Coleman P*HBX12F08001, P*HBX16F10001, P*LBX12F08001, P*LBX16F12001, P*LBX16F14501 Installation Instructions Manual

...Page 1

INSTALLATION

INSTRUCTION

OIL-FIRED

WARM AIR FURNACES

Supersedes: 035-14289-000-A-300

035-14289-000-A-1101

P*HB (UPFLOW)

P*DH (DOWNFLOW

HORIZONTAL)

NRTL/C

CAUTION

THIS PRODUCT MUST BE INSTALLED IN STRICT COM

PLIANCE WITH THE ENCLOSED INSTALLATION IN

STRUCTIONS AND ANY APPLICABLE LOCAL, STATE,

AND NATIONAL CODES INCLUDING BUT NOT LIM

ITED TO, BUILDING, ELECTRICAL AND ME

CHANICAL CODES.

P*LB LOWBOY

WARNING

-

-

-

-

IMPROPERINSTALLATIONMAYCREATEACONDITION

WHERE THE OPERATION OF THE PRODUCT COULD

CAUSE PERSONAL INJURY OR PROPERTY DAMAGE.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance

.

WARNING: Improper installation, adjustment, al

teration, service or maintenance can cause injury

or property damage. Refer to this manual. For as

sistance or additional information,consult a quali

fied installer , service agency or the oil supplier.

-

-

-

Page 2

035-14289-000 Rev. A(0701)

TABLE OF CONTENTS

Introduction

Heat Loss

Unit Location/Clearances

Air Conditioning Applications

Combustion Air

................................................................

..................................................................

..........................................

................................

..........................................................

Downflow/Horizonal Applications

Chimney Venting

.......................................................

Unit Dimensions & Physical Data

Barometric Damper

Fan / Limit Control

Electrical Connections

Fuel Oil Piping

Oil Filter

.....................................................................

Oil Burner Nozzles

Oil Burner Adjustment

Oil Burner Electrodes

Oil Burner Primary Control

Air Blower

..................................................................

Maintenance/Service

Operating Instructions

Oil Burner Air Adjustment

Start Up

...................................................................

Sequence of Operation

Check Out

...............................................................

...................................................

.....................................................

...............................................

...........................................................

....................................................

...............................................

................................................

........................................

............................................

...............................................

..........................................

...........................................

..............................

.........................

2

2

2

2-3

3

3

3

4 - 5

6

6

7

7

8

8

8

8

8

8

9 - 9

9

9

10

10

10

IMPORTANT: SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE

INTRODUCTION

Pleaseread these instructions completely and carefully before

installingand operating thefurnace. Please referto the dataon

pages 4 & 5 for performance and dimensional data.

In the United States the installation of the furnace and related

equipmentshall be installedin accordancewith the regulations

ofANSINFPANo. 31 (latestedition), Installation

Equipment, as well as in accordance with local codes.

In Canada, the installation of the furnace and related equipment shall be installed in accordance with the regulations of

CAN/CSA -- B139--M91 (latest edition), Installation

Oil Burning Equipment, as well as in accordance with local

codes.

Regulations prescribed in the National Codes and Local regu

lations takeprecedence over the general instructions provided

onthis installation manual. When in doubt,please consult your

local authorities.

All models are shipped assembled and pre--wired except model

P*LBX20F19001 where the blower section is separate. The

blower section is shipped together with the burner section, but

must be assembled together during installation. The furnace

shouldbecarefully inspectedfordamage whenbeingunpacked.

ofOilBurning

Code For

NOMENCLATURE

P * HB X 12 F 080 01

Voltage Code = 120 - 1 - 60

Nominal capacity

(MBH Output)

Heating Fuel

F = Fuel Oil

CFM (x100)

Cabinet

X = Non-Standard

Product Identifier

HB = Upflow,

DH = Downflow / Horizontal

LB = Lowboy

Product Generation

May be 1, 2, or 3

Product Category

P = Furnace

HEAT LOSS

The maximum hourly heat loss for each heated space shall be

calculated in accordance with the procedures described in the

following manuals.

In the United States ACCA Manual “J”. titled, “Load Calcula

tion”published by theAir Conditioning Contractors ofAmerica,

describes a suitable procedure for calculating the maximum

hourly heat loss.

InCanada, usethe Heating,Refrigeration andAir Conditioning

Institute of Canada (HRAI), or by any other method which is

suitable for local conditions, provided the results obtained are

insubstantial agreement with andnot less than thoseobtained

using the procedure described in the manual.

LOCATION OF UNIT

The furnace shouldbe located such that the flue connection to

the chimney is short, direct and consists of as few elbows as

possible.Whenpossible, theunit shouldbe centralizedwith re

spect to the supply and return air duct work. A central location

minimizes the trunk duct sizing. .

The minimum installation clearances are listed in Table 1.

-

-

-

TABLE 1 - CLEARANCES TO COMBUSTIBLES (INCHES)

CLEARANCE

FROM

TOP 1

FRONT 24

UPFLOW DOWNFLOW / HORIZONTAL

80 MBH 120 MBH

1

24

SIDES 111111

REAR 1

BOTTOM 0

1

0

S. A. PLENUM 1111131

FLUE PIPE 18* 18* 18* 18* 18* 18* 18*

NOTE: Adquate clearance should be provided over and above these clearances, as required for service access.

* May be 9 inches in Canada

** Elevated on 2-1/2 inch bricks

*** Front clearance required for servicing

2 Unitary Products Group

**** With floor base accessory

80 MBH 120 MBH

LOWBOY

DOWNFLOW HORZ. DOWNFLOW HORZ.

06033

6*** 24 16*** 24 24

Side 1 = 6

Side 2 = 18

111124

0**** 1 0**** 1 0**

Page 3

035-14289-000 Rev. A(0701)

AIR CONDITIONING APPLICATIONS

If the furnace is used in conjunction with air conditioning, the

furnace shall be installed in parallel with or upstream from the

evaporator coil to avoid condensation in the heat exchanger.

In a parallel installation, the dampers or air controlling means

must prevent chilled air from entering the furnace. If the damp

ersare manually operated, theremust be a meansof control to

prevent the operation of either system unless the dampers are

in the full heat or full cool position.

The air heated by the furnace shall not pass through a refrig

eration unit unless the unit is specifically approved for such

service.

The blower speed must be checked and adjusted to compen

satefor the pressure drop causedby the evaporator coil. Refer

toPage 12 for recommended wiring andelectrical connections

of the air conditioning controls.

COMBUSTION AIR

Ifthefurnaceisinstalled ina closetorutility room,two openings

must be provided connecting to a well ventilated space (full

basement,living room or other room opening thereto,but not a

bedroom or bathroom).

One openingshall be located above the level of the upper vent

opening and one opening below the combustion airinletopen

ing in the front of the furnace. Each opening shall have a mini

mum free area of 1

1

square inches per 1,000 Btu/h of total

2

input rating of all appliances installed in the room.

For furnaces located in buildings of unusually tight construc-

tion, such as those with high quality weather stripping, caulking, windows and doors, or storm sashed windows, or where

basement windows are well sealed, a permanent opening

communicating with a well ventilated attic or with the outdoors

shall be provided, using a duct if necessary.

1

The duct opening shall have a free area of 1

square inches

2

per 1,000 Btu/h of total input rating of all appliances to be installed. When a furnace is installed in a full basement, infiltra

tion is normally adequate to provide air for combustion and

draftoperation.Furnace roomsunder 700sq. ft.(65m

3

automatically be treated as confined space.

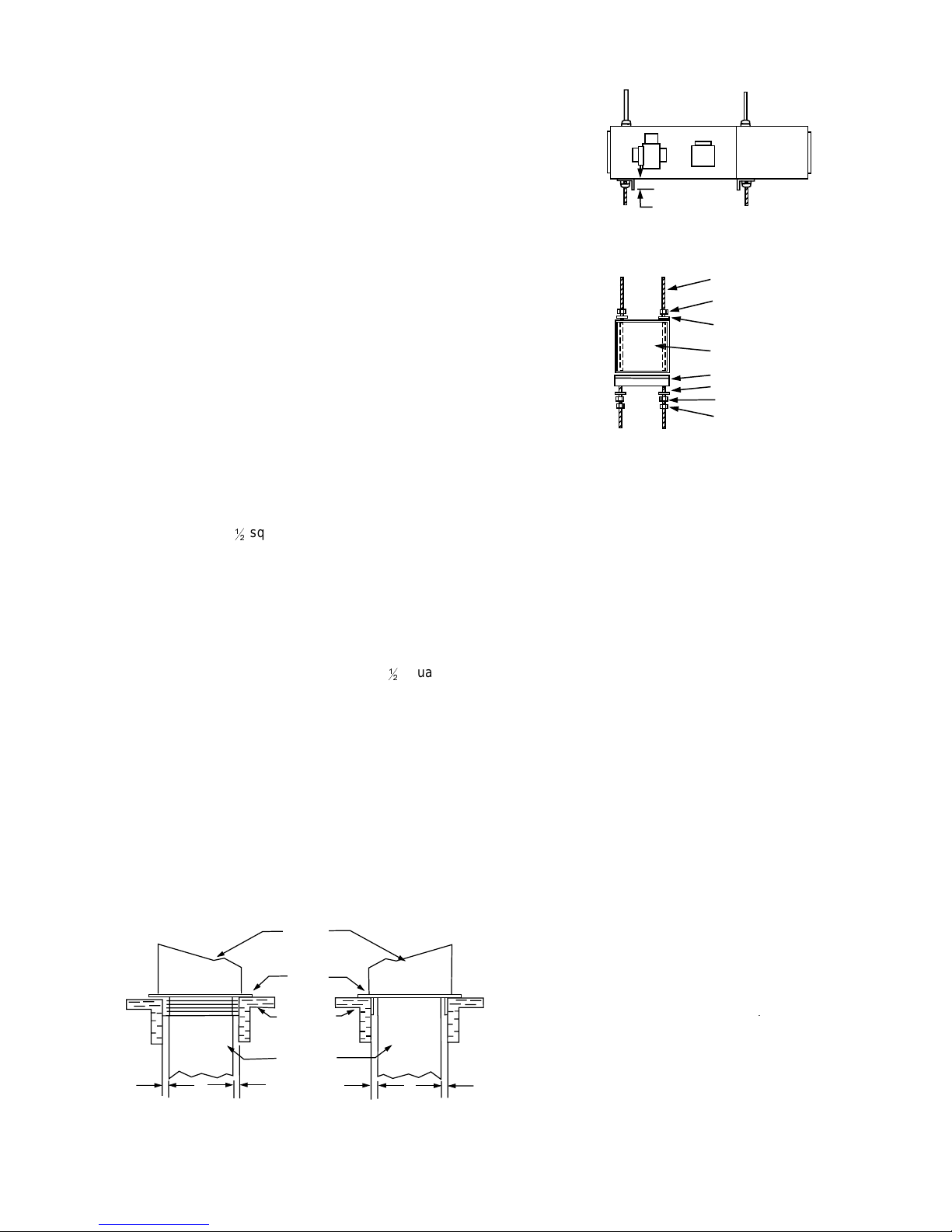

DOWNFLOW/HORIZONTAL FURNACES

Downflow/horizontal models (P*DHX12F08001 & P*

DHX16F12001) are factory shipped for downflow installation.

Downflow

Ifthe furnaceisto beinstalled ina downflowapplication,a com

bustible floor base must be used (either 1CB0312, or

1CB0316). Refer to Figure 1.

DOWNFLOW

FURNACE

SUB BASE

ASSEMBLY

COMBUSTIBLE

FLOOR

DUCT

CONNECTION

20-½ X 20-½

1 IN. 1 IN.

FRONT VIEW

FIGURE 1 - DOWNFLOW APPLICATION

COMBUSTIBLE FLOOR BASE

Unitary Products Group 3

1 IN.

SIDE VIEW

) should

1 IN.

-

2" MIN.

SIDE VIEW

-

THREADED ROD 3/8'

NUT

-

END VIEW

WASHER

FURNACE

SLOTTED ANGLE

WASHER

NUT

JAM NUT.

FIGURE 2 - HORIZONTAL SUSPENDED APPLICATION

-

HANGER ARRANGEMENT

-

Horizontal

For applying the furnace in a horizontal left or horizontal right

application follow these steps.

1. Rotate the furnace 90 degrees to the desired position.

2. Remove three nuts and washers fastening the oil burner

assemblyto thefurnace. Rotatethe oilburner assemblyto

an upright position (ignition transformer and/or protector

relay control should be on top).

3. Realign the oil burner assembly to the combustion cham-

-

ber(firepot) andthensecure withthreenuts andwashers.

4. Remove the cover from the flue collar.

5. Remove the screws securing the flue collar to the furnace

and then rotate the flue collar 90 degrees, such that the

venting attaches to the top.

6. Secure the flue collar to the furnace, then reinstall the flue

collar cover.

7. Horizontal-right applications using model P*DHX12F080

-

alsorequirerelocating thelimit controlto thealternative lo

cation near the top of the unit (refer to Figure 2).

For non-suspended horizontal applications, maintain clear

ances as shown on Table 1. Installation on a combustible floor

requires a clearance of 1". This can be done by using non-combustibles such as 1" channel iron or similar material. The

furnacemust be supported in such a wayto prevent twisting or

sagging of the cabinet.

For suspended horizontal applications maintain clearance as

shown in Table 3. Remove the four circular knockouts on the

top panel and the four knockouts on the bottom panel.

The removedknockoutsallow 3/8" threaded rod to be inserted

through the interior of the furnace. Refer to Figure 2.

Use care when inserting rods since the foil backed insulation

can be easily ripped and torn. Secure the furnace with 2" mini

mum slotted angle or equilavent. The furnace must be sup

ported in such a way to prevent sagging or twisting of the

cabinet.

-

-

-

-

Page 4

035-14289-000 Rev. A(0701)

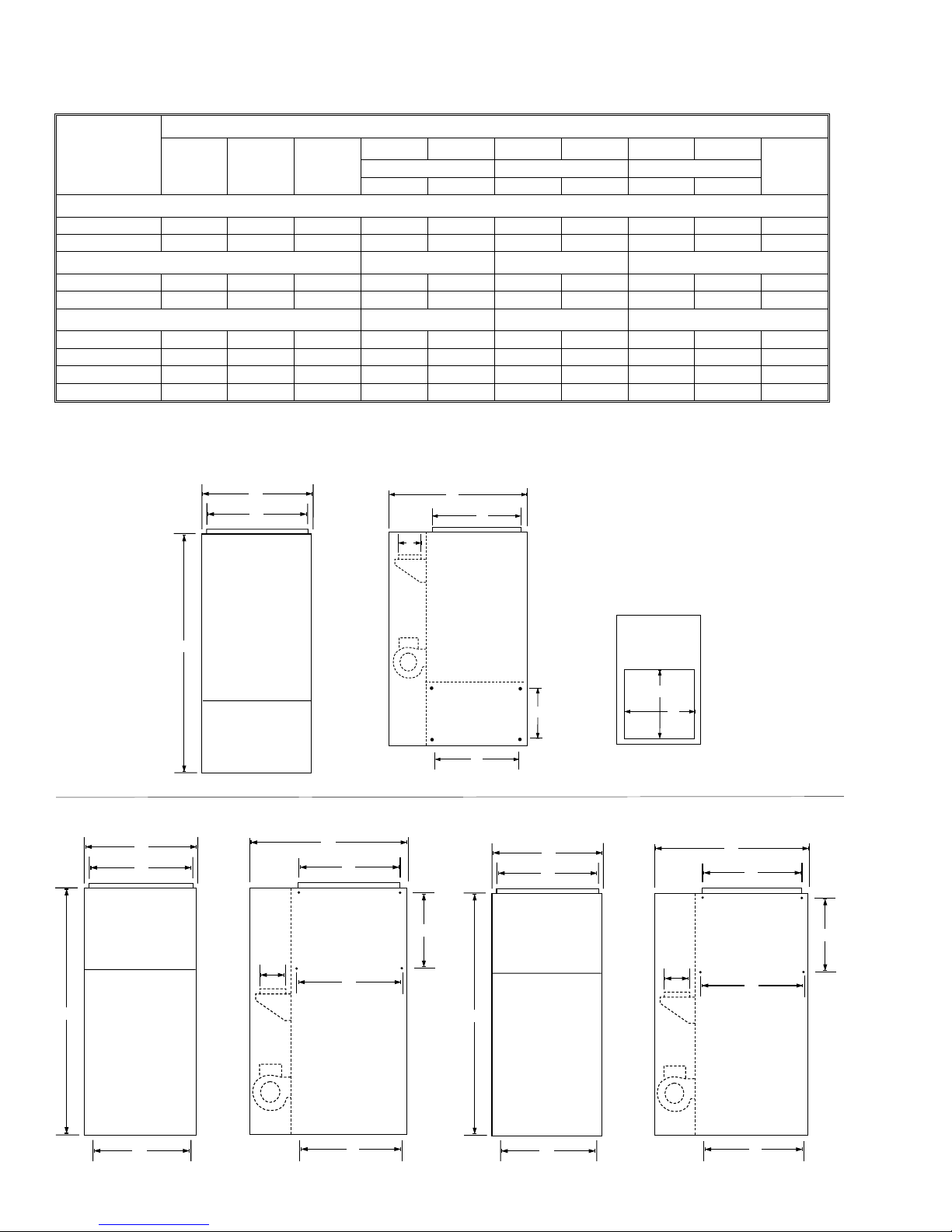

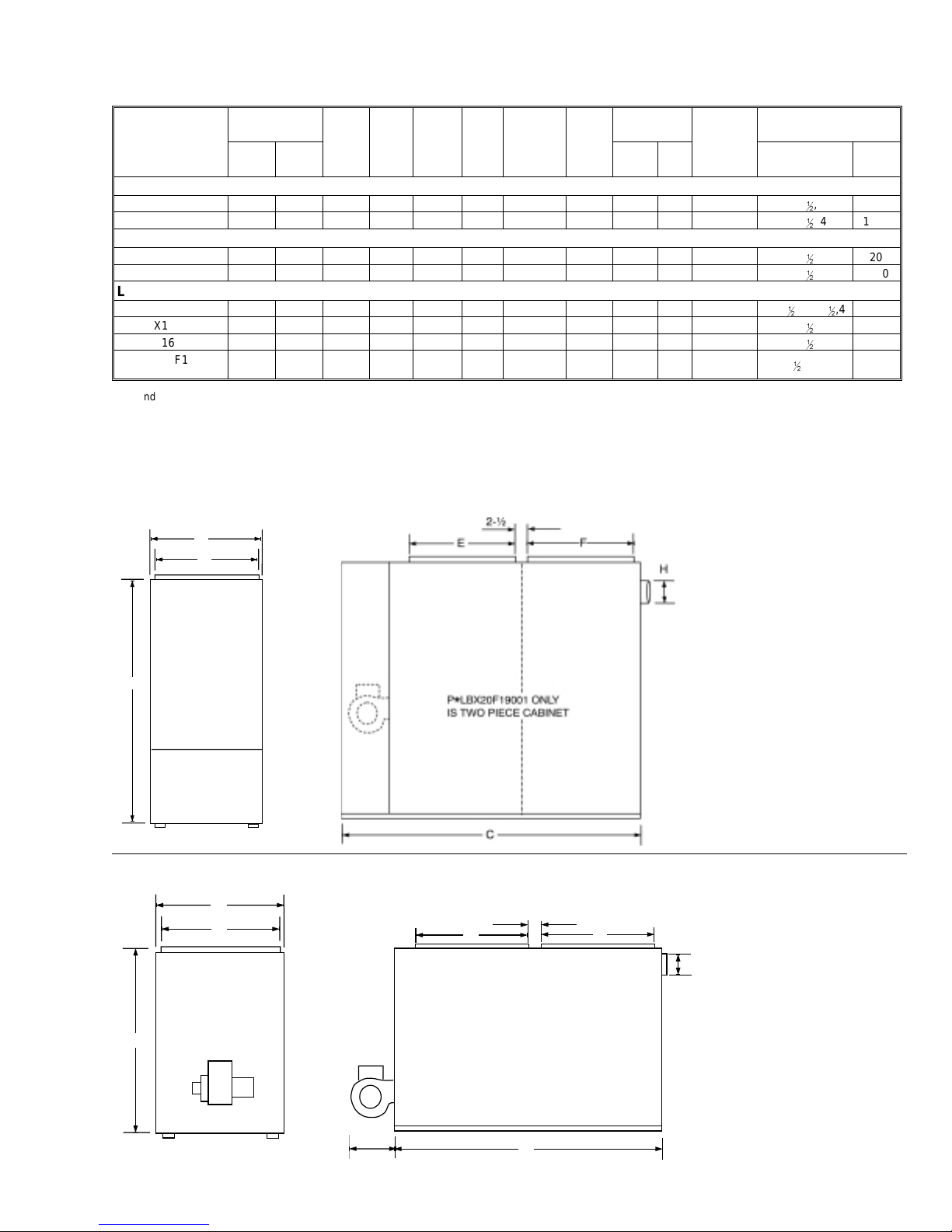

TABLE 2 - UNIT DIMENSIONS

MODEL

A

HEIGHTBWIDTH

C

DEPTH

WIDTH DEPTH WIDTH DEPTH HEIGHT DEPTH

DIMENSIONS - INCHES

DEFG

J

SUPPLYAIR BOTTOM RETURN SIDE RETURN

KH

FLUE

CONNECT .

UPFLOW

P*HBX12F08001 49-5/8 22 31 20-1/2 20 14 22 14 22 5

P*HBX16F10001 58-1/4 22 30-3/4 20-1/2 20 14 22 14 22 6

DOWNFLOW / HORIZONTAL SUPPLY AIR RETURN AIR

P*DHX12F08001 51 22 31-1/4 19 19 18 18 — — 5

P*DHX16F12001 62 22-1/4 22-1/4 20-1/2 20-1/2 18 18 — — 6

LOWBOY SUPPLYAIR RETURN AIR

P*LBX12F08001 31 22 43 20-1/2 18-5/8 20-1/2 18-5/8 — — 5 (REAR)

P*LBX16F12001 41 22 52-1/2 20-1/2 18-5/8 20-1/2 18-5/8 — — 6 (REAR)

P*LBX16F14501 41 22 52-1/2 20-1/2 18-5/8 20-1/2 18-5/8 — — 6 (REAR)

P*LBX20F19001 56 26 49 24 22 24 22 — — 7 (REAR)

UPFLOW - MODELS P*HB

*

,

C

E

H

)

DOWNFLOW/HORIZONTAL - MODEL P*DH16F12001

(Exposed burner)

*

,

0

)

+

-

,

G

J

K

BOTTOM VIEW

F

DOWNFLOW/HORIZONTAL- MODEL P*DH12F08001

*

,

-

0

)

+

-

-

,

/

4 Unitary Products Group

.

/

.

Page 5

035-14289-000 Rev. A(0701)

PHYSICAL & ELECTRICAL DATA

PUT

1

OIL

RATE

GPH

-

AFUE

%

2

CFM @

.5 IWG

E.S.P.

3

UNIT

AMPS

MAX.

OVERCURRENT

PROTECT.

WIRE

SIZE

AWG

BLOWER

SIZE HP TONS NOM.

FILTERS

QTY. &

SIZE

MODEL

HEATINGMBH

INPUT * OUT

UPFLOW

P*HBX12F08001 91 80 .65 82.0 1291 12.0 15 14 10 x 10 1/2 (1) 16 x 25 2, 2P*HBX16F10001 119 100 .85 82.7 1445 12.0 15 14 10 x 10 1/2 (1) 16 x 25 3, 3-

DOWNFLOW / HORIZONTAL

P*DHX12F08001 91 80 .65 82.0 1291 12.0 15 14 11x 10 1/2 (1) 120x 20 2, 2P*DHX16F12001 140 120 1.0 80.1 1593 12.0 15 14 11 x 10 1/2 (1) 20 x 20 3, 3-

LOWBOY

P*LBX12F08001 91 80 .65 85.1 1717 12.0 15 14 12 x 9 1/2 (1) 20 x 20 2, 2P*LBX16F12001 140 120 1.0 83.4 1585 12.0 15 14 12 x12 1/2 (1) 20 x 25 3, 3P*LBX16F14501 168 145 1.20 83.5 1585 12.0 15 14 12 x 12 1/2 (1) 20 x 25 3, 3P*LBX20F19001

* Standard input as shipped. See Table 3, Page 8 for alternate firing rates.

1

For Altitudes above 2000 feet, reduce ratings 4% for each 1000 feet above sea level.

2

AFUE (Annual Fuel Utilization Efficiency) determined using DOE test procedure, isolated combustion.

3

Available external static pressure is at furnace outlet and ahead of cooling unit.

231 190 1.65 78.0 2135 12.0 15 14 12 x 12 3/4 (2) 20 x 25

LOWBOY - MODELS P*LBX16F12001, P*LBX16F14501, P*LBX16F19001

ADD-ON

COOLING

1

, 3 1200

2

1

, 4 1600

2

1

, 3 1200

2

1

, 4 1600

2

1

,3, 3-

2

1

, 4 1600

2

1

, 4 1600

2

1

3-

, 4, 5

2

1

,4 1200

2

CFM

2000

*

,

)

LOWBOY - MODEL P*LBX12F08001 (Exposed Burner)

B

D

E

2-½

F

H

A

Unitary Products Group 5

8-1/2

C

Page 6

035-14289-000 Rev. A(0701)

W

FAN & LIMIT LOCATION

LEFT HORIZONTAL APPLICATION

FAN & LIMIT LOCATION

AIR FLO

BAROMETRIC DAMPER CONTROL

Thisdevice mustbe usedwith allchimney andTypeLvent sys

tems.This control(or draftregulator) automaticallymaintains a

constant negative pressure in the furnace to obtain maximum

efficiency.Itensuresthatproper pressuresarenot exceeded.

If the chimney does not develop sufficient draft, the draft control

cannot function properly. The draft regulator, when installed

should be in the same room or enclosure as the furnace and

should not interfere with the combustion air supplied to the

burner.

The control should also be located near the furnace flue outlet

and installed according to the instructions supplied with the

regulator.The flue outletpressure (measured between the fur

nace and draft regulator) should be set to --0.02 in. w.c.

-

-

AIR FLOW

FAN AND LIMIT CONTROL

Upflow & Lowboy Models

The L6064A temperature sensitive fan switch is actuated by a

helical bi--metal sensing element enclosed in a metal guard,

and controls the circulating air blower. This provides a delay

betweenthe burnerignition andblowerstartupto eliminateex

FIGURE 3 - HORIZONTAL APPLICATION

RIGHT HORIZONTAL APPLICATION

FAN/LIMITLOCATION

CAUTION: Fan/limit control location is critical in the

P*DHX12F08001 horizontal positions. Tooperate effectively as a high limit control, the fan / limit control

mustbeinstalled intheupper position.SeeFigure 3.

CHIMNEY VENTING

The flue pipe should be as short as possible with horizontal

pipessloping upward towardthe chimney ata rate of onequarter inchtothe foot. The flue pipe should not be smaller in cross

sectional area than the flue collar on the furnace.

The flue pipe should connect to the chimney such that the flue

pipe extends into, and terminates flush with the inside surface

ofthe chimney liner.Sealthe joint betweenthe pipe andthe lin

ing.

The chimney outlet should be at least two feet above the high

estpointofapeaked roof.All unusedchimney openingsshould

be closed.

Chimneysmust conformtolocal, provincialor statecodes, orin

the absence of local regulations, to the requirements of NFPA

2.11(latest edition) Chimney,Fireplaces, Ventsand Solid Fuel

Burning Appliances (in Canada CSA B139)..

NOTE: All furnace models are approved for use with

Type Lvent or equivalent.

CAUTION: The furnace must be connected to a flue

having sufficient draft at all times to ensure safe and

proper operation of the appliance.

NOTE: The recommended flue draft pressure is --

0.02in. W.C. (asmeasured upstream of the baromet

ric draft regulator).

The flue pipe must not pass through any floor or ceiling, but

may pass through a wall where suitable fire protection provi

sions have been installed. Refer to the latest edition of ANSI

NFPA31(in theUnited States,or CAN/CSAB--139 in Canada)

for regulations governing the installation of oil burning equip

ment.

See Table 4 for burner set-up.

cessive flow of cold air when the blower comes on. Blower

shutdownis also delayed toremove any residual heatfrom the

heat exchanger and improve the annual efficiency of the fur

nace. Fan settings of 120° Fto130°F (50° Cto55° C) and fan

settingsof 90° F to 100°F (32° Cto37°C) will usually be satis-

factory.

Downflow /Horizontal Models

The L4064W temperature sensitive fan switch contains a

heater--wrapped bi--metal to actuate the fan switch independentof the temperature atthe helical sensing element.The time

fromignition, tothe bloweron functionis approximately30 seconds. If after 1 minute, the blower has not come on, replacementof the control may be necessary.The blowershutdown is

the same as noted for the L6064A control.

Thelimit switchperforms asafety functionandbreaks powerto

the oil burner primary control, which shuts off the burner if the

furnaceover--heats.The limitcontrol isthermally operatedand

automatically resets. The limit control is factory installed, pre--

-

set and is not adjustable.

The limit control and fan control are incorporated in the same

housing and are operated by the same thermal element.

The downflow furnace utilizes an additional auxiliary limit con

trol which is an automatic reset type.

ELECTRICAL CONNECTIONS

The furnace is listed by the Canadian Standards Association

under the NRTL (North American) Standard. It is factory wired

and requires minimal field wiring. All field wiring should con

form to the following standards or by local codes, where they

prevail and by In the United States, refer to the National Fire

Protection Association NFPA--70, National Electrical Code

-

(latestedition), or in Canada, CAN/CSAC22.1Canadian Elec

trical Code, Part 1, and with local codes and regulations.

The furnace should be wired to a separate and dedicated cir

cuit in the main electrical panel; however, accessory equip

ment such as electronic air cleaners and humidifiers may be

included on the furnace circuit. Although a suitably located cir

cuit breaker can be used as a service switch, a separate serv

ice switch is advisable. The service switch is necessary if

reachingthe circuit breakerinvolves becoming closeto the fur

nace, or if the furnace is located between the circuit breaker

and the means of entry to the furnace room.

6 Unitary Products Group

-

-

-

-

-

-

-

-

-

-

Page 7

035-14289-000 Rev. A(0701)

The furnace switch (service switch) should be clearly marked,

installed in an easily accessible area between the furnace and

TABLE 3 - OIL PIPING LENGTHS (FEET)

furnaceroom entry,and be located in sucha manner to reduce

thelikelihood that it wouldbe mistaken asa light switch orsimi

lar device.

Accessories requiring 120 VAC power sources such as elec

tronic air cleaners and humidifier transformers may be pow

ered from the furnace circuit, but should have their own

controls

Do not use the direct drive motor connections as a power

source, since there is a high risk of damaging the accessories

by exposure to high voltage from the auto--generating wind

ings of the direct drive motor.

Thermostat wiring connections and air conditioning contactor

low voltage connections are shown in the wiring diagrams on

Page 12. Some micro--electronic thermostats require addi

tional controls and wiring. Refer to the thermostat manufac

turer's instructions.

CAUTION: A room thermostat with independent

heat/cool circuit is required.

The thermostat should be located approximately 5 feet above

thefloor, onan inside wall where there isgood natural air circu

lation,and where thethermostat will beexposed to averageroom

temperatures. Avoid locations where the thermostat will be ex

posed to cold drafts,heat from nearby lamps and appliances, ex

posure to sunlight, heat from inside wall stacks, etc.

NOTE: Some electronic thermostats do not have adjustable heat anticipators. They may have other type

cycle rate adjustments. Follow the thermostat manufacturer's instructions.

-

-

-

LIFT

1 53 100 68 100

SINGLE STAGE 2-STAGE

3/8" O.D.

TUBING

1/2" O.D.

TUBING

3/8" O.D.

TUBING

2 49 100 65 100

3 45 100 63 100

4 41 100 60 100

5 37 100 58 100

-

6 33 100 55 100

7 29 100 53 100

8 259950100

9 218348100

-

-

10 17 68 45 100

12 13 52 42 100

12 — — 37 100

14 — — 32 100

16

18

— — 27 100

— — 22 88

component in the line. In general, keep single line systems

-

short as possible. If the furnace is to be installed in a sus

-

pendedposition,a twopipesystem maybea betteralternative.

Two--stage oil pumps may be used with both single line and

two line systems. Two--stage pumps are available from your

HVACwholesaler.Table 3lists allowable line lengths (horizontal plus vertical) for single and two stage oil pumps.

1/2" O.D.

TUBING

In retrofit applications where an existing oil line system is in

Set the heat anticipator in the room thermostat to .4

amps. for models P*HBX12F080, P*DHX12F080 &

P*DHX16F120; for other models set heat anticipator at

.2 amps. Setting it lower will cause short cycles. Setting

it higher will cause the room temperature to exceed the

setpoint.

place, a vacuum check will help determine if a two--stage oil

pump is necessary. The vacuum in a system using a single

stageoil pump should not exceed 6" Hg. The vacuum in a systemusing a two--stageoil pumpshould not exceed15" Hg. For

additionalinformation,refertothe instructioninformation sheet

affixed to the oil burner.

Installthe oilfilter asclose tothe burneras possible.For further

HUMIDIFIER

A humidifier is an optional accessory available through most

heating supplies outlets. Installation should be carried out in

accordance with the humidifier manufacturer's installation in

structions. Water or water droplets from the humidifier should

not be allowed to come into contact with the furnace heat ex

changer.Donotuse direct drivemotor connectionsas asource

ofpowerfor 120VAChumidifiersandhumidifier transformers.

details of the oil supply tank and piping requirements, please

referto the instructions and illustrationsin the oil burnerand oil

pump instructions shipped with the furnace.

-

OIL FILTER

All fuel systems should include an oil filter between the fuel oil

storage tank and the oil burner.When using an oil burner noz

zle smaller than 0.65 U.S. Gallons Per Hour, install an addi

tional7to 10micronfilter ascloseas possibleto theoilburner.

PIPING INSTALLATION

The entire fuel system should be installed in accordance with

the requirements of ANSI NFPANo. 31 in the United States or

CAN/CSA B--139 in Canada, and local regulations. Use only

an approved fuel oil tanks piping, fittings and oil filter.

Ensure that all fittings used in a copper oil line system are high

quality flare fittings. Do

not use compression fittings.

Pressurized or gravity feed installations must not exceed 10

PSIG ontheinlet line or the return line at the pump. Apressure

greater then 10 PSIG may cause damage to the shaft seal.

The furnace may be installed with a one pipe system or gravity

feedorlift. Themaximumallowable liftona singlelinesystem is

8ft. Liftshouldbe measuredfromthe bottom(outlet) ofthe tank

to the inlet of the burner.

Sizing a single line system is complex because of the difficulty

estimating the pressure drop through each fitting, bend and

Unitary Products Group 7

OIL BURNER NOZZLES

These furnaces are certified for multiple firing rates, ranging

from60,000to 181,000Btu/h dependingon model.Bymanipu

lating the oil burner nozzle, flame retention head, static plate

and temperature rise, the furnace may be fired at an ideal rate

fora widerange of structures.Refer toTable4,and thefurnace

rating plate to determine the proper combinations.

CAUTION: Before operating the furnace check

burner alignment with the combustion chamber. The

end cone of the air tube must be centered to the ac

commodating ring provided in the design of the com

bustion chamber. Adjust as necessary.

-

-

-

-

-

-

Page 8

035-14289-000 Rev. A(0701)

TABLE 4 - BECKETT AF OIL BURNER SET-UP

MODEL

P*HBX12F08001

P*HBX16F10001

P*LBX12F08001

P*LBX16F12001

P*LBX16F14501

P*LBX20F19001

P*DHX12F0801

OUTPUT

(BTU/H)

BURNER

MODEL

NOZZLE

PUMP

PRESSURE

FLOW RATE HEAD

STATIC

PLATE

UPFLOW

60,000 AF76BO

78,000 AF76BO

90,000 AF76XN

0.50 / 60° A

0.65 / 60° A

0.75 / 60° A

100 PSIG 0.50 GPH F0 3-3/8"

100 PSIG 0.65 GPH F0 3-3/8"

100 PSIG 0.75 GPH F3 2-3/4"

100,000 AF76XN 0.85 / 60° A 100 PSIG 0.85 GPH F3 2-3/4"

79,000 AF65XN

90,000 AF65XN

101,000 AF65XN

119,000 AF65XN

0.65 / 80° A

0.75 / 80° A

0.85 / 80° A

1.00 / 80° A

100 PSIG 0.65 GPH F3 2-3/4"

100 PSIG 0.75 GPH F3 2-3/4"

100 PSIG 0.85 GPH F3 2-3/4"

100 PSIG 1.00 GPH F3 2-3/4"

LOWBOY

60,000 AF63B0PWHS

78,000- AF63B0PWHS

90,000

AF63XNPWH

S

79,000 AF76XN

90,000 AF76XN

101,000 AF76XN

117,000 AF76XN

130,000 AF76YB

143,000 AF76YB

168,000 AF65XO

181,000 AF65XO

0.50 / 60° A

0.50 / 60° A

0.75 / 60° A

0.65 / 80° A

0.75 / 80° A

0.85 / 80° A

1.00 / 80° A

1.10 / 70° A

1.20 / 60° A

1.50 / 70° B

1.65 / 70° B

100 PSIG 0.50 GPH F0 3-3/8"

100 PSIG 0.65 GPH F0 3-3/8"

100 PSIG 0.75 GPH F3 2-3/4"

100 PSIG 0.65 GPH F3 2-3/4"

100 PSIG 0.75 GPH F3 2-3/4"

100 PSIG 0.85 GPH F3 2-3/4"

100 PSIG 1.00 GPH F3 2-3/4"

100 PSIG 1.10 GPH F6 2-3/4"

100 PSIG 1.20 GPH F6 2-3/4"

100 PSIG 1.50 GPH F12 2-3/4"

100 PSIG 1.65 GPH F12 2-3/4"

DOWNFLOW/HORIZONTAL

60,000 AF76BO

78,000 AF76BO

90,000 AF76XN

0.50 / 60° A

0.65 / 60° A

0.75 / 60° A

100 PSIG 0.50 GPH F0 3-3/8"

100 PSIG 0.65 GPH F0 3-3/8"

100 PSIG 0.75 GPH F3 2-3/4"

BURNER PRIMARY (SAFETY) CONTROL

The furnace is equipped with a primary combustion control,

sometimes referred to as the burner relay or burner protector

relay,whichuses alight sensing device(cad cell) locatedin the

burner housing, to monitor and control combustion.

Over time, dust or combustion residuals can build up on the

lens of the cad cell impairing its response to the flame. The

cad cell should be checked for cleanliness and proper align

ment if the primary control frequently shuts down combus

tion.

CIRCULATING AIR BLOWER

These furnaces (with the exception of model P*LBX20F190

which is belt drive) are equipped with direct drive blower sys

tems. Direct drive blower speed adjustments are not normally

requiredin properly sized extended plenumduct systems. The

motor RPM and air CFM delivery will vary automatically to ac

commodateconditions within the usual rangeof external static

pressures typical of residential duct systems.

-

-

Under-sized duct systems may require a higher blower speed

to obtain a reasonable system temperature rise. Some older

duct systems were not designed to provide static pressure.

COMBUSTION CHAMBER

This furnace is equipped with a high quality cerafelt combus

tion chamber. It is held in place by a retaining bracket.

CHECK THE ALIGNMENT OF THE COMBUSTION CHAM

BER AND OIL BURNER BEFORE FIRING. IT IS POSSIBLE

FOR THE COMBUSTION CHAMBER TO SHIFT IF SUB

JECTED TO ROUGH HANDLING DURING TRANSIT.

The combustion chamber should be inspected for damage or

carbon build up whenever the oil burner is removed for repairs

or routine maintenance.

WARNING:Do not start the burner unless the blower

access door is secured in place.

They typically feature special reducing fittings at each branch

run and lack block ends on the trunk ducts.

These systems may require modification to provide some re

sistance to the airflow to prevent over-- amping of the direct

-

drive blower motor. Selecting a lower blower speed may cor

rect this problem.

Direct drive blower speeds are adjusted by changing the “hot”

wires to the motor winding connections. Please refer to wiring

diagram on Page 12, or the wiring diagram label affixed to the

furnace. THE NEUTRAL WIRE (normally the white wire) IS

NEVER MOVED TO ADJUST THE BLOWER SPEED.

It is possible and acceptable to use a single blower speed for

both heating and cooling modes. The simplest method to con

nect the wiring from both modes is to use a “piggy--back con

nector” accommodating both wires on a single motor tap.

8 Unitary Products Group

-

-

-

-

-

-

Page 9

035-14289-000 Rev. A(0701)

Itis alsoacceptable toconnect the selectedmotor speedwith a

pig tail joined to both heating and cooling speed wires with a

wire nut. As a safety precaution against accidental disconnec

tion of the wires by vibration, it is advisable to secure the wire

nut and wires with a few wraps of electricians tape.

CAUTION:Do not connectpower leads between mo

tor speeds. The neutral wire must always be con

nected to the motor's designated neutral terminal.

WARNING: Disconnect the power supply to the fur

nace before opening the blower access door to serv

ice the air filter,fan or motor. Failure to shut off power

could allow the blower to start unexpectedly,creating

a risk of death or personal injury.

If the joining of the blower speed wiring is done in the furnace

junction box, tape off both ends of the unused wire.

Do not use the blower speed wires as a source of power to

accessories as electronic air cleaners and humidifier

transformersunless

will be used. The unused motor taps auto--generate suffi

ciently high voltages to damage accessory equipment.

itis certainthatonly one motor speed

MAINTENANCE AND SERVICE

Routine Maintenance By Home Owner

Otherthan rememberingto arrangefor theannual professional

servicingof thefurnace bythe serviceor installationcontractor,

the most important routine service performed by the home

owneris tomaintain theair filteror filters.Adirty filtercan cause

the furnace to over--heat, fail to maintain indoor temperature

during cold weather, increase fuel consumption and cause

component failure.

The furnace filter(s) should be inspected, cleaned or replaced

monthly. The furnace is factory equipped with a semi-permanenttype filter.Ifthe filteris damaged,replace withfilters

of the same size and type. (See Page 5 for listing).

During the routine service, inspect the general condition of the

furnace watching for signs of oil leaks in the vicinity of the oil

burner, soot forming on any external part of the furnace, soot

forming around the joints in the vent pipe, etc. If any of these

conditions are present, please advice your service or installa

tion contractor.

Annual Service By Contractor

CAUTION: The combustion chamber (firepot)is frag

ile.Usecare wheninspectingand cleaningthisarea.

The heat exchanger should be inspected periodically and

cleaned if necessary. if cleaning is necessary, SHUT OFF

POWER TO THE FURNACE and remove the burner. Using a

stiff brush with a wire handle, brush off scale and soot from in

side the drum and flue pipe. Toclean the radiator, remove the

round covers on the inner front panel to gain access to the

cleaning ports.

When this procedure is done for the first time, carefully cut

away the insulation covering the opening with a sharp knife.

Loosen the nuts on the radiator clean--outs. DO NOT RE

MOVE THE NUTS. Remove the covers carefully to avoid tear

ing the gaskets. A wire brush can be used to loosen dirt and

debris on the inside surfaces of the radiator.

Cleanout all accumulated dirt, sootanddebris with a wire han

dled brush and an industrial vacuum cleaner.Before replacing

the clean--out covers, inspect the gaskets. If the gaskets are

broken, remove the remnants and replace with new gaskets.

Snug the cleanout covers. DO NOT OVER--TORQUE THE

Unitary Products Group 9

CLEAN--OUT NUTS. Replace the inner front panel clean--out

covers.

-

NOTE: A radiator clean--out assembly inadvertently

droppedinto the interior of thefurnace can usually be

-

-

Thedirect driveblower motoris factoryoiled. Undernormal op

-

erating conditions it does not require oiling for the first two

-

years. Oil sparingly (a few drops) in each oil port with SAE 20

non--detergent oil. Oiling is most easily done with a “tele-spout” oilier. This oiler has a long flexible plastic spout. DO

NOT OVER--LUBRICATE.Excess oil causes premature elec

tric motor failure.

Inspect the blower fan. Clean if necessary.

Oil Burner Maintenance: Follow the instructions of the oil

burner manufacturer. (See oil burner manufacturer's instruc

-

tions supplied with furnace). It is advisable to change the oil

burner nozzle and oil filter on an annual basis.

Theventing systemshould becleaned and inspectedfor signs

of deterioration. Replace pitted or perforated vent pipe and fit

tings. The barometric damper should open and close freely.

All electrical connections should be checked to ensure tight

connections. Safety controls such as the high limit controls

should be tested for functionality. The fan control should be

checked to ensure that the “fan off” function continues to stop

the blower fan at temperatures between 90° F to 100° F.

easily retrieved with a magnet on a wire handle or

stout string.

OPERATING INSTRUCTIONS

Before Lighting

1. Open all supply and return air registers and grilles.

2. Open all valves in oil pipes.

3. Turn on electric power supply

To Light Unit

1. Set the thermostat above room temperature to call for

-

-

-

-

-

-

heat.The burner should start.NOTE: It maybe necessary

to press the RESET button on the primary combustion

control relay.

2. After ashort period of time, as thefurnace becomes warm

enoughthe act uponthe fan control(L6064A), or preheats

the bi--metallic element (L4064W), the blower should

start.

3. Set the thermostat below room temperature. The oil

burner should stop.

4. Theair circulationblowerwill continueto runaslong asthe

temperature in the furnace is higher than the “FAN OFF”

setting on the fan control. Typical “fan on” values range

from120° Fto 130° F.Typical“fan off”temperatures range

between 90° F and 100° F. The fan control adjustments

may be altered if the air at the room registers is uncom

fortably high upon blower start up or shutdown, the fan

control settings can be lowered.

5. The adjustments to the fan control settings should be

made by measuring the temperature of the air in the sup

ply air take--off, or within the first few inches of the supply

air trunk. The side mid point of the transition is usually

ideal, providing that the thermometer probe is beyond the

“line of sight” wherein false readings from radiant heat

could be observed. The system temperature rise, the dif

ference in temperature between the supply air and return

air, will typically range between 65° F and 70° F.

-

-

-

-

-

-

-

Page 10

035-14289-000 Rev. A(0701)

Tocheck the operation of the limit switch, shut off power to the

furnace. Temporarily remove the neutral wire from the direct

drive blower motor.Restore the electrical power to the furnace

and set the thermostatabove room temperature. After three or

four minutes of burner operation, the limit control should turn

the burner off.

The progress towards a high limit shut down can be monitored

by watching the dial on the fan / limit control. When the limit

function test is complete, shut off electrical power to the fur

nace, replace the neutral wire to the blower fan motor,then re

storepower. Theblower fan will start upimmediately.Once the

temperature has dropped, the oil burner will resume and con

tinue until the thermostat is satisfied. Restore the thermostat

setting to a comfortable temperature.

To Shut Down Unit

1. Set the thermostat to the lowest possible setting.

2. Set the manual switch (if installed) in the Electrical Power

Supply Line to “OFF”.

NOTE: If the furnace is to be shut down for an ex

tendedperiod of time, close theoil supply valve to the

burner.

OIL BURNER AIR ADJUSTMENT

For complete details, consult the oil burner instruction manual

provided in the furnace documents envelope.

Beckett AF Burner

Adjustthe airshutter by looseningthe lockingscrews and mov-

ing the air shutter, and if necessary, the bulk air band.

Procedure

Startthe burner and allow it to run at least ten minutes. Set the

air shutter to give a good flame visually. The air supply to the

burner is controlled by the air shutter on the left side of the

burner,and the bulk air band. To adjust, loosen the bolt on the

movableshutter. Move theshutter gradually until a good flame

(visually) has been achieved. Re--snug the bolt.

Check the initial draft setting as the furnace warms up. The

draftmaybe measuredat thetest port.In mostcases, thepres

-

sure dropbetween the test port and the oil burner is negligible.

-

The test port draft reading may be interpreted as the “over fire

draft” reading. The draft should be set to -- 0.02 inches w.c.

Check the oil pump pressure. All furnaces are designed to be

operated at 100 psig.

After reaching steady state,take a smoke test. If not indicating

a trace, set the combustion air controls to provide a trace. In

-

-

BURNER ELECTRODES

Adjustment of the electrode tipswith respect to each other, the

nozzle,andto the rest of the burner is very importantto ensure

smooth start ups and to permit efficient combustion.

Beckett AF Burner Settings

•

Electrode gap: 5/32 inch.

•

Distance above horizontal centerline: 7/16 inch.

•

Distance ahead of nozzle: 1/16 inch.

Thedistancefrom thefront ofthe endcone (head)to theface of

the nozzle should be 1--1/8 inches. If a ceramic head is used,

the distance from the end cone to the nozzle face is increased

to 1--3/8 inches.

OIL BURNER SET UP

Theburner air supply is adjustedto maintain the fuelto air ratio

toobtainideal combustionconditions. Alackofair causes“soft”

and “sooty” flames, resulting in soot build--up throughout the

heat exchanger passages. Excess combustion air causes a

brightroaring fire andhigh stacktemperatures resulting inpoor

fuel efficiency.

Preparations

Drill a 1/4" test port in the venting, ideally at least 2 diameters

(12") away from the furnace breaching. If venting horizontally

fromthe furnace,or fromthe flue pipeelbow ifventing vertically

before reaching the furnace (refer to Figure 4).

Before startingthe burner, checkthe burner alignment with the

combustion chamber (firepot), check that the correct nozzle is

tightened into place, and that the burner electrodes are prop

erly positioned.

10 Unitary Products Group

FIGURE 4 - TEST LOCATIONS FOR SMOKE TEST

(TOP - HORIZONTALINSTALLATION)

(BOTTOM - VERTICAL INSTALLATION)

NOTEA:Locateholeatleast6inchesonthe furnace side of the draftcontrol.

-

NOTE B: Ideally, hole should be at least 12 inches from breeching or elbow.

The test port will allow flue gas samples to be taken and stack temperature

to be measured.

Page 11

most cases, adjustment of the end air shutter will be all that is

necessary.

035-14289-000 Rev. A(0701)

ducts. Typical temperature rise values range between 65° F

and 90° F.

When the trace smoke has been established, measure the

orO2inthe flue gas. Typically,the CO2readingwill be ap

CO

2

proximately 13% or the O

reading approximately 3.3%.

2

Open the end air shutter (or open the bulk air band if neces

sary)until the CO

measuring O

readingdrops 1or 2 percentagepoints, or,if

2

content, until the O2reading increases 2 or 3

2

percentage points.

Take another smoke test; it should now be zero smoke. If the

smoke test reads zero, tighten up the end air shutter, and the

bulk air band.

Re--test the draft and the CO

or O2to be certain that the set

2

tings have not shifted.

NOTE: If oily or yellow smoke sports arefound on the

smoketest filter paper,it is usuallya sign of unburned

fuel. This indicates poor combustion. This type of

problem may be caused by excess draft, excess air,

or contaminated fuel. Do not ignore this indicator.

Stack Temperature

Stacktemperaturewill vary depending onfuel input, circulating

air blower speed and burner set up, etc. In general, stack tem

perature should range between 350° Fto450° F,but could be

as high as 550° F, assuming that the combustion air approxi

mately room temperature (65° F--70° F). In general, lower

stack temperature indicates greater efficiency; however, excessive low stack temperature can lead to condensation forming in the chimney and/or venting. Sulfur and similar

contaminants in the fuel oil will mix with condensation to form

acids. Acids andresultant chemical salts will cause rapid deterioration of the chimney and venting components, and may attack the furnace.

If the flue gases are below the range, it may be necessary to

slowdownthe blowerfan. Iftheflue gasesareabove therange,

the blower may require speeding up. Stacktemperature varies

directly with the system temperature rise. System temperature

rise is the difference between the furnace outlet temperature

andthe furnace inlettemperature as measuredin the vicinityof

the connection between the plenum take--offs and the trunk

If the venting from the furnace to the chimney is long or ex

-

posed to cold ambient temperatures, it is advisable to insulate

theventing with aremovable, non--combustible, wrap--around

type insulation to reduce stack temperature loss. The vent

should be inspected annually to ensure that it is intact.

FINAL CHECK OUT

Before the final test cycle, carefully examine the complete

heatingsystem forleaks. The hotvent canbe checkedwith a lit

taper for signs of air movement around joints or seams.

Ensure that all safety devices and electrical components have

been set for normal operation. Ensure that all electrical con

nections are tight and that the wiring is secure.

IMPORTANT:

Please review the following items with the homeowner:

where the circuit breaker or fuse is located in the main

•

electrical panel.

-

-

where the furnace switch is located, and the switch “on”

•

and “off” positions if not obvious.

where the oil shut--off valve from the oil storage tank is

•

located.

• how to operate the thermostat, and other related accessories.

• how to operate the manual reset button on the primary

control,andespecially whennotto pushthereset button.

• how and where to visuallyinspect the venting system for

leaks or other problems.

• how to inspect, clean and replace the air filter, and other

homeowner maintenance procedures.

•

who to call for emergency service and routine annual

service.

•

the terms and conditions of the manufacturer's warranty

and the contractor's warranty.

-

-

Unitary Products Group 11

Page 12

035-14289-000 Rev. A(0701)

BLOWER PERFORMANCE

MODEL SPEED

P*HBX12F08001

P*DHX12F08001

P*HBX16F10001

P*DHX16F12001

P*LBX12F08001

P*LBX16F12001

P*LBX16F14501

P*LBX20F19001

TAP

HIGH 1505 1444 1359 1291 1195

MED HIGH 1423 1381 1291 1220 1144

MED LOW 1170 1144 1118 1063 1005

LOW 813 813 797 763 690

HIGH 1645 1575 1510 1445 1337

MED HIGH 1540 1500 1420 1350 1266

MED LOW 1145 1135 1115 1095 1035

LOW 745 745 725 715 646

HIGH 1752 1691 1659 1593 1525

MED HIGH 1454 1454 1417 1379 1300

MED LOW 975 944 912 879 844

LOW 631 593 552 515 486

HIGH 1917 1885 1820 1717 1608

MED HIGH 1590 1608 1590 1532 1430

MED LOW 1096 1096 1096 1068 1039

LOW 696 647 692 647 598

HIGH 1810 1740 1675 1585 1480

MED HIGH 1570 1540 1495 1445 1348

MED LOW 1090 1080 1070 1065 1036

LOW 710 700 690 665 614

TURNS OPEN

0 2707 2503 2303 2135 1898

1 2372 2233 2085 1870 1594

2 2257 2085 1841 1594 1216

3 2161 1926 1627 1259 795

0.20 0.30 0.40 0.50 0.60

NOTES:

Airlfow is expressed in standard cubic feet per minute.

Motor voltage at 115V

EXTERNAL STATIC PRESSURE, INCHES W.C.

12 Unitary Products Group

Page 13

WIRING DIAGRAM - ALL MODELS

035-14289-000 Rev. A(0701)

Unitary Products Group 13

Page 14

035-14289-000 Rev. A(0701)

SYSTEM TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE REMEDY

Furnace will not start

Furnace will not start

without first pushing

protector relay reset

button

(Happens on a

frequent basis)

Furnace starts, but

cuts out requiring

manually resetting the

oil protector reset but

ton

Thermostat

not calling for heat

No power to furnace

Thermostat faulty

Protector relay faulty

Photo cell wiring

shorted or room light

leaking into photo cell

compartment

Open safety switch

No fuel oil

Clogged nozzle

Clogged oil pump filter Replace oil tank filter or in-line filter if used.

low oil pump pressure

Air getting into fuel oil

lines, or fuel oil line

dirty, clogged or in

some manner defective

Defective burner motor

Photo Cell (Cad Cell)

defective

No fuel oil

Clogged nozzle

Clogged oil filter Replace oil tank filter or in-line filter if used.

Low oil pump pressure

Air getting into fuel oil

lines, or fuel oil line

dirty, clogged, or in

some manner defective

Defective burner motor

Water or contaminants

in oil.

Frozen oil line

Check thermostat and adjust. Also, check thermostat for accuracy; if it is a

mercury switch type, it might be off level.

Check furnace switch, main electrical panel furnace fuse or circuit breaker.

Also look for any other hand operated switch, such as an old poorly located

furnace switch which was not removed during furnace replacement.

Check reset button on protector relay. Remove thermostat wires from pro

tector relay terminals TT. Place a jumper across TT. If furnace starts, replace

thermostat, thermostat sub-base (if equipped), or both.

Check reset button on protector relay. Remove thermostat wires from pro

tector relay terminals TT. Check for 24v across T.T. If no voltage is present,

check for 115v to protector relay. If 115v is present, replace protector relay.

Check photo cell (cad cell) wiring for short circuits. Also check for room light

leaking in to cad cell compartment. Repair light leak if necessary.

Check for open limit or auxiliary limit, open door switch (if equipped). Also,

check internal wiring connections, loose connectors, etc.

Check fuel oil supply. Check that all hand operated fuel oil valves are in the

open position. Fill oil storage tank if necessary.

Replace nozzle with high quality replacement. Use rating plate or table in

this manual as a guide.

Connect pressure gauge to oil pump. Adjust pump pressure, or replace oil

pump if necessary. Ensure that erratic pressure readings are not caused by

defective fuel oil lines.

Check oil lines, Replace any compression fittings found with high quality

flared fittings. Check for any signs of oil leaks. An oil leak is a potential

source of air or contaminants.

Check burner motor. If burner motor is cutting out on over-load, determine

why. Replace, if necessary

If cad cell is dirty, clean it. (Determine why cad cell is getting dirty). If cad cell

is poorly aimed, realign it. NOTE: The photo cell should have a resistance of

100 K ohms in absence of light; a maximum of 1500 ohms in the presence

of light. Ensure that room light is not leaking into the cad cell compartment.

Check fuel oil supply. Check that all hand operated fuel oil valves are in the

open position. Fill oil storage tank if necessary.

Replace nozzle with high quality replacement. Use rating plate or table in

this manual as a guide.

Connect pressure gauge to oil pump. Adjust pump pressure, or replace oil

pump if necessary. Ensure that erratic pressure readings are not caused by

defective fuel oil line.

Check fuel lines. Replace any compression fittings found with high quality

flared fittings. Check for any signs of oil leaks. any oil leak is a potential

source of air or contaminants.

Check burner motor. If burner motor is cutting out on over-load, determine

whey. Replace if necessary.

Drain fuel oil storage tank, replace fuel oil. (Consult with fuel oil supplier).

Gently warm oil line. Insulate oil line. (Outdoor piping size may require in

creased diameter.

-

-

-

14 Unitary Products Group

Page 15

PROBLEM POSSIBLE CAUSE REMEDY

Oil burner sputtering at

nozzle

Excessive fuel oil con

-

sumption

Too much smoke

Furnace will not warm

home to desired tempera

ture

Home does not heat

evenly

Supply air temperature too

hot

Supply air temperature too

cool

035-14289-000 Rev. A(0701)

SYSTEM TROUBLESHOOTING - CONT'D

Electrodes out of adjustment

or defective

Poor transformer high voltage

connections or defective

transformer

Fuel oil filter clogged Replace fuel oil storage tank filter and/or fuel oil in-line filter

Defective oil pump

Fuel oil line partially clogged

or contains air

System temperature rise too

high

Blower fan control out of ad

justment, (fan stops too soon)

Fuel oil leak Check fuel oil line for leaks. Repair or replace if necessary.

Stack temperature too high.

Thermostat improperly adjusted or in poor location.

Insufficient combustion air

adjustment at oil burner, or

improper draft pressure

Heat exchanger partially

clogged

Air flow blocked by dirty air

filter

Thermostat adjustments or

location

Insufficient air flow

Defective high limit control

Under-sized nozzle.

Blower fan motor stopping in

termittently on overload

Burner motor stopping inter

mittently on overload

Improper distribution of heat This is not likely to be furnace problem. Balance duct system.

Air flow blocked or dirty air fil

ter

Insufficient air flow

Fan control “fan on” setting

too low

Excessive duct losses

Check electrode settings. Check electrodes for dirt build-up or

cracks in porcelain.

Check contacts between transformer and electrodes. If OK, replace

transformer.

Check burner motor/fuel oil pump coupling. Check oil pump pres

sure. Replace fuel oil pump if necessary.

Bleed air from oil line. If problem persists, replace oil line.

System temperature rise should not exceed 85° F. Check for

clogged air filters. Check blower fan for excess dirt build-up or de

bris. Speed up blower fan if necessary.

Check fan control settings. The fan control is adjusted with a duct

thermometer in the supply air plenum take-off or first few inches of

-

the supply air trunk duct. The “fan off” setting should be 90° - 100° F.

Once set, the “fan on” setting is normally adjusted 25° -30° F higher

than the “fan off” setting.

Check stack temperature. Stack temperature will normally range

from 350° to 450° F. Check draft regulator. Draft should be set to

0.02" WC.

Check thermostat heat anticipator setting against measured amper

age draw. Increase heat anticipator setting if necessary. If the thermostat is being influenced by drafts, sunlight, duct work, etc,

relocate to a more suitable location.

Adjust the oil burner combustion air band and draft regulator to gain

the highest CO

possible with a Bacharach No.1 smoke.

2

Check for soot build-up in heat exchanger flue passages, especially

in the outer radiator.

Clean or replace air filter

Check thermostat heat anticipator setting against measured amper-

age draw. Increase heat anticipator setting if necessary. If the ther

mostat is being influenced by drafts, sunlight, duck work, etc,

relocate to more suitable location.

Check all dampers. Open closed dampers including registers in un

used rooms. Check system temperature rise. If temperature rise is

too high, speed up blower fan.

Test high limit function of all limit switches. Use a duct thermometer

to assess accuracy of limit control. Check for obstructions to air flow

around limit switch bi-metal elements. Replace control if necessary.

Check nozzle. If problem is not caused by air flow problems, use

larger nozzle, if permitted by rating plate.

-

Check blower fan motor amperage draw. Check motor ventilation

ports, clean if necessary. Replace motor if necessary.

-

Check burner motor. Replace if necessary.

-

Clean or replace air filter.

Check all dampers. Open closed dampers including registers in un

used rooms. Check system temperature rise. If temperature rise is

too high, speed up blower fan.

Check system temperature rise. Slow down blower fan if necessary.

Check supply air duct work. Seal leaky joints and seams. Insulate

ductwork if necessary.

-

-

-

-

-

-

Unitary Products Group 15

Page 16

Subject to change without notice. Printed in U.S.A.

Copyright by Unitary Products Group 1999. All rights reserved.

Unitary

Products

Group

5005 York

Drive

Norman

OK

73069

Code: EBY, L, FSupersedes: 035-14289-A-000-300

035-14289-000-A-1101

Loading...

Loading...