Coleman 9330F4552, 8330-752, 9330C755, 8530-750, 9530A751 Installation Instructions Manual

...Page 1

RV Products Division

INSTALLATION INSTRUCTIONS

FOR

9330F4552 FREE DELIVERY PLENUM KITS

8330-752 CONTROL BOX KIT (12 VDC COOL ONLY)

9330C755 CONTROL BOX KIT (12 VDC HEAT READY)

8530-750 CONTROL BOX KIT (24 VAC COOL ONLY)

9530A751 CONTROL BOX KIT (12 VDC HEAT PUMP)

9430A751 ZONE CONTROL KIT (12 VDC COOL ONLY)

9430A755 ZONE CONTROL KIT (12 VDC HEAT READY)

9630A751 ZONE CONTROL KIT (12 VDC HEAT PUMP)

Coleman is a registered trademark of The Coleman Company, Inc. used under license. Mach is a registered trademark.

1976N350 (9-14) PP

Airxcel, Inc.

RV Products Division

P.O. Box 4020

Wichita, KS 67204

Page 2

TABLE OF CONTENTS

1. Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. General Information and Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. System Match-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Ceiling Plenum Installation Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Control Box Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

7. Control Box Kits (Zone) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8. Wall Thermostats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

9. Routing Thermostat Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

10. Routing Thermostat Wiring (Zone) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

11. Routing 115 VAC Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

12. Securing the Upper Unit to the Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

13. Installing the Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

14. Installing the Control Box (Zone) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

15. Installing the Heater Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

16. Installing the Ceiling Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1. WARNINGS

IMPORTANT NOTICE

These instructions are for the use of qualified individuals

specially trained and experienced in installation of this

type equipment and related system components.

Installation and service personnel are required by some

states to be licensed. PERSONS NOT QUALIFIED

SHALL NOT SERVICE THIS EQUIPMENT.

WARNING

Improper installation may damage equipment, can create

a hazard and will void the warranty.

The use of components not tested in combination with

these units will void the warranty, may make the

equipment in violation of state codes, may create a hazard

and may ruin the equipment.

To prevent the possibility of severe personal injury or

equipment damage due to electrical shock, always be sure

the electrical power to the appliance is disconnected

during installation.

CAREFULLY FOLLOW ALL INSTRUCTIONS

AND WARNINGS IN THIS BOOKLET TO AVOID

DAMAGE TO THE EQUIPMENT, PERSONAL

INJURY OR FIRE.

The words “Shall” or “Must” indicate a requirement

which is essential to satisfactory and safe product

performance.

The words “Should” or May” indicate a

recommendation which is not essential and not

required, but which may be useful or helpful.

WARNING – SHOCK HAZARD

NOTE

2. GENERAL INFORMATION AND

REQUIREMENTS

This mount kit is designed to provide free delivery (no

ducting) air distribution. It is applicable to 47000, 48000

and 49000 Series Roof Top Units Only. The control

box mounts inside the upper unit return air opening. The

minimum recommended roof thickness with this system is

1”. The upper unit and ceiling assembly mount on a

square roof opening 14” to 15” on a side. The roof must

be capable of supporting 110 pounds of static load. Keep

in mind that dynamic loads exist in recreation vehicles.

All manual controls have been removed from the ceiling

plenum. They have been replaced with control relays.

The relays are mounted in the electrical box of the ceiling

plenum. The relays contain 12 VDC coils (which may be

energized by a wall mounted thermostat), with contacts

that control the 115 VAC used to power the roof top unit.

A low voltage controller controls all air conditioning

functions. The low voltage controller controls a 12 VDC

electrical circuit, which is used to energize the relays in

the ceiling plenum. The low voltage controller that

Airxcel, Inc. provides for the system may be a

combination (Heat/Cool).

2

Page 3

These low voltage controllers are capable of operating

both the roof top air conditioner and any furnace with a

12 VDC control circuit of 1 amp or less (continuous

current).

All air conditioning equipment is subject to freeze up

when evaporator air flow is sufficiently reduced. Ducting

of any length creates potential for reduced evaporator air

flow and system freeze up. To protect both the installer

and Airxcel, Inc. from conditions that promote reduced

air flow and system freeze up, Airxcel, Inc. has equipped

the ceiling plenum compressor control circuit with a low

temperature probe. The low temperature probe monitors

3. PACKAGE CONTENTS

The mounting kit package contains the following:

1) Steel mount frame

2) Ceiling shroud assembly

3) Small parts package consisting of:

4. SYSTEM MATCH-UP

the temperature of the air conditioner evaporator coil.

When the temperature of the evaporator coil drops below

28 degrees F, the switch will open, stopping compressor

operation. Compressor operation will resume once the

evaporator warms to 55 degrees F.

IMPORTANT

The low temperature sensor is part of the ceiling

plenum electrical circuit. The probe must be inserted

into the evaporator coil of the roof top unit by the

installer when bolting the ceiling plenum to the roof

top unit.

a) Mounting bolt (x4)

b) Mount screws (x3)

c) Supply duct assembly

d) Shoulder screw/spring (x4)

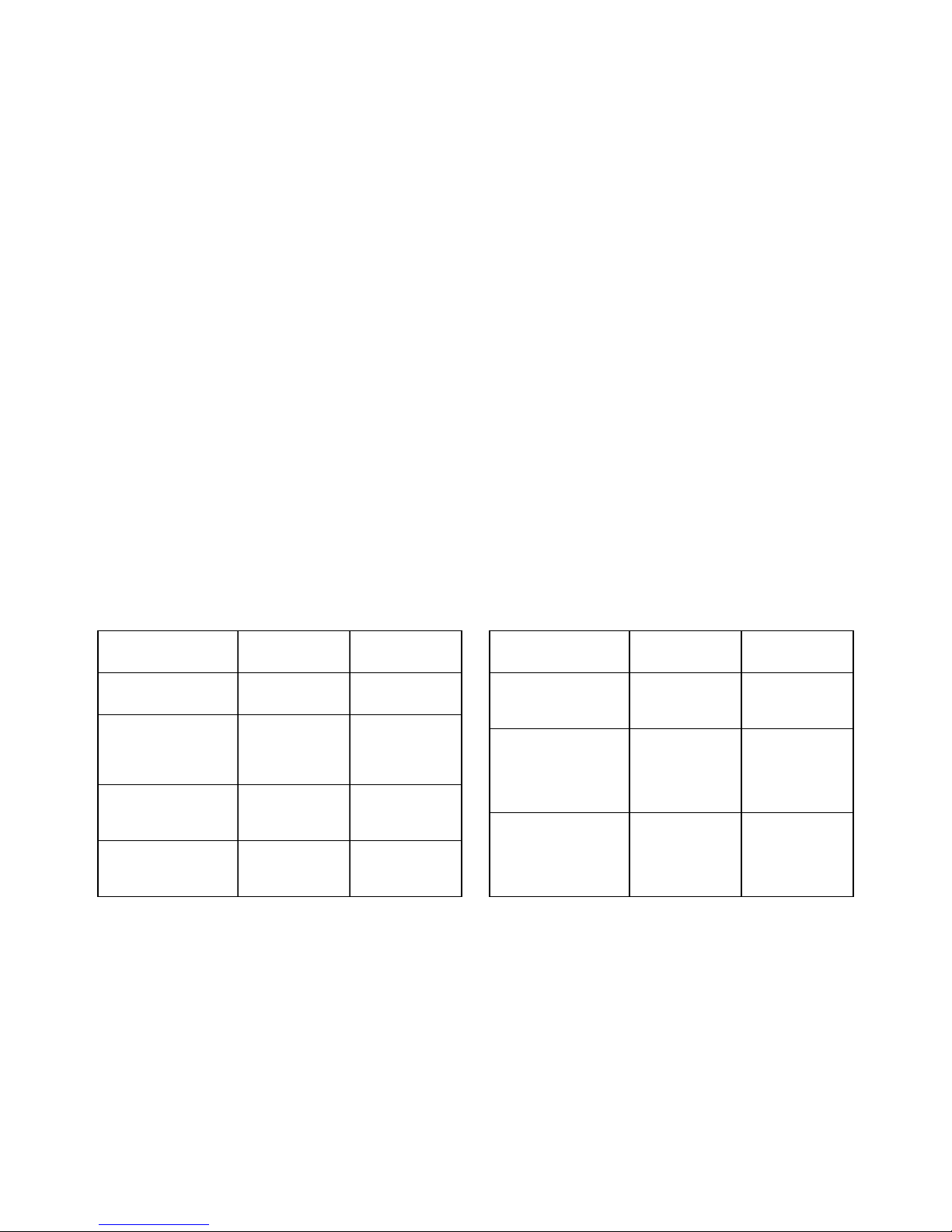

Ceiling Assembly Control Box Wall

Desired Function Kit Thermostat

12 VDC Control 8330-752 7330G335

Cooling Only or 8330-336

12 VDC Control 9330C755 7330G335

Cool/Heat Ready or 8330-336

24 VAC Control 8530-750 7330B344

Cooling Only or 8330B324

12 VDC Control 9530A751 8530A345

Heat Pump

Ceiling Assembly Control Box Wall

Desired Function Kit Thermostat

12 VDC Zone

Control Cooling 9430A751 9330A335

Only

12 VDC Zone

Control 9430A755 9330A335

Cool/Heat Ready

12 VDC Zone

Control Heat 9630A751 9330A335

Pump

3

Page 4

5. CEILING PLENUM INSTALLATION REQUIREMENT

1. The ceiling plenum must be installed under the roof

opening.

The ceiling plenum bolts below the roof top unit.

Compression of the framed ceiling cavity between the

roof top unit and the ceiling plenum is what holds both

components in place.

2. Ceiling cavity depth (the measurement from the ceiling to

the roof – maximum 6”).

3. The 115 VAC service for the roof top unit must be routed

into the ceiling plenum. To prevent wire pinching and to

promote ease of installation, allowances must be made for

routing the 115 VAC supply wiring into the front of the

roof opening.

4. The wirebox has a 9 pin receptacle extending from the

front. This mates with the roof unit 115 volt electrical

conduit. When making this connection, verify that the

plugs are properly aligned and have snapped together

securely.

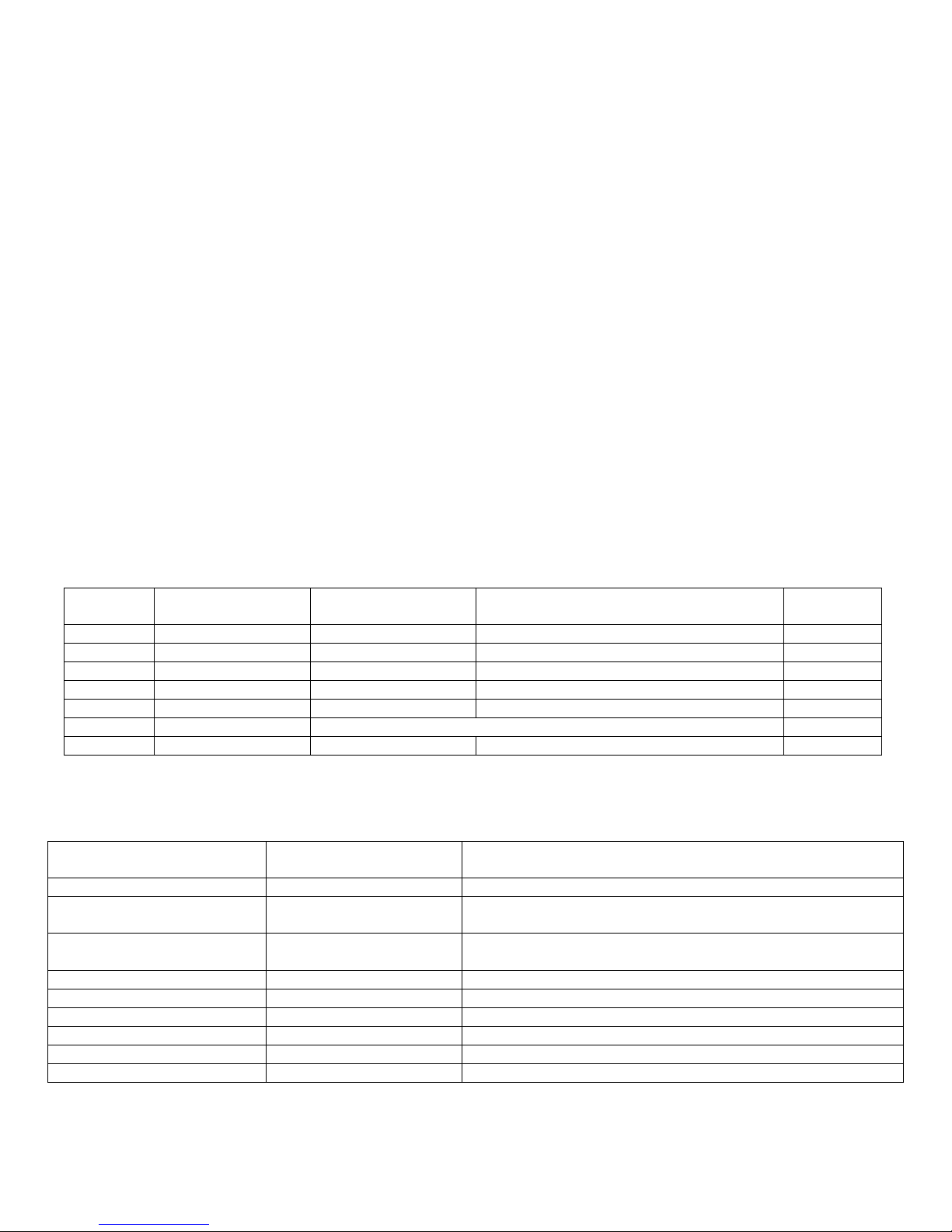

Standard Control Box

Cool Only

Boxes

Yes B BLUE Completes -12 VDC circuit for all relays Yes

Yes Y YELLOW Energizes coil on Compressor Relay Yes

Yes GH GREEN Energizes coil on High Fan Relay Yes

Yes GL GRAY Energizes coil on Low Fan Relay Yes

Yes FREEZE WHITE Evaporator Freeze Sensor Connections Yes

Yes FREEZE

No W WHITE Energizes coil on Heat Relay Yes

Plenum Terminal

Designation

Thermostat Wire

Connection

Zone Control Box

Plenum Terminal

Designation

R+ Red Provides +12 VDC to upper unit control box

Cool Shed

(2 Terminals)

Heat Shed

(2 Terminals)

Room (2 Terminals) Any The remote room temperature sensor attaches here*

Freeze (2 Terminals) White Freeze sensor attaches here

Gen Any Allows system to connect to an automatic start generator system

B- Blue Provides -12 VDC to upper unit control box

Sig 1 Purple Communication line between upper unit control box and thermostat

Sig 2 Black Communication line between upper unit control box and thermostat

* Zone 1 has option of using thermostat as room sensor

Thermostat Wire

Connection

White

Jumper Wire

White

Jumper Wire

5. The wirebox for the heat/cool units will have a two pin

receptacle which mates with the umbilical plug from the

heater assembly.

6. LOW VOLTAGE CONTROL WIRING (WALL

THERMOSTAT)

A. A low voltage terminal strip on the front of the box

connects to the low voltage control wires. The wires

attach by 1/4" quick connects.

B. The low voltage control wiring must be run from the

wall thermostat mounting location to the wirebox low

voltage terminals. To prevent wire pinching and to

promote ease of installation, allowances must be

made for routing the low voltage wiring into the front

of the opening.

Function of Low Voltage Terminal

Extending From Ceiling Plenum

Function of Low Voltage Terminal Extending From Ceiling

Plenum

Removing jumper wire will allow system to be connected to N.C.

contacts of a load shed system

Removing jumper wire will allow system to be connected to N.C.

contacts of a load shed system

Heat Ready

Boxes

4

Page 5

6. CONTROL BOX KITS

1. 8330-752 – 12 VDC Controlled, Cool Only

This kit consists of a control box assembly. The evaporator

freeze sensor is shipped in an envelope for installation by

quick connects to terminal strip “Freeze”.

2. 9330C755 – 12 VDC Controlled, Heat Ready

This kit consists of a control box assembly. The evaporator

freeze sensor is shipped in an envelope for installation by

quick connects to terminal strip “Freeze”. The heater

assembly for the 47000 series is 47233*4551. The heater

assembly for the 48000 and 49000 series is 9233*4551. Heat

kits are purchased separately.

7. CONTROL BOX KITS (ZONE)

1. 9430A751 – 12 VDC Zone Controlled, Cool Only

This kit consists of a control box assembly. The evaporator

freeze sensor is shipped in an envelope for installation by

quick connects to terminal strip marked “FREEZE”.

2. 9430A755 – 12 VDC Controlled, Heat/Cool

This kit consists of a control box assembly. The evaporator

freeze sensor is shipped in an envelope for installation by

quick connects to terminal strip marked “FREEZE”. The

heater assembly for the 47000 series is 47233*4551. The

heater assembly for the 48000 and 49000 series is 9233*4551.

Heat kits are purchased separately.

8. WALL THERMOSTATS

1. Locate and install the thermostat per instructions

found with the thermostat.

2. For 12 VDC thermostats, it is required that the

thermostat 12 volt negative connection be routed

9. ROUTING THERMOSTAT WIRING

1. Following the instructions packed with the

thermostat, determine a location for thermostat

mounting.

2. Following Airxcel, Inc. low voltage wiring

specifications and all local and national electrical

codes:

A. Route the thermostat 12 VDC supply wiring

from the power source to the thermostat

mounting location.

5

3. 8530-750 – 24 VAC Controlled, Cool Only

This kit is similar to the 8330-752 with the exception of a

transformer that is attached to the box assembly.

4. 9530A751 – 12 VDC Controlled, Heat Pump

This kit is similar to the 9330C755 but is wired for the heat

pump function. Backup electric heat is available. The heater

assembly for the 47000 series is 47233*4551. The heater

assembly for the 48000 and 49000 series is 9233*4551. Heat

kits are purchased separately.

3. 9630A751 – 12 VDC Zone Controlled, Heat Pump

This kit consists of a control box assembly. The evaporator

freeze sensor is shipped in an envelope for installation by

quick connects to terminal strip marked “FREEZE”. Backup

electric heat is available. The heater assembly for the 47000

series is 47233*4551. The heater assembly for the 48000 and

49000 series is 9233*4551. Heat kits are purchased

separately.

directly from the converter or battery. It is highly desirable

provide 12 volt control power from the battery side of the

converter. These precautions should prevent control

problems.

Two wires are required:

One supply lead must be +12 VDC and red

in color.

The second supply lead must be -12 VDC

and blue in color.

B. To protect the wall mount thermostat from

over-current damage, a 2 amp fuse has been

provided with the thermostat.

C. Route the thermostat control wiring from the

thermostat mounting location into the front

of the ceiling plenum opening.

Page 6

Four (4) wires are required (5 wires for

heat/cool boxes). These wires are as

follows:

(1) Blue wire for -12 VDC circuit

(1) Yellow wire for compressor circuit

(1) Green wire for high fan circuit

(1) Gray wire for low fan circuit

10. ROUTING THERMOSTAT WIRING (ZONE)

1. Following the instructions packed with the

thermostat, determine a location for thermostat

mounting.

2. Following Airxcel, Inc. low voltage wiring

specifications and all local and national electrical

codes:

A. Route the thermostat control wiring from the

thermostat mounting location into the front

of the ceiling plenum opening.

These wires are as follows:

(1) Red wire to +12 VDC circuit (R+)

(1) Blue wire to -12 VDC circuit (B-)

(1) Purple wire to communication

signal (Sig 1)

(1) Black wire to communication

signal (Sig 2)

(1) Any color for auto generator start

(optional) (Gen)

(2) Any color for room temperature

sensor (zone 1 optional, required

for other zones)

(1) For each heating appliance

(Up to 4)

(2) Any color for cool load shed

(optional)

(2) Any color for heat load shed

(optional)

11. ROUTING 115 VAC WIRING

Following Airxcel, Inc. high voltage wiring specifications and

all local and national electrical codes, route the roof top unit

115 VAC supply wiring from its power source to the wirebox.

High Voltage Wiring Specifications based on Minimum

Overcurrent Protection Device Amperage – (see upper

unit nameplate)

1. U.L. requires copper conductors only with minimum

#12 AWG when using the minimum recommended

overcurrent protection device. Higher rated devices

or longer wiring runs will require #10 AWG or

greater copper conductors.

6

(1) White wire for heat circuit

3. Airxcel, Inc. low voltage wiring specifications:

A. All low voltage wiring should be 18 gauge

minimum.

B. Low voltage wiring must be routed into the front

side of the ceiling plenum opening.

B. See Figure 5 for wiring requirements for

multiple zones.

3. Airxcel, Inc. low voltage wiring specifications:

A. All low voltage wiring should be no

smaller than 18 gauge.

B. Low voltage wiring must be routed into

the front side of the ceiling plenum opening.

C. Low voltage wiring should not be routed

with high voltage wiring.

D. If low voltage and high voltage wires must

cross, they should do so at right angles from

one another.

2. To prevent voltage drops greater than 10% during

starting loads, adhere to the following guideline:

For lengths greater than 50’, use #10 AWG or larger

copper conductors. Match to the overcurrent

protection device provided.

Circuit Protection – Refer to upper unit nameplate

High Voltage Wiring Specifications based on Overcurrent

Protection Device rated higher than the minimum

required (see upper unit nameplate)

Page 7

Follow all local and NEC (National Electrical Code) for

proper sizing of wire AWG based on Overcurrent

Protection Device selected and the length of the wiring run

to the air conditioner.

12. SECURING THE UPPER UNIT TO THE ROOF

The supplied mounting frame is used to secure the upper unit

to the roof per the following steps (See Figure 1).

A. Locate the upper unit mount gasket over the 14” to

15” square opening in the roof.

B. Install the ceiling assembly mount frame using the

four bolts found with the ceiling assembly.

C. Proper tension has been achieved for each bolt when

any portion of each gasket indicating tab has been

pulled down even with the roof (See Figure 1). The

upper unit has now been properly installed with

optimum gasket compression.

Representative of 47000, 48000 and 49000 Series Units

7

FIGURE 1

Page 8

13. INSTALLING THE CONTROL BOX

1. Remove the control box assembly cover which is

held by two sheet metal screws. Feed the field lead

wires and ground through the strain relief found with

the control box.

2. Attach black supply conductor to black “pigtail” lead,

white to white and ground to green with wire nuts

provided in control box kit.

3. Insure that no bare wires can come into contact with

live electrical parts and that wires cannot be pinched

between the control box sides and lid. Insert the

strain relief into the control box entry hole to secure

the field wiring. Reinstall the control box lid.

4. Attach the thermostat wires to the control box per

illustrations below:

A. Control Box 8330-752

B. Control Box 9330C755, 9530A751

C. Control Box 8530-750

5. Connect the roof unit 115 volt electrical conduit to

the wirebox 9 pin receptacle and verify that the plugs

are properly aligned and have snapped together

securely.

6. Locate the two machine screws inside the evaporator

cover of the upper unit. Align the control box over

the screws and use the wing nuts supplied with the

control box to secure it to the upper unit enclosure.

See Figure 2 for control box orientation in 48000 and

49000 series units. See Figure 9 for 47000 series

units.

7. Insert the evaporator freeze sensor between

evaporator fins near the bottom center of the

evaporator and between the bottom two tubes (See

Figure 2). Insert straight in until contacting the

staggered tube directly in back of the insertion point.

When contact has been made, elevate the exposed

end of the sensor approximately 45 degrees, then

continue insertion at a 45 degree angle until the

sensor is completely embedded into the evaporator.

8

FIGURE 2

Page 9

14. INSTALLING THE CONTROL BOX (ZONE)

1. Remove the control box assembly’s cover which is

held by two sheet metal screws.

2. Set the “zone” jumper to the proper zone position for

the particular position the air conditioner or heat

pump will be in the coach (Refer to Figure 3 – Zone

1 is shown). Zones should be numbered from the

front of the back of the coach with Zone 1 in front.

3. Set the “HP”/”NON HP” jumper to “HP” if the unit

is a heat pump or to “NON HP” if the unit is not a

heat pump (Refer to Figure 3 – Non HP is shown).

4. Feed the field lead wires and ground through the

strain relief found with the control box then through

the 7/8” hole in the side of the box.

5. Wire nut the black field power conductor to the

stripped black 12-gauge wire in the control box.

6. Wire nut the white field power conductor to the

stripped white 12-gauge wire in the control box.

7. Wire nut the ground field power conductor to the

stripped green ground wire in the control box.

8. Insure that no bare wires can come into contact with

live electrical parts and that wire cannot be pinched

between the control box sides and lid. Insert the

strain relief into the control box entry hole to secure

the field wiring. Reinstall the control box lid.

Attach the thermostat wires to Zone 1 control box per the

illustration below (Refer to Figure 4):

FIGURE 3

FIGURE 4

9

Page 10

FIGURE 5

10

Page 11

Zone 2 is wired in by jumpering from Sig 1, Sig 2, B- and R+

on Zone 1 box to Zone 2 box. Zone 3 is wired in by

jumpering from Sig 1, Sig 2, B- and R+ on Zone 2 box to

Zone 3 box. Zone 4 is wired in by jumpering from Sig 1, Sig

2, B- and R+ on Zone 3 box to Zone 4 box (See Figure 5).

Connect the roof unit 115 volt electrical conduit to the

wirebox 9 pin receptacle and verify that the plugs are properly

aligned and have snapped together securely.

Position the control box over the screws and use the wing nuts

to fasten the control box to the upper unit enclosure. For

47000 series units, refer to Figure 9 on page 13. Note that the

box is installed with the wiring exiting upwards.

Insert the evaporator freeze sensor between evaporator fins

near the bottom center of the evaporator and between the

bottom two tubes (See Figure 2). Insert straight in until

contacting the staggered tube directly in back of the insertion

point. When contact has been made, elevate the exposed end

of the sensor approximately 45 degrees, then continue

insertion at a 45 degree angle until the sensor is completely

embedded into the evaporator.

15. INSTALLING THE HEATER ASSEMBLY

NOTE

The optional Electric Heating Element is intended to take the

chill out of the indoor air when the air is a few degrees too

cool for comfort. The Electric Heating Element is an effective

“chill chaser”. It is not a substitute for a furnace.

A. If adding the electric heater to 48000 and 49000

series units, position the assembly in the upper unit

return air opening as shown in Figure 6. The heater

bracket must be installed over the metal basepan

extrusion and positioned between the basepan and the

plastic drain pan (See Figure 7). Tighten set screw to

secure the assembly so as to prevent movement.

47000 series units will mount as shown in Figure 10

(see page 13) using wing nuts.

FIGURE 6

Complying with the warnings listed below, connect the 115

VAC supply wiring to its power source. Be sure all power

remains off until beginning checkout procedure.

DANGER

TO PREVENT THE POSSIBILITY OF

SHOCK INJURY FROM APPLIANCE

OPERATION:

THE WHITE WIRE MUST BE

CONNECTED TO NEUTRAL IN THE

SERVICE BOX ENTRANCE AND THE

MECHANICAL GROUND MUST BE

CONNECTED TO A GROUNDING

LUG IN THE SERVICE BOX OR THE

MOTOR GENERATOR

COMPARTMENT.

B. Insert the two-pin connector of the heater umbilical

into the receptacle on the control box. Insure that the

connector snap-locks into position.

TIE ALL WIRING TO INSURE NO CONTACT WITH

THE HEATER OR ANY SHARP EDGES. KEEP IN

MIND THAT HIGH VELOCITY AIR WILL BE

ENCOUNTERED IN THIS AREA.

FIGURE 7

11

Page 12

16. INSTALLING THE CEILING ASSEMBLY

A. Fasten the duct collar to the basepan of the air

conditioner with three (3) screws (See Figure 8).

B. Raise the ceiling assembly and secure to the

mounting frame with four (4) provided shoulder

screw/spring assemblies (See Figure 8).

C. The ceiling assembly shroud is curved to contour to

a crowned ceiling. If installation is to a flat ceiling

and gaps are present on the sides of the shroud,

insert the four optional 3/4 inch screws (provided)

through the mounting posts and secure them to the

mounting frame above. See Figure 8 for screw

locations.

D. Pull fabric duct material through ceiling assembly

discharge opening. Peel the release liner from the

adhesive strip around the discharge opening. Press

the fabric duct material firmly in place around

opening. Cut off excess fabric on inside of ceiling

assembly chute with a box knife taking care not to

tear the fabric beyond the adhesive strip.

E. Make sure the non-allergenic filters are properly

positioned in the ceiling grille. Install the ceiling

grille by positioning on the bottom of the shroud

and engaging the two 1/4 turn fasteners.

F. Turn the selector switch to OFF position.

G. Turn ON the power supply to the roof top air

conditioner.

H. Follow the “System Operation and Checkout” guide

in the thermostat installation instructions to insure

proper operation.

FIGURE 8

12

Page 13

Ş

FIGURE 9

FIGURE 10

13

Loading...

Loading...