Page 1

Gas Barbecue

Use, Care & Assembly Manual

With Grill Lighting Instructions

8400 Series

Model No. 9992-647 (LP Gas)

ASSEMBLER/INSTALLER:

Leave these instructions with the consumer.

CONSUMER/USER:

Read all instructions and keep in a safe place for future reference.

For Outdoor Use Only

www.coleman.com

IMPORTANT

Read this manual carefully before assembling,

using or servicing this grill. Keep this manual for

future reference. If you have questions about

assembly, operation, servicing or repair of this

grill, please call Coleman at 1-800-356-3612 or

TDD: 316-832-8707. In Canada call

1 800 387-6161.

®

NOTE:

1) AA Battery is included.

2) Propane tank is not included.

3) See your dealer for a Rotisserie Kit

that is purchased separately (the

bracket shown in the photo is

provided with the Rotisserie Kit).

Page 2

2

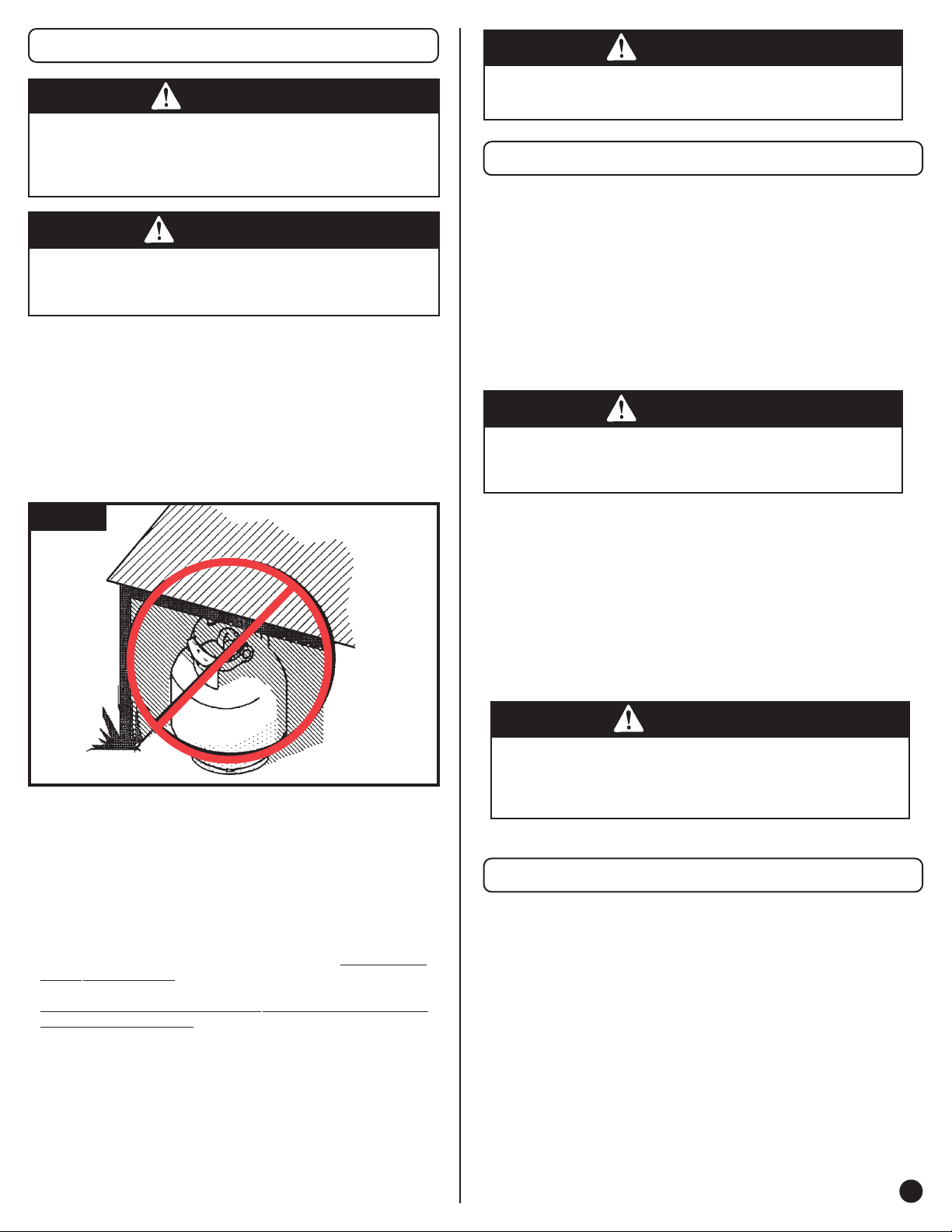

DANGER

• FOR OUTDOOR USE ONLY. NEVER operate grill in enclosed

areas, as this could lead to gas accumulating from a leak, causing

an explosion or a carbon monoxide buildup which could result in

injury or death. DO NOT use in garages, breezeways, sheds or

any enclosed area.

• NOT FOR USE BY CHILDREN.

• If these instructions are ignored, a hazardous fire or explosion could

result in physical injury, death or property damage!

WARNING

Combustion by-products produced when using this product contain

chemicals known to the State of California to cause cancer, birth

defects, or other reproductive harm.

DANGER

This manual contains important information about the assembly, operation

and maintenance of this product and system. General safety information is

presented in these first few pages and is also located throughout the

manual. Particular attention should be paid to information accompanied by

the safety alert symbols: “ DANGER”, “ WARNING”, “ CAUTION”.

Keep this manual for future reference and to educate new users of this

product. This manual should be read in conjunction with the labeling on

the product.

Safety precautions are essential when any mechanical or propane fueled

equipment is involved. These precautions are necessary when using,

storing, and servicing. Using this equipment with the respect and caution

demanded will reduce the possibilities of personal injury or property damage.

The following symbols shown below are used extensively throughout this

manual. Always heed these precautions, as they are essential when using

any mechanical or fueled equipment.

DANGER

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate personal injury, or property

damage.

Contents

General Safety Information

General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

LP Fuel Connections Other Than Portable L.P. Cylinders. . . . . . . . . . . . . . . . . 4

Natural Gas Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Portable L.P. Gas Barbecue Cylinders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

L.P. Gas Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Hose and Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Transporting the Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Filling and Purging Type 1 L.P. Gas Cylinders. . . . . . . . . . . . . . . . . . . . . . . . . . 6

Purging and Evacuating Devices for L.P. Gas Cylinders

with Type 1 Cylinder Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Grill Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Grill Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connecting Type 1 L.P. Gas Cylinders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Natural Gas Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Leak Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fixing a Fuel Leak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Start-Up Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Lighting Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Lighting Main Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Lighting Side Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Using the Rotisserie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Lighting the Rotisserie Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Shutting Off the Grill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

General Use and Correct Burner Flames . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Grilling Tips and Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

In Case of Grease Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cooking Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Care, Maintenance, and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Moving and Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

For Your Additional Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Registration Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your gas

supplier or your fire department.

WARNING

1. Do not store or use gasoline or other

flammable liquids or vapors in the vicinity

of this or any other appliance.

2. An LP cylinder not connected for use

shall not be stored in the vicinity of this

or any other appliance.

3. NEVER use Liquid Propane (L.P.) Gas in a

unit designed for Natural Gas.

Page 3

3

• Installation must conform with local codes or, in the absence of local

codes, with either the National Fuel Gas Code

, ANSI Z223.1 (USA),

Natural Gas and Propane Installation Code, CSA B149.1 (Canada), or

Propane Stor

age and Handling Code, CSA B149.2 (Canada).

• To check local codes, see your local L.P. gas dealer or natural gas

company listed in the Yellow Pages for recommended installation

procedures and regulations.

This appliance is not to be installed in or on a recreational vehicle

and/or boat.

Follow these safety rules before each use:

1. A minimum clearance of 12 inches from the left, right, back and

bottom sides of the grill must be maintained between the grill and

any combustible construction such as wood siding of a building.

2. Never locate the grill under an unprotected combustible material or

overhang.

3. Do not obstruct the flow of combustion and ventilation air. Maintain

a minimum clearance of 3 inches from the back of the grill and

non-combustible construction such as a concrete or brick wall.

5. A minimum of 5 inches clearance from the back of the grill to noncombustible construction is required for the lid to fully open.

6. Keep the ventilation opening(s) of the cylinder enclosure free and

clear from debris.

7. The grill should be level and not facing directly into the wind.

WARNING

Keep any electrical supply cord and the fuel supply hose away from

any heated surfaces. During assembly of grill and when attaching or

replacing the L.P. gas cylinder, insure that the gas supply hose is free

of kinks and is at least 3 inches away from hot surfaces such as the

grill housing.

WARNING

General Installation

• DO NOT move grill while it is lit.

• Keep outdoor cooking gas appliance area clear and free from

combustible materials, gasoline and other flammable vapors and

liquids.

WARNING

• NEVER place more than 15 pounds on a side table or a side burner.

DO NOT lean on grill.

• NEVER use charcoal briquettes or lighter fluid in a gas grill.

• Grill is hot when in use; to avoid burns, DO NOT touch any hot grill

surface. Keep children and pets away from hot grill.

• NEVER leave the grill unattended while it is in use.

• It is your responsibility to assemble, install, operate and care for

your gas grill properly.

• DO NOT vent propane vapor from the cylinder before taking it to be

refilled.

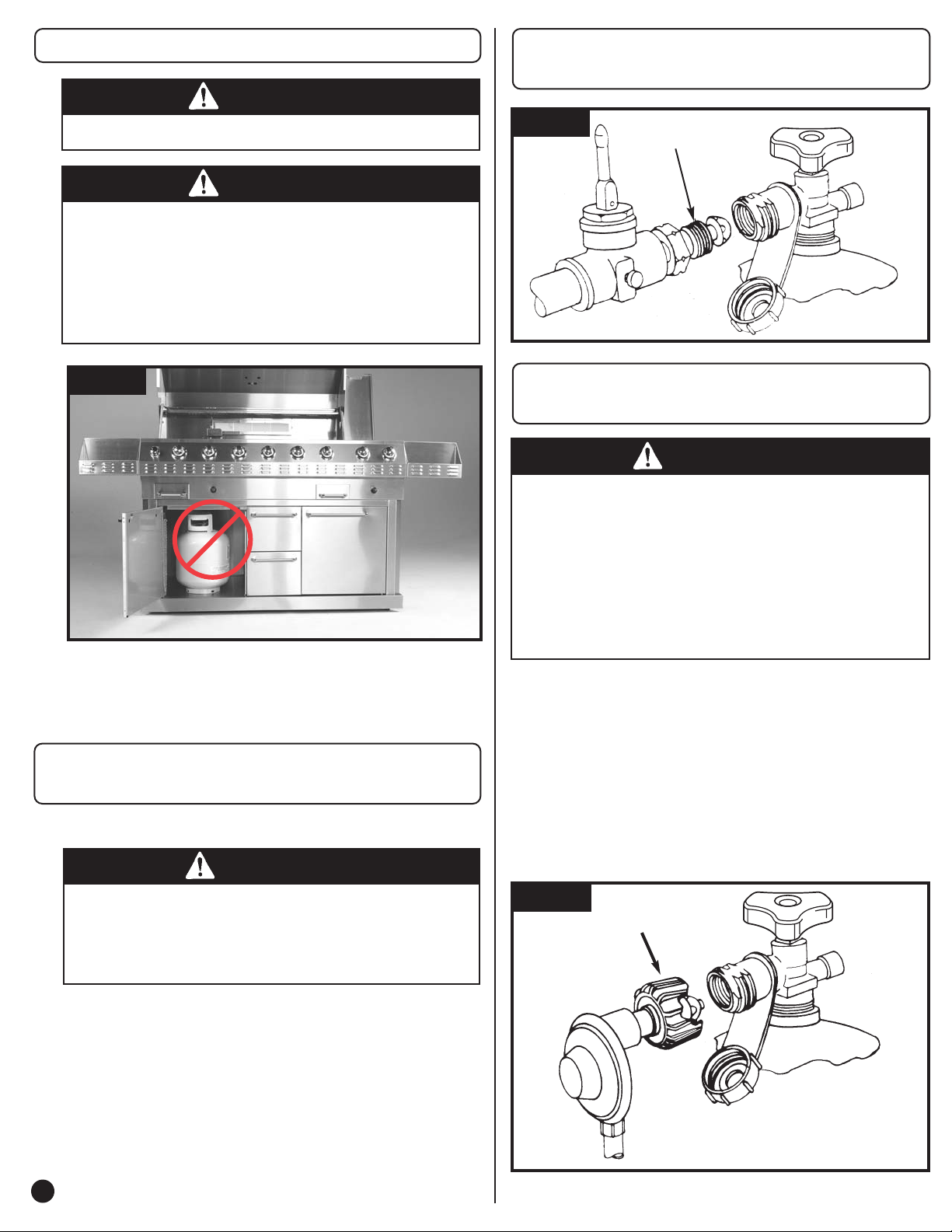

• DO NOT use gas grill indoors or store any propane cylinder(s) indoors,

including in the garage, breezeways, sheds or enclosed areas.

• Under some circumstances, propane may lose the distinctive odor

that was added. Keep the service valve closed and plugged or

capped (as recommended by the manufacturer) when the cylinder is

not connected to the appliance, including “empty” cylinders. Other

strong odors may hide or mask the odor of propane. Colds,

allergies, sinus congestion, and the use of tobacco, alcohol or drugs

may impair your ability to detect the odor of propane.

WARNING

Page 4

4

Longer detachable power-supply cords or extension cords must

be used with care. The marked electrical rating of the cord set or

extension cord must be at least as great as the electrical rating of

the appliance. If the appliance is of the grounded type, the

extension cord should be a grounding-type 3-wire cord. Use

outdoor extension cords with a surface marked with suffix letters

“W-A” and with a tag stating “Suitable for Use with Outdoor

Appliances”. Keep the connection to an extension cord away

from water and off the ground. Arrange the cord so that it will not

drape over the countertop or tabletop where it can be pulled on

by children or tripped over unintentionally.

Never clean any electrical product with water or cleaning fluids.

Store electrical products indoors and out of reach of children

when not in use. DO NOT allow cord to touch any hot surfaces

which could melt insulation.

WARNING

Electrical Grounding instructions: An appliance

equipped with a three-prong (grounding) plug is for

your protection against shock hazard and must be

plugged directly into a properly grounded three-prong

receptacle. DO NOT remove grounding prong from a

three-prong plug.

If the appliance is for connection to other than an L.P. cylinder

(consult the Assembly Instructions) the gas connections must be

made by a qualified installer or a licensed plumber. The gas

supply line must not be installed by the consumer.

The maximum inlet supply pressure is 13.0 inches w.c. for

propane gas. The specified supply pressure is 11.0 inches w.c. for

propane gas.

THE PIPING SYSTEM MUST BE INSTALLED IN ACCORDANCE

WITH NATIONAL FUEL GAS CODE IN THE USA, INCLUDING:

1. The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of 1/2 psi (3.5 kPa).

2. The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

CAUTION

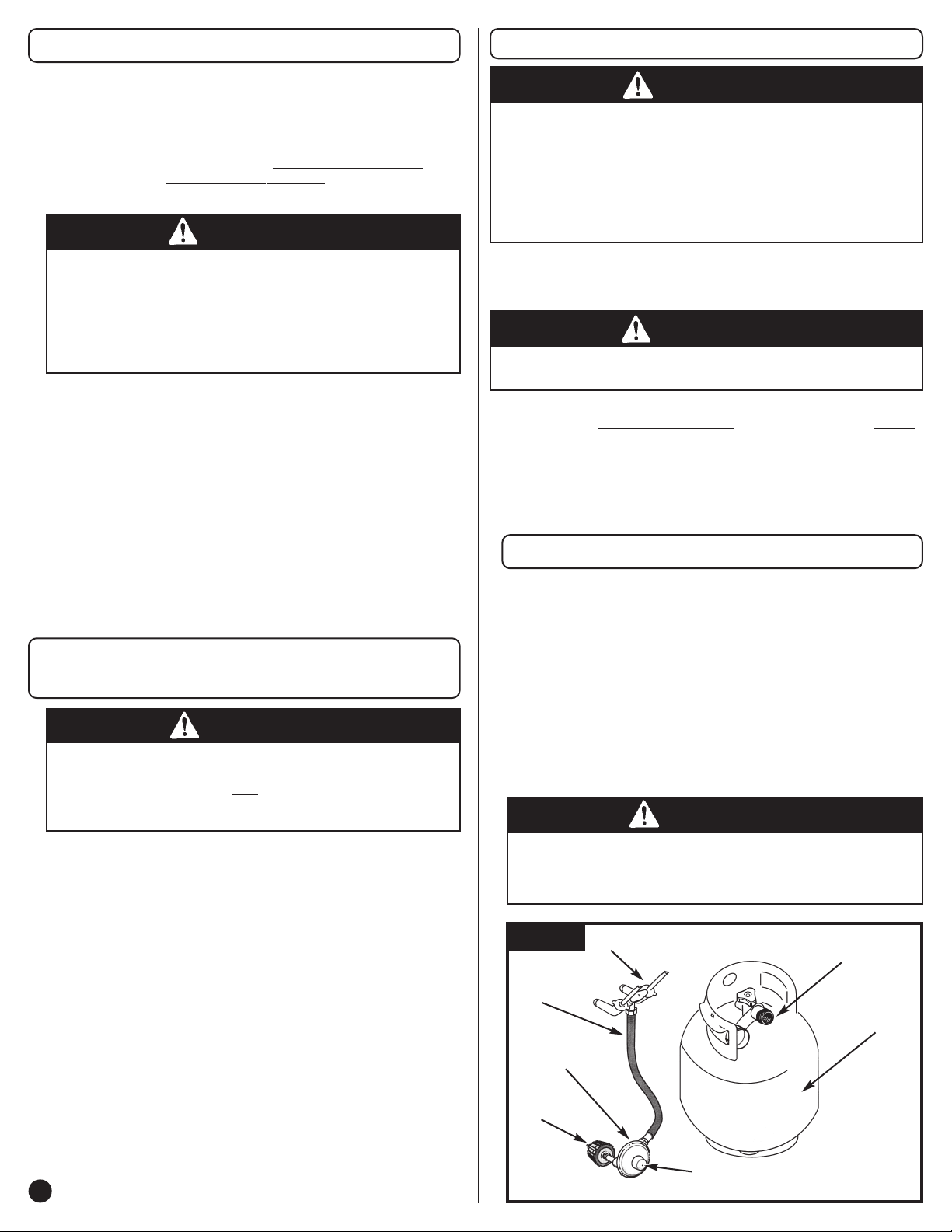

Liquefied Petroleum gas (abbreviated L.P. gas or propane), is

highly flammable. It becomes liquid when stored under high

pressure inside a cylinder and vaporizes when released. L.P. gas

is heavier than air and tends to collect in low areas. It is important

that there are no leaking connections on your gas grill that could

cause a fire or explosion (see the section titled “LEAK TESTING”).

Portable LP gas grills require a fuel delivery system which is

comprised of a valve [A], a hose [B], a regulator [C] with vent hole

[G], an L.P. gas supply cylinder [D], a Type 1 coupling nut [E] and

a Type 1 cylinder valve [F], (Fig. 1). Illustration in (Fig. 1) is for

description purposes only. The valve assembly for this grill is of a

different configuration.

A

B

C

E

D

F

G

WARNING

Your new barbecue grill is equipped with a Type 1 coupling nut

[E]. DO NOT attempt to connect to any other L.P. cylinder not

equipped with a mating Type 1 cylinder valve [F]. This grill is

not to be used with any other cylinder connection device.

Electrical Attachments

LP Fuel Connections Other Than

Portable L.P. Cylinders

Natural Gas Connections

Portable L.P. Gas Barbecue Cylinders

• This section applies to L.P. Gas (Propane) Grills and only

where propane gas is to be piped to the grill.

• Natural gas can be used only

with grills which have been

equipped for use with natural gas.

WARNING

• Gas supply system must be installed in accordance with the U.S.

National Fuel Gas Code.

• This appliance and its individual shut off valve must be disconnected

from the gas supply piping system during any system pressure test in

excess of 1/2 PSI (3.5 KPA).

• Use a system manual shut off valve to shut off the gas supply to this gas

appliance before continuing with installation procedures.

WARNING

A liquid propane tank, not connected for use with this gas barbecue,

shall not be stored in the vicinity of this or any other appliance.

Connections must comply with local requirements and are the

sole responsibility of the person performing the work.

A certified plumber must make connection to gas source.

The maximum inlet supply pressure is 10.5 inches w.c. for natural

gas. The specified supply pressure is 7.0 inches w.c. for natural gas.

When using an electric attachment with the grill, follow the

specification and warning statements accompanying the attachment.

IMPORTANT: If using an external electrical source, the installed

appliance must be electrically grounded according to local codes or,

in the absence of local codes, with the National Electr

ical Code,

ANSI/NFPA 70 or the Canadian Electrical Code CSA C22.1.

Installation and provision for combustion and ventilation air must

conform with the

National Fuel Gas Code, ANSI Z223.1 (USA), or Natural

Gas and Propane Installation Code

, CSA B149.1 (Canada), or Propane

Storage and Handling Code, CSA B149.2 (Canada).

Fig. 1

Page 5

5

DANGER

• DO NOT insert any foreign objects into the valve outlet. You

may damage the valve. A damaged valve can cause a leak,

which could result in explosion, fire, severe personal injury

or death.

WARNING

• Cylinders must be stored outdoors out of the reach of

children and must not be stored in a building, garage or

any other enclosed area (Fig. 2).

Cylinder Specifications

• Any L.P. gas supply cylinder used with this grill must be

approximately 12 inches diameter and 18 inches high. The

maximum fuel capacity is 80% and is approximately 20 pounds

of propane.

• The maximum weight of a properly filled cylinder will be

approximately 38 pounds (47.7 lbs. nominal water capacity).

• The L.P. cylinder must have a shut-off valve terminating in a

Type 1 L.P. gas cylinder valve outlet (see item [F], Fig. 1).

• A Type 1 compatible cylinder with a Type 1 cylinder valve has a

back-check valve which does not permit gas flow, until a

positive seal has been obtained.

• The cylinder must be arranged in an upright position for vapor

withdrawal. It must also include a collar to protect the cylinder

valve. A safety relief device having direct communication with

the vapor space of cylinder must be provided. This will expel

high pressure gas if the cylinder is over filled or overheated

which could result in fire or explosion.

• All L.P. gas cylinders used with this appliance shall be

constructed and marked in accordance with the Specifications

for L.P. Gas Cylinders of the U. S. Department of Transportation

(DOT) or the National Standard of Canada, CAN/CSA-B339,

Cylinders

, Spheres and

Tubes for Transportation of Dangerous

Goods; and Commission, as applicable; and shall be provided

with a listed overfilling prevention device, and a cylinder

connection device compatible with the connection for outdoor

cooking appliances.

• Read labels on the L.P. Gas Supply Cylinder.

• New cylinders are always shipped empty for safety.

• Allow only qualified L.P. gas dealers to fill or repair your L.P. gas

supply cylinder.

• Inform the gas dealer if it is a new or used cylinder to be filled.

• Caution the gas dealer not to overfill the cylinder.

• After filling, have the gas dealer check for leaks and to see that

the relief valve remains free to function.

CAUTION

Have the gas dealer weigh the cylinder after filling to ensure

that the cylinder is not over filled.

The pressure regulator and hose assembly with the Type 1 fitting

supplied with the appliance must be used. Do not use another

hose and regulator assembly other than the one supplied with the

grill or a Coleman® replacement pressure regulator assembly. The

pressure regulator and hose assembly provided is factory set at

an outlet pressure of 11 inches water column (1/2 psi).

• Keep the small vent hole in the regulator clean of dirt and debris

(see item [G], Fig. 1).

• Consult your L.P. gas dealer if you think the regulator is not

working properly.

WARNING

• DO NOT attempt to adjust the regulator as this could

create a situation causing personal injury or property

damage.

WARNING

During assembly of the grill and when attaching or replacing

the L.P. gas cylinder, insure that the gas supply hose is free

of kinks and/or damage and is at least 3 inches away from

hot surfaces such as the grill housing.

L.P. Gas Cylinder

Hose and Regulator

Transporting the Cylinder

• Transport only one cylinder at a time.

• Transport the cylinder in an upright and secure manner with a

control valve turned off and the cap in place.

• DO NOT transport the cylinder in the passenger compartment,

unless you have an open window ventilation.

• DO NOT leave the cylinder in direct sunlight or in a high heat area

such as a closed car trunk. High heat areas could cause the relief

valve to vent gas.

• Use a cylinder cap on the cylinder valve outlet during transport

and when the cylinder is not connected to the grill.

• Keep the cylinder valve closed when not in use.

• Take the cylinder directly home after it has been filled.

The Type 1 connection system has the following features:

1. The system will not allow gas to flow until a positive connection has

been made.

NOTE: The cylinder control valve must be turned off before any

connection is made or removed.

2. The system has a thermal element that will shut off the flow of gas

in the event of a fire.

3. The system has a flow limiting device which, when activated, will

limit the flow of gas to 10 cubic feet per hour.

4. NEVER use grill without leak testing this connection.

Fig. 2

Page 6

6

WARNING

Handle a full cylinder with care. Gas is under high pressure.

DANGER

• NEVER store a spare L.P. gas supply cylinder under the grill

body or inside the grill enclosure or in the vicinity of any heat

producing appliance (Fig. 3).

• NEVER fill the cylinder beyond 80% full.

Failure to follow this information exactly could result in an

explosion and/or fire causing death or serious injury.

• When using cylinder exchange: If your grill is equipped with a

Type 1 cylinder, be sure the exchanged cylinder is a Type 1

cylinder, as a 510 POL cylinder will not fit Type 1 regulator.

• This tank is easily filled with a standard CGA 510 POL filling

connection (Fig. 4).

• New cylinders must be purged before filling. Tell your L.P. Gas

dealer if your cylinder is new and has not been previously filled.

The L.P. Gas cylinder has a Type 1 cylinder valve with a backcheck module in its outlet which will not permit gas to flow until

an evacuation device is installed. To purge the L.P. Gas cylinder,

the back-check module must be opened with an evacuation

device.

Take these instructions to the L.P. gas dealer.

DANGER

Purging and filling of L.P. Gas cylinders must be performed

by personnel who have been thoroughly trained in accepted

L.P. Gas industry procedures. Failure to follow this instruction

may result in explosion, fire, serious personal injury, or

death.

A. Hose end valve with a bleed port (Fig. 4):

Purging can be accomplished using a hose end valve

containing a bleed port which also allows for evacuation without

the use of an adapter.

B. Hose end valve without a bleed port:

When a hose end valve does not have a bleed port, a separate

device must be used for evacuation.

C. Purging using a Type 1 connection (Fig. 5):

L.P. Gas cylinder evacuation can be accomplished during each

purging by using a Type 1 connection. The Type 1 valve outlet

has an external 1 5/16" ACME right-hand thread which will

accept this connection.

TYPE 1

CAUTION

After purging or filling an L.P. Gas cylinder, DO NOT insert a

POL plug into the valve outlet. Insertion of the plug will

prevent the back-check from closing. Use ONLY the provided

cap and strap attached to the outlet. Close the cylinder valve

knob before returning the cylinder to the customer.

For proper purging procedures refer to:

In the US: Safety Bulletin NPGA# 133, “Purging L.P. Gas

Cylinders”, and Safety Bulletin NPGA #130, “Recommended

Procedures for Filling Cylinders”.

Transporting the Cylinder (continued)

Filling and Purging Type 1

L.P. Gas Cylinders

Purging and Evacuating Devices for L.P.

Gas Cylinders with Type 1 Cylinder Valves

Filling and Purging Type 1

L.P. Gas Cylinders (continued)

CGA-510 POL

Fig. 3

Fig. 4

Fig. 5

Page 7

7

1

3

4

7

10

9

8

13

6

2

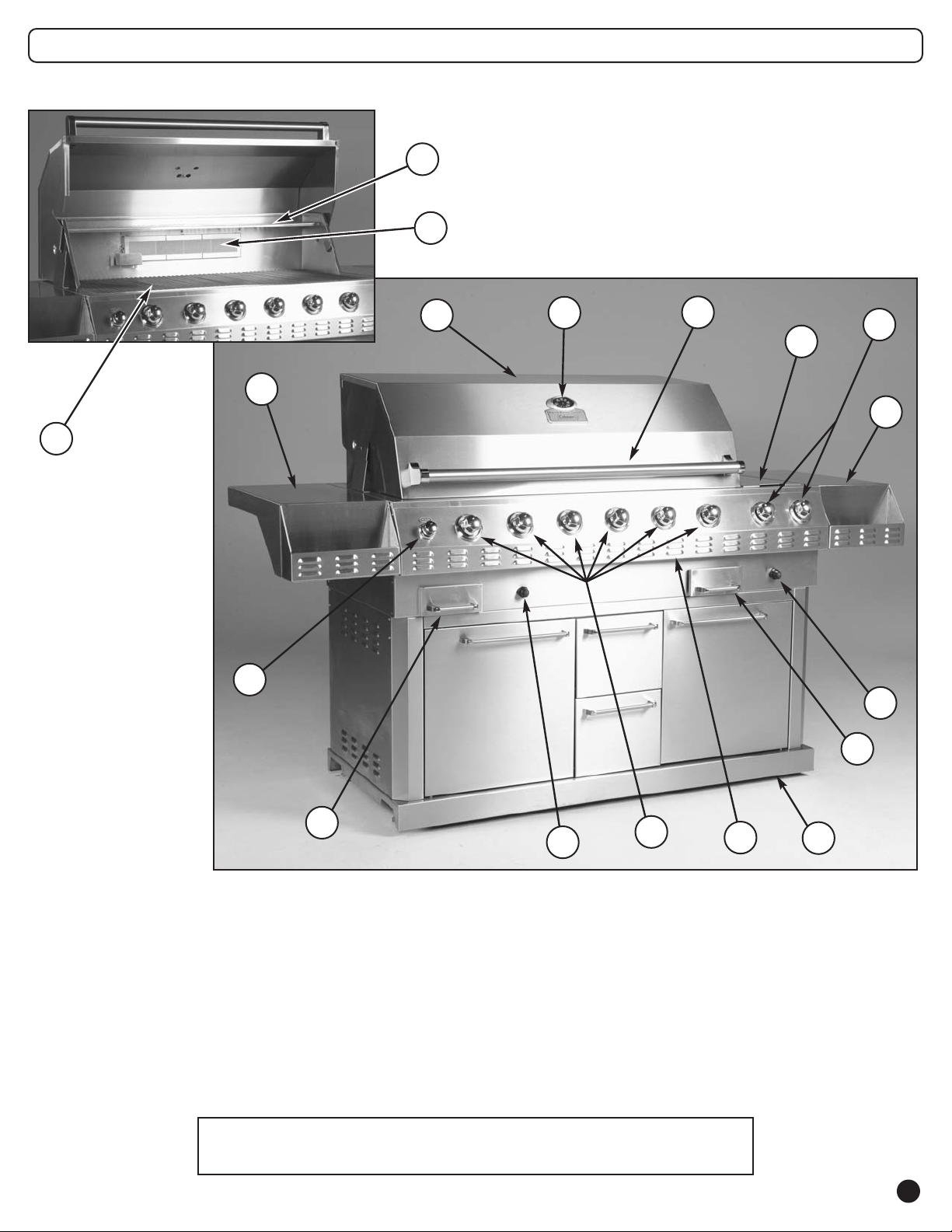

1. Grill Hood

2. Thermometer

3. Hood Handle

4. Side Burners

5. Control Knobs: Side Burners

6. Side Shelf

7. Electronic Igniter: Right Main Burners

and Side Burners

8. Drip Trays

9. Cart with Doors

10. Convection Vents

11. Control Knobs: Main Burners

12. Electronic Igniter: Left Main Burners

and Rear Infrared Burner

13. Control Knob: Rear Infrared Burner

14. Grilling/Cooking Surface

15. Rear Infrared Burner

16. Warming Shelf

Grill Features — 8400 Series

NOTE: See your dealer for a Rotisserie Kit that is purchased separately

(the bracket shown in the photo is provided with the Rotisserie Kit).

15

16

14

5

8

12

11

6

Page 8

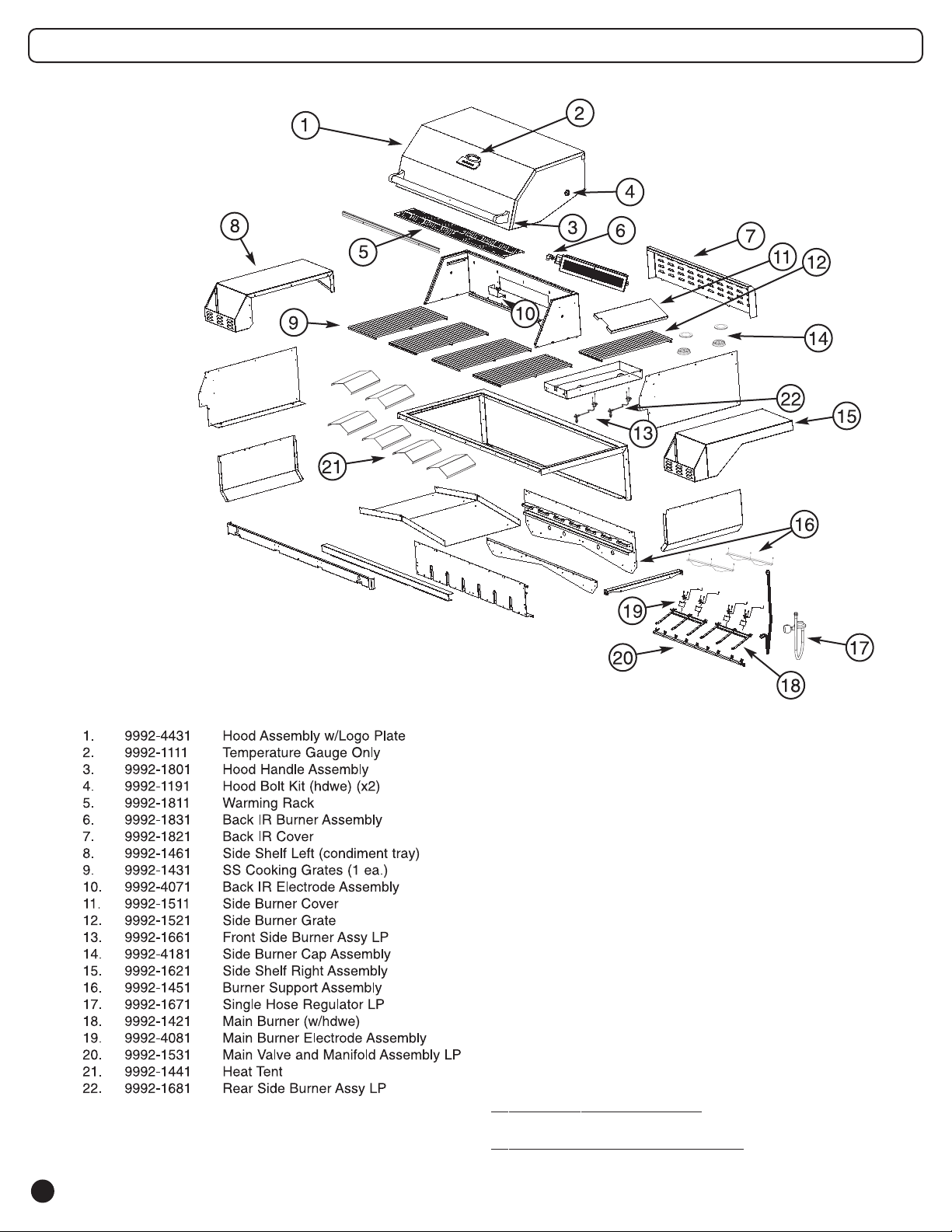

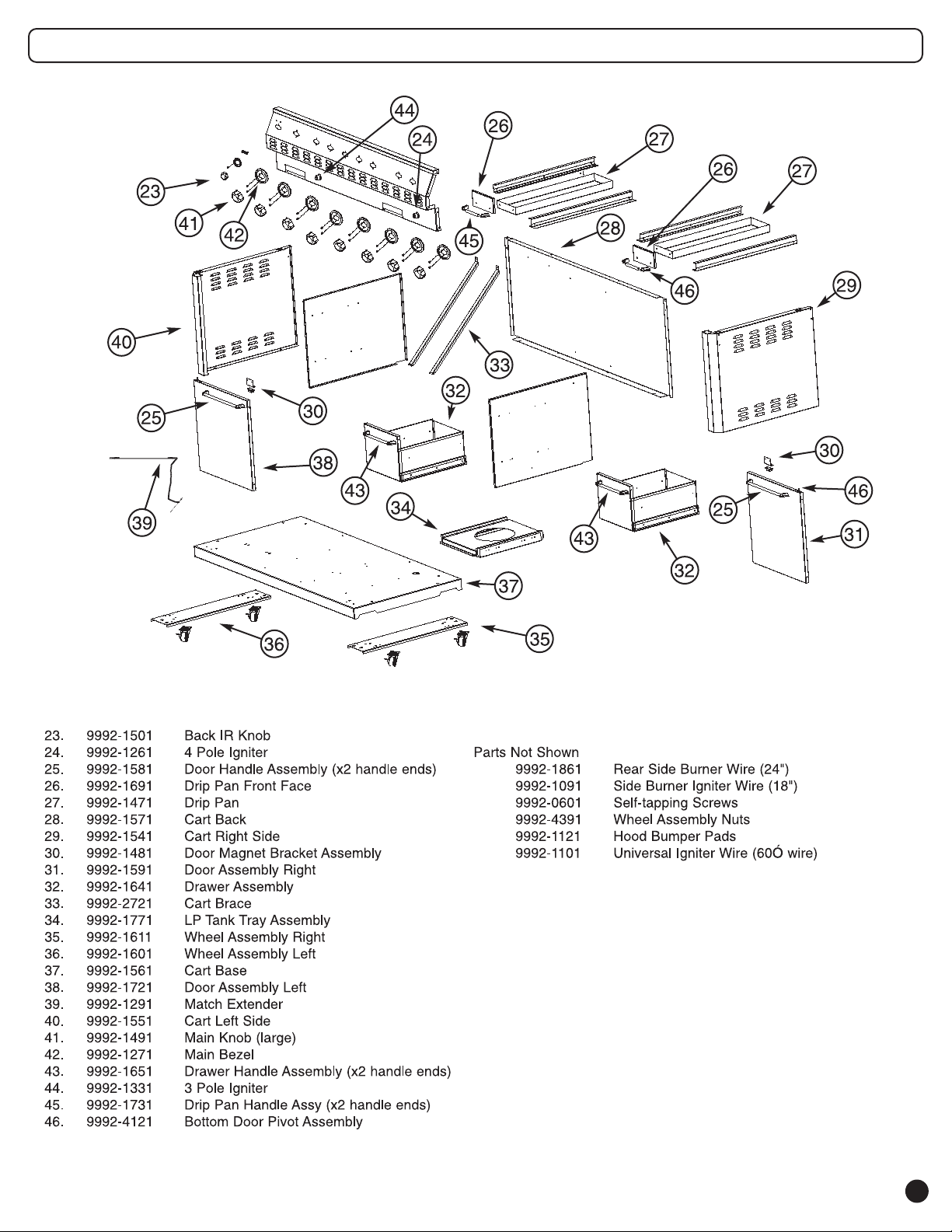

Replacement Parts List — 8400 Series

8

Grill Rotisserie Kit (not shown)

9992-557 8400 Series Grill Rotisserie Kit

Gr

ill Gas Conversion Kit (not shown)

9992-237 8400 Series LP to NG Conversion Kit

Page 9

Replacement Parts List — 8400 Series

9

Page 10

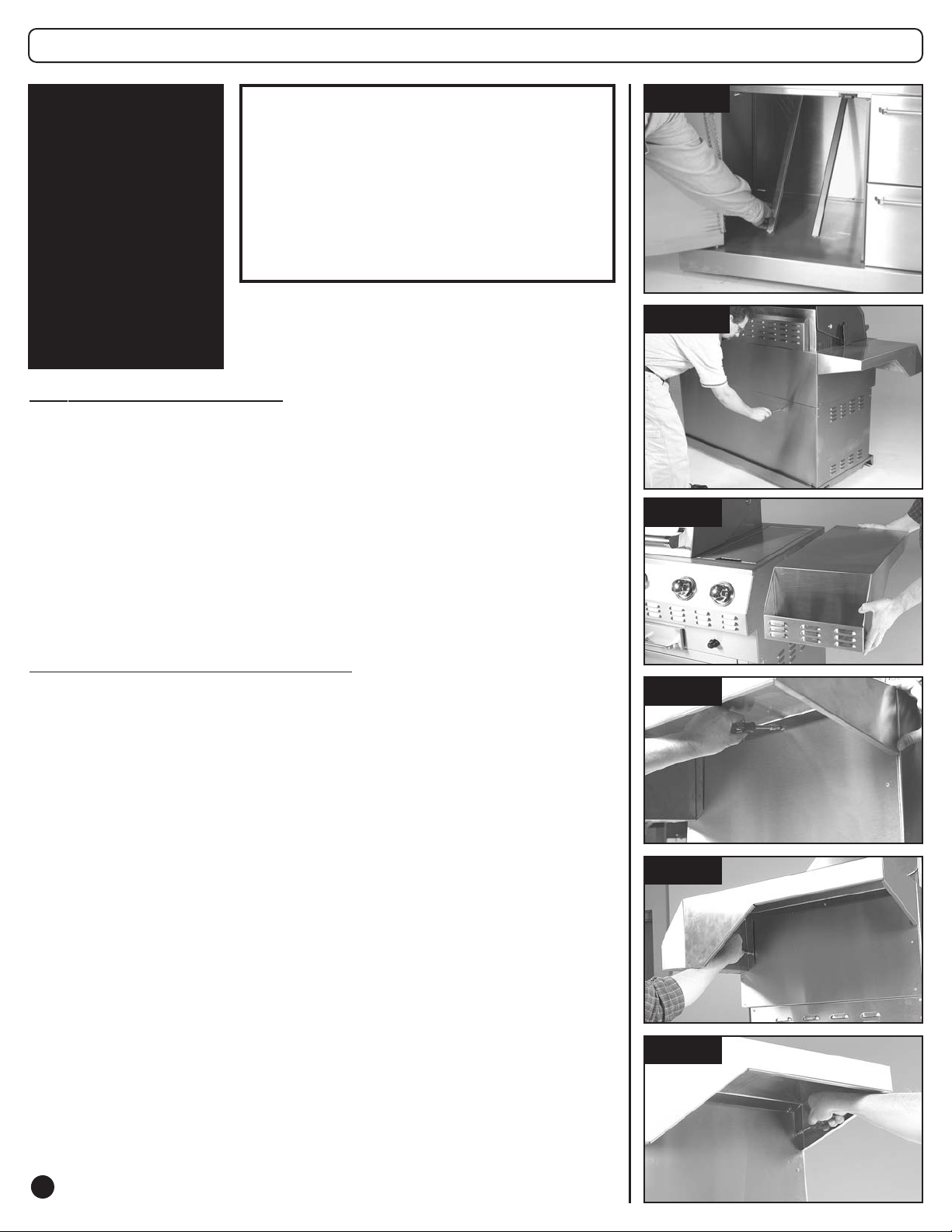

Cart Brace Installation

1.

Open the left grill door. The two cart braces will be installed at an

angle from the cart base to the back side of the compartment.

The top end has a tab with a hole in the center. The bottom end

has two protruding tabs.

2.

Insert the two protruding tabs into the pair of slots located in the

cart base (Fig. 6).

3.

Lock the cart braces in place by inserting (1) self tapping screw

through the back side of the compartment from the outside and

through the hole in the tab in each cart brace (Fig. 7).

Fig. 6

Fig. 7

Grill Assembly — 8400 Series

IMPORTANT:

Remove all

protective plastic

film from stainless

steel parts prior to

assembly/use. This

film is installed at

the factory to

prevent damage

that could occur

during shipment

and handling.

Tools Required (not provided):

— 1/4” Hex Nut Driver

— Phillips Screwdriver

Optional:

— Battery Powered 1/4” Hex Nut Driver

Fig. 9

Fig. 10

Fig. 11

Fig. 8

1.

The right side shelf attaches to the right side of the grill (Fig. 8).

2.

Secure the center of the shelf by inserting (2) self-tapping screws

into the center flange underneath the shelf (Fig. 9). Use a 1/4”

hex nut driver as shown, or use a power tool whenever there is

enough room.

Right Side Shelf Attachment

3.

Secure the front of the shelf by inserting (2) self tapping screws

into the front flange underneath the shelf (Fig. 10).

4.

Secure the rear of the shelf by inserting (2) self tapping screws

into the rear flange underneath the shelf (Fig. 11).

10

Page 11

1.

Place a piece of styrofoam from the packaging in the grill to

leave the grill hood propped open slightly (Fig. 12).

Left Side Shelf Attachment

Grill Assembly — 8400 Series

Fig. 13

Fig. 14

Fig. 15

Fig. 16

11

Fig. 12

2.

The left side shelf attaches to the left side of the grill (Fig. 13).

3.

Secure the center of the shelf by inserting (2) self-tapping screws

into the center flange underneath the shelf (Fig. 14). Use a 1/4”

hex nut driver as shown, or use a power tool whenever there is

enough room.

5.

Secure the rear of the shelf by inserting (2) self tapping screws

into the rear flange underneath the shelf (Fig. 16).

4.

Secure the front of the shelf by inserting (2) self tapping screws

into the front flange underneath the shelf (Fig. 15).

Page 12

12

Grill Assembly — 8400 Series

1.

Install the burners and caps (Fig. 17 and Fig. 18).

Fig. 17

Fig. 18

Fig. 19

2.

Install the grate over the burners (Fig. 19).

Side Burner Installation

Fig. 20

Igniter Battery Installation

1.

The AA battery, spring and igniter cap must be installed before

using (Fig. 20).

2.

Install the AA battery, negative end first.

3.

Slide the spring assembly over the battery.

4.

Screw the igniter cap onto the igniter (Fig. 21).

Fig. 21

Test the Igniter:

A spark should appear at electrode tips.

If the spark does not appear:

-Check the wire connections to the electrode module.

-Check the proper assembly of a fresh AA battery.

NOTE: It does not matter which ignition wire goes to which tab

on the electrode module.

Page 13

13

Grill Assembly — 8400 Series

Fig. 26

1.

Insert the row of six heat tents with the triangle ridges

facing up (Fig. 22). Notice that the heat shields that are

welded underneath the heat tents are placed toward the

back of the grill (Fig. 23).

Interior Parts Installation

Fig. 22

Fig. 24

Fig. 25

2.

Install the four cooking grates on the ledges provided on the grill

to create your cooking surface (Fig. 24).

4.

Remove the labels from the drip trays. Install the drip trays by

sliding them into position as shown (Fig. 26).

Fig. 23

Heat Shield

3.

Place the warming shelf on the support brackets. The ends of the

warming rack rest on the support brackets (Fig. 25).

Page 14

14

IMPOR

TANT!

T

O ENSURE PROPER GAS FLOW

, BURNER

CONTROL VALVES MUST

BE

“OFF” BEFORE

OPENING THE GAS CYLINDER VALVE

.

WARNING: During assembly

of the grill and when attaching or

replacing the L.P. gas cylinder,

insure that the gas supply hose is

free of kinks and/or damage and

is at least 3 inches away from hot

surfaces such as the grill casting.

Fig. 28

LP Cylinder Installation

Fig. 27

1.

Open the right door and slide out the cylinder support. Set the

LP cylinder in the cylinder support location with the outlet valve

facing toward the right side of the grill (Fig. 27).

Grill Assembly — 8400 Series

NOTE: Your 8400 Series grill is set up from the factory to use LP GAS. If you want to use NATURAL

GAS, you must purchase the NATURAL GAS CONVERSION KIT (sold separately). Please skip

to the section titled “Natural Gas Installation”.

Fig. 29

3.

Slide the cylinder support back into the grill (Fig. 29).

2.

Insert the TYPE 1 Nipple of the regulator into the cylinder’s fuel

valve outlet as shown (Fig. 28). Turn the regulator hand wheel

clockwise to tighten. No tools are needed. The hand wheel will

come to a complete stop when the connection is secure, and the

gas will not flow until a positive seal is achieved.

Page 15

15

1. Check that the cylinder valve is closed by turning the cylinder

knob clockwise to a full stop.

2. Check that all the grill burner knobs are in the off position.

3. Remove the protective caps from the cylinder valve and coupling

nut. NOTE: The coupling nut connects to the large outside

threads on the valve outlet.

4. Hold the regulator in one hand and insert the nipple into the

valve outlet. Be sure the nipple is centered in the valve outlet.

Hand-tighten the coupling nut, taking care not to cross-thread

the connection (see Fig. 30).

5. Turn the coupling nut clockwise, tighten to a full stop.

If you cannot complete the final connection, disconnect the

regulator and repeat steps 4 through 6. If you are still unable to

complete the connection, DO NOT use this valve and regulator!

6. Check that the hose has no kinks or sharp bends and clears

areas that will become hot during use. Never put strain on the

hose where it joins a fitting.

7. BEFORE lighting grill, check all connections for leaks using the

procedure as shown in the section titled “LEAK TESTING”.

WARNING

This procedure MUST be performed OUTDOORS only! Be

sure the L.P. cylinder valve is closed. Attach to the grill. Read

and follow the directions on the cylinder and fuel hose

safety tags.

CAUTION

In the connection process, the grill side of the connection

will seal on the back-check in the valve, resulting in a slight

resistance. The connection requires about one-half to

three-quarters additional turn to complete the connection.

To disconnect, turn counterclockwise. Tighten by hand only.

DO NOT use tools.

Connecting Type 1 L.P. Gas Cylinders

Fig. 30

Page 16

16

NA

TURAL GAS CONVERSION KIT (not shown)

Par

t Number Description

9992-237 8400 Series LP to NG Conversion Kit

Natural Gas Installation — 8400 Series

NOTE: This step applies to you only if you are converting your 8400 Series grill to use NATURAL GAS. If

you will be using your grill with LP GAS, this section does not apply to you. Please skip back to the

section titled “LP Cylinder Installation”.

Y

OUR NATURAL GAS COMPANY

MUST INSTALL AND

CONNECT THE GAS SUPPLY LINE TO THE GRILL

.

The 8400 Series Grill is set up at the factory for use with LP GAS. A NATURAL GAS Conversion Kit is

available and must be purchased separately. Follow the installation instructions provided with the

Natural Gas Conversion Kit.

Page 17

17

DANGER

T

O PREVENT F

IRE OR EXPLOSION HAZARD:

• NO SMOKING. DO NOT use or permit sources of ignition

in the area while doing a leak test.

• Perform leak tests outdoors only.

• NEVER perform a leak test with fire or flame.

Leak Testing

• If you detect a leak:

1. Turn off the fuel supply. Push in and turn on the control knobs

to release pressure in the hose, then turn the control knobs

back to off.

2. Wash off soapy solutions with cold water and towel dry.

3. Stop a leak by tightening the loose joint, or by replacing the

faulty part with a replacement part recommended by Coleman.

DO NOT attempt to repair the cylinder valve if it should

become damaged; the cylinder MUST be replaced.

4. If you are unable to stop a leak, shut off the gas supply at the

cylinder valve. Remove the cylinder from the grill. Call a gas

appliance serviceman or L.P. gas dealer. DO NOT use grill

until the leak is corrected.

• When to test for leaks:

1. Perform a leak test each time the gas supply cylinder is

connected to the regulator. Leak test anytime a part of

the gas system is replaced.

2. Perform a leak test at least once each year whether the L.P.

gas supply cylinder has been disconnected or not.

3. Have a dealer check the cylinder for deterioration after 12

years, according to DOT regulations. Immediately replace the

cylinder if any deterioration is found.

How to Check for Leaks

1. Make a soapy solution of equal parts mild liquid dishwashing

detergent and water.

2. Turn off all burner control knobs.

3. Turn on the fuel supply. Turn the cylinder valve knob

counterclockwise (right to left) one rotation.

4. Apply a soap solution to the connections indicated with the

arrows in Fig. 31. If bubbles appear at these areas, a leak

is indicated.

Fixing A Fuel Leak

CAUTION

Inspect the gas supply hoses before each use. Open the

door to inspect the hose assembly below the grill. Also

inspect the hose assembly below the side burner. If there are

cuts, damage, excessive abrasion or wear, replace the hoses

prior to operating the appliance. During assembly of the grill

and when attaching or replacing the L. P. gas cylinder, insure

that all gas supply hoses are free of kinks and/or damage

and are at least 3 inches away from hot surfaces such as the

grill housing. Use only hose replacements specified in the

parts list.

Fig. 31

Page 18

18

1. Regularly check the burner venturi tubes for blockage from an

insect nest. Read “Cleaning the Venturi” in the section titled “Care,

Maintenance, and Cleaning”, and also the section titled

“Troubleshooting”.

2. Check that all the burner venturi [H] are set over the valve

outlets [J] correctly. The valve orifice [K] must be inside the

venturi (Fig. 32).

3. Inspect the gas supply hoses before each use. Hoses can

be burned or chafed if they are routed improperly. See that

the hoses have no kinks, sharp bends or tension. Insure

that the hoses are at least 3 inches away from any hot surface.

4. Use only the gas specified.

5. Keep the grill on a level surface.

6. Keep the grease pan empty at start up.

WARNING

Failure to follow these safety steps before using the grill each

time could result in a fire that could be hazardous to you, your

appliance or property. It is especially important to observe

these steps after the grill has been stored, moved or cleaned.

Start-Up Check List

J

K

H

REPRESENTATIVE ILLUSTRATION

CAUTION

DO NOT add charcoal or lighting fluid!

2

3

4

WARNING

THE FOLLOWING RULES MUST ALWAYS BE

FOLLOWED IN THIS ORDER (Fig. 33):

1. OPEN THE GRILL LID! Any attempt to light the grill with

the lid down could cause an explosion.

2. Check that the burner control knobs are turned to “OFF”.

3. Turn on the fuel supply. For an L.P. gas cylinder, turn the

top cylinder valve knob counterclockwise one rotation

to open.

4. DO NOT stand with your head or arms over the grill.

Lighting Instructions

(2) Right Side Burner Knobs

Rear Infrared

Burner Knob

(Rotisserie)

1

Fig. 32

Fig. 33

Fig. 34

REPRESENTATIVE ILLUSTRATION

(6) Control Knobs for Main Cooking Area

(2) Igniter Switches

Page 19

19

Lighting Main Burners

Lighting Side Burner

1. Push and turn the side burner control knob counterclockwise to the “HIGH” position.

(Fig. 39)

2. Immediately press and hold the electronic igniter button (Fig. 39).

You will hear a snapping sound.

3. If the burner does not light in 4 seconds, turn the control knob to OFF and wait 5 minutes for

the gas to clear before trying again.

4. If the burner does not light on the second try, turn the control knob to OFF and wait 5

minutes for the gas to clear, and then try match-lighting the side burner.

1. Strike and place the burning long wooden match (or butane lighter with extension) through

the spaces in the pot support to the ports of the burner (Fig. 40).

2. Push and turn the side burner control knob counterclockwise to the “HIGH” position.

Match Lighting - Side Burner

CAUTION

Use a LONG wooden match or a butane lighter with an extension. Make sure all burner

controls are off except for the burner being lighted. If a long-reach match or lighter is not

accessible, there is a match extension provided, attached to the inside of the door. Insert

a match in the holder end of the extension, strike and place the burning match near the

BURNER being operated.

1. Push and turn one of the three left main burner control knobs counterclockwise to the

“HIGH” position. Wait 5 seconds. (Fig. 34, 35 and 36)

2. Press and hold the left electronic igniter button. You will hear a snapping sound. (Fig. 36)

3. If the burner does not light in 4 seconds, turn the control knob to OFF and wait 5 minutes for

the gas to clear before trying again.

4. Repeat steps 1 through 3 to light the remaining burners.

NOTE: The right main burners are ignited by using the right side igniters (Fig. 37)

5. If the burner does not light on the second try, turn the control knob to OFF and wait 5

minutes for the gas to clear, and then try match-lighting the burner.

Match Lighting - Main Burners

1. Strike and place the burning long wooden match (or butane lighter with extension) through

the spaces in the grill grates near the ports of the back crossover burner between the heat

tents. (Fig. 38).

2. Push and turn the control knob counterclockwise to the “HIGH” position.

3. Repeat steps 1 and 2 to light the remaining burners.

Fig. 36

Fig. 35

CAUTION

The side burner cover MUST BE OPEN during lighting and while using the side

burner (Fig. 40). NEVER operate the side burner with the side burner cover in the

closed position.

CAUTION

Use a LONG wooden match, match extension, or butane lighter with extension.

Fig. 38

WARNING

• The grill m

ust be level before using the side burner.

• NEVER move the grill with a pot or pan on the side burner.

• Make sure the pot or pan is centered on the side burner.

• To avoid the possibility of tipping over the grill, NEVER place more than 15 pounds on

the side burner. A filled 6-quart aluminum pot weighs approximately 15 pounds.

Fig. 39

Fig. 40

Fig. 37

Page 20

20

Using the Rotisserie — 8400 Series

The grill rotisserie system is designed to cook items from the back using infrared heat. The rotisserie burner is an

infrared type which provides intense searing radiant heat. Preferred by chefs over other cooking methods, this intense

heat sears in the natural juices and nutrients found in quality cuts of meats.

Once lit, the rotisserie burner will reach cooking temperature in 1 minute. The orange/red glow will even out in about 5 minutes.

The rotisserie motor is equipped with metal gears and is capable of turning up to 20 lbs. of food. The motor is mounted on a

bracket on the left side of the grill by sliding the motor over the bracket with the cord facing the back of the grill. Make sure

the rotisserie motor is completely seated on the bracket prior to operating. Make sure the rotisserie cord is away from any

hot surfaces.

CAUTION

Remove the warming rack from the grill when using the rotisserie to prevent warping from the intense heat of the infrared unit.

NOTE: The rotisserie spit rod is centered between the grill hood and the burners. It may be necessary to remove the

grates and heat tents when cooking larger portions of meat on the rotisserie. This is by design, since this configuration

gives you the most possible room above and below the rod for larger pieces of meat.

WARNING

Electrical Grounding Instructions

This appliance (rotisserie motor) is equipped with a three-prong grounding plug for your protection against

shock hazard. It should be plugged directly into a properly grounded three-prong receptacle. Do not cut or

remove the grounding prong from this plug.

A

TTACHING THE ROTISSERIE

(

purchased separately)

* For bracket installation, see instruction sheet provided

with the optional rotisserie kit.

The motor is mounted on a bracket on the left side of the grill

by sliding the motor over the bracket with the cord

facing the back of the grill.

With the rotisserie motor in place and plugged into an

electrical outlet, it is now ready to operate. Slide one of the

meat forks onto the rod (prongs facing away from the handle).

Push the rod through the center of the food, then slide the

second meat fork onto the rod (prongs toward the food).

Center the food to be cooked on the rod, then push the meat

forks firmly together. Tighten the thumb screws. It may also be

necessary to wrap food with butcher’s string, (never use nylon

or plastic string) to secure the loose portions.

Once the food is secure, insert the pointed end of the

rotisserie rod into the motor assembly and rest the other end

on the support on the right-hand side of the grill (Fig. 41). If

needed, remove the cooking grates for more room. Turn the

power switch to the “On” position to start the rotisserie motor.

Pointed End Of Rod

NOTE: Remove the rotisserie when not in use. Store the

unit indoors when not in use. Remove warming shelf

when using the rotisserie.

WARNING

Do not use the rotisserie in the rain.

Fig. 41

Gr

ill Rotisserie Kit

Part Number Description

9992-557 8400 Series Grill Rotisserie Kit

NOTE: Your 8400 Series grill is set up from the factory with a Back Infrared Burner.

An optional

ROTISSERIE KIT to use with the back infrared burner must be purchased separately.

Page 21

21

Lighting the Rotisserie Burner

1. Push and turn on the control knob for the ROTISSERIE BURNER counterclockwise to the

“HIGH” position (Fig. 42 and 43). Wait 5 seconds.

2. Press and hold the electronic igniter button (Fig. 43). You will hear a snapping sound.

3. If the burner does not light in 4 seconds, turn the control knob to OFF and wait 5 minutes for

the gas to clear before trying again.

4. Repeat steps 1 through 3.

5. Once lit, turn the control knob to the desired setting.

6. If the burner does not light, turn off knob and try match-lighting the burner.

1. Strike and place the burning match (or butane lighter with extension) near the

ROTISSERIE BURNER (Fig. 44).

2. Turn on the ROTISSERIE BURNER CONTROL KNOB while holding a match near

the burner.

Match Lighting - Rotisserie Burner

CAUTION

Use a LONG wooden match, match extension, or butane lighter with extension.

CAUTION

NOTE: Do Not operate the main burners and the Rotisserie Burner at the same time. This

can cause warping of the grill hood.

Fig. 43

Fig. 42

Fig. 44

CAUTION

DO NOT touch hot grill parts with your bare hands!

You MUST use protective gloves.

CAUTION

Be certain the gas is shut off at the L.P. cylinder valve anytime

the grill is not in use.

1. Turn all burner control knobs to off.

2. After the burner flame goes out, turn off the fuel supply. For an

L.P. cylinder, turn the L.P. cylinder knob in a clockwise direction

until it stops.

Shutting Off the Grill

Page 22

22

Good

Bad

Yellow

Blue

Holes in

Burner

Yellow

Blue

Burner Control Setting Tips

• The high flame setting is too hot for direct cooking. The high flame

setting is good for quick searing of meat, then finish

cooking on medium or low flame settings.

• Use the high flame setting with the lid

closed to preheat the grill for

5 minutes before cooking and with the lid closed for a maximum of

5 minutes after

cooking to burn off grease drippings.

• Use a medium flame setting for direct cooking of steaks, pork

chops, chicken and hamburgers.

• Use a low flame setting for roasts and rotisserie foods.

• Thick steaks will finish with a better texture and more juice if

first seared on high flame setting and then cooked on a low

flame setting.

Safe Grill Operation

• NEVER leave cooking food unattended. Continually observing

the food will help in maintaining an even temperature, conserve

fuel, improve the food’s flavor and lessen flare-ups.

• To open the grill lid, slowly lift the handle to avoid burning in case

of a grease fire flare-up.

• DO NOT expose any part of your body directly above the

cooking area.

Food Preparation Hints

Your grill can cook a variety of foods. For best results, follow these

instructions:

• Trim excess fat from meat and poultry. Slash any remaining fat

to stop curling, but take care not to cut the meat.

• Frozen meat and poultry should be thawed prior to cooking.

• Frozen fish and vegetables will cook without thawing.

• Salt food after

cooking to help prevent drying out the food.

• Brush naturally lean meats with cooking oil or margarine.

• Cook small pieces of tender foods in foil or on special delicatefood cooking grates (see the section titled “Cooking Methods”).

• Apply barbecue, tomato or sugar-based sauces no sooner than

the last 10 minutes of cooking.

• Turn food with tongs or a spatula; piercing food (especially meat),

tends to dry it out.

Grilling Tips and Hints

WARNING

• Keep the grill area clean and free from combustible

materials, gasoline and other flammable vapors, liquids,

and spare L.P. cylinders.

• DO NOT obstruct the flow of combustion and ventilation air.

• Keep the ventilation opening(s) of the L.P. cylinder

enclosure free and clear of debris.

• A barbecue grill becomes hot during use. DO NOT touch

grates, or cooking surfaces.

• Be sure to tighten all hardware (screws, nuts, bolts, etc.)

at least once a year or before each grilling season.

General Use and Correct Burner Flames

Condition The Grill

• Before using the grill for the first time, or after storage,

operate the grill 15 minutes on the high setting with the lid closed,

to burn away oil.

• Once the oil has burned away, check the burner flame per the

next step.

The Burner Flame

• Open the grill lid. The cooking grates should be in place.

• Keep your arms and face away from being directly above the

cooking area. Look through the cooking grates and observe the

burner’s flame below the heat tents. Keep your arms and face

away from being directly above the cooking area.

• Flames should appear similar to the good flame shown in

Fig. 45 and as follows:

• A good flame should be blue with a yellow tip.

• Some yellow tips on flames up to 1 inch in length are

acceptable as long as no carbon or soot deposits appear.

• If flames are excessively yellow and irregular, the oil

residue may not be completely burned off, or the venturi

may be clogged or may not be properly positioned over the

orifices. Allow the grill to cool before repositioning the venturi over

the valve and orifices.

• Grills that have been in use for a while sometimes begin to

show more yellow flame. A build-up of food deposits, fats

or cooking seasonings can cause yellowing flames.

Clean the burner to remove residue and check for clogged

burner holes or a blocked venturi. Refer to the section titled

“Cleaning the Venturi”. .

• Regular use of your grill will actually help keep it operating

more smoothly.

• Each grill may heat differently. Some units will heat somewhat

more to the center and back of the grill. The flavor of grilled

food will improve the more you use the grill and as you

become familiar with it.

Fig. 45

Page 23

23

Direct Method:

• The heat source is directly below the food.

•

Use for browning meat or cooking hot dogs and hamburgers,

but

check food frequently.

• Use for skillet and stir-fry cooking, but limit the amount of oil

and heat to be used.

• Cook roasts, turkey or duck on low heat. Place meat with

water in a foil pan with a corrugated bottom. Replenish water

as needed.

Indirect Method:

• Light only one side of the grill and place food on the opposite

side for cooking.

• Allow food to cook at a lower temperature which increases

tenderness and reduces grease flare-ups.

• It is a good method for cooking foods that burn easily (vegetables,

fish, etc.).

• Cook casseroles in ovenware or foil pans much like

cooking in a conventional oven.

• Also try placing a pan of water above the lit burner side to

help meat retain its juices. Replenish the water as needed.

Rear Infrared Burner Method:

• Light only the Rear Infrared Burner.

• Place food on the rotisserie accessory (sold separately).

• Allows food to cook slowly and evenly.

Cooking Methods

In Case of Grease Fire

Follow These Steps:

1. Shut off the gas at the burner valve(s) and stay away!

2. Allow the fire to burn itself out.

3. Once the fire is out and the appliance has cooled, shut off the

L.P. cylinder valve.

4. Clean all parts and inspect for damage. Parts to check for

damage are the L.P. cylinder, cylinder valve, regulator, gas supply

hose, burner valve(s) and burner(s).

5. If any of the above mentioned components are damaged, seek

replacement from Coleman before operating the grill again by

calling

1-800-356-3612.

Note:

• Some flare-up adds a smoky flavor and sears food. Excessive

grease fires can cause a potentially hazardous situation and

damage the grill.

• Avoid excessive flare-ups by preheating the grill with the lid

closed

for 5 minutes on the high setting to burn off grease from previous

cooking.

• Cook with the lid down and continually monitor cooking food to

avoid grease fires and flare-ups.

• Trimming excess fat from meat will reduce grease fires and flareups. Cook fatty meat in smaller amounts over indirect heat on a

low setting.

• Be sure to follow the instructions in the section titled

“Care,

Maintenance, and Cleaning”

.

Care, Maintenance and Cleaning

DRIP TRAY

The drip tray is located below the grill, inside the cart, and should be

cleaned periodically to prevent heavy buildup of debris.

NOTE: Allow the drip tray to cool before attempting to clean.

Important: Do not leave the grill outside during inclement

weather unless it is covered (cover sold separately). Rain water

can collect inside of the grill, the grill cart or the drip tray if left

uncovered. If the drip tray is not cleaned after use and the grill

is left uncovered, the drip tray will fill with water causing grease

and water to spill into the grill cart. We recommend cleaning

and storing the drip tray after every use.

COOKING GRATES

The cooking grates can be cleaned immediately after cooking is

completed and after turning off the grill. Wear a barbecue mitt and

scrub the cooking grates with a damp cloth. If the grill is allowed to

cool down, cleaning the grates will be easier if removed from the grill

and cleaned with a mild detergent.

ST

AINLESS STEEL

After initial usage, areas of the grill may discolor from the intense

heat given off by the burners, this is normal and not considered

a defect.

Purchase a mild stainless steel cleaner and rub in the direction of

the grain of the metal. Specks of grease can gather on the surface of

the stainless steel and bake on to the surface and give a worn

appearance. For removal, use an non-abrasive oven cleaner in

conjunction with a stainless cleaner.

NOTE: Always scrub in the direction of the grain.

IGNITER A

CCESS (ABOVE ACCESS DOORS):

To remove the igniter, unscrew the igniter push button and the

locking nut from the front panel above the access doors (Fig. 46).

The igniter will fall out through the bottom. The electrode module is

now visible. Remove the wires that are factory installed from the

electrode module to the burner electrodes. Reverse the procedure to

install a new electrode module.

NOTE: It does not matter which ignition wire goes to which tab

on the electrode module.

Fig. 46

REAR INFRARED BURNER:

Light and burn the rear infrared burner at least once a month

to ensure there is not a build-up of debris or grease on the

burner. This will ensure the ceramic burner will continue to

operate as it should.

Page 24

24

REPRESENTATIVE ILLUSTRATION

Steps For Cleaning Venturi:

1. Remove the cooking grates and the heat tents and set aside.

2. Using a 1/4” hex nut driver, remove the self-tapping screws

holding the front heat shield (Fig. 49 and 50). Set the front

heat shield aside.

3. Using a 1/4” hex nut driver, remove the self-tapping screws

holding the burner support assembly and the main

burner (Fig. 51).

4. Look inside lower end of venturi tubes for nests, webs or

mud (Fig. 52).

5. To remove the above obstructions, use an accessory flexible

venturi brush or bend a small hook on one end of a 20-inch long

flexible wire such as the one shown in Fig. 48.

6. Inspect and clean the burner if needed.

7. Replace the main burner, burner support assembly, and the

front heat shield into the grill.

8. Make sure the valve orifices are inside the venturi tubes (Fig. 53),

then tighten all self-tapping screws.

9. Reinstall the heat tents and the cooking grates.

WARNING

Spider’s nests or wasp’s mud inside the venturi may cause fire

at the valve. If a fire occurs, immediately

turn off the gas

supply at the L.P. cylinder valve (see representative illustration

in Fig. 47). If your grill is set up for use with Natural Gas, turn

off the gas supply at the system manual shut off valve.

Cleaning the Venturi

Note:

Spiders and small insects can spin webs and build nests inside the

venturi tubes. This especially occurs in late summer and fall before

frost when spiders are most active. These nests can obstruct gas flow

and cause a fire in and around the burner valves. Such a fire can

cause operator injury and serious damage to the grill. To help prevent

a blockage and ensure full heat output, clean and inspect the venturi

tubes often (once or twice a month). NOTE: Water or air pressure will

not

normally clear a spider web.

Fig. 49

Fig. 50

Fig. 51

Fig. 52

Fig. 53

Care, Maintenance and Cleaning (continued)

Fig. 48

Fig. 47

Page 25

CAUTION

All cleaning and maintenance should be done only when the

grill is cool & with the fuel supply turned off at the cylinder.

If your grill is set up for use with Natural Gas, turn off the

gas supply at the system manual shut off valve.

Suggested Cleaning Materials:

• Mild dishwashing liquid detergent • Hot water • Wire brush

• Paper clip • Nylon cleaning pad • Soft brass-bristled brush

• Putty knife • Scraper

Component Cleaning:

• BURNER: Wire-brush loose corrosion from the burner exterior.

Clean clogged gas port holes with an opened paper clip.

Replace corroded or damaged burners that would emit excess

gas.

• STAINLESS STEEL: Clean with any multipurpose (low abrasive,

no phosphorous) metal polish or stainless steel polish and a soft

cloth to prevent marring or scratching the surface. NEVER

USE OVEN CLEANER!

• ORIFICES: Unscrew the orifices from the rear of the the valves

(Fig. 54). Wash orifices in solvent and blow air through the small

end holes. Carefully replace the orifices in the valve when they

are dry. Make certain that the orifices are tightly reassembled.

Care, Maintenance and Cleaning (continued)

DANGER

NEVER attempt to operate your grill without orifices in the

valves. A serious and immediate fire hazard would result.

• COOKING GRATES: Clean cooking grates with mild soap and

hot water. Remove stubborn residue with a mild cleanser or

scrub brush. DO NOT use a commercial oven cleaner.

• HEAT TENTS: Wipe off grease residue using a cleaning pad

and a brass-bristle brush to knock off residue. Replace heat

tents to their correct position.

• GRILL INTERIOR: Remove grates and heat tents.

Scrape side with tools and remove excess grease and cooking residue.

Orifices

Valves

REPRESENTATIVE ILLUSTRATION

CAUTION

A collision with the grill, as with any metal object, could cause

injury. Use care when moving a portable gas grill.

Moving the grill:

• Move the grill slowly. DO NOT run with or pull the grill behind

you; it could hit you from behind causing injury.

• DO NOT move the grill while it is lit or hot, or with objects on

the cooking surface(s) or side table(s).

After moving the grill:

• Check all gas connections for leaks that could occur from the

movement.

• Check the venturi tubes to be sure they are still over

the orifices.

Steps to follow before storing grill:

• Clean the grill.

• Coat the burner lightly with cooking oil to retard rusting.

• For outdoor use only. If the grill is stored indoors, detach and

leave the cylinder outdoors. If left outdoors, turn off the fuel

supply to the L.P. cylinder and cover the grill for protection from

the weather. Grill covers may be purchased from a grill dealer

or manufacturer.

WARNING

If the grill is not in use, the gas MUST be turned off at the fuel

supply cylinder.

Place the dust cap on the cylinder valve outlet whenever the

cylinder is not is use. Only install the type of dust cap on the

cylinder valve outlet that is provided with the cylinder valve.

Other types of caps or plugs may result in leakage of propane.

Moving and Storage

Troubleshooting

Problem: Grill will not light when the igniter

button is pushed or has incomplete burner

flame.

Possible Causes and Solutions:

1. Lack of fuel. Check to see that the cylinder valve is open and the

cylinder has fuel.

2. Make sure one of the burners is turned on. Allow up to four

seconds for gas flow to ignite.

3. Make sure the AA battery is fresh.

4. If burner lights with match but not igniter, check the ceramic

electrode position near the burner, the condition of the igniter wire

and its connections. Perform igniter test and replace any

damaged parts.

5. Check for spider webs or insect nest in venturi and clean venturi.

6. Misalignment of venturi on orifices. Position venturi over orifices.

7. Burner ports, orifices, valves or hose have blockage. Clean the

components.

8. Crimped fuel supply hose needs straightened.

9. Regulator failure or damaged hose need to be replaced by an

authorized service dealer.

10. Make sure the hose to the cylinder is properly assembled. See the

section titled “Connecting Type 1 L.P. Gas Cylinders”.

Problem:Yellow flame.

Possible Causes and Solutions:

1. Check for spider webs or insect nest in the venturi and clean

the venturi.

2. New burner may have residual oil which will burn off.

3. Clean off any food residue, grease or seasoning salts on the burner.

4. Air may be in the cylinder if the cylinder was not properly

purged. Use up remaining gas; the yellow flame may

disappear with use.

5. The venturi may be misaligned and needs to be lined up over

the orifice.

Fig. 54

25

Page 26

26

TYPE 1 CONNECTION ILLUSTRATION

Thermal

Sensitive

Handwheel

1-5/16"

Acme Connection

Nipple with

Excess Flow

Valve

Regulator

YOUR NEW GAS GRILL IS EQUIPPED WITH A

TYPE 1 CONNECTION DEVICE WHICH HAS 3

SAFETY FEATURES (FIG. 55):

1. Proof of gas seal between the connector and the cylinder

before gas flow takes place.

2. A flow-limiting device designed to limit the flow of gas in

the event of a regulator or hose failure.

3. The connection has a thermal shut-off which will stop the

flow of gas if the connection reaches a certain temperature.

CURRENT GAS CYLINDERS ARE ALSO

EQUIPPED WITH AN OVERFILL PR

OTECTION

DEVICE (O.P.D.)

WHICH GREATLY REDUCES

THE CHANCE OF ACCIDENTALLY

OVERFILLING THE CYLINDER.

SPECIAL NOTE CONCERNING L.P. GAS CYLINDERS:

It is important to insure that your gas cylinder is properly

purged before it is filled. If you purchase a new cylinder,

please inform your propane gas dealer that this is a new

cylinder and needs to be properly purged before being filled.

SPECIAL NOTE CONCERNING TYPE 1 CONNECTION

DEVICES:

If you notice very small flames on the burner(s), you may have

accidentally activated the flow-limiting device in the Type 1

connection device. Besides a rupture in the gas hose, the

flow-limiting device may activate for one of the two following

reasons:

1. Opening the burner valves before opening the cylinder

valve. SOLUTION: Shut off the burner valves and the L.P.

cylinder valve and open in the proper order:

a). Open the L.P. cylinder valve first

, then

b). Open burner valve and ignite the burner

according to the instructions in this manual for

your grill.

IF YOU STILL HAVE A PROBLEM, THEN THERE MAY BE AIR IN

THE CYLINDER DUE TO IMPROPER PURGING.

2. The L.P. cylinder was not properly purged before it was filled.

SOLUTION: See your L.P. gas supplier.

For Your Additional Safety

DANGER

If a fire occurs at the cylinder valve, DO NOT attempt to move

the cylinder. IMMEDIATELY call the fire department and clear

the area. You can safely spray water with a garden hose from

a distance of at least 15 feet away from cylinder until firemen

arrive.

Troubleshooting

(continued)

For Your Additional Safety

(continued)

Current L.P. gas cylinders are fitted with an Overfill

Protection Device (O.P.D.). T

o insure that you retain this

safety-device, take your cylinder to an L.P. gas service

station for filling, or when exchanging your cylinder at a

cylinder exchange station, request that your replacement

cylinder be fitted with the O.P.D. feature.

Problem: Flame blows out on low setting or

has uneven heat distribution.

Possible Causes and Solutions:

1. Check for spider webs or insect nests in the venturi and clean

the venturi.

2. Cold grill needs to be preheated for 5 minutes on high

setting.

3. The venturi may be misaligned and needs to be lined up

over the orifices.

4. Cold and windy weather will require you to move the grill

away from the wind.

5. Lack of fuel. Check to see that the cylinder valve is open and

that the cylinder has fuel.

Problem: Grill too hot.

Possible Causes and Solutions:

1. Excessive flareups which require the maintenance described

in the section titled “IN CASE OF GREASE FIRE”.

2. A damaged orifice or regulator which requires replacement

with factory authorized parts.

3. Buildup of grease inside the grill will require cleaning and

emptying the grease tray.

4. Choose a lower cooking temperature if using excessively

high settings.

Problem: Fire at any connection.

Possible Causes and Solutions:

IMMEDIATELY shut off cylinder valve and allow grill to cool.

1. Gas is leaking from a faulty connection. Tighten connections

with an adjustable wrench and replace damaged parts.

Perform a leak test on all connections before cooking on the

grill again.

Problem: Flame behind control panel or

control knob area.

Possible Causes and Solutions:

IMMEDIATELY shut off cylinder valve and allow grill to cool.

1. Check for spider webs or insect nest in the venturi and clean

the venturi.

2. Gas is leaking from a faulty connection. Tighten connections

with an adjustable wrench and replace damaged parts.

Perform a leak test on all connections before cooking on the

grill again.

3. The venturi may be misaligned and needs to be lined up over

the orifices.

Fig. 55

Page 27

Here

27

Stamp

First-Class

Place

Please

ATTN: DEPT 586

WICHITA ,KS 67201

PO BOX 2931

PRODUCT REGISTRATION DEPARTMENT

correspondence to the address below.

Please do not send other

PLEASE FOLD AND SEAL WITH TAPE. DO NOT STAPLE.

Coleman¨ Grill Warranty

Registration Card

IMPORTANT!

COMPLETE THE ATTACHED REGISTRATION CARD AND RETURN WITHIN 10

DAYS TO RECEIVE THESE IMPORTANT BENEFITS:

CONFIRM YOUR WARRANTY:

Your prompt product registration confirms your right to the protection available under the terms and

conditions of your Coleman¨ warranty.

PROTECT YOUR PRODUCT:

We will keep the model number and date of purchase of your new Coleman¨ product on file to help

you refer to this information in the event of an insurance claim such as fire or theft.

PROMOTE BETTER PRODUCTS:

We value your input. Your responses will help us develop products designed to best meet

your needs.

Page 28

7) Side burner (if applies)

8) Steamer/Fryer/Warmer (if applies)

9) Side table design

10) Color of the grill

(not including stainless steel)

11) Warming racks

12) Dependable igniter

13) Size of the grill

(available cooking square inches)

14) Integrated storage cabinet

15) Price

16) Rotisserie (if applies)

17) Other

CONGRATULATIONS ON YOUR NEW COLEMAN® GRILL PURCHASE!

If you have any questions about your product, please call Coleman Customer Service at 1-800-356-3612.

For easier/faster warranty registration, please go to the warranty registration section of our Coleman Web site at

www.coleman.com.

Date of Your Birth:

12

Ye a rDayMonth

Store where purchased:

4

5

Product Model Number:

11

What other brands did you consider?:

E-mail Address:

7

Date of Purchase:

1. Regular Price 2. Sale Price 3. Don't Know

2

Yea rDayMonth

Purchase Price: $ .00 (Excluding Tax)

3

1. Mr.

First Name: Last Name:Initial:

2. Mrs. 3. Ms. 4. Miss.

1

Address (Number and Street): Apt #:

City: Zip:State:

Phone #:

The following questions are not required to obtain warranty service but will greatly assist us in

understanding your needs and building better performing products.

1. Own 2. Rent

For your primary residence, do you:

13

6

1. Yes, Please contact me. 2. No, Thanks

Can Coleman contact you with promotional information or updates about Coleman® products?

1. Single 2. Married

Marital Status:15

Number of people in household:16

Thank you for filling out this questionnaire. Your answers are impor tant to us. Please check here [ ] if you prefer not to learn more about Coleman® Outdoor Cooking Products or

obtain information on new interesting opportunities from other companies.

1) High school diploma

2) Some college

3) College degree

4) Some graduate school

5) Graduate degree

14

Education: (Check only one.)

1) Under $15,000

2) $15,000 - $24,999

3) $25,000 - $34,999

4) $35,000 - $49,999

5) $50,000 - $74,999

6) $75,000 - $99,999

7) $100,000 - $149,999

8) Over $150,000

18

Which best describes your family income?

8

1) Received as a gift 8) Magazine

2) Brand 9) In Store Display/Sign

3) Price 10) Packaging

4) Style 11) Size

5)

Recommendation from Store Salesperson

12) Weight

6)

Recommendation from Friend

13) Ease of Use

7) Television 14) Other Features

15) Other

Which factors most influenced your purchase?

(Please check all that apply.)

9

1) Received as a gift

2) First of this type of product owned

3) Addition to Coleman products

4) Replaced old Coleman product

5) Replaced another brand product

6) Purchase in addition to another brand

Which of these best describes this purchase?

(Please check all that apply.)

1) Tent Camping 10) Barbequing

2) RV Camping 11) Rock Climbing

3) Hiking/Backpacking 12) Bicycling

4) Fishing

13) Leisure Walking

5) Boating 14) Canoeing

6) Going to the Beach 15) Kayaking

7) Tailgating 16) Entertaining

8) Picnicking 17) Backyard Entertaining

9) Hunting 18) Attend Auto Racing

Do you participate in any of the following activities?

(Please check all that apply.)

10

Number of kids in household under 18 years of age:

17

1) Amount of BTU's for cooking

2) Cart design

3) Flame control cooking system

4) Power burner

5) Stainless steel material (if applies)

6)

Porcelain or stainless steel cooking grates

What grill feature influenced the purchase of your Coleman® grill? (Please check all that apply.)

19

28

Page 29

Notes

29

Page 30

Notes

30

Page 31

Notes

31

Page 32

The Coleman Company, Inc. • 3600 N. Hydraulic • Wichita, KS 67219 U.S.A.

1-800-356-3612 • TDD: 316-832-8707

9992-033 (2/23/06)

©2006 The Coleman Company, Inc. All rights reserved.

Coleman® and are registered trademarks of The Coleman Company, Inc.

Coleman Gas Barbecue Grill 5/1 Year Limited Warranty

For Warranty, Service and Parts

Locate your model number and serial number on the

label on the grill.

Warranty

The Coleman Company, Inc. ("Coleman") warrants that for the lifetime of the product from the date of purchase, the stainless

steel panels will not break due to defects in materials or workmanship, and that for a period of five years from the date of purchase,

the burner, grates and stainless steel components will be free from defects in material and workmanship. All other components

of this barbecue grill are warranted to be free from defects in material and workmanship for one year from the date of purchase.

Coleman, at its option, will repair or replace this product or any component of the product found to be defective during the warranty

period. Replacement will be made with a new manufactured or remanufactured product or component. If the product is no longer

available, replacement may be made with a similar product of equal or greater value. This is your exclusive warranty.

This warranty is valid for the original retail purchaser from the date of initial retail purchase and is not transferable. Keep the

original sales receipt. Proof of purchase is required to obtain warranty service. Coleman dealers, service centers, or retail stores

selling Coleman® products do not have the right to alter, modify or in any way change the terms and conditions of this warranty.

This warranty does not cover: normal wear of parts such as scratches and dents of the stainless steel components; or

damage resulting from any of the following: negligent use or misuse of the product, including exposing the product to chemicals

or cleaning products not approved by Coleman; use or installation contrary to specified instructions and applicable building codes,

including heating the product to temperatures above its rated specifications which can cause considerable warping; disassembly,

including removal of the product from a built-in installation; repair or alteration by anyone other than Coleman or an authorized

service center; acts of God, such as fire, flood, hurricanes and tornadoes; gas cylinders, propane tanks or other fuel delivery

systems, including connections to a household fuel supply; usage other than single-family household use such as commercial or

industrial use; minor warping or discoloration of certain parts, which is normal and not a defect under this warranty.

COLEMAN SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES CAUSED BY THE BREACH

OF ANY EXPRESS OR IMPLIED WARRANTY, BREACH OF CONTRACT OR OTHERWISE. EXCEPT TO THE EXTENT

PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE IS LIMITED IN DURATION TO THE DURATION OF THE ABOVE WARRANTY. SOME STATES, PROVINCES OR

JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES OR

LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT

APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS

THAT VARY FROM STATE TO STATE OR PROVINCE TO PROVINCE.

How to Obtain Warranty Service

Take this product to an authorized Coleman service center. You can find the nearest authorized Coleman service center by

calling 1-800-356-3612 or TDD 316-832-8707 in the United States, or 1 800 387-6161 in Canada.