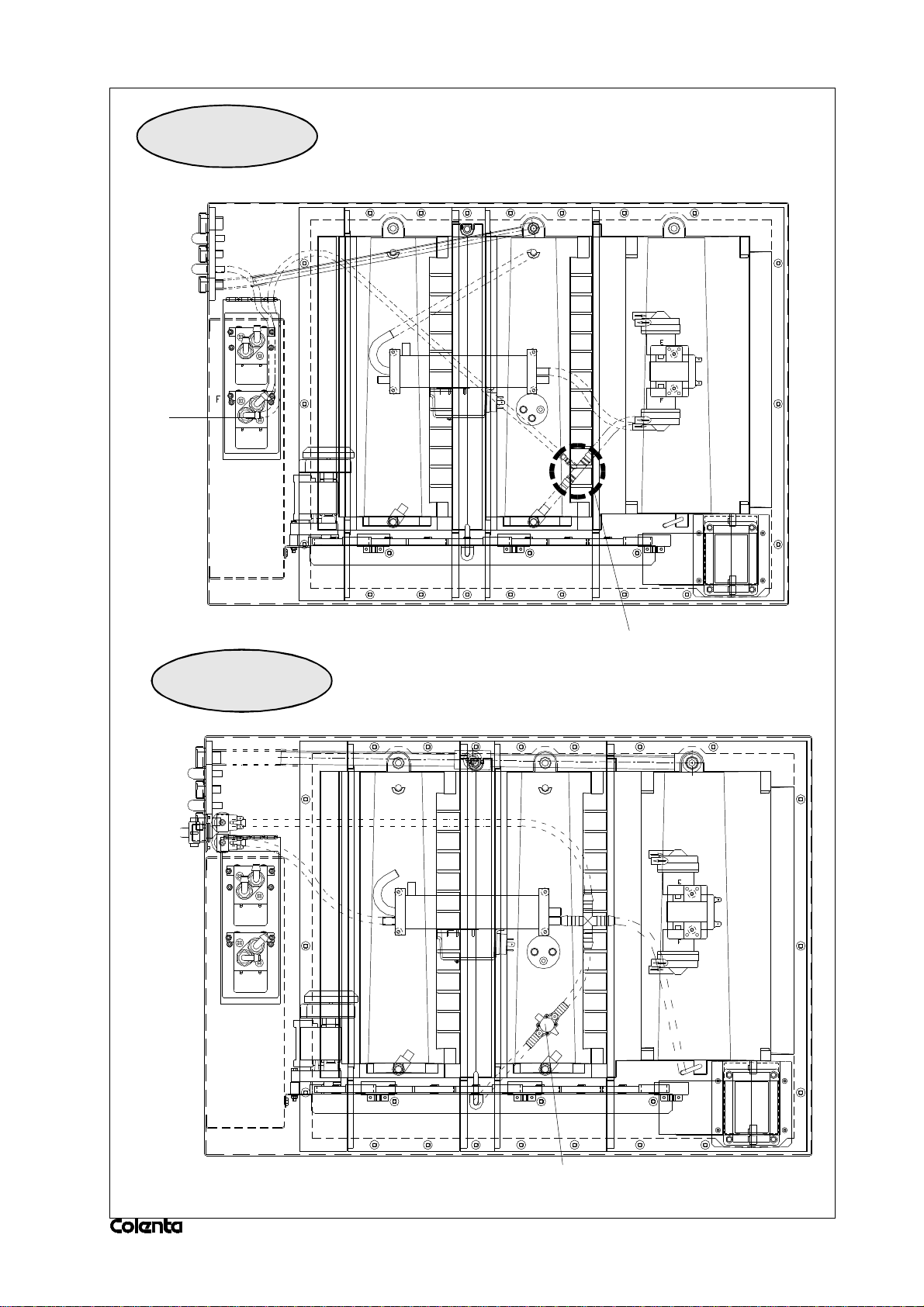

4.Chemistry and water circuts

Following illustrations/drawings and pictures confirms the circulation and

Washwater system of the processor:

Circulationpump

DEVELOPER

TopView

in detail....

Temp.-probe

Heatexanger

Valve to adjust the flowrate

of the intermediate rinse

Temp.-probe DEV

Watervalve

Rep.

DEV

Heatexanger

DEV Replenishment inlet

FR 02/2006 page

Circulationpump

8

Service Manual for MEDIPHOT 900E

Rep.

FIX

FIXER

TopView

in detail....

Circulationpump

Heatexanger

Watervalve

WATER

TopView

FIX Replenishment inlet

in detail....

to Wash and intermediate rinse

Cooling DEV/FIX

Valve to adjust the flowrate

of the intermediate rinse

FR 02/2006 page

9

Service Manual for MEDIPHOT 900E

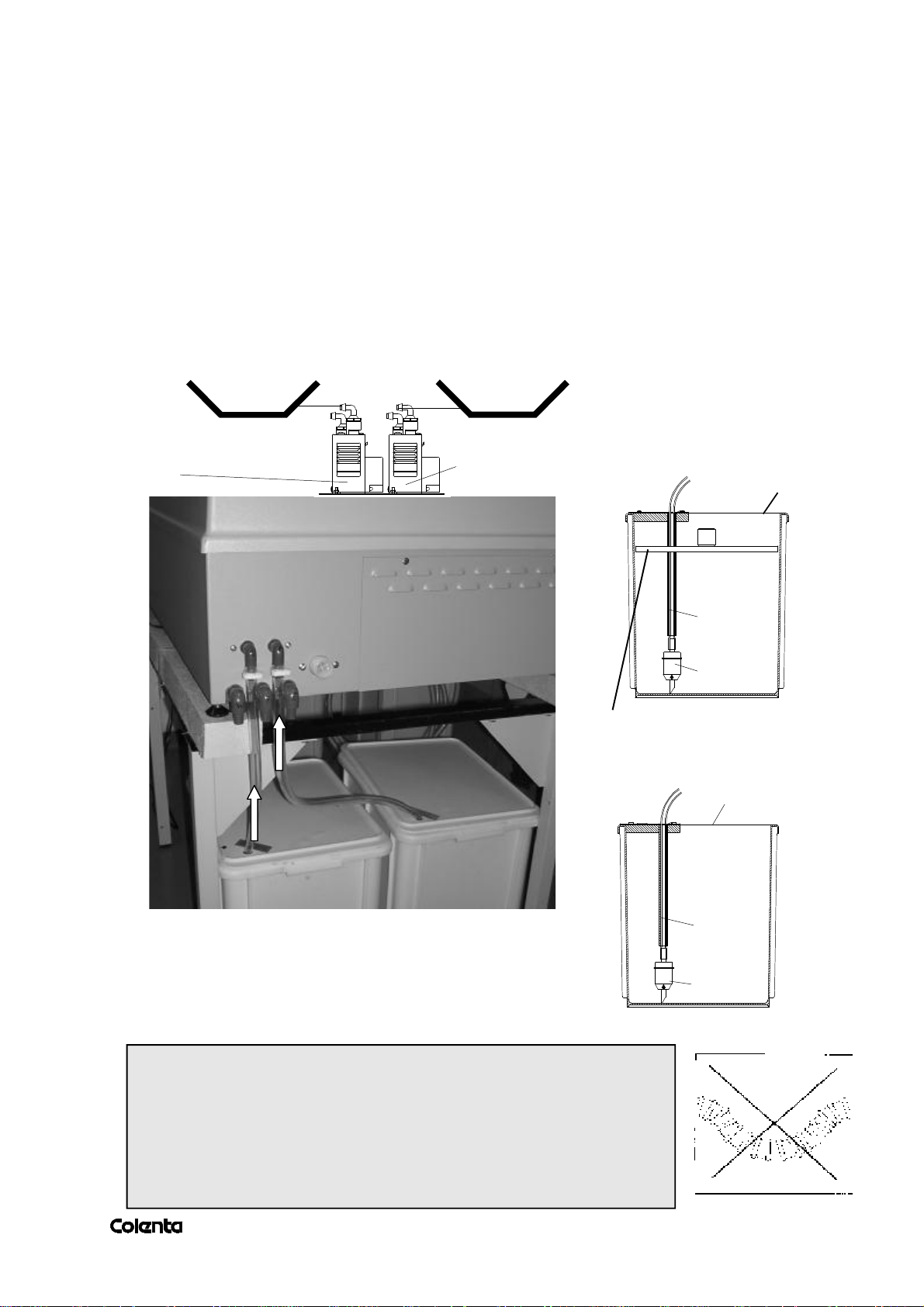

5. REPLENISHMENT

When operating a processor which uses chemicals for the continuous production of plate/film it is very

important that the chemicals within the machine are keep in good working order so as to provide consistent

processing quality. To achieve this consistency we use replenishment solutions, which are formulated by

the chemical manufacturer and injected into the processor precisely for the area of material being

produced. Replenishment of the chemical tanks is done automatically using infra red sensors located at the

entrance to the processor. These sensors accurately monitor the width of material entering the processor,

this information is in then used by the microprocessor (CPU) control software to calculate the surface area

for each plate loaded into the processor. Each sensor, when covered, will generate a pulse, which is then

recorded on a decoder and counted – the more sensors that are covered then the faster the count. When

the count reaches the programmed value of pulse counts it triggers the start of a replenishment cycle.

During each replenishment cycle the replenishment pumps inject fresh solution from small storage bottles/

tank and into the corresponding ”working” tank solutions for a pre-set time.

DEV TANK

Replenisherpump

for DEV

DEV

FIX

DEV

FIX TANK

Replenisherpump

for FIX

USE FLOADING LID

TO PROTECT DEVELOPER

AGAINST OXYDATION

FIX

External Developer

replenisher Tank

Cover

DEV

Standpipe

Filter

Cover

External Fixier

replenisher Tank

WARNING

*) Do not use brass or copper in the drainage system.

*) Chemistry disposal must be in accordance with local

environmental regulations.

*) To avoid back pressure in the drain, the hoses should be

free of bends and with a constant downward gradient.

FR 02/2006 page

FIX

Standpipe

Filter

10

Service Manual for MEDIPHOT 900E

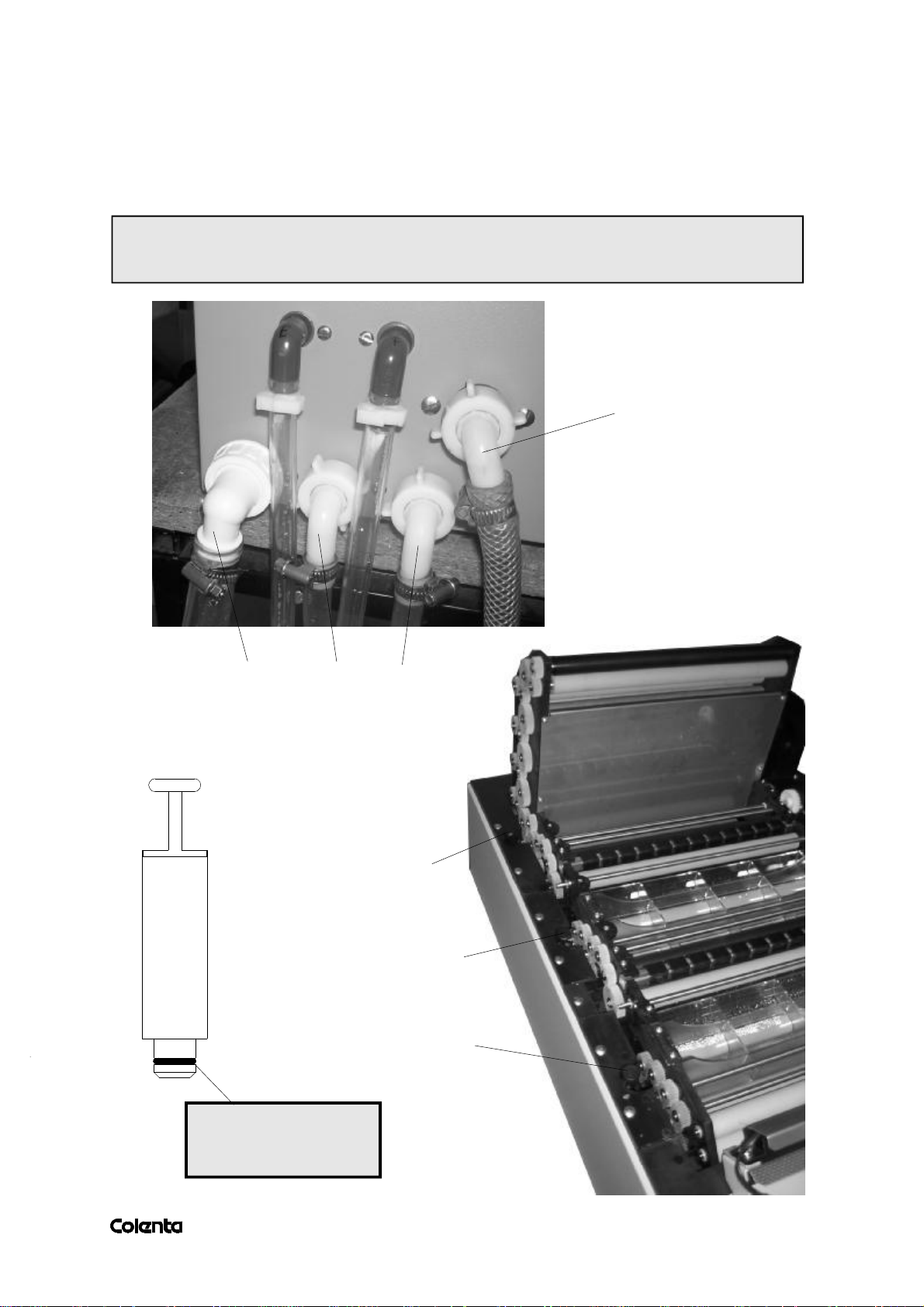

6.CHEMISTRY DRAINS / WATER DRAINS

To drain the filmprocessor (Developer, Fixer and the Wash) just open the drain

tubes according the illustrations below. Take care that all the mentioned drain

taps are close during re-fill up.

IMPORTANAT:Used Developer and used Fixer has to be collected in suitable

conatiners seperately.

WATER Supply Line

DRAINS for:

WATER DEV FIX

Drain Tubes

Lift to drain the WASH

(No-Code)

Lift to drain the FIX

(Blue-Code)

Lift to drain the DEV

(Red-Code)

Check regulary that

the rubber O-Ring is

in correct position.

FR 02/2006 page

11

Loading...

Loading...