Page 1

TECHNICAL GUIDE

COMMERCIAL

036-21326-001-C-0202

GENERAL SPECIFICATIONS

OUTDOOR UNIT:

• Two independentrefrigerant circuits

• Inherently protected fan motors

• Two independent scroll compressors

• V-Coil Design

• Exterior service port connections

• Refrigerant-22 holding charge

• Five-minute compressoranti-shortcycle timer

• Two independent control circuits

• Compressor operation to 40°F

• Field-installedLow Ambient VFD Control to 0ºF

• Five-year limited warranty on compressor

• One-year limited warranty on all other parts

SPLIT-SYSTEM COOLING UNITS

FOUR PIPE SYSTEM

MODELS HL 15 & HL 20

MODELS LL 15 & LL 20

• Simplicity Controls

• Factory installed disconnectand Technicoat coils

INDOOR UNIT:

• Factory-mounted expansion valve and filter-drier in both refrigerant circuit

• Adjustable TXV’s

• Two-inch throwaway filters

• Single point power connection

• One-year limited warranty on all parts

• Field installed drive packages

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

036-21326-001-C-0202

TABLE OF CONTENTS

GENERALSPECIFICATIONS...................... 1

OUTDOORUNIT: ................................1

INDOORUNIT: ..................................1

DESCRIPTION...................................3

APPLICATION FLEXIBILITY OUTDOOR . . . . . . . . . . . . . .3

APPLICATION FLEXIBILITY INDOOR . . . . . . . . . . . . . . . .3

OUTDOORUNIT .................................4

ACCESSORIES (factory & Field Installed) . . . . . . . . . . . . .4

INDOORUNIT ...................................5

ACCESSORIES Indoor unit

(FieldInstalled)...................................5

LIST OF FIGURES

# pg. #

1 TYPICAL INDOOR UNIT

APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2 OUTDOOR PRODUCT NOMENCLATURE . . . . . . . . .4

3 INDOOR PRODUCT NOMENCLATURE . . . . . . . . . . . 5

4 VERTICAL ARRANGEMENTS - LL180 AND LL240 . .6

5 HORIZONTAL ARRANGEMENTS - LL180 AND

LL240...................................... 6

6 CENTEROFGRAVITY ........................9

7 HLCORNERWEIGHT .........................9

8 PIPING AND ELECTRICAL CONNECTION

LOCATIONS ...............................10

9 15TONBLOWERPERFORMANCE .............18

10 20TONBLOWERPERFORMANCE .............18

11 LL HORIZONTAL APPLICATION

CORNERWEIGHTS..........................20

LIST OF TABLES

# pg. #

1 UnitApplicationData ..........................7

2 ARIRatings-CoolingandSound ................7

3 ELECTRICAL DATA COMPRESSORS . . . . . . . . . . . . 7

4 ELECTRICALDATAFANMOTORS ..............7

5 ELECTRICAL DATA, outdoor mca & max. fuse size . . 7

6 OutdoorUnitPhysicalData .....................8

7 IndoorUnitPhysicalData.......................8

8 CONNECTIONS..............................9

9 UNITCLEARANCES ..........................9

10 HLCenterofGravityDimensions.................9

11 PIPING AND ELECTRICAL CONNECTION SIZES . . 10

12 15 ton capacity table - 85º and 95ºF . . . . . . . . . . . . 11

13 15 Ton Capacity Table - 105º and 115ºF . . . . . . . . . 12

14 15TonCapacityTable-125ºF.................13

15 20 Ton Capacity Table - 85º & 95ºF . . . . . . . . . . . . . 14

16 20 Ton Capacity Table - 105º & 115ºF . . . . . . . . . . . 15

17 20TonCapacityTable-125ºF.................16

18 LL18015TonAirFlowTable ...................17

19 LL24020TonAirflowTable ....................17

20 BlowerDriveData ...........................19

21 Blowerdata ................................19

22 Indoorelectricalratings .......................19

23 INDOOR UNIT WEIGHTS AND

CORNERWEIGHTS .........................20

24 UnitDimensionsLL180andLL240 ..............21

12 LL VERTICAL APPLICATION CORNER WEIGHTS .20

13 UNITDIMENSIONSLL180ANDLL240.......... 21

14 LL180 SUPPLY AIR PLENUM DIMENSIONS . . . . . .22

15 RETURN AIR GRILLE FOR LL180 DIMENSIONS . . . 22

2 Unitary Products Group

Page 3

DESCRIPTION

P

036-21326-001-C-0202

Both the outdoor and indoor units are completely piped and

wired at the factory and are shipped ready for immediate

installation. Only the interconnecting liquid and suction lines,

control wiring, and the main power wiring are required to

complete the installation. Every outdoor unit is dehydrated,

evacuated, leak tested and pressure tested at 450 psig

before being pressurized with a holding charge of refrigerant22 for shipment and/or storage.

To eliminatethe costly cabinet deterioration problems usually

associated with outdoor equipment, all sheet metal parts are

constructed of commercial grade (G90) galvanized steel.

After fabrication, each part is thoroughly cleaned to remove

any grease or dirt from its surfaces. The parts that will be

exposed to the weather are then coated with a desert sand

powder paint to assure a quality finish for many years. This

coating system has passed the 750-hour, salt spray test per

ASTM Standard B117.

APPLICATION FLEXIBILITY OUTDOOR

The outdoor units are lightweight and can be installed on

almost any roof.

Units can be lifted using nylon straps with hooks at the holes

provided in the base rails, or they may be lifted with a forklift

through the slotted openings in the base rails.

A quality appearance and low sound levels make these units

suitable for most ground level locations.

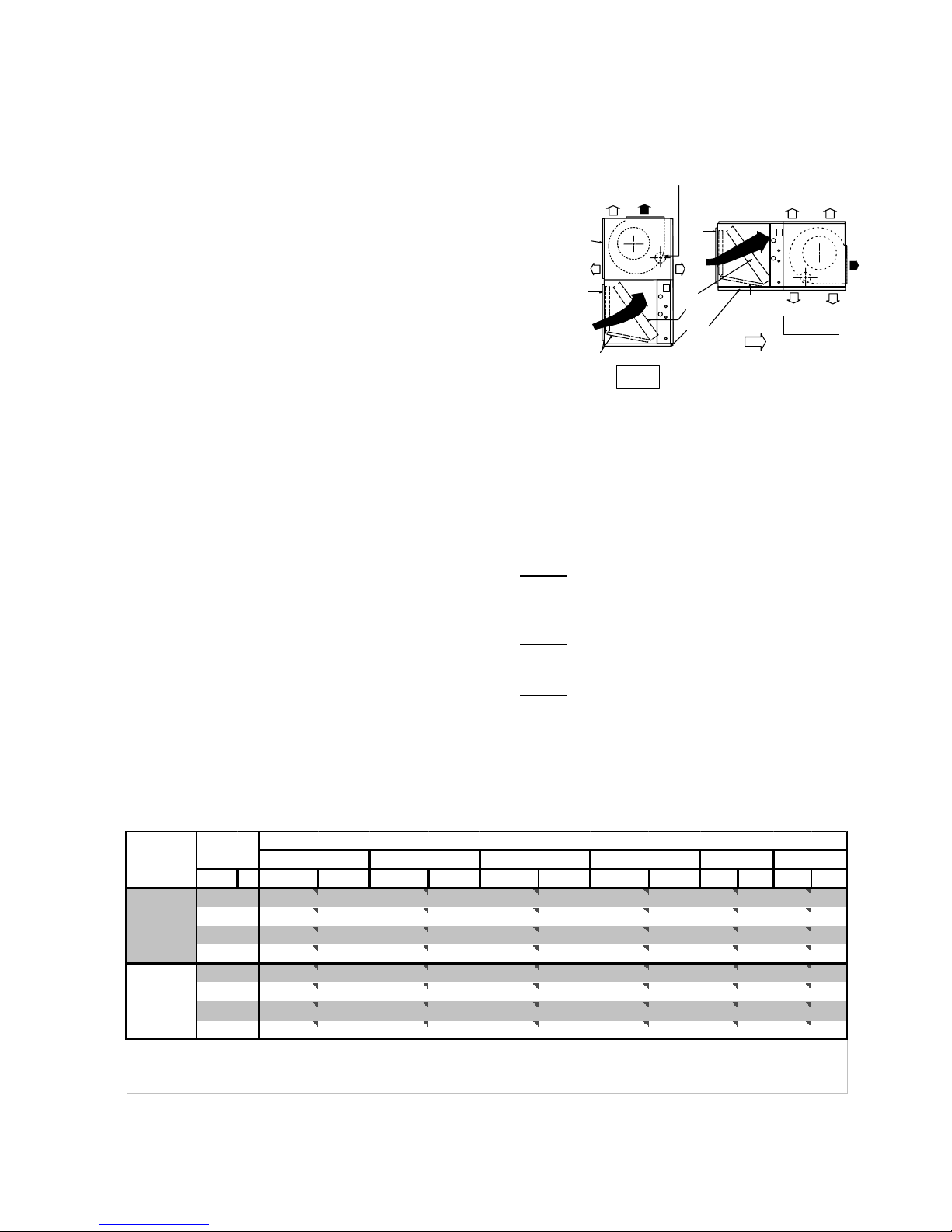

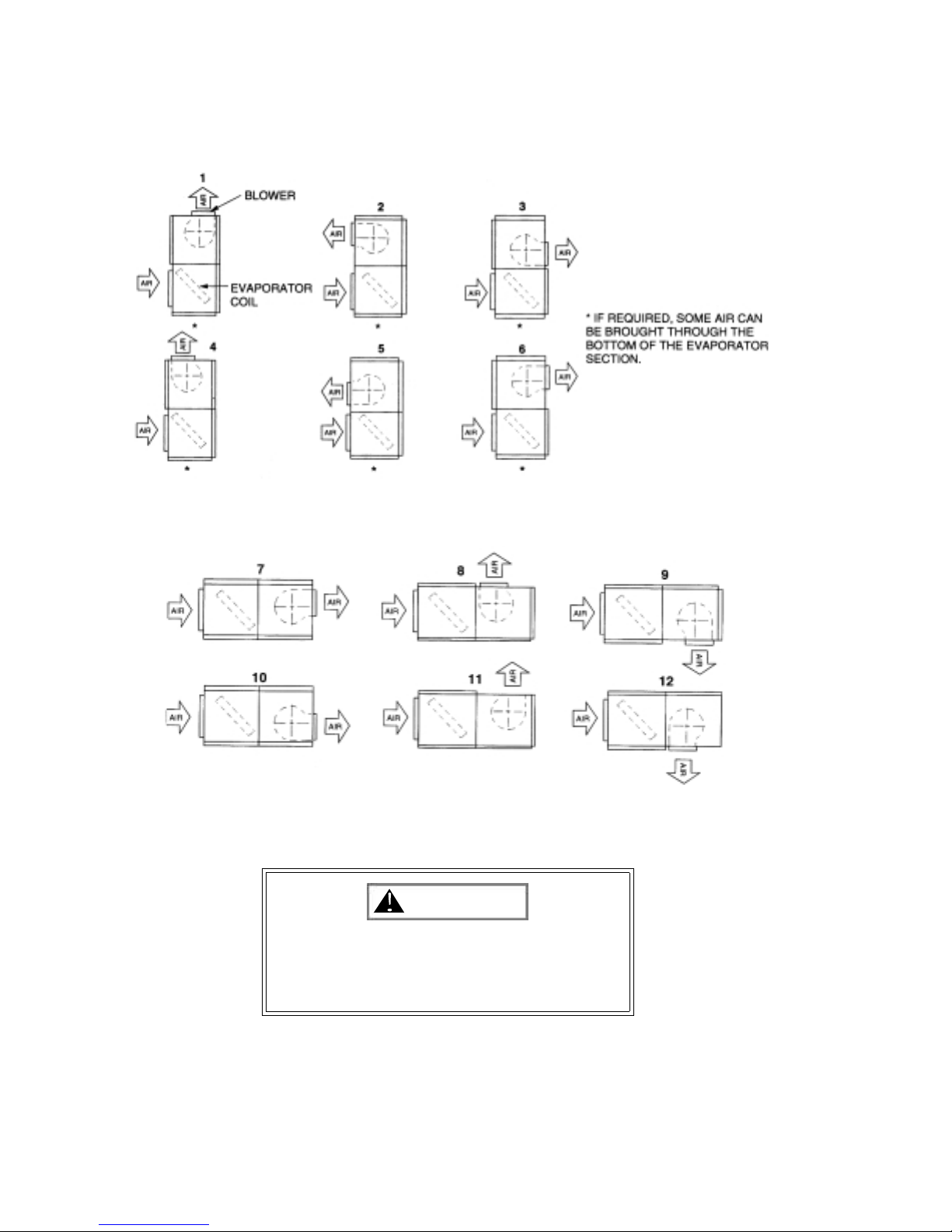

APPLICATION FLEXIBILITY INDOOR

BLOWER M OTOR

LO C A TIO N

AIR OUT

(S td. Arrangem ent)

BLOW ER

SECTIO N

RETURN AIR

DUCT FLANGE

AIR

IN

FILTERS

VERTIC AL

POSITIO N

NOTE:

FIGURE 1 : TYPICAL INDOOR UNIT

APPLICATIONS

The indoor units are built in a single cabinet with one condensate drain pan. These units can be installed in either the vertical or horizontal position for maximum flexibility.

NOTE:

indoor coil keeps the condensate from dripping off the finned

surface onto the filters:

NOTE:

with the condensate drain pan under the entire indoor coil.

On vertical applications, the air velocity across the

On horizontal applications the unit must be installed

RETURN AIR

DUCT FLANGE

BLOW ER

SECTIO N

EVAPOR ATOR

COIL

COIL

SECTIO N

DISCHARGE ARRANGEMENTS

C E R T A IN B L O W E R P O S IT IO N S A R E N O T R E C O M M E N D E D .

BECAUSE TH E BLOW ER M O TOR SH OU LD NO T BE M OU NTED

UPSIDE DO W N.

FILTERS

ALTER NATE AIR

HORIZONTAL

POSITIO N

CONDENSER ONLY CAPACITY

Suction

Model HL

240

180

ress. &

65 75 85 95 105 115

PSIG ºF MBH KW* MBH KW* MBH KW* MBH KW* MBH KW* MBH KW*

61.5 35 255 17.2 243 18.6 231 20.1 219 21.9 207 23.9 195 26.2

68.5 40 275 17.6 263 19.0 250 20.6 238 22.4 225 24.4 212 26.7

76 45 296 18.1 283 19.5 270 21.1 257 22.9 243 24.9 230 27.2

84 50 319 18.7 305 20.0 291 21.6 277 23.4 263 25.5 248 27.7

61.5 35 191 12.7 182 13.7 172 14.9 163 16.2 153 17.7 143 19.4

68.5 40 207 13.0 197 14.0 187 15.2 177 16.5 167 18.0 157 19.8

76 45 224 13.3 214 14.4 203 15.5 193 16.9 182 18.4 171 20.2

84 50 241 13.7 230 14.7 219 15.9 208 17.3 197 18.8 186 20.6

*Power consumption includes outdoor fans and compressors only.

NOTE:

The Supply Air Plenum and the Return Air Grille

accessories can be used on either arrangement.

NOTE: TheBaseaccessorycanonlybeusedonthevertical

arrangement.

Tem perature of Air on Condenser Coil, ºF

Unitary Products Group 3

Page 4

036-21326-001-C-0202

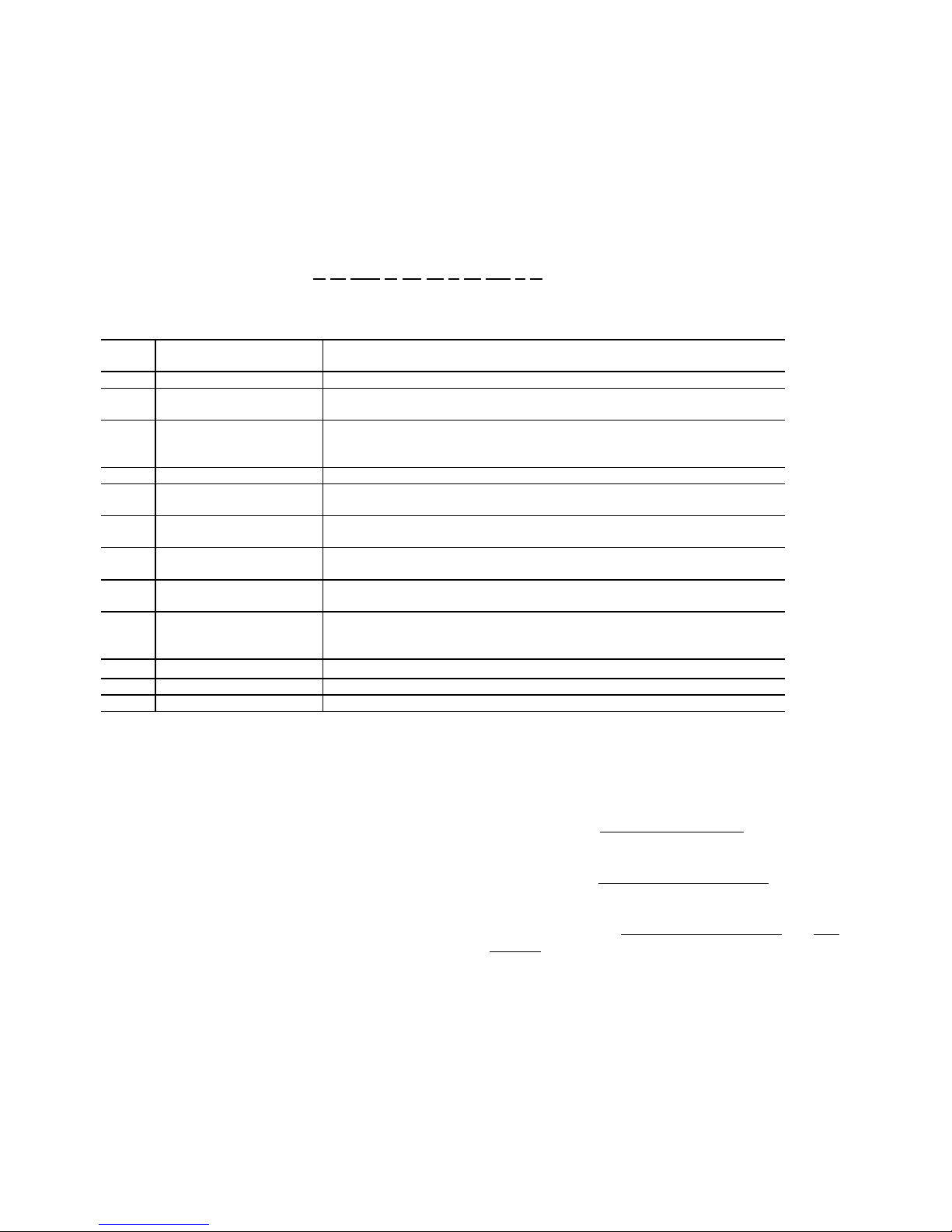

OUTDOOR CONDENSING UNITS AND HEAT PUMPS

PRODUCT NOMENCLATURE

(UPG BRANDS)

H F - 10 C 00 A T A AA 1 A

Model # Model Number

Description

H Product Category

F Product Identifier

-10 Nominal Cooling

Capacity

MBH

C Heat Type

00 Nominal Heating

Capacity

A Airflow Options

T Voltage

A Installation Options

AA Special Options

1 Generation

A Style

Options

H = Air Conditioner Split System E = Split System Heat Pump

F = R-22 Standard Efficiency 2-Pipe

L = R-22 Standard Efficiency 4-Pipe

-07 = 7-1/2 Ton

-10 = 10 Ton

C = Cooling Only

00 = No Heat Installed

A = Standard Motor

T= 208/230-3-60

W= 460-3-60

A = None

B = Disconnect

AA = None

AC = Technicoat

1 = First Generation 2 = Second Generation

A = Style A B = Style B

FIGURE 2 : OUTDOOR PRODUCT NOMENCLATURE

OUTDOOR UNIT

Every unit includes 2 heavy-duty scroll compressors, 2 outdoor fan motors with inherent protection, subfusing and a

copper tube/aluminum fin coil.

All controls are located in the front of the unit in the control

box and are readily accessible for maintenance, adjustment

and service. All wiring (power and control) can be made

through the front of the unit.

-15 = 15 Ton

-20 = 20 Ton

X= 575-3-60

ACCESSORIES (FACTORY & FIELD

INSTALLED)

• Factory installed Non-Fused Disconnect for safety and

convenience.

• Factory installed Technicoat Condenser Coil

sion protection.

• Field Installed VFD (Variable Frequency Drive

Ambient operation down to 0ºF.

s for corro-

) for Low

4 Unitary Products Group

• Field Installed Hot Gas Bypass for low load operation.

• Field installed Pump-Out Kit for applications where liquid

slugging could be an issue.

Page 5

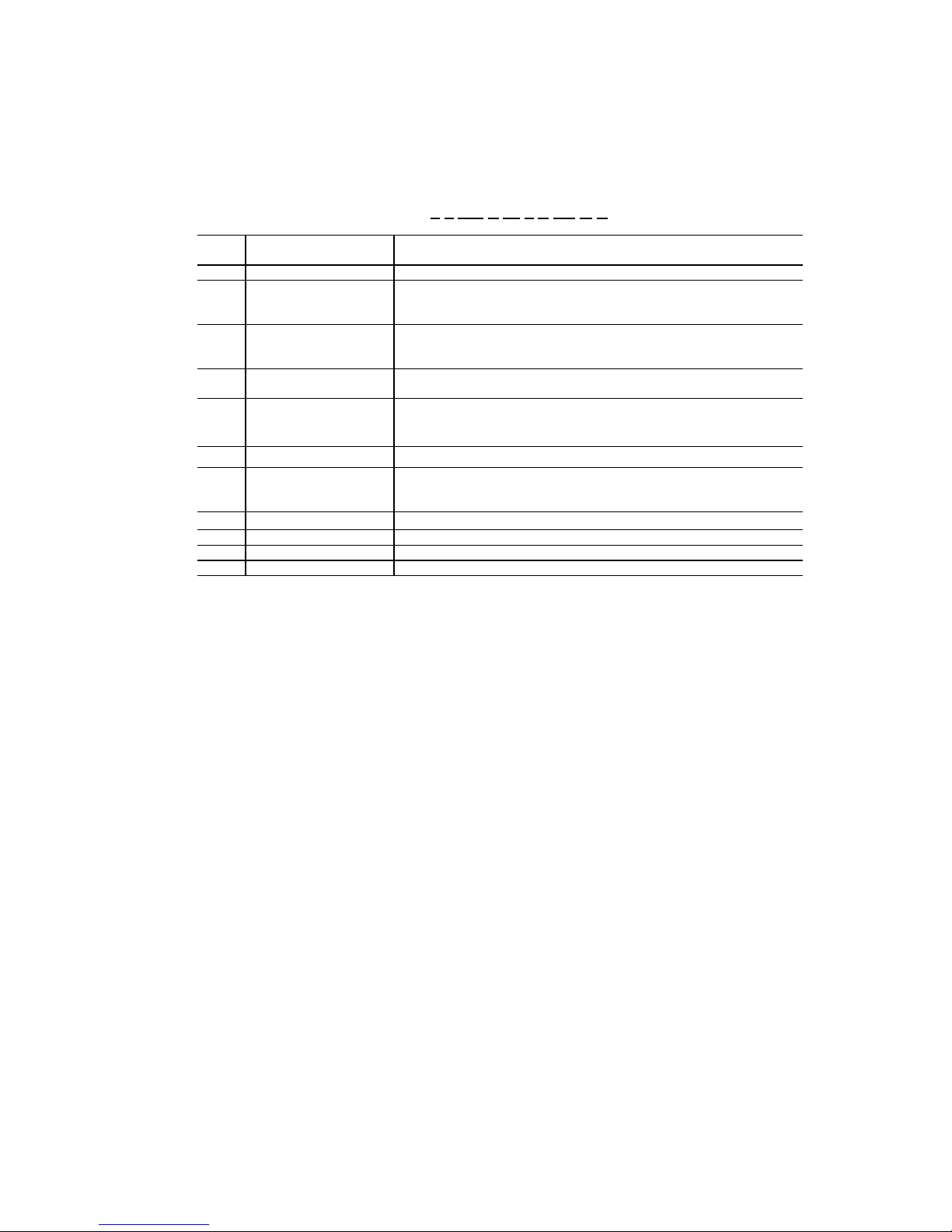

INDOOR SPLIT UPG PRODUCT NOMENCLATURE

L F –10 C 00 T A AA 1 A

036-21326-001-C-0202

Model # Model Number

Description

L Product Category

F

Product Identifier

-10 Nominal Cooling

Capacity

MBH

C Heat Type

00 Nominal Heating

Capacity

A Airflow Options

F Voltage

A Factory Options

AA Special Options

1 Generation

A Product Style

* NOT AVAILABLE IN HEAT PUMP.

Options

L = Air Handling Unit- Cooling F = Air Handling Unit- Heat Pump

F = R-22 Standard Efficiency 2-Pipe

L = R-22 Standard Efficiency 4-Pipe

-07 = 7-1/2 Ton

-10 =10 Ton

C = Cooling Only

00= No Heat Installed

A = None

F = 208/230-1-60

T = 208/230-3-60

W=460-3-60

A = None

AA = None

1 = First Generation 2 = Second Generation

A = Style A B = Style B

FIGURE 3 : INDOOR PRODUCT NOMENCLATURE

INDOOR UNIT

Every unit includes a well-insulated cabinet, copper tube/aluminum fin coil with interlaced circuiting arrangement, 2"

throwaway filters, adjustable TXV’s and centrifugal blowers.

Blower motors and drive kits are ordered separately.

The controls include 208/230/460 volt transformer, blower

motor contactor and relay, and a low voltage terminal block.

The units are shipped in the vertical position ready for field

installation. For horizontalinstallation, the blower module can

be repositioned in the field as shown on pages 3 and 6 for

maximum flexibility.

-15 = 15 Ton

-20 = 20 Ton

S = 208/230-460-3-60

• Base Sections are available to raise vertical indoor units

above the floor. Outdoor air may be introduced through

these bases by cutting an access opening for the outdoor air duct connection. These bases are finished to

match the exterior of the basic unit. They may have to be

insulated in the field for certain applications.

• Suspension Kit is available for indoor units installed horizontally.

• Manual and electronic two stage thermostats are available for cooling applications.

• Both thermostats have a two-position fan switch, AUTO

and ON to provide intermittent or continuous blower

operation.

ACCESSORIES INDOOR UNIT

(FIELD INSTALLED)

• Supply Air Plenums and Return Air Grilles (expanded

metal) accessories are available for free-standing indoor

(15 Ton units only) units located in the conditioned

space. Both accessories are finished to match the exterior of the basic unit, and both can be applied with either

vertical or horizontal units. The supply air plenums are

fully insulated and have double-deflection, adjustable

grilles.

Unitary Products Group 5

Page 6

036-21326-001-C-0202

FIGURE 4 : VERTICAL ARRANGEMENTS - LL180 AND LL240

FIGURE 5 : HORIZONTAL ARRANGEMENTS - LL180 AND LL240

CERTAINBLOWERPOSITIONSARENOT

RECOMMENDED BECAUSE THE BLOWER

MOTOR SHOULD NOT BE MOUNTED UPSIDE

DOWN.

6 Unitary Products Group

.

CAUTION

Page 7

036-21326-001-C-0202

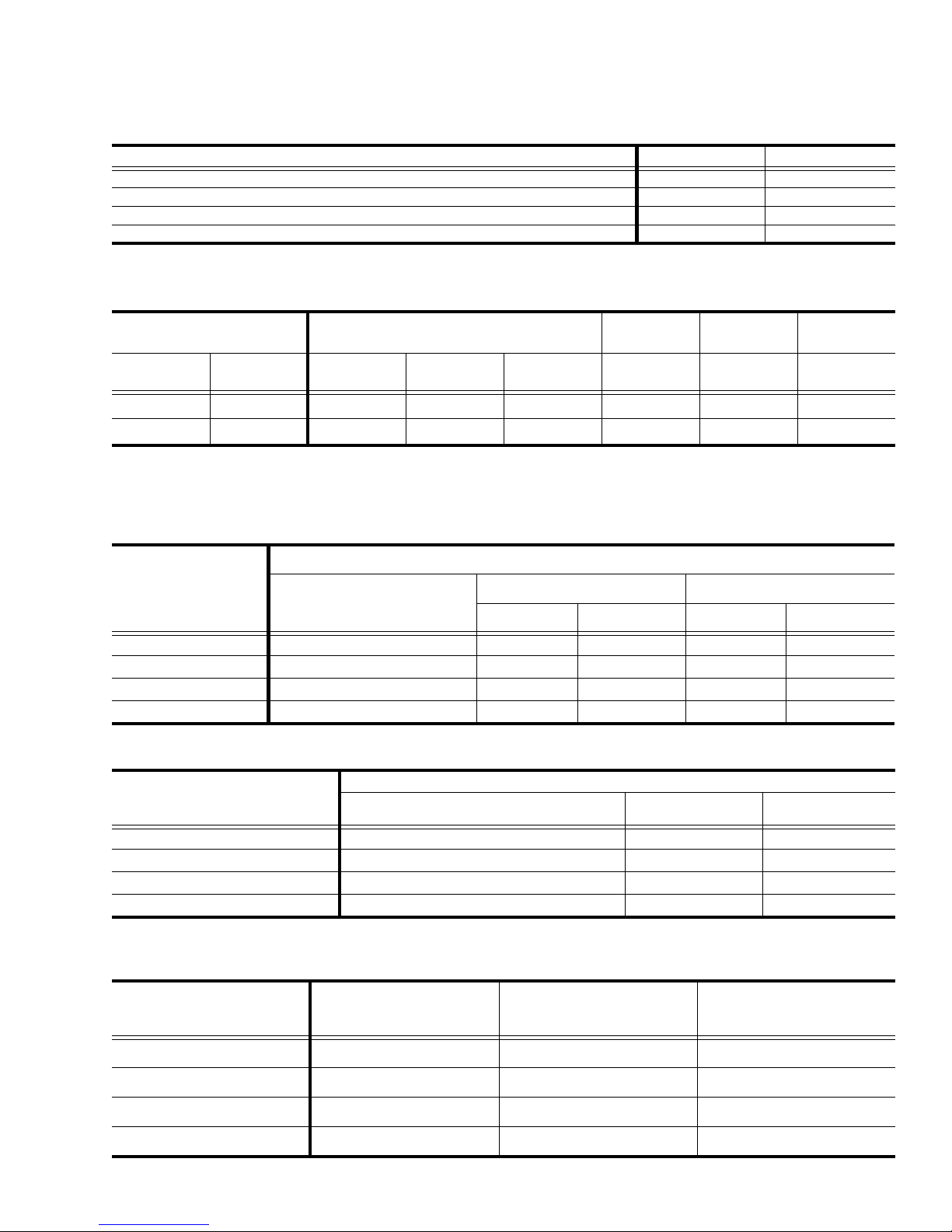

TABLE 1: UNIT APPLICATION DATA

Application Limitations Minimum Maximum

Voltage Variation (208/230-3-60) - Volts 187 253

Voltage Variation (460-3-60) - Volts 414 506

AmbientAir on OutdoorCoil (CoolingCycle) - °F 45 115

AmbientAir on IndoorCoil (Cooling Cycle) - °F 68 86

TABLE 2: ARI RATINGS - COOLING AND SOUND

Model

Outdoor

Unit

HL180 LL180 180 9.7 10.4 89.0 6000 0.35

HL240 LL240 240 9.7 10.4 90.0 8000 0.40

1. Ratings are in accordancew ith ARI standard 340/360.

2. Ratings are in accordance with ARI standard 370.

IndoorUnit

MBH EER IPLV dB CFM IWG

CoolingCapacity

1

Cond. Unit

2

Sound

Rated Airflow Rated ESP

TABLE 3: ELECTRICAL DATA COMPRESSORS

Compressors

Model

Number

HL180 208/230-3-60 25.6 190.0 25.6 190.0

HL180 460-3-60 12.8 95.0 12.8 95.0

HL240 208/230-3-60 42.0 239.0 42.0 239.0

HL240 460-3-60 19.2 125.0 19.2 125.0

Power

Supply

System 1 System 2

RLA LRA RLA LRA

TABLE 4: ELECTRICAL DATA FAN MOTORS

Model

Number

HL180 208/230-3-60 2 3.7

HL180 460-3-60 2 1.85

HL240 208/230-3-60 2 5.8

HL240 460-3-60 2 2.9

TABLE 5: ELECTRICAL DATA, OUTDOOR MCA & MAX. FUSE SIZE

Model

Number

HL180 208/230-3-60 65.1 90

HL180 460-3-60 32.5 45

HL240 208/230-3-60 106.1 125

HL240 460-3-60 49.0 60

1. Maximum fuse or maximum circuit breaker (HACR type per NEC).

Unitary Products Group 7

Power

Supply

Power

Supply

Condenser Fans

Min. Circuit

Ampacity

Qty. FLA

Max.

Fuse

Size

ea.

1

Page 8

036-21326-001-C-0202

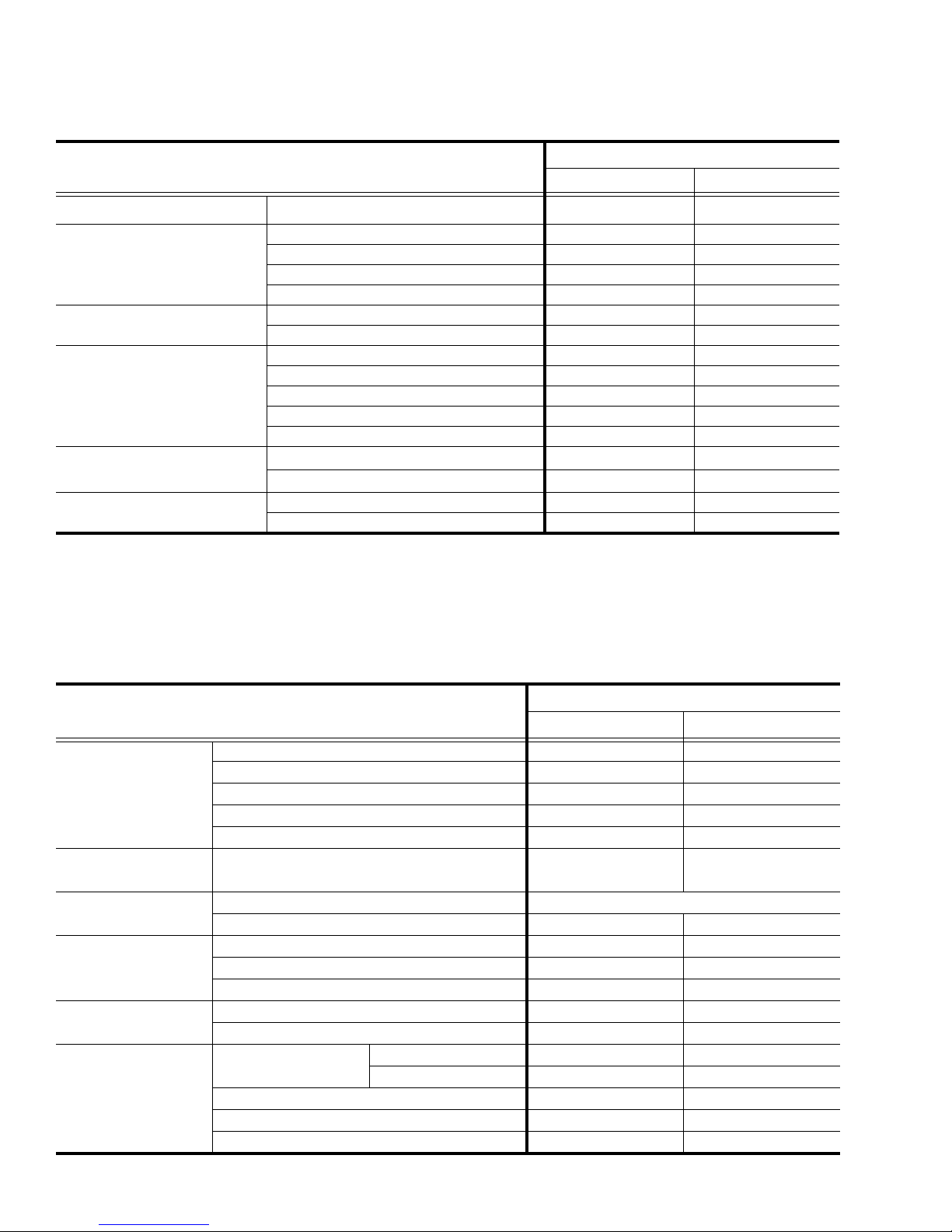

TABLE 6: OUTDOOR UNIT PHYSICAL DATA

Description

Unit Model

HL180 HL240

Compressor

1

Fans

Fan Motors

2

Coil

Refrigerant - 22 (lbs -oz.)

Unit Weight (lbs)

1. These compressors are fully hermetic.

2. The ball bearing, 56 frame, single phase condenser fan motors have internal protection and are directly connected to the condenser fans. Motor

rotation is counterclockwise when viewing the lead end, which is opposite the shaft end.

3. The amount of charge in the unit as shipped from the factory.

4. Total operating charge for the condensing unit, matching indoor unit, and 25 feet of interconnecting pipe.

Rating - (Qty) Tons 2 X 7.5 = 15 Tons 2 X 10 = 20 Tons

Quantity 2 2

Diameter - inches 24 30

Blades/Pitch (°) 3/34 3/22

Nominal CFM 11,600 15,200

HP 1 1.5

RPM 1140 1100

Rows Deep X Rows High 2 X 30 2 X 30

Finned Length - inches each slab 60 78

Face Area - square feet (both slabs) 25 32.5

Tube(Copper) OD - inches 3/8 3/8

Fins(Aluminum) per inch 16 16

Holding Charge (sys1/sys2)

Operating Charge (sys1/sys2)

Shipping 944 1380

Operating 957 1396

3

4

1-0/1-0lbs. 1-0/1-0lbs.

14.0/14.0 lbs. 17.0/17.0 lbs.

TABLE 7: INDOOR UNIT PHYSICAL DATA

Description

Rows Deep X Rows High 3 X 32 3 X 40

Finned length- Inches 83 81

Coil

Centrifugal Blower

(Forward Curve - Qty

Blower Motor

1

Filters

(Throwaway)

Unit Weight (lbs)

Accessory Operating

Weight (lbs)

1. Refer to Table 20 and 22 for more inform ation.

Face Area - Square Feet 18.4 22.5

Tube (Copper) OD - Inches 3/8 3/8

Fins (Aluminum) per Inch 13 16

DiameterXWidth-Inches 15X12-2 18X18-2

HP Field Installed

RPM -- -Quantity Per Unit 4/4 10

Size-Inches 20X21X2&22X24X2 20X25X2

Total Face Area - Square Feet 25.8 34.7

Shipping 720 990

Operating 830 1115

Motor & Drive

Supply Air Plenum 185 N/A

Return Air Grille 25 N/A

Base 140 210

Unit Model

LL180 LL240

3HP 47 -5HP 120 120

8 Unitary Products Group

Page 9

036-21326-001-C-0202

All dimensions are in inches. They are

subject to change without notice. Certified dimensions will be provided upon

C

request.

OUTDOOR UNIT DIMENSIONS

A

Unit

Dimensions (In.)

ABC

B

TABLE 8: CONNECTIONS

Connection Entry Connection Size

15 Ton 20 Ton

Suction Line 1-1/8 ID 1-3/8 ID

Liquid Line 5/8 ID 5/8 ID

Power Wiring 2-1/8 KO 2-1/8 KO

Control Wiring 7/8 KO 7/8 KO

TABLE 9: UNIT CLEARANCES

Location Dimensions

Overhead (Top)

Front access panels 36”

Left Side 30”

Right Side 30”

Rear 24”

Bottom

1

2

120”

0”

15 Ton 37.5 45.75 110.5

20 Ton 37.5 45.75 128.1

Dimensions (in.)

Unit

ABC

15 Ton 23 47 110

20 Ton 23 52 128

TABLE 10: HL CENTER OF GRAVITY DIMENSIONS

APPROXIMATE

CENTER OF GRAVITY

X END

B

C

CONTRO

L BO

46

A

FIGURE 6 : CENTER OF GRAVITY

1. Units must be installed outdoors. Overhanging structures or

shrubs should not obstruct condenser air discharge.

2. Adequate snow clearance must be provided if winter operation

is expected.

UNIT SIZE

15 Ton Outdoor 944 959 205 275 275 205 110 46 47 23

20 ton Outdoor 1124 1141 232 339 339 232 128 46 52 23

SHIPPING

WEIGHT

FIGURE 7 : HL CORNER WEIGHT

Unitary Products Group 9

OPERATING

WEIGHT

LEFT

ABCD

D

CG

A

dim X

LENGTH

FRONT

UNIT

LENGTH

C

WIDTH

dim Y

B

UNIT

WIDTH

DIM X DIM Y

Page 10

036-21326-001-C-0202

FIGURE 8 : PIPING AND ELECTRICAL CONNECTION LOCATIONS

TABLE 11: PIPING AND ELECTRICAL CONNECTION SIZES

CONNECTION ENT RY

A

B

C

D

E

F

10 Unitary Products Group

SIZE

SUCTION LINE SYS #1 1-3/8 ID

LIQUID LINE SYS. #1 5/8 OD

SUCTION LINE SYS. #2 1-3/8 ID

LIQUID LINE SYS. #2 5/8 OD

POWER WIRING 2” KO

CONTROL WIRING 7/8 KO

Page 11

036-21326-001-C-0202

TABLE 12: 15 TON CAPACITY TABLE - 85º AND 95ºF

15 Ton Capacity Tables

HL180 Matched with LL180

AIR ON EVAPORATOR

CFM W.B. GROSS INPUT GROSS SENSIBLE CAPACITY (MBh)

TEMP CAP. POWER (RETURN AIR DRY BULB TEMP.- (F))

(F) (MBh) (kW) 86 83 80 77 74 71 68

4500 72 197.8 15.23 117.3 104.5 91.6 78.8 66.0 #N/A #N/A

67 183.8 14.90 144.8 131.9 119.1 106.3 93.4 80.6 67.8

62 170.5 14.50 168.2 155.4 142.6 129.8 116.9 104.1 91.3

57 173.8 14.43 173.8 171.0 158.2 145.3 132.5 119.7 106.9

5250 72 204.1 15.34 129.7 114.5 99.4 84.2 69.0 #N/A #N/A

67 189.6 15.01 159.4 144.3 129.1 114.0 98.8 83.6 68.5

62 175.9 14.60 174.8 168.3 154.6 139.4 124.3 109.1 93.9

57 179.3 14.53 179.3 177.9 171.5 156.3 141.2 126.0 110.8

6000 72 210.3 15.44 142.1 124.6 107.1 89.6 72.1 #N/A #N/A

67 195.4 15.12 174.1 156.6 139.1 121.6 104.1 86.6 69.2

62 181.3 14.70 181.3 181.3 166.6 149.1 131.6 114.1 96.6

57 184.8 14.64 184.8 184.8 184.8 167.3 149.8 132.3 114.8

6750 72 213.6 15.54 152.3 132.4 112.5 92.6 72.6 #N/A #N/A

67 198.4 15.21 186.0 166.1 146.2 126.3 106.3 86.4 66.5

62 184.0 14.80 184.0 184.0 175.0 155.1 135.2 115.3 95.3

57 187.6 14.73 187.6 187.6 187.6 167.7 147.8 127.8 107.9

7500 72 216.8 15.64 162.6 140.3 117.9 95.6 73.2 #N/A #N/A

67 201.4 15.31 198.0 175.6 153.3 130.9 108.5 86.2 63.8

62 186.8 14.89 186.8 186.8 183.5 161.1 138.8 116.4 94.1

57 190.5 14.82 190.5 190.5 190.5 168.1 145.7 123.4 101.0

Indicates Nominal Capacity Rating Point.

INPUT POWER INCLUDES THE CONDENSER AND COMPRESSOR MOTORS BUT NOT THE INDOOR BLOWER MOTOR

OUTDOOR AMBIENT TEMPERATURE (F):

85º

15 Ton Capacity Tables

HL180 Matched with LL180

AIRONEVAPORATOR

CFM W.B. GROSS INPUT GROSS SENSIBLE CAPACITY (MBh)

TEMP CAP. POWER (RETURN AIR DRY BULB TEMP.-(F)

(F) (MBh) (kW) 86 83 80 77 74 71 68

4500 72 190.9 16.89 114.1 101.3 88.5 75.7 62.8 #N/A #N/A

67 176.8 16.51 142.2 129.4 116.5 103.7 90.9 78.0 65.2

62 162.8 16.18 162.8 153.2 140.3 127.5 114.7 101.8 89.0

57 163.2 16.11 163.2 158.1 145.2 132.4 119.6 106.7 93.9

5250 72 196.2 16.99 126.2 111.0 95.8 80.7 65.5 #N/A #N/A

67 181.7 16.61 156.5 141.4 126.2 111.0 95.9 80.7 65.6

62 167.4 16.27 167.4 162.5 152.0 136.8 121.6 106.5 91.3

57 167.7 16.20 167.7 165.2 157.3 142.1 127.0 111.8 96.6

6000 72 201.5 17.09 138.2 120.7 103.2 85.7 68.2 #N/A #N/A

67 186.6 16.71 170.9 153.4 135.9 118.4 100.9 83.4 65.9

62 171.9 16.37 171.9 171.9 163.6 146.1 128.6 111.1 93.6

57 172.3 16.30 172.3 172.3 169.3 151.8 134.4 116.9 99.4

6750 72 205.1 17.17 148.4 128.5 108.6 88.6 68.7 #N/A #N/A

67 190.0 16.79 182.1 162.9 143.0 123.1 103.1 83.2 63.3

62 175.0 16.45 175.0 175.0 170.9 150.9 131.0 111.1 91.2

57 175.4 16.37 175.4 175.4 173.9 154.0 134.1 114.2 94.2

7500 72 208.8 17.25 158.7 136.3 114.0 91.6 69.2 #N/A #N/A

67 193.4 16.86 193.4 172.4 150.1 127.7 105.4 83.0 60.7

62 178.1 16.52 178.1 178.1 178.1 155.7 133.4 111.0 88.7

57 178.5 16.45 178.5 178.5 178.5 156.2 133.8 111.4 89.1

Indicates Nominal Capacity Rating Point.

INPUT POWER INCLUDES THE CONDENSER AND COMPRESSOR MOTORS BUT NOT THE INDOOR BLOWER MOTOR

OUTDOOR AMBIENT TEMPERATURE(F):

95º

Unitary Products Group 11

Page 12

036-21326-001-C-0202

TABLE 13: 15 TON CAPACITY TABLE - 105º AND 115ºF

15 Ton Capacity Tables

HL180 Matched with LL180

AIRONEVAPORATOR

CFM W.B. GROSS INPUT GROSS SENSIBLE CAPACITY (MBh)

TEMP CAP. POWER (RETURN AIR DRY BULB TEMP.-(F)

(F) (MBh) (kW) 86 83 80 77 74 71 68

4500 72

67

62

57

5250 72

67

62

57

6000 72

67

62

57

6750 72

67

62

57

7500 72

67

62

57

Indicates Nominal Capacity Rating Point.

INPUT POWER INCLUDES THE CONDENSER AND COMPRESSOR MOTORS BUT NOT THE INDOOR BLOWER MOTOR

182.8 18.89 111.9 99.1 86.2 73.4 60.6 #N/A #N/A

168.9 18.42 139.2 126.3 113.5 100.7 87.8 75.0 62.2

156.1 18.00 156.1 150.4 137.6 124.7 111.9 99.1 86.2

157.8 17.99 157.8 152.5 139.7 126.8 114.0 101.2 88.3

187.6 19.03 123.6 108.5 93.3 78.1 63.0 #N/A #N/A

173.4 18.56 153.1 137.9 122.8 107.6 92.4 77.3 62.1

160.2 18.13 160.2 157.4 148.8 133.6 118.5 103.3 88.1

162.0 18.13 162.0 159.3 151.1 135.9 120.7 105.6 90.4

192.4 19.17 135.3 117.8 100.3 82.8 65.3 #N/A #N/A

177.8 18.70 167.0 149.5 132.0 114.6 97.1 79.6 62.1

164.3 18.27 164.3 164.3 160.0 142.5 125.0 107.5 90.1

166.1 18.26 166.1 166.1 162.5 145.0 127.5 110.0 92.5

196.1 19.23 146.1 126.2 106.2 86.3 66.4 #N/A #N/A

181.2 18.76 175.9 159.8 139.8 119.9 100.0 80.1 60.1

167.5 18.33 167.5 167.5 165.4 145.4 125.5 105.6 85.7

169.3 18.32 169.3 169.3 167.5 147.6 127.7 107.7 87.8

199.8 19.30 156.9 134.5 112.2 89.8 67.4 #N/A #N/A

184.7 18.82 184.7 170.0 147.6 125.3 102.9 80.5 58.2

170.7 18.39 170.7 170.7 170.7 148.3 126.0 103.6 81.3

172.5 18.38 172.5 172.5 172.5 150.2 127.8 105.5 83.1

OUTDOOR AMBIENT TEMPERATURE (F):

105º

15 Ton Capacity Tables

HL180 Matched with LL180

AIR ON EVAPORATOR

CFM W.B. GROSS INPUT GROSS SENSIBLE CAPACITY (MBh)

TEMP CAP. POWER (RETURN AIR DRY BULB TEMP.-(F)

(F) (MBh) (kW) 86 83 80 77 74 71 68

4500 72 174.7 20.88 109.7 96.8 84.0 71.2 58.3 #N/A #N/A

67 161.0 20.33 136.1 123.3 110.5 97.6 84.8 72.0 59.1

62 149.4 19.81 149.4 147.6 134.8 122.0 109.1 96.3 83.5

57 152.5 19.88 152.5 146.9 134.1 121.2 108.4 95.6 82.8

5250 72 179.0 21.06 121.1 105.9 90.8 75.6 60.4 #N/A #N/A

67 165.0 20.51 149.7 134.5 119.3 104.2 89.0 73.9 58.7

62 153.1 19.99 153.1 152.2 145.6 130.5 115.3 100.1 85.0

57 156.2 20.05 156.2 153.4 144.8 129.7 114.5 99.4 84.2

6000 72 183.3 21.25 132.5 115.0 97.5 80.0 62.5 #N/A #N/A

67 168.9 20.69 163.2 145.7 128.2 110.7 93.2 75.7 58.2

62 156.8 20.16 156.8 156.8 156.5 139.0 121.5 104.0 86.5

57 159.9 20.23 159.9 159.9 155.6 138.1 120.6 103.1 85.6

6750 72 187.1 21.30 143.8 123.9 103.9 84.0 64.1 #N/A #N/A

67 172.4 20.73 169.6 156.6 136.7 116.8 96.8 76.9 57.0

62 160.0 20.21 160.0 160.0 159.9 139.9 120.0 100.1 80.2

57 163.2 20.27 163.2 163.2 161.1 141.2 121.2 101.3 81.4

7500 72 190.9 21.34 155.1 132.7 110.4 88.0 65.7 #N/A #N/A

67 175.9 20.78 175.9 167.5 145.1 122.8 100.4 78.1 55.7

62 163.3 20.25 163.3 163.3 163.3 140.9 118.5 96.2 73.8

57 166.6 20.32 166.6 166.6 166.6 144.2 121.8 99.5 77.1

Indicates Nominal Capacity Rating Point.

INPUT POWER INCLUDES THE CONDENSER AND COMPRESSOR MOTORS BUT NOT THE INDOOR BLOWER MOTOR

OUTDOOR AMBIENT TEMPERATURE (F):

115º

12 Unitary Products Group

Page 13

TABLE 14: 15 TON CAPACITY TABLE - 125ºF

15 Ton Capacity Tables

HL180 Matched with LL180

AIR ON EVAPORATOR

CFM W.B. GROSS INPUT GROSS SENSIBLE CAPACITY (MBh)

TEMP CAP. POWER (RETURN AIR DRY BULB TEMP.-(F)

(F) (MBh) (kW) 86 83 80 77 74 71 68

4500 72

67

62

57

5250 72

67

62

57

6000 72

67

62

57

6750 72

67

62

57

7500 72

67

62

57

Indicates Nominal Capacity Rating Point.

INPUT POWER INCLUDES THE CONDENSER AND COMPRESSOR MOTORS BUT NOT THE INDOOR BLOWER MOTOR

166.6 22.9 107.4 94.6 81.8 68.9 56.1 #N/A #N/A

153.1 22.2 133.1 120.3 107.4 94.6 81.8 68.9 56.1

142.7 21.6 142.7 142.7 132.0 119.2 106.4 93.5 80.7

147.1 21.8 147.1 141.3 128.5 115.7 102.8 90.0 77.2

170.4 23.1 118.5 103.4 88.2 73.1 57.9 #N/A #N/A

156.6 22.5 146.2 131.1 115.9 100.8 85.6 70.4 55.3

146.0 21.8 146.0 146.0 142.5 127.3 112.1 97.0 81.8

150.4 22.0 150.4 147.6 138.6 123.5 108.3 93.1 78.0

174.2 23.3 129.7 112.2 94.7 77.2 59.7 #N/A #N/A

160.1 22.7 159.4 141.9 124.4 106.9 89.4 71.9 54.4

149.2 22.1 149.2 149.2 149.2 135.4 117.9 100.4 82.9

153.8 22.2 153.8 153.8 148.8 131.3 113.8 96.3 78.8

178.0 23.4 141.5 121.5 101.6 81.7 61.8 #N/A #N/A

163.6 22.7 163.3 153.5 133.5 113.6 93.7 73.8 53.8

152.5 22.1 152.5 152.5 152.5 134.4 114.5 94.6 74.7

157.2 22.2 157.2 157.2 154.7 134.7 114.8 94.9 75.0

181.9 23.4 153.3 130.9 108.6 86.2 63.9 #N/A #N/A

167.2 22.7 167.2 165.0 142.7 120.3 98.0 75.6 53.2

155.8 22.1 155.8 155.8 155.8 133.5 111.1 88.8 66.4

160.6 22.3 160.6 160.6 160.6 138.2 115.9 93.5 71.2

OUTDOOR AMBIENT TEMPERATURE (F):

036-21326-001-C-0202

125º

Unitary Products Group 13

Page 14

036-21326-001-C-0202

TABLE 15: 20 TON CAPACITY TABLE - 85º AND 95ºF

20 Ton Capacity Tables

HL240 & LL240

AIRONEVAPORATOR

CFM W.B. GROSS INPUT GROSS SENSIBLE CAPACITY (MBh)

TEMP CAP. POWER (RETURN AIR DRY BULB TEMP.-(F)

(F) (MBh) (kW) 86 83 80 77 74 71 68

6000 72

67

62

57

7000 72

67

62

57

8000 72

67

62

57

8600 72

67

62

57

9200 72

67

62

57

263.4 21.25 155.9 138.8 121.7 104.6 87.5 #N/A #N/A

243.5 20.69 191.0 173.9 156.8 139.7 122.6 105.5 88.4

227.6 20.42 221.1 204.0 186.9 169.8 152.7 135.6 118.5

219.5 20.19 219.5 216.7 199.6 182.5 165.4 148.3 131.2

273.9 21.38 172.8 152.6 132.4 112.2 91.9 #N/A #N/A

253.2 20.82 211.0 190.8 170.6 150.3 130.1 109.9 89.7

236.7 20.54 233.4 223.5 203.3 183.1 162.9 142.6 122.4

228.2 20.31 228.2 226.8 217.1 196.9 176.7 156.4 136.2

284.4 21.51 189.7 166.4 143.0 119.7 96.4 #N/A #N/A

262.9 20.94 231.0 207.6 184.3 161.0 137.6 114.3 91.0

245.7 20.67 245.7 243.0 219.7 196.3 173.0 149.7 126.4

237.0 20.43 237.0 237.0 234.6 211.3 187.9 164.6 141.3

289.0 21.64 197.6 172.2 146.8 121.5 96.1 #N/A #N/A

267.2 21.06 239.9 214.6 189.2 163.8 138.4 113.0 87.7

249.7 20.79 249.7 248.3 225.5 200.1 174.7 149.4 124.0

240.8 20.55 240.8 240.8 239.6 214.2 188.9 163.5 138.1

293.6 21.76 205.5 178.0 150.6 123.2 95.8 #N/A #N/A

271.4 21.19 248.9 221.5 194.1 166.6 139.2 111.8 84.4

253.7 20.91 253.7 253.7 231.3 203.9 176.5 149.0 121.6

244.6 20.67 244.6 244.6 244.6 217.2 189.8 162.4 134.9

Indicates Nominal Capacity Rating Point.

INPUT POWER INCLUDES THE CONDENSER AND COMPRESSOR MOTORS BUT NOT THE INDOOR BLOWER MOTOR

OUTDOOR AMBIENT TEMPERATURE (F):

85º

AIRONEVAPORATOR

CFM W.B. GROSS INPUT GROSS SENSIBLE CAPACITY (MBh)

TEMP CAP. POWER (RETURN AIR DRY BULB TEMP.-(F)

(F) (MBh) (kW) 86 83 80 77 74 71 68

6000 72

67

62

57

7000 72

67

62

57

8000 72

67

62

57

8600 72

67

62

57

9200 72

67

62

57

253.7 23.11 151.3 134.2 117.0 99.9 82.8 #N/A #N/A

237.2 22.68 188.2 171.1 153.9 136.8 119.7 102.6 85.5

218.5 22.16 218.5 202.7 185.6 168.5 151.4 134.3 117.2

214.5 22.11 214.5 210.5 193.4 176.3 159.1 142.0 124.9

262.8 23.30 167.5 147.3 127.1 106.8 86.6 #N/A #N/A

245.7 22.88 207.5 187.3 167.1 146.9 126.7 106.5 86.2

226.4 22.35 226.4 218.5 201.5 181.3 161.0 140.8 120.6

222.2 22.30 222.2 220.2 209.9 189.7 169.5 149.2 129.0

271.9 23.50 183.7 160.4 137.1 113.7 90.4 #N/A #N/A

254.3 23.07 226.9 203.6 180.3 156.9 133.6 110.3 87.0

234.2 22.54 234.2 234.2 217.3 194.0 170.7 147.4 124.0

229.9 22.49 229.9 229.9 226.4 203.1 179.8 156.4 133.1

269.7 23.60 189.5 164.1 138.7 113.3 88.0 #N/A #N/A

252.2 23.16 233.2 207.8 182.4 157.1 131.7 106.3 80.9

232.3 22.63 232.3 232.3 220.0 194.6 169.2 143.8 118.5

228.0 22.58 228.0 228.0 226.3 200.9 175.5 150.2 124.8

267.6 23.69 195.2 167.8 140.4 112.9 85.5 #N/A #N/A

250.2 23.26 239.5 212.0 184.6 157.2 129.8 102.3 74.9

230.4 22.72 230.4 230.4 222.6 195.2 167.7 140.3 112.9

226.2 22.68 226.2 226.2 226.2 198.7 171.3 143.9 116.5

Indicates Nominal Capacity Rating Point.

INPUT POWER INCLUDES THE CONDENSER AND COMPRESSOR MOTORS BUT NOT THE INDOOR BLOWER MOTOR

14 Unitary Products Group

20 Ton Capacity Tables

HL240 & LL240

OUTDOOR AMBIENT TEMPERATURE (F):

95º

Page 15

TABLE 16: 20 TON CAPACITY TABLE - 105º & 115ºF

20 Ton Capacity Tables

AIRONEVAPORATOR

CFM W.B. GROSS INPUT GROSS SENSIBLE CAPACITY (MBh)

6000

TEMP CAP. POWER (RETURN AIR DRY BULB TEMP.-(F)

(F) (MBh) (kW) 86 83 80 77 74 71 68

72 245.6 25.60 148.7 131.6 114.5 97.4 80.2 #N/A #N/A

67 228.4 25.00 184.5 167.4 150.3 133.2 116.1 99.0 81.9

62 211.9 24.47 211.9 198.0 180.9 163.7 146.6 129.5 112.4

57 210.8 24.50 210.8 204.7 187.6 170.5 153.4 136.3 119.2

7000

72 253.0 25.77 164.4 144.2 124.0 103.7 83.5 #N/A #N/A

67 235.2 25.16 203.2 183.0 162.8 142.5 122.3 102.1 81.9

62 218.3 24.63 218.3 211.3 195.9 175.7 155.4 135.2 115.0

57 217.1 24.66 217.1 214.1 203.2 183.0 162.8 142.5 122.3

8000

72 260.4 25.94 180.1 156.8 133.5 110.1 86.8 #N/A #N/A

67 242.1 25.32 221.9 198.6 175.2 151.9 128.6 105.3 81.9

62 224.7 24.79 224.7 224.7 210.9 187.6 164.2 140.9 117.6

57 223.4 24.82 223.4 223.4 218.8 195.4 172.1 148.8 125.5

8600

72 261.9 26.04 188.1 162.7 137.3 112.0 86.6 #N/A #N/A

67 243.5 25.43 230.7 205.7 180.3 154.9 129.6 104.2 78.8

62 226.0 24.89 226.0 226.0 217.0 191.6 166.2 140.9 115.5

57 224.8 24.92 224.8 224.8 222.4 197.1 171.7 146.3 120.9

9200

72 263.4 26.15 196.1 168.6 141.2 113.8 86.4 #N/A #N/A

67 244.9 25.53 239.5 212.8 185.4 158.0 130.5 103.1 75.7

62 227.3 24.99 227.3 227.3 223.1 195.7 168.2 140.8 113.4

57 226.1 25.03 226.1 226.1 226.1 198.7 171.2 143.8 116.4

Indicates Nominal Capacity Rating Point.

INPUT POWER INCLUDES THE CONDENSER AND COMPRESSOR MOTORS BUT NOT THE INDOOR BLOWER MOTOR

HL240 & LL240

OUTDOOR AMBIENT TEMPERATURE (F):

036-21326-001-C-0202

105º

20 Ton Capacity Tables

AIRONEVAPORATOR

CFM W.B. GROSS INPUT GROSS SENSIBLE CAPACITY (MBh)

TEMP CAP. POWER (RETURN AIR DRY BULB TEMP.-(F)

6000 72

7000 72

8000 72

8600 72

9200 72

(F) (MBh) (kW) 86 83 80 77 74 71 68

237.4 28.09 146.1 129.0 111.9 94.8 77.7 #N/A #N/A

67

62

57

219.5 27.31 180.8 163.7 146.6 129.5 112.4 95.3 78.2

205.4 26.78 205.4 193.2 176.1 159.0 141.9 124.8 107.7

207.1 26.89 207.1 199.0 181.9 164.8 147.7 130.6 113.4

243.1 28.23 161.3 141.1 120.9 100.7 80.4 #N/A #N/A

67

62

57

224.8 27.45 198.9 178.6 158.4 138.2 118.0 97.8 77.5

210.3 26.91 210.3 204.2 190.3 170.0 149.8 129.6 109.4

212.0 27.02 212.0 208.0 196.5 176.3 156.1 135.8 115.6

248.8 28.37 176.5 153.2 129.9 106.5 83.2 #N/A #N/A

67

62

57

230.0 27.58 216.9 193.5 170.2 146.9 123.6 100.2 76.9

215.2 27.04 215.2 215.2 204.4 181.1 157.8 134.4 111.1

217.0 27.15 217.0 217.0 211.1 187.8 164.5 141.1 117.8

254.0 28.49 186.7 161.3 136.0 110.6 85.2 #N/A #N/A

67

62

57

234.8 27.70 228.2 203.6 178.2 152.8 127.4 102.1 76.7

219.7 27.15 219.7 219.7 214.0 188.6 163.3 137.9 112.5

221.5 27.26 221.5 221.5 218.6 193.2 167.8 142.4 117.1

259.2 28.61 196.9 169.5 142.0 114.6 87.2 #N/A #N/A

67

62

57

239.6 27.81 239.6 213.6 186.2 158.7 131.3 103.9 76.5

224.1 27.26 224.1 224.1 223.6 196.2 168.7 141.3 113.9

226.0 27.38 226.0 226.0 226.0 198.6 171.2 143.8 116.3

HL240 & LL240

OUTDOOR AMBIENT TEMPERATURE (F):

Indicates Nominal Capacity Rating Point.

INPUT POWER INCLUDES THE CONDENSER AND COMPRESSOR MOTORS BUT NOT THE INDOOR BLOWER MOTOR

115º

Unitary Products Group 15

Page 16

036-21326-001-C-0202

TABLE 17: 20 TON CAPACITY TABLE - 125ºF

20 Ton Capacity Tables

HL240 & LL240

AIRONEVAPORATOR

CFM W.B. GROSS INPUT GROSS SENSIBLE CAPACITY (MBh)

TEMP CAP. POWER (RETURN AIR DRY BULB TEMP.-(F)

6000 72

7000 72

8000 72

8600 72

9200 72

(F) (MBh) (kW) 86 83 80 77 74 71 68

229.3 30.6 143.5 126.4 109.3 92.2 75.1 #N/A #N/A

67

62

57

210.7 29.6 177.2 160.1 143.0 125.9 108.8 91.6 74.5

198.8 29.1 198.8 188.5 171.3 154.2 137.1 120.0 102.9

203.4 29.3 203.4 193.2 176.1 159.0 141.9 124.8 107.7

233.3 30.7 158.2 138.0 117.8 97.6 77.3 #N/A #N/A

67

62

57

214.3 29.7 194.5 174.3 154.1 133.9 113.6 93.4 73.2

202.2 29.2 202.2 197.1 184.7 164.4 144.2 124.0 103.8

207.0 29.4 207.0 201.9 189.8 169.6 149.4 129.2 108.9

237.2 30.8 172.9 149.6 126.3 102.9 79.6 #N/A #N/A

67

62

57

217.9 29.8 211.8 188.5 165.2 141.8 118.5 95.2 71.9

205.7 29.3 205.7 205.7 198.0 174.6 151.3 128.0 104.6

210.5 29.5 210.5 210.5 203.5 180.1 156.8 133.5 110.2

246.1 30.9 185.3 160.0 134.6 109.2 83.8 #N/A #N/A

67

62

57

226.1 30.0 225.7 201.4 176.1 150.7 125.3 99.9 74.6

213.3 29.4 213.3 213.3 211.0 185.6 160.3 134.9 109.5

218.2 29.6 218.2 218.2 214.7 189.3 164.0 138.6 113.2

255.0 31.1 197.7 170.3 142.9 115.5 88.0 #N/A #N/A

67

62

57

234.3 30.1 234.3 214.4 186.9 159.5 132.1 104.7 77.2

221.0 29.5 221.0 221.0 221.0 196.7 169.2 141.8 114.4

226.0 29.7 226.0 226.0 226.0 198.5 171.1 143.7 116.3

Indicates Nominal Capacity Rating Point.

INPUT POWER INCLUDES THE CONDENSER AND COMPRESSOR MOTORS BUT NOT THE INDOOR BLOWER MOTOR

OUTDOOR AMBIENT TEMPERATURE (F):

125º

16 Unitary Products Group

Page 17

036-21326-001-C-0202

TABLE 18: LL180 15 TON AIRFLOW TABLE

CFM RPM BHP kW RPM BHP kW RPM BHP kW RPM BHP kW RPM BHP kW RPM BHP kW

4400 660 1.5 1.43 725 1.8 1.69 756 2.0 1.86

4600 663 1.6 1.46 733 1.9 1.77 775 2.1 1.99

4800 667 1.6 1.5 741 2.0 1.85 794 2.3 2.12 897 2.7 2.52 946 3.0 2.78

5000 671 1.7 1.55 749 2.1 1.94 811 2.4 2.26

5200 676 1.7 1.61 758 2.2 2.03 828 2.6 2.39 910 3.0 2.77 963 3.4 3.17

5400 682 1.8 1.68 767 2.3 2.13

5600 688 1.9 1.76 776 2.4 2.24 859 2.9 2.68 924 3.3 3.05 981 3.8 3.56

5800 696 2.0 1.85 785 2.5 2.36

6000 647 1.9 1.78 704 2.1 1.95 794 2.7 2.48 885 3.2 2.98 938 3.6 3.36 998 4.2 3.94

6200 654 2.0 1.83 712 2.2 2.06

6400 662 2.0 1.89 722 2.3 2.18 814 2.9 2.74 909 3.5 3.29 954 4.0 3.7

6600 670 2.1 1.97 732 2.5 2.31 824 3.1 2.89 919 3.7 3.45 963 4.1 3.88

6800 679 2.2 2.06 742 2.6 2.45

7000 688 2.3 2.17 754 2.8 2.6

7200 698 2.5 2.3 766 3.0 2.77 855 3.6 3.35 944 4.2 3.96 990 4.8 4.47

7400 708 2.6 2.45

7600 719 2.8 2.61 792 3.3 3.12 877 4.0 3.7 956 4.6 4.31

7800 730 3.0 2.78

Denotes use of 5 hp motor with high static pulley kit.

Note: Airflow tables based on 2” filters, dry evaporator coil

0.4 0.6 0.8 1 1.2 1.4

886 2.4 2.29 928 2.6 2.4

891 2.6 2.4 937 2.8 2.59

903 2.8 2.64 955 3.2 2.98

844 2.7 2.54 917 3.1 2.91 972 3.6 3.36

873 3.0 2.83 931 3.4 3.2 990 4.0 3.75

804 2.8 2.61 897 3.4 3.14 946 3.8 3.53 1007 4.4 4.14

834 3.2 3.03 928 3.9 3.62 971 4.4 4.07

844 3.4 3.19 936 4.1 3.79 980 4.6 4.27

779 3.1 2.94 866 3.8 3.52 950 4.4 4.13 999 5.0 4.68

807 3.5 3.31 888 4.1 3.88 960 4.8 4.49

TABLE 19: LL240 20 TON AIRFLOW TABLE

CFM

6000 612 2.0 1.77 681 2.5 2.24 720 2.7 2.44 763 3.1 2.71

6200 617 2.1 1.87 684 2.6 2.32 724 2.9 2.53 767 3.2 2.82

6400 623 2.2 1.97 688 2.7 2.40

6600 629 2.3 2.07 692 2.8 2.48

6800 634 2.4 2.17 695 2.9 2.57 735 3.2 2.83 781 3.6 3.19

7000 640 2.6 2.27 699 3.0 2.66

7200 646 2.7 2.38 703 3.1 2.75 744 3.4 3.05 791 3.9 3.46

7400 582 2.0 1.74 651 2.8 2.48 707 3.2 2.85 748 3.6 3.16 797 4.1 3.61

7600 590 2.1 1.87 657 2.9 2.59 711 3.3 2.95

7800 597 2.3 2.00 662 3.0 2.69 715 3.4 3.05

8000 603 2.4 2.13 667 3.2 2.80 719 3.6 3.16 762 4.0 3.52 816 4.6 4.08

8200 610 2.5 2.26 673 3.3 2.91 723 3.7 3.26 767 4.1 3.65

8400 617 2.7 2.40 678 3.4 3.02

8600 624 2.8 2.53 683 3.5 3.13

8800 630 3.0 2.66 689 3.6 3.24 735 4.1 3.61 783 4.6 4.06

9000 637 3.1 2.79 694 3.8 3.35

9200 577 2.0 1.80 643 3.3 2.92 699 3.9 3.46 744 4.3 3.85 794 4.9 4.36

9400 584 2.3 2.08 649 3.4 3.06 704 4.0 3.57

9600 591 2.6 2.34 655 3.6 3.19 709 4.1 3.68 753 4.6 4.11 806 5.3 4.67

9800 598 2.9 2.59 661 3.7 3.32 714 4.3 3.80

10000 605 3.2 2.81 667 3.9 3.46 719 4.4 3.91

RPM BHP kW RPM BHP kW RPM BHP kW RPM BHP kW RPM BHP kW RPM BHP kW

Denotes use of high static pulley option.

Note: Airflow tables based on 2” filters, dry evaporator coil

0.4 0.6 0.8 1 1.2 1.4

727 3.0 2.63 771 3.3 2.94

731 3.1 2.73 776 3.4 3.06

739 3.3 2.94 786 3.7 3.32

753 3.7 3.28 803 4.2 3.76

757 3.8 3.40 809 4.4 3.92

727 3.8 3.38 772 4.3 3.79

731 3.9 3.49 777 4.4 3.92

740 4.2 3.73 788 4.7 4.21

748 4.5 3.98 800 5.1 4.51

757 4.8 4.25 812 5.4 4.83

Unitary Products Group 17

Page 18

036-21326-001-C-0202

15 TON BLOWER PERFORMANCE

1.6

1.4

1.2

1

ESP

0.8

0.6

0.4

4200 4700 5200 5700 6200 6700 7200 7700

FIGURE 9 : 15 TON BLOWER PERFORMANCE

20 TON BLOWER PERFORMANCE

1.6

1.4

1.2

1

ESP

0.8

0.6

CFM

0.4

6000 6500 7000 7500 8000 8500 9000 9500 10000

FIGURE 10 : 20 TON BLOWER P ERFORMANCE

18 Unitary Products Group

CFM

Page 19

TABLE 20: BLOWER DRIVE DATA

Unit Model

LL180

LL240

Model Number Blower RPM Range

1LD0436 640-810 4.0-5.0 7/8 11 1-3/16 1 A57

1LD0437 800-1000 5.3-6.3 1-1/8 11 1-3/16 2 A55

1LD0438 580-720 4.0-5.0 1-1/8 12 1-3/16 2 A63

1LD0439 700-830 4.0-5.0 1-1/8 13 1-3/16 2 A68

TABLE 21: BLOWER DATA

036-21326-001-C-0202

Drive Data

Adj. Motor Pulley Fixed Blower pulley Belts

Datum Dia. (In.) Bore (In.) Datum Dia. (In.) Bore(In.) Qty. Designation

Unit

Model

LL180

LL240

Blower Motor Data

HP

3 2LR04603033

5 2LR04605023 184 208 1LD0437 800-1000

5

Model Number

2LR04605032 184 230/460 1LD0437 800-1000

2LR04605023 184 208

2LR04605032 184 208/230/460

Frame size Voltage (3PH-60Hz.)

56

1

Model

Number

208/230/460

1

1LD0436 640-810

1LD0438 580-720

1LD0439 700-830

1LD0438 580-720

1LD0439 700-830

Drive Data

1. Three-phase motors will always be wired for 460 volt power supply. Refer to the wiring diagram inside the motor terminal box.

TABLE 22: INDOOR ELECTRICAL RATINGS

Model

Number

LL180

LL240 5

Blower Motor HP Power Supply FLA

3

5

3 460-3-60 4.8 6.0 15

5 460-3-60 7.6 9.5 15

208-3-60 10.6 13.3 20

230-3-60 9.6 12.0 20

208-3-60 17.5 21.9 35

230-3-60 16.7 20.9 35

208-3-60 17.5 21.9 35

230-3-60 16.7 20.9 35

460-3-60 7.6 9.5 15

Minimum Circuit

Ampacity

Max. Fuse Size

Blower RPM

Range

1

1. Maximum fuse or m aximum circuit breaker (HACR type per NEC).

Unitary Products Group 19

Page 20

036-21326-001-C-0202

Return Air

A

Supply Air

TABLE 23: INDOOR UNIT WEIGHTS AND CORNER WEIGHTS

Unit Size Position

15 Ton Indoor Horizontal 720 830 178 216 239 197 89.5 59

15 Ton Indoor Vertical 720 830 198 224 217 191 89.5 29.5

20 Ton Indoor Horizontal 990 1115 212 195 340 368 100 74

20 Ton Indoor Vertical 990 1115 281 254 276 305 100 36.5

Shipping

Weight

Operating A B C D

Unit

Length

NOTE: All dimensions in inches.

DC

20 Ton Motor Location

15 Ton Motor Location

B

Horizontal Application Corner Weights

FIGURE 11 : LL HORIZONTAL APPLICATION

CORNER WEIGHTS

Unit

Width

Supply Air

20 Ton Motor

Location

Return Air

(Rear Corner)

D

A

FIGURE 12 : LL VERTICAL APPLICATION CORNER WEIGHTS

15 Ton

Motor Location

C

B

20 Unitary Products Group

Page 21

036-21326-001-C-0202

FIGURE 13 : UNIT DIMENSIONS LL180 AND LL240

TABLE 24: UNIT DIMENSIONS LL180 AND LL240

MODELA BCDEFG H J KLM

LL180 89-1/2 85.0 26.0 29-1/2 59 1-7/16 15-7/8 12-7/16 15-13/16 16 16 20-3/4

LL240 100-1/8 95-5/8 33-1/4 36-5/8 73-1/4 2-1/2 18-7/8 16-1/2 15-13/16 21-7/8 18 22-9/16

Unitary Products Group 21

Page 22

036-21326-001-C-0202

FIGURE 14 : LL180 SUPPLY AIR PLENUM DIMENSIONS

1. Shipped knocked down for field assembly

FIGURE 15 : RETURN AIR GRILLE FOR LL180

DIMENSIONS

1

22 Unitary Products Group

Page 23

036-21326-001-C-0202

Unitary Products Group 23

Page 24

Subject to change without notice. Printed in U.S.A. 036-21326-001-C-0202

Copyright © by Unitary Products Group 2001. All rights reserved. Supersedes: 036-21326-001-B-0202

Unitary 5005 Norman

Products York OK

Group Drive 73069

Loading...

Loading...