Page 1

036-21166 -001 REV A (0201)

TECHNICAL GUIDE

GAS-FIRED FURNACES

COMMERCIAL BELT- DRIVE

MID-EFFICIENCY MULTI-POSITION,

(UPFLOW & HORIZONTAL)

130 MBH OUTPUT

78 AFUE

DESCRIPTION

This mid-high efficiency, compact unit employs induced combustion,

reliable hot surface ignition and high heat transfer tubular heat

exchangers. The unit is factory shipped for installation in upflow or

horizontal applicat ion s.

This furnace is designed for residential and commercial applications.The unit is factory assembled, wired and tested to assure safe,

dependable and economical installation and operation.

The unit is Category I listed and may be common vented with another

gas appliance as allowed by the National Fuel Gas Code.

WARRANTY

20-Year limited warranty on the heat exchanger.

10-Year heat exchanger warranty on commercial

applications.

5-Year limited parts warranty.

FEATURES

• Easily applied in upflow, horizontal left or horizontal right installation with no conversion neces sa r y

• Electronic hot surface ignition with high reliability and

dependability

• 100% shut off main gas valve for added safety

• Rollout safety control

• Large belt drive blower for high CFM and static capability

• 1-1/2 HP ball bearing motor

• Reliable hot surface igniter

• Aluminized tubular heat exchanger for long term durability

• High quality inducer motor for quiet operation

• Standard terminals for controlling humidifiers and EAC’s or other

commercial applicati on requirements

P4HUE30N13006MODEL:

• 40 VA control transformer fuse protected

•Eas

• Efficiency ratings of 78 AFUE attained by using tubular heat

• Cooling relay supplied for easy installation of add-on cooling

• Adjustable fan-off settings to eliminate "cold-blow"

• Equipped with timer relay providing motor protection if operated

• 208/230 Volt operation, convertible for 115 volt

• Model is propane convertible

• Attractive baked enamel finish for durability

y to connect power and control wiring

exchangers

on continuous blower or if units are “twinned”

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

036-21166 -001 REV A (0201)

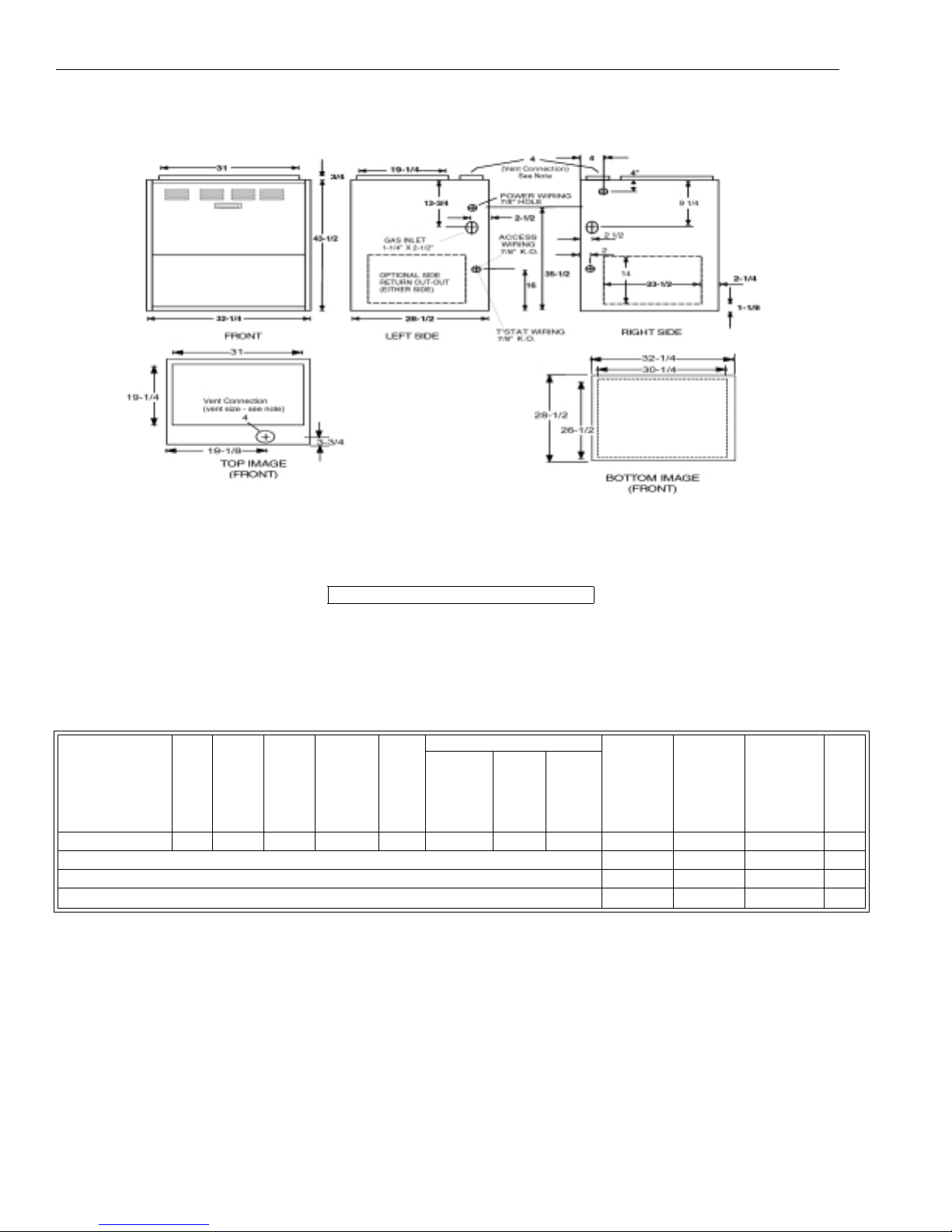

NOTE: Vent must be increased to 5” using adapter provided.

All dimensions are in inches and are approximate.

FIGURE 1 : DIMENSIONS

Blower

Model

Input

MBH

Output

MBH

AFUE

*

Air Temp

Rise °

Max.

Outlet

Temp.

F

°

F

HP Nomi-

nal

Motor

Amps

Size

Total

Unit

Amps

Max.

OverCurrent

Protect.

@230V

P4HUE30N13006 160 130 78 25 - 55 150 1-1/2 10 12 x 15 250

208/230 VAC (ONLY) 15 20 12

115 and 208/230 VAC (SPLIT) 6 & 11 15 12

115 VAC (ONLY)

‡

27 30 10

*. AFUE numbers are determined in accordance with DOE test procedures.

†. Wire size and overcurrent protection must comply with the National electric code (ANSI / NFPA-70-latest edition)

‡. Motor must be converted to 115 VAC operation

• For altitudes above 2,000 feet, reduce capacity 4% for each 1,000 ft. above sea level. Refer to form 650.74-N1.1V

• Wire size based on copper conductors, 60_ C, 3% voltage drop.

• See Replacement Parts list for LP gas and High Altitude conversion kits. External filter kits (bottom and side) are also available for

models above.

• Continuous return air t temperature must not be below 55°F (13°C)

Min. Wire

Size (AWG)

@ 75 Ft.

One Way

†

Oper.

Wgt.

(Lbs)

2 Unitary Products Group

Page 3

FIGURE 2 : FIELD WIRING DIAGRAMS

036-21166 -001 REV A (0201)

FIGURE 3 : FIELD WIRING DIAGRAMS

TABLE 1: FILTER SIZE / ADD-ON COOLING

MODEL NUMBER

P4HUE30N13006 5, 6, 7-1/2 3318 250

*. ESP (External Static Pressure) .75” W.C. is at furnace outlet ahead of cooling coil

Unitary Products Group 3

ADD-ON COOLING

TONS

CFM @ .80 ESP

*

@ 230

APPROX. OPER.

WEIGHT

Page 4

036-21166 -001 REV A (0201)

FIGURE 4 : TYPICAL HEATING & COOLING CONTROL CONNECTIONS

FIGURE 5 : TYPICAL HEATING & COOLING CONNECTIONS: IF A/C UNIT IS TRANSFORMER EQUIPPED

FIGURE 6 : TYPICAL HEATING & COOLING CONNECTIONS: IF THERMOSTAT IS EQUIPPED WITH SEPARATE R

AND RC CONTACTS

H

4 Unitary Products Group

Page 5

TABLE 2:

036-21166 -001 REV A (0201)

BLOWER PERFORMANCE SCFM - UPFLOW / HORIZONTAL (WITHOUT FILTER)

Note: Data below reflects airflows with bottom return opening

VOLTAGE

230 VAC

TABLE 3:

VOLTAGE

208 VAC

+

NOTE:

MOTOR

PULLEY

TURNS

Closed

0.30 040 0.50 0.60 0.70 0.80 0.90 1.00

EXTERNAL

+++ +

STATIC PRESSURE, INCHES, W.C

3467 3318 3163 2950

1 Open 3820 3687 3550 3406 3240 3066 2846 2589

2 Open 3575 3433 3269 3096 2913 2700 2449 2049

3 Open 3375 3205 2996 2807 2585 2293

4 Open 2805 2715 2570 2351 2017

MOTOR

PULLEY

TURNS

Closed

0.30 040 0.50 0.60 0.70 0.80 0.90 1.00

EXTERNAL

+++ +

STATIC PRESSURE, INCHES, W.C

3383 3242 3100 2890

1 Open 3674 3555 3423 3283 3144 2990 2789 2555

2 Open 3543 3379 3213 3055 2888 2673 2420

3 Open 3375 3210 3035 2850 2633 23343

4 Open 3100 2919 2708 2498 2226

Operation at these conditions will cause motor overload.

Operation in the shaded area may cause excessive furnace temperature rise.

Airflow is expressed in standard cubic feet per minute.

.

1860 1026

1307 -- --

.

1804

1889 --

1724 -- --

TABLE 4: UNIT CLEARANCES TO COMBUSTIBLES (ALL SURFACES IDENTIFIED WITH THE UNIT IN A

VERTICAL POSITION

RIGHT

APPLICATION TOP FRONT REAR

UPFLOW 1 6 0 0 3 6 COMBUSTIBLE YES YES YES NO

UPFLOW B-VENT 1 3 0 0 0 1 COMBUSTIBLE YES YES YES NO

HORIZONTAL 1 6 0 0 3 6 COMBUSTIBLE NO YES YES YES (SEE NOTE)

HORIZ. B-VENT 1 3 0 0 0 1 COMBUSTIBLE NO YES YES YES (SEE NOTE)

LEFT

SIDE

SIDE

FLUE FLOOR

NOTE: Line contact only permitted between lines formed by the intersection of the rear panel and side panel (top in horizontal position) of the

furnace jacket and building joists, studs or framing.

Unitary Products Group 5

/

BOTTOM CLOSET ALCOVE ATTIC LINE CONTACT

Page 6

036-21166 -001 REV A (0201)

ACCESSORIES

Propane Conversion Kit - INP0349

This accessory conversio n kit may be used to convert nat ural

gas units for propane (LP) operation. Conversion should be

made by qualified distributor or dealer personnel.

High Altitude pressure switch kits - 1PS0301

This accessory kit may be used to convert units for high altitude operation. Conversion must be made by a qualified distributor or dealer personnel. Please see form 650.74-N1.1V

for detailed instructions.

External Bottom Filter Rack or Horizontal End Return 1BR0332

Application of “High Velocity” rack provides opening for (2)

16” x 19-1/2” filters (not supplied). Attached to the end of the

furnace and provides duct flange s. Wil l acc ept up to 2” filters .

External Side Return Filter Rack - ISR0302

Provides a 16 x 25 cleanable, high velocity type filter and

attaches to the furnace side panel and the return air duct.

The filter is easily replaced. Package contains six filter racks

with filters.

Furnace Twinning Control - (2TC0300124)

This twinning control accessory allows proper operation of

two furnaces when the units are installed on a a common

duct system in a commercial application. This allows a

greater system cfm and heating capacity to be attained than

would be available from a single furnace. Belt drive furnace

also requires application of an

Accessory Sensor Kit

2T03700106.

-

6 Unitary Products Group

Page 7

036-21166 -001 REV A (0201)

Unitary Products Group 7

Page 8

Subject to change without notice. Printed in U.S.A. CD: 6-21142 036-21166 -001 REV A (0201)

Copyright © by Unitary Products Group 2001. All rights reserved. Supersedes: Nothing

Unitary 5005 Norman

Products York OK

Group Drive 73069

Loading...

Loading...