Page 1

TECHNICAL GUIDE

®

LX

SERIES

FOR INSTALLATION IN ALL US REGIONS AND CANADA

SPLIT SYSTEM

HEAT PUMPS

Installation Allowed

16 SEER – R-410A – 1 PHASE

2 THRU 5 NOMINAL TONS

MODELS: CH1624 THRU 60

®

Due to continuous product improvement, specifications

are subject to change without notice.

Visit us on the web at

www.upgnet.com and www.colemanac.com

Additional rating information can be found at

www.ahridirectory.org

WARRANTY SUMMARY*

Standard 5-year limited parts warranty.

Standard 10-year limited compressor warranty.

Extended 10-Years limited parts warranty when product is

registered online within 90 days of purchase for replacement

or closing for new home construction.

*Does not apply to R-22 models, 3-Phase models, or Internet sales.

See Limited Warranty certificate in User's Information Manual for details.

5547666-CTG-A-0718

DESCRIPTION

The CH16 16 SEER Modulating Heat Pumps are the newest

offering in our successful LX Family of split system heat pumps.

These units use a state of the art inverter driven compressor to

precisely meet customers comfort requirements. Using a conventional two-stage heat pump thermostat, the system will automatically modulate capacity and airflow from 50% to 100% of

nominal capacity in 10% increments to meet the comfort

requirements of the consumer, maximizing comfort while minimizing energy bills. Designed to work with Coleman variable

speed or standard ECM indoor air handling equipment it provides consumers and dealers system installation options.

Should the unit ever require service the main control and

inverter control both provide system self-diagnostics.

FEATURES

• Improved Temperature Control - The inverter driven compressor and modulating system will automatically adjust

capacity, in heat or cool mode, to precisely match the comfort

demands of the space providing closer temperature and

humidity control.

• Easier Installation - Time is reduced by being factory

charged for a 15-Ft line set and having a factory installed filter-drier. This means less time spent brazing and charging

the system. The small base dimension and reduced unit

clearances requirements provide more retrofit applications.

• Accessible Information - QR code on unit provides quick

access to technical documents and warranty information at

www.upgnet.com.

• Durable Finish - The automotive grade champagne colored

powder painted and the specially coated wire grill and fasteners add to the corrosion resistant nature of the product allowing it to retain its aesthetics appeal throughout its life.

• Rugged Coil Protection - Coils are protected from mechanical damage by a stamped steel extruded louver coil guard

design.

• Quality Coils - Enhanced aluminum fins are mechanically

bonded to copper tubing.

• Protected Compressor - Compressors are protected by the

system high and low pressure switches. The liquid line filterdrier is factory installed to protect the system against moisture and contaminates.

• Reliable Operation - Ball bearing fan motors provide superior performance in extreme temperatures. Factory installed

accumulator protects the compressor while operating across

a wide range of conditions.

• Environmentally Friendly - CFC-free R-410A refrigerant

delivers environmentally friendly performance with zero

ozone depletion.

• Top Discharge - Warm air is blown up, away from the structure and any landscaping and allows compact location on

multi-unit applications.

• Low Operating Sound Levels - The sturdy cabinet and top

design provides sound performance as low as 76 dBA.

• Better Service Access - Diagonal base valves with open

access for Schrader removal tools and low-loss fittings and

single panel access to the electrical controls. Full corner

access using the swing out electrical box, and removable fan

guard allow easy access for unit service or maintenance.

• Agency Listed - Safety certified by CSA to UL 1995 / CSA

22.2. Performance certified to ANSI/AHRI Standard 210/240

in accordance with the Unitary Small Equipment certification

program.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

5547666-CTG-A-0718

LIST OF SECTIONS

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PHYSICAL AND ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . . . 3

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SYSTEM CHARGE FOR VARIOUS MATCHED SYSTEMS . . . . . . . 4

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SYSTEM CAPACITY - Single Piece and Modular Air Handlers . . 6

SYSTEM CAPACITY - With High Efficiency Motor Furnaces . . .10

APPLICATION & ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . 53

SOUND POWER RATINGS - COOLING . . . . . . . . . . . . . . . . . . . . . 53

SOUND POWER RATINGS - HEATING . . . . . . . . . . . . . . . . . . . . . 53

UNIT OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

MECHANICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 54

TYPICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

TYPICAL FIELD WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

ALTERNATIVE INSTALLATION CLEARANCES . . . . . . . . . . . . . . 56

PERFORMANCE DATA - 2 TON . . . . . . . . . . . . . . . . . . . . . . . . . . 57

PERFORMANCE DATA - 3 TON . . . . . . . . . . . . . . . . . . . . . . . . . . 68

PERFORMANCE DATA - 4 TON . . . . . . . . . . . . . . . . . . . . . . . . . . 83

PERFORMANCE DATA - 5 TON . . . . . . . . . . . . . . . . . . . . . . . . . 100

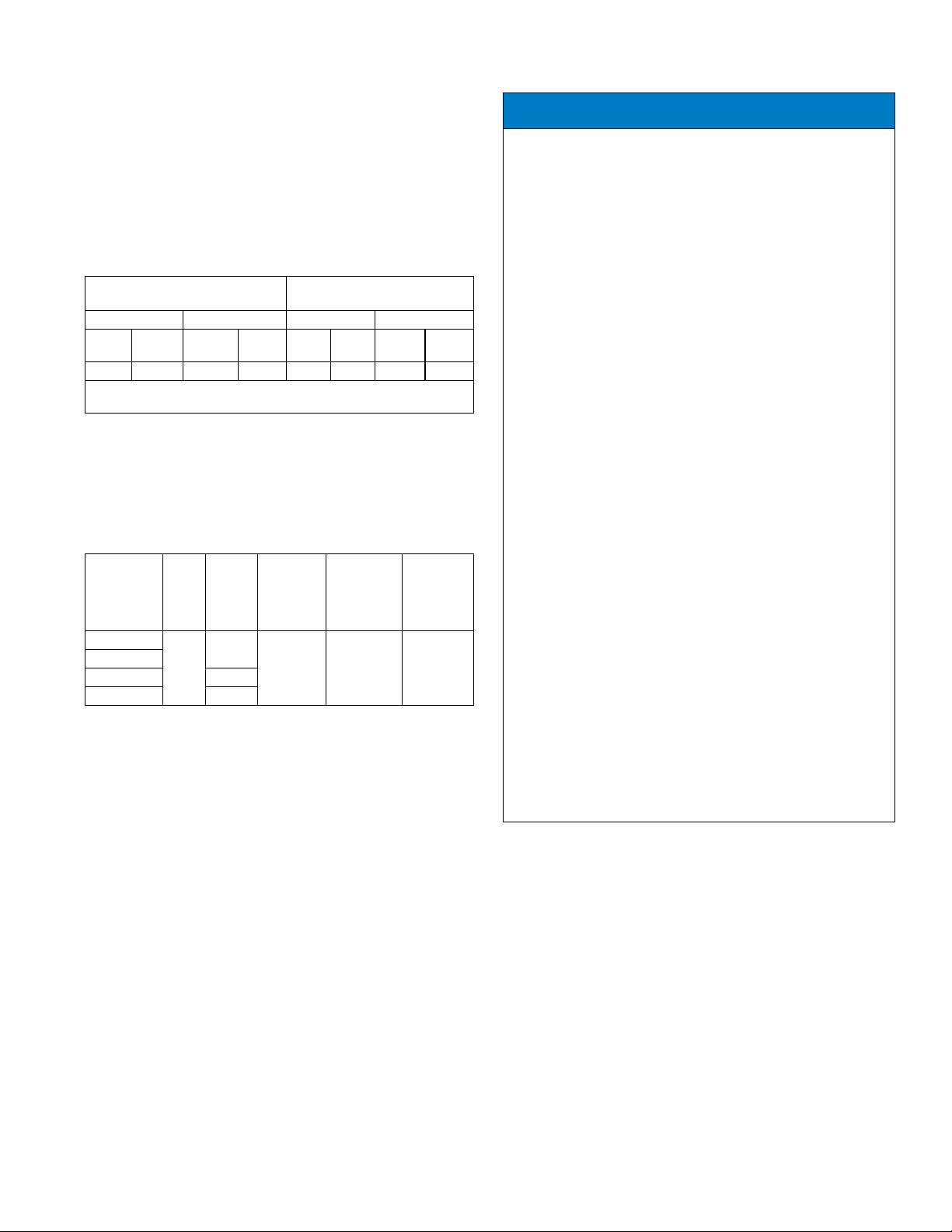

NOMENCLATURE

BRAND

PRODUCT TYPE

NOMINAL

SERIES EFFICIENCY

AND STAGING

REFRIGERANT

NOMINAL UNIT

CAPACITY (MBH)

VOLTAGE

(Voltage-Phase-Hertz)

GENERATION

(MAJOR REVISION)

FACTORY OPTION

STYLE LETTER

(Minor Revision)

Not Used for Ordering

C

C = Coleman

H

H = Heat Pump

16

16 = 16 SEER / Modulating

B

B = R-410A

24 = 2 Ton 48 = 4 Ton

36

36 = 3 Ton 60 = 5 Ton

2

2 = 208/230-1-60

1 = 1st Gen

1

2 = 2nd Gen

etc

S

S = Standard (No Options)

A = Style A

A

B = Style B

etc

2 Johnson Controls Unitary Products

Page 3

5547666-CTG-A-0718

PHYSICAL AND ELECTRICAL DATA

MODEL CH16B2421S CH16B3621S CH16B4821S CH16B6021S

Unit Supply Voltage 208-230V, 1 60Hz

Normal Voltage Range

1

Minimum Circuit Ampacity 17.2 21.0 35.6 34.7

Max. Overcurrent Device Amps

Min. Overcurrent Device Amps

2

3

30.0 35.0 60.0 60.0

20.0 25.0 40.0 50.0

Type Rotary Rotary Rotary Rotary

Compressor

Rated Load 13.19 15.20 23.73 27.42

Locked Rotor 26.0 38.0 44.5 64.5

Crankcase Heater Yes Yes Yes Yes

HS Kit Required with TXV

N/A N/A N/A N/A

Fan Diameter Inches 22 22 24 24

Rated HP 1/8 1/4 1/3 1/3

Fan Motor

Rated Load Amps 1.0 1.0 1.3 1.3

Nominal RPM 970 850 1000 1000

Nominal CFM 2850 3715 4000 4100

Face Area Sq. Ft. 16.15 19.75 23.82 23.82

Coil

Rows Deep 1112

Fins / Inch 22 18 22 18

Liquid Line Set OD (Field Installed) 3/8 3/8 3/8 3/8

Vapor Line Set OD (Field Installed)

Unit Charge (Lbs. - Oz.)

5

4

3/4 3/4 7/8

5 - 9 7 - 2 8 - 6 14 - 14

Charge Per Foot, Oz. 0.62 0.62 0.67 0.75

Operating Weight Lbs. 166 204 214 239

1. Rated in accordance with AHRI Standard 110-2012, utilization range “A”.

2. Dual element fuses or HACR circuit breaker. Maximum allowable overcurrent protection.

3. Dual element fuses or HACR circuit breaker. Minimum recommended overcurrent protection.

4. For applications with non-standard vapor line sizes, see the “Applications & Accessories” section of this Technical Guide.

5. The Unit Charge is correct for the outdoor unit, smallest matched indoor unit, and 15 feet of refrigerant tubing. For tubing lengths other than 15 feet, add or subtract the amount of refrigerant, using the difference in actual lineset length (not the equivalent length) multiplied by the per foot value.

187 to 252

1-1/8

‡

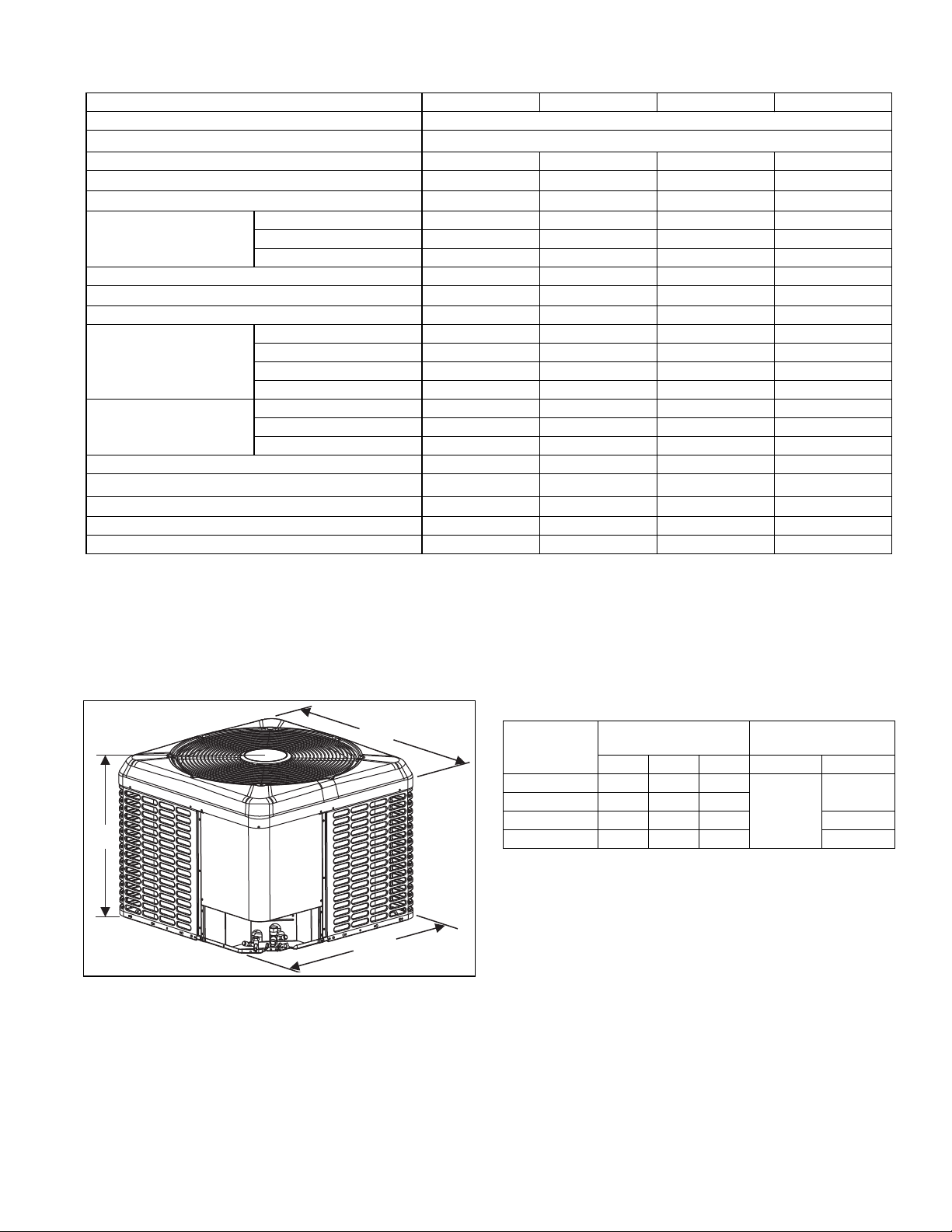

DIMENSIONS

C

Unit

Model

Dimensions

(Inches)

A B C Liquid Vapor

CH16B2421S 33-1/4 29-1/4 29-1/4

CH16B3621S 39-1/2 29-1/4 29-1/4

CH16B4821S 39-1/2 35-1/4 31-3/4 7/8

A

B

A0339-001

CH16B6021S 39-1/2 35-1/4 31-3/4 1-1/8‡

‡ Adapter fitting must be field installed for the required 1-1/8” line set.

All dimensions are in inches and are subject to change without notice.

Overall height is from bottom of base pan to top of fan guard.

Overall length and width include screw heads.

Refrigerant Connection

Service Valve Size

3/4

3/8

Johnson Controls Unitary Products 3

Page 4

5547666-CTG-A-0718

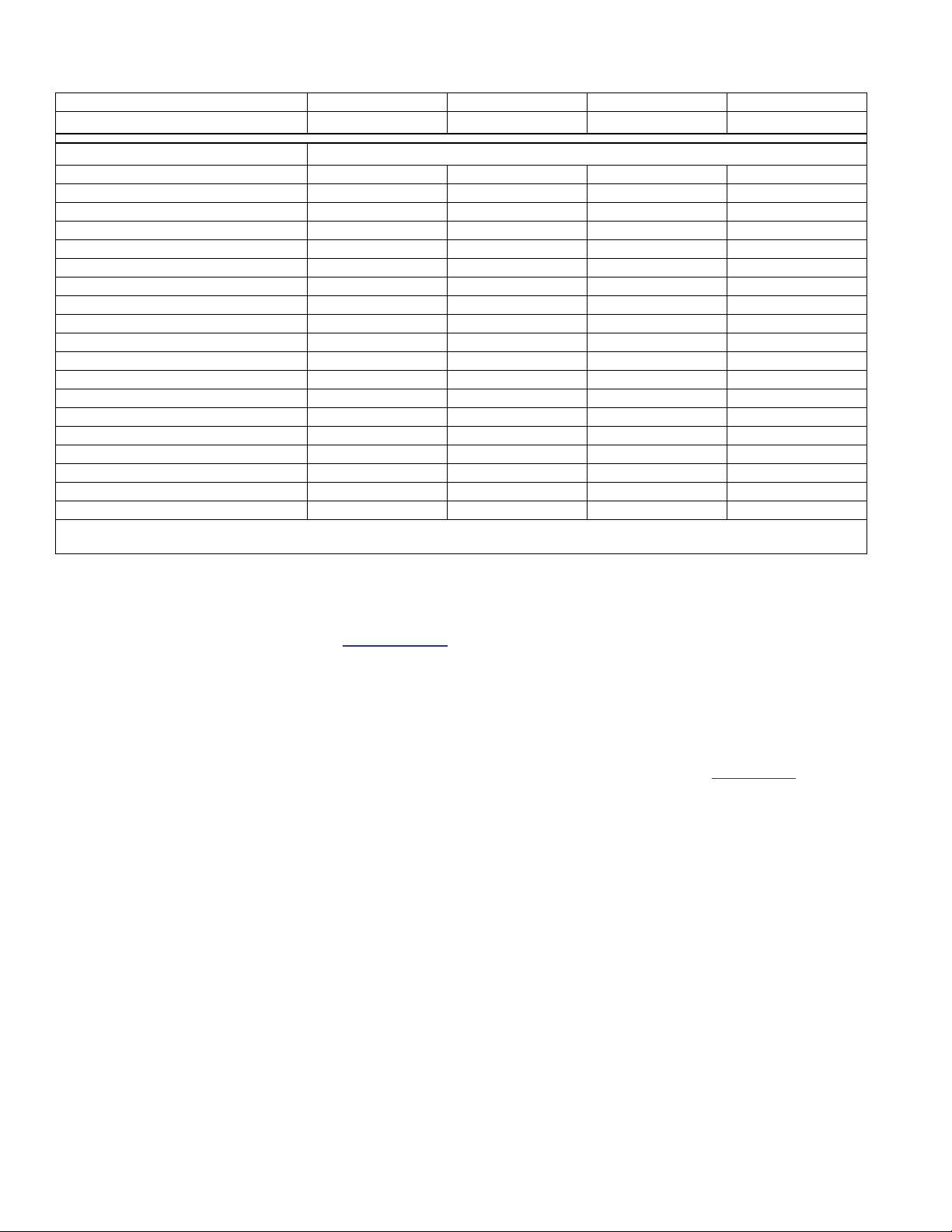

SYSTEM CHARGE FOR VARIOUS MATCHED SYSTEMS

Outdoor Unit CH16B2421S CH16B3621S CH16B4821S CH16B6021S

Required TXV

Indoor Unit

1,2

3,4

AE24B 0–––

AE30B 4–––

AE36B –0––

AE48C ––0–

AE60D –––0

AVC24B 0–––

AVC30B 4–––

AVC36(B,C) 60––

AVC42C –8––

AVC48(C,D) –80–

AVC60C ––8–

AVC60D ––90

CF/CM/CU24(A,B) 0–––

CF/CM/CU30(A,B,C) 4–––

CF/CM/CU36(A,B,C) 60––

CF/CM/CU42(B,C,D) –8––

CF/CM/CU48(C,D) –80–

CF/CM/CU60(C,D) ––8–

CF/CM64D ––90

Some of the combinations shown in the above System Charge table require Advanced Main Air Circulating Fan indoor product. For approved coil

only matches, please see the “COOLING CAPACITY - Upflow, Downflow & Horizontal Furnaces and Coils” table.

FOOTNOTES:

1. For applications requiring a TXV, use S1-1TVM*** series kit.

2. A TXV kit must be used with these indoor units to obtain system performance.

3. CF coils cannot be used in horizontal applications.

4. Charge adders shown above do not indicate that coils are rated for every application. Refer to Performance Data Tables for actual performance for specified

system matches. Obtain certified system ratings from

CHARGING PROCEDURES:

1. Check the Factory Unit Charge listed on the unit data plate to verify the refrigerant charge for the outdoor unit, the smallest matched indoor unit, and the 15 feet of

interconnecting lineset.

2. Verify the indoor metering device and additional charge required for the specific matched indoor unit in the system using the above table.

3. Make sure the unit is locked into high speed and the system stabilizes before charging. Return the heat pump main control jumper to normal when charging is complete. Add additional charge for the amount of interconnecting lineset greater than 15 feet at the rate specified in the Physical and Electrical Data Table.

4. For installations requiring additional charge, weigh in refrigerant for the specific matching indoor unit and actual lineset length.

5. Once the charge adders for matched indoor unit and for lineset have been weighed in, verify the system operation against the temperatures and pressures in the

Charging Chart for the outdoor unit. Locate Charging Charts on the outdoor unit and also in the Service Data Application Guide on

Subcool or the Superheat charging procedure in the Installation Manual according to the type of indoor metering device in the system, and allow ten minutes after

each charge adjustment for the system operation to stabilize. Record the charge adjustment made to match the Charging Chart.

6. Permanently stamp the unit data plate with the TOTAL SYSTEM CHARGE defined as follows: TOTAL SYSTEM CHARGE = Base Charge (as shipped) + charge

adder for matched indoor unit (+ or -) charge adder for actual lineset length + charge adjustments to match the Charging Chart.

BA1 BC1 BC1 BG1

Additional Charge, oz

www.ahridirectory.org.

www.upgnet.com. Follow the

4 Johnson Controls Unitary Products

Page 5

5547666-CTG-A-0718

LIMITATIONS

The unit should be installed in accordance with all National, State and

Local Safety Codes and the limitations listed below:

1. Limitations for the indoor unit, coil, and appropriate accessories

must also be observed.

2. The outdoor unit must not be installed with any duct work in the air

stream. The outdoor fan is the propeller type and is not designed

to operate against any additional external static pressure.

3. The maximum and minimum conditions for operation must be

observed to ensure a system that will give maximum performance

with minimal service.

Minimum / Maximum Operating Limit Conditions

AIR TEMPERATURE AT

OUTDOOR COIL, ° F (° C)

Min. Max. Min. Max.

DB

Cool

35(2)* -20(-29) 125(52)* 75(24) 57(14) 50(10) 72(22) 80(27)

DB

Heat

DB Cool

DB

Heat

*Reference the NOTICE under the “Unit Reduced Capacity Conditions”

section.

4. The maximum allowable equivalent line length for this product is

80 feet.

Standard Lineset Applications

Maximum allowable lineset varies depending on the vertical separation

between the evaporator and condenser. See Table 2 for allowable line

set lengths and sizing.

AIR TEMPERATURE AT

INDOOR COIL, ° F (° C)

WB

DB

Cool

Heat

WB

Cool

DB

Heat

Allowable Vertical Linesets.

Liquid

Model

24

36

48 7/8”

60 1-1/8”

Suction

Line

3/8”

Line

3/4”

Max Line

Length Units on

Equal

Level

80 feet 25 feet 25 feet

Max Suction

Line Riser -

If OD Unit is

Above ID

Unit

Max Liquid

Line Riser -

If OD Unit

is Below ID

Unit

Unit Reduced Capacity Conditions

NOTICE

Intelligence Power Module (IPM) Temperature Protection:

If excessive (IPM) inverter temperatures are sensed, the compressor

speed / capacity is reduced every 60 seconds until an acceptable

condition is reached.

When the inverter temperature returns to an acceptable level, the

system returns to normal operation.

Over / Under Current Protection:

If a low or high Current Condition is sensed, the compressor speed /

capacity is reduced every 30 seconds until an acceptable current

level is reached.

When the system reaches an acceptable current level, the compressor and fan return to normal operating conditions.

Over / Under Voltage Protection:

If a low or high supply Voltage Condition is experienced (below 197

VAC or above 252 VAC), the compressor speed / capacity is automatically reduced every 15 seconds until an acceptable voltage level

is sensed.

When an acceptable voltage level is sensed, the system automatically returns to a normal state of operation.

High Outdoor Ambient Temperature Protection:

During high outdoor ambient temperature conditions above 109°F

(43°C), the compressor speed reduces to protect the system. If the

outdoor ambient temperature goes above 125 °F (52°C), the system

goes into a soft-lockout condition halting operation for system protection. Consider these limitations when installing any of the heat pumps

included in this document.

When the system reaches acceptable operating conditions, the system returns to normal operation.

High Altitude Protection:

If the unit is installed in Altitudes of 6,500 ft / 2,000 m above sea level

or higher, the compressor and outdoor fan reduce speeds to protect

the system. It is not recommended these units be installed at altitudes

greater than 6,500 ft / 2,000 m above sea level.

Low Ambient Protection:

Cooling mode: The unit automatically adjusts to maintain cooling

operation in outdoor ambient conditions down to 35° F (2° C). The

unit reduces capacity and or cycles off if asked to provide cooling

when the outdoor temperature is at or below these conditions.

Heating Mode: The unit provides compressor heat down to an outdoor ambient temperature of -20° F (-29° C). As the outdoor ambient

temperature reduces, available heat reduces for all air source heat

pumps. Make sure the balance point and auxiliary heat are appropriately set and sized for the application of the heat pump.

Johnson Controls Unitary Products 5

Page 6

5547666-CTG-A-0718

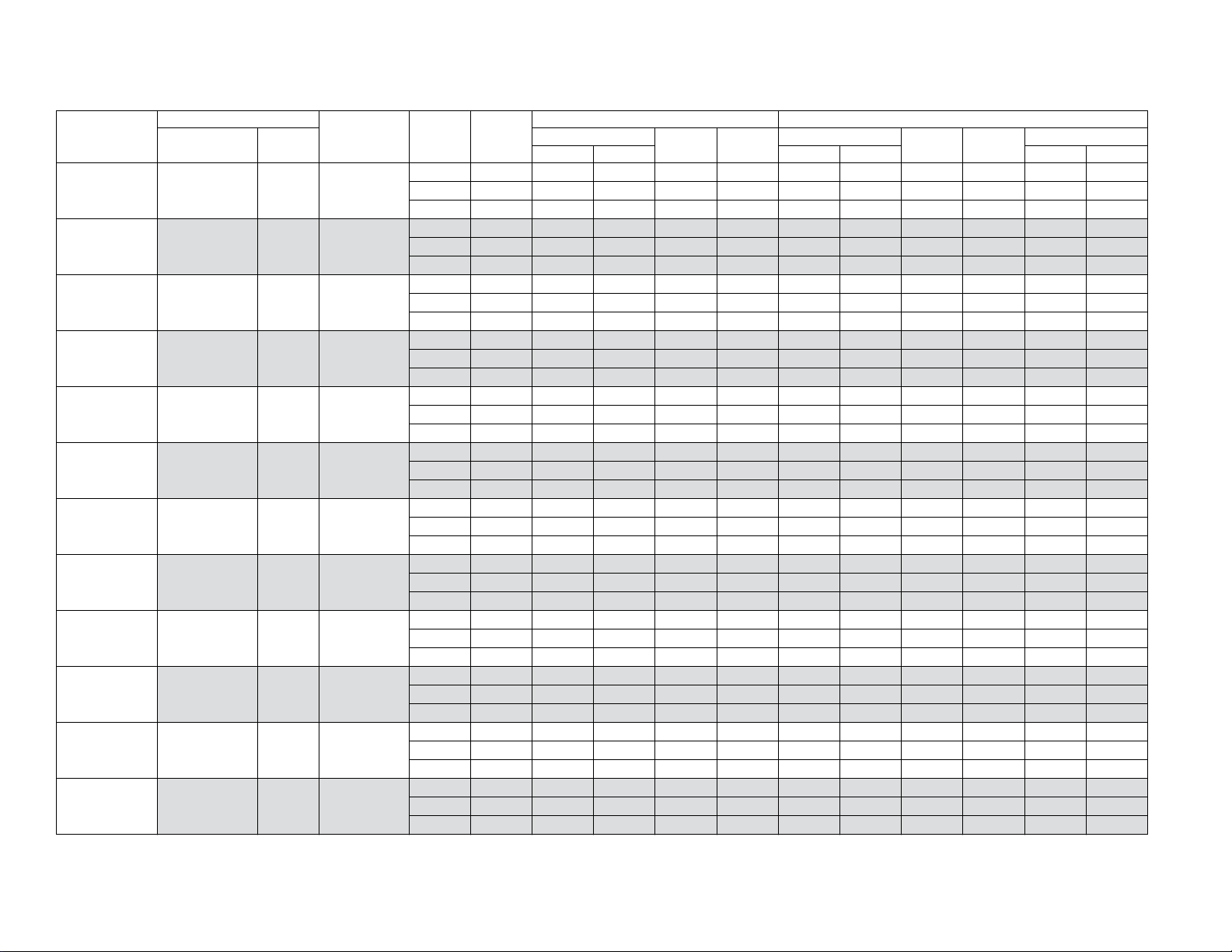

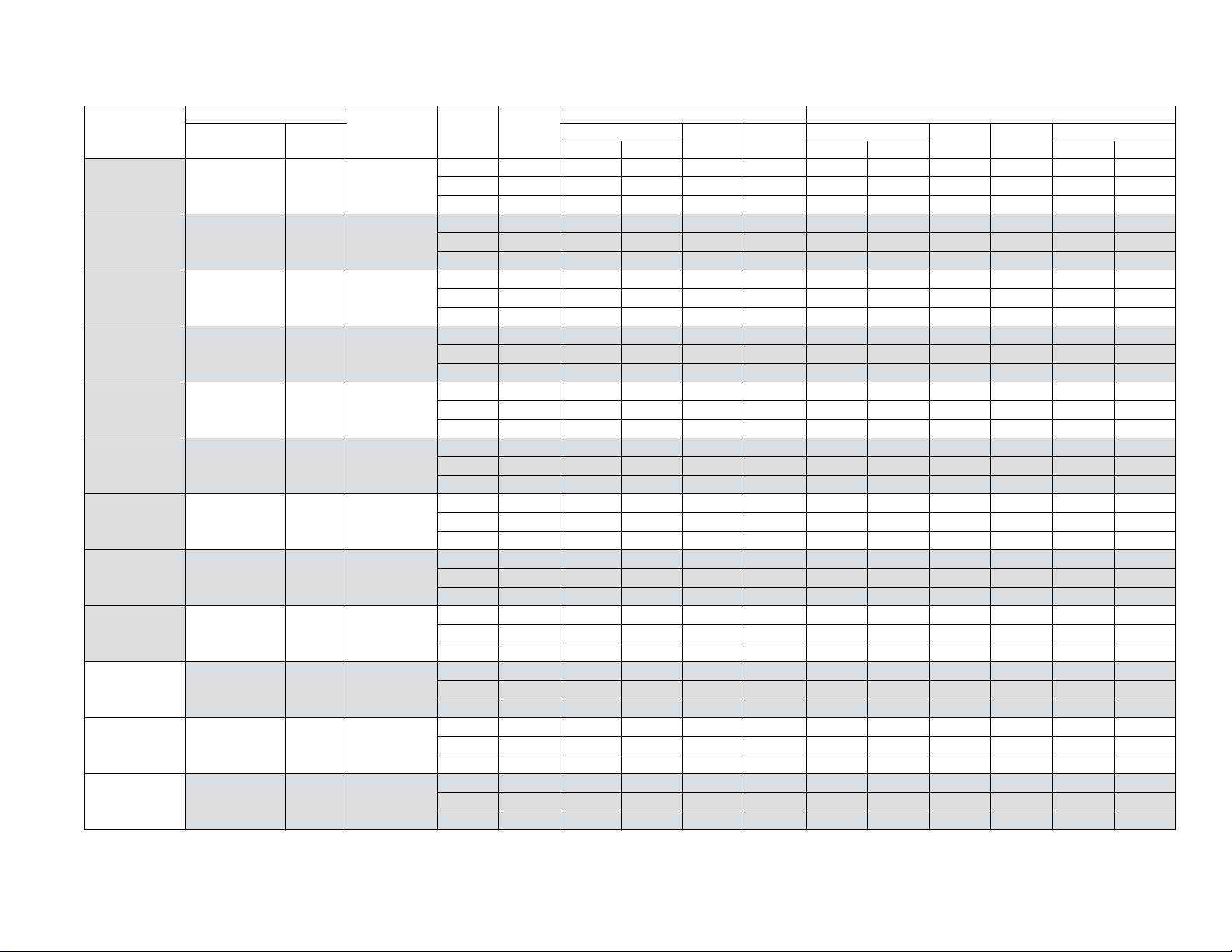

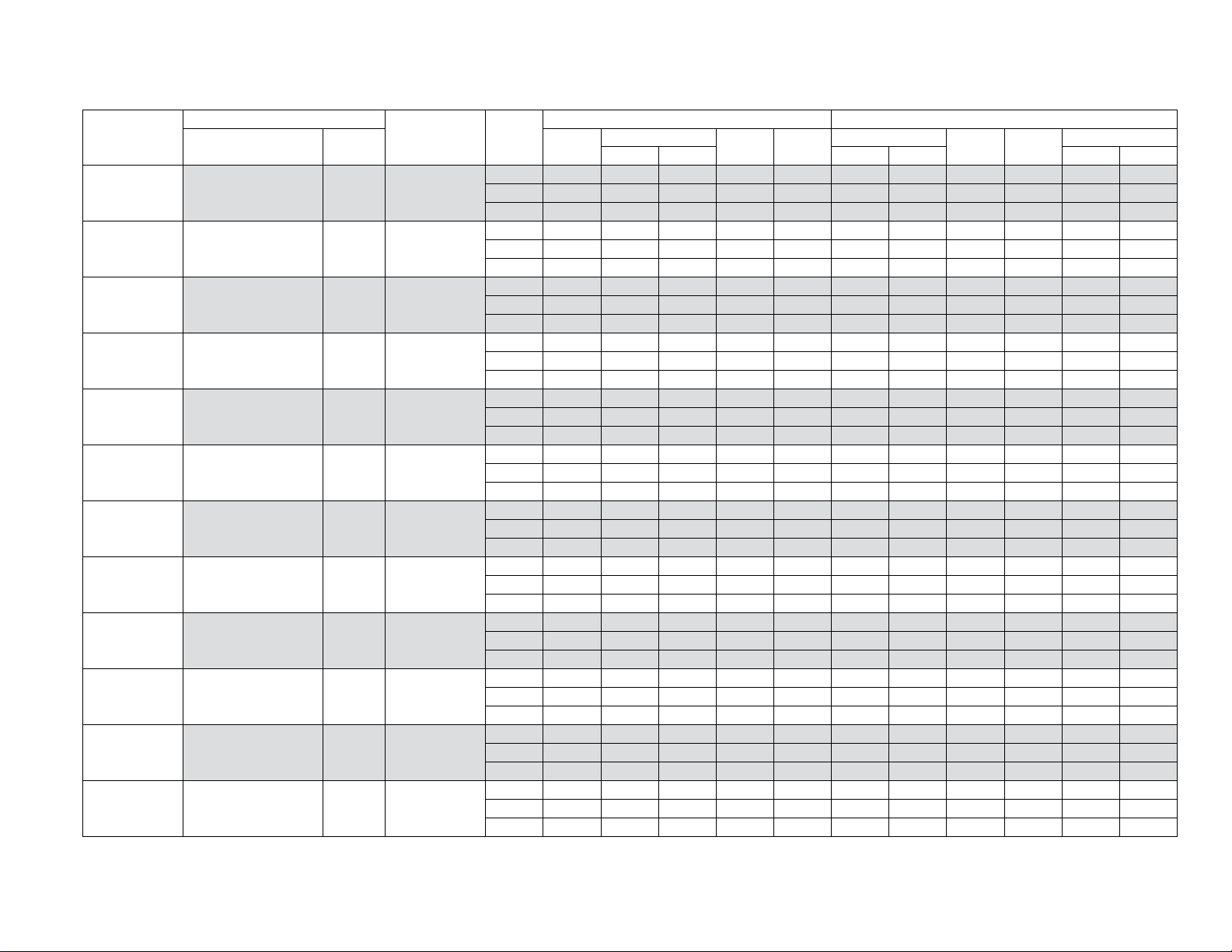

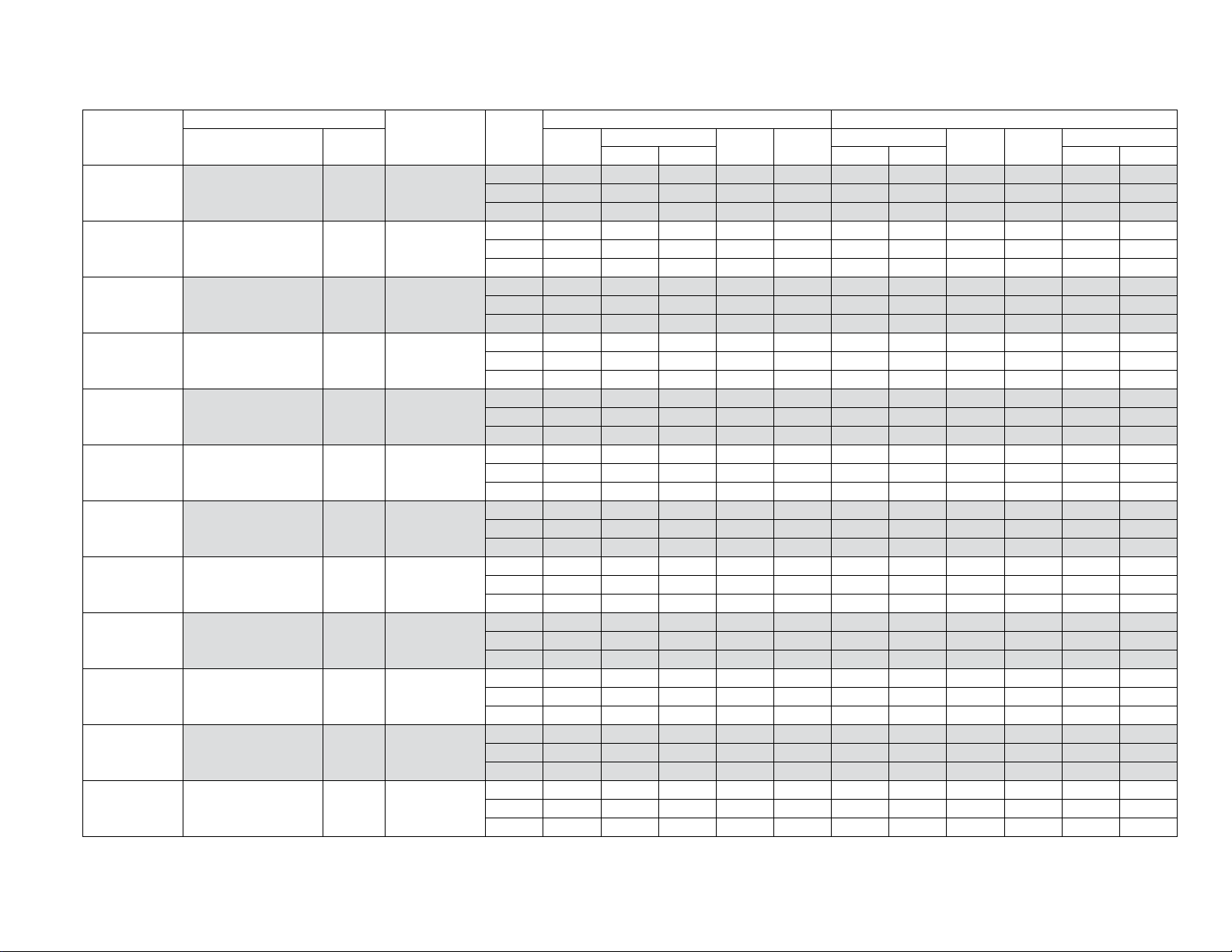

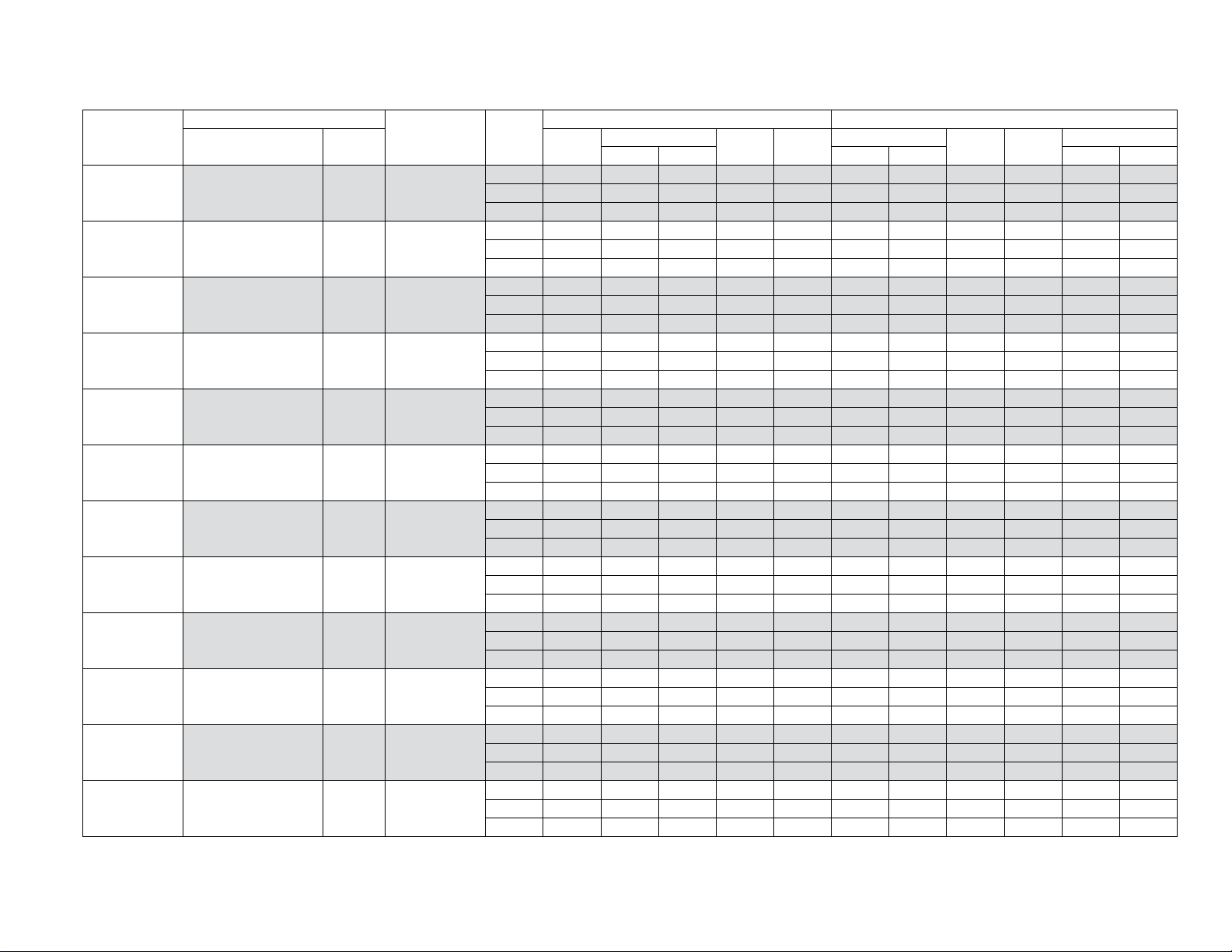

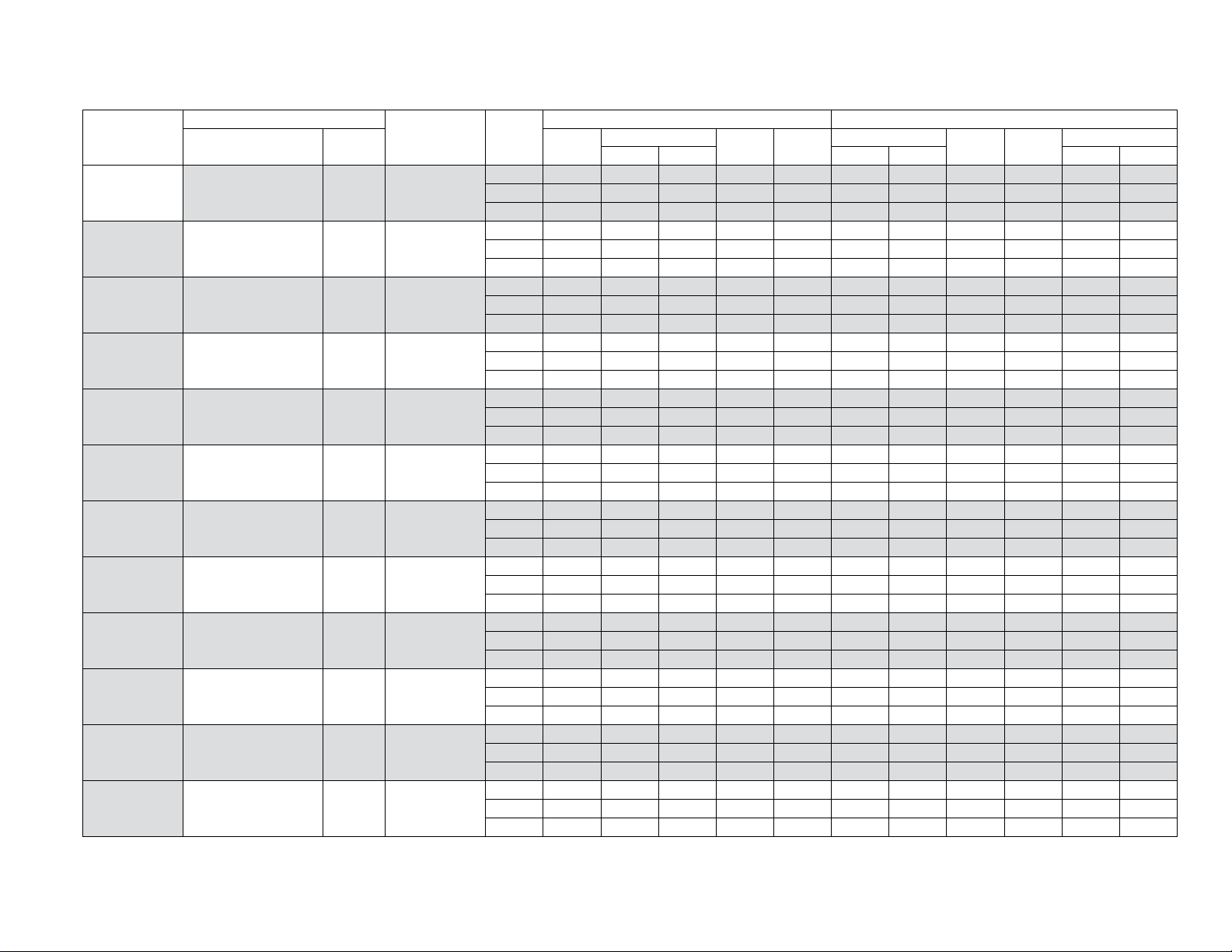

SYSTEM CAPACITY - Single Piece and Modular Air Handlers

UNIT

MODEL

CH16B2421S AE24BBA21 17.5 –

CH16B2421S

CH16B2421S AE30BX21 17.5 –

CH16B2421S AVC24BX21 17.5 –

CH16B2421S AVC30BX21 17.5 –

CH16B2421S AVC36BX21 17.5 –

CH16B2421S AVC36CX21 21.0 –

CH16B2421S ME08BN21 17.5 CF/CM24B

CH16B2421S ME08BN21 17.5 CF/CM30B

CH16B2421S ME08BN21 17.5 CF/CM36B

CH16B2421S ME08BN21 17.5 CM24BBAA1

CH16B2421S MVC08BN21 17.5 CF/CM24B

AIR HANDLER

MODEL WIDTH

COIL

MODEL

AE24BX21 17.5 –

Stage

3

RATED

CFM

High 850 25.2 18.6 17.50 12.30 24.6 15.1 9.30 7.95 3.66 2.64

Med 500 17.8 12.2 – 16.40 – – – – – –

Low 500 15.9 11.4 – 28.60 12.1 – – – 3.92 –

High 850 25.2 18.6 17.50 12.30 24.6 15.1 9.30 7.95 3.66 2.64

Med 500 17.8 12.2 – 16.40 – – – – – –

Low 500 15.9 11.4 – 28.60 12.1 – – – 3.92 –

High 875 24.0 19.2 18.25 12.50 24.0 14.8 9.00 7.45 3.82 2.74

Med 600 18.4 14.5 – 17.45 – – – – – –

Low 600 16.3 13.8 – 31.30 11.9 – – – 4.18 –

High 800 24.0 18.6 18.00 12.25 24.0 14.8 9.00 7.50 3.64 2.64

Med 525 18.0 13.7 – 17.00 – – – – – –

Low 525 16.1 12.7 – 30.55 11.7 – – – 4.00 –

High 900 24.0 19.7 18.00 12.25 24.0 15.1 9.00 7.50 3.70 2.64

Med 525 18.1 13.8 – 17.05 – – – – – –

Low 525 16.1 12.7 – 30.75 11.7 – – – 4.00 –

High 900 24.0 19.7 17.75 12.00 24.0 15.0 9.00 7.45 3.70 2.64

Med 625 18.5 14.8 – 17.05 – – – – – –

Low 625 16.3 14.0 – 29.85 12.0 – – – 4.10 –

High 700 24.0 17.7 17.75 12.25 24.0 14.6 9.00 7.55 3.56 2.64

Med 475 17.6 12.9 – 16.55 – – – – – –

Low 475 15.9 12.2 – 29.45 11.6 – – – 3.86 –

High 925 24.6 19.9 18.25 12.50 24.0 15.0 9.00 7.40 3.82 2.72

Med 650 18.7 15.1 – 17.45 – – – – – –

Low 650 16.4 14.4 – 30.65 12.0 – – – 4.20 –

High 950 25.4 21.2 18.00 12.25 24.2 15.1 9.00 7.45 3.80 2.68

Med 650 18.6 15.2 – 17.25 – – – – – –

Low 650 16.3 14.3 – 30.20 12.1 – – – 4.18 –

High 875 24.0 19.3 18.00 12.25 24.0 15.0 9.00 7.45 3.74 2.68

Med 625 18.5 15.0 – 17.20 – – – – – –

Low 625 16.3 14.0 – 30.10 12.0 – – – 4.14 –

High 925 24.6 19.9 18.25 12.50 24.0 15.0 9.00 7.40 3.82 2.72

Med 650 18.7 15.1 – 17.45 – – – – – –

Low 650 16.4 14.4 – 30.65 12.0 – – – 4.20 –

High 875 24.0 19.2 17.75 12.25 24.0 15.0 9.00 7.45 3.70 2.66

Med 625 18.5 14.8 – 17.15 – – – – – –

Low 625 16.4 14.1 – 30.10 12.0 – – – 4.12 –

COOLING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

1

SEER EER

NET MBH

HEATING

HSPF IV HSPF V

2

COP

6 Johnson Controls Unitary Products

Page 7

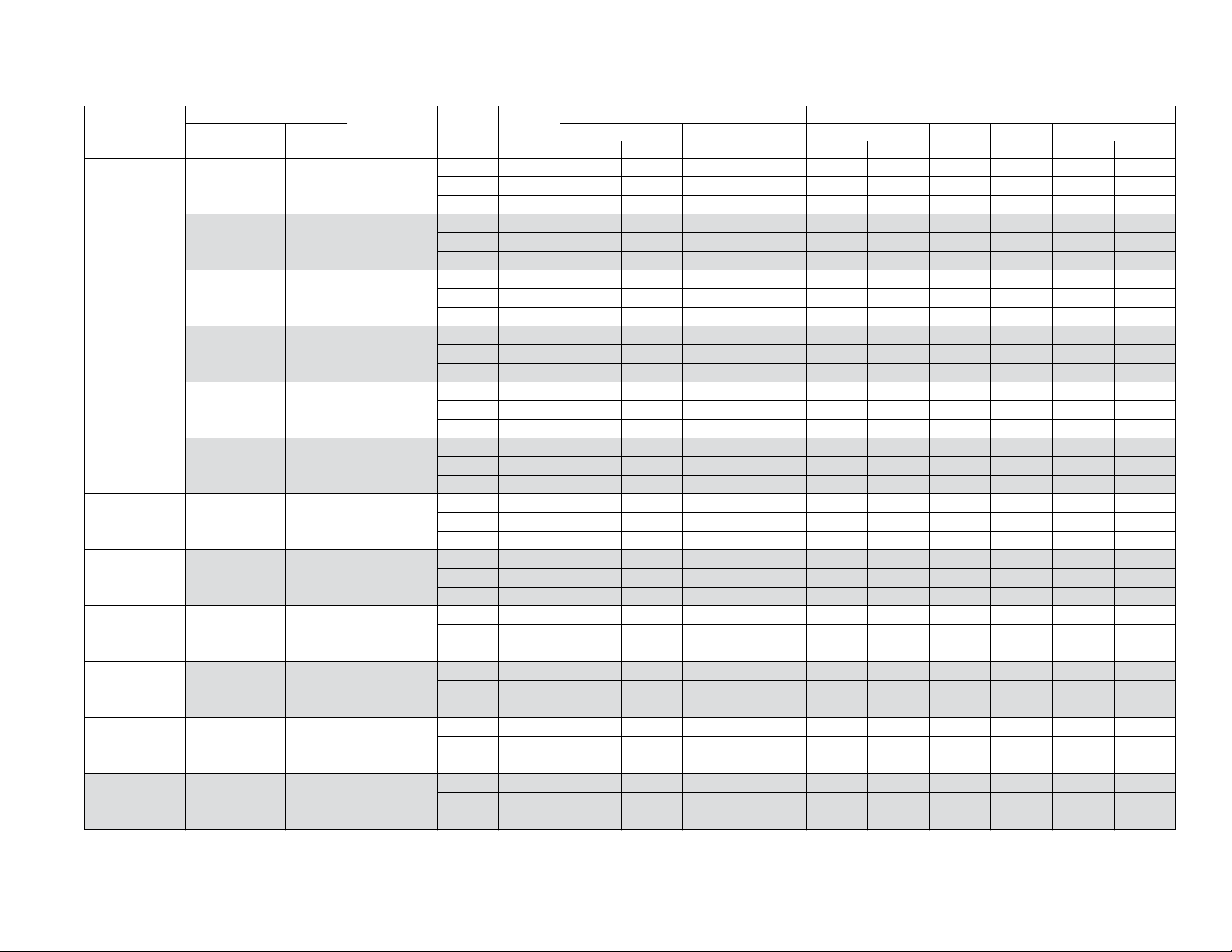

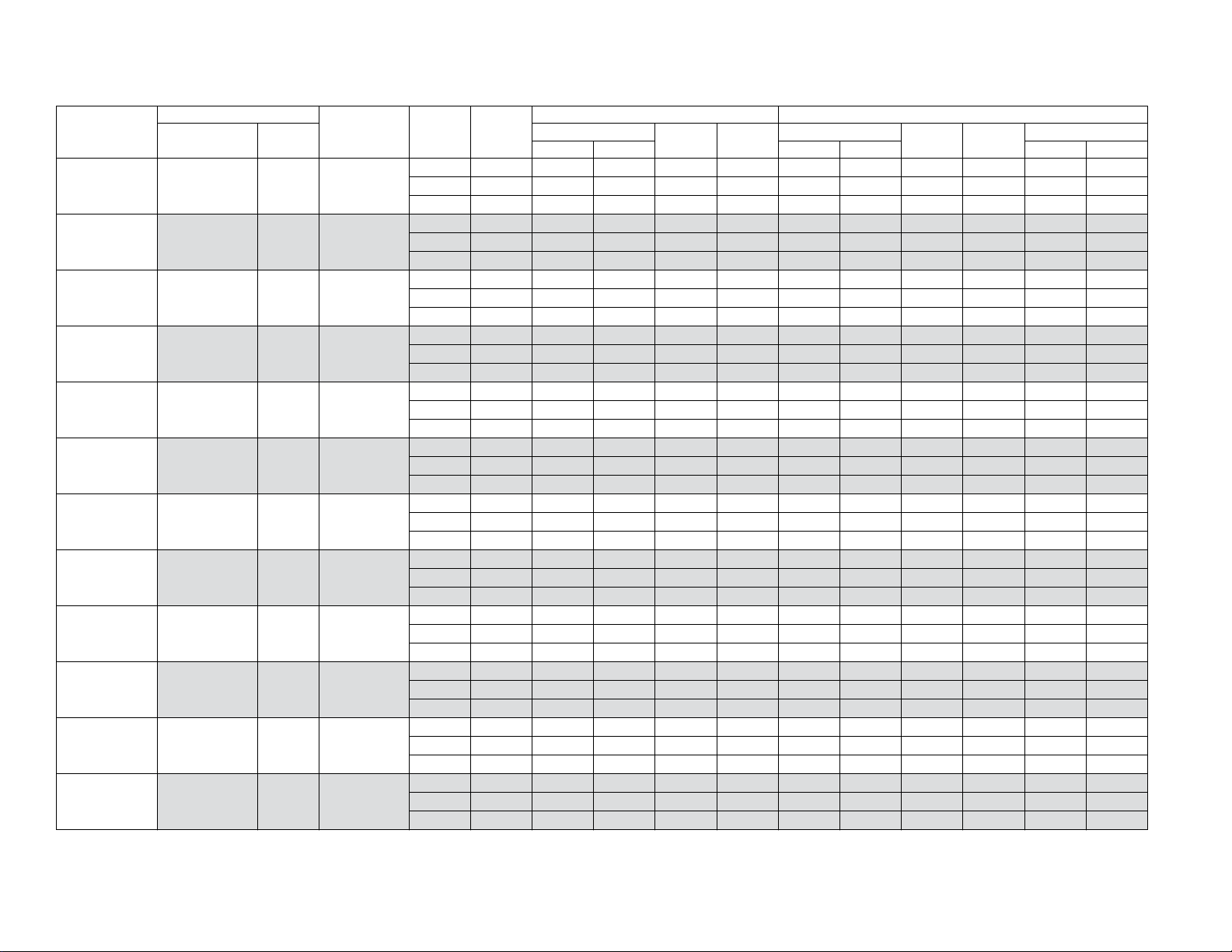

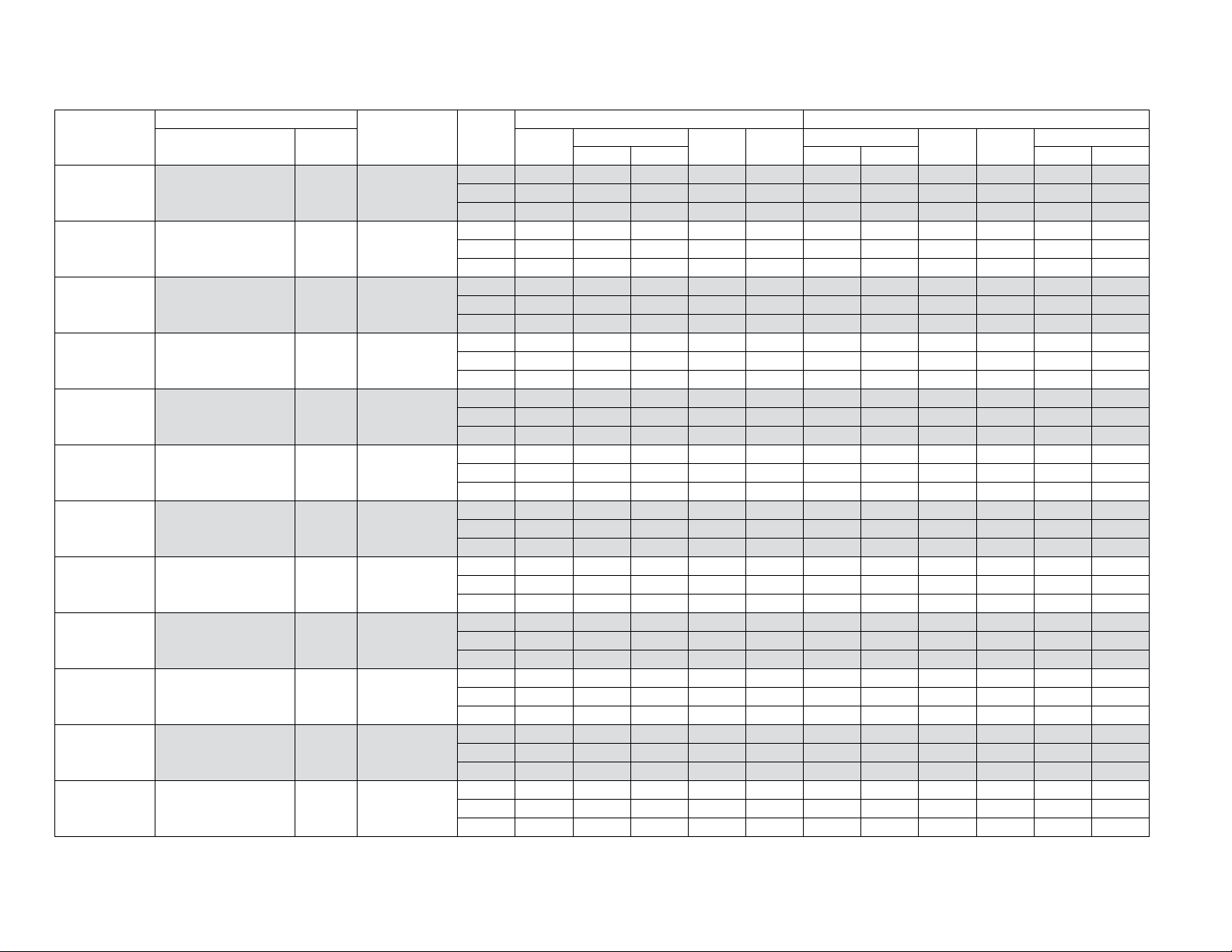

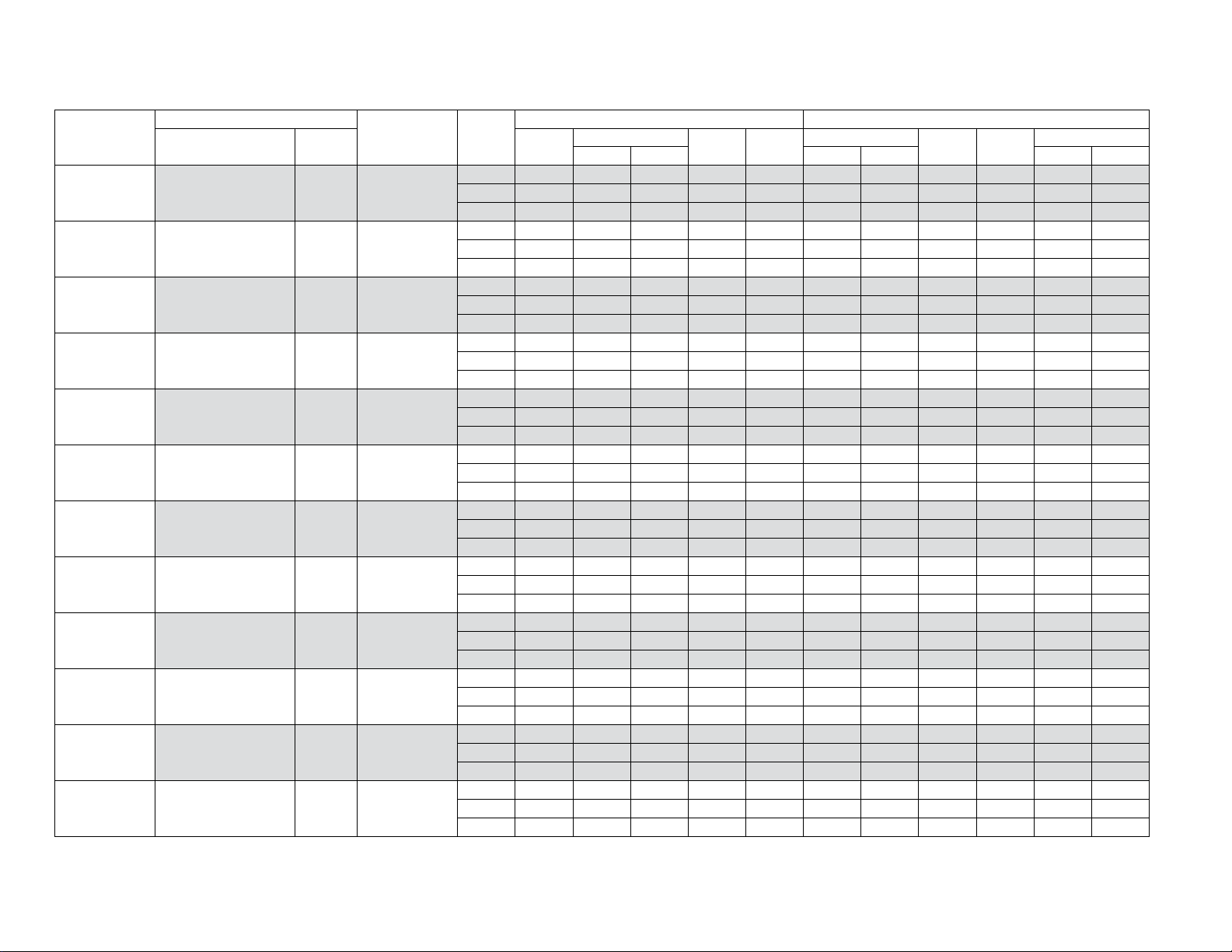

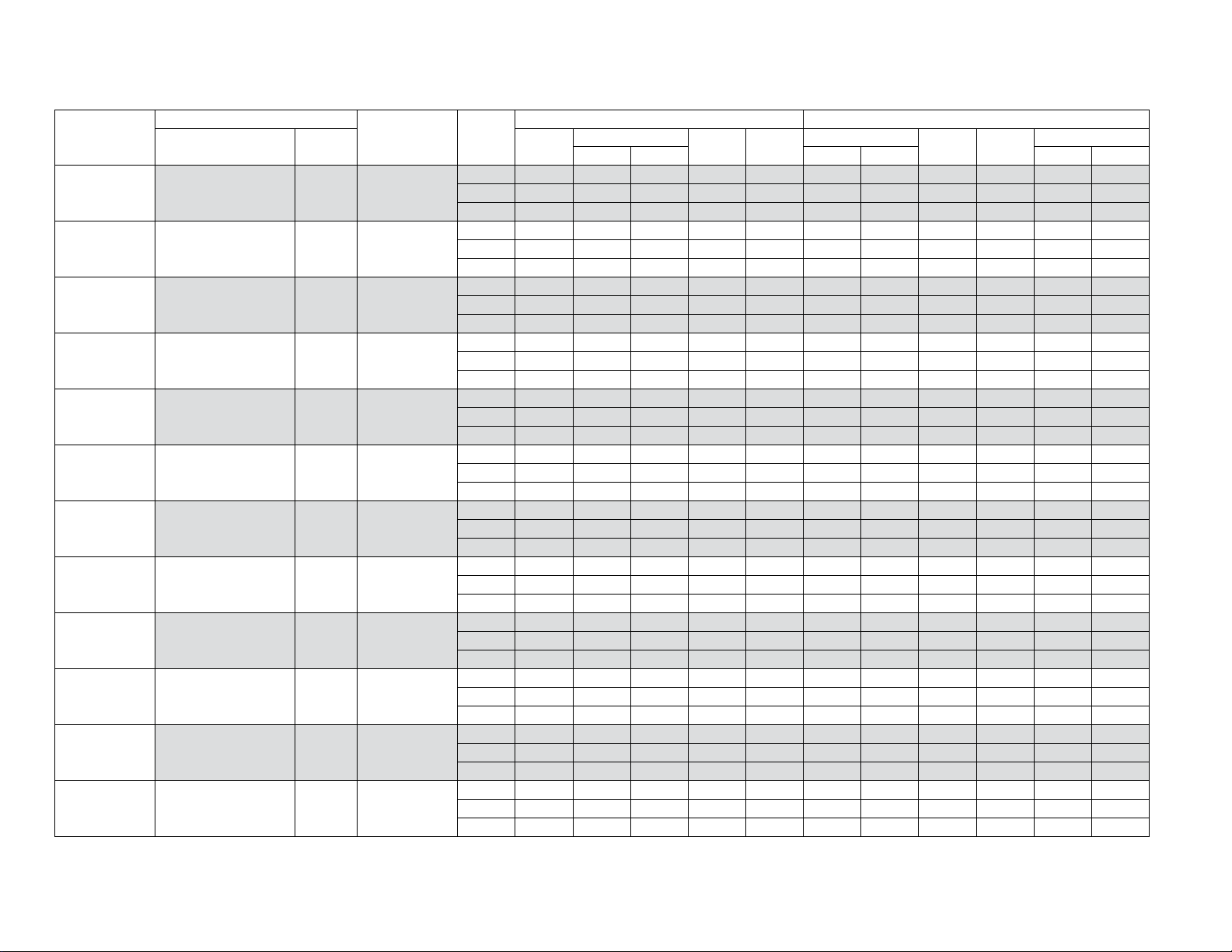

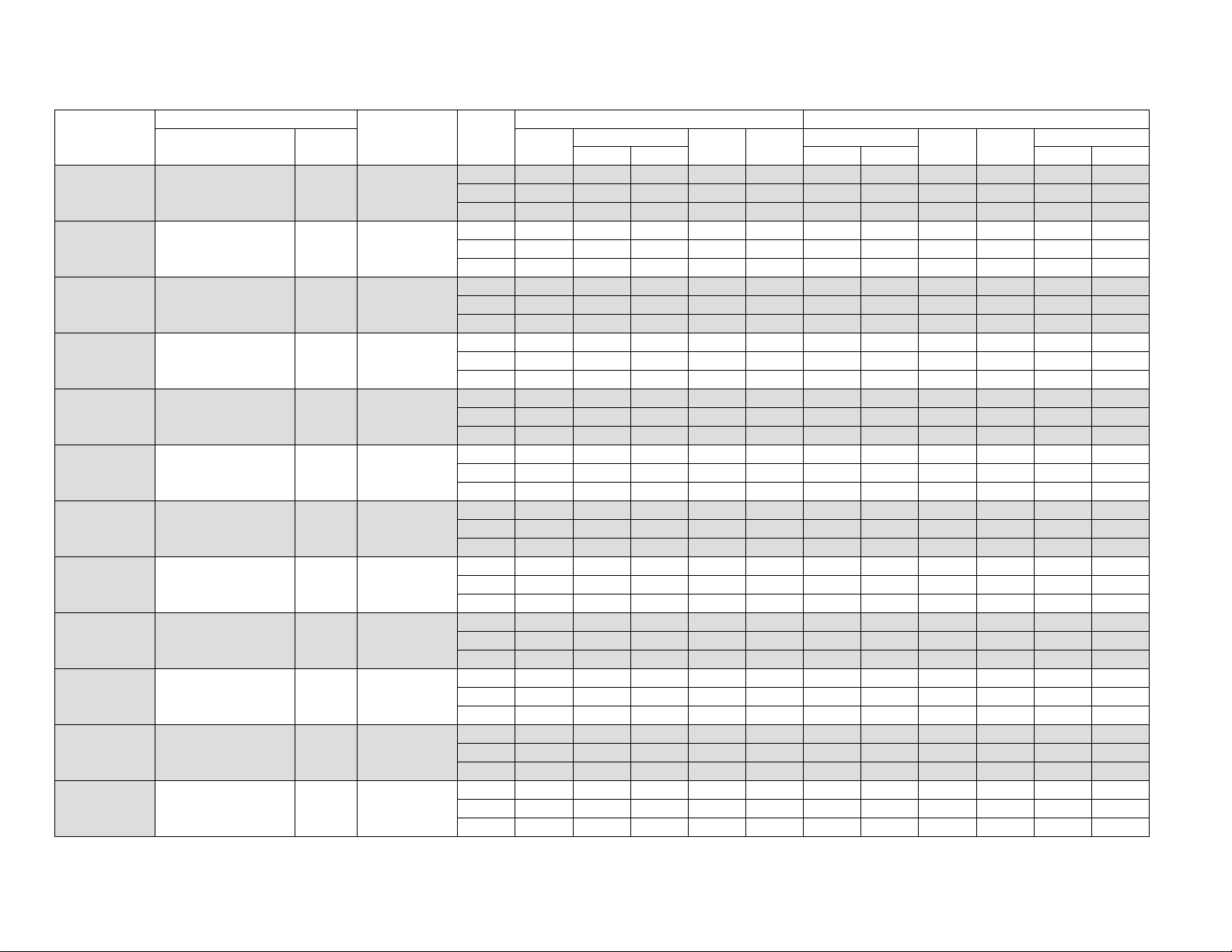

SYSTEM CAPACITY - Single Piece and Modular Air Handlers (Continued)

UNIT

MODEL

CH16B2421S MVC08BN21 17.5 CF/CM30B

CH16B2421S MVC08BN21 17.5 CF/CM36B

CH16B2421S MVC08BN21 17.5 CF24BBAA1

CH16B2421S MVC12BN21 17.5 CF/CM24B

CH16B2421S MVC12BN21 17.5 CF/CM30B

CH16B2421S MVC12BN21 17.5 CF/CM36B

CH16B2421S MVC12BN21 17.5 CF24BBAA1

CH16B2421S MVC14DN21 24.5 CF/CM30D

CH16B2421S MVC14DN21 24.5 CF/CM36D

CH16B2421S MVC16CN21 21.0 CF/CM30C

CH16B2421S MVC16CN21 21.0 CF/CM36C

CH16B3621S AE36BX21 17.5 –

AIR HANDLER

MODEL WIDTH

COIL

MODEL

Stage

3

RATED

CFM

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

High 825 24.0 19.1 17.25 11.75 24.0 15.1 9.00 7.45 3.58 2.60

Med 550 18.1 13.8 – 16.55 – – – – – –

Low 550 16.1 13.0 – 28.70 11.9 – – – 3.94 –

High 850 24.0 19.2 17.25 12.00 24.0 15.0 9.00 7.45 3.64 2.62

Med 600 18.3 14.4 – 16.75 – – – – – –

Low 600 16.2 13.5 – 29.05 12.0 – – – 4.02 –

High 875 24.0 19.2 17.75 12.25 24.0 15.0 9.00 7.45 3.70 2.66

Med 625 18.5 14.8 – 17.15 – – – – – –

Low 625 16.4 14.1 – 30.10 12.0 – – – 4.12 –

High 800 24.0 18.6 17.50 12.00 24.0 14.9 9.00 7.45 3.60 2.62

Med 550 18.1 13.8 – 16.65 – – – – – –

Low 550 16.1 13.0 – 29.10 11.9 – – – 3.96 –

High 875 24.0 19.2 17.00 11.75 24.0 15.3 9.00 7.45 3.58 2.56

Med 650 18.4 15.0 – 16.45 – – – – – –

Low 650 16.3 14.3 – 27.85 12.2 – – – 4.00 –

High 925 24.6 20.0 16.75 10.75 24.6 15.9 8.75 7.20 3.44 2.46

Med 550 18.0 13.8 – 16.10 – – – – – –

Low 550 16.0 12.9 – 27.40 12.0 – – – 3.84 –

High 800 24.0 18.6 17.50 12.00 24.0 14.9 9.00 7.45 3.60 2.62

Med 550 18.1 13.8 – 16.65 – – – – – –

Low 550 16.1 13.0 – 29.10 11.9 – – – 3.96 –

High 950 25.2 21.0 16.25 10.50 25.4 16.1 8.75 7.25 3.38 2.40

Med 550 18.0 13.8 – 16.10 – – – – – –

Low 550 16.0 12.9 – 27.40 12.0 – – – 3.84 –

High 950 25.2 21.0 15.00 10.25 25.4 16.1 8.75 7.20 3.38 2.40

Med 700 18.3 15.5 – 15.25 – – – – – –

Low 700 16.1 14.7 – 24.35 12.5 – – – 3.82 –

High 725 24.0 18.0 17.25 11.75 24.0 14.8 9.00 7.50 3.52 2.60

Med 525 17.9 13.6 – 16.45 – – – – – –

Low 525 16.0 12.6 – 28.75 11.8 – – – 3.90 –

High 900 24.0 19.6 17.25 11.50 24.0 15.3 9.00 7.45 3.60 2.58

Med 625 18.4 14.7 – 16.60 – – – – – –

Low 625 16.2 13.9 – 28.40 12.1 – – – 4.00 –

High 1225 34.8 25.8 16.75 11.25 35.0 22.2 10.00 8.50 3.50 2.72

Med 850 24.6 18.4 – 15.45 – – – – – –

Low 850 22.4 17.2 – 26.90 18.1 – – – 4.12 –

COOLING

SEER EER

5547666-CTG-A-0718

1

NET MBH

HEATING

HSPF IV HSPF V

2

COP

Johnson Controls Unitary Products 7

Page 8

5547666-CTG-A-0718

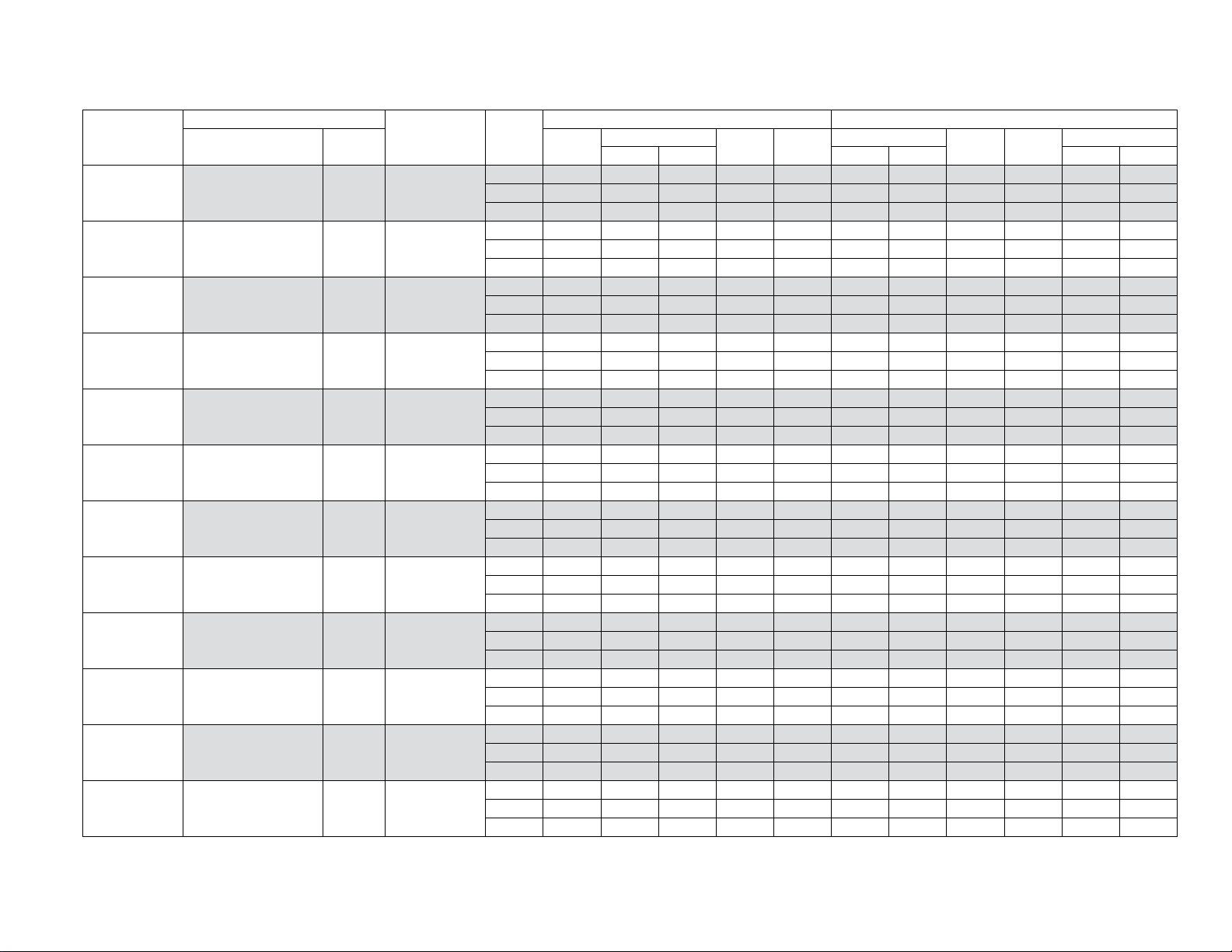

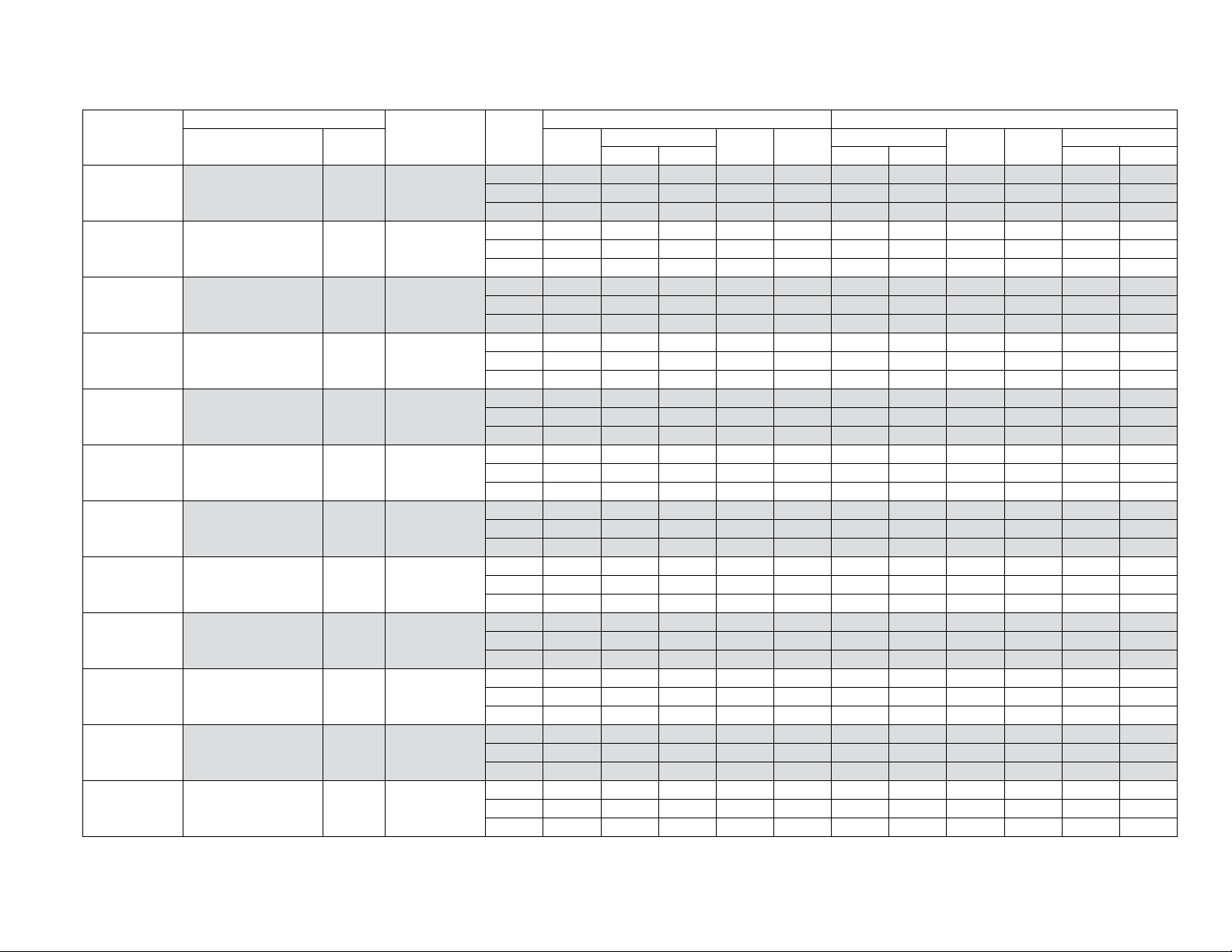

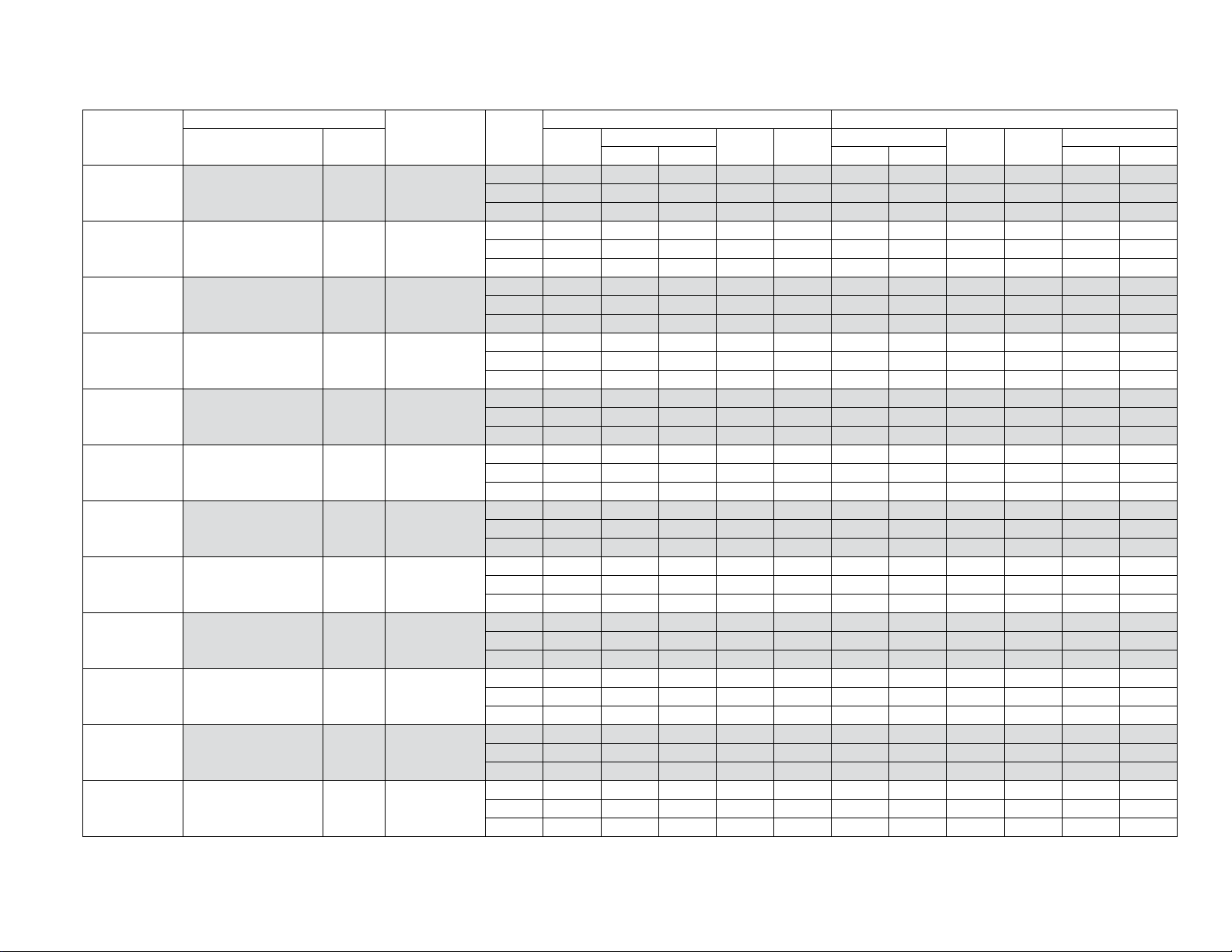

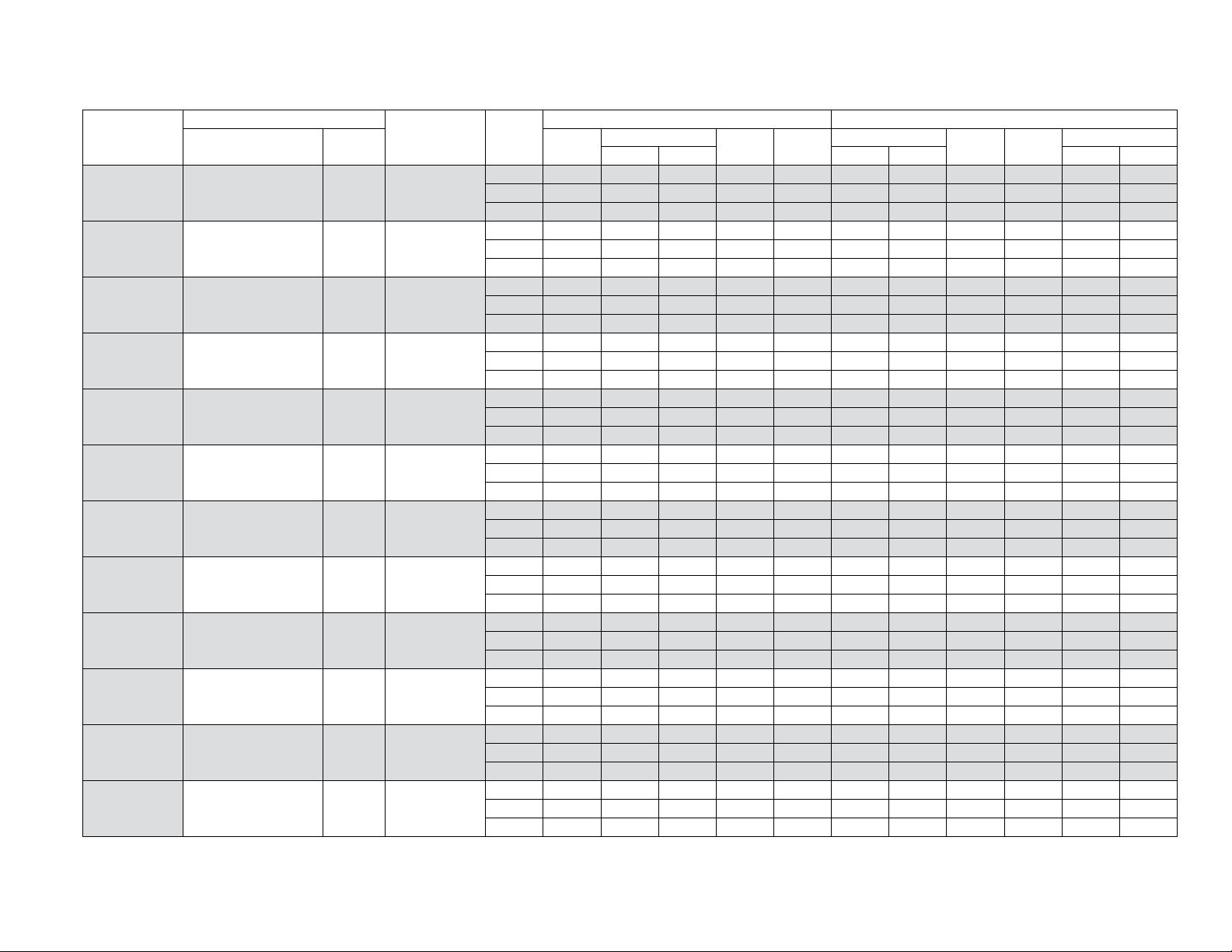

SYSTEM CAPACITY - Single Piece and Modular Air Handlers (Continued)

UNIT

MODEL

CH16B3621S AE36CX21 21.0 –

CH16B3621S AVC36BX21 17.5 –

CH16B3621S AVC36CX21 21.0 –

CH16B3621S AVC42CX21 21.0 –

CH16B3621S AVC48CX21 21.0 –

CH16B3621S AVC48DX21 24.5 –

CH16B3621S ME12BN21 17.5 CF/CM36B

CH16B3621S ME12BN21 17.5 CF36BBCA1

CH16B3621S ME12BN21 17.5 CF42B

CH16B3621S ME14DN21 24.5 CF/CM36D

CH16B3621S ME14DN21 24.5 CF/CM42D

CH16B3621S ME14DN21 24.5 CF/CM48D

AIR HANDLER

MODEL WIDTH

COIL

MODEL

Stage

3

RATED

CFM

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

High 1275 34.8 28.8 16.50 10.50 35.2 22.6 9.50 8.00 3.54 2.66

Med 750 24.6 18.9 – 15.30 – – – – – –

Low 750 22.2 18.0 – 27.55 18.1 – – – 4.14 –

High 1000 34.0 25.6 16.75 10.75 35.0 22.2 9.50 7.70 3.42 2.70

Med 675 23.8 17.8 – 15.25 – – – – – –

Low 675 21.8 16.9 – 28.80 18.1 – – – 4.04 –

High 1175 34.8 27.8 16.75 11.00 35.0 22.2 9.75 8.00 3.56 2.72

Med 825 24.6 19.9 – 15.65 – – – – – –

Low 825 22.4 19.0 – 27.85 18.2 – – – 4.22 –

High 1325 35.4 29.8 16.75 10.75 34.8 22.6 9.75 7.95 3.62 2.70

Med 825 24.6 19.8 – 15.70 – – – – – –

Low 825 22.4 19.0 – 27.60 18.1 – – – 4.26 –

High 1275 35.2 29.2 17.00 11.00 34.8 22.4 9.75 8.20 3.66 2.74

Med 825 24.8 20.0 – 15.75 – – – – – –

Low 825 22.4 19.0 – 27.70 18.1 – – – 4.26 –

High 1225 35.0 28.4 17.25 11.25 34.6 22.2 9.75 7.90 3.68 2.78

Med 800 24.6 19.6 – 15.80 – – – – – –

Low 800 22.4 18.7 – 28.25 18.0 – – – 4.28 –

High 1050 34.0 26.2 16.25 10.75 35.0 22.2 9.50 7.75 3.46 2.70

Med 875 24.6 20.4 – 15.45 – – – – – –

Low 875 22.6 19.7 – 26.90 18.4 – – – 4.16 –

High 1050 34.0 26.2 16.25 10.75 35.0 22.2 9.50 7.75 3.46 2.70

Med 875 24.6 20.4 – 15.45 – – – – – –

Low 875 22.6 19.7 – 26.90 18.4 – – – 4.16 –

High 1050 34.4 26.2 16.25 11.00 34.8 22.2 9.75 7.95 3.52 2.72

Med 875 24.8 20.6 – 15.65 – – – – – –

Low 875 22.4 19.6 – 26.85 18.3 – – – 4.20 –

High 1000 34.0 25.6 16.50 10.75 35.0 22.2 9.00 7.60 3.42 2.70

Med 700 24.0 18.0 – 15.25 – – – – – –

Low 700 21.8 17.2 – 28.60 18.1 – – – 4.04 –

High 975 33.8 25.2 16.50 10.75 34.6 22.0 9.00 7.55 3.48 2.72

Med 675 24.2 17.9 – 15.45 – – – – – –

Low 675 21.8 16.9 – 28.90 17.9 – – – 4.10 –

High 1025 34.2 25.8 17.00 11.25 34.4 22.0 9.75 7.85 3.58 2.78

Med 900 25.0 21.0 – 16.05 – – – – – –

Low 900 22.6 20.0 – 28.05 18.2 – – – 4.34 –

COOLING

SEER EER

1

NET MBH

HEATING

HSPF IV HSPF V

2

COP

8 Johnson Controls Unitary Products

Page 9

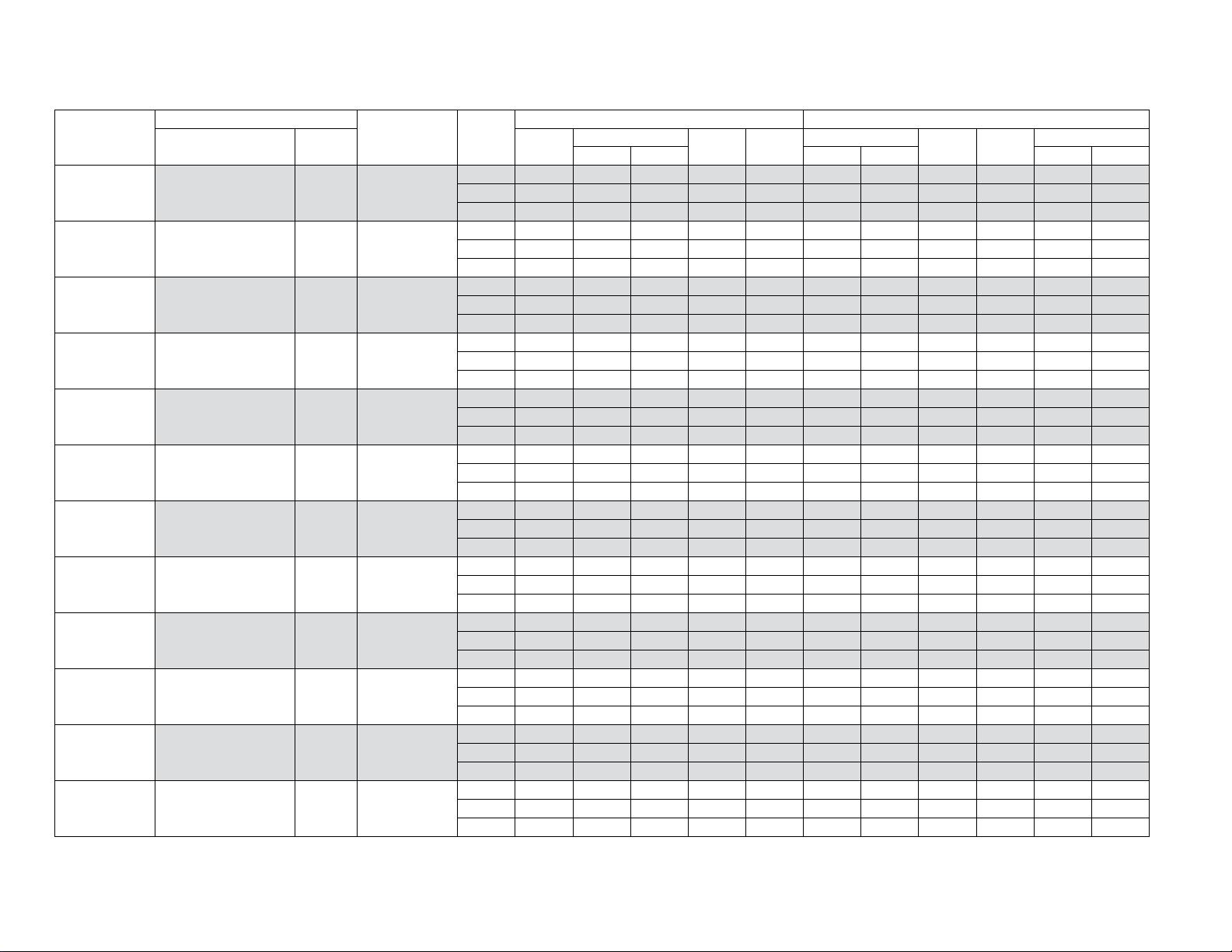

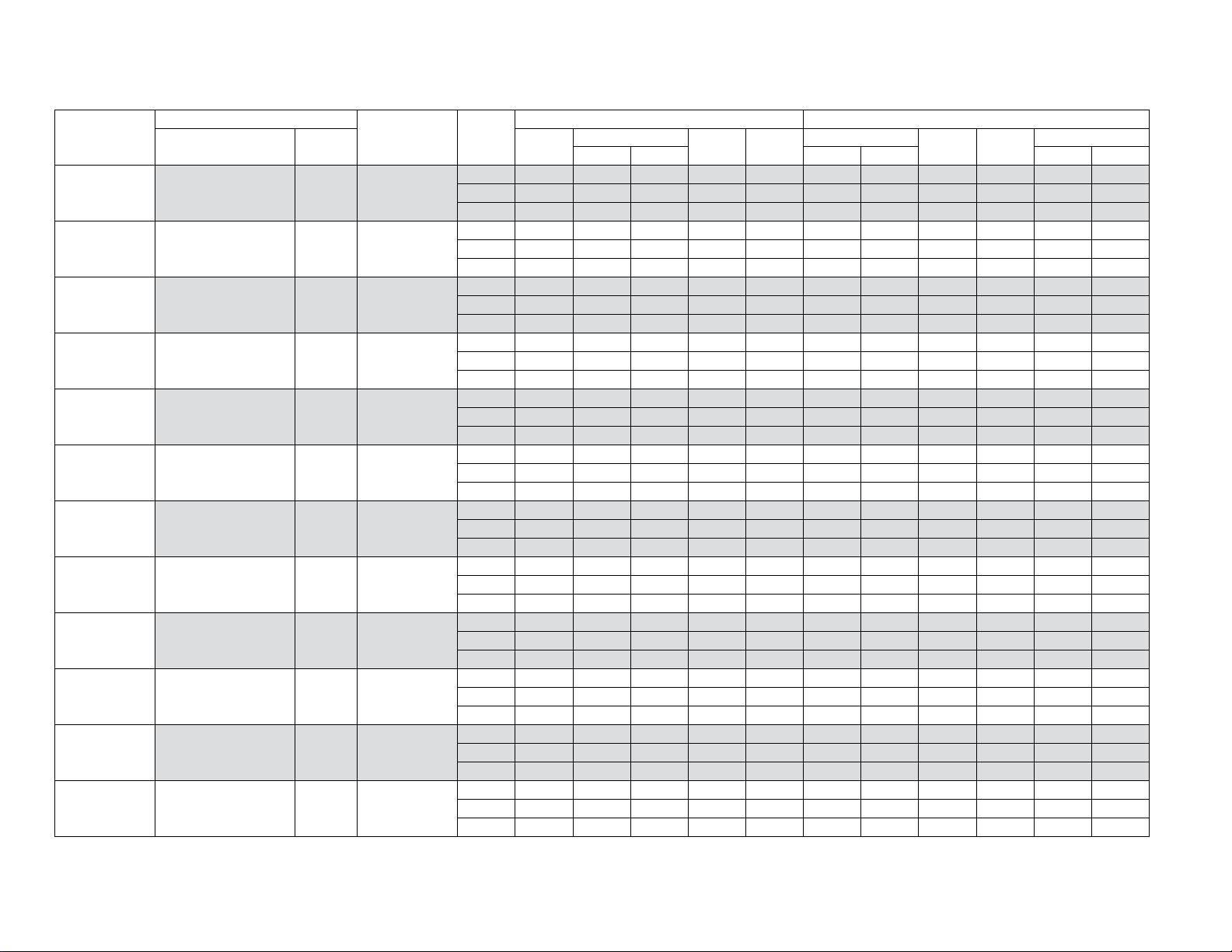

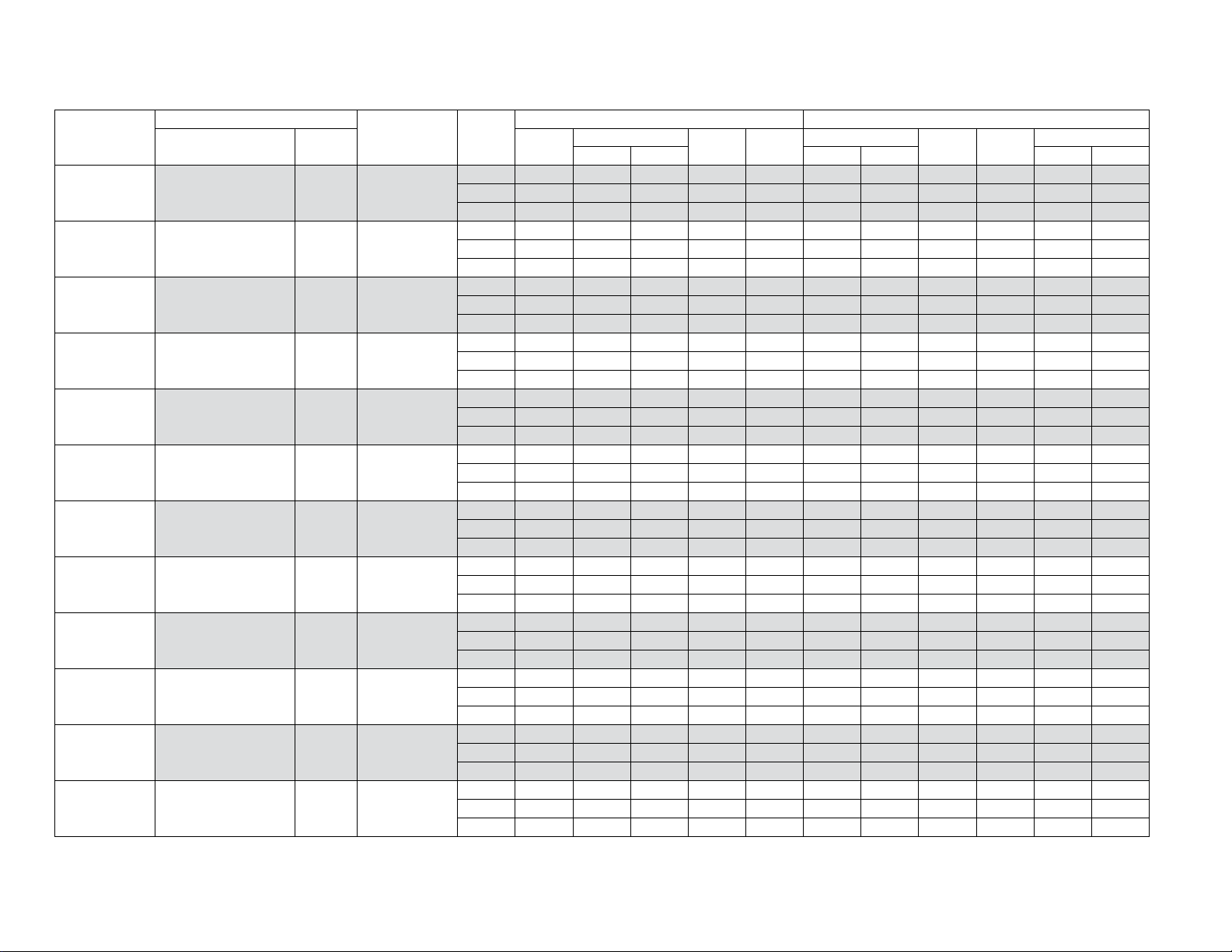

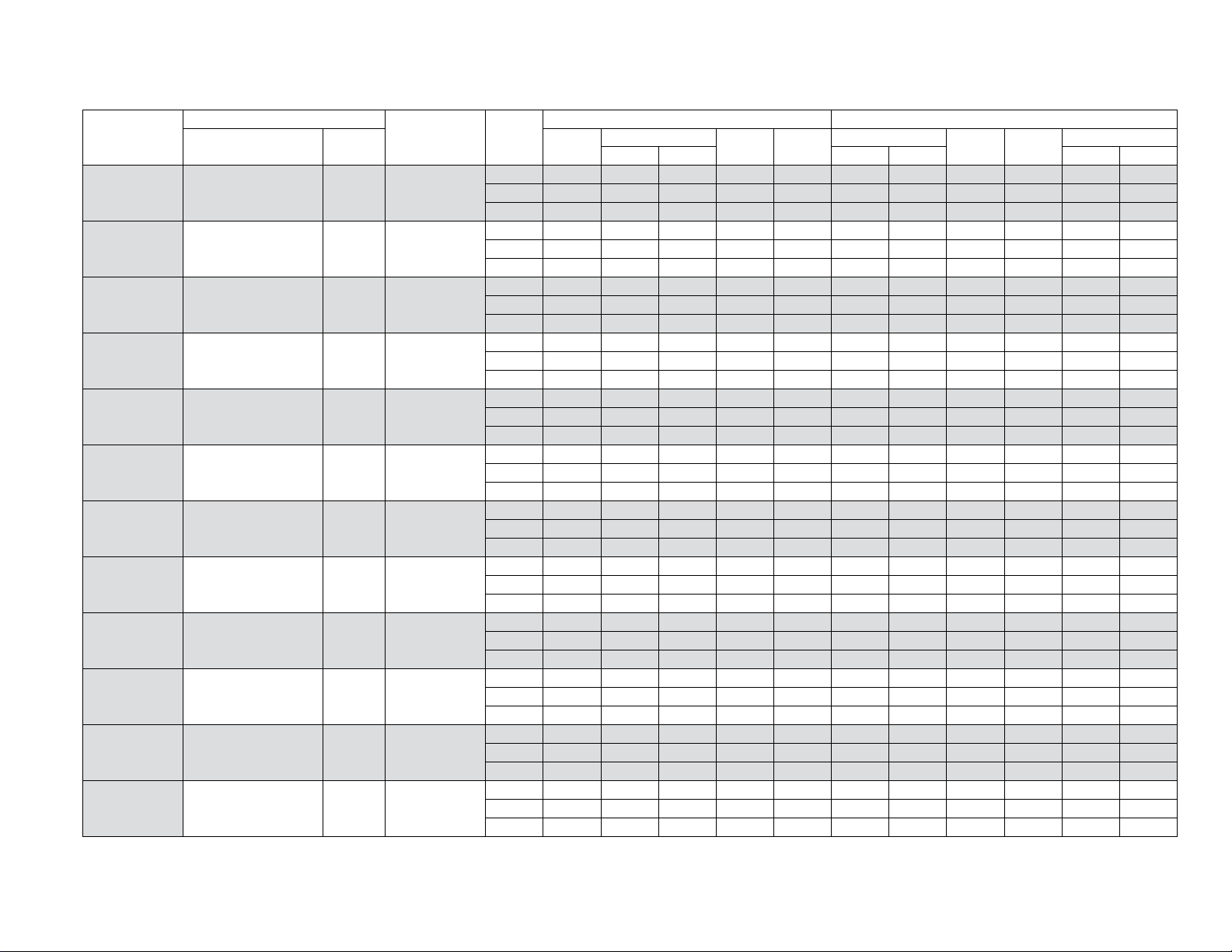

SYSTEM CAPACITY - Single Piece and Modular Air Handlers (Continued)

UNIT

MODEL

CH16B3621S MVC12BN21 17.5 CF42B

CH16B3621S MVC14DN21 24.5 CF/CM42D

CH16B3621S MVC14DN21 24.5 CF/CM48D

CH16B3621S MVC16CN21 21.0 CF/CM36C

CH16B3621S MVC16CN21 21.0 CF/CM42C

CH16B3621S MVC16CN21 21.0 CF42CBCA1

CH16B3621S MVC20DN21 24.5 CF/CM36D

CH16B3621S MVC20DN21 24.5 CF/CM42D

CH16B3621S MVC20DN21 24.5 CF/CM48D

CH16B4821S AE48CBC21 21.0 –

CH16B4821S AE48CX21 21.0 –

CH16B4821S AE48DBC21 24.5 –

AIR HANDLER

MODEL WIDTH

COIL

MODEL

Stage

3

RATED

CFM

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

High 975 34.0 25.0 16.50 11.00 34.6 22.0 9.50 6.75 3.46 2.72

Med 675 24.2 17.8 – 15.55 – – – – – –

Low 675 21.8 16.9 – 28.95 18.0 – – – 4.08 –

High 1325 35.4 29.8 17.00 11.25 35.0 22.2 9.75 7.90 3.64 2.76

Med 850 25.0 20.4 – 16.15 – – – – – –

Low 850 22.6 19.4 – 28.70 17.9 – – – 4.30 –

High 1100 35.0 27.0 17.00 11.50 34.6 21.8 9.75 7.90 3.60 2.80

Med 725 24.6 18.6 – 15.55 – – – – – –

Low 725 22.0 17.6 – 30.40 17.7 – – – 4.20 –

High 1025 34.2 25.8 16.75 11.00 35.0 22.0 9.50 7.60 3.44 2.74

Med 700 24.2 18.3 – 15.50 – – – – – –

Low 700 22.0 17.4 – 29.45 17.9 – – – 4.08 –

High 1025 34.4 26.0 16.75 11.25 34.8 21.8 9.75 8.05 3.50 2.76

Med 700 24.4 18.2 – 15.60 – – – – – –

Low 700 21.8 17.2 – 29.50 17.8 – – – 4.12 –

High 1025 34.4 26.0 16.75 11.25 34.8 21.8 9.75 8.05 3.50 2.76

Med 700 24.4 18.2 – 15.60 – – – – – –

Low 700 21.8 17.2 – 29.50 17.8 – – – 4.12 –

High 1275 35.4 29.4 17.00 11.25 35.0 22.0 9.75 7.85 3.44 2.72

Med 875 24.8 20.6 – 16.00 – – – – – –

Low 875 22.6 19.7 – 28.60 18.0 – – – 4.28 –

High 1300 35.4 29.6 17.25 11.25 34.8 22.0 9.75 7.80 3.64 2.78

Med 900 25.0 21.0 – 16.25 – – – – – –

Low 900 22.6 20.0 – 28.65 18.0 – – – 4.34 –

High 1300 35.6 29.6 17.00 11.50 34.6 22.0 9.75 7.75 3.68 2.80

Med 900 25.0 21.0 – 16.20 – – – – – –

Low 900 22.8 20.2 – 28.65 17.9 – – – 4.36 –

High 1425 47.0 31.8 16.70 10.20 47.0 28.4 9.70 8.10 3.22 2.56

Med 1050 33.4 23.2 – 15.30 – – – – – –

Low 1075 28.0 21.6 – 27.00 22.2 – – – 4.20 –

High 1425 47.0 31.8 16.70 10.20 47.0 28.4 9.70 8.10 3.22 2.56

Med 1050 33.4 23.2 – 15.30 – – – – – –

Low 1075 28.0 21.6 – 27.00 22.2 – – – 4.20 –

High 1675 47.0 35.8 17.00 9.75 48.0 28.2 9.50 7.70 3.16 2.54

Med 1125 33.8 27.4 – 15.85 – – – – – –

Low 1125 28.2 24.6 – 28.60 22.2 – – – 4.36 –

COOLING

SEER EER

5547666-CTG-A-0718

1

NET MBH

HEATING

HSPF IV HSPF V

2

COP

Johnson Controls Unitary Products 9

Page 10

5547666-CTG-A-0718

SYSTEM CAPACITY - Single Piece and Modular Air Handlers (Continued)

UNIT

MODEL

CH16B4821S AE48DX21 24.5 –

CH16B4821S AVC48CX21 21.0 –

CH16B4821S AVC48DX21 24.5 –

CH16B4821S AVC60CX21 21.0 –

CH16B4821S AVC60DX21 24.5 –

CH16B4821S ME14DN21 24.5 CF/CM64D

CH16B4821S MVC14DN21 24.5 CF/CM48D

CH16B4821S MVC16CN21 21.0 CF/CM48C

CH16B4821S MVC16CN21 21.0 CF/CM60C

CH16B4821S MVC16CN21 21.0 CF48CBCA1

CH16B4821S MVC20DN21 24.5 CF/CM48D

CH16B4821S MVC20DN21 24.5 CF/CM60D

AIR HANDLER

MODEL WIDTH

COIL

MODEL

Stage

3

RATED

CFM

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

High 1675 47.0 35.8 17.00 9.75 48.0 28.2 9.50 7.70 3.16 2.54

Med 1125 33.8 27.4 – 15.85 – – – – – –

Low 1125 28.2 24.6 – 28.60 22.2 – – – 4.36 –

High 1275 46.5 33.4 16.50 9.75 48.0 27.6 9.25 7.55 3.12 2.54

Med 850 32.4 23.2 – 15.35 – – – – – –

Low 850 27.4 21.2 – 28.15 21.8 – – – 4.10 –

High 1425 47.5 35.4 16.75 10.00 48.0 28.2 9.50 7.80 3.28 2.62

Med 925 33.0 24.4 – 15.70 – – – – – –

Low 925 27.6 22.2 – 28.55 22.4 – – – 4.36 –

High 1275 47.0 33.6 16.25 9.75 47.5 28.2 9.25 7.55 3.16 2.56

Med 850 32.4 23.2 – 15.25 – – – – – –

Low 850 27.2 21.2 – 27.20 22.0 – – – 4.18 –

High 1400 48.0 35.6 17.00 10.00 46.5 29.4 10.00 8.35 3.40 2.76

Med 1075 34.0 26.6 – 16.10 – – – – – –

Low 1075 27.8 24.2 – 28.35 21.2 – – – 4.44 –

High 1375 48.0 35.4 17.00 10.00 46.0 29.0 10.00 8.40 3.36 2.76

Med 925 33.2 24.6 – 15.95 – – – – – –

Low 925 27.4 22.2 – 28.65 20.6 – – – 4.24 –

High 1450 48.0 36.2 16.75 10.00 47.5 28.0 9.50 7.35 3.26 2.62

Med 900 32.8 24.0 – 15.75 – – – – – –

Low 900 27.6 22.0 – 28.75 21.8 – – – 4.22 –

High 1400 47.5 35.2 16.75 10.00 47.5 28.0 9.50 7.50 3.22 2.60

Med 900 32.8 24.0 – 15.55 – – – – – –

Low 900 27.4 21.8 – 28.10 22.0 – – – 4.18 –

High 1400 48.0 35.8 16.50 10.00 47.0 28.2 9.50 7.35 3.26 2.64

Med 900 32.8 24.0 – 15.55 – – – – – –

Low 900 27.4 21.8 – 28.15 21.6 – – – 4.18 –

High 1400 47.5 35.2 16.75 10.00 47.5 28.0 9.50 7.50 3.22 2.60

Med 900 32.8 24.0 – 15.55 – – – – – –

Low 900 27.4 21.8 – 28.10 22.0 – – – 4.18 –

High 1550 46.5 34.4 17.00 9.75 48.0 27.8 9.50 7.40 3.14 2.54

Med 1025 33.4 25.6 – 15.85 – – – – – –

Low 1025 28.0 23.4 – 28.80 22.0 – – – 4.32 –

High 1375 48.0 35.4 17.00 10.25 47.0 28.2 9.50 7.50 3.30 2.66

Med 950 33.2 24.6 – 15.80 – – – – – –

Low 950 27.4 22.4 – 28.70 21.6 – – – 4.26 –

COOLING

SEER EER

1

NET MBH

HEATING

HSPF IV HSPF V

2

COP

10 Johnson Controls Unitary Products

Page 11

5547666-CTG-A-0718

SYSTEM CAPACITY - Single Piece and Modular Air Handlers (Continued)

UNIT

MODEL

AIR HANDLER

MODEL WIDTH

COIL

MODEL

Stage

3

RATED

CFM

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

COOLING

1

SEER EER

NET MBH

HEATING

HSPF IV HSPF V

High 1550 48.0 37.2 17.00 10.25 46.5 29.8 10.00 8.00 3.50 2.82

CH16B4821S MVC20DN21 24.5 CF/CM64D

Med 1025 33.6 25.8 – 15.95 – – – – – –

Low 1025 27.6 23.4 – 28.50 20.8 – – – 4.30 –

High 1850 56.0 39.0 16.00 9.90 59.0 33.2 9.10 7.95 3.34 2.60

CH16B6021S AE60DBG21 24.5 –

Med 1175 38.0 27.0 – 14.85 – – – – – –

Low 1150 31.2 23.8 – 25.50 25.6 – – – 4.14 –

High 1850 56.0 39.0 16.00 9.90 59.0 33.2 9.10 7.95 3.34 2.60

CH16B6021S AE60DX21 24.5 –

Med 1175 38.0 27.0 – 14.85 – – – – – –

Low 1150 31.2 23.8 – 25.50 25.6 – – – 4.14 –

High 1400 55.5 39.0 16.25 10.00 58.5 32.0 9.25 7.60 3.40 2.74

CH16B6021S AVC60DX21 24.5 –

Med 1075 36.6 27.8 – 15.00 – – – – – –

Low 1075 31.2 25.4 – 27.35 25.4 – – – 4.28 –

High 1775 57.5 44.0 16.25 10.25 58.5 32.6 9.50 7.80 3.60 2.74

CH16B6021S MVC20DN21 24.5 CF/CM64D

Med 1125 37.8 29.2 – 15.25 – – – – – –

Low 1125 31.2 26.4 – 27.10 25.2 – – – 4.28 –

Rated in accordance with DOE test procedures (Federal Register 12-27-79 and 3-18-88) and ANSI/AHRI Standard 210/240.

1. Cooling MBH based on 80°F entering air temperature, 50% RH (Relative Humidity), and rated air flow.

EER (Energy Efficiency Ratio) is the total cooling output in BTUs at 95°F outdoor ambient divided by the total electric power in watt-hours at those conditions.

SEER (Seasonal Energy Efficiency Ratio) is the total cooling output in BTUs during a normal annual usage period for cooling divided by the total electric power input in watt-hours during the same period.

2. Heating MBH based on AHRI standards of 70°F DB (Dry Bulb) entering indoor air, 72% RH (Relative Humidity) outdoor air with 25 feet of interconnecting piping and no supplemental electric heat operation.

HSPF (Heating Seasonal Performance Factor) is the total heating output during a normal annual usage period for heating divided by the total electric power input during the same period.

COP (Coefficient of Performance) equals Heating MBH output divided by (total KW input x 3.412).

— = Not applicable.

CM coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2

COP

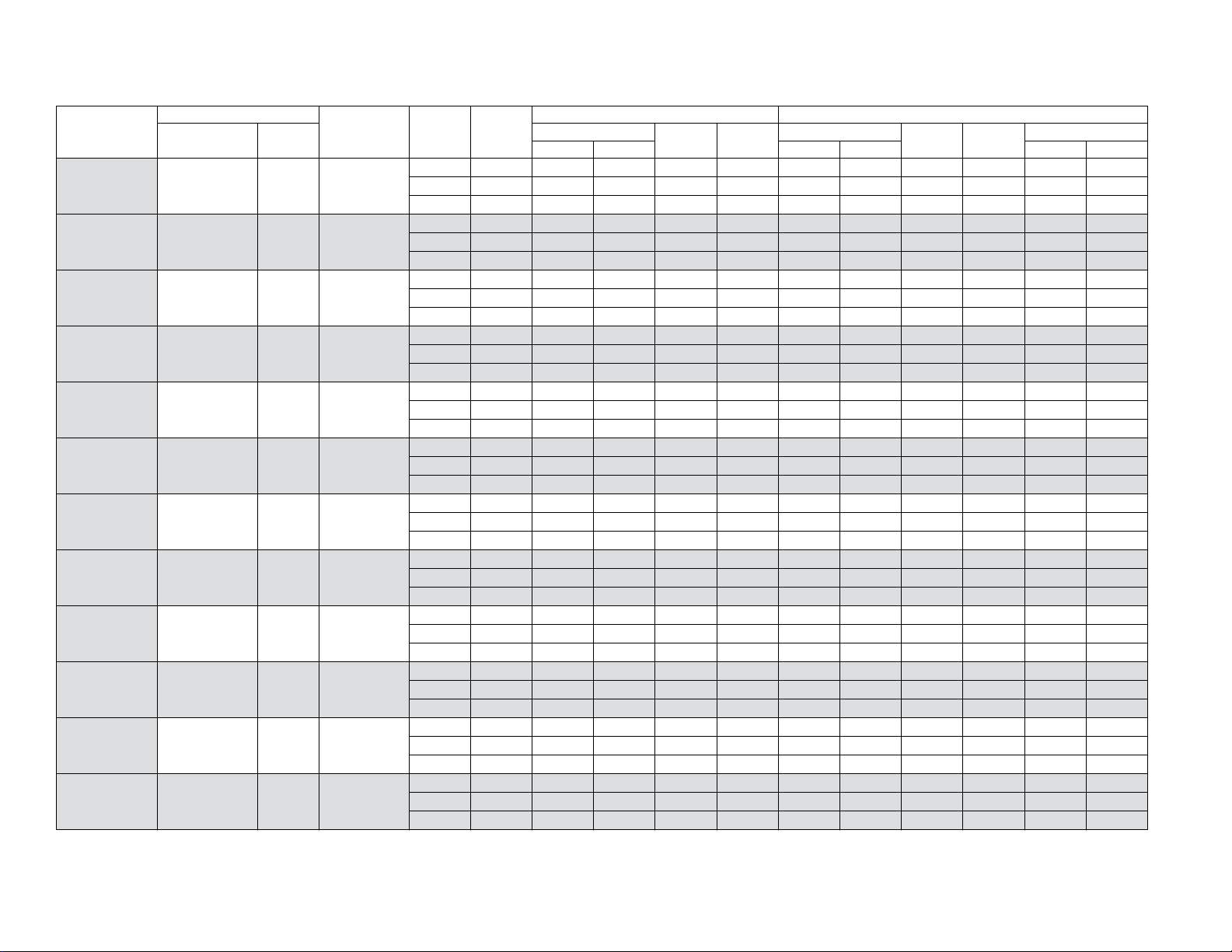

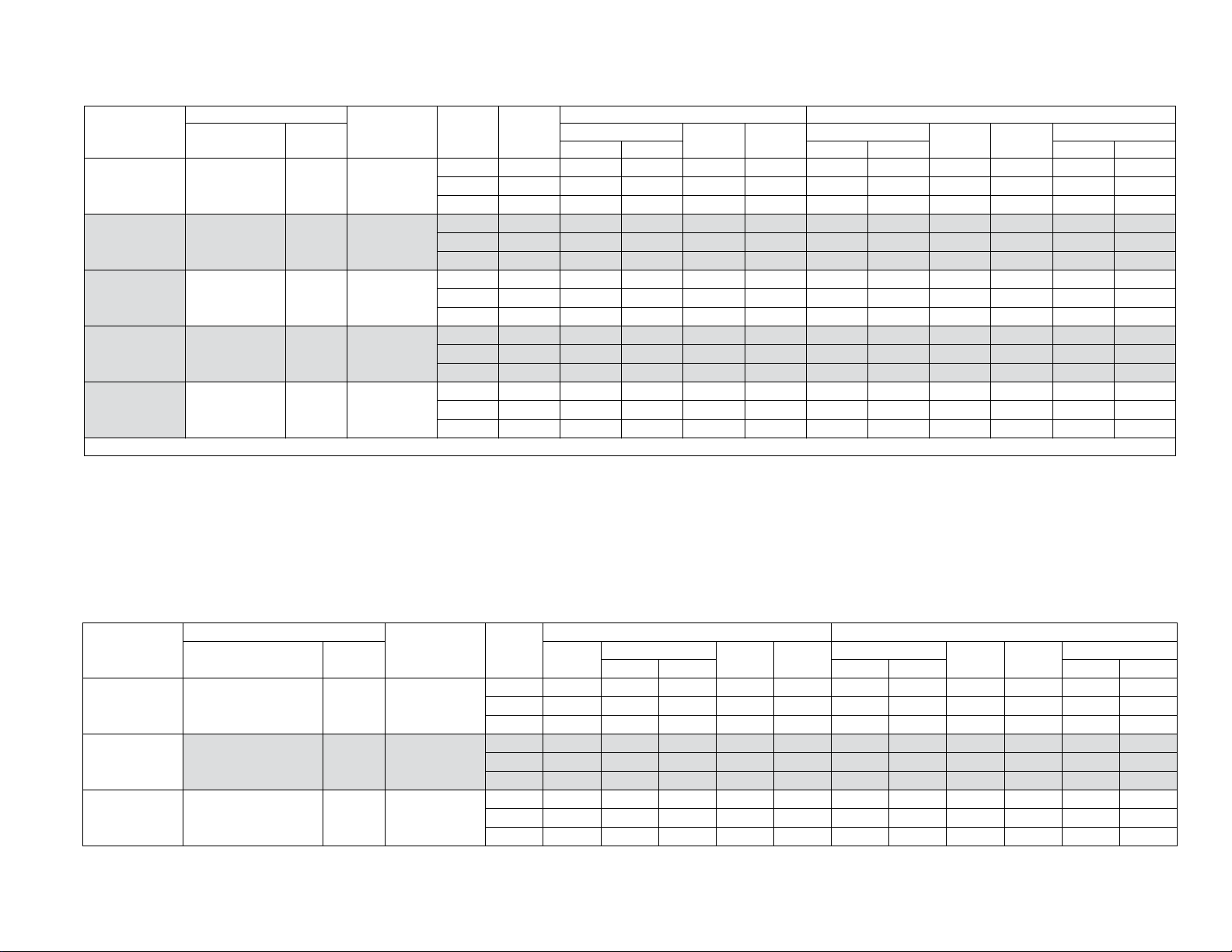

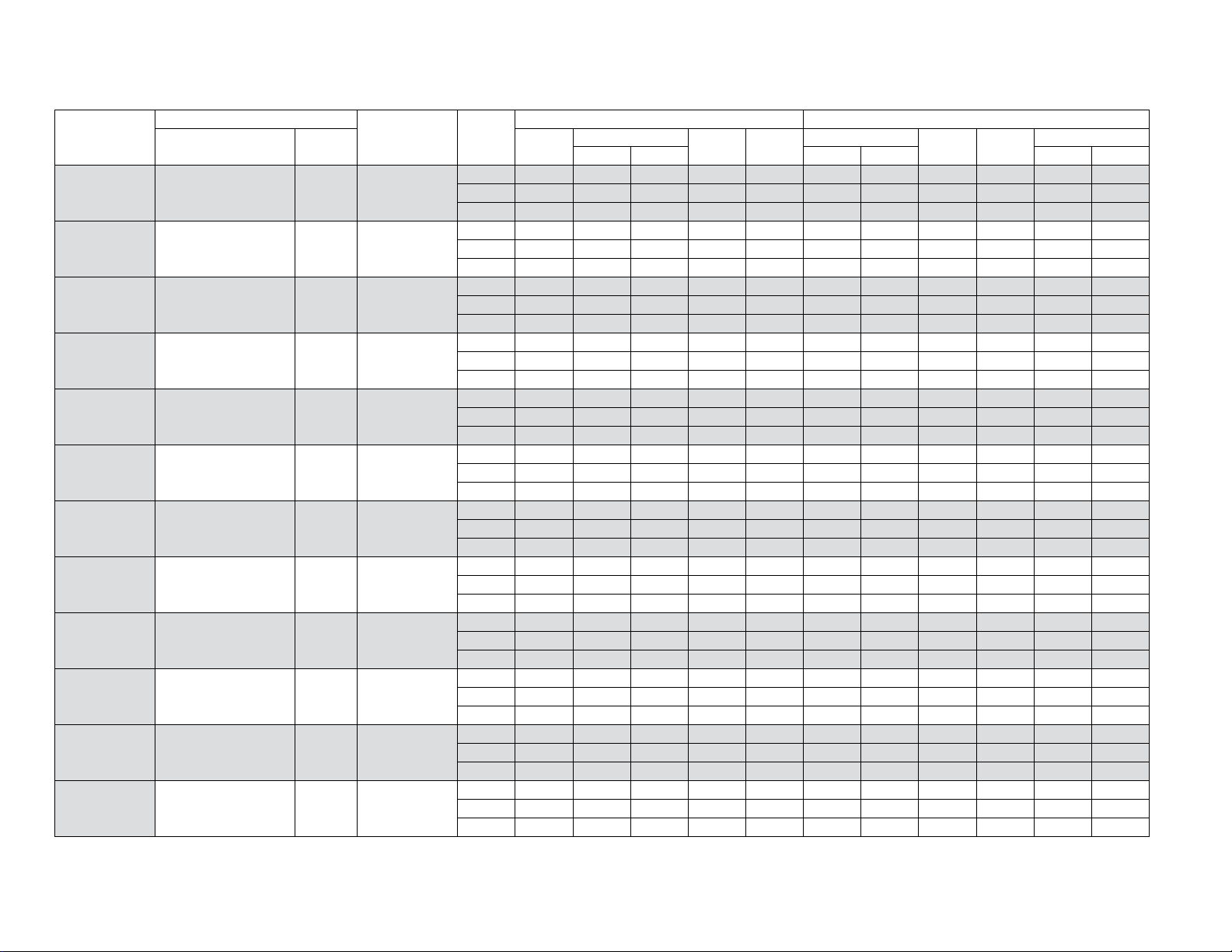

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1

UNIT

MODEL

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

RATED

CFM

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

High 800 24.0 18.6 17.25 11.75 24.0 15.0 9.00 7.50 3.56 2.60

CH16B2421S TM8V060A12MP12C 14.5 CF/CM24A

Med 575 18.2 14.2 – 16.60 ––––––

Low 575 16.1 13.3 – 28.55 12.0 – – – 3.96 –

High 650 24.0 17.4 16.75 11.75 24.0 14.8 8.75 7.30 3.40 2.56

CH16B2421S

TM8V060A12MP12C 14.5 CF/CM30A

Med 450 17.4 12.5 – 15.90 – – – – – –

Low 450 15.7 11.7 – 27.55 11.7 – – – 3.74 –

High 925 24.6 19.3 18.00 12.00 24.6 15.0 9.00 7.40 3.64 2.66

CH16B2421S TM8V060A12MP12C 14.5 CF/CM36A

Med 650 18.5 15.3 – 17.15 ––––––

Low 650 16.4 14.5 – 30.35 12.3 – – – 4.24 –

Johnson Controls Unitary Products 11

COOLING HEATING

NET MBH

SEER EER

NET MBH

HSPF IV HSPF V

COP

Page 12

5547666-CTG-A-0718

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S TM8V060A12MP12C 14.5 CF24ABAA1

CH16B2421S TM8V060A12MP12C 14.5 CF30ABAA1

CH16B2421S TM8V080B12MP12C 17.5 CF/CM24B

CH16B2421S TM8V080B12MP12C 17.5 CF/CM30B

CH16B2421S TM8V080B12MP12C 17.5 CF/CM36B

CH16B2421S TM8V080B12MP12C 17.5 CF24BBAA1

CH16B2421S TM8V080C16MP12C 21.0 CF/CM24C

CH16B2421S TM8V080C16MP12C 21.0 CF/CM30C

CH16B2421S TM8V080C16MP12C 21.0 CF/CM36C

CH16B2421S TM8V100C16MP12C 21.0 CF/CM24C

CH16B2421S TM8V100C16MP12C 21.0 CF/CM30C

CH16B2421S TM8V100C16MP12C 21.0 CF/CM36C

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 800 24.0 18.6 17.25 11.75 24.0 15.0 9.00 7.50 3.56 2.60

Med 575 18.2 14.2 – 16.60 – – – – – –

Low 575 16.1 13.3 – 28.55 12.0 – – – 3.96 –

High 650 24.0 17.4 16.75 11.75 24.0 14.8 8.75 7.30 3.40 2.56

Med 450 17.4 12.5 – 15.90 ––––––

Low 450 15.7 11.7 – 27.55 11.7 – – – 3.74 –

High 875 24.0 19.5 17.75 12.00 24.0 15.1 9.00 7.40 3.72 2.66

Med 625 18.4 15.0 – 16.85 – – – – – –

Low 625 16.4 14.2 – 29.40 12.3 – – – 4.16 –

High 775 24.0 18.4 17.75 12.00 24.0 15.0 9.00 7.45 3.64 2.66

Med 625 18.5 15.1 – 16.90 ––––––

Low 625 16.4 14.2 – 29.45 12.3 – – – 4.14 –

High 800 24.0 18.7 17.75 12.00 24.0 15.0 9.00 7.45 3.66 2.66

Low 625 16.4 14.2 – 29.55 12.3 – – – 4.16 –

High 875 24.0 19.5 17.75 12.00 24.0 15.1 9.00 7.40 3.72 2.66

Med 625 18.4 15.0 – 16.85 ––––––

Low 625 16.4 14.2 – 29.40 12.3 – – – 4.16 –

High 900 24.0 18.6 17.50 11.75 24.0 15.1 9.00 7.45 3.56 2.62

Med 500 17.9 13.4 – 16.70 – – – – – –

Low 500 16.0 12.6 – 29.65 12.1 – – – 4.00 –

High 900 24.0 18.6 17.00 11.75 24.0 15.1 9.00 7.40 3.56 2.62

Med 625 18.2 14.9 – 16.75 ––––––

Low 625 16.4 14.2 – 29.65 12.3 – – – 4.16 –

High 825 24.0 18.9 17.00 12.00 24.0 15.1 9.00 7.40 3.66 2.64

Med 700 18.7 15.4 – 16.70 – – – – – –

Low 700 16.5 14.8 – 28.45 12.5 – – – 4.14 –

High 900 24.0 18.6 17.50 11.75 24.0 15.1 9.00 7.45 3.56 2.62

Med 500 17.9 13.4 – 16.70 ––––––

Low 500 16.0 12.6 – 29.65 12.1 – – – 4.00 –

High 900 24.0 18.6 17.00 11.75 24.0 15.1 9.00 7.40 3.56 2.62

Med 625 18.2 14.9 – 16.75 – – – – – –

Low 625 16.4 14.2 – 29.65 12.3 – – – 4.16 –

High 825 24.0 18.9 17.00 12.00 24.0 15.1 9.00 7.40 3.66 2.64

Med 700 18.7 15.4 – 16.70 ––––––

Low 700 16.5 14.8 – 28.45 12.5 – – – 4.14 –

RATED

CFM

Me 625 18.5 15.0 – 16.90 – – – – – –

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

12 Johnson Controls Unitary Products

Page 13

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S TM8X060A12MP11 14.5 CF/CM24A

CH16B2421S TM8X060A12MP11 14.5 CF/CM30A

CH16B2421S TM8X060A12MP11 14.5 CF/CM36A

CH16B2421S TM8X060A12MP11 14.5 CF24ABAA1

CH16B2421S TM8X060A12MP11 14.5 CF30ABAA1

CH16B2421S TM8X080B12MP11 17.5 CF/CM24B

CH16B2421S TM8X080B12MP11 17.5 CF/CM30B

CH16B2421S TM8X080B12MP11 17.5 CF/CM36B

CH16B2421S TM8X080B12MP11 17.5 CF24BBAA1

CH16B2421S TM8Y060A12MP11 14.5 CF/CM24A

CH16B2421S TM8Y060A12MP11 14.5 CF/CM30A

CH16B2421S TM8Y060A12MP11 14.5 CF/CM36A

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 850 24.0 19.0 17.00 12.00 24.0 15.1 9.00 7.45 3.68 2.64

Med 600 18.4 14.5 – 16.85 – – – – – –

Low 600 16.2 13.7 – 29.10 12.0 – – – 4.04 –

High 800 24.0 18.5 17.00 12.25 24.0 14.9 9.00 7.50 3.64 2.64

Med 550 18.0 14.1 – 16.60 ––––––

Low 550 16.1 13.0 – 29.10 11.9 – – – 3.98 –

High 700 24.0 17.6 17.00 12.00 24.0 14.8 8.75 7.25 3.58 2.66

Med 475 17.7 13.0 – 16.55 – – – – – –

Low 475 16.0 12.3 – 29.45 12.0 – – – 3.94 –

High 850 24.0 19.0 17.00 12.00 24.0 15.1 9.00 7.45 3.68 2.64

Med 600 18.4 14.5 – 16.85 ––––––

Low 600 16.2 13.7 – 29.10 12.0 – – – 4.04 –

High 800 24.0 18.5 17.00 12.25 24.0 14.9 9.00 7.50 3.64 2.64

Med 550 18.0 14.1 – 16.60 – – – – – –

Low 550 16.1 13.0 – 29.10 11.9 – – – 3.98 –

High 575 24.0 16.5 16.50 12.00 24.0 14.6 8.75 7.30 3.40 2.64

Med 425 17.4 12.3 – 16.25 ––––––

Low 425 15.7 11.6 – 28.75 11.9 – – – 3.82 –

High 725 24.0 18.1 17.00 12.00 24.0 14.8 9.00 7.50 3.60 2.66

Med 475 17.7 13.0 – 16.55 – – – – – –

Low 475 15.9 12.3 – 29.35 12.0 – – – 3.94 –

High 700 24.0 17.6 16.50 12.00 24.0 14.8 9.00 7.50 3.58 2.66

Med 475 17.7 13.0 – 16.55 ––––––

Low 475 16.0 12.3 – 29.45 12.0 – – – 3.94 –

High 575 24.0 16.5 16.50 12.00 24.0 14.6 8.75 7.30 3.40 2.64

Med 425 17.4 12.3 – 16.25 – – – – – –

Low 425 15.7 11.6 – 28.75 11.9 – – – 3.82 –

High 850 24.0 19.0 17.00 12.00 24.0 15.1 9.00 7.45 3.68 2.64

Med 600 18.4 14.5 – 16.85 ––––––

Low 600 16.2 13.7 – 29.10 12.0 – – – 4.04 –

High 800 24.0 18.5 17.00 12.25 24.0 14.9 9.00 7.50 3.64 2.64

Med 550 18.0 14.1 – 16.60 – – – – – –

Low 550 16.1 13.0 – 29.10 11.9 – – – 3.98 –

High 700 24.0 17.6 17.00 12.00 24.0 14.8 8.75 7.25 3.58 2.66

Med 475 17.7 13.0 – 16.55 ––––––

Low 475 16.0 12.3 – 29.45 12.0 – – – 3.94 –

RATED

CFM

5547666-CTG-A-0718

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

Johnson Controls Unitary Products 13

Page 14

5547666-CTG-A-0718

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S TM8Y060A12MP11 14.5 CF24ABAA1

CH16B2421S TM8Y060A12MP11 14.5 CF30ABAA1

CH16B2421S TM8Y080B12MP11 17.5 CF/CM24B

CH16B2421S TM8Y080B12MP11 17.5 CF/CM30B

CH16B2421S TM8Y080B12MP11 17.5 CF/CM36B

CH16B2421S TM8Y080B12MP11 17.5 CF24BBAA1

CH16B2421S TM9E040A10MP11 14.5 CF/CM24A

CH16B2421S TM9E040A10MP11 14.5 CF/CM30A

CH16B2421S TM9E040A10MP11 14.5 CF/CM36A

CH16B2421S TM9E040A10MP11 14.5 CF24ABAA1

CH16B2421S TM9E040A10MP11 14.5 CF30ABAA1

CH16B2421S TM9E060B12MP11 17.5 CF/CM24B

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 850 24.0 19.0 17.00 12.00 24.0 15.1 9.00 7.45 3.68 2.64

Med 600 18.4 14.5 – 16.85 – – – – – –

Low 600 16.2 13.7 – 29.10 12.0 – – – 4.04 –

High 800 24.0 18.5 17.00 12.25 24.0 14.9 9.00 7.50 3.64 2.64

Med 550 18.0 14.1 – 16.60 ––––––

Low 550 16.1 13.0 – 29.10 11.9 – – – 3.98 –

High 575 24.0 16.5 16.50 12.00 24.0 14.6 8.75 7.30 3.40 2.64

Med 425 17.4 12.3 – 16.25 – – – – – –

Low 425 15.7 11.6 – 28.75 11.9 – – – 3.82 –

High 725 24.0 18.1 17.00 12.00 24.0 14.8 9.00 7.50 3.60 2.66

Med 475 17.7 13.0 – 16.55 ––––––

Low 475 15.9 12.3 – 29.35 12.0 – – – 3.94 –

High 700 24.0 17.6 16.50 12.00 24.0 14.8 9.00 7.50 3.58 2.66

Med 475 17.7 13.0 – 16.55 – – – – – –

Low 475 16.0 12.3 – 29.45 12.0 – – – 3.94 –

High 575 24.0 16.5 16.50 12.00 24.0 14.6 8.75 7.30 3.40 2.64

Med 425 17.4 12.3 – 16.25 ––––––

Low 425 15.7 11.6 – 28.75 11.9 – – – 3.82 –

High 800 24.0 18.7 17.50 12.00 24.0 15.0 9.00 7.45 3.68 2.66

Med 525 18.0 13.7 – 16.80 – – – – – –

Low 525 16.1 12.9 – 29.80 12.1 – – – 4.06 –

High 875 24.0 19.4 17.75 12.00 24.0 15.1 9.00 7.40 3.74 2.68

Med 625 18.4 15.0 – 17.00 ––––––

Low 625 16.4 14.2 – 29.95 12.3 – – – 4.18 –

High 725 24.0 18.1 16.75 11.50 24.0 15.0 9.00 7.50 3.54 2.62

Med 500 17.8 13.3 – 16.30 – – – – – –

Low 500 16.0 12.6 – 28.35 12.1 – – – 3.92 –

High 800 24.0 18.7 17.50 12.00 24.0 15.0 9.00 7.45 3.68 2.66

Med 525 18.0 13.7 – 16.80 ––––––

Low 525 16.1 12.9 – 29.80 12.1 – – – 4.06 –

High 875 24.0 19.4 17.75 12.00 24.0 15.1 9.00 7.40 3.74 2.68

Med 625 18.4 15.0 – 17.00 – – – – – –

Low 625 16.4 14.2 – 29.95 12.3 – – – 4.18 –

High 675 24.0 17.7 17.25 11.75 24.0 14.9 9.00 7.50 3.50 2.62

Med 500 17.8 13.3 – 16.30 ––––––

Low 500 16.0 12.6 – 28.45 12.1 – – – 3.94 –

RATED

CFM

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

14 Johnson Controls Unitary Products

Page 15

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S TM9E060B12MP11 17.5 CF/CM30B

CH16B2421S TM9E060B12MP11 17.5 CF/CM36B

CH16B2421S TM9E060B12MP11 17.5 CF24BBAA1

CH16B2421S TM9E080B12MP11 17.5 CF/CM24B

CH16B2421S TM9E080B12MP11 17.5 CF/CM30B

CH16B2421S TM9E080B12MP11 17.5 CF/CM36B

CH16B2421S TM9E080B12MP11 17.5 CF24BBAA1

CH16B2421S TM9V040A10MP12C 14.5 CF/CM24A

CH16B2421S TM9V040A10MP12C 14.5 CF/CM30A

CH16B2421S TM9V040A10MP12C 14.5 CF/CM36A

CH16B2421S TM9V040A10MP12C 14.5 CF24ABAA1

CH16B2421S TM9V040A10MP12C 14.5 CF30ABAA1

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 900 24.0 18.6 17.25 11.25 24.0 15.3 9.00 7.40 3.48 2.56

Med 600 18.2 14.5 – 16.50 – – – – – –

Low 600 16.2 13.7 – 28.35 12.3 – – – 4.06 –

High 875 24.0 19.2 17.25 11.75 24.0 14.8 9.00 7.45 3.78 2.70

Med 600 18.4 14.6 – 17.40 ––––––

Low 600 16.4 13.7 – 31.25 11.9 – – – 4.14 –

High 675 24.0 17.7 17.25 11.75 24.0 14.9 9.00 7.50 3.50 2.62

Med 500 17.8 13.3 – 16.30 – – – – – –

Low 500 16.0 12.6 – 28.45 12.1 – – – 3.94 –

High 825 24.0 18.9 16.50 11.75 24.0 15.2 9.00 7.45 3.62 2.62

Med 550 18.1 13.9 – 16.45 ––––––

Low 550 16.1 13.2 – 28.40 12.2 – – – 4.00 –

High 775 24.0 18.4 16.50 11.75 24.0 15.0 9.00 7.40 3.62 2.64

Med 675 18.5 15.4 – 16.55 – – – – – –

Low 675 16.3 14.7 – 28.00 12.5 – – – 4.12 –

High 875 24.0 19.4 16.50 11.75 24.0 15.3 9.00 7.40 3.64 2.60

Med 700 18.6 15.3 – 16.35 ––––––

Low 700 16.5 14.8 – 27.40 12.6 – – – 4.08 –

High 825 24.0 18.9 16.50 11.75 24.0 15.2 9.00 7.45 3.62 2.62

Med 550 18.1 13.9 – 16.45 – – – – – –

Low 550 16.1 13.2 – 28.40 12.2 – – – 4.00 –

High 875 24.0 19.4 17.25 11.75 24.0 15.2 9.00 7.40 3.68 2.64

Med 600 18.2 14.5 – 16.60 ––––––

Low 600 16.3 13.8 – 28.85 12.3 – – – 4.10 –

High 800 24.0 18.6 17.25 11.75 24.0 15.1 9.00 7.45 3.64 2.64

Med 550 18.1 13.9 – 16.60 – – – – – –

Low 550 16.1 13.2 – 28.85 12.2 – – – 4.04 –

High 725 24.0 18.1 17.25 11.75 24.0 15.0 9.00 7.45 3.54 2.62

Med 550 18.1 14.0 – 16.50 ––––––

Low 550 16.1 13.2 – 28.70 12.2 – – – 4.02 –

High 875 24.0 19.4 17.25 11.75 24.0 15.2 9.00 7.40 3.68 2.64

Med 600 18.2 14.5 – 16.60 – – – – – –

Low 600 16.3 13.8 – 28.85 12.3 – – – 4.10 –

High 800 24.0 18.6 17.25 11.75 24.0 15.1 9.00 7.45 3.64 2.64

Med 550 18.1 13.9 – 16.60 ––––––

Low 550 16.1 13.2 – 28.85 12.2 – – – 4.04 –

RATED

CFM

5547666-CTG-A-0718

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

Johnson Controls Unitary Products 15

Page 16

5547666-CTG-A-0718

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S TM9V060B12MP12C 17.5 CF/CM24B

CH16B2421S TM9V060B12MP12C 17.5 CF/CM30B

CH16B2421S TM9V060B12MP12C 17.5 CF/CM36B

CH16B2421S TM9V060B12MP12C 17.5 CF24BBAA1

CH16B2421S TM9V080B12MP12C 17.5 CF/CM24B

CH16B2421S TM9V080B12MP12C 17.5 CF/CM30B

CH16B2421S TM9V080B12MP12C 17.5 CF/CM36B

CH16B2421S TM9V080B12MP12C 17.5 CF24BBAA1

CH16B2421S TM9V080C16MP12C 21.0 CF/CM24C

CH16B2421S TM9V080C16MP12C 21.0 CF/CM30C

CH16B2421S TM9V080C16MP12C 21.0 CF/CM36C

CH16B2421S TM9V100C16MP12C 21.0 CF/CM24C

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 800 24.0 18.6 17.25 11.25 24.0 15.2 9.00 7.45 3.60 2.62

Med 575 18.1 14.3 – 16.45 – – – – – –

Low 575 16.1 13.5 – 28.45 12.3 – – – 4.04 –

High 800 24.0 18.7 16.75 11.25 24.0 15.4 9.00 7.45 3.52 2.56

Med 500 17.7 13.2 – 16.00 ––––––

Low 500 15.9 12.5 – 27.40 12.2 – – – 3.88 –

High 875 24.0 19.2 17.25 11.25 24.0 14.9 9.00 7.45 3.76 2.70

Med 625 18.5 15.0 – 17.25 – – – – – –

Low 625 16.4 14.1 – 30.50 11.9 – – – 4.16 –

High 800 24.0 18.6 17.25 11.25 24.0 15.2 9.00 7.45 3.60 2.62

Med 575 18.1 14.3 – 16.45 ––––––

Low 575 16.1 13.5 – 28.45 12.3 – – – 4.04 –

High 950 25.4 21.2 18.00 12.25 24.2 15.0 9.00 7.40 3.82 2.70

Med 650 18.6 15.2 – 17.35 – – – – – –

Low 650 16.4 14.4 – 30.60 12.0 – – – 4.20 –

High 875 24.0 19.2 17.50 12.25 24.0 15.0 9.00 7.45 3.68 2.64

Med 625 18.5 14.8 – 17.00 ––––––

Low 625 16.4 14.1 – 29.70 12.0 – – – 4.10 –

High 900 24.0 19.6 18.00 12.25 24.0 15.1 9.00 7.45 3.70 2.64

Med 650 18.5 15.1 – 17.05 – – – – – –

Low 650 16.4 14.4 – 29.80 12.1 – – – 4.14 –

High 950 25.4 21.2 18.00 12.25 24.2 15.0 9.00 7.40 3.82 2.70

Med 650 18.6 15.2 – 17.35 ––––––

Low 650 16.4 14.4 – 30.60 12.0 – – – 4.20 –

High 675 24.0 17.7 17.50 12.00 24.0 14.8 9.00 7.45 3.54 2.66

Med 500 17.8 13.3 – 16.60 – – – – – –

Low 500 16.0 12.6 – 29.35 12.1 – – – 3.98 –

High 750 24.0 18.1 17.50 12.00 24.0 14.9 9.00 7.45 3.62 2.66

Med 525 18.0 13.7 – 16.75 ––––––

Low 525 16.1 12.9 – 29.65 12.1 – – – 4.04 –

High 850 24.0 19.0 17.50 12.00 24.0 15.1 9.00 7.45 3.70 2.66

Med 550 18.2 14.0 – 16.95 – – – – – –

Low 550 16.2 13.3 – 30.00 12.1 – – – 4.10 –

High 900 24.0 19.7 17.50 12.25 24.0 15.1 9.00 7.45 3.72 2.66

Med 625 18.5 14.8 – 16.90 ––––––

Low 625 16.3 14.0 – 29.40 12.1 – – – 4.12 –

RATED

CFM

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

16 Johnson Controls Unitary Products

Page 17

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S TM9V100C16MP12C 21.0 CF/CM30C

CH16B2421S TM9V100C16MP12C 21.0 CF/CM36C

CH16B2421S TM9Y040A10MP11 14.5 CF/CM24A

CH16B2421S TM9Y040A10MP11 14.5 CF/CM30A

CH16B2421S TM9Y040A10MP11 14.5 CF/CM36A

CH16B2421S TM9Y040A10MP11 14.5 CF24ABAA1

CH16B2421S TM9Y040A10MP11 14.5 CF30ABAA1

CH16B2421S TM9Y060B12MP11 17.5 CF/CM24B

CH16B2421S TM9Y060B12MP11 17.5 CF/CM30B

CH16B2421S TM9Y060B12MP11 17.5 CF/CM36B

CH16B2421S TM9Y060B12MP11 17.5 CF24BBAA1

CH16B2421S TM9Y080B12MP11 17.5 CF/CM24B

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 700 24.0 17.7 17.50 12.25 24.0 14.7 9.00 7.50 3.60 2.66

Med 600 18.3 14.5 – 16.70 – – – – – –

Low 600 16.3 13.6 – 29.15 12.0 – – – 4.08 –

High 900 24.0 19.7 17.50 12.25 24.0 15.1 9.00 7.40 3.72 2.66

Med 750 18.8 16.2 – 16.85 ––––––

Low 750 16.5 15.6 – 28.80 12.4 – – – 4.20 –

High 800 24.0 18.7 17.50 12.00 24.0 15.0 9.00 7.45 3.68 2.66

Med 525 18.0 13.7 – 16.80 – – – – – –

Low 525 16.1 12.9 – 29.80 12.1 – – – 4.06 –

High 875 24.0 19.4 17.75 12.00 24.0 15.1 9.00 7.40 3.74 2.68

Med 625 18.4 15.0 – 17.00 ––––––

Low 625 16.4 14.2 – 29.95 12.3 – – – 4.18 –

High 725 24.0 18.1 16.75 11.50 24.0 15.0 9.00 7.50 3.54 2.62

Med 500 17.8 13.3 – 16.30 – – – – – –

Low 500 16.0 12.6 – 28.35 12.1 – – – 3.92 –

High 800 24.0 18.7 17.50 12.00 24.0 15.0 9.00 7.45 3.68 2.66

Med 525 18.0 13.7 – 16.80 ––––––

Low 525 16.1 12.9 – 29.80 12.1 – – – 4.06 –

High 875 24.0 19.4 17.75 12.00 24.0 15.1 9.00 7.40 3.74 2.68

Med 625 18.4 15.0 – 17.00 – – – – – –

Low 625 16.4 14.2 – 29.95 12.3 – – – 4.18 –

High 675 24.0 17.7 17.25 11.75 24.0 14.9 9.00 7.50 3.50 2.62

Med 500 17.8 13.3 – 16.30 ––––––

Low 500 16.0 12.6 – 28.45 12.1 – – – 3.94 –

High 900 24.0 18.6 17.25 11.25 24.0 15.3 9.00 7.40 3.48 2.56

Med 600 18.2 14.5 – 16.50 – – – – – –

Low 600 16.2 13.7 – 28.35 12.3 – – – 4.06 –

High 875 24.0 19.2 17.25 11.75 24.0 14.8 9.00 7.45 3.78 2.70

Med 600 18.4 14.6 – 17.40 ––––––

Low 600 16.4 13.7 – 31.25 11.9 – – – 4.14 –

High 675 24.0 17.7 17.25 11.75 24.0 14.9 9.00 7.50 3.50 2.62

Med 500 17.8 13.3 – 16.30 – – – – – –

Low 500 16.0 12.6 – 28.45 12.1 – – – 3.94 –

High 825 24.0 18.9 16.50 11.75 24.0 15.2 9.00 7.45 3.62 2.62

Med 550 18.1 13.9 – 16.45 ––––––

Low 550 16.1 13.2 – 28.40 12.2 – – – 4.00 –

RATED

CFM

5547666-CTG-A-0718

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

Johnson Controls Unitary Products 17

Page 18

5547666-CTG-A-0718

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S TM9Y080B12MP11 17.5 CF/CM30B

CH16B2421S TM9Y080B12MP11 17.5 CF/CM36B

CH16B2421S TM9Y080B12MP11 17.5 CF24BBAA1

CH16B2421S TMLV060A12MP12C 14.5 CF/CM24A

CH16B2421S TMLV060A12MP12C 14.5 CF/CM30A

CH16B2421S TMLV060A12MP12C 14.5 CF/CM36A

CH16B2421S TMLV060A12MP12C 14.5 CF24ABAA1

CH16B2421S TMLV060A12MP12C 14.5 CF30ABAA1

CH16B2421S TMLV080B12MP12C 17.5 CF/CM24B

CH16B2421S TMLV080B12MP12C 17.5 CF/CM30B

CH16B2421S TMLV080B12MP12C 17.5 CF/CM36B

CH16B2421S TMLV080B12MP12C 17.5 CF24BBAA1

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 775 24.0 18.4 16.50 11.75 24.0 15.0 9.00 7.40 3.62 2.64

Med 675 18.5 15.4 – 16.55 – – – – – –

Low 675 16.3 14.7 – 28.00 12.5 – – – 4.12 –

High 875 24.0 19.4 16.50 11.75 24.0 15.3 9.00 7.40 3.64 2.60

Med 700 18.6 15.3 – 16.35 ––––––

Low 700 16.5 14.8 – 27.40 12.6 – – – 4.08 –

High 825 24.0 18.9 16.50 11.75 24.0 15.2 9.00 7.45 3.62 2.62

Med 550 18.1 13.9 – 16.45 – – – – – –

Low 550 16.1 13.2 – 28.40 12.2 – – – 4.00 –

High 800 24.0 18.6 17.25 11.75 24.0 15.0 9.00 7.50 3.56 2.60

Med 575 18.2 14.2 – 16.60 ––––––

Low 575 16.1 13.3 – 28.55 12.0 – – – 3.96 –

High 650 24.0 17.4 16.75 11.75 24.0 14.8 8.75 7.30 3.40 2.56

Med 450 17.4 12.5 – 15.90 – – – – – –

Low 450 15.7 11.7 – 27.55 11.7 – – – 3.74 –

High 925 24.6 19.3 18.00 12.00 24.6 15.0 9.00 7.40 3.64 2.66

Med 650 18.5 15.3 – 17.15 ––––––

Low 650 16.4 14.5 – 30.35 12.3 – – – 4.24 –

High 800 24.0 18.6 17.25 11.75 24.0 15.0 9.00 7.50 3.56 2.60

Med 575 18.2 14.2 – 16.60 – – – – – –

Low 575 16.1 13.3 – 28.55 12.0 – – – 3.96 –

High 650 24.0 17.4 16.75 11.75 24.0 14.8 8.75 7.30 3.40 2.56

Med 450 17.4 12.5 – 15.90 ––––––

Low 450 15.7 11.7 – 27.55 11.7 – – – 3.74 –

High 875 24.0 19.5 17.75 12.00 24.0 15.1 9.00 7.40 3.72 2.66

Med 625 18.4 15.0 – 16.85 – – – – – –

Low 625 16.4 14.2 – 29.40 12.3 – – – 4.16 –

High 775 24.0 18.4 17.75 12.00 24.0 15.0 9.00 7.45 3.64 2.66

Med 625 18.5 15.1 – 16.90 ––––––

Low 625 16.4 14.2 – 29.45 12.3 – – – 4.14 –

High 800 24.0 18.7 17.75 12.00 24.0 15.0 9.00 7.45 3.66 2.66

Med 625 18.5 15.0 – 16.90 – – – – – –

Low 625 16.4 14.2 – 29.55 12.3 – – – 4.16 –

High 875 24.0 19.5 17.75 12.00 24.0 15.1 9.00 7.40 3.72 2.66

Med 625 18.4 15.0 – 16.85 ––––––

Low 625 16.4 14.2 – 29.40 12.3 – – – 4.16 –

RATED

CFM

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

18 Johnson Controls Unitary Products

Page 19

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S TMLV080C16MP12C 21.0 CF/CM24C

CH16B2421S TMLV080C16MP12C 21.0 CF/CM30C

CH16B2421S TMLV080C16MP12C 21.0 CF/CM36C

CH16B2421S TMLV100C16MP12C 21.0 CF/CM24C

CH16B2421S TMLV100C16MP12C 21.0 CF/CM30C

CH16B2421S TMLV100C16MP12C 21.0 CF/CM36C

CH16B2421S TMLX060A12MP11 14.5 CF/CM24A

CH16B2421S TMLX060A12MP11 14.5 CF/CM30A

CH16B2421S TMLX060A12MP11 14.5 CF/CM36A

CH16B2421S TMLX060A12MP11 14.5 CF24ABAA1

CH16B2421S TMLX060A12MP11 14.5 CF30ABAA1

CH16B2421S TMLX080B12MP11 17.5 CF/CM24B

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 900 24.0 18.6 17.50 11.75 24.0 15.1 9.00 7.45 3.56 2.62

Med 500 17.9 13.4 – 16.70 – – – – – –

Low 500 16.0 12.6 – 29.65 12.1 – – – 4.00 –

High 900 24.0 18.6 17.00 11.75 24.0 15.1 9.00 7.40 3.56 2.62

Med 625 18.2 14.9 – 16.75 ––––––

Low 625 16.4 14.2 – 29.65 12.3 – – – 4.16 –

High 825 24.0 18.9 17.00 12.00 24.0 15.1 9.00 7.40 3.66 2.64

Med 700 18.7 15.4 – 16.70 – – – – – –

Low 700 16.5 14.8 – 28.45 12.5 – – – 4.14 –

High 900 24.0 18.6 17.50 11.75 24.0 15.1 9.00 7.45 3.56 2.62

Med 500 17.9 13.4 – 16.70 ––––––

Low 500 16.0 12.6 – 29.65 12.1 – – – 4.00 –

High 900 24.0 18.6 17.00 11.75 24.0 15.1 9.00 7.40 3.56 2.62

Med 625 18.2 14.9 – 16.75 – – – – – –

Low 625 16.4 14.2 – 29.65 12.3 – – – 4.16 –

High 825 24.0 18.9 17.00 12.00 24.0 15.1 9.00 7.40 3.66 2.64

Med 700 18.7 15.4 – 16.70 ––––––

Low 700 16.5 14.8 – 28.45 12.5 – – – 4.14 –

High 850 24.0 19.0 17.00 12.00 24.0 15.1 9.00 7.45 3.68 2.64

Med 600 18.4 14.5 – 16.85 – – – – – –

Low 600 16.2 13.7 – 29.10 12.0 – – – 4.04 –

High 800 24.0 18.5 17.00 12.25 24.0 14.9 9.00 7.50 3.64 2.64

Med 550 18.0 14.1 – 16.60 ––––––

Low 550 16.1 13.0 – 29.10 11.9 – – – 3.98 –

High 700 24.0 17.6 17.00 12.00 24.0 14.8 8.75 7.25 3.58 2.66

Med 475 17.7 13.0 – 16.55 – – – – – –

Low 475 16.0 12.3 – 29.45 12.0 – – – 3.94 –

High 850 24.0 19.0 17.00 12.00 24.0 15.1 9.00 7.45 3.68 2.64

Med 600 18.4 14.5 – 16.85 ––––––

Low 600 16.2 13.7 – 29.10 12.0 – – – 4.04 –

High 800 24.0 18.5 17.00 12.25 24.0 14.9 9.00 7.50 3.64 2.64

Med 550 18.0 14.1 – 16.60 – – – – – –

Low 550 16.1 13.0 – 29.10 11.9 – – – 3.98 –

High 575 24.0 16.5 16.50 12.00 24.0 14.6 8.75 7.30 3.40 2.64

Med 425 17.4 12.3 – 16.25 ––––––

Low 425 15.7 11.6 – 28.75 11.9 – – – 3.82 –

RATED

CFM

5547666-CTG-A-0718

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

Johnson Controls Unitary Products 19

Page 20

5547666-CTG-A-0718

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S TMLX080B12MP11 17.5 CF/CM30B

CH16B2421S TMLX080B12MP11 17.5 CF/CM36B

CH16B2421S TMLX080B12MP11 17.5 CF24BBAA1

CH16B2421S TP9C060B12MP13C 17.5 CF/CM24B

CH16B2421S TP9C060B12MP13C 17.5 CF/CM30B

CH16B2421S TP9C060B12MP13C 17.5 CF/CM36B

CH16B2421S TP9C060B12MP13C 17.5 CF24BBAA1

CH16B2421S TP9C080B12MP13C 17.5 CF/CM24B

CH16B2421S TP9C080B12MP13C 17.5 CF/CM30B

CH16B2421S TP9C080B12MP13C 17.5 CF/CM36B

CH16B2421S TP9C080B12MP13C 17.5 CF24BBAA1

CH16B2421S TP9C080C16MP13C 21.0 CF/CM24C

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 725 24.0 18.1 17.00 12.00 24.0 14.8 9.00 7.50 3.60 2.66

Med 475 17.7 13.0 – 16.55 – – – – – –

Low 475 15.9 12.3 – 29.35 12.0 – – – 3.94 –

High 700 24.0 17.6 16.50 12.00 24.0 14.8 9.00 7.50 3.58 2.66

Med 475 17.7 13.0 – 16.55 ––––––

Low 475 16.0 12.3 – 29.45 12.0 – – – 3.94 –

High 575 24.0 16.5 16.50 12.00 24.0 14.6 8.75 7.30 3.40 2.64

Med 425 17.4 12.3 – 16.25 – – – – – –

Low 425 15.7 11.6 – 28.75 11.9 – – – 3.82 –

High 800 24.0 18.6 17.25 11.25 24.0 15.2 9.00 7.45 3.60 2.62

Med 575 18.1 14.3 – 16.45 ––––––

Low 575 16.1 13.5 – 28.45 12.3 – – – 4.04 –

High 800 24.0 18.7 16.75 11.25 24.0 15.4 9.00 7.45 3.52 2.56

Med 500 17.7 13.2 – 16.00 – – – – – –

Low 500 15.9 12.5 – 27.40 12.2 – – – 3.88 –

High 875 24.0 19.2 17.25 11.25 24.0 14.9 9.00 7.45 3.76 2.70

Med 625 18.5 15.0 – 17.25 ––––––

Low 625 16.4 14.1 – 30.50 11.9 – – – 4.16 –

High 800 24.0 18.6 17.25 11.25 24.0 15.2 9.00 7.45 3.60 2.62

Med 575 18.1 14.3 – 16.45 – – – – – –

Low 575 16.1 13.5 – 28.45 12.3 – – – 4.04 –

High 950 25.4 21.2 18.00 12.25 24.2 15.0 9.00 7.40 3.82 2.70

Med 650 18.6 15.2 – 17.35 ––––––

Low 650 16.4 14.4 – 30.60 12.0 – – – 4.20 –

High 875 24.0 19.2 17.50 12.25 24.0 15.0 9.00 7.45 3.68 2.64

Med 625 18.5 14.8 – 17.00 – – – – – –

Low 625 16.4 14.1 – 29.70 12.0 – – – 4.10 –

High 900 24.0 19.6 18.00 12.25 24.0 15.1 9.00 7.45 3.70 2.64

Med 650 18.5 15.1 – 17.05 ––––––

Low 650 16.4 14.4 – 29.80 12.1 – – – 4.14 –

High 950 25.4 21.2 18.00 12.25 24.2 15.0 9.00 7.40 3.82 2.70

Med 650 18.6 15.2 – 17.35 – – – – – –

Low 650 16.4 14.4 – 30.60 12.0 – – – 4.20 –

High 675 24.0 17.7 17.50 12.00 24.0 14.8 9.00 7.45 3.54 2.66

Med 500 17.8 13.3 – 16.60 ––––––

Low 500 16.0 12.6 – 29.35 12.1 – – – 3.98 –

RATED

CFM

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

20 Johnson Controls Unitary Products

Page 21

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S TP9C080C16MP13C 21.0 CF/CM30C

CH16B2421S TP9C080C16MP13C 21.0 CF/CM36C

CH16B2421S TP9C100C16MP13C 21.0 CF/CM24C

CH16B2421S TP9C100C16MP13C 21.0 CF/CM30C

CH16B2421S TP9C100C16MP13C 21.0 CF/CM36C

CH16B2421S TPLC060A12MP13C 14.5 CF/CM24A

CH16B2421S TPLC060A12MP13C 14.5 CF/CM30A

CH16B2421S TPLC060A12MP13C 14.5 CF/CM36A

CH16B2421S TPLC060A12MP13C 14.5 CF24ABAA1

CH16B2421S TPLC060A12MP13C 14.5 CF30ABAA1

CH16B2421S TPLC080B12MP13C 17.5 CF/CM24B

CH16B2421S TPLC080B12MP13C 17.5 CF/CM30B

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 750 24.0 18.1 17.50 12.00 24.0 14.9 9.00 7.45 3.62 2.66

Med 525 18.0 13.7 – 16.75 – – – – – –

Low 525 16.1 12.9 – 29.65 12.1 – – – 4.04 –

High 850 24.0 19.0 17.50 12.00 24.0 15.1 9.00 7.45 3.70 2.66

Med 550 18.2 14.0 – 16.95 ––––––

Low 550 16.2 13.3 – 30.00 12.1 – – – 4.10 –

High 900 24.0 19.7 17.50 12.25 24.0 15.1 9.00 7.45 3.72 2.66

Med 625 18.5 14.8 – 16.90 – – – – – –

Low 625 16.3 14.0 – 29.40 12.1 – – – 4.12 –

High 700 24.0 17.7 17.50 12.25 24.0 14.7 9.00 7.50 3.60 2.66

Med 600 18.3 14.5 – 16.70 ––––––

Low 600 16.3 13.6 – 29.15 12.0 – – – 4.08 –

High 900 24.0 19.7 17.50 12.25 24.0 15.1 9.00 7.40 3.72 2.66

Med 750 18.8 16.2 – 16.85 – – – – – –

Low 750 16.5 15.6 – 28.80 12.4 – – – 4.20 –

High 800 24.0 18.6 17.25 11.75 24.0 15.0 9.00 7.50 3.56 2.60

Med 575 18.2 14.2 – 16.60 ––––––

Low 575 16.1 13.3 – 28.55 12.0 – – – 3.96 –

High 650 24.0 17.4 16.75 11.75 24.0 14.8 8.75 7.30 3.40 2.56

Med 450 17.4 12.5 – 15.90 – – – – – –

Low 450 15.7 11.7 – 27.55 11.7 – – – 3.74 –

High 925 24.6 19.3 18.00 12.00 24.6 15.0 9.00 7.40 3.64 2.66

Med 650 18.5 15.3 – 17.15 ––––––

Low 650 16.4 14.5 – 30.35 12.3 – – – 4.24 –

High 800 24.0 18.6 17.25 11.75 24.0 15.0 9.00 7.50 3.56 2.60

Med 575 18.2 14.2 – 16.60 – – – – – –

Low 575 16.1 13.3 – 28.55 12.0 – – – 3.96 –

High 650 24.0 17.4 16.75 11.75 24.0 14.8 8.75 7.30 3.40 2.56

Med 450 17.4 12.5 – 15.90 ––––––

Low 450 15.7 11.7 – 27.55 11.7 – – – 3.74 –

High 875 24.0 19.5 17.75 12.00 24.0 15.1 9.00 7.40 3.72 2.66

Med 625 18.4 15.0 – 16.85 – – – – – –

Low 625 16.4 14.2 – 29.40 12.3 – – – 4.16 –

High 775 24.0 18.4 17.75 12.00 24.0 15.0 9.00 7.45 3.64 2.66

Med 625 18.5 15.1 – 16.90 ––––––

Low 625 16.4 14.2 – 29.45 12.3 – – – 4.14 –

RATED

CFM

5547666-CTG-A-0718

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

Johnson Controls Unitary Products 21

Page 22

5547666-CTG-A-0718

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S TPLC080B12MP13C 17.5 CF/CM36B

CH16B2421S TPLC080B12MP13C 17.5 CF24BBAA1

CH16B2421S TPLC080C16MP13C 21.0 CF/CM24C

CH16B2421S TPLC080C16MP13C 21.0 CF/CM30C

CH16B2421S TPLC080C16MP13C 21.0 CF/CM36C

CH16B2421S TPLC100C16MP13C 21.0 CF/CM24C

CH16B2421S TPLC100C16MP13C 21.0 CF/CM30C

CH16B2421S TPLC100C16MP13C 21.0 CF/CM36C

CH16B2421S CP9C060B12MP13C 17.5 CF/CM24B

CH16B2421S CP9C060B12MP13C 17.5 CF/CM30B

CH16B2421S CP9C060B12MP13C 17.5 CF/CM36B

CH16B2421S CP9C060B12MP13C 17.5 CF24BBAA1

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 800 24.0 18.7 17.75 12.00 24.0 15.0 9.00 7.45 3.66 2.66

Med 625 18.5 15.0 – 16.90 – – – – – –

Low 625 16.4 14.2 – 29.55 12.3 – – – 4.16 –

High 875 24.0 19.5 17.75 12.00 24.0 15.1 9.00 7.40 3.72 2.66

Med 625 18.4 15.0 – 16.85 ––––––

Low 625 16.4 14.2 – 29.40 12.3 – – – 4.16 –

High 900 24.0 18.6 17.50 11.75 24.0 15.1 9.00 7.45 3.56 2.62

Med 500 17.9 13.4 – 16.70 – – – – – –

Low 500 16.0 12.6 – 29.65 12.1 – – – 4.00 –

High 900 24.0 18.6 17.00 11.75 24.0 15.1 9.00 7.40 3.56 2.62

Med 625 18.2 14.9 – 16.75 ––––––

Low 625 16.4 14.2 – 29.65 12.3 – – – 4.16 –

High 825 24.0 18.9 17.00 12.00 24.0 15.1 9.00 7.40 3.66 2.64

Med 700 18.7 15.4 – 16.70 – – – – – –

Low 700 16.5 14.8 – 28.45 12.5 – – – 4.14 –

High 900 24.0 18.6 17.50 11.75 24.0 15.1 9.00 7.45 3.56 2.62

Med 500 17.9 13.4 – 16.70 ––––––

Low 500 16.0 12.6 – 29.65 12.1 – – – 4.00 –

High 900 24.0 18.6 17.00 11.75 24.0 15.1 9.00 7.40 3.56 2.62

Med 625 18.2 14.9 – 16.75 – – – – – –

Low 625 16.4 14.2 – 29.65 12.3 – – – 4.16 –

High 825 24.0 18.9 17.00 12.00 24.0 15.1 9.00 7.40 3.66 2.64

Med 700 18.7 15.4 – 16.70 ––––––

Low 700 16.5 14.8 – 28.45 12.5 – – – 4.14 –

High 800 24.0 18.6 17.25 11.25 24.0 15.2 9.00 7.45 3.60 2.62

Med 575 18.1 14.3 – 16.45 – – – – – –

Low 575 16.1 13.5 – 28.45 12.3 – – – 4.04 –

High 800 24.0 18.7 16.75 11.25 24.0 15.4 9.00 7.45 3.52 2.56

Med 500 17.7 13.2 – 16.00 ––––––

Low 500 15.9 12.5 – 27.40 12.2 – – – 3.88 –

High 875 24.0 19.2 17.25 11.25 24.0 14.9 9.00 7.45 3.76 2.70

Med 625 18.5 15.0 – 17.25 – – – – – –

Low 625 16.4 14.1 – 30.50 11.9 – – – 4.16 –

High 800 24.0 18.6 17.25 11.25 24.0 15.2 9.00 7.45 3.60 2.62

Med 575 18.1 14.3 – 16.45 ––––––

Low 575 16.1 13.5 – 28.45 12.3 – – – 4.04 –

RATED

CFM

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

22 Johnson Controls Unitary Products

Page 23

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S CP9C080B12MP13C 17.5 CF/CM24B

CH16B2421S CP9C080B12MP13C 17.5 CF/CM30B

CH16B2421S CP9C080B12MP13C 17.5 CF/CM36B

CH16B2421S CP9C080B12MP13C 17.5 CF24BBAA1

CH16B2421S CP9C080C16MP13C 21.0 CF/CM24C

CH16B2421S CP9C080C16MP13C 21.0 CF/CM30C

CH16B2421S CP9C080C16MP13C 21.0 CF/CM36C

CH16B2421S CP9C100C16MP13C 21.0 CF/CM24C

CH16B2421S CP9C100C16MP13C 21.0 CF/CM30C

CH16B2421S CP9C100C16MP13C 21.0 CF/CM36C

CH16B2421S CPLC060A12MP13C 14.5 CF/CM24A

CH16B2421S CPLC060A12MP13C 14.5 CF/CM30A

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 950 25.4 21.2 18.00 12.25 24.2 15.0 9.00 7.40 3.82 2.70

Med 650 18.6 15.2 – 17.35 – – – – – –

Low 650 16.4 14.4 – 30.60 12.0 – – – 4.20 –

High 875 24.0 19.2 17.50 12.25 24.0 15.0 9.00 7.45 3.68 2.64

Med 625 18.5 14.8 – 17.00 ––––––

Low 625 16.4 14.1 – 29.70 12.0 – – – 4.10 –

High 900 24.0 19.6 18.00 12.25 24.0 15.1 9.00 7.45 3.70 2.64

Med 650 18.5 15.1 – 17.05 – – – – – –

Low 650 16.4 14.4 – 29.80 12.1 – – – 4.14 –

High 950 25.4 21.2 18.00 12.25 24.2 15.0 9.00 7.40 3.82 2.70

Med 650 18.6 15.2 – 17.35 ––––––

Low 650 16.4 14.4 – 30.60 12.0 – – – 4.20 –

High 675 24.0 17.7 17.50 12.00 24.0 14.8 9.00 7.45 3.54 2.66

Med 500 17.8 13.3 – 16.60 – – – – – –

Low 500 16.0 12.6 – 29.35 12.1 – – – 3.98 –

High 750 24.0 18.1 17.50 12.00 24.0 14.9 9.00 7.45 3.62 2.66

Med 525 18.0 13.7 – 16.75 ––––––

Low 525 16.1 12.9 – 29.65 12.1 – – – 4.04 –

High 850 24.0 19.0 17.50 12.00 24.0 15.1 9.00 7.45 3.70 2.66

Med 550 18.2 14.0 – 16.95 – – – – – –

Low 550 16.2 13.3 – 30.00 12.1 – – – 4.10 –

High 900 24.0 19.7 17.50 12.25 24.0 15.1 9.00 7.45 3.72 2.66

Med 625 18.5 14.8 – 16.90 ––––––

Low 625 16.3 14.0 – 29.40 12.1 – – – 4.12 –

High 700 24.0 17.7 17.50 12.25 24.0 14.7 9.00 7.50 3.60 2.66

Med 600 18.3 14.5 – 16.70 – – – – – –

Low 600 16.3 13.6 – 29.15 12.0 – – – 4.08 –

High 900 24.0 19.7 17.50 12.25 24.0 15.1 9.00 7.40 3.72 2.66

Med 750 18.8 16.2 – 16.85 ––––––

Low 750 16.5 15.6 – 28.80 12.4 – – – 4.20 –

High 800 24.0 18.6 17.25 11.75 24.0 15.0 9.00 7.50 3.56 2.60

Med 575 18.2 14.2 – 16.60 – – – – – –

Low 575 16.1 13.3 – 28.55 12.0 – – – 3.96 –

High 650 24.0 17.4 16.75 11.75 24.0 14.8 8.75 7.30 3.40 2.56

Med 450 17.4 12.5 – 15.90 ––––––

Low 450 15.7 11.7 – 27.55 11.7 – – – 3.74 –

RATED

CFM

5547666-CTG-A-0718

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

Johnson Controls Unitary Products 23

Page 24

5547666-CTG-A-0718

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S CPLC060A12MP13C 14.5 CF/CM36A

CH16B2421S CPLC060A12MP13C 14.5 CF24ABAA1

CH16B2421S CPLC060A12MP13C 14.5 CF30ABAA1

CH16B2421S CPLC080B12MP13C 17.5 CF/CM24B

CH16B2421S CPLC080B12MP13C 17.5 CF/CM30B

CH16B2421S CPLC080B12MP13C 17.5 CF/CM36B

CH16B2421S CPLC080B12MP13C 17.5 CF24BBAA1

CH16B2421S CPLC080C16MP13C 21.0 CF/CM24C

CH16B2421S CPLC080C16MP13C 21.0 CF/CM30C

CH16B2421S CPLC080C16MP13C 21.0 CF/CM36C

CH16B2421S CPLC100C16MP13C 21.0 CF/CM24C

CH16B2421S CPLC100C16MP13C 21.0 CF/CM30C

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 925 24.6 19.3 18.00 12.00 24.6 15.0 9.00 7.40 3.64 2.66

Med 650 18.5 15.3 – 17.15 – – – – – –

Low 650 16.4 14.5 – 30.35 12.3 – – – 4.24 –

High 800 24.0 18.6 17.25 11.75 24.0 15.0 9.00 7.50 3.56 2.60

Med 575 18.2 14.2 – 16.60 ––––––

Low 575 16.1 13.3 – 28.55 12.0 – – – 3.96 –

High 650 24.0 17.4 16.75 11.75 24.0 14.8 8.75 7.30 3.40 2.56

Med 450 17.4 12.5 – 15.90 – – – – – –

Low 450 15.7 11.7 – 27.55 11.7 – – – 3.74 –

High 875 24.0 19.5 17.75 12.00 24.0 15.1 9.00 7.40 3.72 2.66

Med 625 18.4 15.0 – 16.85 ––––––

Low 625 16.4 14.2 – 29.40 12.3 – – – 4.16 –

High 775 24.0 18.4 17.75 12.00 24.0 15.0 9.00 7.45 3.64 2.66

Med 625 18.5 15.1 – 16.90 – – – – – –

Low 625 16.4 14.2 – 29.45 12.3 – – – 4.14 –

High 800 24.0 18.7 17.75 12.00 24.0 15.0 9.00 7.45 3.66 2.66

Med 625 18.5 15.0 – 16.90 ––––––

Low 625 16.4 14.2 – 29.55 12.3 – – – 4.16 –

High 875 24.0 19.5 17.75 12.00 24.0 15.1 9.00 7.40 3.72 2.66

Med 625 18.4 15.0 – 16.85 – – – – – –

Low 625 16.4 14.2 – 29.40 12.3 – – – 4.16 –

High 900 24.0 18.6 17.50 11.75 24.0 15.1 9.00 7.45 3.56 2.62

Med 500 17.9 13.4 – 16.70 ––––––

Low 500 16.0 12.6 – 29.65 12.1 – – – 4.00 –

High 900 24.0 18.6 17.00 11.75 24.0 15.1 9.00 7.40 3.56 2.62

Med 625 18.2 14.9 – 16.75 – – – – – –

Low 625 16.4 14.2 – 29.65 12.3 – – – 4.16 –

High 825 24.0 18.9 17.00 12.00 24.0 15.1 9.00 7.40 3.66 2.64

Med 700 18.7 15.4 – 16.70 ––––––

Low 700 16.5 14.8 – 28.45 12.5 – – – 4.14 –

High 900 24.0 18.6 17.50 11.75 24.0 15.1 9.00 7.45 3.56 2.62

Med 500 17.9 13.4 – 16.70 – – – – – –

Low 500 16.0 12.6 – 29.65 12.1 – – – 4.00 –

High 900 24.0 18.6 17.00 11.75 24.0 15.1 9.00 7.40 3.56 2.62

Med 625 18.2 14.9 – 16.75 ––––––

Low 625 16.4 14.2 – 29.65 12.3 – – – 4.16 –

RATED

CFM

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

24 Johnson Controls Unitary Products

Page 25

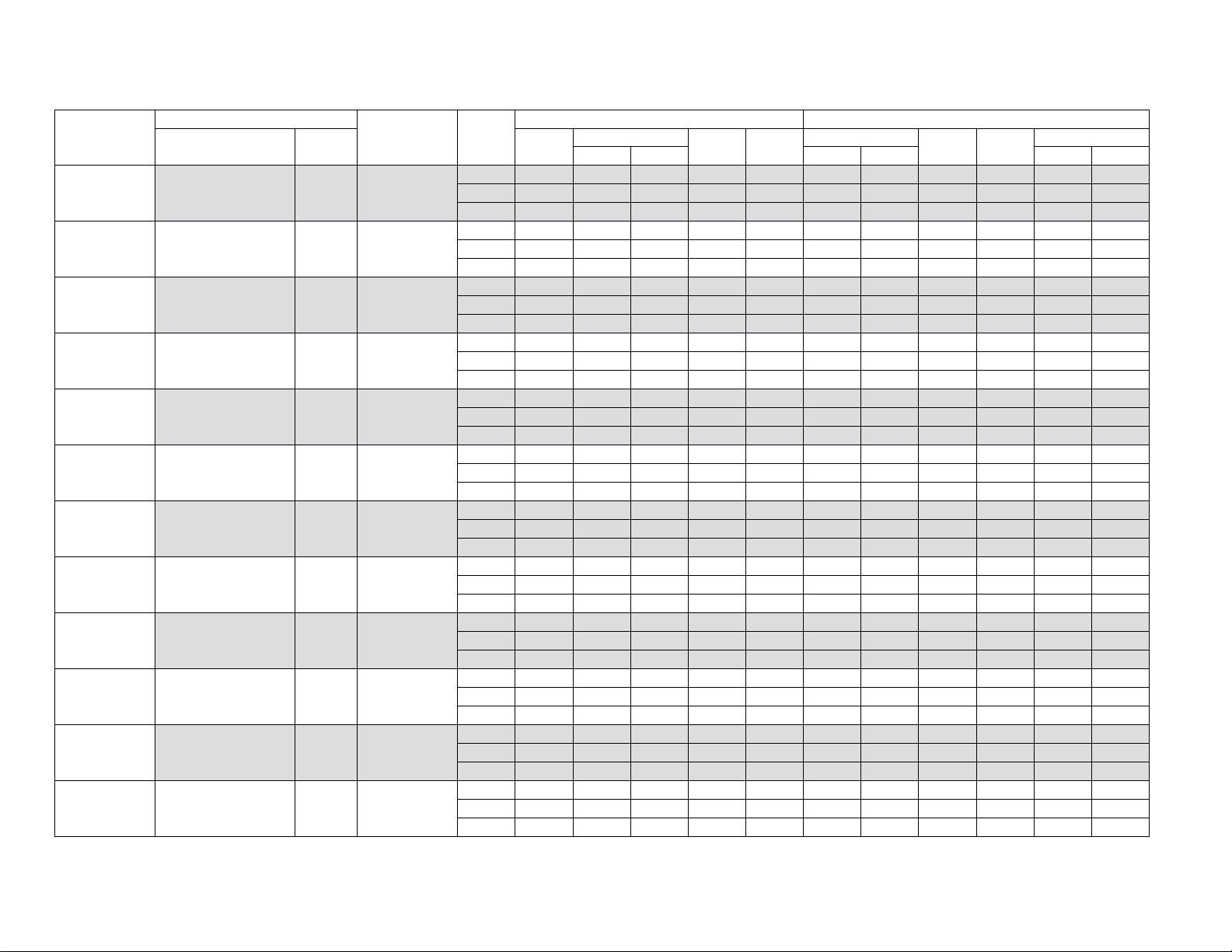

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B2421S CPLC100C16MP13C 21.0 CF/CM36C

CH16B3621S TM8V060A12MP12C 14.5 CF/CM36B

CH16B3621S TM8V060A12MP12C 14.5 CF36BBCA1

CH16B3621S TM8V080B12MP12C 17.5 CF/CM36C

CH16B3621S TM8V080B12MP12C 17.5 CF/CM42C

CH16B3621S TM8V080B12MP12C 17.5 CF42CBCA1

CH16B3621S TM8V080C16MP12C 21.0 CF/CM36C

CH16B3621S TM8V080C16MP12C 21.0 CF/CM42C

CH16B3621S TM8V080C16MP12C 21.0 CF/CM42D

CH16B3621S TM8V080C16MP12C 21.0 CF/CM48C

CH16B3621S TM8V080C16MP12C 21.0 CF/CM48D

CH16B3621S TM8V080C16MP12C 21.0 CF42CBCA1

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 825 24.0 18.9 17.00 12.00 24.0 15.1 9.00 7.40 3.66 2.64

Med 700 18.7 15.4 – 16.70 – – – – – –

Low 700 16.5 14.8 – 28.45 12.5 – – – 4.14 –

High 975 34.0 25.0 16.25 10.75 35.2 22.2 9.50 7.75 3.34 2.66

Med 675 23.8 17.8 – 15.00 ––––––

Low 675 21.6 16.8 – 27.95 18.0 – – – 3.98 –

High 975 34.0 25.0 16.25 10.75 35.2 22.2 9.50 7.75 3.34 2.66

Med 675 23.8 17.8 – 15.00 – – – – – –

Low 675 21.6 16.8 – 27.95 18.0 – – – 3.98 –

High 1000 33.6 25.0 16.00 10.50 35.4 22.4 9.50 7.75 3.30 2.64

Med 675 23.6 17.6 – 14.90 ––––––

Low 675 21.8 16.9 – 27.70 18.0 – – – 3.96 –

High 1000 33.8 25.2 16.25 10.50 35.2 22.4 9.50 7.65 3.36 2.66

Med 675 24.2 17.8 – 15.15 – – – – – –

Low 675 21.8 16.9 – 27.70 17.9 – – – 4.00 –

High 1000 33.8 25.2 16.25 10.50 35.2 22.4 9.50 7.65 3.36 2.66

Med 675 24.2 17.8 – 15.15 ––––––

Low 675 21.8 16.9 – 27.70 17.9 – – – 4.00 –

High 1050 33.8 25.8 16.50 10.75 35.0 22.2 9.50 7.25 3.44 2.70

Med 700 24.0 18.1 – 15.30 – – – – – –

Low 700 21.8 17.2 – 28.55 18.2 – – – 4.04 –

High 1050 34.4 26.2 16.75 11.00 35.0 22.2 9.75 7.75 3.50 2.72

Med 725 24.4 18.5 – 15.30 ––––––

Low 725 21.8 17.4 – 29.00 18.1 – – – 4.12 –

High 1050 34.4 26.2 16.75 11.00 34.8 22.2 9.75 7.75 3.52 2.72

Med 725 24.4 18.5 – 15.30 – – – – – –

Low 725 21.8 17.4 – 29.05 18.1 – – – 4.12 –

High 1050 34.6 26.2 16.50 11.00 34.6 22.2 9.50 7.30 3.54 2.72

Med 725 24.4 18.6 – 15.20 ––––––

Low 725 22.0 17.6 – 29.10 17.9 – – – 4.16 –

High 1050 34.6 26.2 16.25 11.00 34.6 22.2 9.50 7.30 3.56 2.74

Med 725 24.4 18.5 – 15.20 – – – – – –

Low 725 22.0 17.6 – 29.15 17.9 – – – 4.16 –

High 1050 34.4 26.2 16.75 11.00 35.0 22.2 9.75 7.75 3.50 2.72

Med 725 24.4 18.5 – 15.30 ––––––

Low 725 21.8 17.4 – 29.00 18.1 – – – 4.12 –

RATED

CFM

5547666-CTG-A-0718

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

Johnson Controls Unitary Products 25

Page 26

5547666-CTG-A-0718

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B3621S TM8V080C16MP12C 21.0 CF48CBCA1

CH16B3621S TM8V100C16MP12C 21.0 CF/CM36C

CH16B3621S TM8V100C16MP12C 21.0 CF/CM42C

CH16B3621S TM8V100C16MP12C 21.0 CF/CM42D

CH16B3621S TM8V100C16MP12C 21.0 CF/CM48C

CH16B3621S TM8V100C16MP12C 21.0 CF/CM48D

CH16B3621S TM8V100C16MP12C 21.0 CF42CBCA1

CH16B3621S TM8V100C16MP12C 21.0 CF48CBCA1

CH16B3621S TM8V100C20MP12C 21.0 CF/CM36C

CH16B3621S TM8V100C20MP12C 21.0 CF/CM42C

CH16B3621S TM8V100C20MP12C 21.0 CF/CM42D

CH16B3621S TM8V100C20MP12C 21.0 CF/CM48C

FURNACE

MODEL WIDTH

COIL

MODEL

Stage

High 1050 34.6 26.2 16.50 11.00 34.6 22.2 9.50 7.30 3.54 2.72

Med 725 24.4 18.6 – 15.20 – – – – – –

Low 725 22.0 17.6 – 29.10 17.9 – – – 4.16 –

High 1050 33.8 25.8 16.50 10.75 35.0 22.2 9.50 7.25 3.44 2.70

Med 700 24.0 18.1 – 15.30 ––––––

Low 700 21.8 17.2 – 28.55 18.2 – – – 4.04 –

High 1050 34.4 26.2 16.75 11.00 35.0 22.2 9.75 7.75 3.50 2.72

Med 725 24.4 18.5 – 15.30 – – – – – –

Low 725 21.8 17.4 – 29.00 18.1 – – – 4.12 –

High 1050 34.4 26.2 16.75 11.00 34.8 22.2 9.75 7.75 3.52 2.72

Med 725 24.4 18.5 – 15.30 ––––––

Low 725 21.8 17.4 – 29.05 18.1 – – – 4.12 –

High 1050 34.6 26.2 16.50 11.00 34.6 22.2 9.50 7.30 3.54 2.72

Med 725 24.4 18.6 – 15.20 – – – – – –

Low 725 22.0 17.6 – 29.10 17.9 – – – 4.16 –

High 1050 34.6 26.2 16.25 11.00 34.6 22.2 9.50 7.30 3.56 2.74

Med 725 24.4 18.5 – 15.20 ––––––

Low 725 22.0 17.6 – 29.15 17.9 – – – 4.16 –

High 1050 34.4 26.2 16.75 11.00 35.0 22.2 9.75 7.75 3.50 2.72

Med 725 24.4 18.5 – 15.30 – – – – – –

Low 725 21.8 17.4 – 29.00 18.1 – – – 4.12 –

High 1050 34.6 26.2 16.50 11.00 34.6 22.2 9.50 7.30 3.54 2.72

Med 725 24.4 18.6 – 15.20 ––––––

Low 725 22.0 17.6 – 29.10 17.9 – – – 4.16 –

High 1225 35.0 28.4 16.25 11.00 35.0 22.4 9.50 7.25 3.54 2.70

Med 850 24.6 20.0 – 15.55 – – – – – –

Low 850 22.2 19.1 – 27.00 18.3 – – – 4.18 –

High 1225 35.0 28.4 16.50 11.00 35.0 22.4 9.75 7.65 3.58 2.72

Med 850 24.8 20.2 – 15.70 ––––––

Low 850 22.4 19.3 – 27.20 18.2 – – – 4.22 –

High 1225 35.0 28.4 16.75 11.00 34.8 22.4 9.75 7.65 3.58 2.72

Med 850 24.8 20.2 – 15.75 – – – – – –

Low 850 22.4 19.3 – 27.30 18.2 – – – 4.22 –

High 1150 34.8 27.6 16.50 11.00 34.6 22.2 9.75 7.65 3.60 2.74

Med 775 24.4 19.2 – 15.35 ––––––

Low 775 22.2 18.3 – 27.45 18.1 – – – 4.20 –

RATED

CFM

COOLING HEATING

NET MBH

TOTAL SENS. 47°F OD 17°F OD 47°F OD 17°F OD

SEER EER

NET MBH

HSPF IV HSPF V

COP

26 Johnson Controls Unitary Products

Page 27

SYSTEM CAPACITY - With High Efficiency Motor Furnaces1 (Continued)

UNIT

MODEL

CH16B3621S TM8V100C20MP12C 21.0 CF/CM48D

CH16B3621S TM8V100C20MP12C 21.0 CF42CBCA1

CH16B3621S TM8V100C20MP12C 21.0 CF48CBCA1

CH16B3621S TM8V120C20MP12C 21.0 CF/CM36C

CH16B3621S TM8V120C20MP12C 21.0 CF/CM42C

CH16B3621S TM8V120C20MP12C 21.0 CF/CM42D

CH16B3621S TM8V120C20MP12C 21.0 CF/CM48C

CH16B3621S TM8V120C20MP12C 21.0 CF/CM48D

CH16B3621S TM8V120C20MP12C 21.0 CF42CBCA1