Page 1

Manual text copy out of a scanned original Version.

Visit my site www.behringer24.de

A

LWAYS USE THE RIGHT KIND OF FUEL

Substances in gasoline which do not vaporize

will form gums in the generator of your lantern.

The length of service you get from your lantern

and generator depends greatly upon the kind of

fuel you use.

Use only Coleman Stove and Lantern Fuel, or

clean white white gasoline. Never use fuel containing lead compounds or lubricating oils. Store

your fuel in a clean, closed metal container.

(Glass containers are dangerous - may break.)

If Coleman Stove an Lantern Fuel or "white"

gasoline is not readily available, most oil companies will gladly tell you where to obtail it.

T

O FILL TANK

Close fuel valve tightly to the right. Remove

Filler Cap and fill lantern with 1 3/5 pints of

fresh, clean fuel. Never use fuel containing lead

compounds or lubricating oils. Lantern should sit

level all during filling. Fuel for the lantern may

be strained through several thicknesses of finely

woven cloth or, more convenient, a No. 0

Coleman Filtering Funnel. After filling, replace

Filler cap and tighten firmly with fingers.

Never remove filler cap while lantern is lighted,

nor near open flame or excessive heat.

T

O PUMP

Fuel valve and Filler Cap must be closed firmly.

Turn Pump plunger two turns to the left. Place

thumb over small hole in end of Pump Plunger

and pump 35 to 40 full strokes of air into

lantern. Good pressure is important. Now turn

Pump Plunger clear to right until tight and push

it clear down. Oil Pump Leather occasionally to

keep it soft and pliable.

T

O TIE ON COLEMAN MANTLES

Remove Ball Nut at very top of lantern. Lift off

the ventilator and take out the Pyrex Glass

Globe.

Tie mantle around groove in burner cap (see

drawing). Flat side of mantle should face generator. Distibute folds of mantle evenly at top and

cut off suplus string. Burn mantle according to

instructions on mantle envelope.

A

LWAYS USE GENUINE COLEMAN MANTLES

These are the perfect functional counterpart of

the Generator, Air intake, and Mixing Chamber

of Coleman Lanterns. Saturated with top-quality,

light-producing chemicals, they are significantly

designed in shape, size, and weave to glow with

maximum brilliance in type of illumination

approximating natural day-light. Reinforced bottoms and absence of side seams give them

longer life. Moisture-proofed and denitrated

against deterioration. To make shure you get

coleman uniform quality, look for the Coleman

name stamped on genuine Coleman mantles.

Let cool after burning it off before lighting

lantern. Good air pressure in the lantern will

help to shape it and 30 minutes burning on first

lighting will help its strength.

Written 2005 by A. Behringer - www.behringer24.de

Owner's Manual - Coleman 200A

Page 2

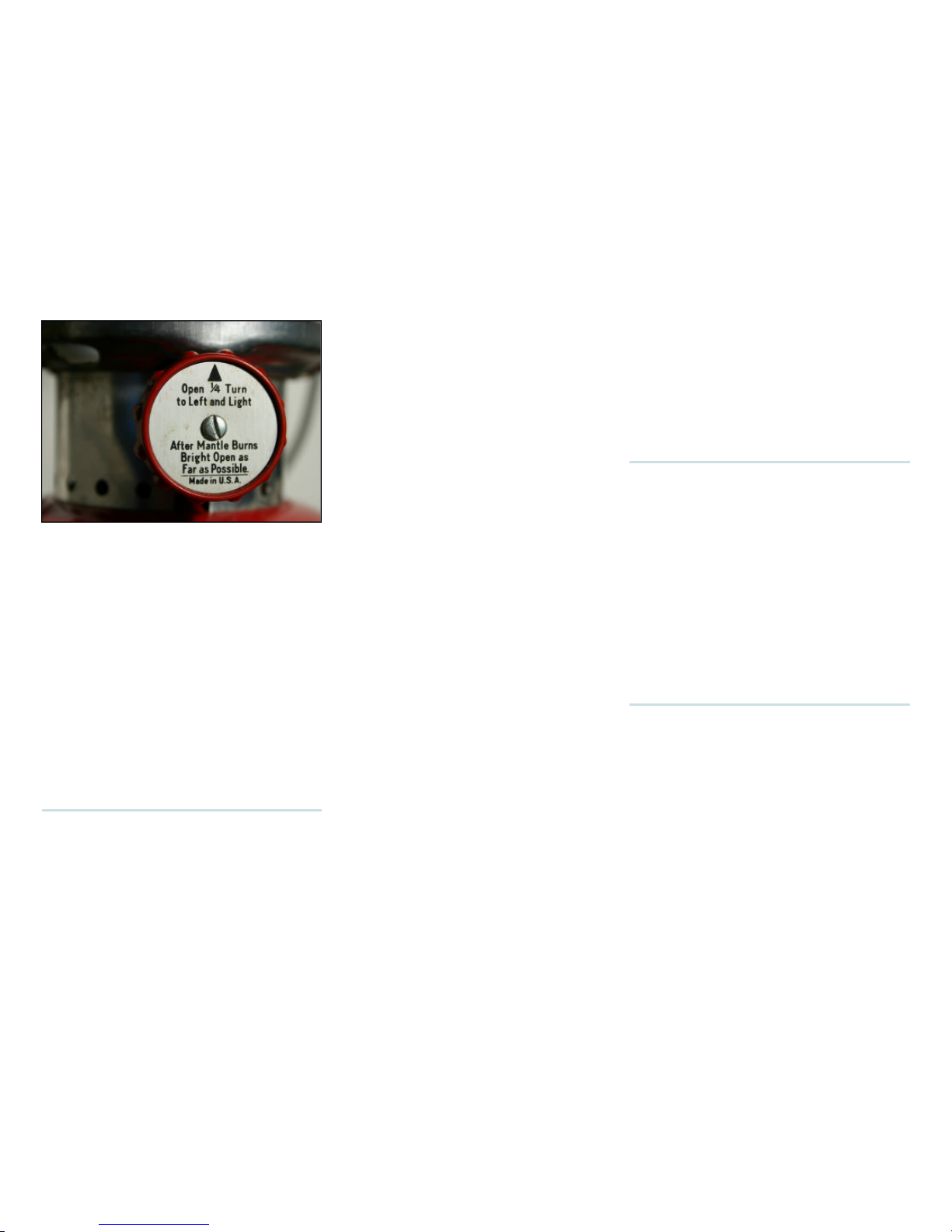

T

O LIGHT

Rotate the cleaning needle lever at base of

frame. Several turns will clean the Generator

Tip. Leave lever pointing down.

Open Fuel valve one fourth turn. Push lighted

match through lighter hole and hold it und mantle. Matle will light instantly when air and gas

mixture reaches them. When Mantle burns

brightly, open Fuel valve all the way to the left.

If lantern dows not burn brightly with Fueal

Valve wide open, rotate Cleaning Needle Lever

several times. Lantern may flicker a bit but

should quickly steady down. Air pressure may

be added to the tank at any time to give

brighter light.

T

O TURN OFF

Close Fuel Valve firmly. Light will dim and go

out in a few seconds.

G

ENERAL SUGGESTIONS

If lantern blazes and smokes more than a few

seconds when first lit, then close valve and

repopen one fourth turn as soon as light dims.

If lantern does not light, check air pressure

and fuel content. Remove Generator and

unscrew Gas Tip to make sure point of needle

has not been bent or curled. Open valve slightly

to make sure gasoline will come through valve.

If mantle burns black, make sure screens in

Burner Caps are clean and open. Check Air

Intake Tube for possible obstruction, such as

spider's nest.

If light dims, check Fuel valve to be certain it

is wide open. Rotate cleaning lever to remove

carbon, if any.

If light pulsates after installation of a new

Generator, pump in additional air pressure until

light is steady.

If lantern is on emergency standby in case

of storm or power failure, empty all gasoline

from Fount occasionally, refill with clean, fresh

fuel. Store in a cool a place as possible.

The gasket in filler cap may deteriorate with

age. It might be well to install a new No. 2206361 Gasket and Disc Assembly occasionally.

If you have occasion to write the dealer or

the factory, mention that your Lantern is a

Model 200A Lantern. If you mail the Lantern,

send it less Globe and ventilator to avoid breakage.

G

ENERATOR

The generator is the heart of your Coleman

lantern. Here liquid fuel is changed into the gas

that burns in the mantles. Factory-tested

Coleman generators - precision-built from bestgrade materials - are made to fit and function

perfectly with other parts.

T

O INSTALL

Be sure Fuel Valve is closed. Turn Cleaning

Needle lever up. Unscrew Jamb Nut at lower

end of Generator. Lift Generator and unhook

Gas Tip Cleaning Needle.

To install new Generator: Pull Cleaning Needle

down about one inch. Slide jamb Nut down over

Generator. Place Cleaning Needle between forfinger and thumb with Generator in upright

position. Push gas tip end of generator into Air

Intake Tube and hook Needle through hole in

Eccentric Block. Tighten Jamb Nut only enough

to prevent leakage.

G

LOBE

The Genuine Pyrex Globe on your Coleman

Lantern is made of the best quality heat-resisting glass obtainable. It is glass of superior

transparency and light-refracting qualities.

However, even pyrex Globes can be broken.

When this happens, you can purchase a new

one from your coleman dealer.

Written 2005 by A. Behringer - www.behringer24.de

Loading...

Loading...