Page 1

TECHNICAL GUIDE

Echelon

MODELS: FC9V*UP

GAS-FIRED

CONDENSING / HIGH EFFICIENCY

TWO STAGE VARIABLE

UPFLOW FURNACES

UP TO 95% AFUE

NATURAL GAS

40 - 120 MBH INPUT

EFFICIENCY

RATING

CERTIFIED

ISO 9001

Certified Quality

Management System

Due to continuous product improvement, specific ations

are subject to change without notice.

Visit us on the web at www.york.com for the most

up-to-date technical information.

Additional rating information can be found at

www.gamanet.org.

260614-CTG-C-0407

DESCRIPTION

These Category IV, highly efficient, compact, condensing

type furnaces are designed for residential and commercial

installations in a basement, closet, alcove, recreation room or

garage where the ambient temperature is above 32°F, or

higher. They may be either side wall or thru-roof vented using

approved plastic type combustion air and vent piping. All

units are factory assembled, wired and tested to assure

dependable and economical installation and operation.

WARRANTY

Lifetime limited warranty on both heat exchangers to the original purchaser; a 20-year limited warranty from original installation date to subsequent purchaser.

10-year warranty on the heat exchanger in commercial applications.

5-year limited parts warranty.

FEATURES

• Two stage heating operation includes:

- Two stage gas valve

- Two stage inducer operation

- Variable speed ECM blower operation

• Provides increased comfort level & very quiet unit operation

• Adjustable delay timer allows two stage operation with single stage thermostat

• Compact, easy to install, ideal height 40" cabinet

• Blower-off delay for cooling SEER improvement.

• Easy to connect power/control wiring.

• Built-in, high level self diagnostics with fault code display.

• Low unit amp requirement for easy replacement application.

• Integrated control module for reliable, economical operation.

• May be installed as either two-pipe (sealed combustion) or

single pipe vent (using indoor combustion air)

• Top intake & vent connection allows installation in narrow

locations.

• Electronic Hot Surface Ignition saves fuel cost with

increased dependability and reliability.

• Induced combustion system with inshot main burners for

quiet, efficient operation.

• No special vent termination kit required.

• 100% shut off main gas valve for extra safety.

• 24V, 40 VA control transformer and blower relay supplied

for add-on cooling.

• Hi-tech tubular aluminized steel primary heat exchanger.

• Secondary (condensing) heat exchanger of 29-4C highgrade stainless steel.

• Timed on, adjustable off blower capability for maximum

comfort.

• Solid removable bottom panel allows easy application.

• Easy access from front of unit for cleaning, maintenance or

service.

• Protection from intake, exhaust or condensate blockage.

• Insulated blower compartment for quiet operation.

• EcoTrak comfort system allows dealer to customize comfort settings based on regional location.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

260614-CTG-C-0407

1-1/2” GAS

PIPE ENTRY

7/8” JUNCTION

BOX HOLE

T-STAT WIRING

7/8” K.O.

CONDENSATE

DRAIN 7/8” K.O.

OPTIONAL RETURN AIR

CUT-OUT (either side)

FOR USE WITH

EXTERNAL FILTER

FRAME

7/8

LEFT SIDE

23-3/4

30-1/8

13-7/8

7/8

26-3/4

1-1/2

C

A

FRONT

1-1/4

1-1/2” GAS

PIPE ENTRY

7/8” JUNCTION

24-3/8

BOX HOLE

T-STAT WIRING

7/8” K.O.

CONDENSATE

DRAIN 7/8” K.O.

RIGHT SIDE

5/8

5/8

B

40

20

D

BOTTOM IMAGE

RETURN END

2

24-17/16

TOP IMAGE

SUPPLY END

CABINET AND DUCT DIMENSIONS

Models

Nominal

CFM

Cabinet

Size

A (in.) B (in.) C (in.) D (in.)

FC9V040A12UP11 1200 A 14-1/2 13-1/2 11-1/2 6-1/4

FC9V060B12UP12 1200 B 17-1/2 16-1/4 14-1/2 8-1/2

FC9V080B12UP11 1200 B 17-1/2 16-1/4 14-1/2 8-1/2

FC9V080C16UP12 1600 C 21 19-3/4 18 8-7/8

FC9V100C20UP12 2000 C 21 19-3/4 18 8-7/8

FC9V120D20UP12 2000 D 24-1/2 23-1/4 21-1/2 10-5/8

Cabinet Dimension

ELECTRICAL AND PERFORMANCE DATA

High Fire

Air Temp. Rise

Models

Input

High/Low

Output

High/Low

Nominal

Airflow*

Cabinet

Width

Total Unit AFUE

MBH MBH CFM In. Amps % °F °F

FC9V040A12UP11 40/26 38/24 1200 14-1/2 9 94.0 35 - 65 35 - 65

FC9V060B12UP12 60/39 56/36 1200 17-1/2 9 95.0 40 - 70 20 - 50

FC9V080B12UP11 80/52 75/49 1200 17-1/2 9 92.5 45 - 75 45 - 75

FC9V080C16UP12 80/52 75/49 1600 21 12 95.0 45 - 75 20 - 50

FC9V100C20UP12 100/65 93/60 2000 21 14 95.0 45 - 75 20 - 50

FC9V120D20UP12 120/78 112/73 2000 24-1/2 14 95.0 40 - 70 20 - 50

Operating

Wgt.

Models

Input

High/Low

Max. Outlet

Air Temp.

Blower

Blower

Size

MBH °F HP Amps In. Lbs.

Max.

Overcurrent

Protect

Min. Wire Size

(awg) @ 75 ft.

One Way

FC9V040A12UP11 40/26 165 1/2 7.7 11 x 8 20 14 121

FC9V060B12UP12 60/39 170 1/2 7.7 11 x 8 20 14 135

FC9V080B12UP11 80/52 175 1/2 7.7 11 x 8 20 14 142

FC9V080C16UP12 80/52 175 3/4 9.6 11 x 10 20 14 157

FC9V100C20UP12 100/65 175 1 12.8 11 x 11 20 12 164

FC9V120D20UP12 120/78 170 1 12.8 11 x 11 20 12 180

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

The furnace shall be installed so that the electrical components are protected from water.

* Wire size and overcurrent protection must comply with the National Electric Code.

NOTES:

1. For altitudes above 2000 ft. reduce capacity 4% for each 1000 ft. above sea level.

2. Wire size based on copper conductors, 60°C, 3% voltage drop.

3. Continuous return air temperature must not be below 55°F.

4. All filters must be high velocity cleanable type.

Low Fire

Air Temp. Rise

2 Unitary Products Group

Page 3

260614-CTG-C-0407

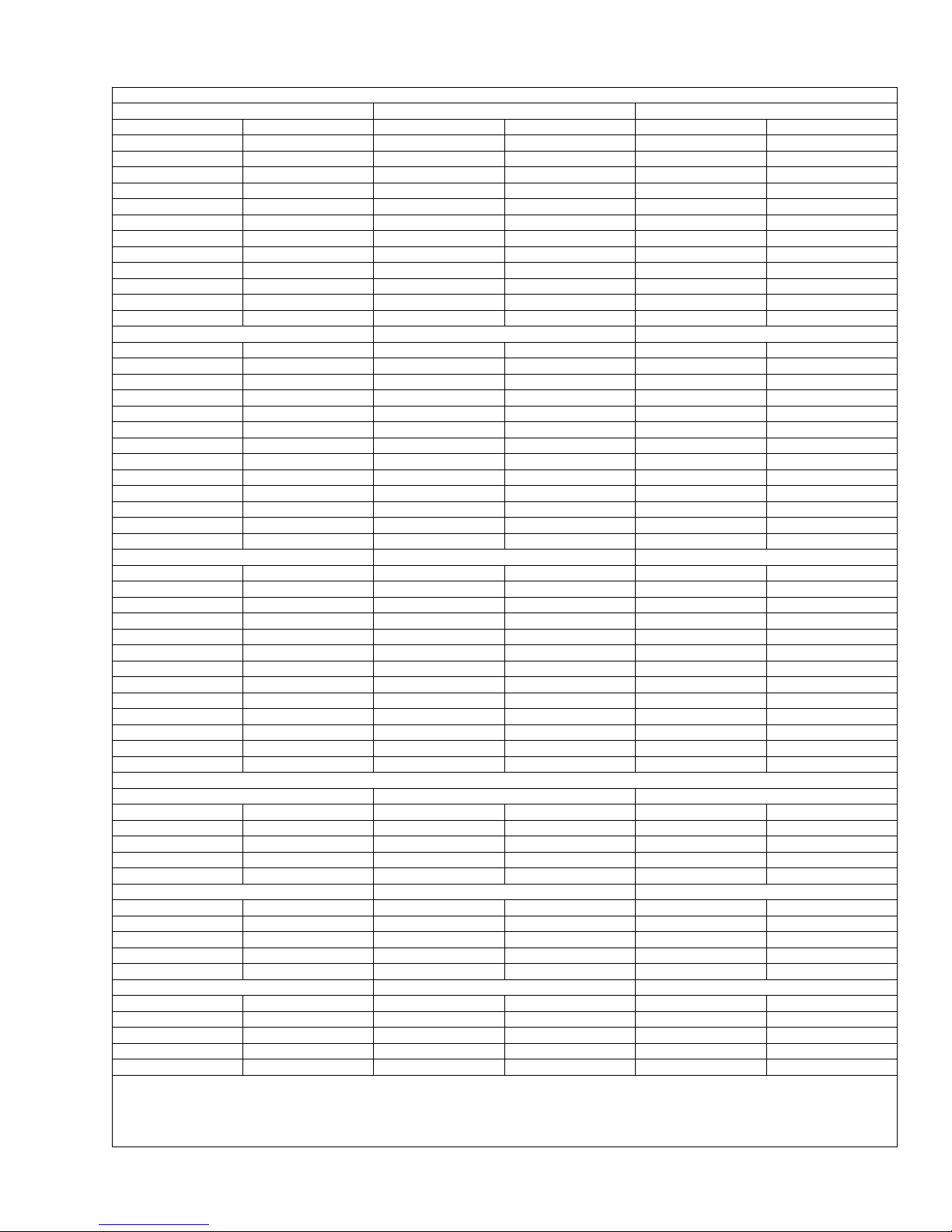

AIR FLOW DATA

HIGH / LOW SPEED COOLING AND HEAT PUMP CFM

FC9V040A12UP11 FC9V060B12UP12 Jumper Settings

High Low High Low COOL Tap ADJ Tap*

1340 995 1330 900 A B

1205 885 1130 800 B B

1255 920 1220 850 A A

1150 835 1040 730 B A

1170 855 1120 770 A C

1025 755 920 650 C B

1045 780 950 660 B C

835 625 740 540 D B

950 705 860 610 C A

785 590 690 540 D A

865 665 790 570 C C

725 605 630 530 D C

FC9V080B12UP11 FC9V080C16UP12 JUMPER SETTINGS

High Low High Low COOL Tap ADJ Tap*

1310 890 1660 1110 A B

1100 740 1550 1050 B B

1220 830 1610 1070 A A

1000 670 1440 960 B A

1090 720 1470 990 A C

900 610 1370 920 C B

880 610 1290 850 B C

680 510 1130 790 D B

810 580 1230 850 C A

630 500 1050 720 D A

730 530 1110 760 C C

590 500 950 660 D C

FC9V100C20UP12 FC9V120D20UP12 Jumper Settings

High Low High Low COOL Tap ADJ Tap*

2210 1480 2280 1510 A B

1780 1180 1860 1190 B B

2040 1350 2090 1370 A A

1620 1050 1630 1060 B A

1840 1250 1880 1250 A C

1560 1010 1620 1030 C B

1470 940 1500 960 B C

1370 890 1410 880 D B

1460 930 1490 920 C A

1250 790 1290 790 D A

1310 810 1360 840 C C

1090 690 1140 690 D C

HIGH / LOW HEAT CFM

FC9V040A12UP11 FC9V060B12UP12 Jumper Settings

High Low High Low HEAT Tap ADJ Tap*

1045 740 1110 710 A Any

905 645 960 640 B Any

825 595 870 600 C Any

765 590 830 570 D Any

FC9V080B12UP11 FC9V080C16UP12 Jumper Settings

High Low High Low HEAT Tap ADJ Tap*

1330 880 1490 990 A Any

1180 810 1350 900 B Any

1100 730 1220 820 C Any

1010 670 1120 770 D Any

FC9V100C20UP12 FC9V120D20UP12 Jumper Settings

High Low High Low HEAT Tap ADJ Tap*

1880 1230 2150 1420 A Any

1670 1080 1930 1290 B Any

1530 980 1850 1190 C Any

All CFM’s are shown at 0.5” w.c. external static pressure.These units have variable speed motors that automatically adjust to provide const ant CFM from 0.0” to

0.6” w.c. static pressure. Fro m 0.6 ” to 1.0” static pressure, CFM is reduced by 2% per 0.1” increase in static. Op erat ion on duct systems with greater than 1.0” w.c.

external static pressure is not recommended.

NOTE: At some settings, LOW COOL and/or LOW HEAT airflow may be lower that what is required to operate an airflow switch on certain models of ele ctron ic air

cleaners. Consult the instructions for the electronic air cleaner for further details.

* The ADJ “D” tap should not be used.

1430 900 1660 1070 D Any

Unitary Products Group 3

Page 4

260614-CTG-C-0407

FILTER PERFORMANCE

The airflow capacity data published in the “Blower Performance” table listed above represents blower performance

WITHOUT filters. To determine the approximate blower performance of the system, apply the filter drop value for the filter being used or select an appropriate value from the “Filter

Performance” table shown below.

NOTE: The filter pressure drop values in the “Filter Performance” table shown below are typical values for the type of

filter listed and should only be used as a guideline. Actual

pressure drop ratings for each filter type vary between filter

manufacturer.

FILTER SIZES

Input/Output

BTU/H

40/38 1200 A 16 x 25 14 x 25

60/56 1200 B 16 x 25 16 x 25

80/75 1200 B 16 x 25 16 x 25

80/75 1600 C 16 x 25 20 x 25

100/93 2000 C 16 x 25 20 x 25

120/112 2000 D (2) 16 x 25 22 x 25

CFM

Cabinet

Size

Side Return

Filter in.

Bottom Return

Filter in.

APPLYING FILTER PRESSURE DROP TO

DETERMINE SYSTEM AIRFLOW

To determine the approximate airflow of the unit with a filter in

place, follow the steps below:

1. Select the filter type.

2. Select the number of return air openings or calculate the

return opening size in square inches to determine the

proper filter pressure drop.

3. Determine the External System Static Pressure (ESP)

without the filter.

4. Select a filter pressure drop from the table based upon

the number of return air openings or return air opening

size and add to the ESP from Step 3 to determine the

total system static.

5. If total system static matches a ESP value in the airflow

table (i.e. 0.20, 0.60, etc.,) the system airflow corresponds to the intersection of the ESP column and Model/

Blower Speed row.

FILTER PERFORMANCE - PRESSURE DROP INCHES W.C. AND (KPA)

Minimum Opening Size

Airflow Range

0 - 750 230

751 - 1000 330 0.04 0.03 0.20

1001 - 1250 330 0.08 0.07 0.20

1251 - 1500 330 0.08 0.07 0.25

1501 - 1750 380 658 0.14 0.08 0.13 0.06 0.30 0.17

1751 - 2000 380 658 0.17 0.09 0.15 0.07 0.30 0.17

2001 & Above 463 658 0.17 0.09 0.15 0.07 0.30 0.17

1 Opening 2 Openings 1 Opening 2 Opening 1 Opening 2 Opening 1 Opening 2 Opening

Sq. in. Sq. in. In w.c. In w.c. In w.c. In w.c. In w.c. In w.c.

Disposable Washable Fiber Pleated

0.01 0.01 0.15

Filter Type

UNIT CLEARANCES TO COMBUSTIBLES

Application

Upflow 1 3 0 0 0 0 Combustible Yes Yes

Top Front Rear Left Side Right Side Flue

In. In. In. In. In. In.

4 Unitary Products Group

Floor/

Bottom

Closet

Alcove

Attic

Page 5

260614-CTG-C-0407

For additional connection diagrams for all UPG equipment refer to “Low Voltage System Wiring” document available online at www.upgnet.com

in the Product Catalog Section.

(Optional)

C

TWO STAGE

24-Volt Common

AIR CONDITIONING

Y1

Y2

First Stage Cool

Second Stage Cool

R

24-Volt Hot

24V HUMIDIFIER

Interface

Comfort Alert

C

VARIABLE SPEED

24-Volt Common

FURNACE CONTROL

C

*PP32U72124

*PP32U71124

THERMOSTAT

24-Volt Common

C

*DP22U70124

THERMOSTAT

24-Volt Common

C

*DN22C00124

THERMOSTAT

24-Volt Common

Y1

Y/Y2

First Stage Cool

Single/Second Stage Cool

Y2

Y1

First Stage Cool

Second Stage Cool

Y2

Y1

First Stage Cool

Second Stage Cool

Y

Y2

First Stage Cool

Second Stage Cool

R

24-Volt Hot

R

24-Volt Hot

R

24-Volt Hot

R

24-Volt Hot

G

W2

W/W1

Single/First Stage Heat

E/W1

First Stage Heat

E/W1

First Stage Heat

W

First Stage Heat

Fan

Second Stage Heat

G

W2

Fan

Second Stage Heat

G

W2

Fan

Second Stage Heat

G

W2

Fan

Second Stage Heat

(O)

HUM

CFM CONTROL

DHM

(X/L)

Malfunction Light

Reversing Valve– Energized in Cool

Dehumidification - Open on Humidity Rise

L

HM

Dehumidistat

Humidistat

Malfunction Light

( ) CONVENIENCE TERMINAL

NO FUNCTION IN THIS APPLICATION.

set to MLTI STG

Step 16 of Thermostat

Comfort Alert Features

User Configuration Menu

Step 1 of Thermostat User

Configuration Menu must be

24-Volt

Common, is optional

Connection of the "C" Termainal,

is optional

Connection of the "C"

Termainal, 24-Volt Common,

must be set to ON to use

Configuration Menu

when used with batteries

when used with batteries

must be set to MS 2

Step 1 of Thermostat User

in the 'YES' position

for Dehumidification

CFM Control must be

Humidistat Jumper on

the E2 position and the

E2/P Switch must be in

C

*PP32U70124

THERMOSTAT

C

*DN22U00124

THERMOSTAT

AC10 2 Stage Scroll A/C w/ Variable Speed Furnace - PV8/9; (F,L)*8/9V, (G,L)*8/9V, XYG8V-*, XYF8V-*, XYG9V-*, XYF9V-*

Thermostat Chart - AC

Unitary Products Group 5

Y

Y2

First Stage Cool

24-Volt Common

24-Volt Common

Second Stage Cool

Y

Y2

First Stage Cool

Second Stage Cool

R

RC

E/W1

First Stage Heat

24-Volt Hot (Cool XFMR)

24-Volt Hot (Heat XFMR)

R

RC

E/W1

First Stage Heat

24-Volt Hot (Cool XFMR)

24-Volt Hot (Heat XFMR)

G

W2

Fan

Second Stage Heat

G

W2

Fan

Second Stage Heat

Termainal, 24-Volt

Thermostat Installer

Common, is optional

Connection of the "C"

Termainal, 24-Volt

Connection of the "C"

Setup Number 0170 -

when used with batteries

Common, is optional

when used with batteries

Number 1 - System Type -

Thermostat Installer Setup

System Type - must be

set to 8 - 2 Heat/2 Cool

Multistage Conventional

must be set to 6 - 2

Number 15 - Compressor

Heat/2 Cool Conventional

Thermostat Installer Setup

Protection - must be set to 5

Page 6

260614-CTG-C-0407

C

Y1

HEAT PUMP

TWO STAGE

VARIABLE SPEED

24-Volt Common

C

Y1

24-Volt Common

FURNACE CONTROL

C

Y1

*PP32U71124

24-Volt Common

R

Y2 OUT

First Stage Heat/Cool

Y/Y2

First Stage Cool

W1 OUT

24-Volt Hot

Second Stage Cool Output

R

W/W1

24-Volt Hot

Single/Second Stage Cool

R

24-Volt Hot

First Stage Heat/Cool

W2 OUT

O

First Stage Auxiliary Heat Output

Second Stage Auxiliary Heat Output

G

W2

Fan

Second Stage Heat

Single/First Stage Heat

Reversing Valve–Energized in Cool

(O)

CFM CONTROL

Reversing Valve–Energized in Cool

Fan

O

W2

G

Second Stage Auxiliary Heat

Reversing Valve–Energized in Cool

Y2

X/L

Malfunction Light

Second Stage Heat/Cool

(Y 2)

(X/L)

Malfunction Light

L

Y2

Malfunction Light

Second Stage Heat/Cool

W

BSG

Auxiliary Heat

Bonnet Sensor

BS

Bonnet Sensor

Bonnet Sensor (Optional)

HUM

Dehumidification - Open on Humidity Rise

(Optional)

24V HUMIDIFIER

E/W1

Dehumidistat

HM

Humidistat

DHM

First Stage Auxiliary Heat

Heat Pump to ON

Change FFuel Jumper on

Set W2 Delay on furnace to OFF

( ) CONVENIENCE TERMINAL. NO

FUNCTION IN THIS APPLICATION.

Dehumidification

Menu must be set to Heat Pump 2

and the Humidistat Jumper on CFM

E2/P Switch must be in the E2 position

Step 1 of Thermostat User Configuration

Control must be in the 'YES' position for

C

Y1

*DP22U70124 *PP32U72124

24-Volt Common

First Stage Heat/Cool

Y

C

*PP32U70124 *DN22H00124

THERMOSTAT THERMOSTAT THERMOSTAT

RC

24-Volt Common

First Stage Heat/Cool

24-Volt Hot (Cool XFMR)

W/031-01996- Series Demand Control; Hot Heat Pump Mode OR Conventional

HP24 Two Stage H/P - H*5B, YZE - w/Variable 2 Stage Furnace, 2 Stage Cooling Ready - PV8/9, (F,L)*8/9V, (G,L)*8/9V, XYG8V-*, XYF8V-*, XYG9V-*, XYF9V-*

Thermostat Chart - HP

6 Unitary Products Group

R

W2

24-Volt Hot

Second Stage Auxiliary Heat

E

R

Emergency Heat

24-Volt Hot (Heat XFMR)

Fan

O

Y2

Malfunction Light

Second Stage Heat/Cool

E/W1

First Stage Auxiliary Heat

set to Heat Pump 2

Step 1 of Thermostat User

Configuration Menu must be

on thermostat not necessary

Selection of GAS/ELEC switch

G

L

Reversing Valve–Energized in Cool

G

Fan

L

O/B

Reversing Valve

Malfunction Light

Y2

AUX

Auxiliary Heat

Second Stage Heat/Cool

System Type - must be set to

12 - 3 Heat/2 Cool Heat Pump

Pump Backup Heat Source is Fossil Fuel

Thermostat Installer Setup Number 0170 -

Thermostat Installer Setup Number 0200 -

Thermostat Installer Setup Number 0190 -

Reversing Valve (O/B) Operation - must be

set to 0 - O/B Terminal Energized in Cooling

Thermostat Installer Setup Number 0210 -

External Fossil Fuel Kit - must be set to 0 -

Backup Heat Source - must be set to 1 - Heat

Pump Backup Heat

External Fossil Fuel Kit is Controlling Heat

Page 7

260614-CTG-C-0407

ACCESSORIES

PROPANE (LP) CONVERSION KIT -

1NP0347 - All units

This accessory conversion kit may be used to convert natural

gas (N) units for propane (LP) operation. Conversions must

be made by qualified distributor or dealer personnel.

CONCENTRIC VENT TERMINATION -

1CT0302 (2")

1CT0303 (3")

For use through rooftop, sidewall. Allows combustion air to

enter and exhaust to exit through single common hole. Eliminates unslightly elbows for a cleaner installation.

SIDEWALL VENT TERMINATION KIT -

1HT0901 (3")

1HT0902 (2")

For use on sidewall, two-pipe installations only. Provide a

more attractive termination for locations where the terminal is

visable on the side of the home.

CONDENSATE NEUTRALIZER KIT - 1NK0301

Neutralizer cartridge has a 1/2" plastic tube fittings for installation in the drain line. Calcium carbonate refill media is also

available from the Source 1 Parts (p/n 026-30228-000).

EXTERNAL SIDE RETURN FILTER RACK -

1SF0101 - Fits all cabinet sizes

Attaches to side of furnace cabinet in side return applications.

Holds any 16x25x1 permanent or disposable filter.

SIDE RETURN FILTER RACK -

1SR0302 - All Models

1SR0200 - All Models

BOTTOM RETURN FILTER RACK -

1BR0114 or 1BR0214 - For 14-1/2” cabinets

1BR0117 or 1BR0217 - For 17-1/2” cabinets

1BR0121 or 1BR0221 - For 21” cabinets

1BR0124 or 1BR0224 - For 24-1/2” cabinets

HIGH ALTITUDE PRESSURE SWITCHES -

For installation where the altitude is less than 8,000 feet it is

not required that the pressure switch be changed. For altitudes above 8,000 feet see kits below. Conversion must be

made by qualified distributor or dealer personnel.

1PS0501 - 060 MBH

1PS0502 - 080/1200 MBH

1PS0503 - 080/1600, 120 MBH

1PS0505 - 100 MBH

1PS0506 - 040 MBH

ROOM THERMOSTATS - A wide selection of compatible

thermosets are available to provide optimum performance

and features for any installation.

1H/1C, manual change-over electronic non-programmable

thermostat.

1H/1C, auto/manual changeover, electronic programmable,

deluxe 7-day, thermostat.

1H/1C, auto/manual changeover, electronic programmable.

* For the most current accessory information, refer to the

price book or consult factory.

Unitary Products Group 7

Page 8

NOTES

Subject to change without notice. Printed in U.S.A. 260614-CTG-C-0407

Copyright © by York International Corp. 2007. All rights reserved. Supersedes: 260614-CTG-B-0806

Unitary 5005 Norman

Products York OK

Group Drive 73069

Loading...

Loading...