Page 1

ASSEMBLY

INSTRUCTIONS FOR

9943 SERIES

GAS BARBECUE GRILL

9943-054 (04/26/02)

LOOK INSIDE FOR:

Easy Assembly Instructions

Repair Parts List

Safety, Maintenance

and Cleaning Tips

Coleman Company, Inc.

3600 N. Hydraulic

Wichita, KS 67219

Internet site:

www.coleman.com

1-800-356-3612

TDD: 316-832-8707

9-Volt

Battery

Included

LP Tank

Sold

Separately

WARNING:

THE EDGES OF SHEET METAL PARTS CAN CAUSE INJURY

IF NOT HANDLED WITH CARE

.

USE EXTREME CAUTION!

IMPORTANT!

TO ENSURE PROPER GAS FLOW, BURNER

CONTROL VALVES MUST

BE “OFF” BEFORE

OPENING THE GAS CYLINDER VALVE.

AASSSSEEMMBBLLEERR//IINNSSTTAALLLLEERR::

L

EAVE THESE INSTRUCTIONS WITH THE CONSUMER

.

CCOONNSSUUMMEERR//UUSSEERR::

R

EAD ALL THESE INSTRUCTIONS AND KEEP THEM IN A

SAFE PLACE FOR FUTURE REFERENCE

.

WARNING

Combustion by-products produced when using this product contain

chemicals known to the State of California to cause cancer, birth

defects, or other reproductive harm.

Page 2

(Pg. 2)

ÖÖ

#2 Phillips Screwdriver

ÖÖ

3/8”, 7/16” and 11/16” Open End Wrenchs

ÖÖ

3/8” Square Drive Ratchet Wrench

ÖÖ

3/8” Square Drive Extension

ÖÖ

Electric or Cordless Screwdriver

ÖÖ

#2 Phillips driver bit

ÖÖ

#T-20 6-Lobe Screwdriver

TORX BIT SOCKET INCLUDED

ADDITIONAL TOOLS NEEDED:

OPTIONAL TOOLS:

ÖÖ

#T-20, 3/8” Square Drive Torx Bit Socket

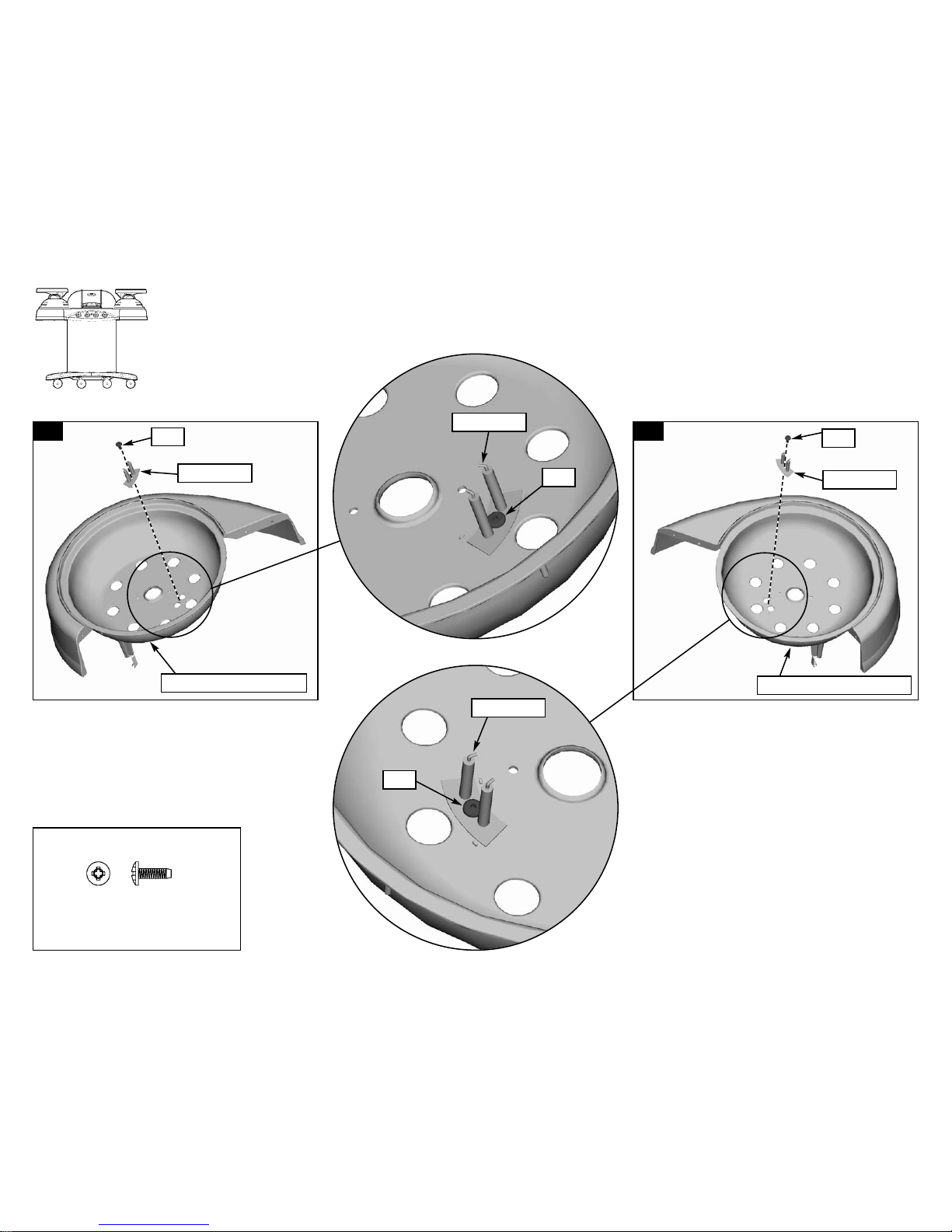

Page 3

(Pg. 3)

1-A

1-A. Assemble the Electrode to the Left Burner

Casting using one self-tapping screw (KE).

ÖÖ

Tighten all fasteners.

ÖÖ

Assemble the Electrode to the Left Burner Casting per illustration (1-A).

ÖÖ

Assemble the Electrode to the Right Burner Casting illustration (1-B).

Step

1

1-B

KE

Electrode

Electrode

Electrode

Right Burner Casting

Electrode

KE

Left Burner Casting

1-B. Assemble the Electrode to the Right Burner

Casting using one self-tapping screw (KE).

ÖÖ

Tighten all fasteners.

KE

KE

(KE)

#6-32 x 3/8 Self-tapping Screw

(2) Qty.

Hardware shown actual size

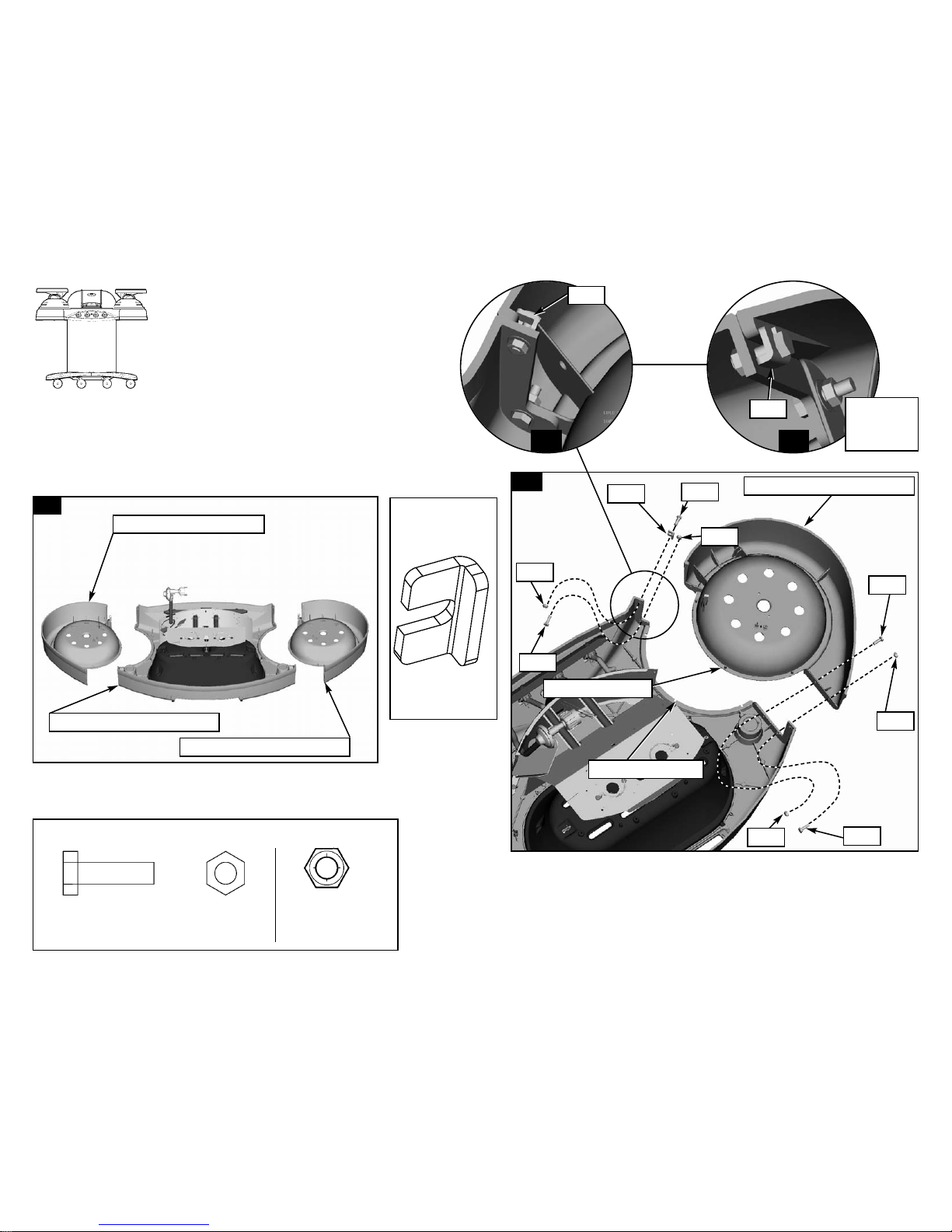

Page 4

(Pg. 4)

ÖÖ

NOTE: The grill is upside-down during this

assembly step.

ÖÖ

Assemble the CONSOLE CASTINGS.

ÖÖ

Use a large piece of cardboard or a ground

cloth to protect the painted finish on the

castings.

ÖÖ

Lay all three castings on a level surface with

the top (smooth) surface downward.

2-A

2-B.

Assemble the Right Console Casting to the Center Console Casting. Three Alignment Pins

mate with three Alignment Holes in castings. Fasten with four SCREWS (MG) and four HEX

NUTS (BV) and one Clip (NH). See Detail 2-C and Detail 2-D for location of Clip (NH).

Tighten the fasteners.

ÖÖ

Repeat Step 2-B to assemble the Left Console Casting to the Center Console Casting.

2-A. Lay all three castings on a level surface with the smooth

(top) surface downward.

2-B

Right Console Casting

Left Console Casting

Center Console Casting

Step

2

(MG)

1/4-20 x 7/8 Hex Head Cap Screw

(8) Qty.

Hardware shown actual size

Hardware

shown actual

size

(BV)

1/4-20 Hex Nut

(8) Qty.

(NH)

Clip

(2) Qty.

Right Console Casting

Alignment Pin

Alignment Hole

NH

MG

BV

NH

NH

BV

MG

MG

BV

MG

BV

Another

View of

Clip (NH)

2-C

2-D

Page 5

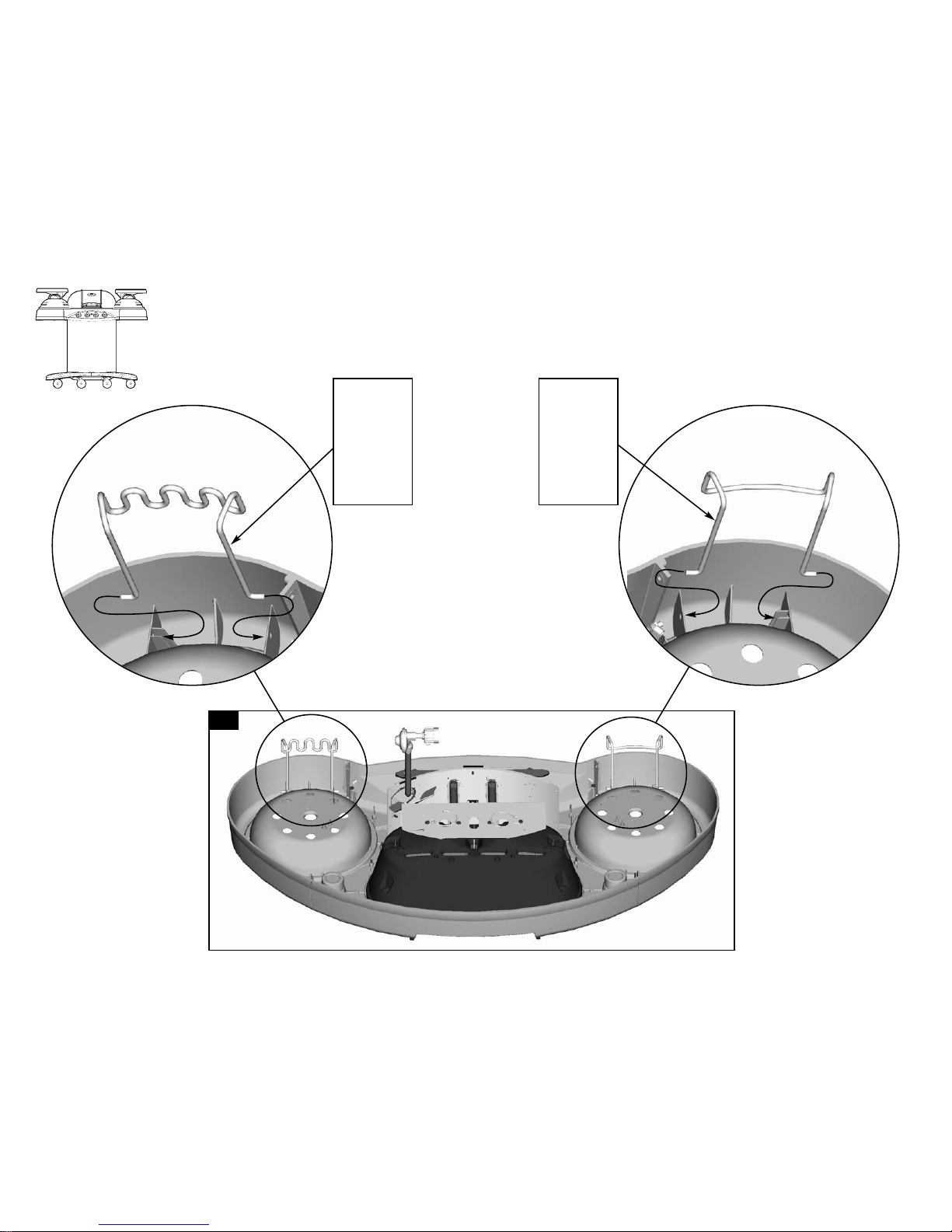

(Pg. 5)

ÖÖ

NOTE: The grill is upside-down during this assembly step.

ÖÖ

Assemble the Tool Rack to the console.

ÖÖ

Assemble the Towel Rack to the console.

3-A

Step

3

Squeeze

the Towel

Rack to

slip into

the

mounting

holes.

Squeeze

the Tool

Rack to

slip into

the

mounting

holes.

Page 6

(Pg. 6)

ÖÖ

NOTE: The grill is upside-down during this assembly step.

ÖÖ

Assemble the 9-VOLT BATTERY to the ELECTRODE MODULE.

ÖÖ

Attach two wires (27” long) from the ELECTRODE MODULE labeled LB1 and LB2 to the LEFT BURNER (thread thru wire clip).

ÖÖ

Attach two wires (27” long) from the ELECTRODE MODULE labeled RB1 and RB2 to the RIGHT BURNER.

ÖÖ

Verify that two wires are attached from the MAIN BURNER to the ELECTRODE MODULE labeled MB1 and MB2 (factory installed).

ÖÖ

Verify that two wires are attached from the IGNITER BUTTON to the ELECTRODE MODULE on the left side (factory installed).

Step

4

4-A

4-B

Left Burner

Right Burner

4-C

Right Burner

Electrode Wires

Left Burner

Electrode Wires

Main Burner

Electrode Wires

Igniter Button

Wires

NOTE: Wires are

factory installed to the

Electrode Module.

9-Volt Battery

ELECTRODE MODULE

Left Side

Caution: Insure that the

wires DO NOT touch hot

surfaces such as the grill

casting!

ELECTRODE

MODULE

ELECTRODE

MODULE

MB1

LB1

RB1

MB2

LB2

RB2

Thread Wires

through Wire

Clip

Thread Wires

through Wire

Clip

Page 7

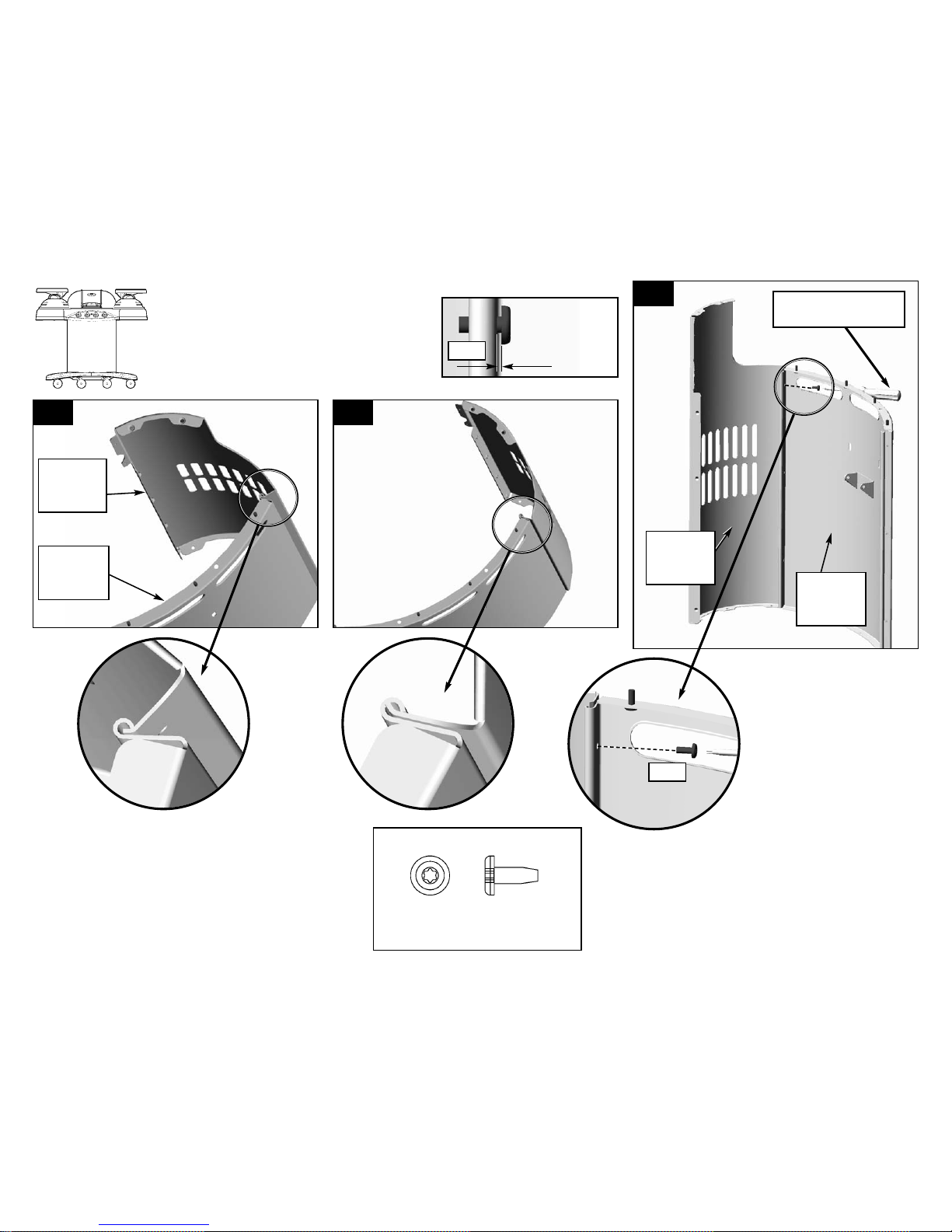

(Pg. 7)

5-A 5-B

5-C

5-A. Assemble the PEDESTAL LEFT PANEL to the

PEDESTAL BACK PANEL.

ÖÖ

Insert the flat lip of the PEDESTAL LEFT PANEL

into the curled lip of the PEDESTAL BACK

PANEL, taking care to align the bolt holes.

ÖÖ

Assemble the PEDESTAL PANELS.

(DX)

#10-24 x 1/2 Self-tapping Screw

(2) Qty. Per Side Panel

Hardware shown actual size

5-C. LOOSELY fasten together with one SCREW (DX).

One at top only.

ÖÖ

NOTE: You will tighten this screw LATER, after the

panels are fastened to the grill console in Step 8-B

(this helps with alignment).

ÖÖ

Repeat Step 5 to assemble the RIGHT PANEL.

Pedestal

Left

Panel

Pedestal

Back

Panel

DX

Step

5

Use Tool Through

Opening

Stop (1) Turn

Before Tight

DX

Pedestal

Back

Panel

Pedestal

Left

Panel

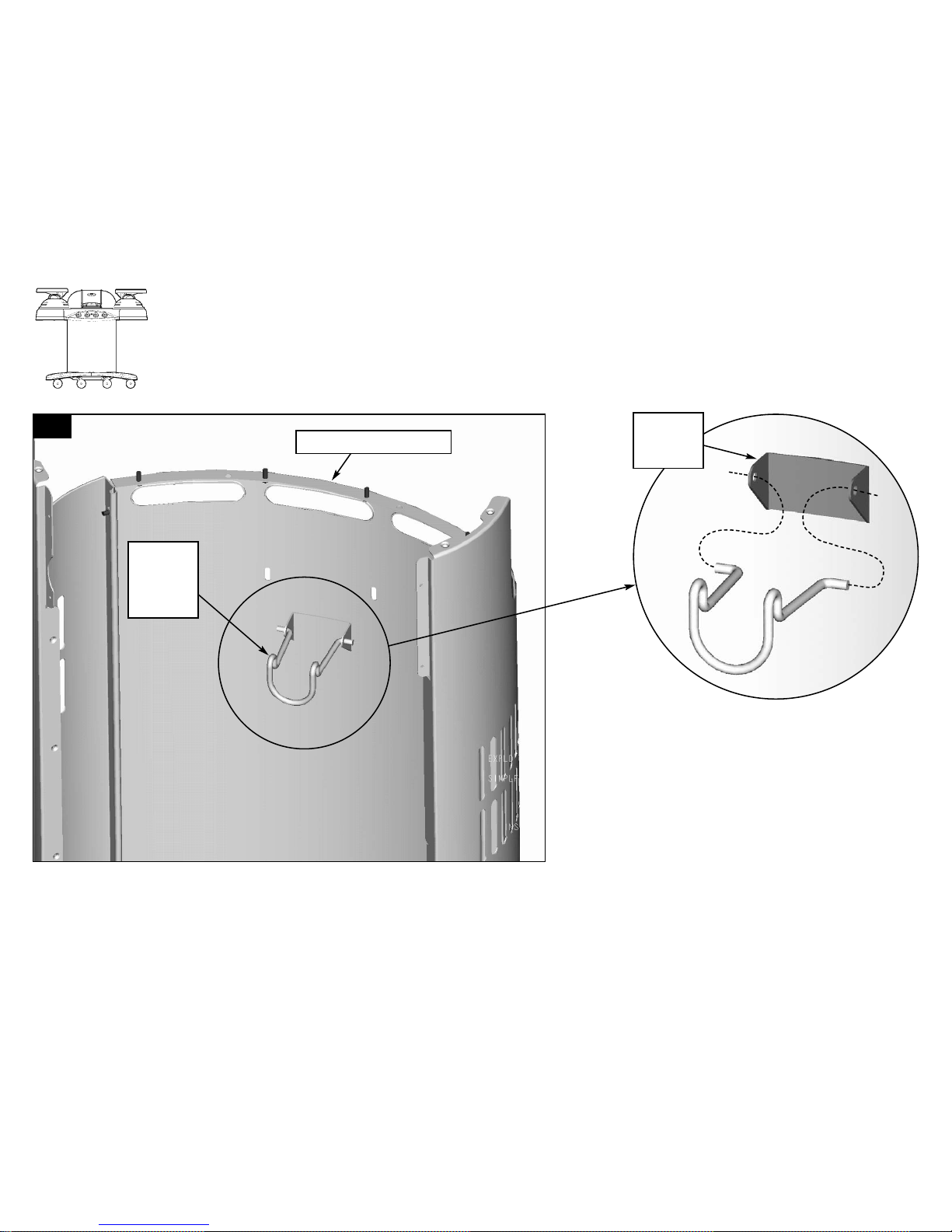

Page 8

(Pg. 8)

ÖÖ

Assemble PROPANE TANK RETAINER WIRE to the Pedestal Back Panel.

6-A

6-A. Assemble Propane Bottle Retainer Wire to the Pedestal Back Panel.

ÖÖ

Squeeze the Wire and insert into Bottle Retainer Bracket on Pedestal Back Panel.

Step

6

Propane

Bottle

Retainer

Wire

Bottle

Retainer

Bracket

Pedestal Back Panel

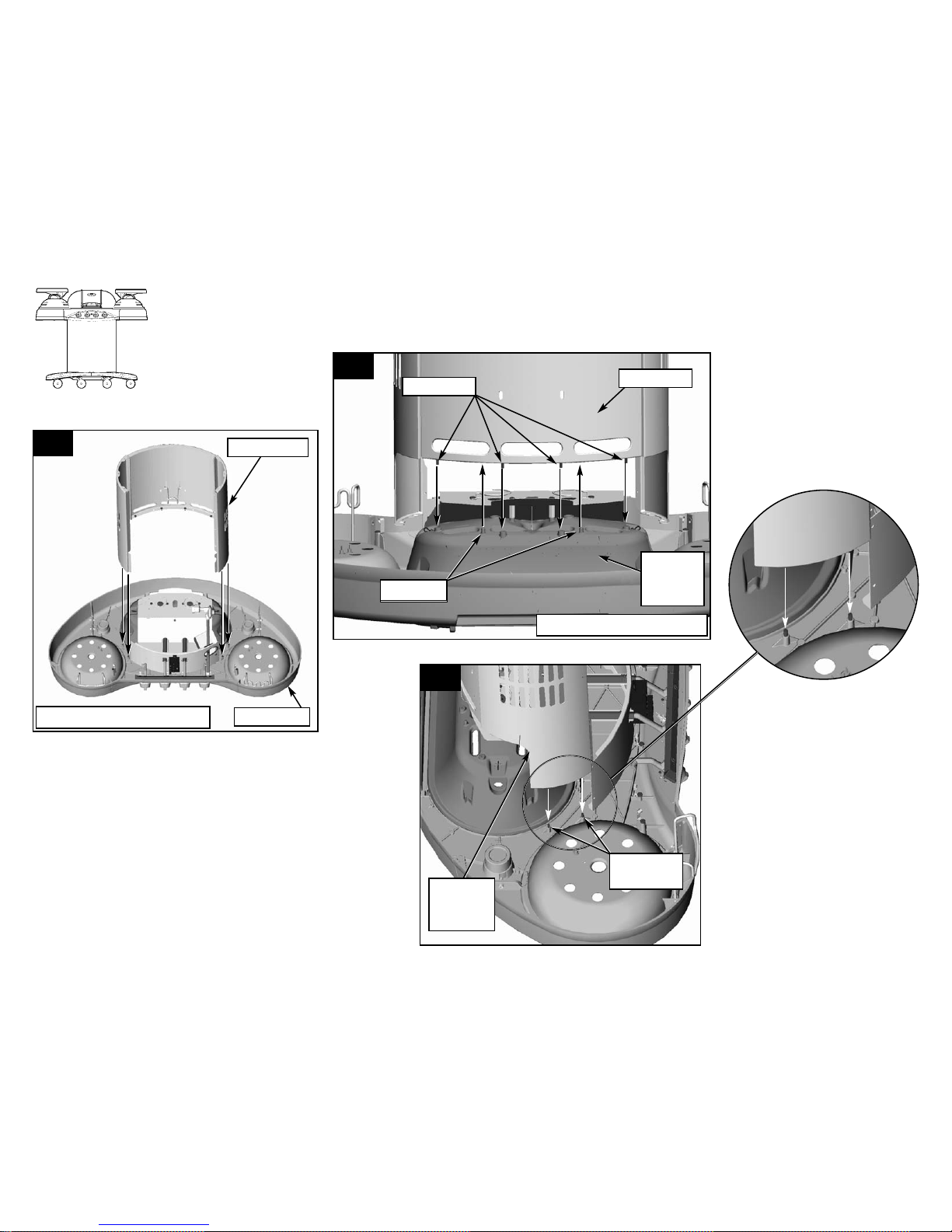

Page 9

(Pg. 9)

ÖÖ

NOTE: The grill is upside-down during this assembly step.

ÖÖ

Place the PEDESTAL onto the CONSOLE.

Step

7

7-A

7-B

7-C

7-A. Place the PEDESTAL onto the CONSOLE.

ÖÖ

Align the studs and pins with the assembly holes.

7-B. Align four studs with holes in

the Center Burner Casting.

ÖÖ

Align two pins (part of the

casting) with two holes in the

Pedestal.

7-C. Align two

studs with

holes in the

right pedestal

panel

(shown).

ÖÖ

Align two

studs with

holes in the

left pedestal

panel on the

opposite side

(not shown).

Pins (2)

View From Back Of Grill

View From Front Of Grill

Console

Pedestal

Studs (4)

Center

Burner

Casting

Pedestal

Right

Pedestal

Panel

Studs (2)

Per Side

Page 10

(Pg. 10)

ÖÖ

NOTE: The grill is upside-down during this assembly step.

ÖÖ

Fasten the PEDESTAL to the CONSOLE per Step (8-A).

ÖÖ

Tighten and secure the Pedestal Panel Fasteners per Step (8-B).

Step

8

8-A

8-B

EY

EY

EY

8-A. Assemble four HEX NUTS (EY),

one on each stud that protrudes up

from the casting into the pedestal

(they can be reached through the

front door opening).

ÖÖ

Assemble two on the right pedestal

panel (shown in Illustration 7-C and

8-A). and two on the left pedestal

panel (not shown).

ÖÖ

Tighten all fasteners.

8-B. Tighten the two screws (DX) loosely fastened earlier in Step 5-C.

Ö

Lock the two screws (DX) holding the PEDESTAL PANELS together with (2)

HEX NUTS (EY).

Ö

One HEX NUT (EY) assembles onto the right pedestal panel as shown. One

HEX NUT (EY) assembles onto the left pedestal panel.

Ö

Tighten all fasteners.

(EY)

#10-24 Hex Nut

(6) Qty.

Hardware shown actual size

DX

EY

DX

Page 11

(Pg. 11)

ÖÖ

NOTE: The grill is upside-down during this assembly step.

ÖÖ

Fasten the FRONT CONSOLE PANEL to the PEDESTAL.

Step

9

9-A. Assemble four SCREWS (CW) through the FRONT CONSOLE PANEL to the PEDESTAL.

ÖÖ

Tighten all fasteners.

9-A

(CW)

#10-24 x 3/8 Self-tapping Screw

(4) Qty.

Hardware shown actual size

CW

CW

CW

CW

Page 12

(Pg. 12)

10-A

10-B

ÖÖ

NOTE: The grill is upside-down during this assembly step.

ÖÖ

HINT: A second person may be helpful when aligning the Base Casting.

ÖÖ

Assemble the Base Casting to the Pedestal.

Step

10

(EY)

#10-24 Hex Nut

(9) Qty.

Hardware shown actual size

10-A. Carefully place the Base Casting onto the

Pedestal.

ÖÖ

The Base Casting has nine factory installed

studs. Carefully align the nine studs with the

nine matching holes in the Flange of the

Pedestal.

10-B. Assemble nine Hex Nuts (EY) to the nine

studs in the Base Casting.

ÖÖ

Tighten all fasteners.

Base Casting

Flange of Pedestal

with Nine Holes

EYEY

(9) Places

EY

EY

EY

Page 13

(Pg. 13)

11-A

11-B

11-A. Assemble locking casters to front of base.

ÖÖ

Assemble non-locking casters to back of base.

ÖÖ

Make sure hex bottoms out on base.

11-B. Fasten wheels tight against the Base Casting.

ÖÖ

Use an 11/16” open end wrench to tighten the Hex Collar against

the Base Casting.

ÖÖ

NOTE: The grill is upside-down during this assembly step.

ÖÖ

Assemble casters.

ÖÖ

Level and tighten the casters.

Hex Collar

Front

Step

11

Non-Locking Caster

Locking Caster

Base

Page 14

(Pg. 14)

12-A

ÖÖ

NOTE: Use a ground cloth to protect the paint finish during this step.

ÖÖ

Check that all fasteners are tightened before turning the grill Right-Side-Up.

ÖÖ

Carefully turn the grill Right-Side-Up.

Step

12

Protect with groundcloth

Protect with groundcloth

Control Panel this side.

Page 15

(Pg. 15)

ÖÖ

Complete Assembly of the Console to the Pedestal.

Step

13

13-A. Assemble four HEX NUTS (EY) onto the four studs that protrude through

the center burner casting.

ÖÖ

Tighten all fasteners.

EY

(EY)

#10-24 Hex Nut

(4) Qty.

Hardware shown actual size

13-A

View of Inside of Main Burner

Page 16

(Pg. 16)

ÖÖ

Assemble the BURNER to the RIGHT CONSOLE.

ÖÖ

Slip BURNER TUBE through RIGHT CONSOLE per detail 14-A.

ÖÖ

Align BURNER TUBE with VALVE TUBE per detail 14-B.

ÖÖ

Slip BURNER TUBE over VALVE TUBE per detail 14-C.

ÖÖ

Fasten BURNER in place per detail 14-D.

Step

14

11-D. Fasten the burner in place with two WINGNUTS (JD).

ÖÖ

Tighten all fasteners.

14-A

14-B

14-D

14-C

Burner

JD

JD

Burner Tube

Valve Tube

Right Console

(JD)

#10-24 Stamped Wing Nut

(2) Qty.

Hardware shown actual size

Caution: Assemble the

wires BELOW the burner

tubes!

Page 17

(Pg. 17)

ÖÖ

Assemble the BURNER to the LEFT CONSOLE.

ÖÖ

Slip BURNER TUBE through LEFT CONSOLE per detail 15-A.

ÖÖ

Move the Flexible Fuel Hose downward to give clearance for inserting the burner tube.

ÖÖ

Slip BURNER TUBE over VALVE TUBE per detail 15-C. The Flexible Fuel Hose and Wiring

must be routed BELOW

the burner tube per detail 15-D.

ÖÖ

Fasten BURNER in place per detail 15-D.

Step

15

15-A

(JD)

#10-24 Stamped Wing Nut

(2) Qty.

Hardware shown actual size

15-B

15-D

15-C

Left Console

Left Burner

Flexible Fuel Hose

Burner Tube

JD

JD

15-D. Fasten the burner in place with two WINGNUTS (JD).

ÖÖ

Tighten all fasteners.

Valve Tube

Flexible

Fuel Hose

Caution: Assemble the

wires BELOW the burner

tubes!

TEST THE IGNITER:

A SPARK SHOULD APPEAR AT

ELECTRODE TIP

.

I

F THE SPARK DOES NOT

APPEAR

:

-CHECK THE WIRE

CONNECTIONS TO THE

MODULE

.

-CHECK PROPER

ASSEMBLY OF FRESH

9-VOLT BATTERY.

Page 18

(Pg. 18)

16-A

16-A. Assemble the DOOR LATCH with two SCREWS (CW).

NOTE: You may have to adjust door latch to insure proper

alignment of door latch post. Refer to Step 18-B.

ÖÖ

Assemble the DOOR LATCH to the PEDESTAL.

Step

16

KE

Door Latch

KE

(KE)

#6-32 x 3/8 Self-tapping Screw

(2) Qty.

Hardware shown actual size

Page 19

(Pg. 19)

17-A

17-A. Attach the DOOR HANDLE to the DOOR with two SCREWS (FZ).

17-B

ÖÖ

Assemble the DOOR HANDLE to the DOOR.

ÖÖ

Assemble the DOOR LATCH POST to the DOOR.

Step

17

(LF)

#8-32 x 1/2 Self-tapping Screw

(2) Qty.

Hardware shown actual size

17-B. Attach the DOOR LATCH POST to the DOOR with two SCREWS (CW).

(KE)

#6-32 x 3/8 Self-tapping Screw

(2) Qty.

Hardware shown actual size

KE

KE

LF

LF

Door Latch Post

Door Handle

Page 20

18-A

(Pg. 20)

ÖÖ

Assemble the DOOR to the PEDESTAL.

ÖÖ

Adjust the DOOR LATCH on the PEDESTAL for proper door closure.

Step

18

18-A. Attach the DOOR to the PEDESTAL with four SCREWS (GA).

(GA)

#10-24 x 3/8 Flat Head Screw

(4) Qty.

Hardware shown actual size

18-B. Adjust the DOOR LATCH on the PEDESTAL for proper

door closure.

ÖÖ

Tighten all fasteners.

Door Latch

GA

(4) Places

Door

Page 21

(Pg. 21)

19-B

ÖÖ

Assemble the MAIN BURNER LID.

ÖÖ

Adjust the DOOR LATCH on the PEDESTAL for proper door closure.

Step

19

19-A

19-A. Attach the MAIN BURNER LID with two clevis pins (HB).

ÖÖ

Lock the clevis pins in place with two hairpin cotters (IC).

19-B. Detail showing location of clevis pin (HB) and hairpin (IC).

IC

HB

IC

HB

IC

HB

(HB)

3/16 Dia x 1-3/16 LG Clevis Pin

(2) Qty.

Hardware shown actual size

(IC)

Hair Pin

(2) Qty.

Page 22

(Pg. 22)

ÖÖ

Assemble the WARMING RACK and SUPPORT WIRE into the middle burner lid.

ÖÖ

Note: Steps 20-A and 20-B are pre-assembled at the factory. Proceed to Step 20-C.

Step

20

20-A

20-B

20-C

20-D

Warming Rack

Support Wire

Left Hole in Lid

20-A. Insert the SUPPORT WIRE into the left end of the WARMING RACK.

20-C. Insert the WARMING RACK through the Left Hole in the lid (far

enough to clear the Right Hole), then slide the WARMING RACK

into the Right Hole of the lid.

ÖÖ

Center the Warming Rack in the lid.

20-D. Insert the SUPPORT WIRE into the Left Pivot.

ÖÖ

Squeeze the SUPPORT WIRE to fit into the Right Pivot.

20-B. Thread the SUPPORT WIRE through the right end of the WARMING RACK.

Right Pivot

Left Pivot

Page 23

(Pg. 23)

ÖÖ

Assemble the SIDE TRAYS to the grill.

Step

21

21-A

21-A. Insert one SIDE TRAY POST into the grill. Align the notch in the

collar with the grill casting. It should not rotate in the hole.

ÖÖ

Place the SIDE TRAY onto the POST. It can be rotated from the

forward position (above the burner) to a limited outward position

(away from the burner).

ÖÖ

Repeat Step 21-A for the left SIDE TRAY.

21-B. SIDE TRAYS installed.

Side Tray Post

Side Tray

Collar

21-B

Page 24

(Pg. 24)

ÖÖ

Place DRIP PAN, SIDE BURNER GRID, and ROUND GRILL CASTING onto the left grill per Fig 22-A.

ÖÖ

Place DRIP PAN, SIDE BURNER GRID, and ROUND GRIDDLE CASTING onto the right grill per Fig 22-A.

Step

22

22-A

Drip Pan

Side Burner Grid

Round Griddle Casting

Drip Pan

Side

Burner

Grid

Round Grill Casting

Align Side Burner Grid

Between Rivet Heads

on the Drip Pan

Page 25

(Pg. 25)

ÖÖ

Place one Heat Tent on the main burner casting.

ÖÖ

Place two D-GRILLS on the main burner casting.

Step

23

23-A

23-C

23-B

23-B. HEAT TENT installed.

23-C. D-GRILLS installed.

Heat Tent

D-Grill

Heat Tent

D-Grill

Page 26

(Pg. 26)

ÖÖ

Place two SIDE LIDS on the side burners.

Step

24

24-A 24-B

24-A. Place one SIDE LID on each side burner. 24-B. SIDE LIDS can also be placed onto the SIDE TRAYS.

SIDE LID SIDE LID

SIDE TRAY

SIDE LID

Page 27

(Pg. 27)

ÖÖ

Open the front access door to place two GREASE CUPS under the main burner.

ÖÖ

Place the GREASE CUPS into the two wire holders below the main burner. See illustrations 25-A and 25-B.

ÖÖ

Place the GREASE DRIP TRAY into the holder behind the main burner lid. See illustrations 25-C and 25-D.

Step

25

25-C

25-D

GREASE DRIP TRAY

REAR VIEW OF GRILL

REAR VIEW OF GRILL

25-C. Place the GREASE DRIP TRAY into the holder.

25-D. Detail showing correct installation of the GREASE DRIP TRAY.

25-A

25-B

25-A. Place the GREASE CUPS into the wire holders.

25-B. Detail showing correct installation of the GREASE CUPS.

Grease Cups

Wire Holders

FRONT VIEW WITH DOOR OPEN

FRONT VIEW WITH DOOR OPEN

Page 28

(Pg. 28)

ÖÖ

Assemble an LP CYLINDER to the Cylinder Caddy. See detail 26-A.

ÖÖ

Place the CYLINDER RETAINER WIRE over the Cylinder Collar. See detail 26-B.

ÖÖ

Attach the TYPE 1 fitting to the Fuel Valve Outlet per detail 26-C.

Step

26

26-A

26-B

26-C

26-A. Set LP CYLINDER in the cylinder caddy with

the outlet valve facing toward the front of the

grill.

26-B. Place the CYLINDER RETAINER WIRE over

the Cylinder Collar, by rotating the wire from the

upward positon over the cylinder collar.

26-C. Insert the TYPE 1 Nipple of the regulator into

the cylinder’s Fuel Valve Outlet as shown. Turn

the regulator hand wheel clockwise to tighten.

No tools are needed. The hand wheel will come

to a complete stop when the connection is

secure, and gas will not flow until a positive seal

is achieved.

Type 1 Nipple

Fuel Valve Outlet

WARNING: During assembly of

grill and when attaching or replacing the

L.P. gas cylinder, insure that the gas

supply hose is free of kinks and/or

damage and is at least 3” away from hot

surfaces such as the grill casting.

IMPORTANT!

TO ENSURE PROPER GAS FLOW, BURNER

CONTROL VALVES MUST

BE “OFF” BEFORE

OPENING THE GAS CYLINDER VALVE

.

Cylinder Retainer Wire

Cylinder Collar

LP Cylinder

Cylinder Caddy

Page 29

(Pg. 29)

REPAIR PARTS

Description

Side Tray/Post Kit

Lid Assembly - Side

Lid Assembly - Center

Griddle - Side

Burner

D-Grill-Center

Grid - Side

Drip Pan Assembly

Warming Rack

Electrode and 27” Wires

Tool Hook/Towel Hook

Grease Cup

Latch Post

Door Assembly

Door Handle

Bottle Retainer

Caster Set (4 pc)

Heat Tent

Drip Tray

Grill - side

Main Burner

Igniter Switch

Knob & Bezel Kit

Control Panel Overlay

Trim Ring

Electrode Module

20” Igniter Wire

Hose/Valve/Regulator

Misc. Parts Kit

D-Griddle-Center (sold sepertely)

Part #

9943-2701

9943-4101

9943-4201

9942A3181

9943A3201

9941-3161

9943-3151

9943-5301

9943-3181

9943-4851

9943-1421

9943-0461

9943-0821

9943-5601

9943-1721

9943-0901

9943-0411

9943-1151

9943-1161

9942-3161

9943-5341

9943-2801

9943-1501

9943-1951

9943-0601

9943-2601

9943-0921

9943-6101

9943-0351

9941-3181

Key123456789101112131415161718192021222324252627282930

Page 30

(Pg. 30)

REP

AIR PARTS

21

22

23

24

25

26

27

28

Page 31

(Pg. 31)

REPAIR PARTS

1

10

11

12

13

14

15

16

17

18

19

20

13

11

9

2

7

8

3

4

6

5

Page 32

(Pg. 32)

For WARRANTY, SERVICE and PARTS

Locate your model number and serial number on the label found on the inside of your grill door.

C

ARE AND

CC

LEANING OF

GG

RILL

PP

ARTS

Ö

BEFORE cleaning any part of the grill, allow the grill to cool down completely.

Ö

Clean the grill with warm soapy water and a soft cloth.

Ö

NEVER USE OVEN CLEANERS.

Ö

To protect the integrity of your grill against the effects of the environment, use a grill cover when the grill

is not in use.

Ö

Failure to comply with the owner’s USE & CARE MANUAL INSTRUCTIONS & ASSEMBLY INSTRUCTIONS

can void right of warranty.

Leak test gas supply connections outdoors as

indicated by arrows.

WARNING! The edges of sheet metal parts can

cause injury if not handled with care.

USE EXTREME CAUTION!

WARNING! WHEN LEAK TESTING:

DO NOT smoke.

DO NOT use fire to test for leaks.

DANGER:

NEVER store a spare LP gas supply cylinder under the

grill body nor inside grill enclosure to avoid the possibility

of an explosion. Refer to the Use and Care manual.

IMPORTANT:

Be sure to tighten up all hardware (screws, nuts, bolts,

etc.) at least once a year or each grilling season.

READ OWNER’S USE AND CARE MANUAL:

For proper filling and purging of the cylinder

For leak testing all gas supply connections

For correct grill lighting instructions

For use and storage of the grill and cylinder

BEFORE USING YOUR GRILL

COLEMAN GAS BARBECUE GRILL WARRANTY

C

ASTINGS

- L

IMITED LIFETIME

B

URNER

- L

IMITEDTEN

(10) Y

EARS

E

LECTRONIC IGNITION COMPONENTS

- L

IMITEDTHREE

(3) Y

EARS

C

OOKING SURFACES

- L

IMITED

(2)

YEARS

O

THER PARTS

- L

IMITED ONE

(1) Y

EAR

The Coleman Company, Inc. (“Coleman”) warrants that for the period that you own this product, it will be free from defects in

material and workmanship. This warranty applies to the following parts for the following time periods: the castings are

warranted for LIFETIME against burn through; the burner is warranted for ten (10) years; electronic ignition components are

warranted for three (3) years; cooking surfaces are warranted for two (2) years; and other parts are warranted for one (1) year,

except the propane cylinder and paint finish. We DO NOT WARRANT in any way the propane cylinder (see label on cylinder

for cylinder manufacturer’s warranty) or the paint finish of the product. Coleman, at its option, will repair or replace this product

or any component of the product found to be defective during the warranty period. Replacement will be made with a new or

remanufactured product or component. If the product is no longer available, replacement may be made with a similar product

of equal or greater value. This is your exclusive warranty.

This warranty is valid for the original retail purchaser from the date of initial retail purchase and is not transferable. Keep the

original sales receipt. Proof of purchase is required to obtain warranty performance. Coleman dealers, service centers, or

retail stores selling Coleman products do not have the right to alter, modify or any way change the terms and conditions of this

warranty.

This warranty does not cover normal wear of parts or damage resulting from any of the following: negligent use or misuse of

the product, use on improper voltage or current, use contrary to the operating instructions, disassembly, repair or alteration by

anyone other than Coleman or an authorized service center. Further, the warranty does not cover Acts of God, such as fire,

flood, hurricanes and tornadoes.

Coleman shall not be liable for any incidental or consequential damages caused by the breach of any express or implied

warranty. Except to the extent prohibited by applicable law, any implied warranty of merchantability or fitness for a particular

purpose is limited in duration to the duration of the above warranty. Some states, provinces or jurisdictions do not allow the

exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty lasts, so the

above limitations or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other

rights that vary from state to state or province to province.

DO NOT RETURN THIS PRODUCT TO THE PLACE OF PURCHASE.

Take the product to an authorized Coleman service center. You can find the nearest authorized Coleman service center by

calling 1-800-356-3612. If a service center is not conveniently located, you may call the same number for instructions on

shipping the product to the Coleman Company, Inc. You may also call the same number if you have any questions concerning

this warranty.

NOT VALID IN MEXICO.

Loading...

Loading...