COHU 6110, 6112 Installation And Operation Manual

6110 SERIES

Megapixel IEEE-1394a Camera

INSTALLATION AND OPERATION MANUAL

Preliminary 3a 4-14-05

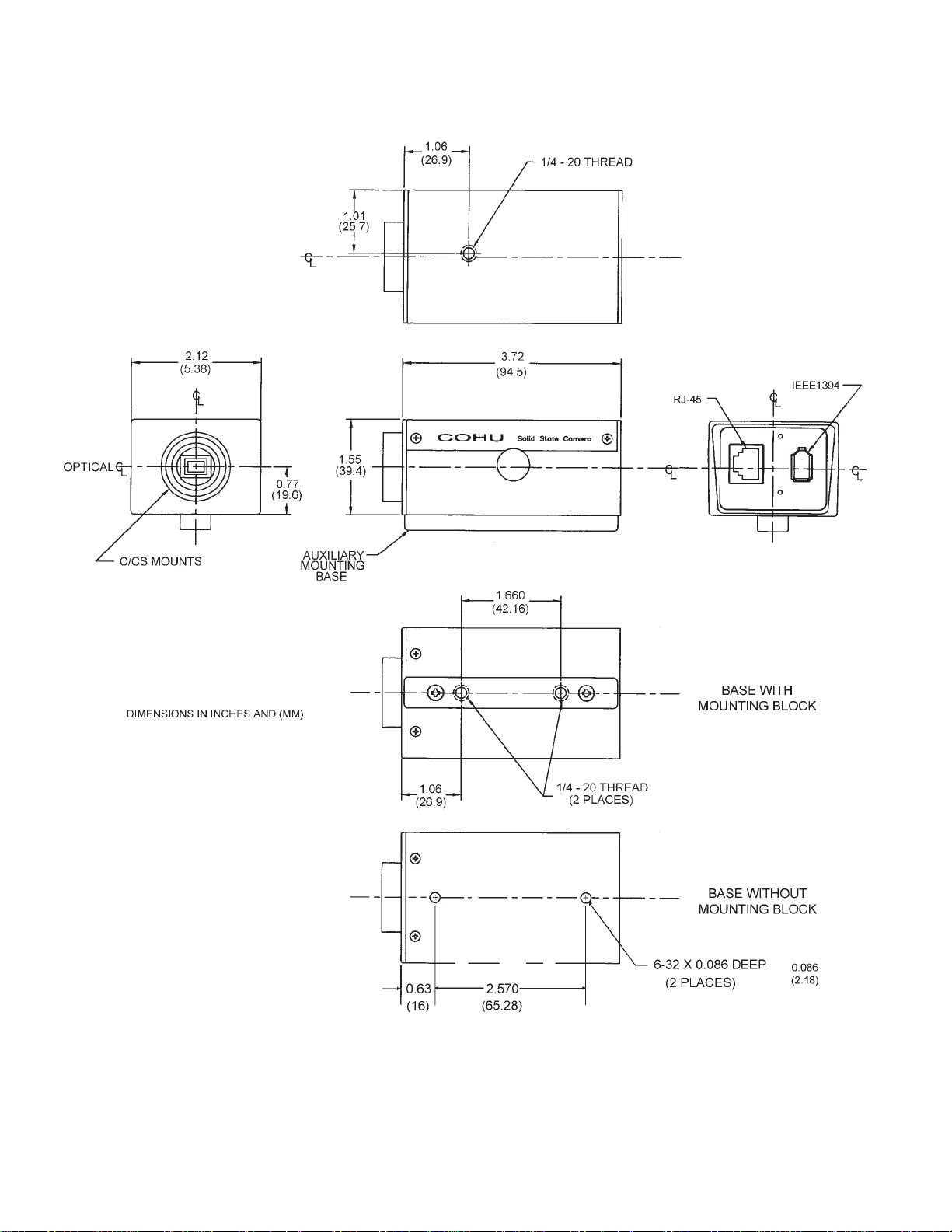

Figure 1. Monochrome Progressive Scan Camera

Lens Optional

Technical Manual 6X-1051

Phone: 858-277-6700

Fax: 858-277-0221

Cohu Electronics • 3912 Calle Fortunada • San Diego, CA 92123-1827

www.cohu-cameras.com

info@cohu.com

April 14, 2005

Preliminary 3a 4-14-05

6110 CAMERA

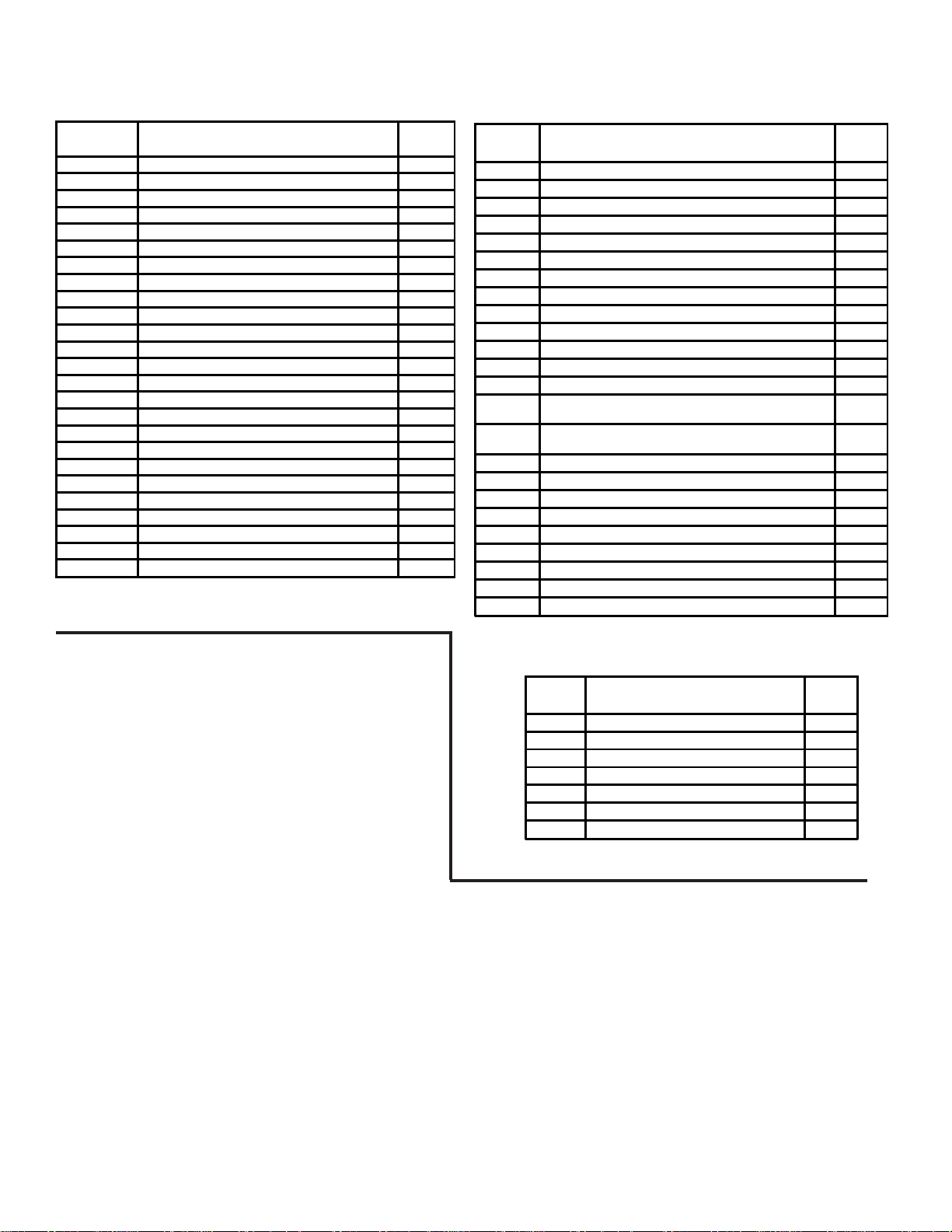

LIST OF SECTIONS

SECTION TITLE PAGE

1.0 GENERAL DESCRIPTION 3

1.1 Electrical C har acte r istics 3

1.2 Mechanical Characteristics 4

2.0 INSTALLATION 5

2.1 Equipment Supplied 7

2.2 Equipment Required but Not Supplied 7

2.3 Cabling Requirements 7

2.4 P ower Requirements 8

2.5 Mounting Requirements 8

2.6 Installation Procedure 10

3.0 Operation 14

3.1 Control Inputs & Outputs 14

3.2 Software Control 14

3.3 Frame Rates 14

3.4 Menu Items 14

3.5 "Camera" Drop-down Menu Items 14

3.6 "Mode" Menu Drop-down Items 19

3.7 "Rate" Drop-down Menu Items 19

3.8 "Cohu" D rop-down Menu Items 19

3.9 "Help" Drop-down Menu Items 19

3.10 Pop-up Viewer Windows 19

4.0 Handling Instructions 21

4.1 Unpacking & Receiving Instructions 21

4.2 Static Discharge Protections 22

4.3 Preparation for Shipment & Storage 24

INSTALLATION AND OPERATION

LIST OF FIGURES

FIG. TITLE PAGE

1 Monochrome Progressive Scan Camera 1

2 Sensor Optical Black Areas 3

3 Sensor Sensitivity Characteristic 3

4 Model Number Interpretation Diagram 5

5 Dimensions, Model 6112 6

6 Typical Installation Interconnections 8

7 Auxilia ry Input (RJ-45) Cable Diagram 9

8 Trigger Input Functional Diagram 11

9 Strobe Output Functional Diagram 11

10 Strobe Timing Reference 13

11 Strobe Output Field Reference 15

12 "Camera" Window (with typical selections) 18

13 "Camera" Drop-down Menu (Camera Stopped) 18

"Camera" Drop-down Menu with Select

14

Camera" Selected

"Camera" Drop-down Menu after "Init Camera"

15

Selected

16 "Camera Control" Window 20

17 "Check Link" Verify Window 22

18 "Maximum Speed" Window 22

19 "Problem Acquiring Image" Window 22

20 "Partial Scan Setup " Window 23

21 "C amera Identification" Window 23

22 "Strobe Setup" Windows 23

23 "Debug" Window 24

24 "Set Serial Number" Window 24

20

20

LIST OF TABLES

TABLE TIT LE PAGE

1Specifications 4

2 Key Points to Rem embe r 7

3 Items Supplied 10

4 Items Re quired but Not Suppli e d 10

5Cables Required 11

6 Drop-down Menu Items 12

7 "Camera" Drop-down Menu Items 17

2

6X-1050

Preliminary 3a 4-14-05

V

H

2 Pixels

40

2

8

Pin 1

Pin 11

OPTICAL BLACK POSITION

(Top View)

INSTALLATION AND OPERATION

1.0 GENERAL DESCRIPTION

This introduction briefly describes the overall

characteristics of the Model 6112 Camera

(figure 1) related to its installation and operation.

1.1 Electrical Characteristics

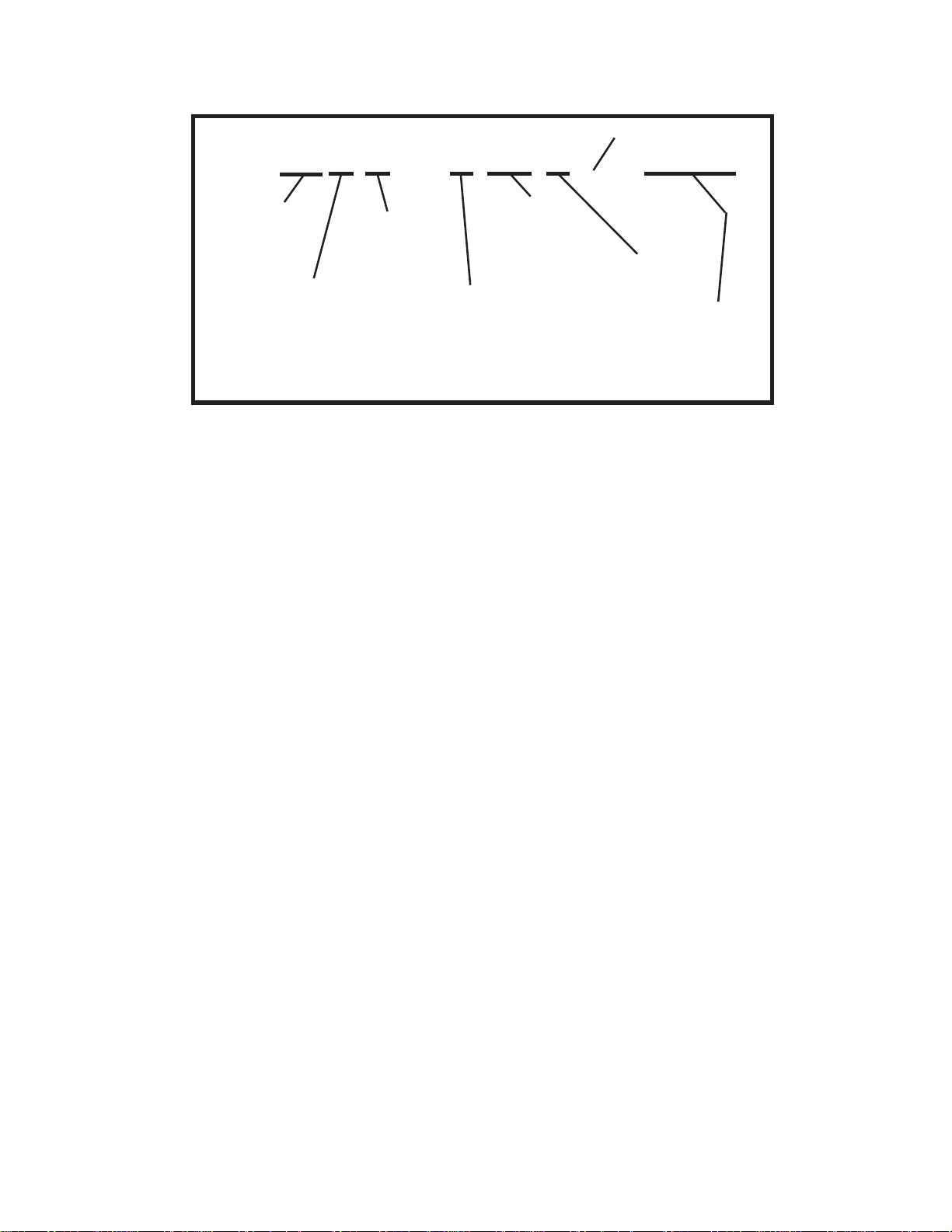

A model number interpretation diagram

appears in figure 4. That diagram shows the

various basic configurations of the Camera. Table

1 lists the specifications.

1.1.1 Sensor Characteristics

The sensor is a 1/2-inch (8 mm) 4:3 aspect

ratio package. It is a monochrome CCD interline

transfer progressive scan sensor. The glass

faceplate is 0.75 mm thick with a reflective index

of 1.5. There are 1360 horizontal and 1024

vertical active pixels. Pixels are square: 4.65 µm

x 4.64 µm.

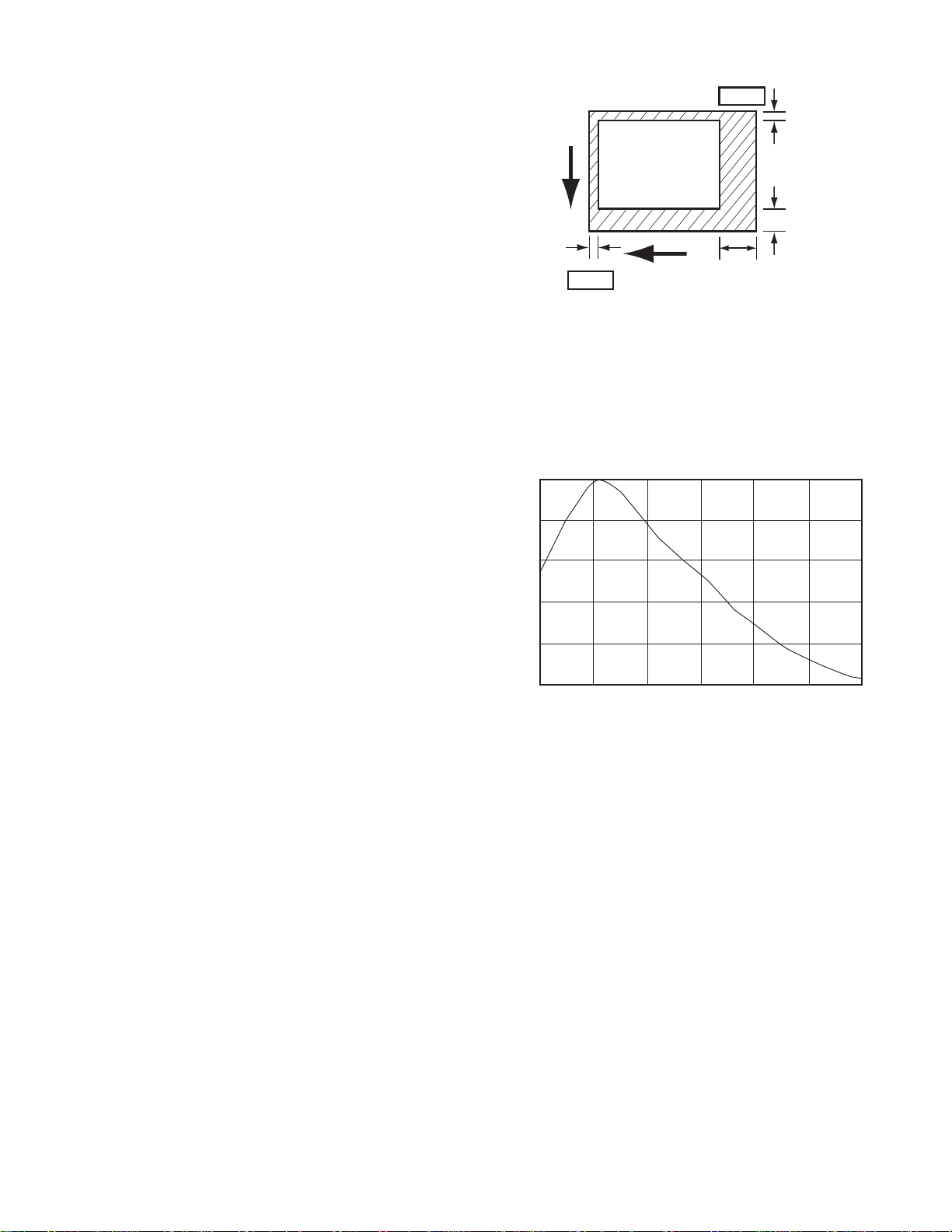

Figure 2 shows the optical black pixels

surrounding the active area. Figure 3 graphs the

spectral sensitivity of the sensor. Note that this

is the sensitivity curve of the sensor itself — not

including any lens or light source.

The Camera obtains enhanced sensitive and

low dark current through use of a Hole Accumulation Diode (HAD) sensor.

The sensor offers an electronic shutter with

variable charge store time so that a full frame

image can be obtained without a mechanical

shutter.

6110 CAMERA

Figure 2. Sensor Optical Black Areas

Sensor Sensitivity Characteristics

1

0.8

0.6

0.4

Relative Response

0.2

0

400

Figure 3. Sensor Sensitivity Characteristic

(excludes lens characteristics and light source characteristics)

500

600

700

Wavelength (nm)

800

900 1000

1.1.2 IEEE-1394a Connector (6-pin)

This connector is the six pin version of a

1394a connector. Two pins are used to carry

power to the camera. The camera derives operating power for video and processing control from

this connector. (Strobe circuits obtain dedicated

power from the RJ-45 connector.)

1.1.3 RJ-45 10 Wire Connector

Only seven of the 10 pins on this connector

are used: two for the trigger input to capture

scenes, four to strobe external scene lighting

circuits, and one to provide Vcc input for these

strobe circuits. These are opto-isolate circuit

functions. Power for these circuits is provided

6X-1050

from outside the camera to maintain complete

isolation from the other camera circuits.

1.2 Mechanical Characteristics

The 6110 has optical and mechanical interfaces identical to the Cohu model 2600 camera.

It can be mechanically substituted in place of a

2600 camera.

Dimensions are shown in figure 5. Note that

these dimensions do not include the adjustable

CS-mount. Also note that the base of the Camera

is dimensioned both with and without the mounting block. It can be removed if desired.

The CS-mount lens adapter threads into the

front of the housing. Adding the 5-mm extension

3

Preliminary 3a 4-14-05

6110 CAMERA

INSTALLATION AND OPERATION

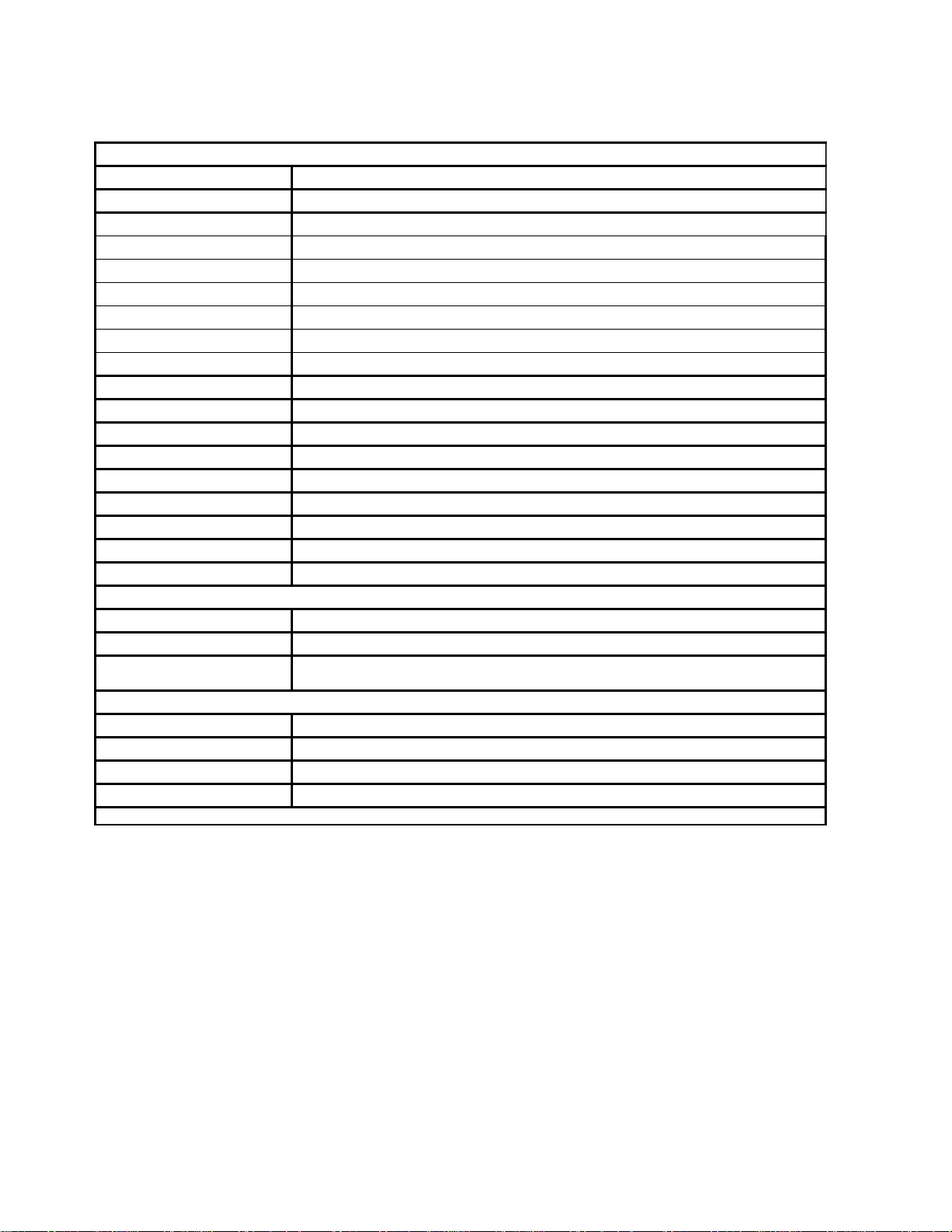

Table 1. Specifications

ELECTRICAL

Sensor 1/2-inch format 4.65 micron x 4.65 micron

Active Pixels 1360 (H) x 1024 (V)

Resolution 1024 x 1024 tv lines

Sensitivity 3 lux, faceplate for full video, min gain, 1/30 sec exposure

Frame Rate 4 f/s at full resolution; 15 f/s at 256 lines/frame

Scanning 1280 (H) x 960 (V); Fewer than 960 lines can be selected

Trigger Input Optoisolated input for scene captureon RJ-45 auxiliary connector

Shutter Programmable 1/15 to 1/20,000 sec; up to 5 sec integration

Gain 0 to 30 dB manually programmable

S/N 60 dB

Gamma 1.0 fixed

ImageProcessing Mirror imaging and ROI

VideoOutput IEEE-1394A IIDC [D-cams] compliant [16 bit format]

Sync Internal; optional opto-isolated hardware trigger or software trigger

Control Outputs 4 optoisolated strobing outputs

C o ntr o ls G a i n, s hutte r, o ffs e t, fra m e rate , R O I win d o w vi a D-c a m re gi s te rs

Power, video and control 12 V dc (8 to 30 V dc IEEE-1394a compatible less than 3 watts

Power, auxiliary input Vcc required for opto-isolated strobe outputs

ME CHANICAL

Dimensions 1.53 high x 2.13 wide x 3.74 long in inches (39 x 54 x 95 mm)

Weight 1.0 lb (454 grams)

Connectors (2)

Temperature -5 to 60 °C (23 to 140 °F) operating; -20 to 70 °C (-4 to 158 °F) storage

Humidity <95 %, non-condensing

Shock 80 g (IEC 68)

Vibration (less lens) 8 g (IEC 68)

IEEE1394a (6 wire) video/control/power;

RJ45 (10 wire) Optoisolated trigger input; 4 discretes optoisolated outputs

ENVIRONMENTAL

ring (provided) allows C-mount lenses to be used

with the Camera.

Two connectors are located at the rear

panel. One is an IEEE-1394a six-pin connector

that carries video/control input power and the

other is an RJ-45 10-pin connector to support the

auxiliary functions of triggering and strobing. The

RJ-45 has power input on pin 7 to drive the

strobe stages. Triggering is directly driven by the

externally applied trigger signal.

The camera can be mounted in four ways:

1. By the lens

4

2. To the top of the case

3. Directly to the bottom of the case, and

4. To a removable mounting block on the bottom of

the case.

The top of the case has a single 1/4-20 hole

for mounting purposes.

The bottom of the case has a pair of

threaded 6-32 x 0.086-inch deep holes for direct

mounting or these mounting points can be used

6X-1050

Preliminary 3a 4-14-05

INSTALLATION AND OPERATION

611 2 — 1 00 0 xxxx

Series

Monochrome

2k Camera

Sensor

1 1/2-inch format

monochrome

Figure 4. Model Number Interpretation Diagram

to attach the removable mounting block which

then provides two 1/4-20 mounting holes.

1.2.1 CS-mount or C-mount Lens

Use a manual-iris lens compatible with the

1/2-inch sensor in the camera. Either a CS-mount

lens or a C-mount lens can be used. Use of a Cmount lens will require that the 5-mm extender

supplied with the Camera be threaded onto the

C-mount lens before it is then threaded onto the

CS-mount adapter.

2.0 INSTALLATION

This section covers the general requirements of installing the camera including cabling

and power requirements. In addition to the actual

installation requirements, this section covers a

number of other items including static discharge

protection and proper shipping and handling of

the Camera. Refer to table 2 for a summary of

key points to remember about installing and

using the Camera.

Section 4 of this manual covers Receiving

Inspection, Static Precautions, and Return Shipment to the Factory.

2.1 Equipment Supplied

Table 3 lists the equipment supplied with the

basic camera model number. Other items may

be supplied if they wereordered with the camera.

Power

2 12 V dc over

IEEE-1394a

Camera

Output

1 IEEE-1394a

6110 CAMERA

Not

Assigned

Accessories

0 None

Lens

Option

Manual iris

CS- or C-mount

2.2 Equipment Required but Not Supplied

Table 4 is a list of equipment required to

make the camera operational in a minimum

configuration. Other items may be required

depending on the application.

2.3 Cabling Requirements

The rear panel provides two connectors for

interconnections with other equipment.

As a minimum, the IEEE-1394a connector

must be used. It provides several functions

including operating power to the camera, picture

data out to the viewing PC, and control functions

for the camera.

The RJ-45 connector offers two auxiliary

functions that may not be required. This is an

opto-isolated port and thus requires its own

supply power on pin 7. It has a trigger input to

capture a scene image and four programmable

strobe outputs to “fire” strobe lights during the

integration period of the sensor.

2.3.1 IEEE-1394a Cable

Installation cables for IEEE-1394a are best

obtained from a reliable cable manufacturer and

not built on-site. Use only a cable of the highest

quality. All six wires are required since the camera draws its operating power from this cable.

6X-1050

5

Preliminary 3a 4-14-05

6110 CAMERA

INSTALLATION AND OPERATION

6

Figure 5. Dimensions, Model 6112

6X-1050

Preliminary 3a 4-14-05

INSTALLATION AND OPERATION

6110 CAMERA

Table 2. Key Points to Remember

ITEM KEY POINTS

STROBE OUTPUTS

1 Using the strobe outp uts requires a cable with an RJ-45 connector

2 Using the strobe outputs requires that power be supplied to the RJ-45 connector

3 Strobe outputs must be current limited to pro tect the internal em itter follower drive transistor

4 Strobe outputs are optoisolated from other camera circuits

5 Start & stop times on the strobe setup window must be within the frame time being used

S hu tte rin g impac ts the s tro b e ti m e s tha t c a n b e s e t. W he n the s e n so r is b e i ng s hutte re d , th e inte g r a tio n

6

interval during which time the scene is obtained occurs during the last part of the vertical interval

TRIGGER INPUT

External triggering for scene capture can be implemented either through the software interface or by

7

ahardwire connection on the RJ-45 connector

8 Hardwire triggering does not use the Vcc power input on the RJ-45 rear panel connector

POWER INPUTS

9 P ower for camera video and control circuits is supplied via the 1394a cable (a 6-wire cable)

10 When strobe outputs are to be used, power must also be supplied to the RJ-45 auxiliary connector

OP E R A TIN G C O N S ID E RA T IO N S

11 Selecting some of the control functions requires stopping the camera (stop is equivalent to pause)

12 At full resolution, maximum frame rate is 4 frames per second

13 For setup and adjustm ent purposes, select the Draft mode for 12 frames per second operation

14 A tif or bmp image of the scene can be saved to an external hard drive or other device

For test bench cables, though, it is possible

to buy RJ-45 10-pin cable connectors and use a

punch-down tool to install the required wires onto

the connector.

2.3.2 RJ-45 Auxiliary Cable

Only seven of the 10 pins of this connector

are used. One pin is input power for the strobe

outputs, four are strobe output lines, and two

provide trigger input for scene capture. Depending on the length of this cable run and the noise

environment of the installation it may not require

overall shielding or shielding of the trigger lines.

Figure 7 is the wiring diagram for a cable showing overall shielding for longer runs.

2.4 Power Requirements

Operating power for the camera must be

supplied via the 1394a cable. Power for the

strobe outputs must be supplied to the RJ-45

connector if they are to be used.

6X-1050

2.4.1 Power Over 1394a

The IEEE-1394a specification provides for

devices to obtain operating power over a 1394a

cable (6-wire type). The 6100 makes use of this

feature so the device it is connected to must

provide this power. Powered 1394a sources

must be capable of supplying any voltage from 8

to 30 V dc.

The Camera requires 12 V dc from the

1394a cable at less than 3 watts

If the Camera is to be operated with Viewer

software running on a laptop computer it is likely

that this computer will have a 4-pin (non-powered) 1394a connector. In this case an external

power supply adaptor will be required to interconnect between the 4-pin 1394a connector on the

laptop and a 6-pin 1394a cable (powered type) —

which then provides this adapter voltage to the

Camera. These adapters are spcifically made for

1394a applications.

2.4.2 Strobe Power via RJ-45

If power is required to the RJ-45 auxiliary

connector, it is applied to pin 7. This power is

7

Preliminary 3a 4-14-05

6110 CAMERA

6-wire 1394a Cable

6110

Camera

IEEE-1394a

AUX RJ-45

7-wire Cable

Scene

Illumination

NOTE:

PC must be running appropriate software

to interface with camera. This can include the

Cohu 6110 GUI interface, third-party software

such as National Instruments Lab View, or software

written or modified for the specific application.

Trigger drives the cathode/anode of an optoisolator diode

in the camera

1394a Port

with

Power Out

INSTALLATION AND OPERATION

PC

PC MONITOR

Monitor

Cable

Auxiliary Interface

+

Trigger (scene capture)

-

+Vcc Out

Strobed Inputs

(emitter follower

Note: External emitter

resistors required

driven)

DRIVERS

Illumination

Outputs

(strobed)

Local

Site

Interface

Figure 6. Typical Installation Interconnections

labeled +Vcc on the illustrations because the

actual voltage applied depends on the circuit

externally connected to the strobe outputs. A

typical input range would be from 3.3 V dc to 15 V

dc.

The strobed outputs are common collector

(emitter follower) circuits. Each output is specified

to provide a maximum of 35 mA in continuous

operation. An external 100 ohm series resistor is

shown in figure 9 to protect the internal drive

transistor from an accidental short to ground. This

assumes a 5 V dc input for Vcc on pin 7.

2.5 Mounting Requirements

The dimensions shown in figure 5 related to

mounting the Camera. The Camera can be

mounted in four different mounting configurations:

1. By the lens (being careful to ensure that the

attached cables do not provide excessive pressure

on the camera)

2. By the single 1/4-20 threaded hole on the top of

the case

3. By the two 6-32-0.086 threaded holes on the

bottom of the case

4. By two 1/4-20 threaded holes on a mounting

adapter that can be installed on the bottom of

the case. The Camera is typically shipped with

this mounting block installed.

The following paragraphs describe some of

the features of the Camera related to the installation process.

2.6 Installation Procedure

Prior to installing the camera it may be

necessary to prepare an auxiliary interface if

the triggering and strobe lines on the RJ-45

connector are to be used. See figures 6 and 7.

The camera can only be operated by

Viewer software running on a PC interfaced via

a IEEE-1394a cable.

Installing the Camera is straightforward. It

is only necessary to mount the Camera to a

suitable base, install the lens, attach the

cable(s), apply power, and operate it using the

Viewer software.

8

6X-1050

Loading...

Loading...