COILTRONICS SD10-R47, SD10-1R0, SD10-1R5, SD10-2R2, SD10-3R3 Service Manual

...

Description

• Six sizes of shielded drum core inductors with low

profiles (as low as 1.0mm) and high power density

• Inductance range from .47uH to 1000uH

• Current range from 6.00 to 0.088 Amps

• Ferrite shielded, low EMI

Applications

• Digital cameras, CD players, cellular phones, and PDAs

• PCMCIA cards

• GPS systems

Environmental Data

• Storage temperature range:-40C to +125C

• Operating ambient temperature range:-40C to +85C

(range is application specific).Temperature rise is

approximately 40C at rated rms current

• Infrared reflow temperature:+240C for 30 seconds

maximum

Packaging

• Supplied in tape and reel packaging, 3800 (SD10, SD12

and SD18), 2900 (SD20 and SD25), and 3500 (SD52)

per reel

®

SD Series

High Power Density,

Low Profile, Shielded Inductors

(1) Open Circuit Inductance Test Parameters: 100KHz, 0.25Vrms, 0.0Adc.

(2) RMS current for an approximate ∆T of 40°C without core loss.It is

recommended that the temperature of the part not exceed 125°C.

(3) Peak current for approximate 30% roll off at 20°C.

(4) DCR limits @ 20°C.

5) Applied Volt-Time product (V-uS) across the inductor at 100kHz necessary to

generate a core loss equal to 10% of the total losses for 40°C temperature rise.

Part Number Rated OCL (1) Part Irms (2) Isat (3) DCR (4) Volt

Inductance +/-20% Marking Amperes Amperes (Ω)u-sec

(µH) (µH) Typ. T yp.

SD10-R47 0.470 0.453 A 2.59 3.54 0.0249 2.1

SD10-1R0 1.00 1.119 B 1.93 2.25 0.0448 3.3

SD10-1R5 1.50 1.563 C 1.60 1.91 0.0653 3.9

SD10-2R2 2.20 2.081 D 1.35 1.65 0.0912 4.5

SD10-3R3 3.30 3.339 E 1.24 1.31 0.1078 5.7

SD10-4R7 4.70 4.893 F 1.04 1.08 0.1535 6.9

SD10-6R2 6.20 6.743 G 0.94 0.92 0.1870 8.1

SD10-8R2 8.20 8.889 H 0.800 0.800 0.2607 9.3

SD10-100 10.0 10.07 J 0.760 0.752 0.2888 9.9

SD10-150 15.0 15.55 K 0.613 0.605 0.4429 12.3

SD10-220 22.0 22.21 L 0.498 0.506 0.6718 14.7

SD10-330 33.0 32.20 M 0.412 0.420 0.9807 17.7

SD10-470 47.0 46.63 N 0.337 0.349 1.47 21.3

SD10-680 68.0 70.01 O 0.301 0.285 1.84 26.1

SD10-820 82.0 83.48 P 0.258 0.261 2.50 28.5

SD10-101 100 102.0 Q 0.225 0.236 3.29 31.5

SD10-151 150 149.2 R 0.200 0.195 4.15 38.1

SD10-221 220 222.2 S 0.161 0.160 6.41 46.5

SD10-331 330 330.4 T 0.130 0.131 9.83 56.7

SD10-471 470 468.3 U 0.117 0.110 12.10 67.5

SD12-R47 0.470 0.490 A 3.19 3.86 0.0246 2.84

SD12-1R2 1.20 1.21 B 2.62 2.45 0.0366 4.47

SD12-1R5 1.50 1.69 C 2.19 2.08 0.0521 5.28

SD12-2R2 2.20 2.25 D 1.83 1.80 0.0747 6.09

SD12-3R3 3.30 3.61 E 1.55 1.42 0.1043 7.71

SD12-4R7 4.70 4.41 F 1.46 1.29 0.1177 8.53

SD12-6R2 6.20 6.25 G 1.21 1.08 0.1699 10.15

SD12-8R2 8.20 8.41 H 1.02 0.931 0.2399 11.77

SD12-100 10.0 10.89 J 0.938 0.818 0.2844 13.40

SD12-150 15.0 15.21 K 0.782 0.692 0.4089 15.83

SD12-220 22.0 22.09 L 0.628 0.574 0.6338 19.08

SD12-330 33.0 32.49 M 0.519 0.474 0.9289 23.14

SD12-470 47.0 47.61 N 0.428 0.391 1.37 28.01

SD12-680 68.0 68.89 O 0.341 0.325 2.16 33.70

SD12-820 82.0 82.81 P 0.326 0.297 2.36 36.95

SD12-101 100 98.0 Q 0.308 0.273 2.64 40.19

SD12-151 150 151.3 R 0.251 0.220 3.96 49.94

查询SD10-100供应商

(1) Open Circuit Inductance Test Parameters: 100KHz, 0.25Vrms, 0.0Adc.

(2) RMS current for an approximate ∆T of 40°C without core loss.It is

recommended that the temperature of the part not exceed 125°C.

(3) Peak current for approximate 30% roll off at 20°C.

(4) DCR limits @ 20°C.

5) Applied Volt-Time product (V-uS) across the inductor at 100kHz necessary to

generate a core loss equal to 10% of the total losses for 40°C temperature rise.

Part Number Rated OCL (1) Part Irms (2) Isat (3) DCR (4) Volt

Inductance +/-20% Marking Amperes Amperes (Ω)u-sec

(µH) (µH) Typ. T yp.

SD12-221 220 222.0 S 0.229 0.181 4.76 60.49

SD12-331 330 334.9 T 0.186 0.148 7.25 74.30

SD12-471 470 462.3 U 0.167 0.126 8.95 87.29

SD12-681 680 670.8 V 0.149 0.104 11.30 105

SD12-821 820 800.9 W 0.129 0.095 14.93 115

SD12-102 1000 992.3 X 0.121 0.086 17.20 128

SD18-R47 0.47 0.49 A 3.58 4.63 0.0201 2.35

SD18-R82 0.82 0.81 B 3.24 3.60 0.0247 3.02

SD18-1R2 1.20 1.21 C 2.97 2.95 0.0294 3.70

SD18-1R5 1.50 1.69 D 2.73 2.49 0.0345 4.37

SD18-2R2 2.20 2.25 E 2.55 2.16 0.0398 5.04

SD18-3R3 3.30 3.61 F 2.07 1.71 0.0605 6.38

SD18-4R7 4.70 4.41 G 1.77 1.54 0.0824 7.06

SD18-6R2 6.20 6.25 H 1.61 1.30 0.1000 8.40

SD18-8R2 8.20 8.41 J 1.38 1.12 0.1351 9.74

SD18-100 10.0 10.89 K 1.28 0.982 0.1584 11.09

SD18-150 15.0 15.21 L 1.06 0.831 0.2278 13.10

SD18-220 22.0 22.09 M 0.876 0.689 0.3366 15.79

SD18-330 33.0 32.49 N 0.715 0.568 0.5057 19.15

SD18-470 47.0 47.61 O 0.578 0.470 0.7732 23.18

SD18-680 68.0 68.89 P 0.514 0.390 0.9798 27.89

SD18-820 82.0 82.81 Q 0.446 0.356 1.30 30.58

SD18-101 100 102.01 R 0.419 0.321 1.47 33.94

SD18-151 150 151.29 S 0.345 0.263 2.18 41.33

SD18-221 220 222.01 T 0.296 0.217 2.95 50.06

SD18-331 330 334.89 U 0.248 0.177 4.20 61.49

SD18-471 470 479.61 V 0.201 0.148 6.39 73.58

SD18-681 680 681.21 W 0.167 0.124 9.28 87.70

SD18-821 820 823.69 X 0.145 0.113 12.35 96.43

SD18-102 1000 1004 Y 0.136 0.102 14.01 107

SD20-R47 0.47 0.490 A 3.59 4.00 0.0200 2.28

SD20-1R2 1.20 1.21 B 3.07 2.55 0.0275 3.58

SD20-1R5 1.50 1.69 C 2.88 2.15 0.0312 4.23

SD20-2R2 2.20 2.25 D 2.45 1.87 0.0429 4.88

SD20-3R3 3.30 3.61 E 2.17 1.47 0.0547 6.18

SD20-4R7 4.70 4.41 F 2.05 1.33 0.0612 6.83

SD20-6R2 6.20 6.25 G 1.89 1.12 0.0720 8.13

SD20-8R2 8.20 8.41 H 1.61 0.966 0.1000 9.43

SD20-100 10.0 9.61 J 1.53 0.903 0.1100 10.08

SD20-150 15.0 15.21 K 1.25 0.718 0.1655 12.68

SD20-220 22.0 22.09 L 1.12 0.596 0.2053 15.28

SD20-330 33.0 32.49 M 0.913 0.491 0.3100 18.53

SD20-470 47.0 47.61 N 0.745 0.406 0.4650 22.43

SD20-680 68.0 68.89 O 0.610 0.337 0.6947 26.98

SD20-820 82.0 82.81 P 0.576 0.308 0.7785 29.58

SD20-101 100 98.01 Q 0.495 0.283 1.06 32.18

SD20-151 150 151.3 R 0.435 0.228 1.37 39.98

SD20-221 220 222.0 S 0.356 0.188 2.04 48.43

SD20-331 330 327.6 T 0.294 0.155 2.99 58.83

SD20-471 470 470.9 U 0.263 0.129 3.74 70.53

SD20-681 680 681.2 V 0.216 0.107 5.56 84.83

SD20-821 820 823.7 W 0.204 0.098 6.22 93.28

SD20-102 1000 1004.9 X 0.172 0.088 8.73 103

SD25-R47 0.47 0.466 A 3.88 6.00 0.0177 2.13

SD25-R82 0.82 0.770 B 3.58 4.67 0.0208 2.74

SD25-1R2 1.20 1.15 C 3.33 3.81 0.0240 3.34

SD25-1R5 1.50 1.61 D 3.12 3.23 0.0274 3.95

SD25-2R2 2.20 2.14 E 2.93 2.80 0.0311 4.56

®

SD Series

High Power Density,

Low Profile, Shielded Inductors

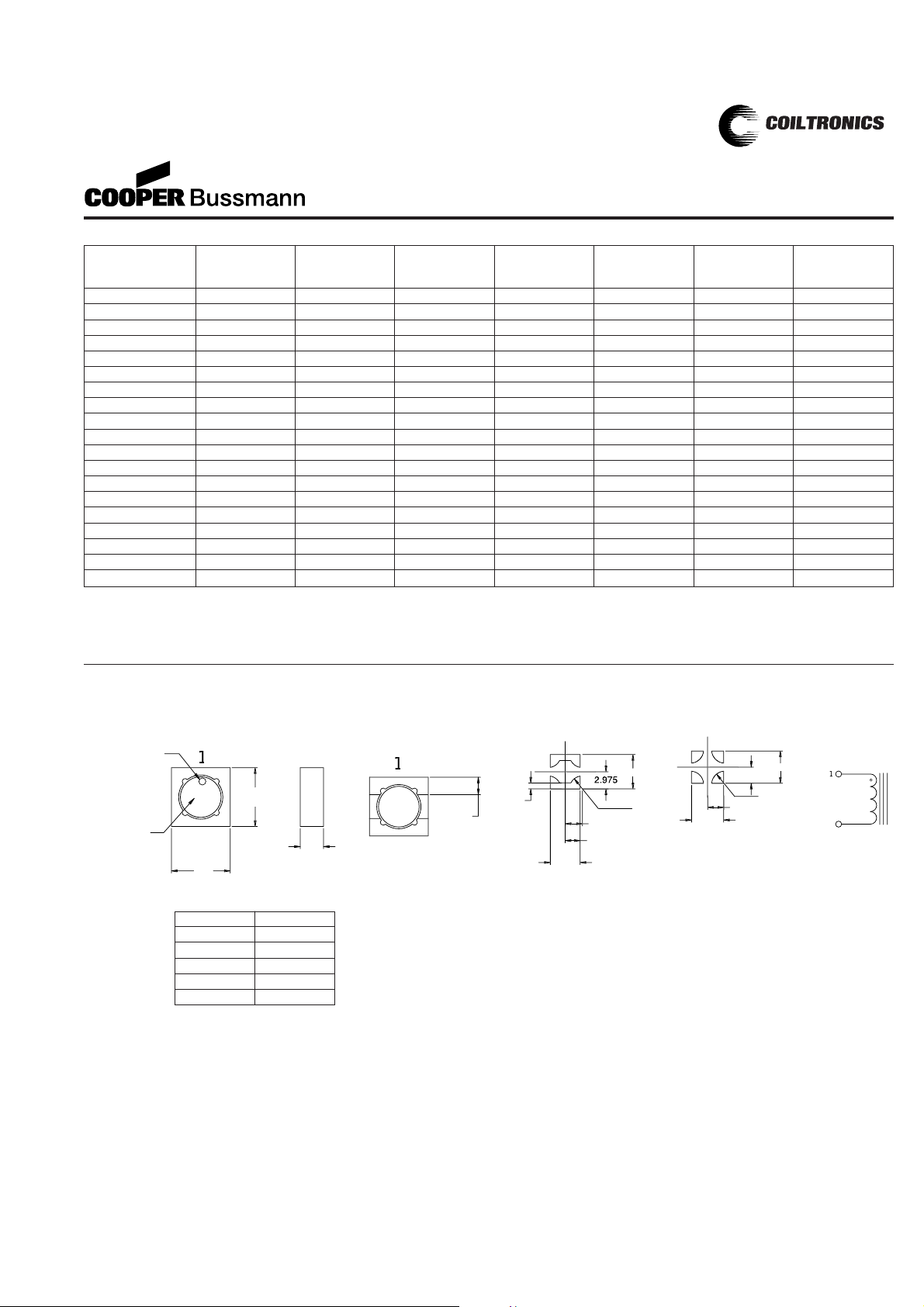

Mechanical Diagrams

TOP VIE

W

BOTTOM VIE

W

RECOMMENDED PCB LAY

OUT

SC

HEMATI

C

5.2

M

ax

5.2

Max

a

H

1.5 Typ

.

Ref

.

S

IDE VIE

W

identifi

er

Part markin

g

(

Note A

)

R2.2

50

2.97

5

5.950

2.975

4 PAD LAYOUT

R2.2

50

5.95

1.

0

2.975

5.15

2.575

2 PAD LAY

OUT

5.950

(

see chart below

)

Part Number Rated OCL (1) Part Irms (2) Isat (3) DCR (4) Volt

Inductance +/-20% Marking Amperes Amperes (Ω)u-sec

(µH) (µH) Typ. T yp.

SD25-3R3 3.30 3.43 F 2.64 2.21 0.0384 5.78

SD25-4R7 4.70 5.03 G 2.39 1.83 0.0467 6.99

SD25-6R8 6.80 6.93 H 2.19 1.56 0.0556 8.21

SD25-8R2 8.20 7.99 J 1.92 1.45 0.0724 8.82

SD25-100 10.0 10.35 K 1.80 1.27 0.0824 10.03

SD25-150 15.0 14.45 L 1.67 1.08 0.0956 11.86

SD25-220 22.0 22.81 M 1.34 0.857 0.1478 14.90

SD25-330 33.0 33.07 N 1.11 0.711 0.2149 17.94

SD25-470 47.0 47.89 O 0.919 0.592 0.3156 21.58

SD25-680 68.0 68.64 P 0.741 0.482 0.4850 25.84

SD25-820 82.0 82.17 Q 0.713 0.441 0.5242 28.27

SD25-101 100 100.79 R 0.670 0.398 0.5937 31.31

SD25-151 150 148.4 S 0.553 0.328 0.8723 38.00

SD25-221 220 222.4 T 0.446 0.268 1.34 46.51

SD25-331 330 332.2 U 0.359 0.219 2.07 56.85

SD25-471 470 472.4 V 0.293 0.184 3.10 67.79

SD25-681 680 677.2 W 0.262 0.154 3.88 81.17

SD25-821 820 826.7 X 0.230 0.139 5.04 89.68

SD25-102 1000 1003.4 Y 0.216 0.126 5.70 98.80

Series HT

SD10 1.0mm max

SD12 1.2mm max

SD18 1.8mm max

SD20 2.0mm max

SD25 2.5mm max

(1) Open Circuit Inductance Test Parameters: 100KHz, 0.25Vrms, 0.0Adc.

(2) RMS current for an approximate ∆T of 40°C without core loss.It is

recommended that the temperature of the part not exceed 125°C.

(3) Peak current for approximate 30% roll off at 20°C.

(4) DCR limits @ 20°C.

5) Applied Volt-Time product (V-uS) across the inductor at 100kHz necessary to

generate a core loss equal to 10% of the total losses for 40°C temperature rise.

®

SD Series

High Power Density,

Low Profile, Shielded Inductors

SD Series

A) Part Marking: Line 1:(1st digit indicates the inductance value per part marking

designator in chart above)

(2nd digit is a bi-weekly production date code)

(3rd digit is the last digit of the year produced)

Line 2: 12 (indicates the product size code)

Loading...

Loading...