COHU 3950 SERIES iVIEW Installation And Operation Manual

3950 iVIEW

INSTALLATION AND OPERATION

COHU, INC. ELECTRONICS DIVISION

Installation and Operation Manual

.

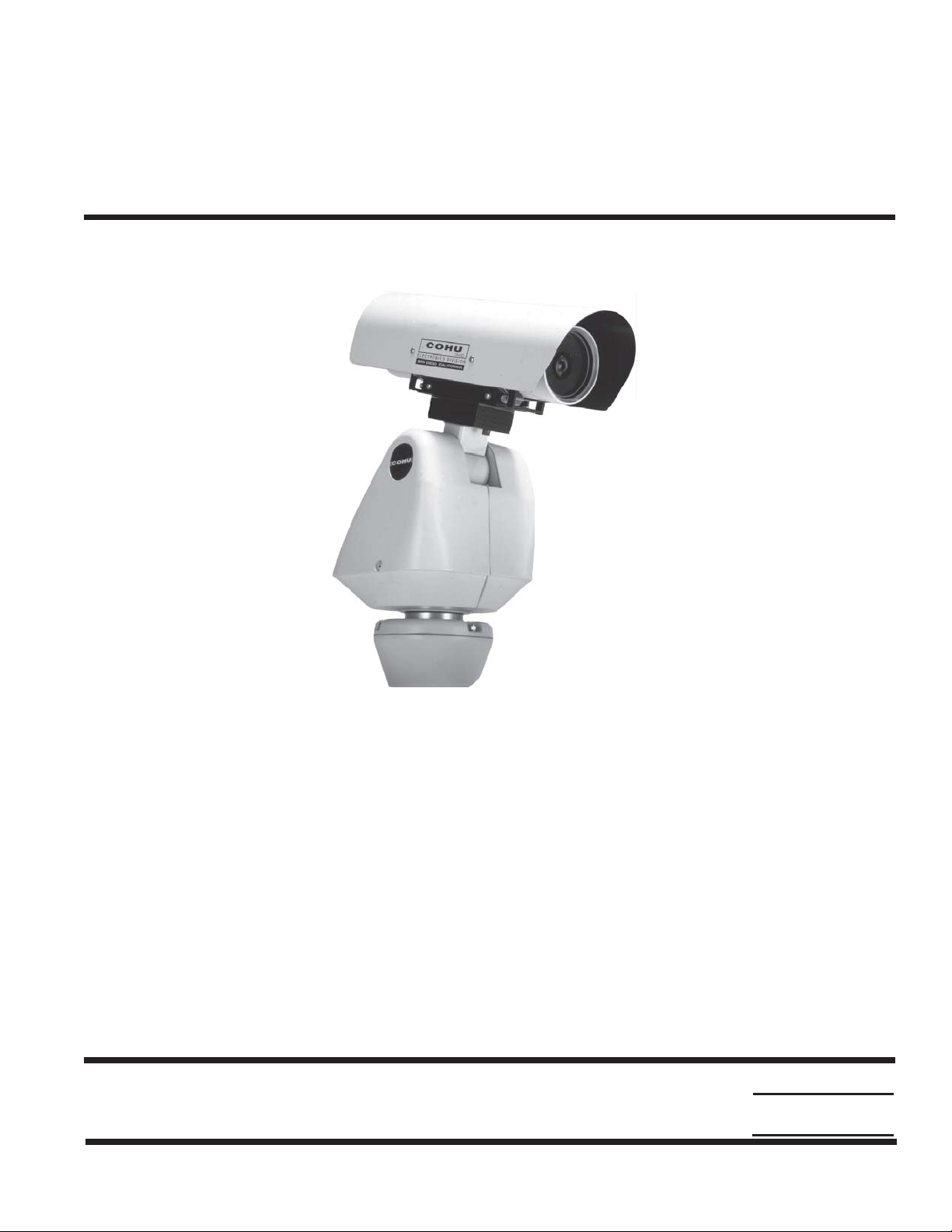

Figure 1. iView

3950 SERIES iVIEW

CAMERA/POSITIONER SYSTEM

Phone: 858-277-6700

FAX:

Cohu Electronics • 3912 Calle Fortunada • San Diego, CA 92123-1827

6X-1027a

858-277-0221

WEB: www.cohu-cameras.com

Email: info@cohu.com

August 12, 2005

COHU

Cohu Inc., Electronics Division

1

INSTALLATION AND OPERATION

SECTION TITLE PAGE

1.0 GENERAL DESCRIPTION 4

1.1 Elect rica l Characte r istics 4

FCC STATEMENTS

NOTE: This equipment has been

tested and found to comply with

the limits for a Class A Digital

Device, pursuant to Part 15 of

the FCC Rules. These limits are

designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance

with the instruction manual, may

cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which

case the user will be required to

correct the interferecne at his

own expense.

1.2 Mechanical Characteristics 4

2.0 INSTALLATION 5

2.1 Unpacking and Receiving Inspection 6

2.2 Static Discharge Protection 6

2.3 Equipment Supplied 8

2.4 Equipment Required But Not Supplied 9

2.5 Power Requirements 11

2.6 Pedestal Mount Installation 11

2.7 Wall Mount Installation 12

2.8 Pole Mount Installation 12

2.9 Cabling Requirements 14

2.10 GUI Interface 18

2.11 Preparation for Shipment and Storage 23

3.0 OPERATION 23

3.1 Local Panel Control 23

3.2 Local Laptop PC Control 23

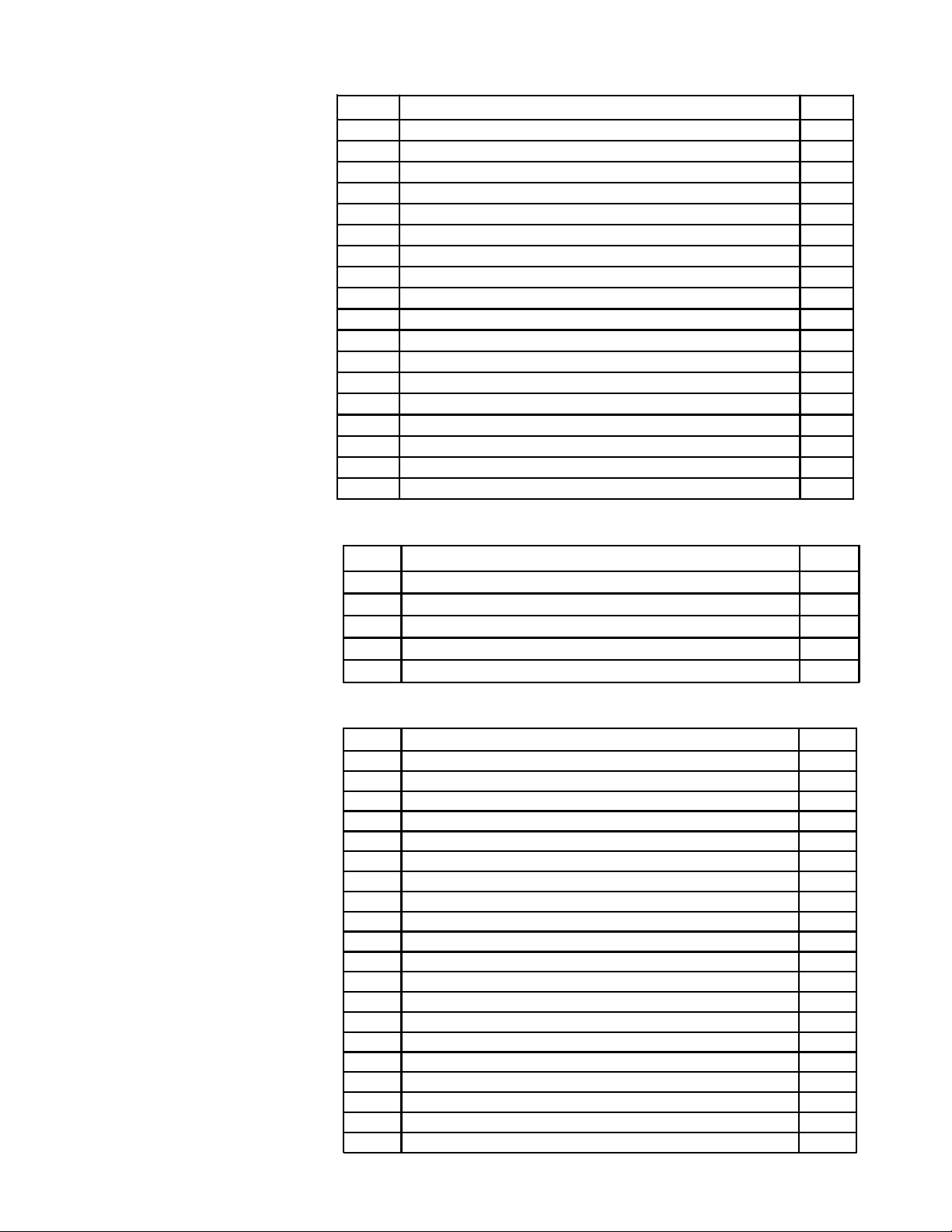

TABLE TIT LE PAGE

3950 iVIEW

LIST OF SECTIONS

LIST OF TABLES

1 Specifications 3

2 Equipme nt vs. Mo d el Number 5

3 Required Cable Characteristics 16

4 Connector Pin Functions 115 V ac or 230 V ac 20

5 Communications Settings 22

This device complies with part 15

of the FCC Rules. Operation is

subject to the following two conditions: (1) this device may not

cause harmful interference, and

(2) this device must accept any

interference received, including

interference that may cause undesired operation.

Changes or modifications to this

equipment not expressly approved

by Cohu Electronics could void

the users authority to operate the

equipment.

2

LIST OF FIGURES

FIGURE TITLE PAGE

1iView 1

2 M odel Number Interpretation 5

3 Typical Pedestal Mount Installation 7

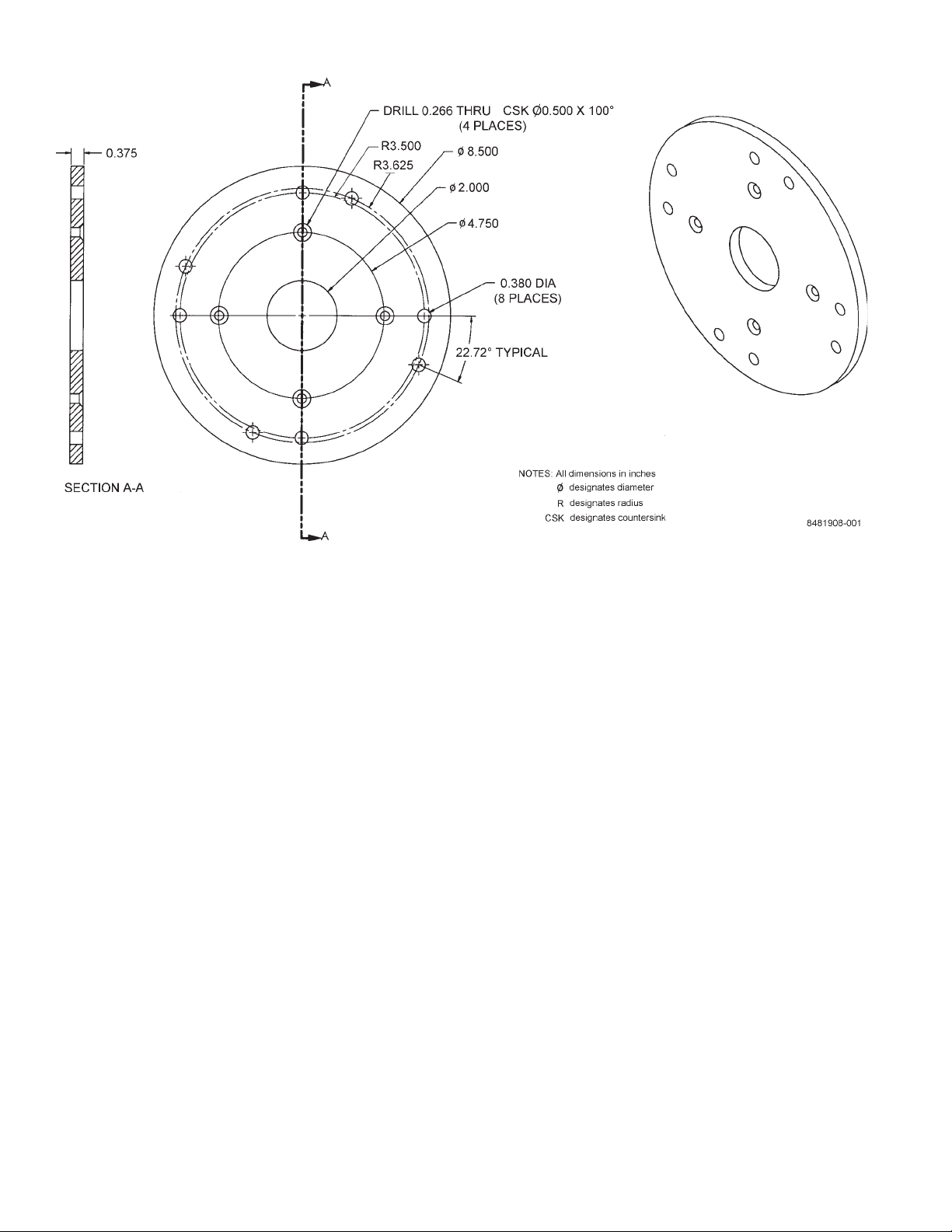

4 Dimensions, Large Pedestal Base (LPED) 8

5 Typical Wall Mount Installation 9

6 Typical Pole Mount Installation 10

7 A rm and Adapter Plate Dimensions 11

8 P ole Mount Bracket Dimensions 12

9 Interconnection Diagram, iView to Local Control Panel 13

10 Interconnection Diagram, iView to Equipment Cabinet 14

11 Cable CA-297A (RS-422) Stripped Leads Version 15

12 Cable CA-297B (RS-422) BNC Plug & Power Plug 15

13 Cable CA-297C (RS-422) BNC Plug, Power Plug, & 232/422 Converter 17

14 Cable CA-297D Model 9300 Local Control Panel to iView 3955 18

15 Cable CTC-30, Test/Setup Wiring Diagram 19

16 Typical RS-232 to RS-422 Converter 19

17 Typical Win MPC Application 20

18 Typical Win MPC "Home" Screen 21

19 W in MPC Communications Functions Screen 22

20 Pedestal Test Stand 23

6X-1027a

3950 iVIEW

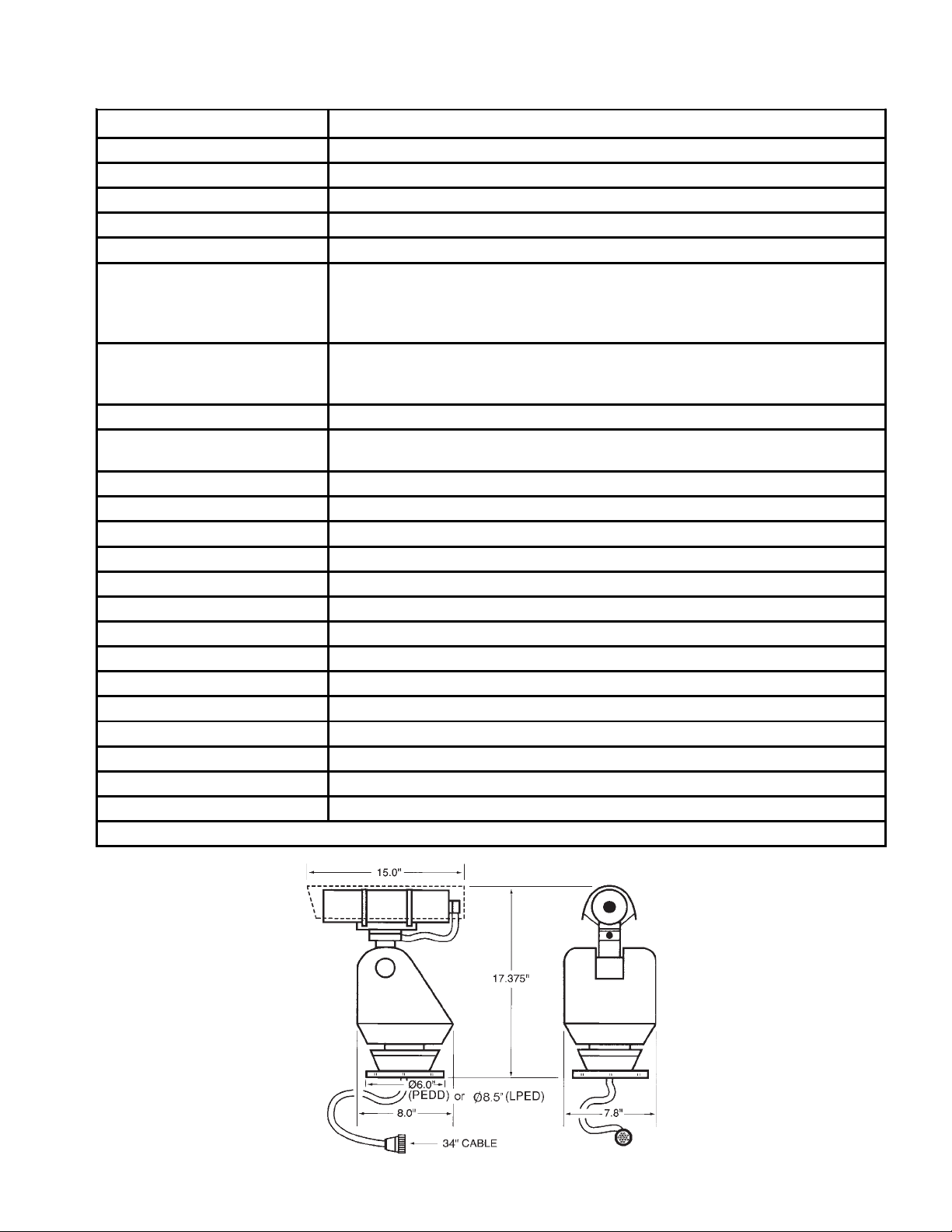

SP E CIF ICATION CHARACTERIS TIC

Resolution 470 horizontal tv lines

Day/Night Switchover Day (color) / night (mono), manual or auto

Sensitivity

Power Input

Power Connsumption 50 Watts with camera heaters on (camera and positioner)

Communications

Preset Speed >100°/second preset, at 0.5° accuracy

Title Generation 8 lines

Privacy Zones 8 programmable zones can be set for video blanking

Alarm Inputs 2 available

Environmental -40 to +55 °C

Pressurization Pressurized with dry nitrogen; IP Rating IP67, NEMA 4X

INSTALLATION AND OPERATION

Table 1. Specifications

Imager 1/4 inch color interline transfer CCD, progressive scan

Lens Integral 23X optical, 3.6 to 82.8 mm with 10X digital, auto/manual focus

Sync Phase adjust line lock

3.0 lux at 1/60 s (color day)

0.2 lux at 1/4 s (color day)

0.3 lux at 1/60 s (mono night)

0.02 lux 1/4 s (mono night)

115 V ac nominal (103.5 - 126.5), 60 Hz

230 V ac nominal (207 - 253), 50 Hz

24 V ac nominal (21.6 - 26.4), 60 Hz

Opto-isolated serial port RS-422 with digital position feedback;

RS-232 and RS-485 available

Protocol Non-propritary Cohu standard, others optional (see figure 2, protocols)

Firmware Stored in flash memory; upgrade via serial port

Pan/Tilt 360° continuous pan; +40º to -90º down

Presets 64

Tours 8, each of 32 presets with dwell timer per preset per tour

Sectors 16 in the horizontal plane

Humidity 100 percent, relative

Weight 28 lb (16 kg) approximate

6X-1027a

3

INSTALLATION AND OPERATION

3950 iVIEW

1.0 GENERAL DESCRIPTION

The 3950 iView series is a camera system that

integrates a high performance digital signal processing camera, pan-and-tilt Positioner, and control

receiver into one package.

Throughout this manual the entire assembly will

typically be referred to the “3950,” the “Positioner” or

the “iView.”

Specifications are cont ained in table 1. A model

number interpretation is provided in figure 2. This

can be used to interpret an existing model number.

WARNING

Some versions of this Positioner operate from

115 V ac or 230 V ac. Use all appropriate care

when installing and maintaining any equipment operating from these voltages.

1.1 ELECTRICAL CHARACTERISTICS

The camera uses digital signal processing (DSP).

It has an internal source ID generator. Integration

control plus a built-in video storage card provides full

color continuous video even at very low light levels.

The positioner speeds are variable with maximums of 100° per second in pan mode and 20° per

second in tilt while sustaining 90 mph winds. Pan

range is a continuous 360 degrees while the tilt

range is +40 to -90 degrees from the horizontal.

There are 64 preset positions with a preset accuracy of one-quarter degree. When responding to

standard pan-preset the Positioner can move with a

pan speed of 100° per second.

This camera/positioner will operate in temperature

ranges from -40° to +55° C and with winds of up to

90 mph. The enclosure protects against salt, grime,

dirt, and moisture.

Each iView “address” within a surveillance system

can be selected electronically from the Monitoring

Center. There are no mechanical dip switches to set

at the camera, and each unit responds to the central

command only if addressed. This provides greater

integration flexibility for the designer and more

dynamic camera control for the operator

1.1.1 Control Software

The Cohu camera system control software, is

designed to control the camera, camera DSP

functions, positioner, lens functions, as well those of

auxiliary equipment such as VCRs, screen splitters,

and monitor selection. The protocol and message

structure for camera is common for all cameras. No

proprietary protocol and message structure is used.

Three versions of control software are available:

Win MPC

Win MPC Graphical User Interface (GUI) software

is available for setting the address and performing

field tests for each iView . This can be obtained at no

cost from either the cohu-cameras.com web site or

by mail on floppy disk

Cams

The Cams protocol software is intended for

controlling multi-camera/positioner systems when

the Cohu MPC Master Control Panel is the central

control “intelligence” for the system. All control and

respond commands among the various equipment

in the system pass through the Master Control

Panel.

Net Cams

The Net Cams software is intended for controlling

multi-camera/positioner systems when a Windows

based PC is the central control “intelligence” for the

system. All control and respond commands among

the various equipment in the system pass through

the Net Cams Server.

The integrated receiver/driver, cont ained within the

iView, communicates using Cohu protocol messages to control all camera functions. All iView

functions are operable via RS-422 serial communications.

The Positioner is fully compatible with existing

Cohu controllers. In case of power failure, all 64

preset positions of all Positioners are stored in

nonvolatile memory .

4

1.2 MECHANICAL CHARACTERISTICS

Although the camera/positioner is a single mechanical assembly for installation purposes, it

actually consists of two subassemblies: (1) the

camera and (2) the positioner.

All camera circuits are contained within a sealed

and pressurized environmental housing having a

clear window at one end for viewing by the camera

6X-1027a

3950 iVIEW

CAMERA

SERIES

CONFIGURATION

3 - 230 Vac

4 - 24 Vac

5 - 115 Vac

POWER

INSTALLATION AND OPERATION

3 9 5 x — x 0 0 0 / ××××

VIDEO

FORMAT

3 - NTSC Phase Adj LL

7 - PAL Phase Adj LL

PROTOCOLS

1 - Cohu

Protocols of other manufacturers may also

be implemented by the camera/positioner

Figure 2. Model Number Interpretation

WALL

POLE

PEDD

LPED

(Wall Mount)

(Pole Mount)

(Pedestal, Small Base)

( Pedestal, Large Base)

UNASSIGNED

lens. This barrel is fully covered by a sun shield

spaced slightly away from the housing itself. This

minimizes heat buildup due to sunlight and also

serves to minimize sun flair by shading the lens at

some camera angles.

The pan/tilt positioner is a sealed unit intended for

outdoor use under rain, snow , and other typical

harsh weather conditions. Either a small (PEDD) or

larger (LPED) mounting base is installed to the pan/

tilt positioner depending on the model of iView

ordered.

A single multiconductor cable passes through the

base to provide for all signal and operating power

connections for both the pan/tilt unit and the camera.

This 34-inch cable has a 16 pin connector at the

other end for connection with the system cable

routed to its area.

Table 2. Equipment vs. Model Number

MOUNT

CONFIG.

Pedestal

Wall

CAMERA /

POSITIONER

ARM

•

•••

ADAPTER

PLATE

A Schrader valve on the rear panel of the camera

should be used to add dry nitrogen up to 5 psig

(pounds square inch gauge) to the barrel in the

event a “Low Pressure” message is received from

the control software.

2.0 INSTALLATION

An iView can typically mounted in any one of three

mechanical configurations depending on the mounting accessories supplied. This is determined by the

model number:

1. Pedestal Mount (PEDD and LPED models)

The simplest configuration. Only the iView is

supplied. It bolts directly onto the top of a site-

supplied pedestal having the

correct hole pattern or to an

adapter plate providing the proper

hole pattern. Figure 3 illustrates a

POLE

BRACKET

small diameter pedestal mount

base attached to the iView .

Figure 4 shows the larger LPED

base. It has two four-hole patterns on it. Depending on the

model of iView ordered one of

these two plates will be attached.

Pole

NOTE: Dot ( • ) designates items supplied for each mounting configuration.

••••

6X-1027a

5

INSTALLATION AND OPERATION

3950 iVIEW

2. Wall Mount (WALL model)

This mounting arrangement requires an arm that

bolts to the wall and an adapter plate between the

arm and the bottom of the Positioner. The arm is

typically supplied with this adapter plate already

installed.

3. Pole Mount (POLE model)

This mounting arrangement is similar to the Wall

Mount -- except that the mounting arm attaches to a

bracket fastened to a pole instead of directly bolting

to a wall.

Table 2 summarizes the major items supplied for

each of these three installation methods. Each of

these installations will be expanded upon in a later

sections.

2.1 UNPACKING AND RECEIVING INSPECTION

This item was thoroughly tested and carefully

packed in the factory. Upon acceptance by the

carrier, they assume responsibility for its safe arrival.

Should you receive this item in a damaged condition,

apparent or concealed, a claim for damage must be

made to the carrier.

in the event that an open unit were available, the

following precautions should be followed:

CAUTION

This Positioner/Camera contains sensitive devices

that can be damaged by static discharge. Use appropriate static control methods when working inside either the Positioner or Camera.

Components used in modern electronic equipment, especially solid state devices, are susceptible

to damage from static discharge. The relative

susceptibility to damage for semiconductors varies

from low with TTL to high with CMOS. Most other

semiconductors fall between TTL and CMOS in

susceptibility to static discharge. As a minimum,

therefore, observe the following practices when

working inside this or any other electronic equipment:

1. Use conductive sheet stock on the work bench

surface.

2. Connect the sheet stock to ground through an 1

megohm or greater value resistor.

To return the product to the factory for service,

please contact the Customer Service Department

for a Return Authorization Number.“

If a visual inspection shows damage upon receipt

of this shipment, it must be noted on the freight bill

or express receipt and the notation signed by the

carrier's agent. Failure to do this can result in the

carrier refusing to honor the claim.“

When the damage is not apparent until the unit is

unpacked, a claim for concealed damage must be

made. Make a mail or phone request to the carrier

for inspection immediately upon discovery of the

concealed damage. Keep all cartons and packing

materials.

Since shipping damage is the carrier's responsibility , the carrier will furnish you with an inspection

report and the necessary forms for filing the concealed-damage claim

2.2 STATIC DISCHARGE PROTECTION

Procedures in this manual do not require entry

into the housing of the positioner/camera. However

6

3. Use a wrist strap connected to ground through an 1

megohm or greater value resistor when working at

the bench.

4. Maintain relative humidity of the room above 30

percent. This may require a room humidifier .

Working on circuits with relative humidity below 30

percent requires extraordinary procedures not

listed here.

5. Use antistatic bags to store and transport an

exposes chassis, circuit boards, and components.

Use new antistatic bags. Old, used bags loose

their static protection properties.

This list serves as a reminder of the minimum

acceptable practices. Be sure that all static discharge devices at the work bench are properly

installed and maintained.“ S tandard grounding mat s

and wrist straps purchased for use at work benches

are supplied with leads having current limiting

resistors for safety. Never substitute with a grounding lead not having the resistor.

6X-1027a

3950 iVIEW

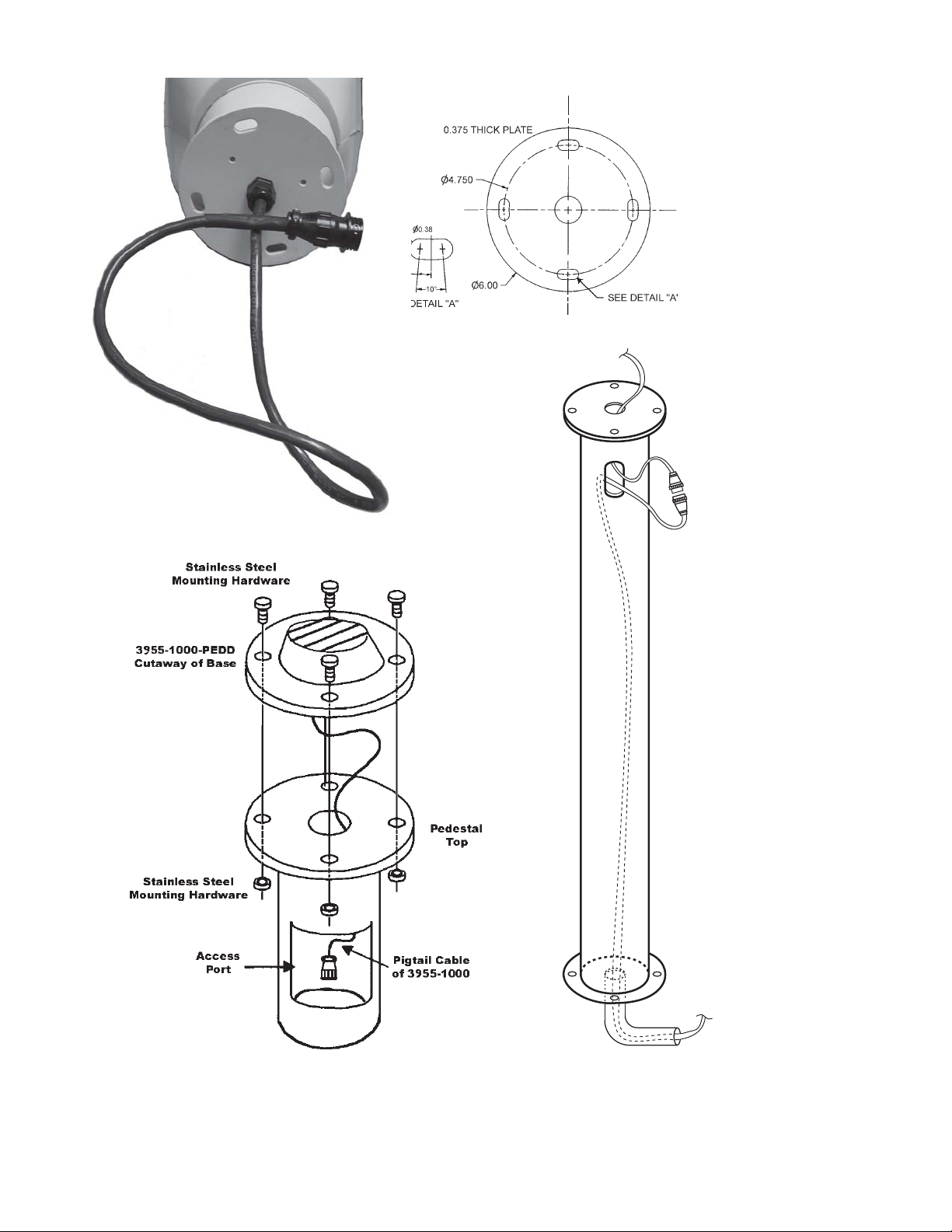

Positioner with 34-inch

“pigtail” and connector

INSTALLATION AND OPERATION

Positioner Small

Pedestal Baseplate

(PEDD) Dimensions

Base is permanently

attached to the iView

Dimensions of

Large Pedestal

Base (LPED) are

shown in fig. 4

TO

POSITIONER

CONNECT

AND

PLACE

INSIDE

THROUGH

CONDUIT

TO

CONTROL

EQUIPMENT

6X-1027a

CONDUIT

Figure 3. Typical Pedestal Mount Installation

7

INSTALLATION AND OPERATION

3950 iVIEW

Dimensions of Small Pedestal Base (PEDD) are shown in fig. 3

Figure 4. Dimensions, Large Pedestal Base (LPED)

2.3 EQUIPMENT SUPPLIED

Depending on the mounting configuration, several

variations of equipment can be supplied. See table 2

for a list of the basic differences between models as

related to mounting.

PEDD (Small Pedestal Base). See figure 3.

Pedestal mounting is the most basic of the three

mounting arrangements. Taller pedestals should

have an access plate near the top so that a strain

relief can secure the cable assembly in place. This

not only prevents the weight of the cable from pulling

on the connector but it is also a good general practice with all cable runs.

LPED (Large Pedestal Base) See figure 4.

The Large Pedestal Base option (figure 4) provides an 8.5-inch diameter base plate having two

four-hole patterns for mounting to various pole and

arm platforms currently installed at many locations.

One hole pattern is on a 7.00-inch diameter with

the four holes spaced 90 degrees apart.

8

Base is permanently attached to the iView

Farther out from that pattern is a 7.25-inch diameter pattern displaced by 22.720 degrees from the

first pattern. This pattern also consisting of four

holes spaced 90 degrees apart.

All eight of these mounting holes are of 0.380inch diameter. Up to 3/8-inch mounting hardware

can be used. Stainless steel hardware should be

used.

WALL (Wall Mount). See figure 5.

With a wall mount, the Pedestal bolts to the end of

an arm which is attached to a wall. Figure 6 gives

dimensions of the arm and adapter plate. This arm

is typically shipped with the adapter bracket attached. This wall must not only have four mounting

bolts but also a hole centered between these bolts

through which the cables must pass. A weather-tight

gasket should be used between the arm and wall.

Since the Positioner pigtail cable is about 34 inches

long it is likely that the connectors will be behind or

inside the wall or junction box in that area.

6X-1027a

Loading...

Loading...