Cold Jet SDI Select 60 Original Instructions Manual

OM.SS60.20141016

OPERATOR MANUAL

Original Instructions

September 2018

OPERATOR MANUAL

SDI Select

™

60

OM.SS60.20141016

Copyright © 2018 Cold Jet, LLC

All rights reserved. Printed in the USA.

Due to continued product development this information may change without notice. The information and intellectual

property contained herein is confidential between Cold Jet and the client and remains the exclusive property of Cold Jet. If

you find any problems in the documentation, please report them to us in writing. Cold Jet does not warrant that this

document is error-free.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording or otherwise without the prior written permission of Cold Jet.

This manual reflects the product configuration as was current at the time of initial prototypes. An item’s display in this

catalog does not guarantee the item’s availability at any time in the future. Images shown are for representation purposes

only. Products may vary from the images displayed. Cold Jet is not liable for typographical errors or changes to

specifications presented.

OM.SS60.20141016

OM.SS60.20141016

OM.SS60.20141016

CONTENTS

CONTENTS 1

SAFETY GUIDELINES 1

General Safety Requirements 1

Electrostatic Discharge 2

CO2 Safety 2

COMPONENT GUIDE 3

Specifications 3

Unit Operation 9

Maintenance 15

Troubleshooting 16

SDI Select 60 Blasts Air But Not Dry Ice 18

CONTACTING COLD JET 19

APPENDIX A: BLAST AIR QUALITY 21

Plant Air (Central Compressed Air System) 21

Using Portable Air (85 - 500 hp / 64 - 373 kw) 22

APPENDIX B: TRANSFORMER CONFIGURATION 23

High Voltage Connection: 23

Normal / Medium Voltage Connection: 24

SYMBOL GLOSSARY 25

Yellow Warning Triangle/Black Graphical Symbols 26

Blue Mandatory Action Circle/White Graphical Symbols 27

Red Circle-With-Slash/Black Graphical Symbols 28

Other Symbols 28

WARRANTY 29

SCHEMATICS 31

INDEX 33

OM.SS60.20141016

SECTION 1

SAFETY GUIDELINES

The SDI Select™ 60 is safe and easy to operate; however, certain precautions must be followed

during its use. To understand all the necessary precautions, you must read the entire SDI Select 60

manual before operating the unit.

The SDI Select 60 should only be operated by authorized and trained personnel.

IN THIS SECTION

General Safety Requirements. . . . . . . 1

Electrostatic Discharge. . . . . . . . . . . 2

CO

Safety. . . . . . . . . . . . . . . . . . . . . 2

2

GENERAL SAFETY REQUIREMENTS

• Always wear personal protective equipment including safety glasses, gloves, and 32+NRR ear

plugs and ear muffs.

• Always operate the SDI Select 60 with protective clothing to cover all exposed skin.

• Always direct the blast stream in a safe direction. Never direct the blast stream at yourself or others.

• Never use a wire tie to hold the applicator trigger in the ON position. Doing so violates safety

regulations, can damage the applicator and voids warranty coverage of the applicator.

• Always turn source air OFF and bleed down the system before disconnecting the air supply hose.

• Always turn source air OFF and remove the applicator control line before removing the blast hose.

• Always follow all of the governing codes of your local/national body.

• Always ensure the finger guard over the feeder exhaust port is installed. The finger guard on the

feeder protects from a potential personal injury site located inside the SDI Select 60.

• Always ensure all panels are installed before operating.

• Only operate the SDI Select 60 at or below the recommended hose or blasting unit pressure levels.

• Always ensure the blast hose is free of kinks.

• Always ensure that both ends of all hoses are properly attached and tightened before

pressurizing any hoses.

• Always electrostatic ground the material being cleaned.

• Always ensure hoses and tubes are free of nicks and gouges.

• Always repair any damage to the SDI Select 60 before attempting to start or operate the unit.

• Always ensure the ventilation holes are free of obstruction.

• Always wear gloves to protect hands from exposure to cryogenic temperatures and sharp blade

surfaces.

1

SDI SELECT 60 USER MANUAL

OM.SS60.20141016

ELECTROSTATIC DISCHARGE

Static discharge may ignite flammables.

Electrostatic discharge can be hazardous to the operator and the equipment. The static charge of

varies with the amount of dry ice and humidity present.

CO

2

GROUND THE MATERIAL BEING CLEANED

Always ground the material being cleaned to assure safe operation while blasting.

1. Know your environment.

• Electrostatic buildup changes as humidity levels change and will vary by location.

Electrostatic discharge is higher at low humidity levels and occurs most often during

winter.

2. Attach static bond cable.

• To minimize electrostatic buildup between the part being cleaned and the

applicator, attach the static bond cable between the target surface and the blast hose

connection or to an electrically conductive supporting structure. Use a conductivity

tester for confirmation.

3. Plug into a grounded power outlet.

• This step is critical for electrostatic dissipation. If the ground is not connected, a

charge may build up on the unit or the applicator.

CO2 SAFETY

• The SDI Select 60 uses solid state carbon dioxide (CO2). CO2 is nontoxic, non-corrosive and

nonconductive. It is approved by the FDA and USDA.

• Solid CO

CO

• Vapor CO

the SDI Select 60 with a proper ventilation system that maintains the concentration levels of

the governing codes of your local/national body.

• Always review and observe all safety guidelines when using materials that displace oxygen.

• All operators and supervisors should familiarize themselves with the literature on the

physiological characteristics of CO

obtained from the governing codes of your local/national body.

• Always use a CO

is extremely cold (-109 °F/-78 °C). Always protect skin from direct contact with

2

pellets, nuggets or slices. Direct contact with skin or eyes quickly causes tissue damage.

2

can displace the oxygen from any breathing environment rapidly. Only operate

2

before using the SDI Select 60. The information can be

2

monitoring device when using the SDI Select 60 in a confined space.

2

2

OM.SS60.20141016

Weight (empty)

334 lbs (161 kg) / 365 lbs (166 kg) with optional pressure

regulator

Dimensions

28 x 24 x 43 in (72 x 61 x 110 cm)

Dry Ice Capacity

60 lbs (27.2 kg) – Dry Ice Block

50 lbs (22.6 kg) – Dry Ice Pellets

Trough/Hopper is 12 x 10 x 12 in (300 x 250 x 300 mm)

Variable Feed Rate

0 - 6 lbs/min (0 - 2.7 kg/min)

Power Requirements

100 - 140 VAC 1 . 50/60 Hz 8 A

200 - 240 VAC 1 . 50/60 Hz 4 A

Feeder Drive

1 HP, 3 Phase AC Variable Speed Motor

Blast Pressure Range

20 - 250 PSI ( 1.4 – 17.2 bar) with optional pressure regulator

Supply Pressure Range

65 - 250 PSI (4.5 - 17.2 bar)

SECTION 2

COMPONENT GUIDE

The SDI Select 60 is designed with you in mind. Its unrivaled innovation and unmatched

performance, based on years of customer input, saves you real time and real money. The SDI Select

60 is simply the most powerful and efficient dry ice blast cleaning system ever made. It is blazingly

fast, remarkably economical, and environmentally friendly.

IN THIS SECTION

Specifications. . . . . . . . . . . . . . . 3

Unit Operation. . . . . . . . . . . 9

Maintenance. . . . . . . . . . . 15

Troubleshooting. . . . 16

SPECIFICATIONS

REQUIRED COMPRESSED AIRFLOW VOLUME DEPENDS ON THE NOZZLE BEING

USED.

MOST COLD JET NOZZLES NEED 50 - 180 CFM (1.4 - 5.1 M3/MIN) AT 80 PSI (5.5

BAR) BLAST PRESSURE.

3

SDI SELECT 60 USER MANUAL

OM.SS60.20141016

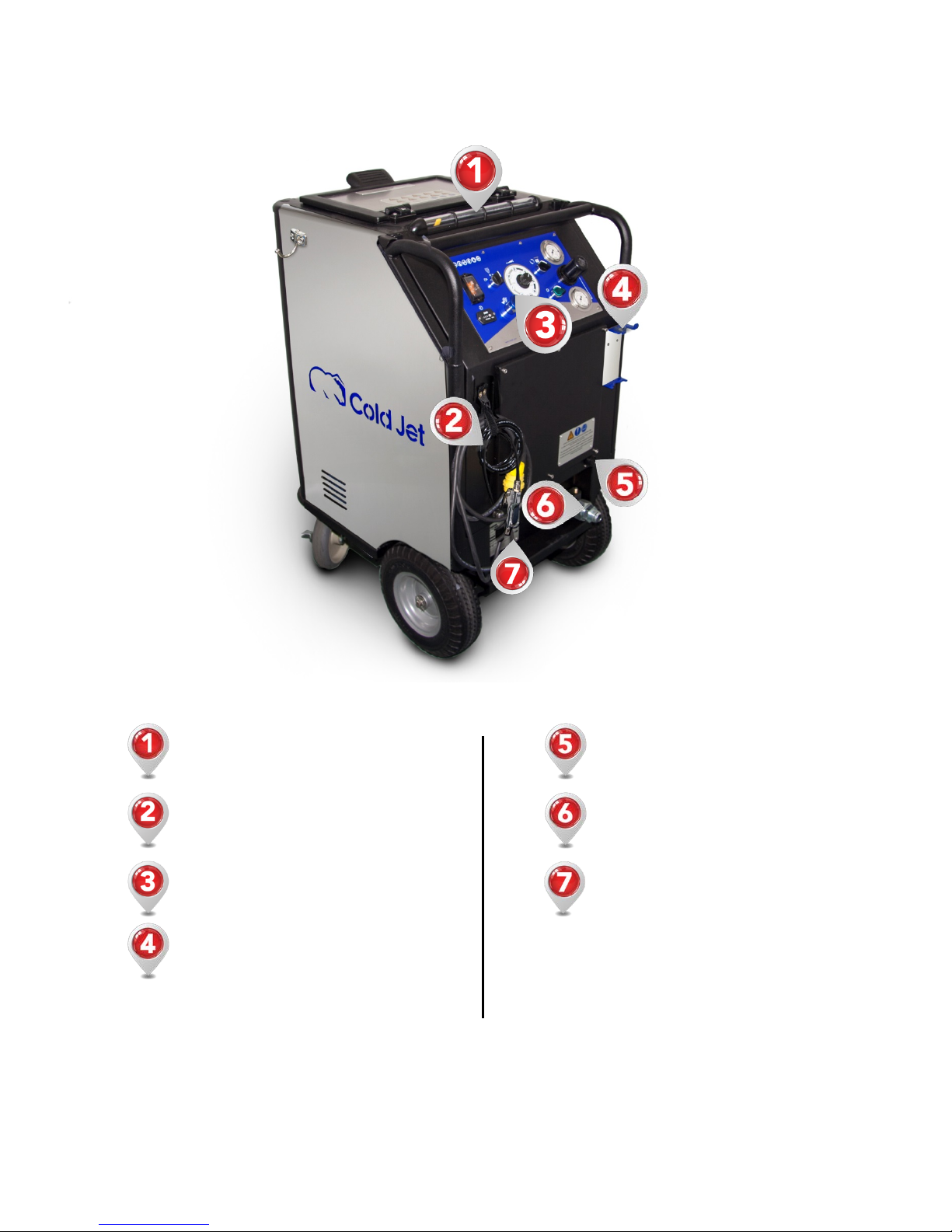

FRONT VIEW

dry ice pellet / nugget loading lid

dry ice block loading door

air supply

whip check cable

bleed valve

brakes

4

COMPONENT GUIDE

OM.SS60.20141016

REAR VIEW

dry ice level indicator

blast cable connector

power cord

blast hose connector

control panel (see p.6)

compressed air nozzle

nozzle hanger

5

SDI SELECT 60 USER MANUAL

OM.SS60.20141016

power switch

CONTROL PANEL

hour meter

agitation control switch

disable blast button

dry ice feed rate control

6

pusher plate retract switch

regulator bypass switch

(optional)

incoming air pressure

blast pressure control

(optional)

regulated air pressure

(optional)

COMPONENT GUIDE

OM.SS60.20141016

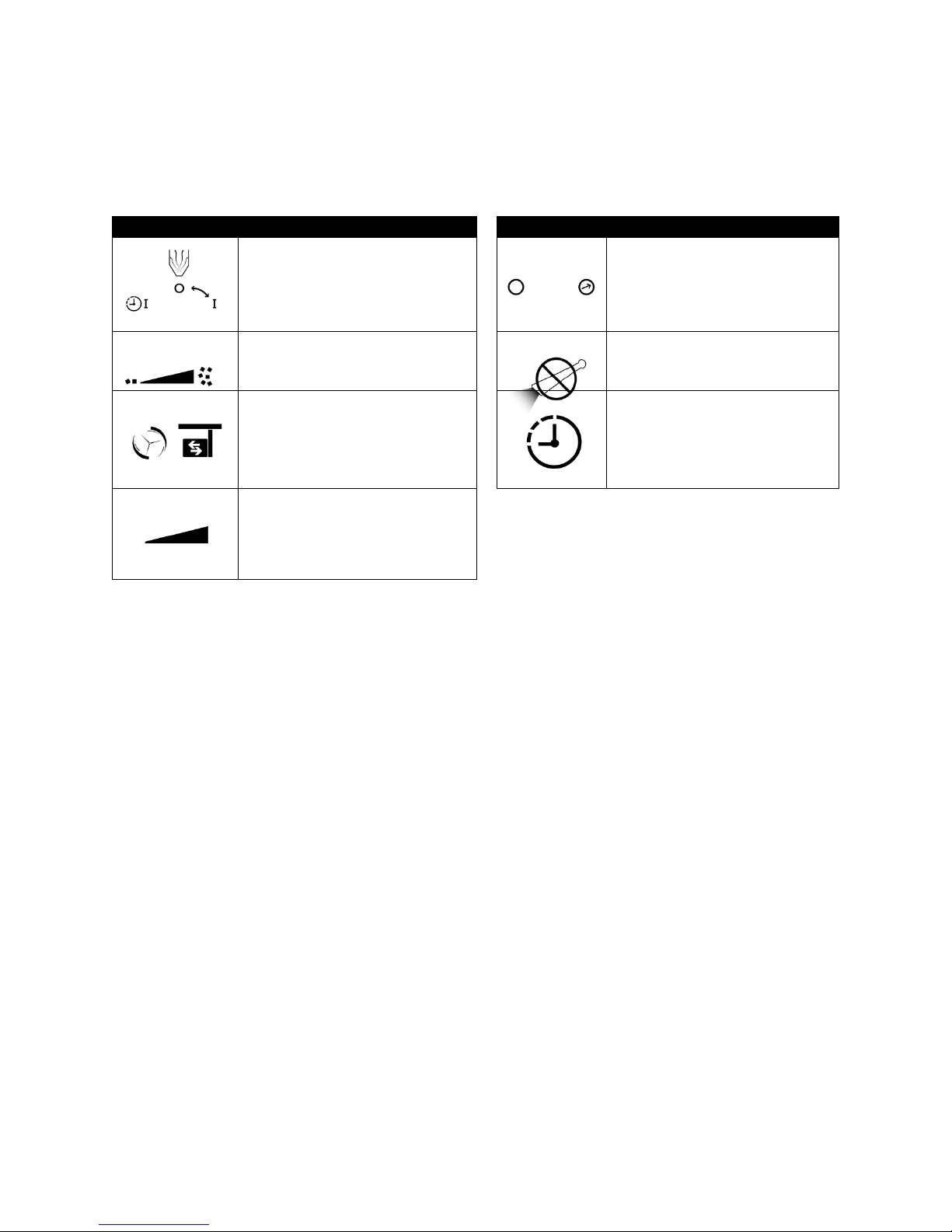

Symbol

Meaning

Symbol

Meaning

agitation control –

intermittent/off/on

variable dry ice feed rate

pusher plate retract

regulated air pressure

regulator bypass –

bypass/regulated

disable blast

hour meter

7

Loading...

Loading...