Page 1

ENGLISH

FRENCH

SPANISH

PPRROOPPAANNEE

FFOORRCCEEDD--AAIIRR

HHEEAATTEERRSS

Models: 5070 and 5075 Series

ANSI Z83.7-CSA 2.14 - (2000)

CONSTRUCTION HEATER

INSTRUCTIONS FOR USE

IMPORTANT

Read this manual carefully before assembling, using or servicing this

heater. Keep this manual for future reference. If you have questions about

assembly, operation, servicing or repair of this heater, please call Coleman

at 1-800-835-3278 or TDD: 316-832-8707. In Canada call 1 800 387-6161.

This product is designed and approved for use as an

indoor construction heater in accordance with ANSI

and CSA standards. It is intended for temporary

heating of unoccupied buildings under construction,

alteration or repair. It is not intended for home or

recreational use.

CERTIFIED

®

©2006 The Coleman Company, Inc.

®

Page 2

2

GENERAL

SAFETY

INFORMATION

Safety Information continues on next page

This manual contains important information about the assembly, operation and maintenance of this construction heater. General safety information is presented in these first few

pages and is also located throughout the manual. Particular attention should be paid to

information accompanied by the safety alert symbol “ WARNING”.

Keep this manual for future reference and to educate new users of this product. This manual

should be read in conjunction with the labeling on the product.

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS

PROVIDED WITH THIS HEATER CAN RESULT IN DEATH, SERIOUS

BODILY INJURY AND PROPERTY LOSS OR DAMAGE FROM HAZARDS

OF FIRE, EXPLOSION, BURN, ASPHYXIATION, CARBON MONOXIDE

POISONING, AND/OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW THE

INSTRUCTIONS SHOULD USE OR SERVICE THIS HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION SUCH AS AN

INSTRUCTION MANUAL, LABELS, ETC., CONTACT THE MANUFACTURER.

WARNING: FIRE, BURN, INHALATION, AND EXPLOSION HAZARD.

KEEP SOLID COMBUSTIBLES, SUCH AS BUILDING MATERIALS, PAPER

OR CARDBOARD, A SAFE DISTANCE AWAY FROM THE HEATER AS

RECOMMENDED BY THE INSTRUCTIONS. NEVER USE THE HEATER IN

SPACES WHICH DO OR MAY CONTAIN VOLATILE OR AIRBORNE COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE, SOLVENTS, PAINT

THINNER, DUST PARTICLES OR UNKNOWN CHEMICALS.

WARNING

NOT FOR HOME OR RECREATIONAL VEHICLE USE.

This product is designed and approved for use as an indoor construction heater in accordance

with standard ANSI Z83.7 - CSA

2.14 - (2000).

We cannot foresee every use which may be made of our heaters. Check with your local fire

safety authority if you have questions about heater use.

Other standards govern the use of fuel gases and heat producing products for specific uses.

Your local authorities can advise you about these.

This indoor construction heater should not be used in areas directly exposed to water spray,

rain, and/or dripping water.

CARBON MONOXIDE POISONING:

This construction heater is a combustion appliance. All combustion appliances

produce carbon monoxide (CO) during the combustion process. This product is designed to

produce extremely minute, non-hazardous amounts of CO if used and maintained in

accordance with all warnings and instructions. Do not block air flow into or out of the

heater.

Early signs of carbon monoxide poisoning may resemble the flu with headaches,

dizziness and/or nausea. If these symptoms are present during operation of this product get

fresh air immediately!

Page 3

ENGLISH

3

MAKE SURE ADEQUATE VENTILATION IS PROVIDED. Provide a fresh

outside air opening at least three (3) square feet (0.3 m

2

) or its equivalent, i.e., 1' x 3' (0.3 m

x 0.9 m) for each heating unit. DO NOT USE THIS HEATER IN LIVING QUARTERS

OR WHILE SLEEPING! California lists carbon monoxide as a reproductive toxin under

Proposition 65.

PROPANE GAS:

This product is fueled by propane gas. Propane gas is invisible, odorless, and

flammable. An odorant is normally added to help detect leaks and can be described as a

“rotten egg” smell. The odorant can fade over time so leaking gas is not always detectable

by smell alone.

Propane gas is heavier than air and leaking propane will sink to the lowest level

possible. It can be ignited by ignition sources including matches, lighters, sparks or open

flames of any kind many feet away from the original leak. Use only propane gas set up for

vapor withdrawal.

Propane gas should be stored and used in compliance with local ordinances and

codes or with ANSI/NFPA58. Turn off propane when not in use.

FIRE/EXPLOSION:

During operation, this product can be a source of ignition. Keep heater area clear

and free from combustible materials, gasoline, paint thinner, cleaning solvents and other

flammable vapors and liquids. Do not use heater in areas with high dust content.

MINIMUM HEATER CLEARANCES FROM COMBUSTIBLE MATERIALS: TWO

(2) FEET (0.6 M) FROM SIDES AND REAR, FOUR (4) FEET (1.2 M) FROM TOP,

AND SIX (6) FEET (1.8) FROM THE OUTLET. Keep heater at least six (6) feet (1.8 m)

away from propane tanks and keep propane hoses away from outlet opening of the heater.

ADDITIONAL SAFETY INFORMATION:

• Never alter or modify heater, propane hose/regulator assembly or propane cylinders.

Do not attach duct work of any kind to this heater.

• Always inspect heater, propane hoses and propane cylinders before use. Do not use

if leaking propane or if damaged. Replace hoses that have excessive wear, abrasion

or cuts. Use only Coleman repair parts and Coleman propane hoses and regulator

assemblies.

• KEEP OUT OF REACH OF CHILDREN.

• Heater will remain hot up to thirty (30) minutes after being turned off.

• Operate heater only on level, stable surface.

• Use only the electrical voltage and frequency specified on product decal.

• Electrical grounding instructions — this heater is equipped with a three-prong

(grounding) plug for your protection against shock hazard and should be plugged

directly into a properly grounded three-prong receptacle.

• Use only a three-prong, grounded extension cord.

• Make sure heater is plugged into outlet before igniting heater.

• Keep the appliance area clear and free from combustible materials, gasoline and

other flammable vapors and liquids.

• Do not block or obstruct the flow of combustion and ventilation air.

• Blower (forced air) and radiant type heaters must not be directed toward any

propane-gas container within 20 feet (6 m).

GENERAL

SAFETY

INFORMATION

Continued

Page 4

4

Product Identification

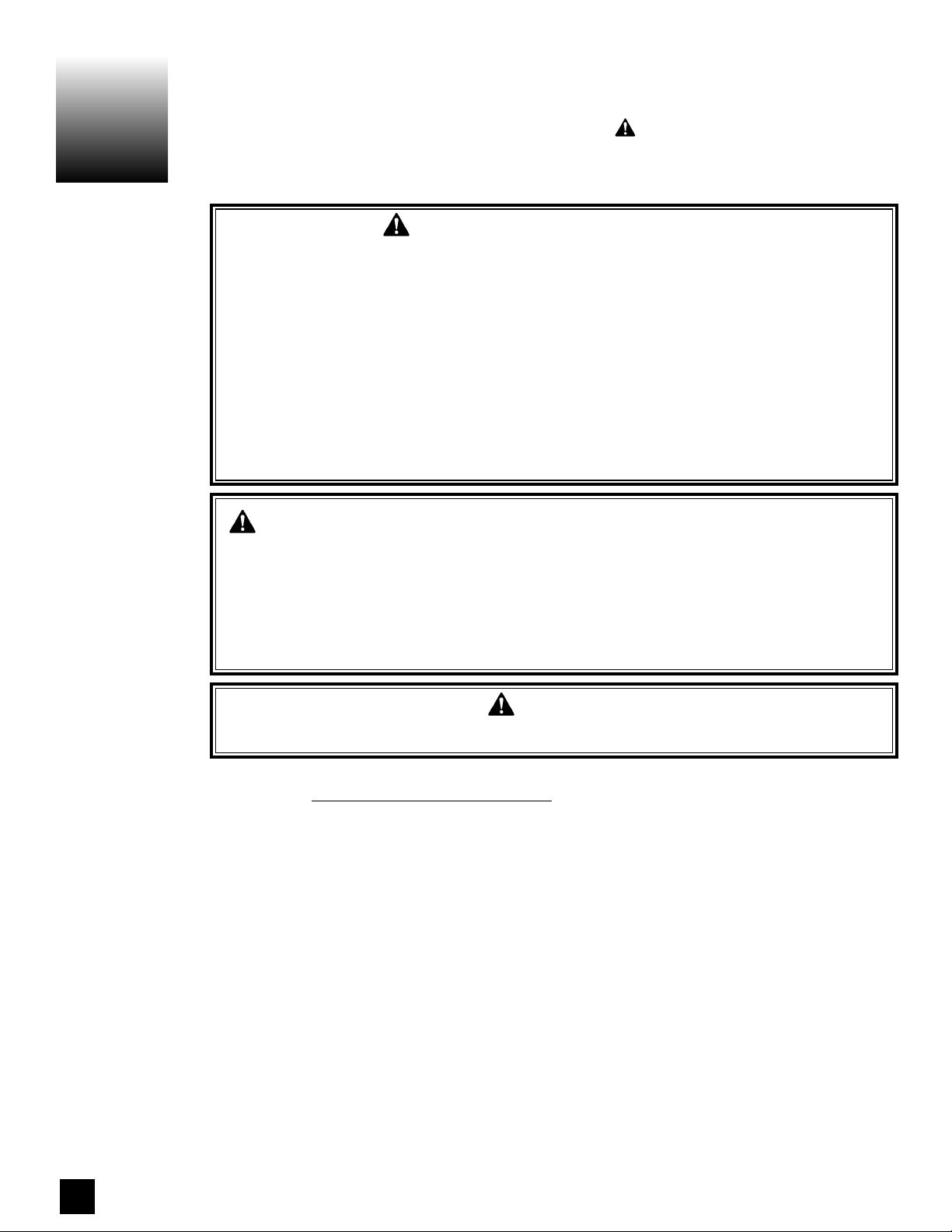

Figure 1 - 40,000 BTU/Hr. Model

Figure 2 - 50,000 to 80,000 BTU/Hr. Model

Top Shell

POL Fitting

Propane

Hose/Regulator

Assembly

Automatic

Valve Button

Burner Valve

Knob

Inlet

Connection

CONTENTS

SECTION PAGE

General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . 2,3

Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Propane Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5, 6

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6, 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 – 9

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9, 10

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Preventative Maintenance Schedule. . . . . . . . . . . . . . . . . . . 11

Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12, 13

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Technical and Repair Service . . . . . . . . . . . . . . . . . . . . . . 44

PRODUCT

IDENTIFICATION

Piezo Ignitor

Button

Page 5

ENGLISH

5

1. Remove all packing items applied to heater for shipment. Keep plastic cover caps

(attached to inlet connection and hose/regulator assembly) for storage.

2. Remove all items from carton.

3. Check all items for shipping damage. If heater is damaged, promptly inform dealer

where you bought heater.

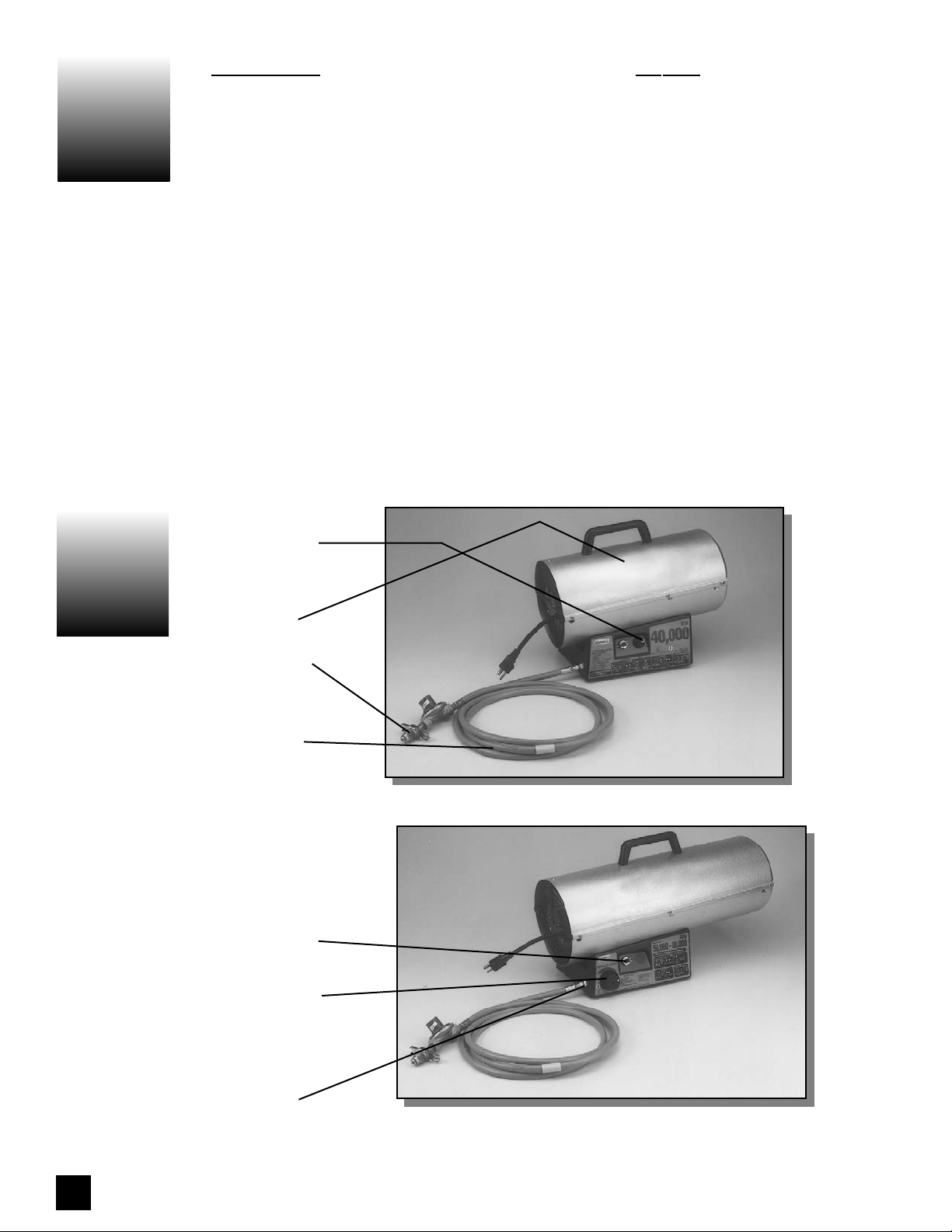

The Fuel System: The hose/regulator assembly attaches to the propane gas supply. The

propane gas moves through the thermoelectric valve and out the nozzle.

The Air System: The motor turns the fan. The fan pushes air into and around the combustion chamber. This air is heated and provides a stream of clean, hot air.

The Ignition System: The piezo spark ignitor (Model 5070A) or Electronic Module

(Model 5075A) sends voltage to the electrode. The spark at the electrode ignites the fuel

air mixture.

The Safety Control System: This system causes the heater to shut down if the heater

overheats for any reason including loss of electric power. (The fan will continue to operate

if electric power is not lost.)

UNPACKING

THEORY OF

OPERATION

Propane Supply Information continues on next page

PROPANE

SUPPLY

Propane gas and propane tank(s) are to be furnished by the user.

Use this heater only with a propane vapor withdrawal supply system. See Chapter 5 of the

Standard for Storage and Handling of Liquefied Petroleum Gas, ANSI/NFPA 58. Your local

library or fire department will have this booklet.

The amount of propane gas ready for use from propane tanks varies. Two factors decide

this amount:

1. The amount of propane gas in tank(s).

2. The temperature of tank(s)

Cross Section Operational View (5070A Model Shown)

Fan

Motor

Cool Air In (Back)

Power Cord

Hose/Regulator

Assembly

Electrode

Clean Heated Air

Out (Front)

Combustion Chamber

Air For Heating

Combustion Air

Fuel

Ignitor

Page 6

6

Continued

NUMBER OF TANKS REQUIRED

Average Temperature (°F)

At Tank Location 32° 20° 10° 0° -10°

(0°C) (-7°C) (-12°C) (-18°C) (-23°C)

5070A751 (40,000 BTU/Hr.) 1-20# 1-40# 1-100# 2-100# 3-100#

5075A751 (80,000 BTU/Hr.) 1-100# 2-100# 2-100# 3-100# 3-100#

Less gas is vaporized at lower temperatures. You may need two or more 100-pound tanks

or one larger tank in colder weather. Your local propane gas dealer will help you select the

proper supply system.

WARNING

Test all gas piping and connections for leaks after preparation or servicing.

Never use an open flame to check for a leak. Apply a mixture of liquid soap

and water to all joints. Bubbles forming show a leak. Correct all leaks before

using product.

1. Determine propane supply needed. (See Propane Supply).

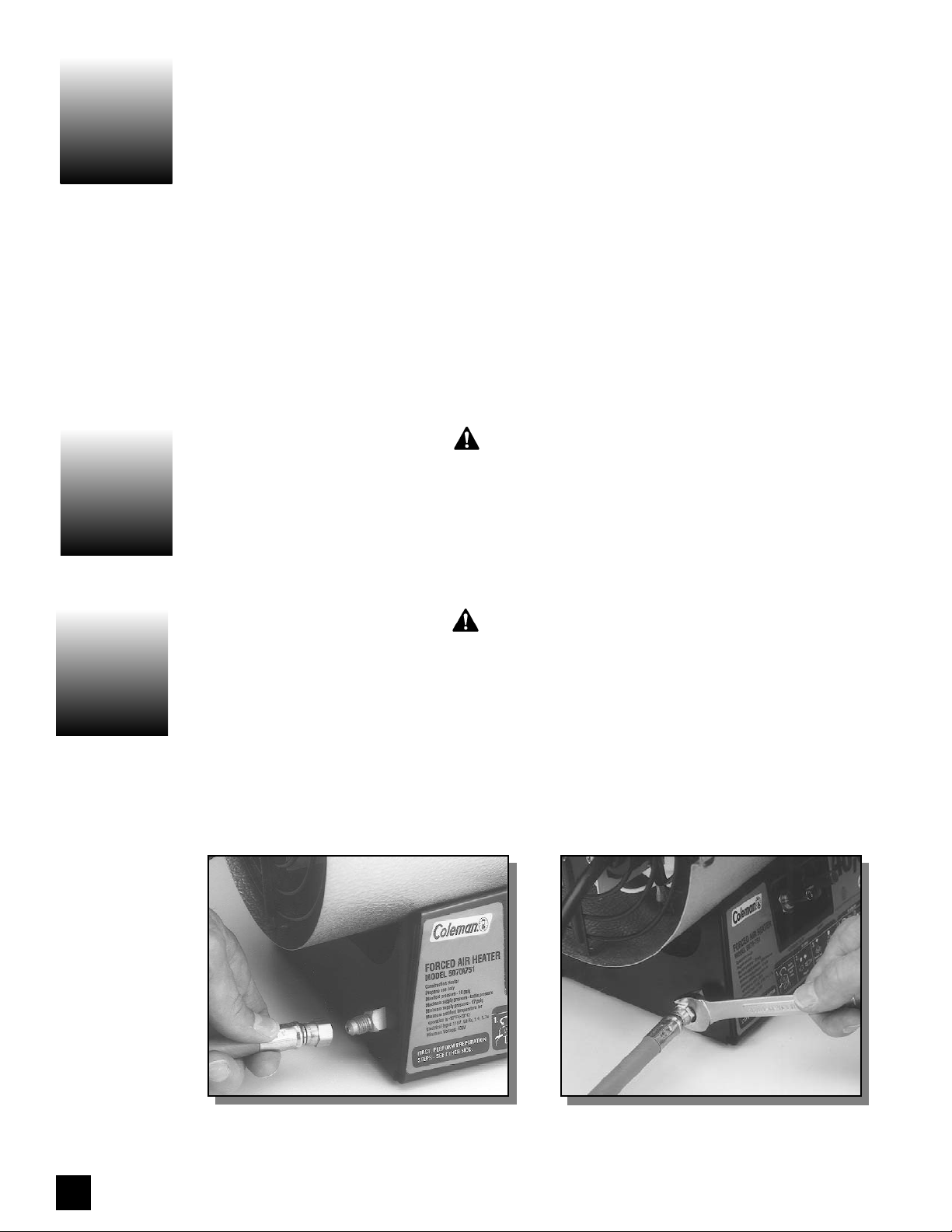

2. Connect hose to inlet connector. T ighten firmly in clockwisedirection using

9

/

16" wrench.

PROPANE

SUPPLY

Continued

VENTILATION

PREPARATION

WARNING

Provide at least a 3-square-foot (0.3 m2) opening of fresh, outside air while

running heater. If proper outside air ventilation is not provided, carbon

monoxide poisoning can occur. Provide proper outside air ventilation before

running heater.

Hose and Inlet Connector

Tighten with Wrench

The chart below shows the minimum number of 20-pound or larger tanks needed to run

these heaters at the temperature indicated for at least 10 hours. Do not operate them with

tanks smaller than indicated. Reduced performance will result.

Page 7

ENGLISH

7

Continued

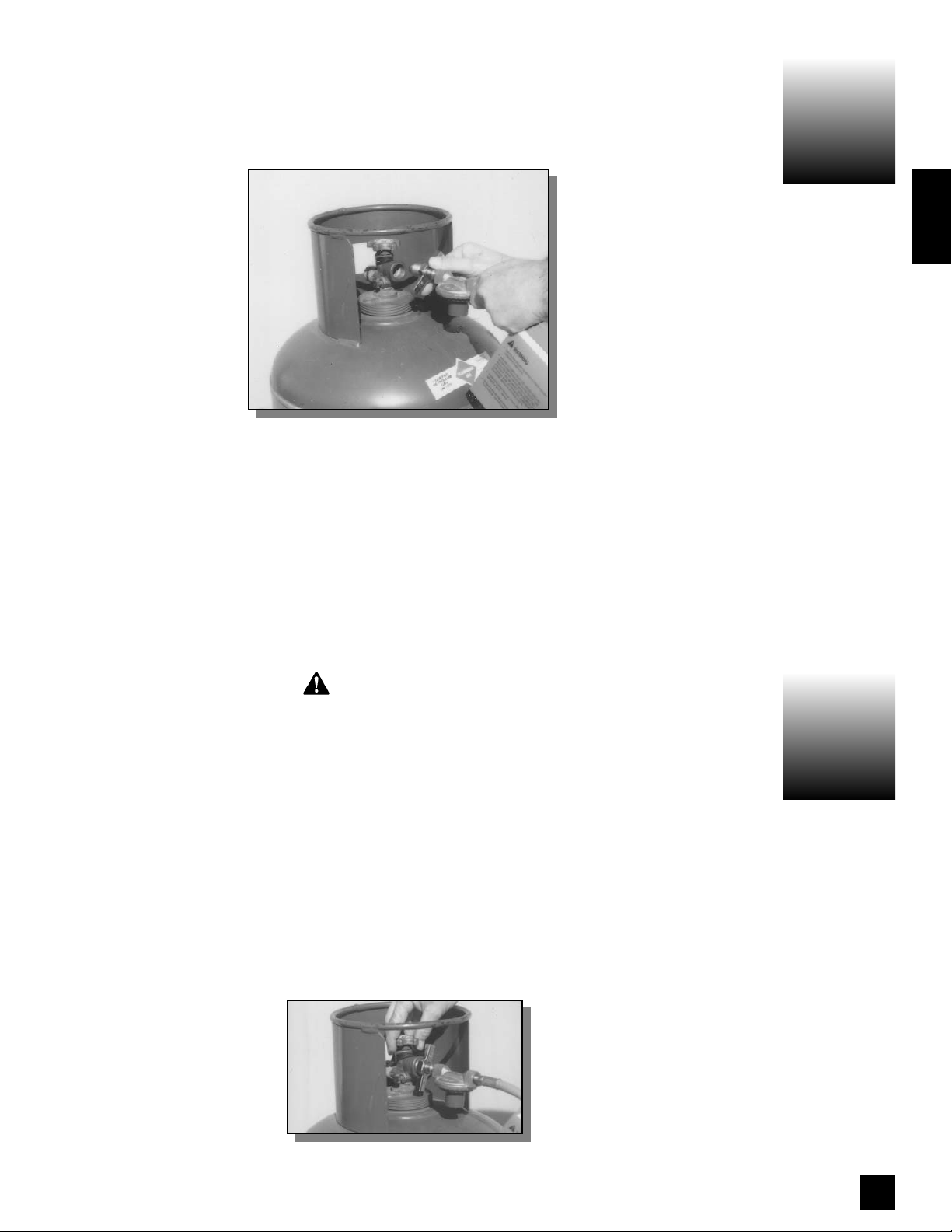

3. Connect POL fitting on hose/regulator assembly to propane tank(s).

Turn POLfitting counterclockwise into threads on tank. Tighten firmly.

IMPORTANT

: Tighten regulator with vent pointing down. Pointing vent down protects

regulator from weather damage.

PREPARATION

Continued

Regulator With Vent Pointing Down

4. Open valve on propane tank(s) slowly.

Note

: If not opened slowly , excess-flow check

valve on propane tank will stop gas flow . If this happens, close propane valve and open

again slowly .

5. Check all connections for leaks. Apply mixture of liquid soap and water to gas joints.

Bubbles forming show a leak that must be corrected before using heater.

6. Close propane supply valve.

OPERATION

WARNING

Review and understand the warnings in the General Safety Information

Section. They are needed to safely operate this heater. Follow all local ordinances or codes when using this heater.

To Start Heater

1. Follow all preparation, ventilation, and safety information.

2. Locate heater on stable and level surface. Make sure strong drafts do not blow into front

or rear of heater. Do not use in areas directly exposed to water spray, rain, and/or dripping

water.

3. Open valve on propane tank(s) slowly. Note: If not opened slowly, excess-flow check valve

on propane tank will stop gas flow . If this happens, close propane valve and open again

slowly .

Page 8

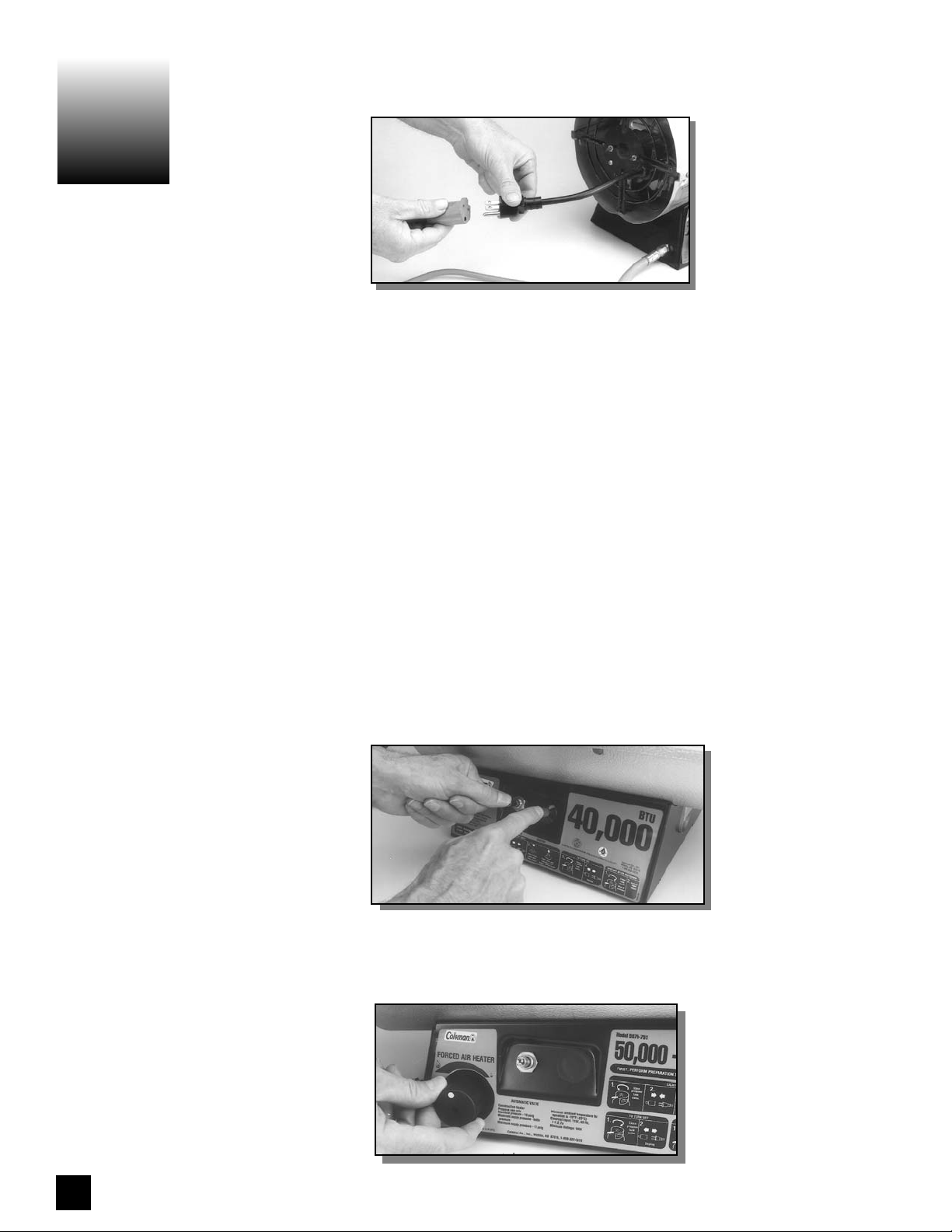

4. Plug power cord of heater into a three-prong, grounded extension cord. Extension cord must

be at least six feet long. Extension cord must be ULlisted.

Extension Cord Size Requirement

Up to 50 feet (15 m) long, use 18 AWG rated cord.

51 to 100 feet (30 m) long, use 16 AWG rated cord.

101 to 200 (61 m) feet long, use 14 AWG rated cord.

5. Plug extension cord into a 120 volt/60 hertz, three-hole, grounded outlet. The motor will

start, turning the fan forcing air through the heater.

6. T o light:

Model 5070A

Push in and hold automatic valve button. Push ignitor (Red) button. You may need to push

the ignitor button 3 – 8 times until heater lights. Note: Hose may be filled with air . If so,

keep automatic valve button pressed and wait 20 seconds before pressing ignitor again.

When heater lights, keep automatic valve button pushed in. Release button after

30 seconds.

Model 5075A

Push in & hold automatic valve button. NOTE: Hose may be filled with air. If so, continue

to keep automatic valve button pressed. When heater lights, keep automatic valve button

pushed in. Release button after 30 seconds.

8

Continued

OPERATION

Continued

5070A751 Model Shown

7. If heater goes out, repeat step 6.

8. Adjust burner valve to desired heat level. (5075A751 Model only)

Page 9

ENGLISH

Continued

9

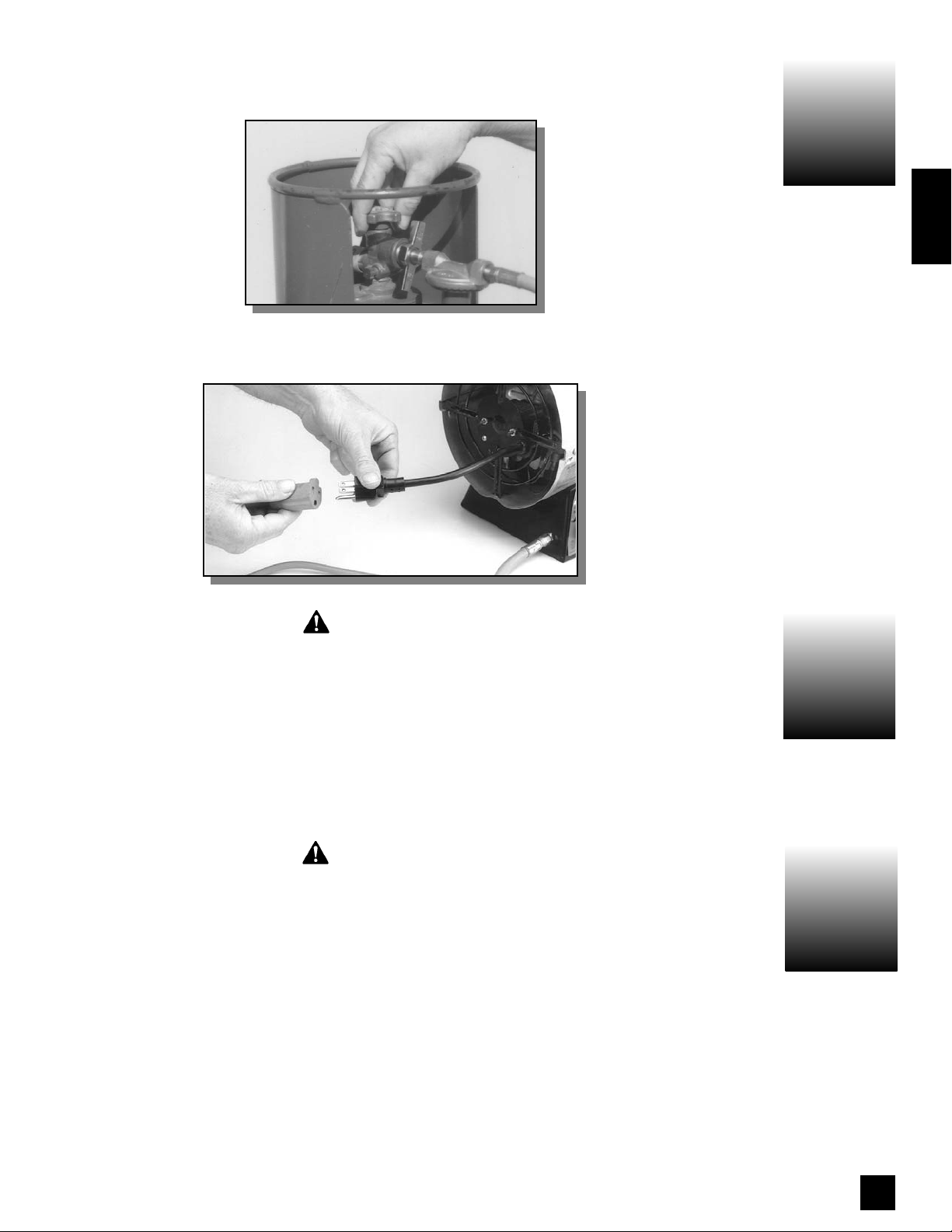

To Stop Heater

1. Tightly close valve on propane tank(s).

2. Wait a few seconds. Heater will burn gas left in hose.

3. Unplug heater.

OPERATION

Continued

WARNING

Disconnect heater from propane supply tank(s) before storage.

1. Store propane tank(s) in safe manner. See Chapter 5 of Standard for Storage and

Handling of Liquefied Petroleum Gases, ANSI/NFPA 58. Follow all local codes.

2. Place plastic cover caps over brass fittings on inlet connection and hose/regulator

assembly of heater.

3. Store heater in a dry, clean, and safe place.

STORAGE

WARNING

Never attempt to service heater while it is plugged in, connected to propane

supply, operating or hot. Severe burns and electrical shock can occur.

1. Keep heater clean. Clean heater annually or as needed to remove dust and debris. If

heater is dirty or dusty, clean heater with a damp cloth.

2. Inspect heater before each use. Check connections for leaks. Apply mixture of liquid

soap and water to connections. Bubbles forming show a leak. Correct all leaks before

using heater.

3. Inspect propane hose/regulator assembly before each use. Replace hoses that have

excessive wear, abrasion, or cuts. Inspect “O” ring for damage. Replace if cut or

cracked.

4. Have heater inspected yearly by a qualified service person.

5. Keep inside of heater free from combustible and foreign objects.

MAINTENANCE

Page 10

10

Continued

MAINTENANCE

Continued

6. FAN - Clean every 500 hours of operation or as needed.

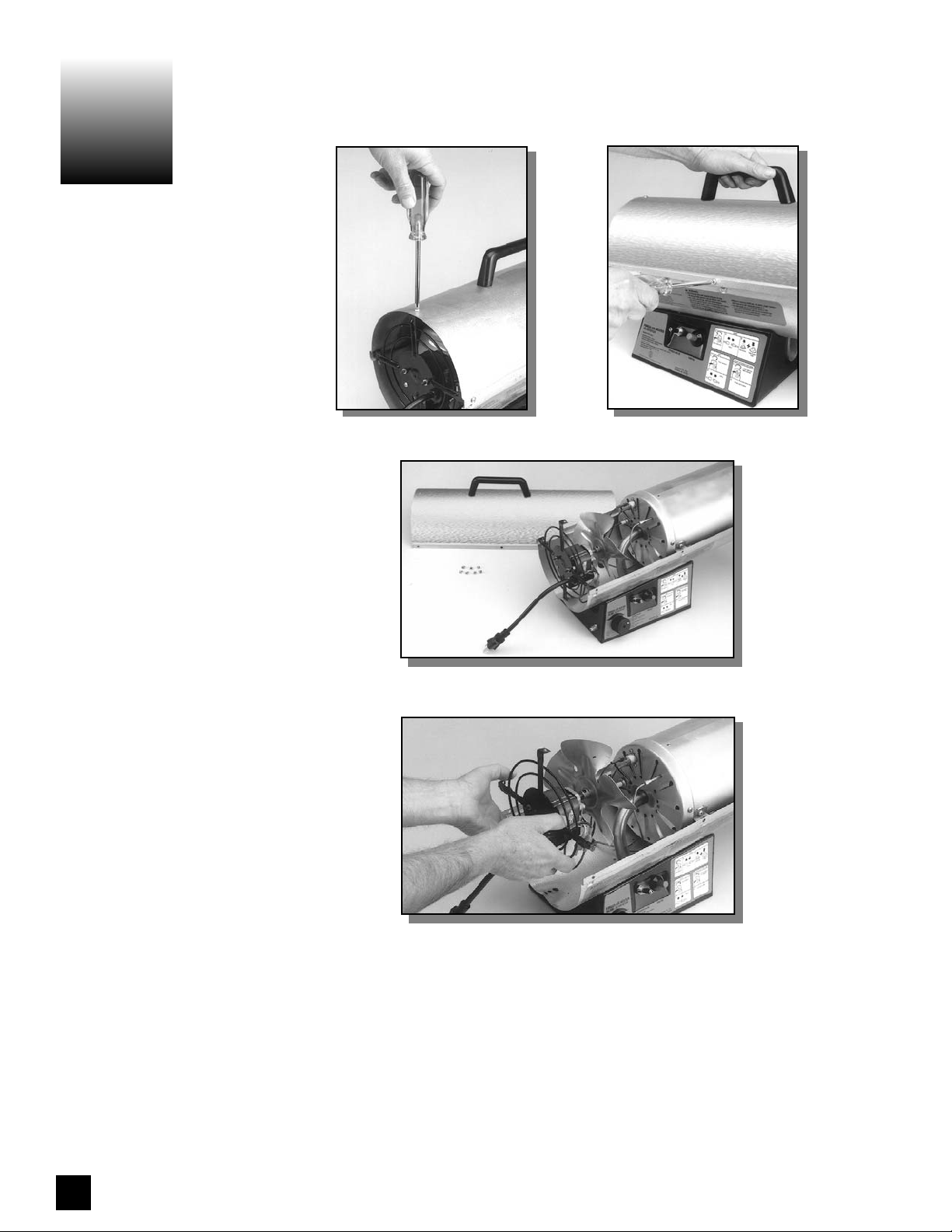

A. Remove screws along each side of heater and on top of the motor guard using

a Phillips screwdriver. These screws attach top and lower shells together.

B. Lift top shell off.

C. Lift out motor/guard assembly.

IMPORTANT: Do not allow the motor/guard assembly to rest on the fan or damage may be

caused to the blades.

D. Clean fan using soft cloth moistened with kerosene or solvent. Dry fan

thoroughly. Clean inside the shell adjacent to where the fan runs.

E. Replace motor/guard assembly and top shell.

7. ELECTRODE

A. Make sure gap between electrode wire and burner nozzle is .20 (0.5 cm) to

.25" (0.6 cm). Access electrode from inside combustion chamber. No other

maintenance is needed for electrode.

Page 11

ENGLISH

11

Continued

TROUBLE-

SHOOTING

WARNING

Never attempt to service heater while it is plugged in, connected to propane

supply, operating or hot. Severe burns and electrical shock can occur.

SYMPT

OM POSSIBLE CAUSE REMEDY

Fan does not turn No electrical power to heater Check voltage to electrical outlet.

when heater is If voltage is good, check heater

plugged in. power cord for breaks.

Fan blades bent Replace fan. See Replacing Fan,

Page 13.

Defective motor Replace motor. See Replacing Motor,

page 12.

Heater will not User did not follow prepara- Repeat preparation and operaignite. tion or operation instruc- tion instructions. See Preparation,

tions properly pages 6 & 7 and Operation, pages 7,

8 & 9.

No spark at electrode. To test

for spark, follow step 9 under Replacing Electrode,

page 13. If you see spark at

ignitor, have heater serviced

by qualified service person.

If no spark seen:

A) Loose or disconnected A) Check ignitor wire. Tighten

ignitor wire or reattach loose ignitor wire.

See page 5 for ignitor

wire location.

B) Wrong spark gap B) Set gap between ignitor electrode

and target plate to .20" (0.5 cm).

C) Piezo ignitor loose C) Tighten piezo ignitor to base

of heater.

D) Bad electrode D) Replace electrode. See Replacing

Electrode, page 13.

E) Bad piezo ignitor E) Replace ignitor.

F) Bad electronic module F) Replace electronic module.

Heater shuts down High surrounding air tem- This can happen when running

while running. perature causing thermal heater in temperatures above

limit device to shut down 85°F (29°C). Run heater in cooler

heater. temperatures.

Restricted air flow Check heater inlet and outlet.

Remove any obstructions.

Damaged fan Replace fan. See Replacing Fan,

page 13.

Excessive dust or debris in Clean heater. See Maintenance,

surrounding area pages 9 & 10.

WARNING

Use only in areas

free of high dust

content.

ITEM HOW OFTEN HOW TO

Fan Clean every 500 hours of See Fan, page 10

operation or as needed.

Electrode Clean and regap every 500 See Electrode, page 10

hours of operation or replace

as needed.

PREVENTIVE

MAINTENANCE

SCHEDULE

Page 12

WARNING

Never attempt to service heater while it is plugged in, connected to propane

supply, operating, or hot. Severe burns and electrical shock can occur.

REPLACING MOTOR

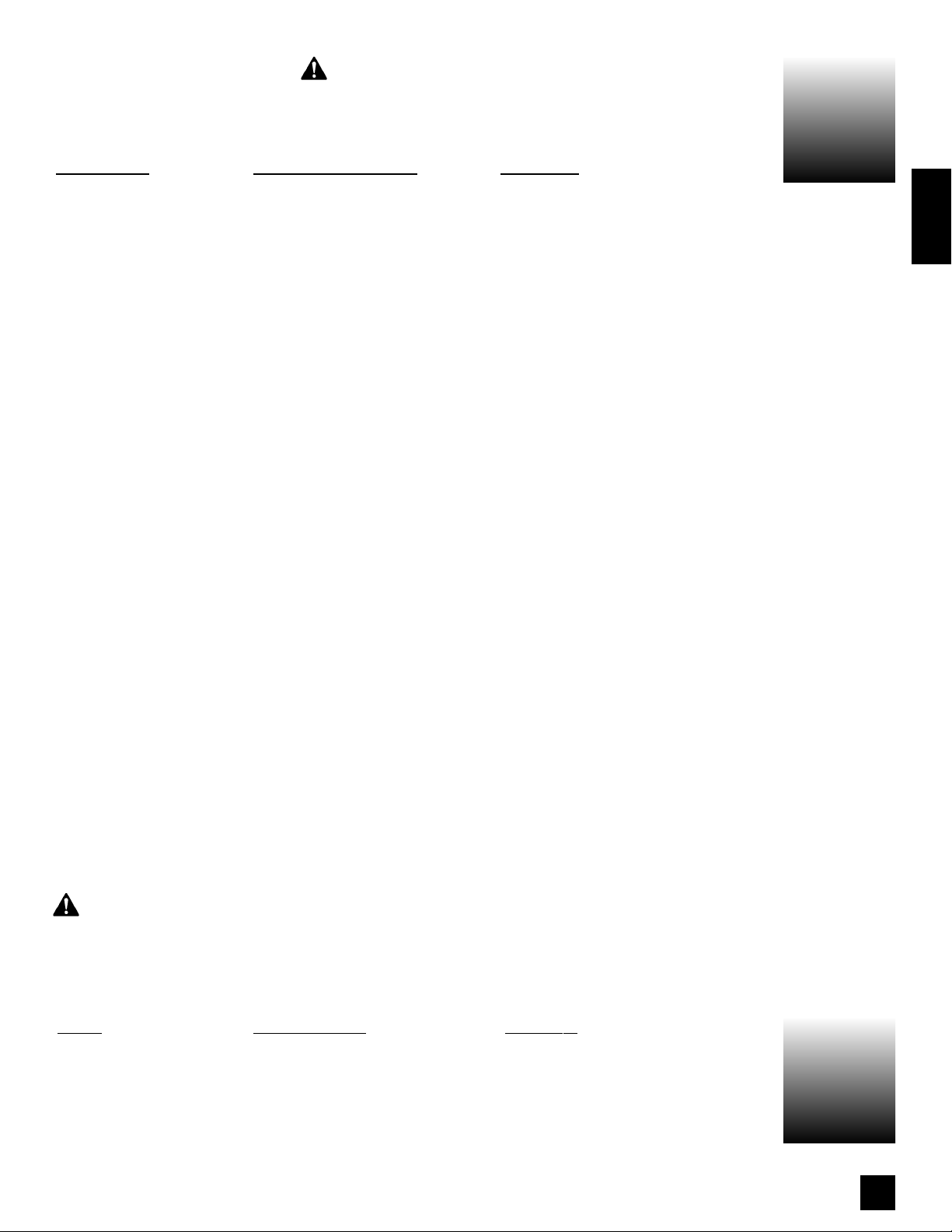

1. Remove top shell (see FAN under maintenance).

12

SERVICE

PROCEDURES

Continued

2. Lift out motor/guard assembly.

3. Use a 1/8" hex wrench to loosen setscrew which holds fan to motor shaft.

4. Remove fan from motor shaft (it may be necessary to pry the fan from the shaft) being

careful not to damage the blades.

5. Remove the ground wire screw and two wire leads from the motor.

6. Remove two nuts and two screws which attach the motor to the guard.

7. Discard motor.

8. Attach new motor to guard using two screws and nuts.

9. Replace fan on shaft with approx. 3/8" (1 cm) of shaft showing through fan hub.

10.Tighten setscrew firmly (40-50 inch pounds).

11.Install ground wire and wire leads to motor.

12.Set motor/guard assembly in the lower shell. Turn fan to check for interference.

13.Install the top shell.

Page 13

ENGLISH

13

REPLACING FAN

1. Remove motor/guard assembly (follow steps 1 through 4 above).

2. File the setscrew mark off the motor shaft.

3. Replace fan (follow steps 9 through 13 above).

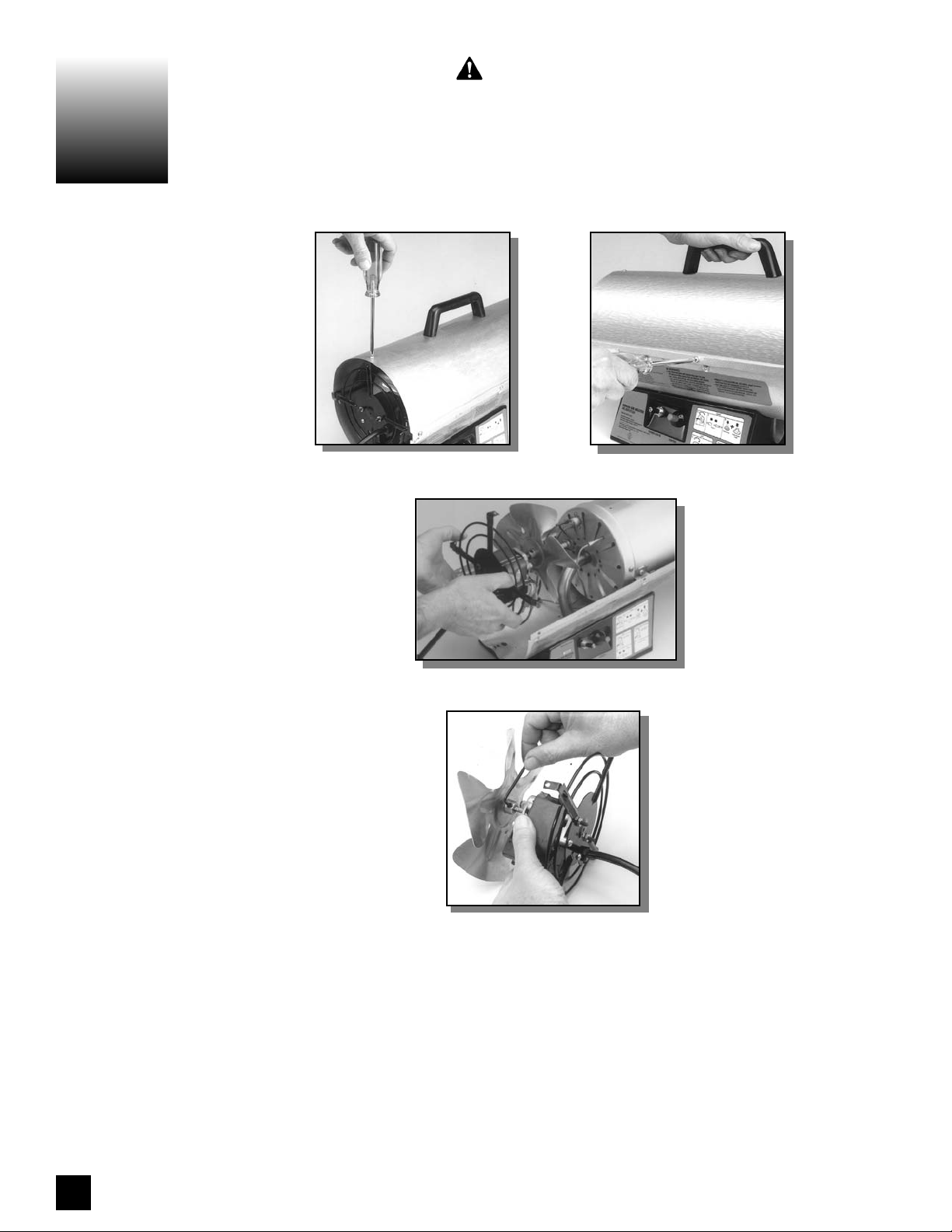

REPLACING ELECTRODE

1. Remove shell and motor/guard assembly (see FAN under maintenance).

2. Pull wire off of electrode.

3. Remove screw holding electrode to diffuser.

4. Remove electrode from diffuser.

5. Place new electrode in diffuser.

6. Install screw, insure electrode gap is .20 (0.5 cm) to .25 (0.6 cm) inch.

7. Push ignitor wire on electrode wire.

8. Reinstall motor/guard assembly and upper shell.

9. For Model 5070A, push ignitor button and check for spark between deflector and electrode. For Model 5075A check for sparks between deflector & electrode after

plugging in. Do not connect propane supply.

Continued

SERVICE

PROCEDURES

Continued

SPECIFICATIONS

FORCED AIR HEATER SPECIFICATIONS

40,000 BTU/HR - MODEL 5070A

Input Rating (BTU/HR) 40,000

Fuel Propane Vapor Only

Fuel Consumption

Gallons/Hour .44 (1.7 L)

Pounds/Hour 1.8 (0.8 kg)

Regulator Output Pressure 10 PSI (70 kPa)

Hose 10 Ft. (3 m)

Hot Air Output (CFM Approx.) 150

Motor 3,000 RPM

Power Required 115 Volt/60 Hz

Amps 1.1

Ignition Manual/Piezo

Weight (pounds) 14 (6.4 kg)

Size (HWL) (IN) 14 x 8.5 x 16.5

(35.6 x 21.6 x 41.9 cm)

Temperature Operating Range -10°F to 85°F

(-23° to 29.4°C)

FORCED AIR HEATER SPECIFICATIONS

50,000 TO 80,000 BTU/HR - MODEL 5075A

Input Rating (BTU/HR) 80,000 Max

Fuel Propane Vapor Only

Fuel Consumption

Gallons/Hour .9 (3.4 L)

Pounds/Hour 3.7 (1.7 kg)

Regulator Output Pressure 10 PSI (70 kPa)

Hose 10 Ft. (3 m)

Hot Air Output (CFM Approx.) 300

Motor 3,000 RPM

Power Required 115 Volt/60 Hz

Amps 2.6

Ignition Electronic Module

Weight (pounds) 17 (7.7 kg)

Size (HWL) (IN) 14 x 8.5 x 22.5

(35.6 x 21.6 x 57.2 cm)

Temperature Operating Range -10°F to 85°F

(-23° to 29.4°C)

Page 14

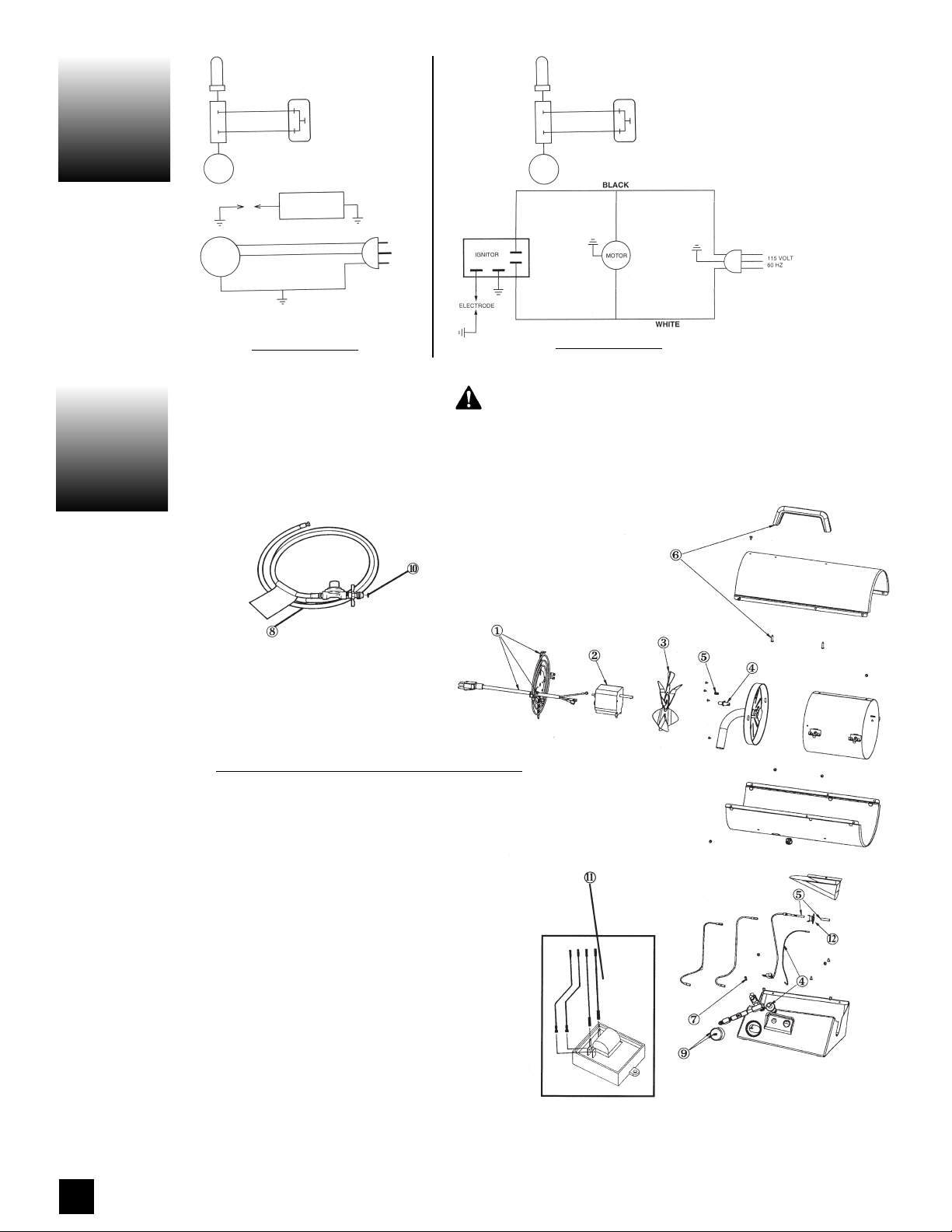

WIRING

DIAGRAM

14

WARNING

Use only original replacement parts. Do not substitute or use generic parts.

Improper replacement parts could cause serious or fatal injuries.

REPLACEMENT

PA RT S

THERMAL

SAFETY

SWITCH

T.E.

VALV E

PIEZO

IGNITOR

MOTOR

BLACK

WHITE

GREEN

I.D. PART NO. DESCRIPTION

NO.

1 5070-2851 Guard & Pigtail Assembly

2 5070-2801 Motor (5070A Model)

5075-2801 Motor (5075A Model)

3 5070-2891 Fan Blade for Heater (5070A Model)

5075-2891 Fan Blade for Heater (5075A Model)

4 5070-3111 Electronic Ignition Assembly (5070A Model)

5 5070-3271 Thermocouple & Clip

5075-3271 Thermocouple, Clip & Spacer

6 5070-2001 Handle & Screws

7 5070-2181 Gas Tip (5070A Model)

5075-2181 Gas Tip (5075A Model)

8 5080-5651 Hose & Regulator

9 5080-1491 Knob & Screw (5075A Model)

10 5410A1381 O-ring

11 5075B3001 E.I. Module Assembly*

(5075A Model)

12 5070A2701 Thermostat

*

Used on heaters manufactured after August 2002.

THERMAL

SAFETY

SWITCH

T.E.

VALV E

MODEL 5070A

MODEL 5075A

Page 15

FRENCH

CCHHAAUUFFFFEERREETTTTEESS

ÀÀ AAIIRR PPUULLSSÉÉ,,

AAUU GGAAZZ PPRROOPPAANNEE

Modèles des séries 5070 et 5075

MODE D’EMPLOI

IMPORTANT

Lisez attentivement ce manuel avant d’assembler, d’utiliser ou de réparer la

chaufferette; gardez-le pour le consulter au besoin. Pour toutes questions

concernant l’assemblage, le fonctionnement, l’entretien ou la réparation,

veuillez composer le 1 800 835-3278 ou le 316-832-8707 aux États-Unis, ou

bien le 1 800 387-6161 au Canada.

Cet appareil est conçu et homologué pour emploi en tant

que radiateur de construction, conformément aux normes

ANSI et CGA. Il est destiné au chauffage temporaire des

bâtiments

inhabités pendant leur construction ou leur

rénovation. Il ne convient pas au chauffage domiciliaire ou

récréatif.

ANSI Z83.7-CSA 2.14 - (2000)

RADIATEUR DE CONSTRUCTION

©2006 The Coleman Company, Inc.

CERTIFIED

®

®

Page 16

16

GÉNÉRALITÉS

DE

SÉCURITÉ

Autres renseignements de sécurité en page suivante

Ce manuel renferme des renseignements importants sur l’assemblage, le fonctionnement et

l’entretien des chaufferettes de construction. Les généralités de sécurité sont fournies non

seulement dans les premières pages, mais aussi ici et là dans le manuel. Prêtez toujours

attention quand vous voyez le symbole « AVERTISSEMENT».

Gardez ce manuel pour le consulter au besoin et pour apprendre aux nouveaux utilisateurs à

l’employer. Lisez-le de préférence de concert avec les étiquettes apposées sur la chaufferette.

AVERTISSEMENTS GÉNÉRAUX DE RISQUES:

L’INOBSERVATION DES PRÉCAUTIONS ET DES INSTRUCTIONS

FOURNIES AVEC L’APPAREIL PEUT ENTRAÎNER MORT, BLESSURES

CORPORELLES GRAVES ET DOMMAGES OU PERTES MATÉRIELS PAR

SUITE DES RISQUES D’INCENDIE, D’EXPLOSION, DE BRÛLURES,

D’ASPHYXIE, D’INTOXICATION OXYCARBONÉE OU DE CHOC

ÉLECTRIQUE. CE RADIATEUR NE DOIT ÊTRE UTILISÉ OU RÉPARÉ QUE

PAR DES PERSONNES CAPABLES D’ASSIMILER ET D’OBSERVER LES

INSTRUCTIONS FOURNIES. SI VOUS AVEZ BESOIN D’AIDE OU DE

RENSEIGNEMENTS – NOTICE D’EMPLOI OU ÉTIQUETTES, PAR

EXEMPLE – VEUILLEZ ENTRER EN RAPPORT AVEC LE FABRICANT.

AVERTISSEMENT: RISQUE D’INCENDIE, DE BRÛLURES ET

D’EXPLOSION. GARDEZ LES SOLIDES COMBUSTIBLES (MATÉRIAUX

DE CONSTRUCTION, PAPIER ET CARTON, PAR EX.) À LA DISTANCE

CONSEILLÉE DE L’APPAREIL. N’EMPLOYEZ PAS LA CHAUFFERETTE

DANS LES LOCAUX QUI CONTIENNENT OU PEUVENT CONTENIR

COMBUSTIBLES VOLATILS OU AÉROPORTÉS, ESSENCE, SOLVANTS,

DISSOLVANTS, FIBRES OU PRODUITS CHIMIQUES INCONNUS.

AVERTISSEMENT

NE CONVIENT PAS AUX MAISONS OU VÉHICULES DE PLAISANCE.

Cet appareil est conçu et homologué pour être employé en tant que radiateur de construction destiné à l’intérieur, conformément aux

exigences de la norme ANSI Z83.7 - CSA

2.14 - (2000).

Nous ne pouvons pas entrevoir toutes les utilisations auxquelles puissent être soumises nos chaufferettes. Vérifiez auprès des autorités

de sécurité contre l’incendie, au niveau municipal, si vous avez toute question au sujet de l’emploi de la chaufferette.

D’autres standards régissent l’utilisation des gaz combustibles et combustibles gazeux destinés à des utilisations spécifiques. Les autorités

locales vous renseigneront à ce sujet.

Conçue pour l’intérieur, la chaufferette de construction ne devrait pas servir dans les lieux où elle puisse être exposée à de la pulvérisation

d’eau, à la pluie ou à un dégouttement d’eau.

OXYCARBONISME

Cette chaufferette est un appareil à combustion qui, comme tous les appareils de ce genre, dégage de l’oxyde de carbone (CO) en

fonctionnant. Elle est conçue pour produire

des quantités infimes et non dangereuses de CO lorsque utilisée et entretenue conformément à tous les avertissements et aux instructions. N’obstruez jamais ses prises d’air.

Les premiers indices d’oxycarbonisme peuvent rappeler les symptômes de la grippe – maux de tête, étourdissement ou nausée.

En présence de tels symptômes lors du fonctionnement de la chaufferette, sortez immédiatement à l’airlibre!

Page 17

FRENCH

17

ASSUREZ-VOUS QUE L’APPROVISIONNEMENT EN AIR NEUFSOIT

SUFFISANT. Une bouche d’air d’au moins 0,3 m

2

(3 pi2) ou l’équivalent, soit 0,3 x 0,9 m (1 x

3 pi), est requise pour chaque unité. N’UTILISEZ PAS CETTE CHAUFFERETTE DANS

LES LOCAUX HABITÉS OU PENDANT LE SOMMEIL! En Californie, d’après la

Proposition 65, l’oxyde de carbone est répertorié comme agent toxique pour la reproduction.

GAZ PROPANE:

Cet appareil brûle le propane – gaz invisible, inodore et inflammable. Un odorisant

(odeur d’œufs pourris) y est généralement ajouté pour faciliter la détection des fuites. L’odeur

pouvant s’affaiblir avec le temps, le nez seul ne peut pas toujours déceler les fuites.

Étant plus lourd que l’air, le propane qui fuit s’accumule au niveau le plus bas et peut

être enflammé par allumettes, briquets, étincelles ou flammes nues se trouvant même à une

distance de la fuite. N’utilisez que les bonbonnes standard pour l’alimentation.

Le gaz propane devrait être entreposé et employé selon les règlements ou les codes

municipaux ou selon la norme ANSI/NFPA 58. Fermez le propane s’il ne sert pas.

INCENDIE OU EXPLOSION:

Ce produit peut être une source d’inflammation pendant son fonctionnement. Veillez à

ce que la chaufferette soit à l’écart (et sa vicinité exempte) de matériaux combustibles,

d’essence, de solvants, de dissolvants et d’autres liquides ou vapeurs inflammables.

N’employez pas la chaufferette dans les locaux à haute teneur en poussières. LES

DÉGAGEMENTS MINIMAUX DE LA CHAUFFERETTE AUX MATIÈRES

COMBUSTIBLES SONT DE 0,6 M (2 PI) POUR LES CÔTÉS ET L’ARRIÈRE ETDE

1,2 M (4 PI) POUR LE DESSUS. LA CHAUFFERETTE DOIT ÊTRE PLACÉE À AU

MOINS 1,8 M (6 PI) DE LA PRISE ÉLECTRIQUE. Gardez-la, en outre, à au moins 1,8 m

(6 pi) des bonbonnes de propane et ses tuyaux souples, éloignés des orifices d’admission.

AUTRES RENSEIGNEMENTS DE SÉCURITÉ:

• Ne modifiez jamais la chaufferette, l’ensemble tuyau et régulateur ou les bonbonnes

de propane. Ne raccordez pas de gaine quelle qu’elle soit à la chaufferette.

• Examinez soigneusement la chaufferette, les tuyaux souples et les bonbonnes de

propane avant l’utilisation. Ne l’employez pas en cas de fuites ou de dommages.

Remplacez les tuyaux s’ils sont très usés ou fendus. N’employez que les pièces de

rechange Coleman ainsi que les ensembles tuyau souple et régulateur Coleman.

• GARDEZ LA CHAUFFERETTE HORS DE LAPORTÉE DES ENFANTS.

• La chaufferette restera chaude jusqu’à trente (30) minutes après son extinction.

• Pour l’utilisation, placez la chaufferette sur une surface plate et stable.

• Utilisez la tension et la fréquence précisées sur la décalcomanie du produit.

• Instructions de mise à la terre – cette chaufferette est équipée d’une fiche à trois

broches (dont une de mise à la terre), pour vous protéger des risques de chocs

électriques. Cette fiche doit être branchée directement sur une prise appropriée,

convenablement mise à la terre.

• N’employez qu’une rallonge pourvue d’une fiche tripolaire (à mise à la terre).

• Assurez-vous que la chaufferette soit convenablement branchée avant de l’allumer.

• Gardez la proximité de l’appareil exempte de matières combustibles, d’essence et

de vapeurs ou liquides inflammables.

• N’entravez ou n’obstruez en aucun cas le flux d’air de combustion et de ventilation.

• Les appareils à ventilateur (air pulsé) et à rayonnement ne doivent pas être orientés

vers des bonbonnes de gaz propane se trouvant à moins de 6 m (20 pi).

GÉNÉRALITÉS

DE

SÉCURITÉ

(suite)

Page 18

18

Identification du produit

Figure 1 – Modèle de 40 000 btu/h

Figure 2 – Modèle de 50 000 à 80 000 btu/h

Carter du

dessus

Raccord CL

Ensemble

tuyau souple

et régulateur

de propane

Bouton de la

soupape

automatique

Bouton de

commande

du brûleur

Branchement

d’admission

TABLE DES

MATIÈRES

SECTION PAGE

Généralités de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16, 17

Identification du produit . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Déballage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Théorie du fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . 19

Alimentation en propane . . . . . . . . . . . . . . . . . . . . . . . . . . . 19, 20

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Préparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20, 21

Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 à 23

Rangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23, 24

Dépistage des pannes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Calendrier d’entretien préventif . . . . . . . . . . . . . . . . . . . . . . 25

Méthodes de dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26, 27

Données techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Schéma de câblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pièces de rechange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Service des réparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

IDENTIFICA-

TION

DU

PRODUIT

Bouton de

l’allumeur piézo

Page 19

FRENCH

19

1. Retirez l’emballage qui protégeait l’appareil pendant l’expédition. Gardez les bouchons

de plastique (se trouvant au branchement d’admission et à l’ensemble tuyau souple et

régulateur), vous vous en servirez pour le rangement.

2. V idez complètement le carton d’emballage.

3. Assurez-vous qu’aucun des éléments n’ait subi d’avaries en cours d’expédition. Si la

chaufferette est abîmée, informez-en sans délai le marchand qui vous l’a vendue.

Approvisionnement en carburant : L’ensemble tuyau souple et régulateur se fixe à la

bonbonne de propane. Le gaz traverse la soupape thermoélectrique et sort par l’ajutage.

Alimentation en air: Le moteur fait tourner l’hélice. L’hélice propulse l’air dans et

autour de la chambre de combustion. Cet air est réchauffé et procure un écoulement continu d’air propre et chaud.

Système d’allumage: L’allumeur piézo à étincelle (du modèle 5070A) ou le module

électronique (du modèle 5075A) fait parvenir la tension à l’électrode. L’étincelle à l’électrode enflamme le mélange carburant et air.

Système de commande de sécurité: A pour fonction d’arrêter la chaufferette si

celle-ci surchauffe pour une raison quelconque – y compris s’il y a coupure de courant.

(L’hélice continue à fonctionner s’il n’y a pas perte de courant.)

DÉBALLAGE

THÉORIE DU

FONCTION-

NEMENT

Autres renseignements d’alimentation en propane à la page suivante

ALIMENTATION

EN PROPANE

Il incombe à l’utilisateur de procurer le gaz propane ainsi que la (les) bonbonne(s).

N’alimentez ce radiateur qu’avec les bonbonnes de propane standard. Consultez le chapitre

5 «Entreposage et manipulation des gaz de pétrole liquéfiés» de la norme ANSI/NFPA 58.

Cette norme peut être consultée à la bibliothèque ou au service d’incendie.

La quantité de gaz propane contenue dans les bonbonnes et donc utilisable varie. Deux facteurs déterminent cette quantité.

1. La quantité de gaz propane dans la (les) bonbonne(s).

2. La température de la (des) bonbonne(s).

Coupe transversale du fonctionnement (modèle 5070A illustré)

Ventilateur

Moteur

Entrée d’air froid (arrière)

Cordon d’alimentation

Ensemble tuyau

souple et régulateur

Électrode

Sortie d’air propre

et chaud

(avant)

Chambre de combustion

Air à chauffer

Air de combustion

Carburant

Allumeur

Page 20

20

voyez la page suivante

NOMBRE DE BONBONNES REQUISES

Température moy. où

se trouve la bonbonne 0

°C / 32 °F -7 °C /20 °F -12 °C / 10 °F -18 °C / 0 °F -23 °C /-10 °F

5070A751C (40 000 btu/h) 1 de 20 lb 1 de 40 lb 1 de 100 lb 2 de 100 lb 3 de 100 lb

5075A751C (80 000 but/h) 1 de 100 lb 2 de 100 lb 2 de 100 lb 3 de 100 lb 3 de 100 lb

Il se vaporise moins de gaz à basse température. Deux bonbonnes de 100 lb ou plus – ou

une bonbonne de plus grande capacité – peuvent être requises par temps plus froid. Votre

fourniseur de propane vous aidera à choisir le système d’alimentation approprié.

AVERTISSEMENT

Faites l’essai de détection des fuites après la préparation ou l’entretien. Ne

vous servez surtout jamais d’une flamme! Mettez une solution de savon

liquide et d’eau à tous les raccordements. La formation de bulles signale une

fuite. Éliminez toutes les fuites avant de mettre l’appareil en marche.

1. Établissez l’alimentation en propane requise. (Voyez «Alimentation en propane»).

2. Branchez le tuyau souple au raccord d’admission. Serrez fermement, en tournant en sens

horaire, à l’aide d’une clé de

9

/16 po.

ALIMENTATION

EN PROPANE

(suite)

VENTILATION

PRÉPARATION

AVERTISSEMENT

Pour le fonctionnement, prévoyez une prise d’air (air neuf provenant de l’extérieur) d’au moins 0,3 mètre carré (3 pi

2

). L’oxycarbonisme risque de survenir si la ventilation est inadéquate. Ouvrez la bouche d’air frais avant de

mettre la chaufferette de construction en marche.

Tuyau souple et raccord d’admission

Serrez à l’aide d’une clé

Le tableau ci-dessous montre le nombre minimal de bonbonnes de 20 lb nécessaires pour

faire fonctionner la chaufferette à la température indiquée au moins 10 heures. Ne vous

servez pas de bonbonnes plus petites, le rendement en serait réduit.

Page 21

FRENCH

21

tournez la page s.v.p.

3. Branchez le raccord CL de l’ensemble tuyau-régulateur à la (aux) bonbonne(s). Tournez

le raccord en sens antihoraire dans le filetage de la bonbonne. Serrez à fond.

IMPORTANT

: Serrez le régulateur en orientant le purgeur vers le sol. Orienter le purgeur

vers le sol protège le régulateur des dommages découlant des conditions atmosphériques.

PRÉPARATION

(suite)

Régulateur avec purgeur orienté vers le sol

4. Ouvrez le robinet de la (des) bonbonne(s) lentement.

Remarque

: Si vous ne l’ouvrez pas

lentement, le clapet limiteur de débit de la bonbonne arrêtera le débit de gaz. Si ceci arrive,

fermez le robinet de la bonbonne de propane puis rouvrez-le lentement.

5. Vérifiez qu’il n’y ait pas de fuites. Mettez une solution de savon liquide et eau aux raccordements. La formation de bulles signale une fuite. Éliminez-la avant la mise en marche.

6. Fermez le robinet d’alimentation en propane.

FONCTION-

NEMENT

AVERTISSEMENT

Lisez et assimilez les avertissements donnés sous «Généralités de

sécurité», ils sont essentiels au fonctionnement sans danger. Observez tous

les règlements ou codes municipaux lors de l’utilisation de la chaufferette.

Mise en marche de la chaufferette

1. Observez les instructions de préparation, ventilation et sécurité.

2. Posez l’appareil sur une surface plate et stable. Assurez-vous qu’il n’y ait pas de grand

refoulement d’air sur l’avant ou l’arrière de la chaufferette. N’employez pas celle-ci

dans les endroits où elle puisse être exposée à de la pulvérisation d’eau, à la pluie ou à

un dégouttement d’eau.

3. Ouvrez le robinet de la (des) bonbonne(s) lentement. Remarque:Si vous ouvrez le robinet

trop vite, le clapet limiteur de débit arrêtera le gaz. En ce cas, fermez le robinet puis rouvrezle lentement.

Page 22

4. Branchez le cordon de la chaufferette à une rallonge à 3 broches (à mise à la terre), d’au

moins 1,8 m (6 pi) de longueur. Le cordon de rallonge doit êtr e homologué ULC.

Exigences quant au cordon de rallonge

Jusqu’à 15 m (50 pi) de long, utilisez une rallonge numéro 18, calibre américain de fil.

De 15 à 30 m (51 à 100 pi), utilisez une rallonge numéro 16, calibre américain de fil.

De 30 à 61 m (101 à 200 pi), utilisez une rallonge numéro 14, calibre américain de fil.

5. Branchez la rallonge sur prise tripolaire (mise à la terre) de 120 volts, 60 hertz. Le moteur

démarrera et fera tourner l’hélice qui propulse l’air à travers la chaufferette.

6. Allumage:

Modèle 5070A

Enfoncez, sans le relâcher, le bouton de la soupape automatique. Appuyez sur l’allumeur

(rouge) jusqu’à 3 à 8 fois pour allumer la chaufferette. Remar que: Le tuyau peut être rempli

d’air. En ce cas, tenez le bouton de la soupape automatique enfoncé pendant 20 sec avant

d’appuyer de nouveau sur l’allumeur. Ne relâchez ce bouton que 30 sec après l’allumage.

Modèle 5075A

Enfoncez, sans le relâcher, le bouton de la soupape automatique. REMARQUE: Le tuyau

peut être rempli d’air. En ce cas, tenez le bouton de la soupape automatique enfoncé. Ne

relâchez ce bouton que 30 secondes après l’allumage de la chaufferette.

22

voyez la page suivante

FONCTION-

NEMENT

(suite)

Modèle 5070A751 illustré

7. Si la chaufferette s’éteint, répétez les directives du paragraphe 6.

8. Ajustez le bouton de commande selon la température désirée (modèle 5075A751

seulement).

Page 23

FRENCH

tournez la page s.v.p.

23

Arrêt de la chaufferette

1. Fermez le robinet de la (des) bonbonne(s) de propane à fond.

2. Attendez un instant (pour que le gaz qui reste dans le tuyau brûle).

3. Débranchez la chaufferette.

FONCTION-

NEMENT

(suite)

AVERTISSEMENT

Débranchez la chaufferette de la (des) bonbonne(s) avant de la ranger.

1. Rangez le propane comme il se doit. Consultez le chapitre 5 «Entreposage et manipulation

des gaz de pétrole liquéfiés» de la norme ANSI/NFPA 58. Observez tous les codes municipaux.

2. Placez les bouchons de plastique sur les garnitures de laiton, au branchement d’admission

et à l’ensemble du tuyau souple et régulateur de la chaufferette.

3. Rangez la chaufferette en lieu sûr, dans un endroit sec et propre.

RANGEMENT

AVERTISSEMENT

Ne tentez pas de réparer une chaufferette reliée à une bonbonne, fonctionnant ou chaude. Brûlures et chocs électriques graves pourraient en résulter.

1. Maintenez la chaufferette propre. Nettoyez-la tous les ans – ou au besoin – pour enlever

saleté et débris. Si elle est sale ou poussiéreuse, nettoyez-la avec un linge humide.

2. Examinez la chaufferette avant chaque utilisation. Vérifiez qu’il n’y ait pas de fuites en

mettant une solution de savon liquide et d’eau aux raccordements. La formation de

bulles signale une fuite. Éliminez toute fuite avant de mettre l’appareil en marche.

3. Examinez l’ensemble tuyau souple et régulateur avant chaque utilisation. Remplacez les

tuyaux très usés ou fendus. Assurez-vous que le joint torique ne soit pas endommagé.

Remplacez-le s’il est fendu ou craqué.

4. Demandez à un dépanneur compétent de vérifier le radiateur une fois par an.

5. Gardez l’intérieur de la chaufferette exempt de carburant et de corps étrangers.

ENTRETIEN

Page 24

24

voyez la page suivante

ENTRETIEN

(suite)

6. HÉLICE - Nettoyez-la toutes les 500 heures de fonctionnement ou au besoin.

A. Enlevez les vis du carter (côtés et dessus) avec un tournevis à pointe cruci-

forme (Phillips). Elles fixent le carter du dessus au carter du dessous.

B. Levez le carter du dessus.

C. Levez l’ensemble moteur et protecteur.

IMPORTANT: Veillez à ce que l’ensemble moteur et protecteur ne repose pas contre

l’hélice car ceci risquerait d’endommager les pales.

D. Nettoyez l’hélice avec un linge doux imbibé de kérosène ou de solvant.

Asséchez-la à fond. Nettoyez l’intérieur du carter au niveau de l’hélice.

E. Replacez l’ensemble moteur et protecteur ainsi que le carter du dessus.

7. ÉLECTRODE

A. Assurez-vous que l’écartement du fil électrode et de l’ajutage du brûleur soit

de 0,5 à 0,6 cm (0,20 à 0,25 po). L’accès à l’électrode se fait de l’intérieur de

la chambre de combustion. L’électrode ne requiert aucun autre entretien.

Page 25

FRENCH

25

tournez la page s.v.p.

DÉPISTAGE

DES

PANNES

AVERTISSEMENT

Ne tentez pas de réparer une chaufferette reliée à une bonbonne, fonctionnant ou chaude. Brûlures et chocs électriques graves pourraient en résulter.

INDICE

CAUSE POSSIBLE SOLUTION

L’hélice ne tourne pas Absence de courant électrique Vérifiez la tension à la prise. Si elle est

quand la chaufferette à la chaufferette bonne, assurez-vous que le cordon de

est branchée. la chaufferette ne soit pas coupé.

Pales de l’hélice faussées Remplacez l’hélice. Voyez la marche

à suivre à la page 27.

Moteur défectueux Remplacez le moteur. Voyez la

marche à suivre à la page 26.

La chaufferette L’utilisateur n’a pas convena- Répétez les instructions de

ne s’allume pas. blement suivi les directives de Préparation aux pages 20 et 21 et de

préparation et de fonctionnement Fonctionnement aux pages 21, 22 et 23.

Absence d’étincelle à l’électrode.

Pour faire la vérification, agissez tel

qu’indiqué au par. 23 de la page 27.

S’il se produit une étincelle, ayez

recours aux services d’un

dépanneur compétent.

Si vous ne voyez pas d’étincelle:

A) Fil de l’allumeur étant soit A) Vérifiez le fil de l’allumeur.

desserré soit déconnecté Serrez ou rattachez-le s’il y a lieu.

Voyez l’emplacement du fil de

l’allumeur à la page 19.

B) Écartement inexact B) Réglez l’écartement entre l’élec-

trode de l’allumeur et la plaque à

0,5 cm (0,20 po).

C) Allumeur piézo desserré C) Serrez l’allumeur piézo à la base

de la chaufferette.

D) Électrode défectueuse D) Remplacez l’électrode tel

qu’indiqué à la page 27.

E) Allumeur piézo défectueux E) Remplacez l’allumeur.

F) Module électronique défectueux F) Remplacez le module électronique.

La chaufferette Température ambiante élevée, Ceci peut arriver quand la chaufferette

s’arrête au cours ce qui active le dispositif de fonctionne bien qu’il fasse plus de

du fonctionnement. limite thermique qui fait arrêter 29,4 °C (85 °F). Ne vous servez de la

la chaufferette chaufferette que par temps plus frais.

Écoulement d’air restreint Vérifiez l’entrée et la sortie de la

chaufferette. Enlevez les obstructions.

Hélice endommagée Remplacez l’hélice tel qu’indiqué à

la page 27.

Proximité contenant une quantité Nettoyez la chaufferette. Voyez les

excessive de poussières ou de débris conseils d’entretien aux pages 23 et 24.

AVIS

Ne l’employez pas

dans les locaux à

haute teneur en

poussières.

PIÈCE QUAND COMMENT

Hélice Nettoyez-la toutes les 500 heures Voyez «Hélice», page 24

de fonctionnement ou au besoin.

Électrode Nettoyez-la et rectifiez l’écartement Voyez «Électrode», page 24

toutes les 500 heures de fonctionnement. Remplacez-la au besoin.

CALENDRIER

D’ENTRETIEN

PRÉVENTIF

Page 26

AVERTISSEMENT

Ne tentez pas de réparer une chaufferette reliée à une bonbonne, fonctionnant ou chaude. Brûlures et chocs électriques graves pourraient en résulter.

REMPLACEMENT DU MOTEUR

1. Enlevez le carter du dessus (voyez «HÉLICE» sous «Entretien»).

26

MÉTHODES DE

DÉPANNAGE

voyez la page suivante

2. Levez l’ensemble moteur et protecteur.

3. Avec une clé hexagonale (1/8 po), desserrez la vis d’arrêt ancrant l’hélice à l’arbre moteur.

4. Séparez l’hélice de l’arbre moteur (il vous faudra peut-être utiliser un dispositif comme

levier), en prenant soin de ne pas abîmer les pales.

5. Enlevez la vis du fil de terre et les deux conducteurs du moteur.

6. Retirez les deux écrous et les deux vis qui immobilisent le moteur au protecteur.

7. Mettez le moteur usé au rebut.

8. Fixez le moteur neuf au protecteur à l’aide des deux vis et écrous.

9. Remettez l’hélice sur l’arbre; 1 cm (0,4 po) d’arbre dépassera du moyeu de l’hélice.

10.Serrez fermement la vis d’arrêt (pression de 40-50 po-lb).

11.Attachez le fil de terre ainsi que les conducteurs au moteur neuf.

12.Réinstallez l’ensemble moteur et protecteur. Vérifiez que l’hélice tourne librement.

13.Replacez le carter du dessus.

Page 27

FRENCH

27

REMPLACEMENT DE L’HÉLICE

1. Enlevez l’ensemble moteur et protecteur (paragraphes de 1 à 4 de la page précédente).

2. Limez la marque ayant été laissée par la vis d’arrêt sur l’arbre moteur.

3. Remplacez l’hélice (paragraphes de 9 à 13 de la page précédente).

REMPLACEMENT DE L’ÉLECTRODE

1. Enlevez l’ensemble moteur et protecteur (voyez «HÉLICE» sous «Entretien»).

2. Retirez le fil de l’électrode.

3. Enlevez la vis immobilisant l’électrode au diffuseur.

4. Séparez l’électrode du diffuseur.

5. Placez une électrode neuve dans le diffuseur.

6. Posez la vis; vérifiez l’écartement de l’électrode, il doit être de 0,5 à 0,6 cm (0,20 à 0,25 po).

7. Poussez le fil de l’allumeur sur le fil de l’électrode.

8. Remettez l’ensemble moteur et protecteur ainsi que le carter du dessus en place.

9. Modèle 5070A : enfoncez l’allumeur et vérifiez qu’il se produise une étincelle entre le

déflecteur et l’électrode. Modèle 5075A : vérifiez qu’il se produise des étincelles

entre le déflecteur et l’électrode après le branchement électrique. Ne branchez pas

l’appareil à la bonbonne de propane.

tournez la page s.v.p.

MÉTHODES DE

DÉPANNAGE

(suite)

DONNÉES

TECHNIQUES

CHAUFFERETTE À AIR PULSÉ

DE 40 000 BTU/H - MODÈLE 5070A

Évaluation (btu/h) 40 000

Carburant vapeur de propane seul.

Consommation horaire de carburant

1,7 L (0,44 gal ÉU) / 0,8 kg (1,8 lb)

Pression de sortie, régulateur 70 kPa (10 psi)

Tuyau souple 3 m (10 pi)

Débit d’air chaud/min 4,2 m

3

(150 pi3)

Moteur 3 000 tr/min

Courant requis 115 volts, 60 Hz

Ampères 1,1

Allumage manuel/piézo

Poids 6,4 kg (14 lb)

Dimensions 35,6 x 21,6 x 41,9 cm

(haut. x larg. x long.) 14 x 8,5 x 16,5 po

Gamme de temp. -23 à 29,4 °C (-10 à 85 °F)

CHAUFFERETTE À AIR PULSÉ DE

50 000 À 80 000 BTU/H - MODÈLE 5075A

Évaluation (btu/h) 80 000 max.

Carburant vapeur de propane seul.

Consommation horaire de carburant

3,4 L (0,9 gal ÉU) / 1,7 kg (3,7 lb)

Pression de sortie, régulateur 70 kPa (10 psi)

Tuyau souple 3 m (10 pi)

Débit d’air chaud/min 8,5 m

3

(300 pi3)

Moteur 3 000 tr/min

Courant requis 115 volts, 60 Hz

Ampères 2,6

Allumage module électronique

Poids 7,7 kg (17 lb)

Dimensions 35,6 x 29,6 x 57,2 cm

(haut. x larg. x long.) 14 x 8,5 x 22,5 po

Gamme de temp. -23 à 29,4 °C (-10 à 85 °F)

Page 28

THERMAL

SAFETY

SWITCH

T.E.

VALV E

PIEZO

IGNITOR

MOTOR

BLACK

WHITE

GREEN

SCHÉMA DE

CÂBLAGE

28

AVERTISSEMENT

N’employez que des pièces de rechange authentiques, jamais de pièces de

rechange d’autres marques. Des pièces incorrectes pourraient causer des

blessures graves, voire mortelles.

PIÈCES DE

RECHANGE

NONODE PIÈCE DÉSIGNATION

1 5070-2851 Ensemble protecteur et

toron de raccordement

2 5070-2801 Moteur (modèle 5070A)

5075-2801 Moteur (modèle 5075A)

3 5070-2891 Hélice (modèle 5070A)

5075-2891 Hélice (modèle 5075A)

4 5070-3111 Ensemble d’allumage électronique (modèle 5070A)

5 5070-3271 Thermocouple et pince

5075-3271 Thermocouple, pince et bague

d’écartement

6 5070-2001 Poignée et vis

7 5070-2181 Bec de gaz (modèle 5070A)

5075-2181 Bec de gaz (modèle 5075A)

8 5080-5651 Tuyau souple et régulateur

9 5080-1491 Bouton et vis (modèle 5075A)

10 5410A1381 Joint torique

11 5075B3001 Ensemble du module

d’allumage électronique*

(modèle 5075A)

12 5070A2701 Thermostat

*

Pour appareils fabriqués après août 2002

THERMAL

SAFETY

SWITCH

T.E.

VALV E

MODÈLE 5070A

THERMORUPTEUR

DE SÉCURITÉ

THERMORUPTEUR

DE SÉCURITÉ

NOIR

ALLUMEUR

PIÉZO

MOTEUR

NOIR

ALLUMEUR

MOTEUR

BLANC

ÉLECTRODE

VERT

BLANC

SOUPAPE

T.E.

SOUPAPE

T.E.

115 VOLTS

60 HZ

MODÈLES 5075A

Page 29

SPANISH

CCAALLEEFFAACCTTOORR AA

GGAASS PPRROOPPAANNOO CCOONN

VVEENNTTIILLAACCIIÓÓNN FFOORRZZAADDAA

Modelos: Series 5070 y 5075

INSTRUCCIONES DE USO

IMPORTANTE

Lea cuidadosamente este manual antes de ensamblar, usar o dar servicio al

calefactor. Guarde este manual para referencia futura. Si tiene dudas acerca

del ensamblaje, funcionamiento, servicio o reparación de esta unidad, sírvase llamar a Coleman al 1-800-835-3278 o a la línea para personas con dificultad auditiva 316-832-8707. En Canadá llame al 1 800 387-6161.

Este producto ha sido diseñado y aprobado para ser usado

como un calefactor para interiores de acuerdo con las

normas ANSI y CGA. Esta unidad ha sido creada con el fin de

calentar temporalmente edificios desocupados en

construcción o que están siendo remodelados o reparados.

No está hecha para uso doméstico ni recreativo.

ANSI Z83.7-CSA 2.14 - (2000)

CALEFACTOR DE CONSTRUCCION

CERTIFIED

®

©2006 The Coleman Company, Inc.

®

Page 30

30

INFORMACIÓN

GENERAL

SOBRE SEGURI-

DAD

La Información General sobre Seguridad continúa en la página siguiente

El presente manual contiene información importante relacionada con el ensamblaje, funcionamiento y mantenimiento de este calefactor para construcciones. Estas primeras páginas incluyen información general sobre seguridad, las cuales se repiten en distintas secciones del manual. Debe prestarse especial atención a toda información acompañada por el

símbolo de alerta y seguridad “ ADVERTENCIA”.

Guarde este manual para referencia futura y para enseñar el uso de esta unidad a otras personas. Este manual debe leerse conjuntamente con las etiquetas fijadas al producto.

ADVERTENCIA GENERAL DE PELIGRO:

EL NO CUMPLIR CON LAS PRECAUCIONES E INSTRUCCIONES

PROVISTAS CON ESTE CALEFACTOR PUEDE RESULTAR EN MUERTE,

HERIDAS CORPORALES SERIAS Y PÉRDIDA DE LA PROPIEDAD O

DAÑOS PROVENIENTES POR RIESGOS DE FUEGO, EXPLOSIÓN,

QUEMADURA, ASFIXIA, ENVENENAMIENTO POR MONÓXIDO DE

CARBONO Y/O DESCARGA ELÉCTRICA. SÓLO LAS PERSONAS QUE

PUEDAN COMPRENDER Y SEGUIR LAS INSTRUCCIONES DEBERÁN

USAR O DARLE SERVICIO A ESTE CALEFACTOR. SI USTED NECESITA

ASISTENCIA O INFORMACIÓN DEL CALEFACTOR TALES COMO UN

MANUAL DE INSTRUCCIONES, ETIQUETAS, ETC., PÓNGASE EN

CONTACTO CON EL FABRICANTE.

ADVERTENCIA: PELIGRO DE FUEGO, QUEMADURAS, INHALACIÓN Y

EXPLOSIÓN. MANTENGA LOS COMBUSTIBLES SÓLIDOS, COMO LOS MATERIALES DE CONSTRUCCIÓN, PAPELES O CARTONES A UNA DISTANCIA PRUDENCIAL DEL CALEFACTOR SEGÚN SE RECOMIENDA EN LAS INSTRUCCIONES.

NUNCA USE EL CALEFACTOR EN LUGARES QUE CONTENGAN, O PUEDAN CONTENER, COMBUSTIBLES VOLÁTILES O EN SUSPENSIÓN, O PRODUCTOS COMO

LA GASOLINA, LOS SOLVENTES, EL DILUYENTE DE PINTURA, LAS PARTÍCULAS

DE POLVO, O LAS SUSTANCIAS QUÍMICAS DESCONOCIDAS.

ADVERTENCIA

UNIDAD NO ADAPTADA PARA USO DOMÉSTICO NI EN VEHÍCULOS RECREATIVOS.

Este producto está diseñado y aprobado para ser usado en interiores como un calefactor para la construcción de acuerdo con el estándar

ANSI Z83.7 - CSA2.14 - (2000).

No podemos prever todos los usos que se les puedan dar a nuestros calefactores. Verifique con su departamento de bomberos local si

tiene dudas con respecto al uso del calefactor .

Otras normas regulan el uso de gases combustibles y productos generadores de calor para usos específicos. Las autoridades locales pueden

aconsejarle acerca de las mismas.

Este calefactor para la construcción de uso en interiores no debe utilizarse en áreas directamente expuestas a salpicaduras con agua, lluvia

y/o goteo.

ENVENENAMIENTO CON MONÓXIDO DE CARBONO:

Este calefactor para la construcción funciona por combustión. T odos los aparatos de esta índole producen monóxido de carbono

(CO) durante su proceso de combustión. Este producto ha sido diseñado para producir cantidades extremadamente ínfimas y no peligrosas

de CO, siempre que se use y mantenga de acuerdo con todas las advertencias e instrucciones adjuntas. No bloquee el flujo del aire que

entra o sale del calefactor.

Los primeros síntomas de envenenamiento por monóxido de carbono son similares a los de la gripe, incluyendo dolores de

cabeza, mareos y/o náuseas. Si tiene estos síntomas mientras la unidad está funcionando, ¡salga a tomaraire fresco de inmediato!

Page 31

SPANISH

31

ASEGÚRESE DE CONTAR CON VENTILACIÓN ADECUADA. Debe haber una abertura

para que circule el aire de por lo menos tres (3) pies cuadrados (0.3 m

2

) o su equivalente, por

ej., 1' x 3' (0.3 m x 0.9 m) por cada unidad. ¡NO USE ESTE CALEFACTOR EN

DEPENDENCIAS HABITADAS O MIENTRAS DUERME! El estado de California incluye

el monóxido de carbono como una toxina reproductiva en la Proposición 65.

GAS PROPANO:

Este producto funciona con gas propano. Este gas es invisible, inodoro e inflamable.

Normalmente, se le agrega cierto olor para ayudar a detectar fugas, el cual puede describirse

como un olor a “huevo podrido”. Éste puede desvanecerse con el tiempo por lo que las fugas no

siempre pueden detectarse sólo por el olor.

El gas propano es más pesado que el aire y cuando hay fugas siempre se desplazan a los

niveles más bajos posibles. Varias fuentes de combustión pueden ocasionar que el gas se

inflame. Éstas pueden ser fósforos, encendedores, chispas o llamas abiertas de cualquier tipo

ubicadas a muchos pies de distancia de la fuga original. Use la unidad sólo con un sistema de

gas propano con eliminación de vapores.

El gas propano debe guardarse y usarse según lo especifican las ordenanzas y códigos

locales o la norma ANSI/NFPA 58. Apague el suministro de gas cuando no lo utilice.

FUEGO/EXPLOSIÓN:

Durante el funcionamiento, este producto representa una fuente de ignición. Mantenga el

área del calefactor libre de todo material combustible, gasolina, diluyente de pintura, solventes

de limpieza y otros vapores y líquidos inflamables. No use el calefactor en áreas con alto

contenido de polvo. LAS DISTANCIAS MÍNIMAS DEL CALEFACTOR ACUALQUIER

MATERIAL COMBUSTIBLE SON: DOS (2) PIES (0.6 M) ALOS LADOS Y DESDE

ATRÁS, CUATRO (4) PIES (1.2 M) DESDE LAPARTE SUPERIOR Y SEIS (6) PIES (1.8

M) DESDE LA SALIDA. Mantenga el calefactor a por lo menos seis (6) pies (1.8 m) de los

tanques de propano y mantenga las mangueras alejadas de la abertura de salida del calefactor.

INFORMACIÓN ADICIONAL SOBRE SEGURIDAD:

• Nunca altere o modifique el calefactor, el conjunto de regulador/manguera ni los

cilindros de gas propano. No conecte ningún tipo de tubería a este calefactor.

• Siempre inspeccione el calefactor, las mangueras y los cilindros de gas antes de usar

la unidad. No lo use si hay fuga de gas o está dañado. Reemplace las mangueras

que evidencian desgaste excesivo, abrasión o cortaduras. Use sólo los repuestos,

mangueras y reguladores Coleman.

• MANTENGA LAUNIDAD FUERADEL ALCANCE DE LOS NIÑOS.

• El calefactor se mantendrá caliente hasta treinta (30) minutos después de apagado.

• Opere el calefactor sólo sobre una superficie nivelada y estable.

• Use sólo el voltaje eléctrico y la frecuencia especificados en la calcomanía del producto.

• Instrucciones de puesta a tierra. Este calefactor está equipado con un enchufe de

tres espigas (con conexión a tierra) que lo protege a usted contra descargas eléctricas y debe conectarse directamente en el tomacorriente para tres espigas con conexión a tierra.

• Use sólo un cordón de extención de tres espigas con conexión a tierra.

• Asegúrese que el calèfactor esté conectado su calefactor sea inspeccionado anualmente por un centro de reparaciones autorizado.

• Mantenga el área del aparato clara y libre de materiales combustibles, gasolina y otros

vapores y líquidos inflamables.

• No bloquee u obstruya el flujo del aire de ventilación y combustión.

• Calefactores tipo ventilador (de aire forzado) y de tipo radiantes no deben ser dirigidos

hacia ningún contenedor de gas de propano dentro de 20 pies (6 m).

INFORMACIÓN

GENERAL

SOBRE

SEGURIDAD

Continuación

Page 32

32

Identificación del producto

Figura 1 - Modelo de 40,000 BTU/h.

Figura 2 - Modelo de 50,000 a 80,000 BTU/h.

Cubierta superior

Conjunto de

regulador/manguera

de gas propano

Acoplamiento POL

Botón de válvula

automática

Conexión de

entrada

CONTENIDO

SECCIÓN PÁGINA

Información general sobre seguridad . . . . . . . . . . . . . . . . . . 30, 31

Identificación del producto . . . . . . . . . . . . . . . . . . . . . . . . 32

Desembalaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Teoría de funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Suministro de gas propano . . . . . . . . . . . . . . . . . . . . . . . . . 33, 34

Ventilación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Preparación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34, 35

Operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 – 37

Almacenamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37, 38

Localización de averías . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Programa de mantenimiento preventivo. . . . . . . . . . . . . . . . 39

Procedimientos de servicio . . . . . . . . . . . . . . . . . . . . . . . 40, 41

Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Diagrama de conexiones. . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Repuestos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Servicio de reparación . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

IDENTIFICACIÓN

DEL PRODUCTO

Botón del

encendedor tipo

piezo

Page 33

SPANISH

33

1. Quite todos los artículos de empaque que recubren la unidad para su despacho. Guarde

los casquillos plásticos (colocados en la conexión de entrada y en el conjunto de regulador/manguera) para su futuro almacenamiento.

2. Saque todo de la caja.

3. Verifique que todo esté en perfectas condiciones. Si el calefactor está dañado, informe

de inmediato al distribuidor donde adquirió la unidad.

Sistema de combustible: El conjunto regulador/manguera se conecta al suministro de gas.

El gas propano pasa por la válvula termoeléctrica y sale por la boquilla.

Sistema de aire: El motor hace girar el ventilador. El ventilador empuja el aire hacia adentro y a la cámara de combustión. El aire se calienta y suministra un flujo limpio y caliente.

Sistema de encendido: El encendedor tipo piezo (Modelo 5070A) o el Módulo

Electrónico (Modelo 5075A) envía voltaje al electrodo. La chispa en el electrodo enciende

la mezcla combustible/aire.

Sistema de control de seguridad: Este sistema hace que el calefactor interrumpa su funcionamiento cuando alcanza temperaturas muy altas por cualquier motivo incluyendo la

falta de energía eléctrica. (El ventilador seguirá funcionando si hay energía eléctrica).

DESEMBALAJE

TEORÍA DE

FUNCIONAMIENTO

La sección de información sobre Suministro de Gas Propano continúa en la página siguiente

SUMINISTRO DE

GAS PROPANO

El usuario debe proveer el gas propano y el tanque(s).

Use este calefactor sólo con un sistema de suministro de gas propano con eliminación de

vapores. Consulte el Capítulo 5 de la Norma estándar para el almacenamiento y manipuleo

de gas de petróleo licuado (Standard for Storage and Handling of Liquefied Petroleum Gas)

ANSI/NFPA 58. Su biblioteca o departamento de bomberos local tiene esta publicación.

La cantidad de gas propano en los tanques varía. Dos factores determinan la misma:

1. La cantidad de gas propano en el tanque(s).

2. La temperatura del tanque(s).

Sección transversal - Diagrama de funcionamiento (Modelo 5070A ilustrado)

Ventilador

Motor

Entrada de aire frío (Atrás)

Cordón eléctrico

Conjunto de regulador/manguera

Electrodo

Salida del aire

limpio y caliente

(Adelante)

Cámara de combustión

Aire para la calefacción

Aire para la combustión

Combustible

Encendedor

Page 34

34

Continúa

NÚMERO DE TANQUES NECESARIOS

Temperatura promedio (en °F)

donde están los tanques 32° 20° 10° 0° -10°

(0°C) (-7°C) (-12°C) (-18°C) (-23°C)

5070A751 (40,000 BTU/h.) 1-20 lb. 1-40 lb. 1-100 lb. 2-100 lb. 3-100 lb.

5075A751 (80,000 BTU/h.) 1-100 lb. 2-100 lb. 2-100 lb. 3-100 lb. 3-100 lb.

El gas se evapora menos cuando las temperaturas son más bajas. Dos o más tanques de 100

libras, o uno más grande, pueden requerirse en climas más fríos. Su distribuidor de gas

propano local le ayudará a escoger el sistema de suministro adecuado.

ADVERTENCIA

Revise todas las tuberías y conexiones de gas por fugas después de

preparar la unidad o darle servicio. Nunca use llama para verificar fugas.

Aplique una mezcla de jabón líquido y agua a todas las uniones. La formación de burbujas indica que hay una fuga. Repare todas las fugas antes de

usar la unidad.

1. Determine el tipo de suministro de gas propano necesario. (Consulte la sección

Suministro de Gas Propano).

2. Fije la manguera a la conexión de entrada. Ajústela firmemente en sentido horario con

una llave de 9/16".

SUMINISTRO DE

GAS PROPANO

CONTINUACIÓN

VENTILACIÓN

PREPARACIÓN

ADVERTENCIA

Debe haber una abertura, de por lo menos 3 pies cuadrados (0.3 m2), para

que circule el aire mientras la unidad está funcionando. Si no hay ventilación

exterior suficiente, puede ocasionarse envenenamiento por inhalación de

monóxido de carbono. Asegúrese de contar con ventilación exterior adecuada antes de poner en funcionamiento la unidad.

Manguera y conexión de entrada

Ajuste con llave

El cuadro a continuación muestra el mínimo número de tanques de 20 libras, o más

grandes, necesarios para hacer funcionar a estos calefactores a la temperatura indicada

durante 10 horas como mínimo. No los haga funcionar con tanques de menos libras que

las indicadas ya que obtendrá menor rendimiento.

Page 35

SPANISH

35

Continúa

3. Conecte el acoplamiento POL del conjunto regulador/manguera al tanque(s) de gas

propano. Enrosque el acoplamiento POL en sentido antihorario en el tanque. Ajuste

firmemente. IMPORTANTE: Ajuste el regulador con el orificio de ventilación hacia

abajo. Esto evita que los agentes climáticos puedan dañarlo.

PREPARACIÓN

CONTINUACIÓN

Regulador con orificio de ventilación hacia abajo

4. Abra lentamente la válvula del tanque(s) de gas propano. Nota: Si no la abre lentamente,

la válvula de sentido de flujo excesivo del tanque detendrá el flujo de gas. Si esto

ocurre, cierre la válvula de gas y vuelva a abrirla lentamente.

5. Revise todas las conexiones por fugas. Aplique una mezcla de jabón líquido y agua a

todas las uniones. La formación de burbujas indica que hay una fuga que debe ser

reparada antes de usar la unidad.

6. Cierre la válvula de suministro de gas propano.

OPERACIÓN

ADVERTENCIA

Revise y entienda las advertencias de la sección Información General sobre

Seguridad. Esto es necesario para operar el calefactor en forma segura. Siga

todas las ordenanzas o códigos locales cuando use este calefactor.

Para encender el calefactor

1. Siga todas las indicaciones de preparación, ventilación y seguridad.

2. Coloque el calefactor sobre una superficie estable y nivelada. Asegúrese de que la

unidad no esté expuesta a fuertes ráfagas de viento ni la use en áreas directamente

expuestas a salpicaduras de agua, lluvia y/o goteo.

3. Lentamente abra la válvula del tanque(s) de gas propano. Nota: Si no se la abre lenta-

mente, la válvula de sentido de flujo excesivo del tanque detendrá el flujo de gas. Si

esto ocurre, cierre la válvula de gas y vuelva a abrirla lentamente.

Page 36

4. Enchufe el cordón eléctrico del calefactor al cordón de extención de tres espigas con

conexión a tierra. El cordón de extención debe medir seis pies de largo como mínimo.

El cordón de extención debe estar aprobado por UL.

Requisitos de tamaño del cordón de extención

Hasta 50 pies (15 m) de largo, use un cordón de 18 AWG.

De 51 a 100 pies (30 m) de largo, use un cordón de 16 AWG.

De 101 a 200 pies (61 m) de largo, use un cordón de 14 AWG.

5. Enchufe el cordón de extención en un tomacorriente de 120 voltios/60 hertz de tres espigas

con conexión a tierra. El motor arrancará, haciendo girar el ventilador y forzando a que el

aire atraviese el calefactor.

6. Para encender:

Modelo 5070A

Oprima y mantenga presionado el botón de la válvula automática. Oprima el botón ignitor

(rojo). Puede que tenga que oprimir el botón de 3 a 8 veces para que el calefactor se encienda. Nota: La manguera puede estar llena de aire. De ser así, mantenga el botón de la válvula presionado y deje que transcurran 20 segundos antes de volver a presionar el encendedor.

Cuando se encienda el calefactor, mantenga presionado el botón de la válvula. Suelte el

botón al cabo de 30 segundos.

36

Continúa

OPERACIÓN

CONTINUACIÓN

Modelo 5070A751 ilustrado

Modelo 5075A

Oprima y mantenga presionado el botón de la válvula automática. NOTA: La manguera

puede estar llena de aire. De ser así, mantenga el botón de la válvula presionado. Cuando

se encienda el calefactor, mantenga presionado el botón de la válvula automática. Suelte el

botón al cabo de 30 segundos.

7. Si el calefactor se apaga, repita el paso 6.

8. Ajuste la válvula del quemador al nivel de calor deseado.

(Modelo 5075A751 solamente)

Page 37

SPANISH

Continúa

37

Para apagar el calefactor

1. Cierre completamente la válvula del tanque(s).

2. Deje que transcurran unos cuantos segundos. El calefactor quemará el gas que haya

quedado en la manguera.

3. Desconecte el calefactor.

OPERACIÓN

CONTINUACIÓN

ADVERTENCIA

Desconecte el calefactor del tanque(s) de gas propano antes de guardarlo.

1. Guarde el tanque(s) de manera segura. Consulte el Capítulo 5 de la Norma estándar para

el almacenamiento y manipuleo de gas de petróleo licuado (Standard for Storage and

Handling of Liquefied Petroleum Gas)ANSI/NFPA58. Siga todas las indicaciones de los

códigos locales.

2. Coloque los casquillos de plástico sobre los acoplamientos de bronce en la conexión de

entrada y en el conjunto regulador/manguera del calefactor.

3. Guarde el calefactor en un lugar seco, limpio y seguro.

ALMACENAMIENTO

ADVERTENCIA

Nunca intente dar servicio al calefactor mientras esté conectado al suministro de gas propano, funcionando o caliente. Pueden ocasionarse quemaduras graves y descargas eléctricas.

1. Mantenga limpio el calefactor. Limpie el calefactor una vez por año, o según sea necesario, para quitarle el polvo y la suciedad. Si el calefactor está sucio o tiene polvo,

límpielo con un paño húmedo.

2. Inspeccione el calefactor antes de cada uso. Revise las conexiones por evidencia de

fugas. Aplique una mezcla de jabón líquido y agua a las conexiones. La formación de

burbujas indica que hay una fuga. Repare todas las fugas antes de usar la unidad.

3. Inspeccione el conjunto regulador/manguera antes de cada uso. Reemplace las

mangueras que evidencien desgaste excesivo, abrasión o cortaduras. Inspeccione el aro

“O” por daños. Reemplácelo si está cortado o fisurado.

4. Haga que un técnico especializado inspeccione anualmente el calefactor.

5. Mantenga el interior del calefactor sin combustible ni objetos extraños.

MANTENIMIENTO

Page 38

38

Continúa

MANTENIMIENTO

CONTINUACIÓN

6. VENTILADOR - Límpielo cada 500 horas de operación, o según sea necesario.

A. Quite los tornillos colocados a cada lado del calefactor y en la parte superior del pro-

tector de motor usando un destornillador Phillips. Estos tornillos sirven para unir la

cubierta superior con la inferior.

B. Levante y desprenda la cubierta superior.

C. Levante y saque el conjunto motor/protector.

IMPORTANTE: No apoye el conjunto motor/protector sobre el ventilador ya que pueden

dañarse las aspas del mismo.

D. Limpie el ventilador con un paño suave, embebido en kerosene o solvente. Seque

el ventilador completamente. Limpie la parte interior de la cubierta en el sitio

adyacente a donde gira el ventilador.

E. Vuelva a colocar el conjunto motor/protector y la cubierta superior.

7. ELECTRODO

A. Asegúrese de que la separación entre el cable del electrodo y la boquilla del que-

mador sea de 0.20 (0.5 cm) a 0.25" (0.6 cm). Logre acceso al electrodo desde la parte

interior de la cámara de combustión. El electrodo no requiere ningún otro tipo de

mantenimiento.

Page 39

SPANISH

39

Continúa

LOCALIZACIÓN

DE AVERÍAS

ADVERTENCIA

Nunca intente dar servicio al calefactor mientras esté conectado al suministro de gas propano, funcionando o caliente. Pueden ocasionarse quemaduras graves y descargas eléctricas.

SÍNT

OMA CAUSA PROBABLE SOLUCIÓN

El ventilador No llega energía eléctrica Verifique el voltaje del tomacorriente

no gira cuando al calefactor. eléctrico. Si el voltaje es el correcto,

el calefactor verifique que el cordón eléctrico

está conectado. del calefactor no esté cortado.

Aspas del ventilador dobladas. Reemplace el ventilador. Consulte

la sección Cómo reemplazar el

ventilador en la página 41.

Motor defectuoso. Reemplace el motor. Consulte la

sección Cómo reemplazar el motor

en la página 40.

El calefactor El usuario no siguió adecuadamente Repita las instrucciones de las

no se enciende. las instrucciones de preparación u secciones preparación y operación.

operación. Consulte la sección Preparación en las

páginas 34 y 35 y la sección Operación

en las páginas 35, 36 y 37.

No hay chispa en el electrodo. Para

probar la chispa siga el paso 9, bajo

el título Cómo reemplazar el electrodo,