Page 1

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

FOR

230/240 VAC, 1ø, 50Hz

MACH 9 RV ROOF TOP AIR CONDITIONER /

HEAT PUMP AND REMOTE CONTROLLER

P/N: 1980-040 01-12-2016

RV Products Division

TABLE OF CONTENTS

I.

General Information 2

II.

Heat Pump Sizing 2

III.

Selecting an Installation Location 2

I V.

Installing the Roof Top Unit 2

V.

Securing the Heat Pump to the

Roof

4

VI.

Electrical Wiring 4

VII.

System Wiring Diagram 5

VIII.

Installing the 9430A451 Ceiling

Assembly

6

IX.

Operation and Maintenance 8

i.

Model & Serial Numbers 8

ii.

Operating Guidelines 8

iii.

Adjusting the Air Flow 8

iv.

Hand Held Controller 8

v.

Initial Conguration of the Hand Held

Controller

8

vi.

Selecting the Manual Mode of

Operation

8

vii.

Follow Me 10

viii.

Fahrenheit or Celsius (F/C) 10

ix.

Time and Day Set Up 10

x.

7-Day Programming 10

xi.

LED Lights & Buttons on Ceiling

Assembly

11

xii.

Routine Maintenance 11

xiii.

Warranty 11

SERVICE CONTACT:

Coast RV Pty Ltd.

PO BOX 6287 • SILVERWATER NSW 1811 Australia

Tel: +61-2-9645 7600 • technical@coastrv.com.au

Page 2

2

These instructions are a general guide for installing the

MACH 9, 230/240 VAC 50Hz Coleman-Mach roof top

heat pumps. For specic heat pump details, it will be

necessary to refer to ALL printed documents supplied

with this conditioner.

IMPORTANT NOTICE

These instructions are for the use of qualied

individuals specially trained and experienced in

installation of this type equipment and related system

components.

Installation and service personnel are required

by some states to be licensed. PERSONS NOT

QUALIFIED SHALL NOT INSTALL NOR SERVICE

THIS EQUIPMENT.

NOTE: The words “Shall” or “Must” indicate a

requirement which is essential to satisfactory and safe

product performance. The words “Should” or “May”

indicate a recommendation or advice which is not

essential and not required but which may be useful or

helpful.

WARNING! – SHOCK HAZARD To prevent the

possibility of severe personal injury or equipment

damage due to electrical shock, always be sure

the electrical power source to the appliance is

disconnected.

CAREFULLY FOLLOW ALL INSTRUCTIONS AND

WARNINGS IN THIS BOOKLET TO AVOID DAMAGE

TO THE EQUIPMENT, PERSONAL INJURY OR FIRE.

WARNING! Improper installation may damage

equipment, can create a hazard and will void the

warranty.

The use of components not tested in accordance

with these units will void the warranty, may make the

equipment in violation of state codes, may create a

hazard and may ruin the equipment.

SAFETY WARNING! This appliance is not

intended for use by young children or inrm persons

unless they have been adequately supervised by

a responsible person to ensure they can use the

appliance safely.

I. GENERAL INFORMATION

OEM – Please make sure all documentation

accompanies the heat pump.

INSTALLER AND/OR DEALER – Please make sure all

documentation is presented to the product consumer.

INQUIRIES ABOUT THE A/C UNIT – Inquiries to your

Airxcel, Inc. representative or to Airxcel, Inc. pertaining

to product installation should contain both the model

and serial numbers of the roof top unit. These rooftop

heat pumps have model and serial number identication

in two locations; (1) Rating Plate sticker - may be

viewed by removing the upper unit outer plastic shroud,

(2) Model/Serial number sticker (silver color) - located

on the return air section of the basepan of the roof

top unit. Additionally, if the heat pump is installed, the

Manufacturer and Model Number may be viewed from

the rear at the center of the basepan under the plastic

shroud.

II. HEAT PUMP SIZING

The ability of a heat pump in the cooling mode to cool

a vehicle or maintain a consumer desired temperature

is dependent on the heat gain of the vehicle. The

physical size, the window area, the quality and amount

of insulation, the exposure to sunlight, the number of

people using the vehicle and the outside temperature,

may increase the heat gain such that the capacity of the

air conditioner is exceeded.

As a general rule, air supplied (discharge air) in the

cooling mode will be 15 to 20 degrees F. (8 to 12

degrees C) cooler than the air entering (return air) the

ceiling assembly bottom air grilles.

For example, if the air entering the heat pump is 80

degrees F. (27 degrees C) (return air), the supply air

(discharge air) into the vehicle will be 60 to 65 degrees

F. (15 to 19 degrees C). As long as this temperature

difference (15 to 20 degrees F, 8 to 12 degrees C) is

being maintained, the unit is operating properly.

Again, give careful consideration to the vehicle heat gain

variables. During extreme outdoor temperatures, the

heat gain of the vehicle may be reduced by:

• Parking the vehicle in a shaded area

• Keeping windows and doors closed

• Avoiding the use of heat producing appliances

• Using window shades (blinds and/or curtains)

For a more permanent solution to high heat gain

situations, additional vehicle insulation, window awnings

and/or window glass tinting should be considered.

III. SELECTING AN INSTALLATION LOCATION

Your Coleman-Mach heat pump has been designed for

use primarily in recreational vehicles.

Is the roof of the vehicle capable of supporting both the

roof top unit and ceiling assembly without additional

support structures? Inspect the interior ceiling mounting

area to avoid interference with existing structural

members such as: bunks, curtains, tracks or room

dividers. The depth of the ceiling assembly shroud is

51mm. Be sure to check clearance to doors which must

be swung open (refrigerator – closets - cabinets).

Most of the time, roof mount heat pumps are installed

at existing roof vent locations. If there is no roof vent

(existing mounting hole), the following placement

locations are recommended.

Motorhomes – a single unit or the forward of two

units should be mounted within 2.7m of the driver

compartment.

Travel Trailers or Mini-Homes – a location should be

selected that is near the door slightly forward of the

vehicle center length.

Vans – location should be in the center of the roof (side

to side – front to back).

Truck with Camper – location should be between

1.2 and 1.5m from the rear of the camper to achieve

maximum cooling effect.

IV. INSTALLING THE ROOF TOP UNIT

DANGER! SHOCK HAZARD DISCONNECT ALL

POWER TO THE VEHICLE BEFORE PERFORMING

ANY CUTTING TO THE VEHICLE. CONTACT WITH

HIGH VOLTAGE CAN RESULT IN EQUIPMENT

DAMAGE, PERSONAL INJURY OR DEATH.

Page 3

3

IMPORTANT

TO PREVENT DAMAGE TO THE WIRING AND

BATTERY, DISCONNECT THE BATTERY CABLE

FROM THE POSITIVE BATTERY TERMINAL BEFORE

PERFORMING ANY CUTTING TO THE VEHICLE.

Once the location for your heat pump has been

determined (See Section III), a reinforced and framed

roof hole opening must be provided (may use existing

vent hole). Before cutting into the vehicle roof, verify that

the cutting action will clear all structural members and

crossbeams. Additionally, the location of any inner roof

plumbing and electrical supplies must be considered.

A. If a roof vent is already present in the desired

mounting location for the heat pump, the following

steps must be taken.

1. Remove all screws which secure the roof vent to

the vehicle. Remove the vent and any additional

trim materials. Carefully remove all caulking from

around the roof opening to obtain clean exterior

roof surface.

2. It may be necessary to seal some of the old roof

vent mounting screw holes which may fall outside

of the heat pump basepan gasket.

3. Examine the roof opening. If the opening is

smaller than 356mm x 356mm, the opening must

be enlarged.

B. If a roof vent opening is not used, a new opening

(See Figure 1) will have to be cut into the vehicle

roof. A matching opening will also have to be cut

into the interior vehicle ceiling. If the ceiling opening

is carpeted, snagging could occur. After the opening

in the roof and interior ceiling are the correct size,

a framed support structure must be provided

between the exterior roof top and interior ceiling.

The reinforced framed structure must provide the

following guidelines:

1. Capable of supporting both the weight of the roof

top heat pump and the interior ceiling assembly.

2. Capable of holding or supporting the roof outer

surface and interior ceiling apart, so that when

the roof top heat pump and ceiling assembly are

bolted together, no collapsing occurs.

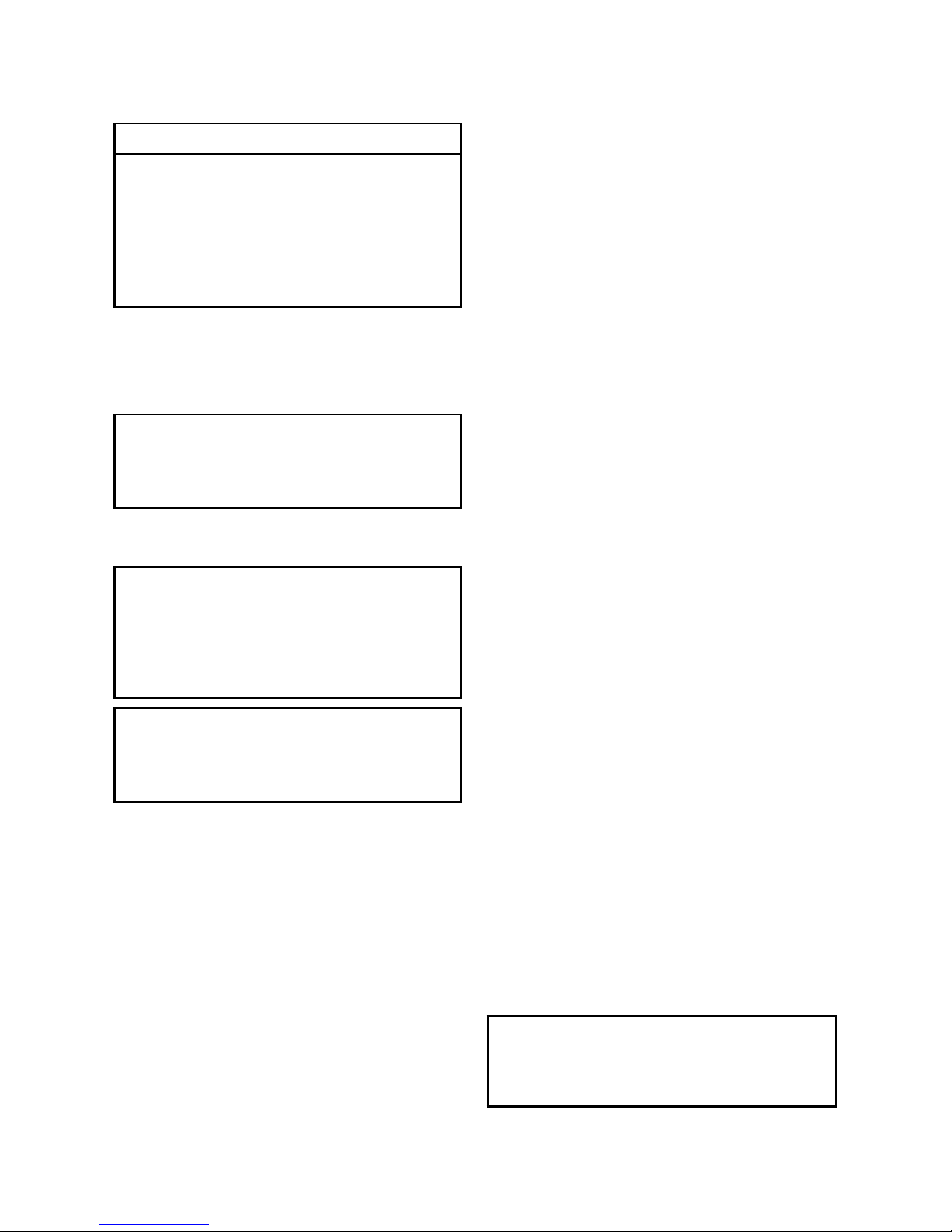

Airxcel, Inc. recommends that the spacing from the

vehicle roof top to the interior ceiling top be no less than

25mm. A typical support frame is shown in Figure 1.

The frame must provide an opening through the frame

to allow passage for the power supply wiring. Route the

supply wiring through the frame at the same time the

support frame is being installed.

C. The heat pump must be mounted as near level front

to rear and side to side as possible when the vehicle

is parked level. Figure 2 shows the maximum

allowable degree deviations.

IMPORTANT – Allow 600mm of supply wiring

through the support frame (working length).

After the support frame is installed, seal off all gaps

between the frame and both the roof exterior and the

supply wiring.

If the roof of the vehicle is sloped such that the heat

pump cannot be mounted within the maximum allowable

degree deviations, an exterior leveling shim will need to

be added to make the unit level. A typical front to back

leveling shim is shown in Figure 3.

Once the heat pump has been leveled, some additional

shimming may be required above the interior ceiling

assembly. The heat pump and the interior ceiling

assembly must have a squared installation relationship

before they are secured together.

D. After the mounting hole is properly prepared, remove

the carton and shipping pads from around the heat

pump. Carefully lift the unit to the top of the vehicle.

Do not use the outer plastic shroud for lifting. Place

the heat pump over the prepared mounting hole.

The pointed end (nose) of the shroud must face

towards the front of the vehicle. Pull down all loose

electrical connectors from the heat pump through

the mounting opening and let hang.

25 mm

MINIMUM

THICKNESS

356 to 381 mm

356 to 381 mm

HOLE FOR WIRES

TYPICAL ROOF OPENING

FIGURE 1

SIDE TO SIDE DEVIATION FRONT TO BACK DEVIATION

LEVEL TO 15° LEFT SIDE HIGH PERMISSIBLE LEVEL TO 15° NOSE HIGH PERMISSIBLE

FIGURE 2

HEIGHT VARIES

TO MAKE

UNIT LEVEL

356 mm

356 mm

FIGURE 3

Page 4

V. SECURING THE HEAT PUMP TO THE ROOF

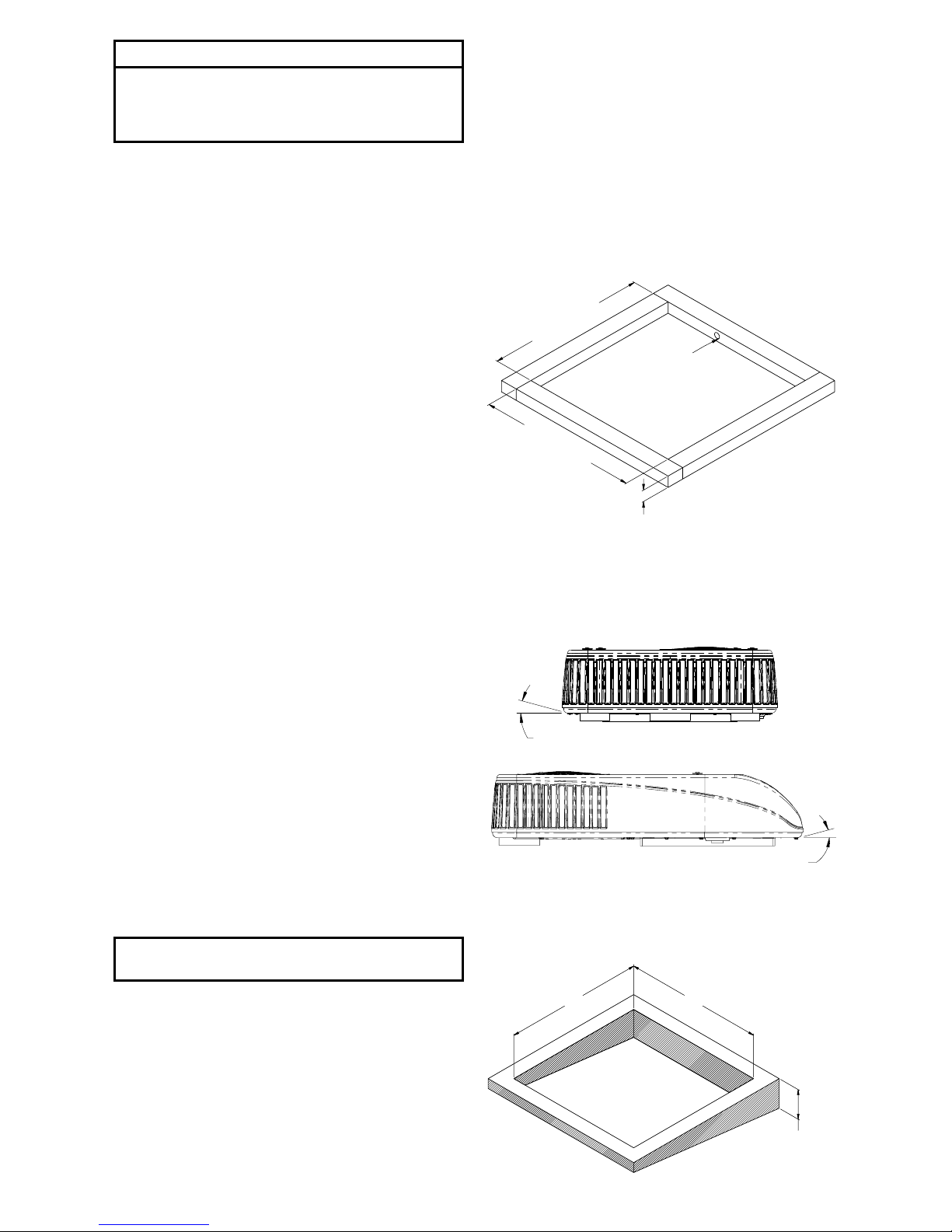

A mounting frame is supplied with the ceiling assembly.

Follow the steps below to secure the heat pump to the

roof. Refer to Figure 4.

A. Locate the heat pump mount gasket over the 356mm to

381mm square opening in the roof.

B. Install the ceiling assembly mount frame using the

four bolts, washers and springs found with the ceiling

assembly.

C. Proper tension has been achieved for each bolt when

the spring coils have just come together (See Figure

4). The upper unit has now been properly installed with

optimum gasket compression.

D. If the heat pump is equipped with an optional evaporator

condensate pump, a 13 mm I.D. hose must be provided

that runs from the 356 mm square opening, through the

vehicle ceiling and down the side wall to allow water to

drain under the vehicle. The hose must not be allowed

to kink shut while making a bend. Connect the top end

of the drain hose to the barbed tting shown in Figure 4.

VI. ELECTRICAL WIRING

ROUTING 230/240 VAC Wiring - See Figure 4

Following high voltage wiring specications and all local

and national electrical codes, route the 230/240 VAC

supply wiring from its power source through the strain

relief and connect to the power strip. Tighten screws to

8 Kg-centimeters torque. Some OEM units are equipped

with a pre-wired power umbilical with plug which will

snap-lock into the OEM supplied mating part.

High Voltage Wiring Specications

Refer to most recent Australian/NZ Standard for Wiring

Rules

INSTALLER MUST PROVIDE A TWO POLE

DISCONNECT FOR ACTIVE AND NEUTRAL.

MAXIMUM OVERCURRENT PROTECTIVE DEVICE

FOR THESE UNITS: 15 AMPS

DANGER – SHOCK HAZARD!

MAKE SURE THAT ALL POWER SUPPLY TO THE UNIT IS

DISCONNECTED BEFORE PERFORMING ANY WORK ON

THE UNIT TO AVOID THE POSSIBILITY OF SHOCK INJURY

OR DAMAGE TO THE EQUIPMENT.

DANGER! - WHEN USING NON-METALLIC SHEATH

CABLES (ROMEX, ETC.), STRIP SHEATH BACK TO EXPOSE

100-150mm OF THE SUPPLY LEADS.

STRIP THE INDIVIDUAL WIRE LEAD ENDS FOR WIRE

CONNECTION (ABOUT 19mm BARE WIRE). INSERT THE

SUPPLY WIRES INTO THE ELECTRICAL CONNECTOR

CLAMP. SHEATH MUST PROTRUDE PAST THE CLAMP

BUSHING INSIDE THE BOX. MAKE SURE SHEATH CABLE

IS CENTERED IN CLAMP BEFORE TIGHTENING CLAMP ON

SHEATH CABLE!!

DO NOT OVER TIGHTEN!! THIS COULD RESULT IN

PINCHING THROUGH THE PLASTIC WIRE INSULATION

AND CAUSE SHORTING OR “HOT” WIRES TO GROUND

(SHOCK HAZARD). THE CLAMP IS INTENDED FOR STRAIN

RELIEF OF THE WIRES. SLIGHT PRESSURE IS USUALLY

SUFFICIENT TO ACCOMPLISH THIS.

IF OTHER THAN NON-METALLIC CABLES ARE USED FOR

SUPPLY CONDUCTORS, APPROPRIATE STRAIN RELIEF

CONNECTORS OR CLAMPS SHOULD BE USED.

IN NO CASE SHOULD CLAMPING OR PINCHING ACTION BE

APPLIED TO THE INDIVIDUAL SUPPLY LEADS (NEUTRAL

AND “HOT” WIRES).

ROOFTOP UNIT

MOUNTING GASKET

MOUNTING SPRING

CEILING ASSEMBLY PATCH CORD

FROM UPPER UNIT CONTROL

OPTIONAL POWER PLUG

OPTIONAL CONDENSATE DRAIN ADAPTER

POWER CONNECTION STRIP

MOUNTING FRAME

ROOF STRUCTURE

POWER CONNECTION STRIP

WITHOUT OPTIONAL POWER PLUG

WASHER

MOUNTING BOLT

FIGURE 4

4

Page 5

VII. SYSTEM WIRING DIAGRAM

5

BLOWER

MOTOR

FAN

MOTOR

WHT

ORNG

BLU

PUR

COMPR

YEL

BLK

RED

TERMINAL

BLOCK

1

BLK

C

S

R

OVERLOAD

COMPR.

RUN

CAPACITOR

FAN

CAPACITOR

BLOWER

CAPACITOR

BLU

RED

BLU

RED

WHT

RED

BLK

ORG

PUR

BLU

YEL

GRN

WHT

BLK

BLK

BLK

WHT

BLK

OPTIONAL COMPONENTS

AND WIRING

23

CONDENSATE

PUMP MOTOR

REVERSING

VALVE

SOLENOID

4

BRN

BLK

WHT

BLK

BLU

RED

L

N

-

+

OUT

AC

POWER

SUPPLY

WHT

BLK

3

1 EVAPORATOR

FREEZE SENSOR

2 OUTDOOR

FREEZE SENDOR

1

4

E N A

GRN/YEL

GND

COM

N.O

COMPRESSOR

RELAY

COM

REV. VALVE

RELAY

N.O

FAN

SWITCH

RELAY

FAN

SPEED

RELAY

FREEZE

B

-12

VDC

+12

VDC

R

WRW

FAN

HI LOW

LINE 2

HIGH VOLTAGE

SUPPLY WIRING

4 FOR THIS APPLICATION,

REMOVAL OF TAB IS NOT

REQUIRED.

YEL

PUR

BLK

RED

GRN/YEL

WHT

BLK

WHT

BLU

P.C. BOARD

BLACK

WHITE

GND

3 124

PATCH CORD

INDOOR

TEMPERATURE

SENSOR

IRC

RECEIVER

BOARD

AN

3 "W" CONNECTIONS

FOR FURNACE CONTROL

RES

2

(Fasten to middle

of mount frame)

Page 6

6

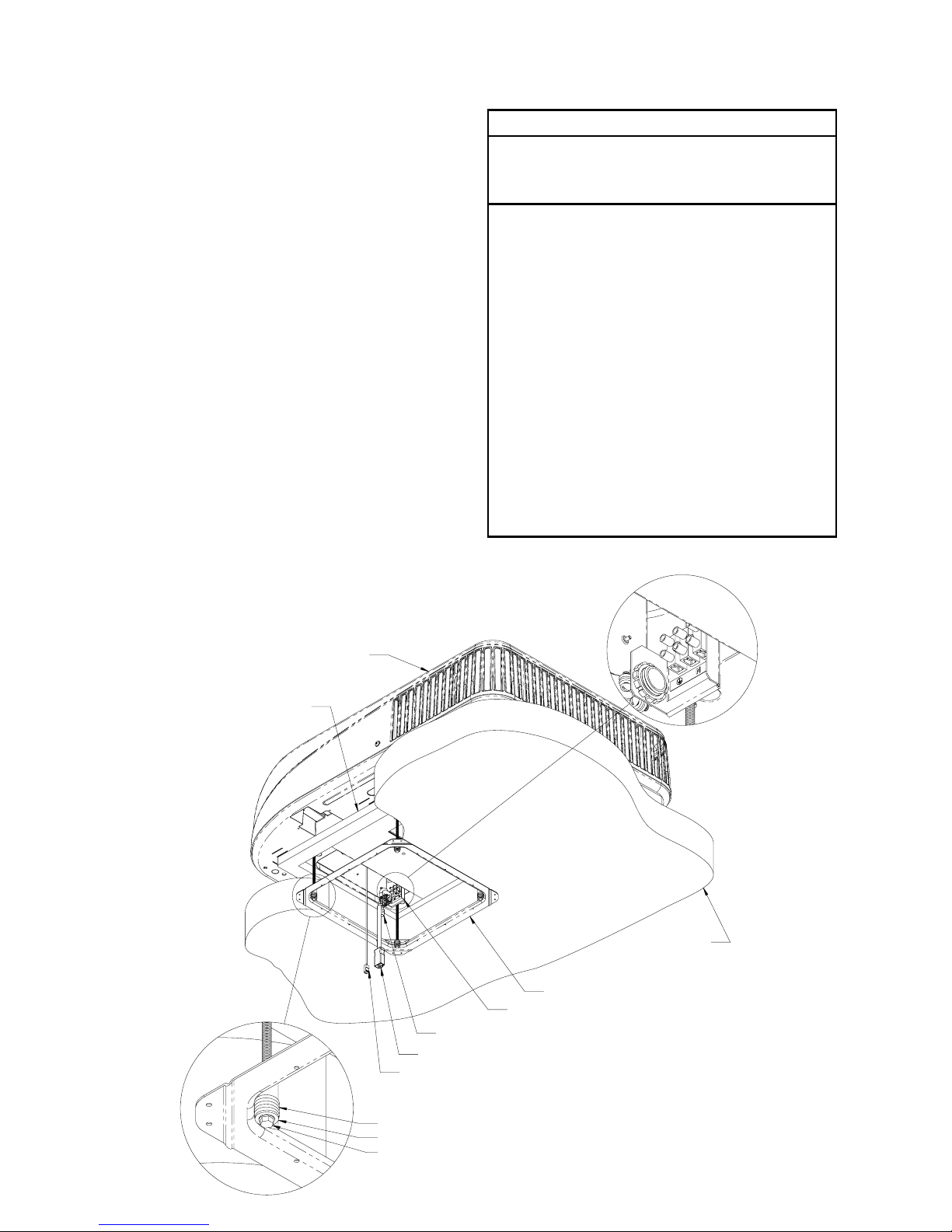

VIII. INSTALLING THE 9430A451 CEILING

ASSEMBLY (Refer to Figures 5 and 6)

NOTE: The following step by step instructions must

be performed in sequence to insure a quick and easy

installation.

A. Remove the grilles and lters from the ceiling

assembly shroud.

B. Locate the cloth duct assembly and attach to the

upper unit basepan with three of the provided short

screws.

C. Raise the ceiling assembly chute to align with the

cloth duct assembly. Attach the chute to the steel

mount frame with 4 short screws provided. Unfurl

the cloth duct to drop through the ceiling assembly

opening.

D. Gently peel off the release liner from the VHB (Very

High Bond) double sided tape. Press the cloth duct

uniformly around the perimeter of the opening to

adhere the cloth duct to the plastic chute. Carefully

trim the excess cloth duct (a razor knife is very

effective for this).

E. Plug in the room temperature sensor to the receptacle

on the ceiling assembly shroud. Raise the shroud

up near the mount frame and push the temperature

sensor up through the center opening of the air chute

and allow the sensor to hang over the side of the

chute. Plug in the patch cord from the upper unit to

the receptacle on the ceiling shroud as shown in the

magnied section of Figure 6.

F. Align the shroud with the air chute insuring that no

wires are trapped between plastic parts. Attach

the shroud to the steel frame with 4 short screws

provided.

G. Attach the room temperature sensor to a middle

hole of the steel mount frame using spacer, shoulder

washer, and #6 screw provided. Refer to Figure 5.

H. Replace the lters and retaining grilles. Using the

long screws provided, mount the hand held remote

control holster to an interior wall at a height of 24 cm.

in a location to prevent outlet air from playing onto

the remote control and within “line of sight” to the

ceiling assembly sensor. Avoid locations near heat

producing appliances or direct exposure to sunlight.

This is particularly important if using the “follow me”

mode of the system in which the temperature sensing

will be by the hand held remote instead of the sensor

mounted in the ceiling assembly return air stream.

I. Install the batteries into the hand held unit.

J. Restore power to the system.

#6 SCREW - MUST BE INSTALLED WITH HAND SCREW DRIVER

SHOULDER WASHER

ROOM TEMPERATURE SENSOR

ROOM

TEMPERATURE

SENSOR

CEILING

ASSEMBLY CHUTE

CLOTH AIR DUCT

ASSEMBLY

SPACER

FIGURE 5

Page 7

7

CEILING ASSEMBLY PATCH CORD

ROOM TEMPERATURE SENSOR

TOP SIDE OF CEILING SHROUD

CEILING ASSEMBLY

SHROUD

CEILING ASSEMBLY

GRILLES

CEILING ASSEMBLY

FILTERS

This concludes the installation of the system. The following

pages contain the operating and maintenance instructions.

FIGURE 6

Page 8

X. OPERATION AND MAINTENANCE

These instructions are a general guide for operating

and maintaining the MACH 9, 230/240 VAC, 50Hz,

Coleman®-Mach® roof top heat pumps and remote hand

held controller.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety. Children should be supervised to ensure

that they do not play with the appliance and Cleaning

and user maintenance shall not be made by children

without supervision.

i. MODEL & SERIAL NUMBER

Your air conditioner or heat pump has been designed for

years of safe, dependable operation. These instructions

contain a general description on the operation of the unit,

how to set up and operate the controller, and a list of

routine maintenance items.

The rst thing you should do is to write down the model

number and serial number of the unit. Both numbers can

be found on the data label on the unit.

Model No. __________________________________________

Serial No. ___________________________________________

ii. OPERATING GUIDELINES

• The air conditioner is designed to provide cooling

and dehumidication. A heat pump reverses the

refrigerant cycle to provide heating in cool weather.

The performance of both units can be optimized by

following the simple guidelines:

• Keep doors and windows closed to prevent the loss

of conditioner air.

• Keep the curtains closed to reduce heat gain.

• Set the temperature to a reasonable temperature.

• A low fan speed will reduce sound level and improve

dehumidication when the unit is cooling.

• Properly adjust the air ow with the slides on the front

and rear of the ceiling assembly.

• Never obstruct the air ow to the ceiling assembly.

• Do not spray water or any cleaning uid into the

ceiling assembly. The ceiling assembly should be

cleaned with a damp cloth.

• Do not put any object, including your hands, into the

openings of the ceiling assembly.

Reverse Cycle Operation

• Operation of the reverse cycle in ideal environmental

conditions may allow the unit to run in temperatures

as low as 4 to 5 Celsius.

• However operation of the reverse cycle in cold

environments combined with high humidity/

precipitation can result in the unit entering a defrost

cycle to alleviate icing of the outdoor coil. This can

happen at temperatures as high as 5 to 7.5 Celsius.

• At temperatures lower than those listed above, the

unit may enter a defrost cycle in order to allow the unit

to continue to operate. At the end of this cycle, the

indoor blower is shut off to minimize any cold air from

entering the coach and the reversing valve of the Heat

pump is unenergized, shifting the unit back into A/C

mode thawing the outdoor coil to remove frost or ice

that may have formed. This will take approximately

3 minutes, after which the reversing valve is reenergized and the unit will begin to operate in reverse

cycle again. This defrost cycle may allow the unit to

run at temperatures as low as 0 to 1 Celsius. (For

more information on the operation of the defrost cycle,

refer to the Service Manual.)

iii. ADJUSTING THE AIR FLOW

The conditioned air is distributed through the ceiling

assembly. Slides on the front and rear of the ceiling

assembly can be moved to throttle the air ow to the front

and rear. The round supply louvers can be adjusted to

direct air ow from the ceiling assembly. The louvers

can be opened and closed to adjust airow and also

spin 360 degrees allowing air ow to be directed where

desired. (Use of the supply louvers in heating mode is

suggested to keep air from stratifying in the coach.)

iv. HAND HELD CONTROLLER

The remote controller controls the operation of the air

conditioner or heat pump with an infrared signal to a

sensor on the ceiling assembly. For the best reception,

the remote should be pointing at the ceiling assembly

when changing set points and conguring the air

conditioner or heat pump.

Note: Should the remote be lost, the air conditioner

or heat pump can be controlled by buttons on the

ceiling assembly.

v. INITIAL CONFIGURATION

OF THE REMOTE CONTROLLER

The controller has been factory congured to operate

the heat pump. Should you wish to verify the correct

conguration, the controller must be in either the Heat

ELE or the Auto-changeover (Auto) mode.

A. Heat ELE mode.

1. Press the Power Button.

2. Using the Mode button, scroll through the various

setting by repeatedly pressing the Mode button until

Heat ELE is shown.

3. Press the MODE & FAN Buttons for 5 seconds. The

temperatures on the screen will disappear and HP

should appear at the bottom of the screen. If nHP is

shown, press the UP & DOWN buttons to select HP.

4. After 5 seconds, the remote will revert to normal

operation.

B. Auto-changeover Mode

1. Press the Power Button.

2. Using the Mode button, scroll through the various

setting by repeatedly pressing the Mode button until

Auto is shown.

3. Press the MODE & FAN Buttons for 5 seconds.

The temperatures on the screen will disappear and

HP, nHP or Gas should appear at the bottom of the

screen. If nHP or Gas is shown, press the UP &

DOWN buttons to select HP.

4. After 5 seconds, the remote will revert to normal

operation.

vi. SELECTING THE MANUAL MODE

OF OPERATION

The air conditioner (if equipped with heat) or heat pump

has ve modes of operation- Cooling, Heating, Auto

(Auto-changeover), Dry and Fan. To select the desired

operation, press the MODE button. Then use the UP or

DOWN button to select the set point temperature. Select

the desired fan speed by pressing the FAN button. To

advance to the next mode, press the MODE button.

COOLING: The unit will operate in cooling mode to

maintain the set point temperature. In the Cooling Mode,

four fan selections are available: High speed continuous,

Low speed continuous, Auto High or Auto Low. In Auto,

the Fan cycles on & off with the compressor. Use the

Fan button to select the desired setting. To advance to

the Heating mode, press the MODE button.

8

Page 9

9

Return Air Louver

Return Air Louver

Rear Slide

Supply Louvers

Front Slide

POWER

UP DOWN

MODE

HEAT

COOL

DRY

AUTO

FAN

HIGH

LOW

AUTO

FAN

CLOCK PROGRAM

Follow Me F/C

SET TEMP ROOM TEMP

COOL

HEAT

AUTO

DRY

HIGH

LOW

AUTO

AM

PM

TIMER

7-DAY PROGRAM

MON

TUE

WED

THU

FRI

SAT

SUN

MORN

DAY

EVE

NITE

ON

OFF

BATTERY INDICATOR

(Only visible when battery is low)

MODE

Scroll to Select System Operating

Functions

FOLLOW ME

Turns Follow Me Mode ON and OFF

POWER

Turns Unit On or Off

FAN

Scroll to Select Fan Speed

F / C

Select either Fahrenheit or Celsius

UP / DOWN

Adjust various set points including

Temperature and Time

Page 10

Typical Cooling Screen

HEATING: The unit will operate in heating mode to

maintain the set point temperature. There are two

selections in the Heating Mode – Heat Pump (ELE)

and GAS (gas furnace). (Heating only functions on air

conditioners with electric heat, heat pumps or vehicles

with an auxiliary source of heat, e.g. a gas furnace.)

A. Vehicles without a gas furnace

1. Using the Mode button, scroll through the various

setting by repeatedly pressing the Mode button

until HEAT ELE is shown.

2. Using the UP & DOWN buttons, select the

desired set point temperature.

3. Press the FAN button to select either High or Low

Fan speed.

4. Press the mode button twice to go to Auto Mode,

bypassing the HEAT GAS set up.

B. Vehicles with a gas furnace

1. Repeat steps 1-3 above.

2. Press the MODE button once and Heat GAS is

shown.

3. Using the UP & DOWN buttons, select the

desired set point temperature.

4. In HEAT GAS, the fan speed is selected

automatically; the user can not select the fan

speed.

5. Press the MODE button to go to AUTO mode.

NOTE: HEAT GAS should only be used if a gas furnace

is to be operated with the controller. In Gas heat mode,

Follow Me is automatically turned on. See description of

Follow Me below.

AUTO: The unit will automatically heat and cool,

depending on the set point temperature. (Heating only

functions on air conditioners with electric heat, heat

pumps or vehicles with an auxiliary source of heat, e.g. a

gas furnace). Use the UP & DOWN buttons to select the

desired set point temperature. In the Auto mode, the fan

speed is selected automatically. To advance to the Dry

mode, press the MODE button.

DRY: This mode is for dehumidication when the

vehicle is not in use. The unit will operate in the cooling

mode to provide dehumidication. Use the UP & DOWN

buttons to select the desired set point temperature. If the

room temperature in is above the set point, the unit will

operate for 15 minutes and then turn off for 3 minutes. If

the room temperature is below the set point, the unit will

operate for 6 minutes and then turn off for 15 minutes.

In the Dry mode, the fan speed is selected automatically.

To advance to the Fan mode, press the MODE button.

FAN: The indoor fan is run to circulate air, but the

compressor does not operate. In the Fan Mode, two fan

selections are available: High speed continuous or Low

speed continuous. Use the FAN button to select.

vii. FOLLOW ME

In normal operation a temperature sensor in the ceiling

assembly senses the temperature and controls the operation

of the Air Conditioner or Heat Pump. Follow Me switches this

control to a temperature sensor on the hand held controller.

To activate Follow Me, press the Follow Me button for 3

seconds and release. On or Off will ash on the screen.

Press the Follow Me button again to change the setting. In

Gas heat mode, Follow Me is automatically turned on.

viii. F/C

Selects whether the temperature is displayed in

Fahrenheit or Celsius. Press and hold the F/C button for

3 seconds and release. CEL or FAH will be displayed.

Press the F/C button again to change the selection.

ix. TIME AND DAY SET UP

1. Press the CLOCK button and hold for 3 seconds.

2. The hour and AM or PM will ash. To change the hour,

press the UP or DOWN button.

3. To change the minute, press and release the PROGRAM

button. To change the minute, press the UP or DOWN

button.

4. To change the day, press and release the PROGRAM

button. To change the day, press the UP or DOWN button.

5. Press the CLOCK button to return to the normal screen.

x. 7-DAY PROGRAMMING

The 7-day program schedule allows different set point

temperatures for different times of each day of the

week. The schedule includes four periods – Morning,

Day, Evening and Night- for each day of the week. Each

period has a start time, a set point temperature for Heat,

Cool and Auto modes. For 7-day programming:

1. Press the CLOCK and PROGRAM buttons simultaneously

and hold for three seconds.

2. The rst selection is for the day of the week. Press the UP

or DOWN button to select Monday (MON).

3. Press the PROGRAM button to select the settings for the

Morning period. Press the UP or DOWN button to select

Morning.

4. Press the PROGRAM button to select the hour for the

period to begin. Use the UP and DOWN button to select

the hour.

5. Press the PROGRAM button to select the minute for the

period to begin. Use the UP and DOWN button to select

the minute.

6. Press the PROGRAM button to select the set point

temperature for Cooling. Press the UP or DOWN button to

select the desired temperature.

7. Press the PROGRAM button to select the set point

temperature for Heating. Press the UP or DOWN button

to select the desired temperature.

8. Press the PROGRAM button to select the set point

temperature for Auto. Press the UP or DOWN button to

select the desired temperature.

9. Repeat this procedure to select the start times and set

point temperatures for Monday Day, Monday Evening and

Monday Night.

10. Repeat this procedure for the remaining days of the week.

If the unit is in the COOL, HEAT, or AUTO mode, it can

be run in either the Manual Run mode or the 7-Day

Preprogrammed Run mode. Pushing the PROGRAM

button will toggle between the Manual Run mode and

7- Day Preprogrammed Run mode. While in the 7-Day

Preprogrammed Run mode, PROGRAM will appear at

the bottom of the screen. The set point temperatures

maybe changed by pushing the UP & DOWN buttons.

The manually set temperature will remain in effect until

the start of the next preprogrammed period. The 7-Day

preprogrammed mode is not available in the Fan only

or Dry mode.

10

Page 11

xi. LED LIGHTS AND BUTTONS ON THE

CEILING ASSEMBLY.

The ceiling assembly has a two color LED to indicate if

the unit is in Cooling or Heating. Two manual override

buttons - one for cooling the other for heating – can be

used if the remote controller is lost or malfunctions.

xii. ROUTINE MAINTENANCE

One of the biggest advantages to your new Coleman-Mach

heat pump is that the maintenance needed to keep the unit

in good working order is minimal. In fact about the only

thing you, the owner, must take care of is the cleaning and

replacement of the lters.

The ceiling assembly and the outside shroud can

be cleaned with a damp cloth. When required a mild

detergent can be used.

Filters are made from long life non-allergenic natural

bers which can be cleaned and reused, and which

completely lter the circulated air when the heat pump

is in operation. If the lters are not cleaned at regular

intervals, they may become partially clogged with lint,

dirt, grease, etc. A clogged lter will produce a loss of

air volume and may eventually cause an icing-up of the

cooling (evaporator) coil.

IMPORTANT: Do not operate your heat pump for extended

periods of time without the lter installed.

An even more serious condition occurs when the heat pump is

operated without a lter. When this happens the lint, grease, etc.

that are normally stopped by the lter are now accumulating in

the cooling coil. This not only leads to a loss of air volume and

a possible icing-up of the cooling coil, but could also result in

serious damage to the operating components of the heat pump.

Cleaning and/or changing the lters:

1. Remove the two grilles from the ceiling assembly by

pulling the tabs on the grilles as shown in illustration.

2. Remove and clean or replace the two lters. The

lters should be washed in warm water or vacuumed

clean. The lters should be inspected once a month

and cleaned or replaced as required.

3. Re-install the lters and grilles in the ceiling

assembly.

NOTE: If the unit is operated in a dusty environment, the lters

should be inspected and cleaned more frequently.

xii. WARRANTY

For Full WARRANTY Terms and conditions

on products purchased in Australia or New

Zealand, please visit www.coastrv.com.au or

www.coastrv.co.nz

11

INFRARED

RECEIVER

Manual

Override

Buttons for

Heating &

Cooling

TWO color LED

(Red for Heating and

Blue for Cooling)

Tabs to Access Filter

Tabs to Access Filter

Page 12

Place Model No. / Serial No. Sticker Here

Name of Purchaser:

Street:

City: State: Zip:

DATE OF PURCHASE:

(Heat pump)

Coast RV Pty Ltd

trading as Coast to Coast RV Services

ABN 49 097 104 492 - ACN 101 461 330

PO Box 6287, Silverwater NSW 1811

AUSTRALIA

Ph (02) 9645 7600 - Fax (02) 9645 7699

Email: warranty@coastrv.com.au

Web: www.coastrv.com.au

Coast to Coast RV Services

PO Box 58-054, Botany AUCKLAND 2163

NEW ZEALAND

Ph (09) 274 8700 – Fax (09) 274 8701

Email: enquiry@coastrv.co.nz

Web: www.coastrv.co.nz

Loading...

Loading...