MAINTENANCE AND

USER'S INFORMATION,

SERVICE

HIGH EFFICIENCY SEALED COMBUSTION For Installation In:

GAS FURNACE 1. Manufactured (Mobile) Homes

_ODELS_ D_AA and _AH 2. Recreational Vehicles & Park Models

{S_ngl@ Stag@ _@wnH@w On_y} 3. Modular Homes & Buildings

TABLE OF CONTENTS

CONTACT INFORMATION FOR USA ....................... 1 To Turn Off the Appliance: ............................... 4

CONTACT INFORMATION FOR CANADA ................... 1 FURNACE USER MAINTENANCE ......................... 5

SAFETY ................................................ 1 Air Filters ............................................ 5

While you are away .................................... 2 Removing Filters ...................................... 5

SEASONAL SERVICE INFORMATION ...................... 2 Blower Care .......................................... 5

Your Service Technician ................................ 2 Motor Lubrication ...................................... 5

DESCRIPTION ......................................... 2 SERVICE AND MAINTENANCE MANUAL ..................... 6

WARRANTY AND RESPONSIBILITIES ..................... 2 SAFETY SECTION ...................................... 6

GAS SUPPLY .......................................... 3 FURNACE MAINTENANCE SECTION ...................... 6

Natural Gas Operation .................................. 3 FURNACE CLEANING SECTION .......................... 6

Propane Gas Operation ................................. 3 Burner Removal/Cleaning ............................... 6

INSTRUCTIONS FOR EXAMINING THE Cleaning the Heat Exchanger ............................ 6

FURNACE INSTALLATION ............................... 3 THE FURNACE CONTROLS AND THEIR FUNCTION .......... 6

Observing Burner Operation ............................. 3 SEQUENCE OF OPERATION ............................. 7

If Furnace Fails to Operate Properly ....................... 3 Continuous Blower ..................................... 7

HOW YOUR GAS FURNACE WORKS ...................... 4 Heating Cycle ......................................... 7

IF FURNACE FAILS TO OPERATE PROPERLY .............. 4 Hot Surface Ignition System .............................. 7

When You Call For Service Assistance ..................... 4 TROUBLESHOOTING ................................... 7

To Contact Your Serviceman ............................. 4 FURNACE CONTROL DIAGNOSTICS ...................... 8

SAFETY INFORMATION ................................. 4 REPLACEMENT PARTS LIST .............................. 9

Read the Instructions Below Before Trying WIRING DIAGRAM ...................................... 12

to Start the Furnace .................................... 4 LIMITED WARRANTY .................................... 14

START-UP AND SHUTDOWN INSTRUCTIONS ............... 4

Operating Instructions: .................................. 4

Management System

CONTACT INFORMATION FOR USA CONTACT INFORMATION FOR CANADA

• Contact us by mail: Go to website at www.york.com click on "contact", then click on

DISTRIBUTED BY: MANUFACTURED BY:

StyleCrest York International Contact us by mail:

801 W. 37th Street 5005 York Drive York International

Building #7 Norman, OK 73069 Consumer Relations

Wichita, Ks 67219 5005 York Drive

"contact form" and follow the instructions.

Norman, OK 73069

The manufacturer recommends that the user read all SECTION I" SAFETY

sections of this manual and keep the manual for

future reference.

&WARNING

FIRE OR EXPLOSION HAZARD - Failure to follow safety warnings

exactly could result in serious injury, death, or property damage.

--Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

--WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone (including

cell phone) in your building.

Leave the building immediately.

Immediately call your gas supplier from a neighbor's phone. Fol-

low the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

1. The furnace area must be kept clear and free of combustible mate-

rials, gasoline and other flammable vapors and liquids.

2. Insulating materials may be combustible. The furnace must be

kept free and clear of insulating materials. The furnace area must

be examined when installed in an insulated space or when insula-

tion is added to be sure that the insulation material has been kept

away from the furnace.

3. Follow the instructions exactly as shown on the OPERATING

INSTRUCTION LABEL or the Start-up and Shutdown Instructions

on Page 4 of this manual when lighting the furnace or turning the

furnace off.

4. Should the gas supply fail to shut off or if overheating occurs, shut

off the gas valve to the furnace before shutting off the electrical

supply.

5. Do not use this furnace if any part has been under water. A flood-

damaged furnace is extremely dangerous. Attempts to use the fur-

nace can result in fire or explosion. A qualified service agency

should be contacted to inspect the furnace and replace all gas

controls, control system parts, electrical parts that have been wet

or the furnace if deemed necessary.

Johnson Controls Unitary Products 129099-BUM-J-0112

129099-BUM-J-0112

6. NEVER...Store flammable materials of any kind near your fur-

nace. Gasoline, solvents, and other volatile liquids should be

stored only in approved containers outside your home. These

materials vaporize easily and are extremely dangerous.

7. NEVER...Store cleaning materials near your furnace. Materials

such as bleaches, detergents, powdered cleansers, etc., can

cause corrosion of the heat exchangers.

8. NEVER... Use the area around your furnace as a storage area for

items which could block the normal flow of air. This flow of air is

required for ventilation of the various furnace components.

AWARNING

FIRE OR EXPLOSION HAZARD

This furnace is designed and approved for use with Natural Gas

and (LP) Propane Gas ONLY. DO NOT BURN ANY LIQUID FUEL

OR SOLID FUEL IN THIS FURNACE.

Burning any unapproved fuel will result in damage to the furnace heat

exchanger, which could result in Fire, Personal Injury, and/or Property

Damage.

While you are away

Your furnace is equipped with a safety device which will shut off the

supply of gas to the burner in case of malfunction. For this reason it is

never practical to assume that the furnace will operate unattended for a

long period of time, especially if there is a possibility of damage to your

property because of freezing. So, if you plan to be away from home,

arrange for someone to check your house every day.

SEASONAL SERVICE INFORMATION

During extreme cold weather, ice may form on the furnace roof jack

crown. Small amounts of ice forming on the roof jack will present no

problem to proper furnace operation. However, excessive ice formation

could restrict the combustion air supply to the burner causing inefficient

burner operation.

When the temperature is very cold, near zero or below, it is recom-

mended that the roof jack be inspected every day or more frequently if

required. If ice has started to collect on the roof jack crown, it should be

carefully broken off.

Your Service Technician

Your furnace's best friend is your qualified service technician. If the unit

gives any indication of improper operation, call your service technician.

If the service technician is allowed to perform the normal routine care of

your furnace, he can many times detect potential difficulties and make

corrections before trouble develops. Preventative maintenance of this

type will allow you to operate the unit with a minimum of concern, and at

the same time will pay for itself in added years of comfort.

DESCRIPTION

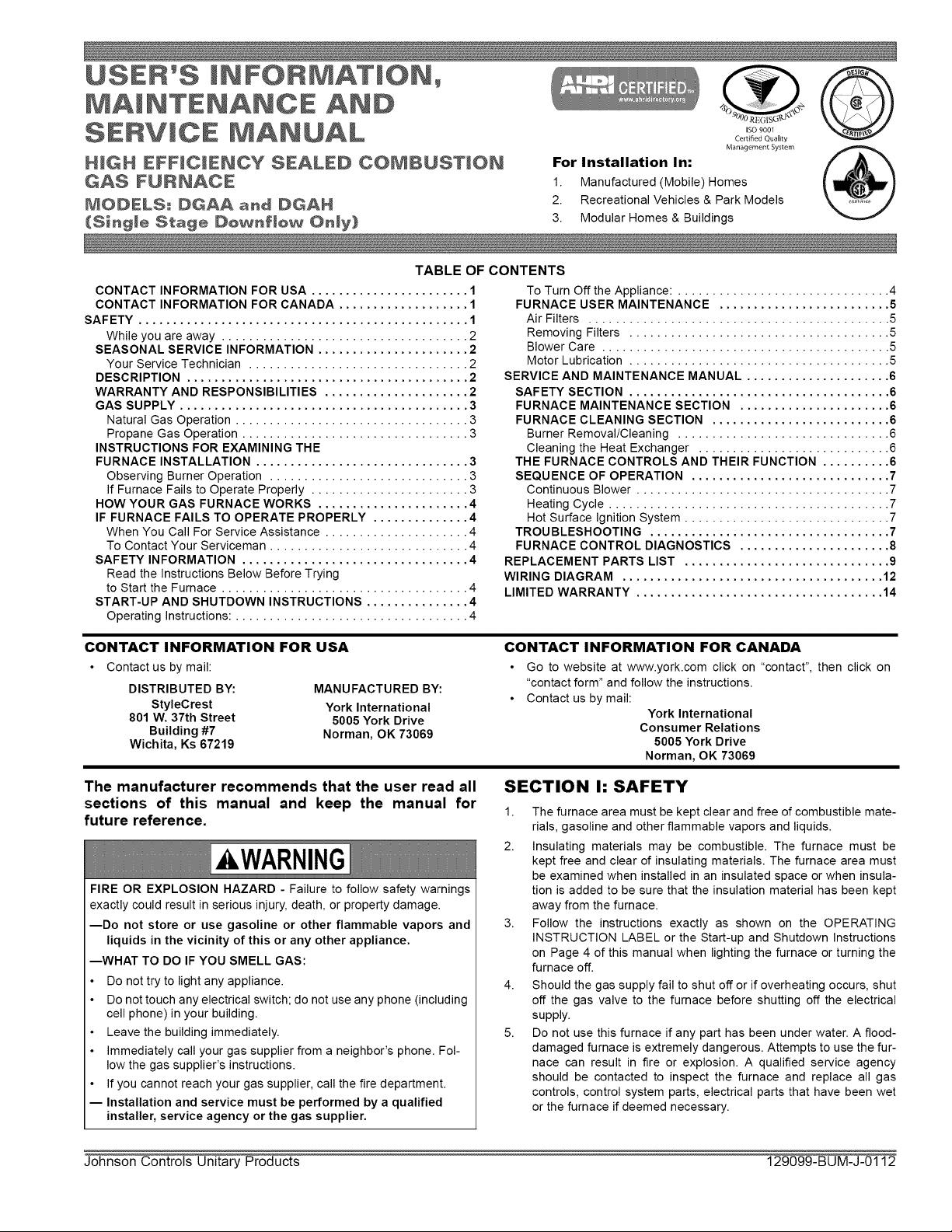

This furnace shall be installed in the downflow position. Figure 1 shows

a typical model in the downflow position. The furnace is equipped with

an induced-draft vent blower and atmospheric burner. Combustion air is

drawn through the roof jack and pushed into the burner box. Flue gas is

forced from the heat exchanger by the vent blower and discharged

through the flue pipe to the outside atmosphere.

This is a forced air furnace. The furnace circulating air blower draws

cool air from the house, passes it over the hot furnace heat exchanger

and circulates the warmed air through the ductwork to the house.

The furnace is equipped with the controls necessary for proper opera-

tion. The various components referred to in this manual and on the fur-

nace rating plate are identified in Figure 1.

-- VENT PIPE

BLOWER MOTOR

CAPACITOR --

BLOWER--

MOTOR

PRESSURE

SWITCH _,

CONTROL--

BOARD

SILICONE

TUBE

GAS VALVE --

GAS BURNER _

ASSEMBLY

FIGURE 1: Component Locations

FLUE

COLLAR

-- BLOWER

H--'--- COMBUSTION

AIR PIPE

SAFETY SHUTOFF

SWITCH

--BOOSTER DRAFT

ASSEMBLY

AIR CONDITIONING

COIL PANELS

WARRANTY AND RESPONSIBILITIES

It is the sole responsibility of the home owner to make certain that the

gas furnace has been correctly set up and converted to the proper fuel

(Propane or Natural gas) and adjusted to operate properly.

The manufacturer warrants the furnace to be free from defects in mate-

rial or workmanship for the stated time in the warranty agreement (see

warranty certificate packed with the furnace).

However, the manufacturer will not be responsible for any repair costs

to correct problems due to improper set-up, improper installation, fur-

nace adjustments, improper operating procedure by the user, etc.

It is also the sole responsibility of the home owner to make sure that the

home if located above 2,000 ft. altitude be derated.

Some specific examples of service calls which cannot be included in

warranty payments are:

1. Converting the furnace to use another type of fuel.

2. Correcting faulty duct work in the home.

3. Correcting wiring problems in the electrical circuit to the furnace.

4. Resetting circuit breakers or other switches.

5. Adjusting the burner air shutter or service calls made to correct

problems caused by improper air adjustment.

6. Correcting problems caused by improper gas supply pressure to

the furnace.

7. Instructional training on how to light and operate furnace.

8. Furnace problems caused by installation of air conditioner, heat

pump, or other air quality device.

9. Problems caused by improper installation of the furnace flue

assembly (roof jack).

10. Adding a roof jack extension because of unusual wind conditions

or snow conditions.

11. Adjusting thermostats.

12. Problems caused by construction debris which has fallen into the

flue or combustion air openings.

13. Replacement of fuses.

14. Problems caused by plugged or restricted orifices by any means.

You should establish a firm understanding of these responsibilities with

your manufactured housing dealer, service company or gas supplier so

there will be no misunderstanding at a later time.

2 Johnson Controls Unitary Products

129099-BUM-J-0112

GAS SUPPLY

The gas supply to your home will either be Natural Gas or Propane gas.

Your furnace will be factory equipped to operate on only one of these

two different gases.

A small metal tag secured to the furnace next to the gas valve will spec-

ify the type of gas your furnace is equipped to use.

If the gas is different from that specified on the metal tag, the furnace

can be converted by following the instructions on the furnace safety

label inside lower front panel. Parts for conversion are contained in the

small bag attached to the gas valve. Be sure the proper size orifice is

used, as specified on the furnace name plate.

[ kCAUTION

The furnace must be converted by a qualified technician. Improper

conversion can cause unsafe operation, explosion, and/or fire or

asphyxiation.

Natural Gas Operation

The furnace is designed for 7" W.C. inlet pressure. Pressure is reduced

to 3 1/2" W.C. by the pressure regulator in the gas valve.

Propane Gas Operation

Inlet pressure to the gas valve must be 11" W.C. When properly con-

verted to Propane gas, the pressure is regulated at 10" W.C.

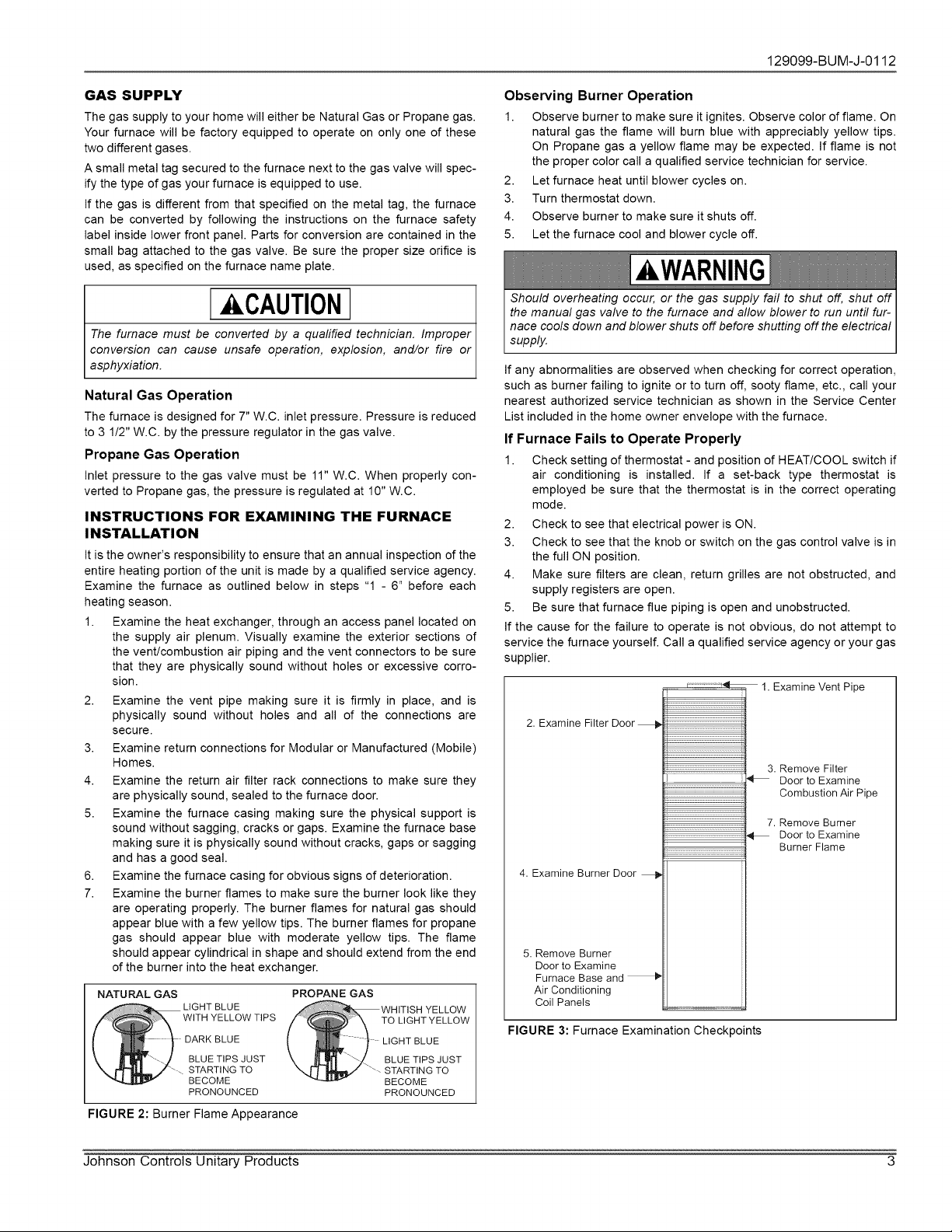

INSTRUCTIONS FOR EXAMINING THE FURNACE

INSTALLATION

It is the owner's responsibility to ensure that an annual inspection of the

entire heating portion of the unit is made by a qualified service agency.

Examine the furnace as outlined below in steps "1 - 6" before each

heating season.

1. Examine the heat exchanger, through an access panel located on

the supply air plenum. Visually examine the exterior sections of

the vent/combustion air piping and the vent connectors to be sure

that they are physically sound without holes or excessive corro-

sion.

2. Examine the vent pipe making sure it is firmly in place, and is

physically sound without holes and all of the connections are

secure.

3. Examine return connections for Modular or Manufactured (Mobile)

Homes.

4. Examine the return air filter rack connections to make sure they

are physically sound, sealed to the furnace door.

5. Examine the furnace casing making sure the physical support is

sound without sagging, cracks or gaps. Examine the furnace base

making sure it is physically sound without cracks, gaps or sagging

and has a good seal.

6. Examine the furnace casing for obvious signs of deterioration.

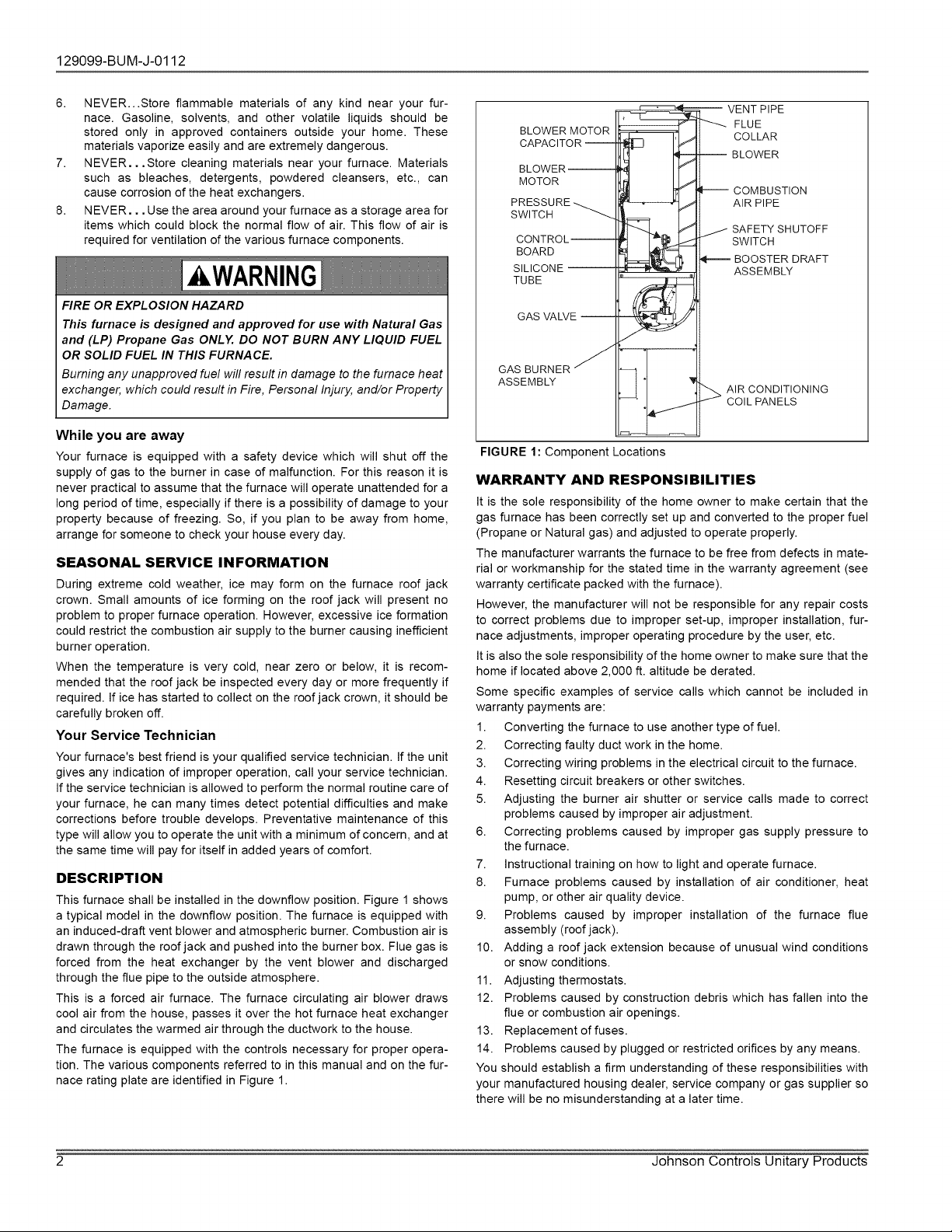

7. Examine the burner flames to make sure the burner look like they

are operating properly. The burner flames for natural gas should

appear blue with a few yellow tips. The burner flames for propane

gas should appear blue with moderate yellow tips. The flame

should appear cylindrical in shape and should extend from the end

of the burner into the heat exchanger.

NATURAL GAS

_ LIGHT BLUE

WITH YELLOW TIPS

DARK BLUE

BLUE TIPS JUST

. STARTING TO

BECOME

PRONOUNCED

FIGURE 2: Burner Flame Appearance

PROPANE GAS

TO LIGHT YELLOW

LIGHT BLUE

BLUE TIPS JUST

"_ STARTING TO

BECOME

PRONOUNCED

Observing Burner Operation

1. Observe burner to make sure it ignites. Observe color of flame. On

natural gas the flame will burn blue with appreciably yellow tips.

On Propane gas a yellow flame may be expected. If flame is not

the proper color call a qualified service technician for service.

2. Let furnace heat until blower cycles on.

3. Turn thermostat down.

4. Observe burner to make sure it shuts off.

5. Let the furnace cool and blower cycle off.

AWARNING

Should overheating occur, or the gas supply fail to shut off, shut off

the manual gas valve to the furnace and allow blower to run until fur-

nace cools down and blower shuts off before shutting off the electrical

supply,

If any abnormalities are observed when checking for correct operation,

such as burner failing to ignite or to turn off, sooty flame, etc., call your

nearest authorized service technician as shown in the Service Center

List included in the home owner envelope with the furnace.

If Furnace Fails to Operate Properly

1. Check setting of thermostat - and position of HEAT/COOL switch if

air conditioning is installed. If a set-back type thermostat is

employed be sure that the thermostat is in the correct operating

mode.

2. Check to see that electrical power is ON.

3. Check to see that the knob or switch on the gas control valve is in

the full ON position.

4. Make sure filters are clean, return grilles are not obstructed, and

supply registers are open.

5. Be sure that furnace flue piping is open and unobstructed.

If the cause for the failure to operate is not obvious, do not attempt to

service the furnace yourself. Call a qualified service agency or your gas

supplier.

1. Examine Vent Pipe

2. Examine FilterDoor_ ................................................................

3. Remove Filter

Door to Examine

....::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::.... CombustionAirPipe

................................................................7. Remove Burner

................................................................._ Door to Examine

i...........................................................

4. Examine Burner Door

5. Remove Burner

Door to Examine

Furnace Base and t_

Air Conditioning

Coil Panels

FIGURE 3: Furnace Examination Checkpoints

Burner Flame

Johnson Controls Unitary Products 3

129099-BUM-J-0112

HOW YOUR GAS FURNACE WORKS

Your furnace is a very easy appliance to take for granted. Season after

season, it sits there in your home, keeping you warm and comfortable.

For this reason, you may never have given much thought to the way

your furnace operates. In order to get the safest and most efficient oper-

ation from your furnace, you should understand how your furnace does

its job.

When you set your thermostat to provide more heat in your home, you

are starting the heating cycle of the furnace. First, the inducer motor

starts to purge the heat exchanger of any remaining gases. Next, the

hot surface ignitor glows and after a warm-up period the gas valve

opens and ignition occurs. A short time later, the blower starts and dis-

tributes the warm air throughout the home. When the temperature set-

ting on your thermostat is reached, the gas valve closes, the main

burner is turned off, and the blower continues to run until the remaining

warm air in the system is distributed. When the blower stops, the heat-

ing cycle has ended.

IF FURNACE FALLS TO OPERATE PROPERLY

1. Check setting of thermostat - and position of heat/cool switch if air

conditioning is installed. If a set-back type thermostat is employed

be sure that the thermostat is in the correct operating mode.

2. Check to see that electrical power is "ON".

3. Check to see that the lever or switch on the gas control valve is in

the full "ON" position.

4. Make sure filters are clean, return grilles are not obstructed, and

supply registers are open.

5. Be sure that furnace flue piping is open and unobstructed.

When You Call For Service Assistance

Very often time can be saved if you will give the service agency the

MODEL and SERIAL NUMBER of your furnace. This will enable him to

determine the specific components used, and perhaps to better identify

the possible problem and be better prepared if a service call is required.

To Contact Your Serviceman

(fill in)

COMPANY:

ADDRESS:

TELPHONE:

All appliances need maintenance by serviceman at the beginning of

each heating season. Call your nearest authorized service technician

to:

1.

Replace filters. Clean all lint and dust from around furnace.

2.

Remove fan and clean all dust and lint from unit with stiff bristle

brush.

3. Inspect combustion chamber, the transition into the blower com-

partment, flue collar, and roof jack.

4. Check the gas valve and line connections for leaks.

5. Make any adjustments necessary for good operation.

NOTICE

The coil panel provides a good removable access for inspecting

inside the furnace casing. Smoke or reflected light inside the casing

indicates the presence of leaks in the heat exchanger.

SAFETY INFORMATION

Read the Instructions Below Before Trying to Start the

Furnace

&WARNING

If you do not follow these instructions exactly, a fire or explosion may

result causing property damage, personal injury, and/or loss of life.

1. This appliance does not have a pilot. It is equipped with an ignition

device which automatically lights the burner. Do not try to light the

burner by hand.

2. BEFORE OPERATING; smell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

3. Use only your hand to push the gas control switch to the "on" posi-

tion. Never use tools. If the switch will not operate by hand, don't

try to repair it, call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

4. Do not use this appliance if any part has been under water. Imme-

diately call a qualified service technician to inspect the appliance

and to replace any part of the control system and any gas control,

which has been under water.

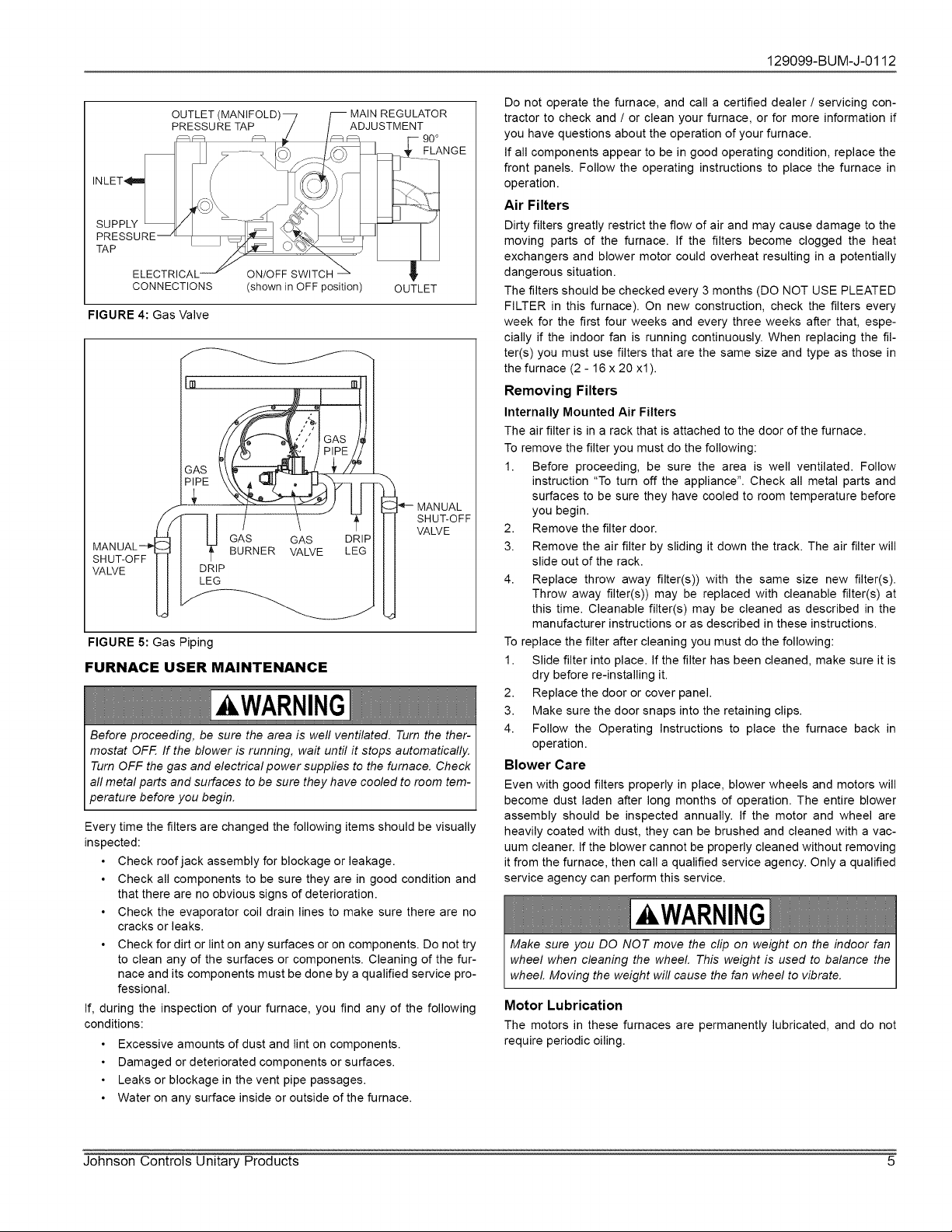

START-UP AND SHUTDOWN INSTRUCTIONS

Operating Instructions:

1. STOP! Read the safety information above.

2. Set the thermostat to the lowest setting.

3. Turn off all electric power to the appliance.

4. Remove furnace door.

5. Move gas control switch to the "OFF" position. Do not force. See

Figure 4.

6. Wait five (5) minutes to clear out any gas. If you then smell gas,

STOP! Follow Step 2 (refer to Safety Information on Page 4). If you

don't smell gas, go to next step.

7. Move gas control switch to the "ON" position. Do not force. See

Figure 4.

8. Replace burner door.

9. Turn on all electric power to the appliance.

10. Set thermostat to the desired setting. Burner will light, which may

take 30-60 seconds.

11. After three (3) trials for ignition, if the appliance will not operate fol-

low the instructions, "TO TURN OFF THE APPLIANCE" and call

your service technician or gas supplier.

To Turn Off the Appliance:

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is to be per-

formed.

3. Remove burner access panel.

4. Move gas control switch to the "OFF" position. See Figure 4.

5. Replace burner access panel.

&WARNING

Should overheating occur, or the gas valve fail to shut off, turn the

external manual gas valve in the gas supply line to the furnace to the

"off" position and let the furnace cool off before shutting off the electri-

cal power supply. Refer to Figure 5.

4 Johnson Controls Unitary Products

CONNECTIONS (shown in OFF position) OUTLET

FIGURE 4: Gas Valve

FIGURE 5: Gas Piping

FURNACE USER MAINTENANCE

_WARNING

Before proceeding, be sure the area is well ventilated. Turn the ther-

mostat OFF. If the blower is running, wa# until it stops automatically.

Turn OFF the gas and electrical power supplies to the furnace. Check

all metal parts and surfaces to be sure they have cooled to room tem-

perature before you begin.

Every time the filters are changed the following items should be visually

inspected:

Check roof jack assembly for blockage or leakage.

Check all components to be sure they are in good condition and

that there are no obvious signs of deterioration.

Check the evaporator coil drain lines to make sure there are no

cracks or leaks.

Check for dirt or lint on any surfaces or on components. Do not try

to clean any of the surfaces or components. Cleaning of the fur-

nace and its components must be done by a qualified service pro-

fessional.

If, during the inspection of your furnace, you find any of the following

conditions:

Excessive amounts of dust and lint on components.

Damaged or deteriorated components or surfaces.

Leaks or blockage in the vent pipe passages.

Water on any surface inside or outside of the furnace.

129099-BUM-J-0112

Do not operate the furnace, and call a certified dealer / servicing con-

tractor to check and / or clean your furnace, or for more information if

you have questions about the operation of your furnace.

If all components appear to be in good operating condition, replace the

front panels. Follow the operating instructions to place the furnace in

operation.

Air Filters

Dirty filters greatly restrict the flow of air and may cause damage to the

moving parts of the furnace. If the filters become clogged the heat

exchangers and blower motor could overheat resulting in a potentially

dangerous situation.

The filters should be checked every 3 months (DO NOT USE PLEATED

FILTER in this furnace). On new construction, check the filters every

week for the first four weeks and every three weeks after that, espe-

cially if the indoor fan is running continuously. When replacing the fil-

ter(s) you must use filters that are the same size and type as those in

the furnace (2 - 16 x 20 xl ).

Removing Filters

Internally Mounted Air Filters

The air filter is in a rack that is attached to the door of the furnace.

To remove the filter you must do the following:

1. Before proceeding, be sure the area is well ventilated. Follow

instruction "To turn off the appliance". Check all metal parts and

surfaces to be sure they have cooled to room temperature before

you begin.

2. Remove the filter door.

3. Remove the air filter by sliding it down the track. The air filter will

slide out of the rack.

4. Replace throw away filter(s)) with the same size new filter(s).

Throw away filter(s)) may be replaced with cleanable filter(s) at

this time. Cleanable filter(s) may be cleaned as described in the

manufacturer instructions or as described in these instructions.

To replace the filter after cleaning you must do the following:

1. Slide filter into place. If the filter has been cleaned, make sure it is

dry before re-installing it.

2. Replace the door or cover panel.

3. Make sure the door snaps into the retaining clips.

4. Follow the Operating Instructions to place the furnace back in

operation.

Blower Care

Even with good filters properly in place, blower wheels and motors will

become dust laden after long months of operation. The entire blower

assembly should be inspected annually. If the motor and wheel are

heavily coated with dust, they can be brushed and cleaned with a vac-

uum cleaner. If the blower cannot be properly cleaned without removing

it from the furnace, then call a qualified service agency. Only a qualified

service agency can perform this service.

AWARNING

Make sure you DO NOT move the clip on weight on the indoor fan

wheel when cleaning the wheel. This weight is used to balance the

wheel. Moving the weight will cause the fan wheel to vibrate.

Motor Lubrication

The motors in these furnaces are permanently lubricated, and do not

require periodic oiling.

Johnson Controls Unitary Products 5

129099-BUM-J-0112

SECTION I1: SERVICE AND MAINTENANCE

MANUAL

SAFETY SECTION

This section has been designed to assist a qualified service agency in

performing service and maintenance on this appliance. The homeown-

ers and/or end user must never attempt to perform any service or main-

tenance on the appliance especially when it involves the removal or

adjustment of any parts and/or components.

The following safety rules must be followed when servicing the furnace.

AWARNING

ELECTRIC SHOCK, FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in dangerous

operation, serious injury, death or property damage.

Improper servicing could result in dangerous operation, serious injury,

and death or property damage.

• Before servicing, disconnect all electrical power to the fur-

Race.

• When servicing controls, label all wires prior to disconnecting.

Reconnect wires correctly.

• Verify proper operation after servicing.

FURNACE MAINTENANCE SECTION

The furnace should be cleaned and adjusted by a certified dealer or

qualified service contractor once a year or before the start of every

heating season. The following items must be cleaned and serviced or

replaced if there are signs of deterioration.

1. The roof cap (if applicable).

2. The furnace vent pipe. Should it be necessary to service the vent/

air intake system, the manufacturer recommends this service be

conducted by a qualified service agency. The operation of this

appliance requires the reassembly and resealing of the vent/air

intake system.

3. The furnace burner, ignitor and flame sensor.

FURNACE CLEANING SECTION

NOTE: The cleaning operations listed below must be performed only by

a qualified service agency.

Burner Removal/Cleaning

The main burner should be checked periodically for dirt accumulation. If

cleaning is required, follow this procedure:

1. Turn off the electrical power to the unit.

2. Turn off the gas supply at the external manual shut-off valve and

loosen the ground union joint.

3. Remove the upper access panel.

4. Disconnect wires from flame sensor, rollout switch and HSI igniter.

Remove igniter carefully, as it is easily broken.

5. Remove the screws that hold the burner assembly to the combus-

tion air box and remove the assembly.

6. Remove burner from the burner assembly.

7. Rinsing in hot water may clean burners.

8. Reassemble in the reverse order.

Cleaning the Heat Exchanger

It is recommended that replacement gaskets be available before

removing burner assembly and combustion air box.

Lower Heat Exchanger Access

1. Turn off the electrical power to the unit and turn off gas supply at

the shutoff valve.

2. Remove the blower and burner compartment access doors. Dis-

connect the gas supply piping at the union to permit removal of the

entire burner and gas control assembly from the vestibule panel.

Use the wrench boss on the gas valve when removing or installing

this piping.

3. Unplug the igniter from the wire harness. Disconnect sensor wires.

Identify and note the location of all leads for ease of reinstallation.

4. Remove the screws holding the burner assembly to the vestibule

panel and remove this assembly. Handle the assembly carefully

since it contains the igniter, which is fragile and easily broken. The

lower portion of the heat exchanger will now be exposed. Remove

any soot and scale. Vacuum loose soot, scale and dirt from the

heat exchanger.

5. After cleaning is complete, replace all components in reverse

order. Re-gasket all surfaces which required a gasket. Reconnect

all wiring. Reattach vent pipe and gas supply lines before restoring

service to furnace. Restore electrical power, check gas supply pip-

ing for leaks, and then verify furnace operation.

[ CAUTIONI

Label all wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous operation. Verify proper

operation after servicing.

THE FURNACE CONTROLS AND THEIR FUNCTION

1. Limit Control - This furnace is protected by two (2) high tempera-

ture limit switches. The lower limit switch is an automatic reset

type.

2. Upper Limit Control - The upper limit switch near left side of

blower is a manual reset type limit switch. If burner does not func-

tion, turn system switch to "OFF" and push reset button in center

of limit switch.

3. Gas Valve - The gas valve is 100% shut-off type and will fail safe if

for some reason the gas is turned off. It is also of the snap opening

type which opens to fire position.

6 Johnson Controls Unitary Products

SEQUENCE OF OPERATION

Continuous Blower

On cooling/heating thermostats with fan switch, when the fan switch is

set in the ON position, a circuit is completed between terminals R and G

of the thermostat. The blower motor is energized through the cool fan

terminal on the ignition control module.

Intermittent Blower - Cooling

On cooling/heating thermostats with fan switch, when the fan switch is

set in the auto position and the thermostat calls for cooling, a circuit is

completed between the R, Y and G terminals. The motor is energized

through the cool fan terminal and runs on the selected speed. The fan

off setting is fixed at 60 seconds for SEER enhancement.

Heating Cycle

When the system switch is set on HEAT and the fan is set on AUTO,

and the room thermostat calls for heat, a circuit is completed between

terminals R and W of the thermostat. When the proper amount of com-

bustion air is being provided, a pressure switch activates the ignition

control.

The ignition control provides a 30-second warm-up period. The gas

valve then opens for 10 seconds. If the flame is not detected within 2

seconds of the gas valve opening, the gas valve is shut off and a retry

operation begins. If the flame is lost for 2 seconds during the 10 second

stabilization period, the gas valve is shut off and a retry operation

begins. During a retry operation the ventor starts a 15 second inter-

purge and the ignitor warm-up time is extended to 27 seconds. If the

flame is established for more than 10 seconds after ignition, during a

retry, the control will clear the ignition attempt (retry) counter. If three

retries occur during a call for heat, the furnace will shut down for one

hour. If at the end of the one hour shut down there is a call for heat, the

furnace will initiate a normal start cycle. If the problem has not been cor-

rected the furnace will again lockout after three retries.

A momentary loss of gas supply, flame blowout, or a faulty flame probe

circuit will result in a disruption in the flame and be sensed within 0.8

seconds. The gas valve will de-energize and the control will begin a

recycle operation. A normal ignition sequence will begin after a 15 sec-

ond inter-purge. If during the three recycles the gas supply does not

return, or the fault condition is not corrected the ignition control will lock-

out for 60 minutes.

During burner operation, a momentary loss of power for 50 milliseconds

or longer will de-energize the gas valve. When the power is restored,

the gas valve will remain de-energized and the ignition sequence will

immediately restart.

As the gas starts to flow and ignition occurs, the flame sensor begins its

sensing function. If a flame is detected during the 10 second flame sta-

bilization period the circulating blower will energize 30 seconds after the

gas valve opens (20 seconds after the flame stabilization period ends).

Normal furnace operation will continue until the thermostat circuit

between R and W is opened. When the thermostat circuit opens, the

ignition control is de-energized. When the ignition control is de-ener-

gized, the gas flow stops, and the burner flames are extinguished. The

ventor continues to operate for 15 seconds after the gas flow stops.

The blower motor continues to operate for the amount of time set by the

fan-off delay "Jumper" located on the ignition control board. Refer to

Figure 6. The heating cycle is complete, and the furnace is ready for the

start of the next heating cycle.

129099-BUM-J-0112

LINE VOLTAGE

BLACK - HIGH SPEED

RED -LOW SPEED

FAN OFF

JUMPER

ADJUSTMENT

FANON _

JUMPER _-

M-

FUSE 3A

FIGURE 6: Furnace Control Board

Hot Surface Ignition System

AWARNING

HOT SURFACE IGNITION SYSTEM

Do not attempt to light this furnace by hand (with a match or any other

means). There may be a potential shock hazard from the components

of the hot surface ignition system. The furnace can only be lit auto-

matically by its hot surface ignition system.

TROUBLESHOOTING

The following visual checks should be made before troubleshooting:

1. Check to see that the power to the furnace and the ignition control

module is ON.

2. The manual shut-off valves in the gas line to the furnace must be

open.

3. Make sure all wiring connections are secure.

4. Review the sequence of operation. Start the system by setting the

thermostat above the room temperature. Observe the system's

response. Then use the troubleshooting section in this manual to

check the system's operation.

AWARNING

Never bypass pressure switch to allow furnace operation. To do I

so will allow furnace to operate under potentially hazardous con- I

ditions. [

Do not try to repair controls. Replace defective controls with [

UPG Source 1 Parts.

Never adjust pressure switch to allow furnace operation.

Johnson Controls Unitary Products 7

129099-BUM-J-0112

FURNACE CONTROL DIAGNOSTICS

The furnace has built-in, self diagnostic capability. If a system problem

occurs, a fault code is shown by a blinking green LED. It is located

behind a clear view port in the blower compartment door. DO NOT turn

off furnace power as this action will clear the control's memory of the

fault.

The control continuously monitors its own operation and the operation

of the system. If a failure occurs, the LED will indicate the failure code. If

the failure is internal to the control, the light will stay on continuously. In

this case, the entire control should be replaced as the control is not field

repairable.

Flash sequence codes 1 through 6 are as follows: LED will turn "on" for

one second and "off" for one second. This pattern will be repeated the

number of times equal to the code. For example, six "on" flashes equals

a number 6 fault code.

All flash code sequences are broken by a 2 second "off" period.

IGNITION CONTROL

Normal flame sense current is approximately

3.7 microamps DC (ua)

Low flame signal control lockout point is

0.9 microamps DC (ua)

1 FLASH: Ignition failure.

2 FLASH: Combustion air pressure switch closed, this indicates that the

normally open pressure switch contacts are stuck in the closed position.

The control confirms these contacts are open at the beginning of each

heat cycle. This would indicate a faulty pressure switch or mis-wiring.

3 FLASH: Combustion air pressure switch failed to close, this indicates

the normally open pressure switch contact did not close at the begin-

ning of the heat cycle. This could be caused by a number of problems;

faulty inducer, blocked vent pipe, broken pressure switch hose or faulty

pressure switch.

4 FLASH: Limit Switch Open, this indicates that a primary or auxiliary

limit switch has opened its normally closed contacts. With this fault code

the control will operate the supply air blower and inducer. This condition

may be caused by: dirty filter, improperly sized duct system, incorrect

blower speed setting, incorrect firing rate or faulty blower motor.

5 FLASH: Gas flow with no call for heat. Check gas valve and gas valve

wiring.

RAPID FLASHES: Reverse Polarity, reverse polarity indicates reverse

line voltage polarity. Both heating and cooling will be affected. Check

polarity of both.

STEADY ON: Normal Operation.

60 MINUTE AUTOMATIC RESET FROM LOCKOUT: This control

includes a "watchdog" type circuit that will reset from a lockout condition

after 60 minutes. Operational faults 1, 3, 4 and Steady On will be reset.

This provides protection to an unoccupied structure if a temporary con-

dition exists causing a furnace malfunction. An example would be a low

incoming gas supply pressure preventing unit operation. When the gas

pressure is restored, at some point the "watchdog" would restart the

unit and provide heat for the house.

NOTE: If a flame is detected the control flashes the LED for 1/8 of a

second and then enters a flame stabilization period.

(Seconds) 0 5 32

THERMOSTAT

INDUCER

IGNITOR

MAIN VALVE

CIRCULATING

BLOWER

FIGURE 7: Furnace Event Control Schedule

I

OFF_ ION

I

ION

I

o ,

I ION

OFF

OFF

Thermostat Calling for Heat

Fan on Delay

12 Seconds

I

I

I

I

I

I

I

I

I OFF

OFF

( Thermostat Satisfied

I

I

I

I

I

I

I

I

I

!

I

R

,IoFF

IPost i v

IiPurge I

I

OFF

OFF

lOFFI

ON

I

60, 90, 120, 180 SEC. _OFF

Selectable Fan Off Delay

A

/

8 Johnson Controls Unitary Products

129099-BUM-J-0112

SECTION II1: REPLACEMENT PARTS LIST

All components, assemblies, accessories, and replacement parts for this furnace are available through your qualified service installer or refer to the

service center list in your booklet. It is not recommended that the homeowner purchase, install, or replace any components of this furnace. Contact

your local contactor, dealer, or service provider for additional information.

\_J

o . .o

,[ [] J

1°

*_ IIII ÷

od

CONTROL BOX DETAIL

Johnson Controls Unitary Products 9

129099-BUM-J-0112

DGAA

ITEM DESCRIPTION DGAA056BDTB DGAA070BDTB DGAA077BDTB DGAA090BDTB

Switch, Pressure $1-32435972000 S 1-32435972000 S1-32435972000 S1-32435972000 <

2 Tubing Silicone (2' Req'd) $1-02812499000 $1-02812499000 $1-02812499000 $1-02812499000

Limit Switch, Manual(Upper) $1-02535358000 $1-02535358000 $1-02535358000 $1-02535358000

4 Assembly, Booster (w/Motor) $1-37319801821 $1-37319801821 $1-37319801821 $1-37319801821

Control Board, Integrated $1-03101932002 $1-03101932002 $1-03101932002 $1-03101932002

6 Valve, Gas $1-02543267000 $1-02543267000 S1-02543267000 $1-02543267000

7 Bracket, Mounting (Gas Valve) $1-07319801064 $1-07319801064 $1-07319801064 $1-07319801064 <

8

9 Exchanger, Heat (w/Gaskets) $1-37319804651 $1-37323792001 $1-37323792002 $1-37323792003

10 Sensor, Flame $1-02535354000 $1-02535354000 $1-02535354000 $1-02535354000

_1 _ Switch, System $1-7681-3301 $1-7681-3301 $1-7681-3301 $1-7681-3301

Transformer (115-24V, 40 VA) $1-2940A3541 $1-2940A3541 $1-2940A3541 $1-2940A3541

3 Switch, Limit S1-02535380000 S 1-02535380000 $1-02535381000 $1-02535381000

14 Burner Assembly, Auto Ignition $1-37319801403 $1-37319801403 $1-37319801403 $1-37319801403

(Includes items 10 & 15)

15 Ignitor, Hot Surface $1-02541021000 $1-02541021000 $1-02541021000 $1-02541021000

16 Filter (2 Req'd) (16x20x1) $1-1214-2511 $1-1214-2511 $1-1214-2511 $1-1214-2511

17 Panel, Door (Upper) Accessory (See Page 4)

18 Panel, Door (Lower, Tall) 7900-7611 7900-7611 7900-7611 7900-7611

................................Motor (See Note 2) (old-see note 4) S1-1468-220P S1-1468-220P S1-1468-220P S1-1468-220P

Motor new-seenote4 $1-02435603000$1-02435603000$1-02435603000$1-02435603000

20 Assembly, Motor Mount (See Note 2) $1-37319806100 $1-37319806100 $1-37319806100 $1-37319806100

21 Plug, Connector $1-02521192000 $1-02521192000 $1-02521192000 $1-02521192000

Capacitor, Run (See Note 3)(Old-see note 4) $1-02420063000 $1-02420063000 $1-02420063000 $1-02420063000

Capacitor (New-see note 4) S 1-02435602000 S 1-02435602000 S 1-02435602000 S 1-02435602000

............................................................Capacitor (Units built on/after 8/11/2008) $1-02435813000 $1-02435813000 $1-02435813000 $1-02435813000

23 Wheel, Blower $1-02619654003 $1-02619654003 $1-02619654003 $1-02619654003

24* Top, Casing $1-07319801342 $1-07319801342 $1-07319801342 $1-07319801342

25* Diagram, Wiring 155887 155887 155887 155887

26* Strike, Door S1-02118364000 S 1-02118364000 S 1-02118364000 S1-02118364000

27* Latch, Door $1-02118365000 $1-02118365000 S 1-02118365000 S1-02118365000

28* Housing, Blower $1-37323864001 $1-37323864001 $1-37323864001 $1-37323864001

29* Gasket, Combustion Air Box $1-01006900005 $1-01006900005 $1-01006900005 $1-01006900005

30* Gasket, Burner S1-01006742000 $1-01006742000 $1-01006742000 $1-01006742000

31" Gasket, Booster Assembly $1-01006900015 $1-01006900015 $1-01006900015 $1-01006900015

32* Gasket, Heat Exchanger $1-01006900001 $1-01006900001 $1-01006900001 $1-01006900001

NOTE:

*Not Shown

New replacement parts shown in bold face type at the first printing of parts list dated 1/12.

Major components and suggested stocking items are shown with shaded item number.

"<" Across from row indicates a change in that row.

--- Not applicable to specified model.

2.

For Serial Numbers lower then 001207164- Replacement DGAA motors also require Motor Mount

Assembly 373-19806-100 if replaced motor has integral, flex-arm motor mount.

3.

DGAA with 5-Ton Blowers are provided as an accessory item and are not standard equipment from

the factory. See Page 4

4.

The "old" motor must use the "old" run capcitor. The "new" motor can use either capacitor.

Serial No. WOF6528688 and above were built with the new motor.

10 Johnson Controls Unitary Products

DGAH

ITEM DESCRIPTION DGAH056BBSB DGAH077BBSB

Switch, Pressure $1-32435972000 $1-32435972000 <

2 Tubing Silicone (2' Req'd) $1-02812499000 $1-02812499000

LimitSwitch, Manual (Upper) $1-02535358000 $1-02535358000

4 Assembly, Booster (w/Motor) $1-37319801821 $1-37319801821

Control Board, Integrated $1-03101932002 $1-03101932002

6 Valve, Gas $1-02543267000 $1-02543267000

7 Bracket, Mounting (Gas Valve) $1-07319801064 $1-07319801064 <

8

9 Exchanger, Heat (w/Gaskets) $1-37319804651 $1-37323792002

10 Sensor, Flame $1-02535354000 $1-02535354000

Switch, System $1-7681-3301 $1-7681-3301

Transformer (115-24V, 40 VA) $1-2940A3541 $1-2940A3541

Switch, Limit $1-02535380000 $1-02535381000

14 Burner Assembly, Auto Ignition $1-37319801403 $1-37319801403

(Includes itemss 10 & 15)

15 Ignitor, Hot Surface $1-02541021000 $1-02541021000

16 Filter (2 Req'd) (16x20x1) $1-1214-2511 $1-1214-2511

17 Panel, Door (Upper) Accessory (See Page 4)

18 Panel, Door (Lower, Short) 7900-7671 7900-7671

Motor $1-02431948000 $1-02431948000

20 Assembly, Motor Mount ......

21 Plug, Connector $1-02521192000 $1-02521192000

::22 Capacitor, Run ......

23 Wheel, Blower S1-02619654003 S 1-02619654003

24* Top, Casing $1-07319801342 $1-07319801342

25* Diagram, Wiring 157953 157953

26* Strike, Door S 1-02118364000 S1-02118364000

27* Latch, Door $1-02118365000 $1-02118365000

28* Housing, Blower $1-37323864001 $1-37323864001

29* Gasket, Combustion Air Box $1-01006900005 $1-01006900005

30* Gasket, Burner $1-01006742000 $1-01006742000

31" Gasket, Booster Assembly $1-01006900015 $1-01006900015

32* Gasket, Heat Exchanger $1-01006900001 $1-01006900001

129099-BUM-J-0112

NOTE: *Not Shown

New replacement parts shown in bold face type at the first printing of parts list dated 1/12.

Major components and suggested stocking items are shown with shaded item number,

"<" Across from row indicates a change in that row.

--- Not applicable to specified model.

3. DGAH with 5-Ton Blowers are provided as an accessory item and are not standard equipment from

the factory, See page 4.

BURNER ORIFICE CHART (Normal Altitude Only, See Note 5)

MODEL

NATURAL GAS

LP GAS

ACCESSORY DESCRIPTION DGAA DGAH

5-Ton BlowerAss'y Motor $1-02431975000 $1-02431975000

7900-7751 Run Capacitor (20 MFD) $1-02420051000 $1-02420051000

NOTES

5 Contact Customer Service for installations at altitudes over 2000 feet above sea level.

"<" Across from row indicates a change in that row.

--- Not Applicable to specified model.

056 070 077

S1-9951-1361 S1-9951-1541 S1-9951-1611

$1-9951-0821 $1-9951-0931 $1-9951-0981

ACCESSORY PARTS LIST

Door Panel (Upper) 7900-7631 7900-7631

Motor Mount $1-37319802930 $1-37319802930

Blower Wheel $1-1472-2761 $1-1472-2761

O9O

$1-9951-1771

$1-9951-1061

Johnson Controls Unitary Products 11

Y

..-[

8

0

'11

r-

m

GO

-W

5"

E]

B

i

E3

6-)

BLOWER SPEED CHART

CHARTE DE VITESSE

DE LA SOUFFLERIE}

INPUT CF# COOL

(ENTREE) (PCM/ HIGH HEAT

(CL[MA) (CHAU_

BLK REO

056 I_OO (NOI_) (ROUG)

BLK REO

O70 1200 (NOIR) (ROgG)

BLK REO

077 1200 (NOIR) (ROU6)

BLK RE8

O9O mOO (NOLO) (ROUS)

WIRE COLOR KEY

(CODE DE COULEUR

DC FILAGE)

BLK BLACK

(NO/R/ (NOIR)

BLU BLUE

BLEU (GLEU)

RED RED

(ROUG_ ROUGE}

YEL YELLOW

{ AUN (AUNE)

_T WHITE

(BLANC) (t_LANC]

BRN BRO'_#_

(BRUN (_Rux)

GRN GREEN

(VERT (VERT)

PRP PURPLE

(POURPRE) (POURPRE)

OR ORAXGE

{ORA) (ORANGE',

CAUTION

OPE ALL DISCONNECTS BEFORE

SERV[CING THIS UNIT

r:RE_CAUTION

OUVREZ LES OISJONCTEURS AVANT

DE _ROCE'DER AVEC LE SERVICE

BOX DOWNFLOW FURNACE

(FOURNAISE 80X

VENTZLEE PAR LE BAS)

LADDER DIAGRAM

DIAGRAMME ELEMENTAIRE

_/_ POWER SUPPLY 115 160 SEE NOTE IOS

/ALIMENTATION 115 160 VOIR NOTE I)

} TOGGLE S?_]TCH.A

_(CO_MUTATEUR (MOTEUR OE

LEV]ER)

(RELAIS CHAUF/CLIM) 50UFFLER[E)

....

LL_ .... ( ..... 1 _

_ALi/y,700L =

ij RELA[S

RELA? ' o'I CT} (9'INDUCT

S

MOTEUR)

qT (4OVA)

_N 'q

HEAT/COOL THERMOSTAT

(THERMOSTAT CLIMA/CHAUFJ

--4 I

GN,S

(EN TERRE)

GAS VALVE !

RELAY

E TERRE)

(RELAIS _?E SOUPAPES

DE GAZ)

NOTES:

i ALL FIELD WIRING PER; (A) NATIONA

(B) CANA©IA

(C) LOCAL 0

2 IF ANY OF THE ORIGINAL WIRE AS SU

REPLACED, IT MUST BE REPLACED WIT

TEMPERATURE RATING OF AT LEAST 22

51 CONNECTORS SUITABLE FOR COPPER CO

4, ALL REPLACEMENT COMPONENTS MUST B

5 PROVIDE OISCONNECTS FOR ALL POWER

6, MOTORS ARE INHERENTLY PROTECTED

7 SSI 1S IN SERIES WITH LSI AND LS2

L ELEC CODE (NEC) AND/OR/

N ELEC CODE (CEC) AND/OR/

R CITY CODES.

PPLIEO WITH THE FURNACE MUST BE

H WIRING MATERIAL HAVING A

PF (105_C).

NDUCTORS ONLY

E PROPERLY GROUNDED.

SUPPLIES

NOTES:

II TOUT FILAGE EN CHANTIER SELON: (A CODE ELEC NATIONAL (CEN') ET/OU/

(B CODE ELEC CANADiEN (CEC) ET/OU/

(c CODES LOCAUX ET MUNICIPAUXI

2 SI LE FILAGE DOlT ETRE REMPLACE E N PATRIE OU EN TOUT, IL DOlT

L'ETRE AVEC UN MATERIAUX POUVANT RESISTER A DES TEMPERATURES

O'AU MOINS 22PF (105_C)

5. SEULEMENT DES MARETTES POUR FIL D E CUIVRE.

€ TOUTE COMPOSANTE DE REMPLACEMENT DOlT [ETRE BIEN MISE EN TERRE.

5 FOURNISSEZ LES DISJONCTEURS POUR L*ALIMENTAITON

6 LES MOTEU_S SONT PROTEGES DE PAR LEUR CONCEPTION.

7 SSI OE SE_IE AVEC LSI ET LSZ

CONNECTION DIAGRAM

(DIAGRAMME DE RACCORDEMENT)

BRN

__1 2 _RN

GAS VALVE

I O'_N GR

IGND

(E TERRE)

FLAME SENSOR

YEL YEL

CAPTEUR DE

FLAMME) _R

, P5/S_

HOT _ R_

I NITER

(IGNITION DE _i

SdRFACE CHA _}E

BLK

6LK

GRN

L BRN

!

_RN

6NO = _

[EN TERRE} /'IRC ®

BLU "_

BLU

8RY

FURNAC_ CONTROL

PI/SI ( NTROLE DE LA

WHT FOURNAISE)

WHT RED

RED 2¢v 9EC 5LU

_LK _ _

O;_N LSI aLU LS2 o*w

DE SURCHARGE

DE TIn/

LEGEND

OS DISCONNECT SWITCH

v AS VALVE

IGN HOT SURFACE IGNITER

PI/SI 9 PIN PLG & SOCKET ON FRNA CE CONTROL BOARD

P2/$2 6 PI PLUG & SOCKET ON FURNACE CONTROL BOARD

o3/95 2 DIN PLUG & SO(KET AT HOT SURFACE IGNITOR

: 4/._-4 9 PIN *_L & SO KET

LSI,2 AUXILIARY LIMIT SWITCH ON !?LOWER INLET

ILP PRESSURE S_ITCH

IRC R 1,, CAPACITOR

IT TRAN_,FORMER, 4OVA

IDENTIFIED RU_ CAPACITOR

24V CO NECT[O ROOM THERM STAT

O FIELD CON ECT[ON

FACTORY WIRIN AND _}EVICES

FIELD WIRING A O DEVICES

• _ RELAY CONTACT! C IGNITION

_L • CONTROL _30ARD

LEGENDE

OS COMMUTATEUR DE DISJONCTON

GV SOUPAPE DE GAZ

IGN IGNITION DE SURFACE CHAUOE

PI/SI PRISE & RECEPTACLE A 9 PTS S UR LA PLAOUETTE DE CONTROLE D'IGNIT[ ON

P2/$2 PRISE & RECEPTACLE A 6 PTS SU R LA PLAQUETTE DE CONTROLE D'IGNIT[O N

P5/$3 PRISE ET RECEPTACLE A 2 PTS i} 'IGNITION DE SURFACE CHAUDE

P4/S4 PRISE ET RECEPTACLE A 9 PTS

LSI,Z COMMUTATEUR AUXILIAIRE DE PRE SSION SUR _OITIER DE SOUFFLERiE

ILP COMMUTATEUR DE PRESS[ON

IRC CAPACITEUR DE FONCTIONNEMENT ID ENTIFIE

IT TRANSFORMEUR, _OVA

@ CAPACITEUR DE FONCTIONNEMENT IDENTIF IE

2#v RACCORDEMENT OU THERMOSTAT DE PIECE

0 RACCOROEMENT DE CHANTIER

FILAGE DE L'USINE ET APPARE[LS

FILAGE DE CHANT[ER ET APPAREIL s

Fq

_L _ CONTACTE9 DES RELAIS 9UR LA PLAQUETT E OE CONTROLE ©'IGNiTiON

155887 UWD A 0705

¢o

(.o

O

(.o

¢__

6

Y

c

o

"11

r-

m

_0

_3

B

3

i

E3

©

>

-I-

WIRE COLOR KEY

(CODE DE COULEUR

DU FILAGE)

BLK 8LACK

[NO{R} _NOIR)

BLU BLUE

[BLEU} (BLEU)

RED RED

{ROUG_ (ROUGE)

YEL YELLOW

(JAUN} (JAUNE)

WHT WHITE

{BLANC} (BLANC)

BAN BROWN

{BRUN) {SPUN)

GRN GREEN

(VENT) (VENT)

PRP PURPLE

(POURPRE) (POURPRE)

ORN ORANGE

(ORA) (ORANGE}

CAUTION

OPEN ALL DISCO ECTS BEFORE

SERVIC[ G THiS (NIT

PRE_CAUTION

OVREZ LES DISJONCTE RS AVAT

DE PROCE'DER AVEC LE SERVICE

BOX DOWNFLOW FURNACE

(FOURNAISE 80X

VENTILEE PAR LE BAS)

LADDER DIAGRAM

DIAGRAMME E[EMENTAIRE CONNECTION DIAGRAM

(DIAGRAMME DE RACCORDEMENT)

POWER SUPPLY 115160 SEE NOTE I

OS _/ _ (ALIMENTATION 115 160 VOIR NOTE I)

HEAT/COOL

RELAY

lj {RELAIS

RELAY D'I DUCT) (D'INDUCT

MOTEUR)

8

i {RELA[S

°RELAY !}'IG ]TION II'_R _?M

IT (#OVA}

o

I COOL r({) -- _0

HEAT/COOL THERMOSTAT

',THERMOSTAT CL[MA/CHAUFJ

NOTES:

I. ALL FIELD WIRING pER; A) NATIONA

(B CA ADIA

{C) LOCAL O

2. IF ANY OF THE ORIGINAL WIRE AS SU

REPLACED, IT MUST BE REPLACED WIT

TEM_ERATURE qATING OF AT LEAST 22

'ONNECTORS SUITABLE FOR COPPER CO

4 ALL REPLACEMENT COMPONENTS MUST

5. PROVIDE DISCONNECTS FOR ALL POWER

6 MOTORS ARE INHERENTLY ROTECTED

7 SSI IS IN SERIES WITH LSI AND LS

NOTES_

I. TOUT FILAGE EN CHANTIER SELON, (A

(B

(C

2. SI LE FILAGE DOIT ETRE REMPLACE

L'EtRE AVEC UN MATER[AUX POUVANT

D'AU _O/NS 22PF (105_C)

3, SEULEMENT DES MARETTES POUR FIL D

4 TOUTE COMPOSANTE OE REMPLACEMENT

5 FOURN[SSEZ LES DISJONCTEURS POUR

8 LES MOTEURS SONT PROTE.GESDE PAR

7 SSI DE SERIE AVEC LSI ET LS2

I

(EN TERRE)

FLAME SENSOR

(CAPTEUR DE

FLAMME]

(EN TERRE)

YEL

GRN

YEL

_RN

_v_ _ Ps/s5

........ __

RELAY

[IGNITION ©E

SURFACE CHAUDE)

BE GAZ) BLK

_LK

DE SURCHARGE

DE T]R/

L ELEC CODE (NEC) AND/OR/

N ELEC CODE (CEC) AND/OR/

R CITY CODES

PPLIED WITH THE FURNACE MUST BE

H WIRING MATERIAL HAVING A

PF (I05"CI

NDUCTOR5 ONLY.

E PROPERLY GROUNOED

SUPPLIES.

CODE ELE.C. NATIONAL (CEN) ET/OU/

CODE ELEC CANADIEN [CEC) ET/OU/

CODES LOCAUX ET MUNICIPAUX.

N PATRIE ou EN TOUT, IL OOIT

RESISTER A DES TEMPERATURES

E CU]VRE.

30IT [ETRE _]EN MISE EN TERRE.

L'ALIMENTAITON

LEUR CONCEPTION

LEGEND

DS DISCONNECT 5_ITCH

GV GAS VALVE

IGN HOT SURFACE IGNITER

PI/SI 9 PIN PLUG & SOCKET ON FURNACE CONTROL BOARD

P /S 6 _IN PLUC & _;OCKET ON FURNACE CONTROL OA_D

P3/$3 2 PIN PLUG a SOCKET AT HOT SURFACE IGNIT R

R4/$4 9 PIN PLUG & SOCKET

LSh AUXILIARy LIMIT SWITCH ON EiLO WER INLET

ILF' PRESSbRE SW[TH

IRC RN CA_ACITOR

IT TRANSFORMER, 4OVA

@ IDENTIFIED H CA_)AC[TOR

24v CO_,NE{T[O ROOM THERMOSTAT

0 FIELD CONNECTIO

FACTORY WIRIS,G AND 2EV[CES

FIELD WlRIS, O A O DEVICES

• • RELAY CO TACTS ON IGNITIO

?? ..............

GRN

G_ _RN

(EN TERRE}

BLU I

BLU

GAY

FURNACE CONTROL

PI/SI tCONTROLE nE LA

WHT FOURNAISE)

WHT RED

I

RED 2¢v SEC BLU J

BLK _ ....... WHT

...... I

OR LSI BL LS2 GAY

WHT BLK

SLK

(COMM TATE JR

(IISVCA NEUT.

LEGENDE

DS COMMUTATEUR DE I][SJONCTON

GV SOUPAPE DE GAZ

]GN IGNITION DE SURFACE CHAUDE

RI/SI PRISE & RECEPTACLE A 9 PTS S UR LA PLAOUETTE DE CONTROLE D'IGNIT[ ON

P8/$2 PRISE & RECEPTACLE A 6 _TS SU R LA PLAOUETTE OE CONTROLE D']GN[TIO N

PS/S5 PRISE ET RECEPTACLE A _ PTS D 'IGNITION DE SURFACE CHAUDE

P4/S¢ PRISE ET RECEPTACLE A 9 PTS

LSI,2 COM_UTATEUR AUXILIAIRE DE PRE SS[ON SUN BOITIER DE 50UFFLERIE

ILP COMMUTATEUR DE PRESSION

IRC CAPACITEUR DE FONCT[ONNEMENT 1© ENT[FiE

IT TRANSFORMEUR, 4OVA

@ CAPACITEUR DE FONCTIONNEMENT I©ENTIF IE

z_ Z4V RACCORDEMENT OU THERMOSTAT OE PIECE

0 RACCORDEMENT DE CHANTIER

FILAGE DE L'USINE ET APPARE[LS

FILAGE DE CHANTIER ET APPAREIL S

_ ....................................... OLED' ........

157955 UWD A 0705

¢o

(.o

0

(.o

L

6

LimitedWarranty

For Manufactured Housing Furnace

UPG warrants this product to be free from defects in factory workmanship and material under normal use and service and will replace parts that prove to have

such defects according to the terms outlined below.

FURNACE MODELS

Furnace Model Heat Exchanger l Parts Coverage Labor and Trip Coverage*

DGAA, DGAH 10 years / 2 years 1years

The warranty period for any replacement heat exchanger or part provided here under shall not extend beyond the warranty period stated above. The heat

exchanger warranty is on a parts only basis: no labor, freight or other service charges are allowed.

The warranty period will begin on the purchase date of the residence when the product is installed as original equipment, or the installation date when installed

in a residence previously purchased by the consumer. Return the Warranty Registration Card to UPG promptly after product installation or purchase for your

benefit and protection. The warranty period will begin upon product shipment from UPG in the absence of a recorded Warranty Registration Card.

This warranty applies to the original consumer/purchaser and any subsequent purchaser. The warranty does not apply if the furnace is removed from the orig-

inal residence, or if the residence has been moved from the original location where the furnace was placed in service.

This warranty applies only to products installed: (1) in the United States of America or Canada; (2) in accordance with UPG recommendations and specifica-

tions outlined in the Installation Manual provided with the product; (3) in accordance with all national, state/provincial, and local codes; and (4) in the original

residence.

Exclusions

1. Shipping/freight, or material charges.

2. Damages resulting from transportation, mishandling, improper application, installation or servicing.

3. Damages resulting from accident, abuse, fire, flood, or other acts of nature.

4. Use of the product in a corrosive atmosphere.

5. Alteration, tampering, defacing or removing the product serial number will serve to void the warranty.

6. Damages resulting from inadequacy or interruption of electrical service, improper energy supply, blown fuses, improper wiring external to the

unit or other like damages.

7. Damages resulting from the use of components not approved by UPG.

8. This warranty does not cover consequential damages, incidental damages or incidental expenses including damages to property.

9. Damages caused by failure to perform normal or routine maintenance as set out in the operation and service instructions.

10. Cleaning, replacement of filters, or any other routine maintenance as set out in the User's Information, Maintenance and Service Manual.

11. Replacement or cleaning of nozzles or orifices.

12. Fuses either internal or external to the product.

13. Excessive fuel or electricity consumption.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABIL-

ITY AND FITNESS FOR A PARTICULAR PURPOSE. SOME STATES DO NOT ALLOW THE DISCLAIMER OF IMPLIED WARRANTY, SO THAT THE ABOVE

DISCLAIMER MAY NOT APPLY TO YOU.

SOME STATES ALLOW ONLY A PARTIAL LIMITATION ON IMPLIED WARRANTIES, OR LIMIT THE DURATION OF IMPLIED WARRANTIES TO THE

DURATION OF THE EXPRESS WARRANTY. IN SUCH STATES, THE DURATION OF IMPLIED WARRANTIES IS HEREBY EXPRESSLY LIMITED TO THE

DURATION OF THE EXPRESS WARRANTY ON THE FACE HEREOF. IN NO EVENT, WHETHER AS A RESULT OF BREACH OF WARRANTY OR CON-

TRACT TORT (INCLUDING NEGLIGENCE) STRICT LIABILITY OR OTHERWISE, SHALL UPG BE LIABLE FOR SPECIAL, INCIDENTAL, OR CONSE-

QUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO LOSS OF USE OF THE EQUIPMENT OR ASSOCIATED EQUIPMENT, LOST REVENUES OR

PROFITS, COST OF SUBSTITUTE EQUIPMENT. THIS WARRANTY DOES NOT COVER CONSEQUENTIAL DAMAGES. THE ABOVE LIMITATIONS

SHALL INURE TO THE BENEFIT OF UPG SUPPLIERS AND SUBCONTRACTORS. THE ABOVE LIMITATION ON CONSEQUENTIAL DAMAGES SHALL

NOT APPLY TO INJURIES TO PERSONS IN THE CASE OF CONSUMER GOODS.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, OR FOR STRICT

LIABILITY IN TORT, SO THAT THE ABOVE EXCLUSIONS AND LIMITATIONS MAY NOT APPLY TO YOU. UPG DOES NOT ASSUME, OR AUTHORIZE

ANY PERSON TO ASSUME FOR UPG ANY LIABILITY FOR THE SALE OF THIS PRODUCT. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS.

YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

TO OBTAIN WARRANTY SERVICE

Consult the Authorized Service Center list packed with the furnace installed in the manufactured home or contact your installing or servicing dealer.

Or, look in the Yellow Pages of the telephone book under Mobile Homes-or Manufactured Housing-Repair and Service for the name and telephone number of

the nearest authorized manufactured housing service center. If local authorized service cannot be obtained, or you are unable to contact your installing dealer,

contact the authorized distributor in your area. If there is no distributor in your area, and you cannot obtain proper service under the terms of the warranty,

please write: Unitary Products Group (UPG) Customer Relations Department, PO Box 19014, Wichita, KS 67204-9014.

Subject to change without notice. Published in U.S.A.

Copyright _>2012 by Johnson Controls, Inc. All rights reserved.

Johnson Controls Unitary Products

Wichita, KS 67204-9014

P.O. Box 19014

Supersedes:

129099-BUM-J-0112

129099-BUM-I-0711

Loading...

Loading...