Cold Jet RDS 500 Cub Parts & Maintenance Manual

MODEL

Parts &

Maintenance

Manual

1-800

-3DRY-ICE

CJI# 2W0238A

1

Serial No.: ___________________

Voltage: 100-120 Volts AC

Model No.: RDS 500 Cub

Control No.: 2A0145

Diagram: 6G0116

Voltage: 200-230 Volts AC

Model No.: RDS 500 Cub

Control No.: 2A0145

Diagram: 6G0117

This manual illustrates the safety, operation, and maintenance features of the RDS 500 Cub.

The design contain ed in th is m anual was or iginated by, and is the exc lusive pr operty of Cold Jet, I nc. It is not to be used

in any way detrimental to the interests of Cold Jet, Inc.

No part of this design or manua l ma y be reproduced, transm itted, stored in a retr ieval s ystem , or translated into an y other

language or computer language, in whole or i n part, in any form or by any means, whether it be el ectronic, mechanical ,

magnetic, optical, manual or otherwise, without the express written consent of Cold Jet, Inc.

1-800

-3DRY-ICE

Copyright 2000 by

Cold Jet, Inc.

All Rights Reserved

Printed in U.S.A

2

Special Notes

All information contained within this manual, or information derived from exposure to the technology

or equipment supplied by Cold Jet, Inc. remains "CONFIDENTIAL" between Cold Jet, Inc. and the

purchaser or authorized user. Any unauthorized transfer of information to any person or company not

in the direct employ of Cold Jet Incorporated, or not in the direct employ of, or for, the purchaser, or

the authorized user, is strictly prohibited by agreement.

Warranty Compliance

All procedures, specifications, main tenance and configurations of any and all Cold Jet systems and

their supporting equipment, as well as the installation thereof, must have the express written

knowledge and approval of Cold Jet, Inc. or warranties can become invalidated. Furthermore the use

of Cold Jet systems in any unsafe, unspecified, or in any unauthorized manner can immediately

invalidate any and all warranties.

For Your Information

If you have questions about our product lines, applications for our equipment, the environmental

impact of our equipment or would like more technical information please visit our web site at

www.coldjet.com.

1-800

-3DRY-ICE

3

1-800

-3DRY-ICE

4

Table of Contents

Special Notes ....................................................................................................................................3

Warranty Compliance ........................................................................................................................3

For Your Information ..........................................................................................................................3

1. Troubleshooting ____________________________________________________________ 7

2. Maintenance _______________________________________________________________ 9

Preventive Maintenance .........................................................................................................9

On a Daily Basis ..........................................................................................................9

On a Weekly Basis .......................................................................................................10

On a Monthly Basis ......................................................................................................11

Every Three Months ..................................................................................................... 12

500 Hour Scheduled Maintenance ..........................................................................................13

Tuning Fork Replacement ......................................................................................................14

Appendix A: Performance ______________________________________________________ 17

Appendix B: Specifications _____________________________________________________ 19

Appendix C: Electrical Schematics _______________________________________________ 21

120 Volt ..................................................................................................................................21

230 Volt ..................................................................................................................................22

Appendix D: Assemblies _______________________________________________________ 23

1-800

-3DRY-ICE

5

1-800

-3DRY-ICE

6

Section 5

Section 5 Troubleshooting

Section 5 Section 5

Problem Check This

Machine will not start.

Troubleshooting

Troubleshooting Troubleshooting

1. Is the unit plugged in ?

2. Is the power Switch in the ON position?

3. Reset E-stop.

4. Is the FEEDER RESET ready? If not, press to

reset.

5. Is the 24V Power fuse blown (the indicator will be

red)?

1. Is the air supply CONNECTED and the air supply

on?

2. Is the air supply gauge showing pressure?

3. Is the OPTIONAL pressure regulator open?

Machine will NOT blast.

Machine blasts AIR but NOT

4. Is applicator cable CONNECTED to Cub and the

applicator?

5. Is the BLAST pressure gauge showing pressure

when the trigger is pulled?

6. The NOZZLE may be clogged, blast with air only

to unclog the nozzle.

1. Set feeder speed.

2. Check Vibrator.

pellets.

3. Unclog NOZZLE.

If these recommendations DO NOT solve your problem, contact our Technical Service hotline:

1-800-777-9101.

1-800

-3DRY-ICE

7

1-800

-3DRY-ICE

8

Section 6

Section 6 Maintenance

Section 6 Section 6

Maintenance

Maintenance Maintenance

Preventive Maintenance

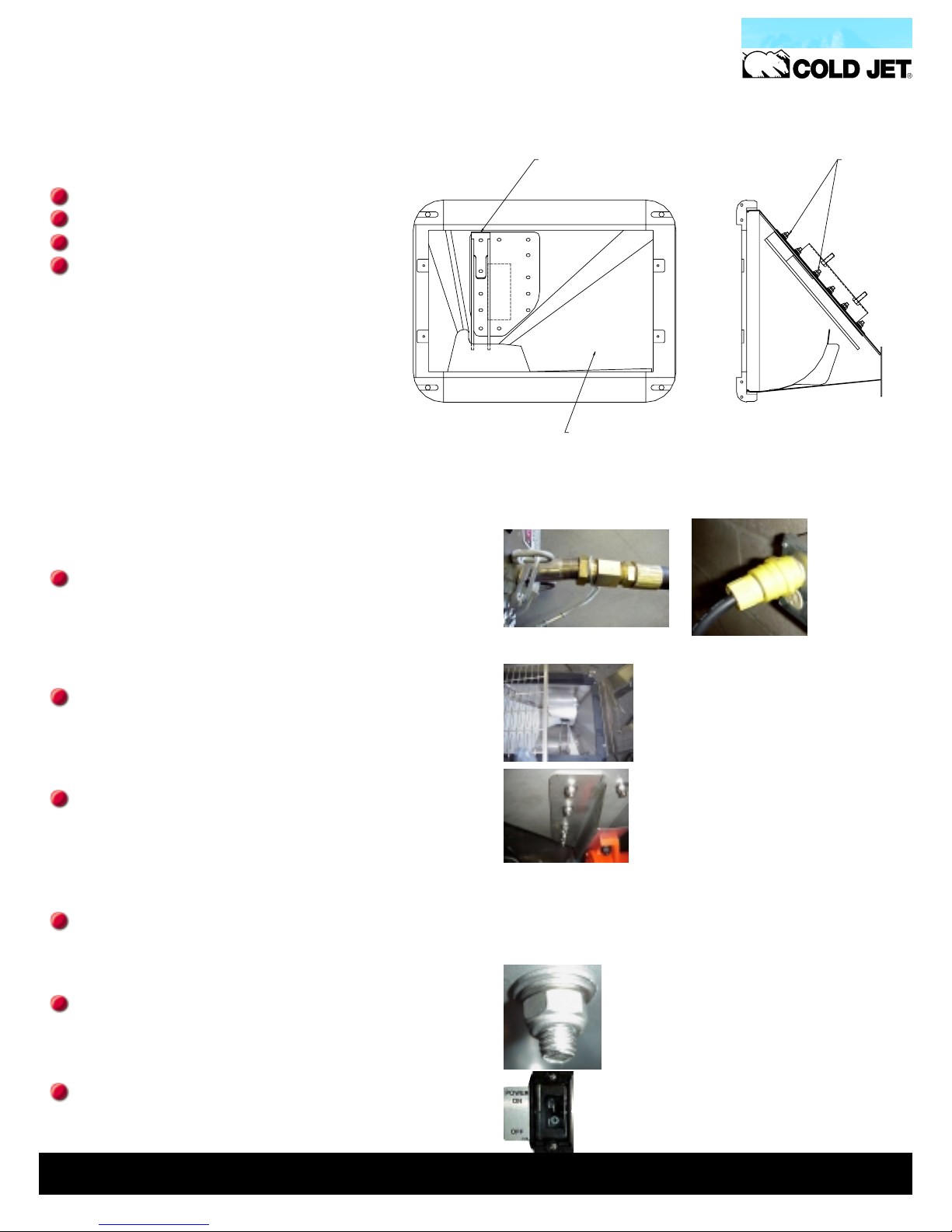

On a Daily Basis

1. Drain water out of the coalescing filter before using

the machine. (turn pet-cock fully open to drain the

water)

2. While in operation check all gauges.

3. Make sure the feeder reset light is on.

Figure 1

Figure 2

4. Make sure the caster wheels will lock.

5. Check the air and blast hoses for damage, like cuts

or scuff marks.

6. Make sure the applicator’s blast cable is NOT

wound around the blast hose .

Figure 6

Figure 3

Figure 4

1-800

-3DRY-ICE

Figure 5

9

On a Weekly Basis

1. Look through the hopper to check the rotor

for nicks or gouges.

(Use a flashlight).

2. Make sure the Cub’s screws are tight.

1-800

-3DRY-ICE

10

On a Monthly Basis

1. Make sure the nozzle airflow exit end is not

deformed or burred.

2. Tighten all screws on Applicator Rotary

Union.

1-800

-3DRY-ICE

11

Every Three Months

Every Three Months

Every Three MonthsEvery Three Months

1. Make sure the vibrator motor bolts are at a

torque setting of 40 ft-lbs.

1-800

-3DRY-ICE

12

500 Hour Scheduled Maintenance

If you are not an authorized Cold Jet service technician,

please call to schedule this service.

1. Check pads and rotor

2. Check upper and lower tension springs

3. Check voltage and amperage on DC drive

4. Check specs on AC controller

5. Check brushes in the vibrator motor

6. Check condition of power cord

7. Check all light bulbs

8. Check all gauges

9. Check static ground reel

10.Inspect hoses for damage

11.Replace consumable parts

Check the tuning fork

Check the filter element

12.Check the accessories

13.Safety test the unit

14.Check all valves

1-800

-3DRY-ICE

13

Tuning Fork Replacement

The tuning fork is easy to replace, and should take only 15-20 minutes to complete

INSTALL NEW VIBRATING

Tools required:

Large Phillips screwdriver

3/32” Hex key

13 mm socket wrench

Anti-seize compound or graphite lubricant

PELLET AGITATOR 3J0504

REMOVE HOPPER SCREEN

REPLACE AFTER NEW AGITATOR

IS INSTALLED

USE THREAD LUBRICANT

TIGHTEN TO 15 FT/LBS

Remove t h e old tuning fork

Remove compressed air supply and electric

power from the machine.

Remove the safety screen from the top of the

hopper (do not let anything fall into the

feeder).

Open the side door of the machine and remove

the old tuning fork by unscrewing the two 8 mm

ny-lock nuts that hold it in .

Install the new tuning fork

Use a small quantity of anti-seize compound or

graphite lubricant on the studs to prevent galling

during assembly.

Torque the nuts to approximately 11.5 ft-lb. Be

sure to install washers in the order they were removed.

Attach the power cable and press the power

button (DO NOT ATTACH THE COMPRESSED

AIR HOSE)!

1-800

-3DRY-ICE

14

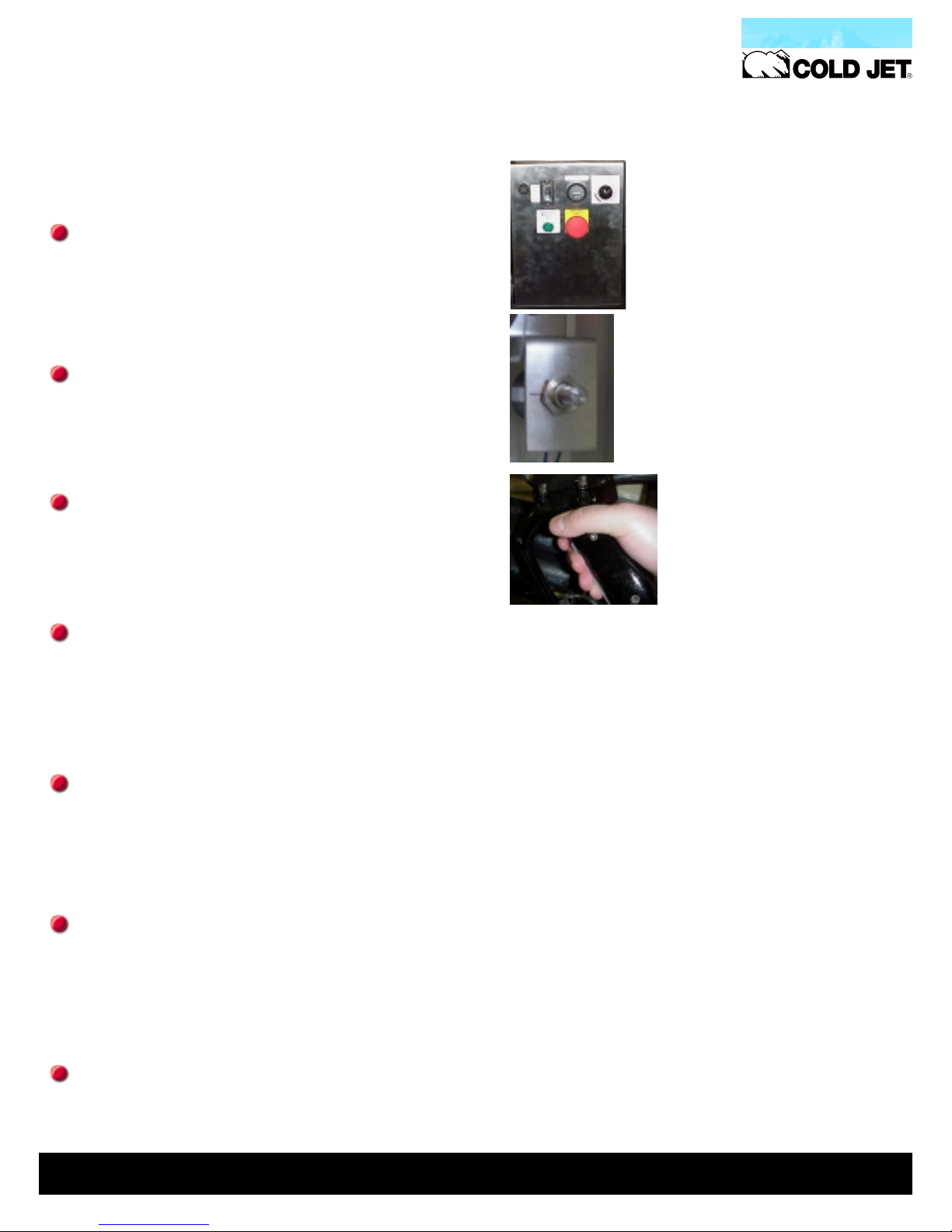

Fine tuning the tuning fork

Open the Controls enclosure on the front of the

Cub

Loosen the potentiometer shaft from the silicone

seal.

Pull the blast gun trigger; this will cause the vibrator motor to jump to HIGH for around 1 to 2

seconds, followed by a drop to LOW.

Once the machine is vibrating on LOW, adjust

the potentiometer shaft clockwise or counter

clockwise until the tips of the tuning fork vibrate

between ¼” and ½”.

It may be necessary to bend one of the tuning

fork tines to avoid chatter on the hopper shield.

This will be obvious because of excessive noise.

Once the vibrator motor is tuned, shut off the

blast trigger, and re-seal the potentiometer shaft

with silicone.

Disconnect the power to the machine and reinstall the safety screen.

1-800

-3DRY-ICE

15

1-800

-3DRY-ICE

16

7.0

6.5

6.0

5.5

5.0

4.5

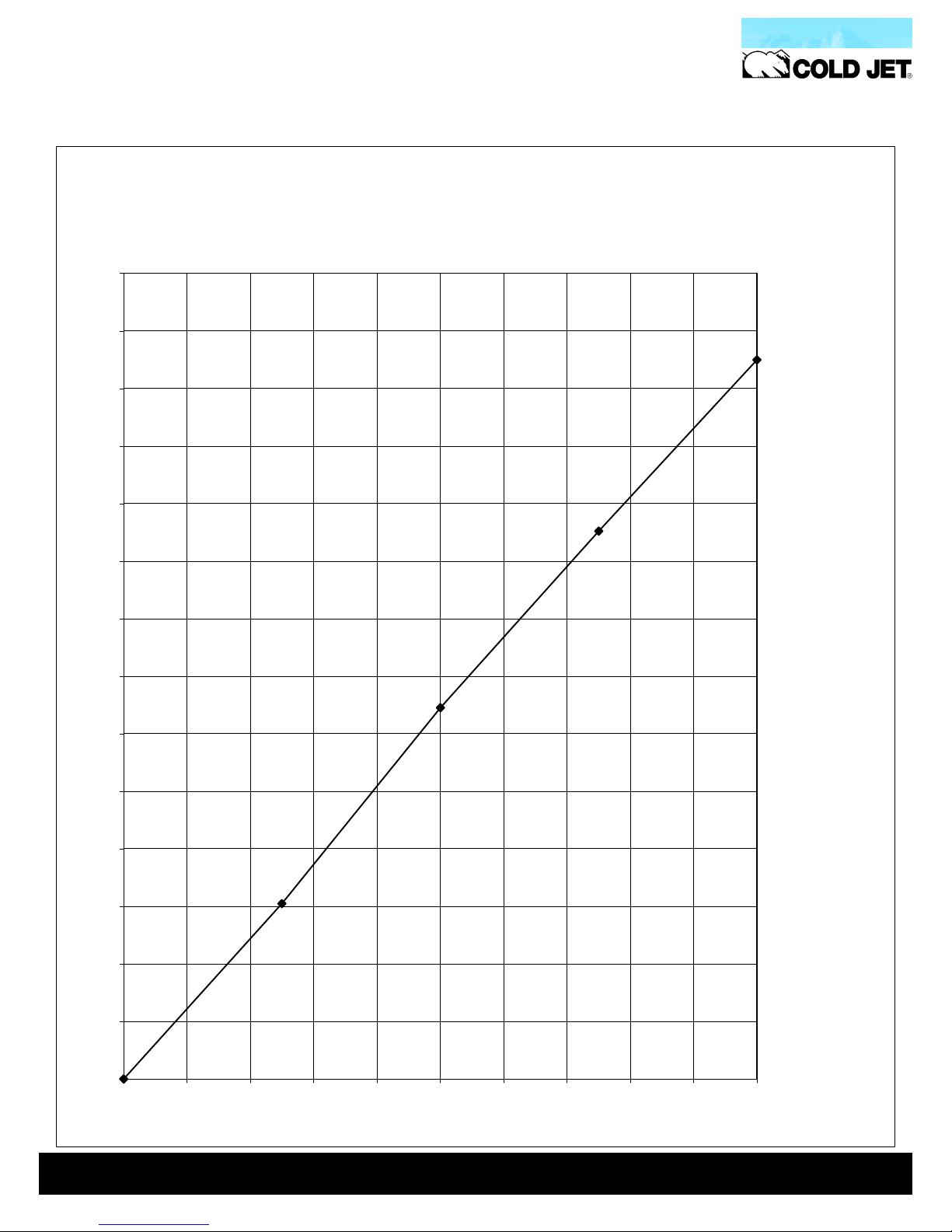

Appendix A

Appendix A Performance

Appendix A Appendix A

PELLET FEED RATES

STANDARD AND OPTIONAL ROTORS

Performance

Performance Performance

Standard-Feed

4.0

3.5

3.0

2.5

Pellet Feed (pounds-per-minute)

2.0

1.5

1.0

0.5

0.0

0 102030405060708090100

1-800

-3DRY-ICE

Feed Rate Setting(%)

17

Loading...

Loading...