COHU 3610 SERIES Technical Reference Manual

3610 SERIES

DSP COLOR CAMERA

TECHNICAL REFERENCE MANUAL

RS-232C SERIAL CONTROL

FCC

Figure 1. Machine Vision Color Camera

Technical Manual 6X-1042D

www.cohu-cameras.com/content/contactus

June 22, 2012

www.cohu-cameras.com

info@cohu.com

3610 CAMERA

TECHNICAL REFERENCE

Table of Contents

1.0 General Description 3

1.1 Electrical Characteristics 3

1.1.1 Sensor Characteristics 3

1.2 Mechanical Characteristics 3

2.0 Installation 6

2.2 Equipment Supplied 6

2.3 Equipment Required But Not Supplied 7

2.4 Cabling Requirements 7

2.5 Power Requirements 7

2.6 Sync Requirements 10

2.6.1 H And V Drive Characteristics 10

2.7 Mounting Requirements 10

2.8 Cs- And C-Mount Adapters 10

2.9 Serial Control Input (Rs-232C) 10

2.10 Installation Procedure 12

3.0 Operation 13

3.1. Dsp3600 Gui Home Screen 13

3.1.1 Gamma Control 13

3.1.2 Freeze Image 13

3.1.3 Back Light Compensation (Blc) 14

3.1.3.1 Off (Fixed Weighted Average) 18

3.1.3.2 Automatic Weighted Average 18

3.1.3.3 Brighten Dark Areas 18

3.1.3.4 Darken Bright Areas 18

3.1.4 Save Button 18

3.1.5 Eeprom Button 19

3.2 Lens/Aperture (Lens Dialog) Window 19

3.2.1 Lens Area 19

3.2.2 Aperture Area 19

3.3 Set AE Windows (Set Weight) Window 19

4.0 Static Discharge Protection 21

5.0 Unpacking And Receiving Inspection 22

6.0 Preparation For Shipment And Storage 25

7.0 Warranty 27

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This eqiupment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

CAUTION: Changes or modications to this device not

expressly approved by Cohu Electronics could void the

user’s authority to operate the device.

2

FCC STATEMENTS

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this

device must accept any interference received, including

interference that may cause undesired operation.

6X-1042D

TECHNICAL REFERENCE

3610 CAMERA

1.0 GENERAL DESCRIPTION

This introduction briey describes overall

characteristics of the Camera (gure 1) related to

its installation and operation.

1.1 Electrical Characteristics

The 3610 Series provides a small, lightweight, highly sensitive machine vision CCD

Camera with all electrical connections via a single

rear panel connector.

Setup and control settings are implemented

by a graphical user interface (GUI) communicating through an RS-232C serial interface with the

Camera.

The Camera operates in either NTSC or PAL

format depending on the model. This Camera operates at an internal clock rate of 28.63636 MHz

(NTSC) or 28.375 MHz (PAL). Table 1 lists specications for this 3610 Camera.

Table 2 is a list of major features of the Camera — primarily those associated with the GUI.

The Camera is available in two different

operating power congurations: 5 V dc and 12 V

dc. Only manual iris lenses can be used with the 5

V dc Camera. The 12 V dc Cameras are available

in three congurations: (1) an auto iris version

(2) a dc iris version or (3) a freeze frame version

— which requires the use of a manual iris lens.

Manual iris versions of the camera can be

optioned for horizontal and vertical drive inputs If

these inputs are not used the camera operates in

standard crystal sync reference mode.

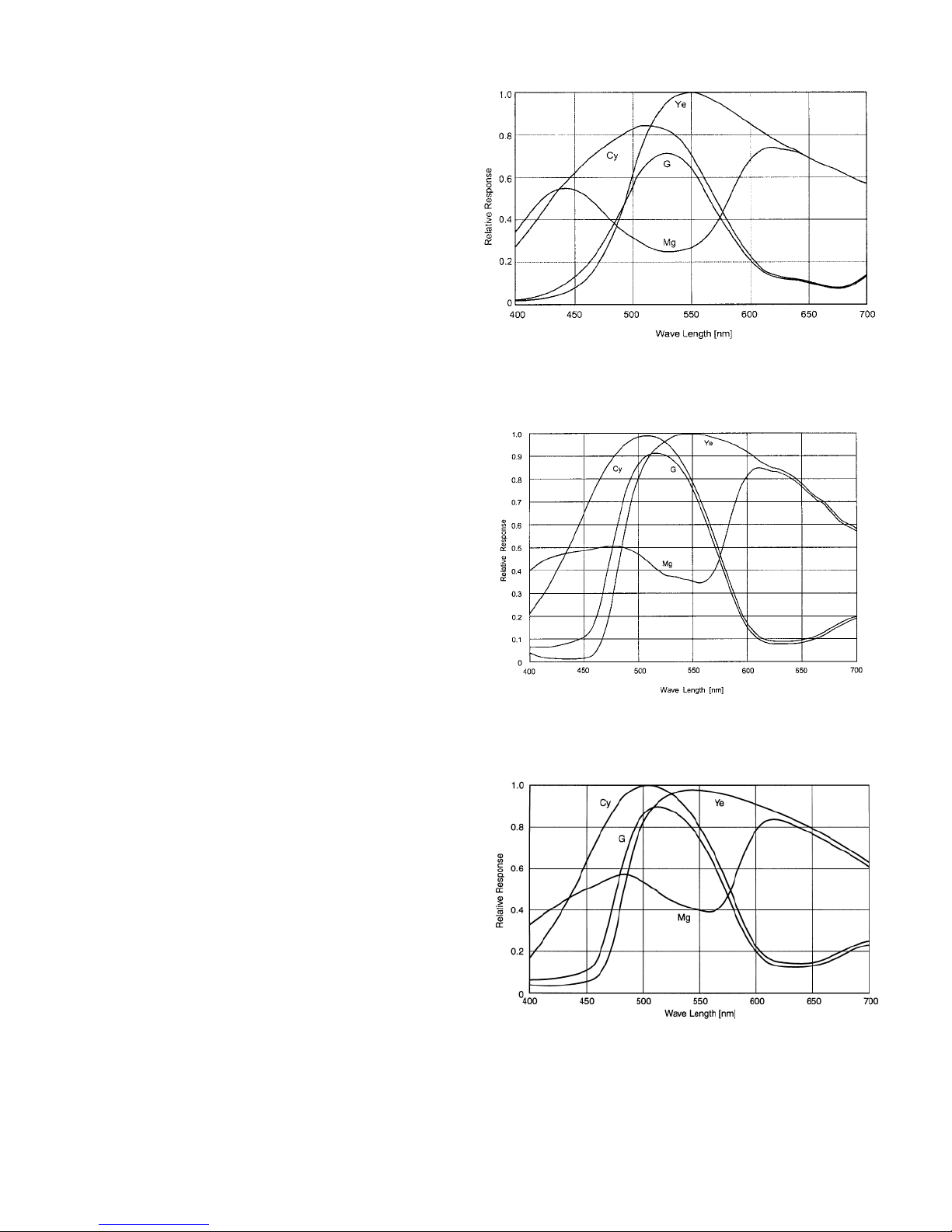

1.1.1 Sensor Characteristics

Figure 2 shows the relative response characteristic of the three sensor sizes available for this

camera. These characteristic curves apply to both

NTSC and PAL sensors. The curves show Cyan,

Green, Yellow and Magenta responses.

These graphs exclude both the lens characteristics and the light source characteristics.

Note however that the IR cut lter shown in

gure 3 will modify the overall response of the

Camera to light. This low pass lter starts block-

ing light above about 500 nanometers and at 600

nm passes only about 50 percent. Rolling off the

response at these longer wavelengths minimizes

the effect of infrared on the color response of the

Camera.

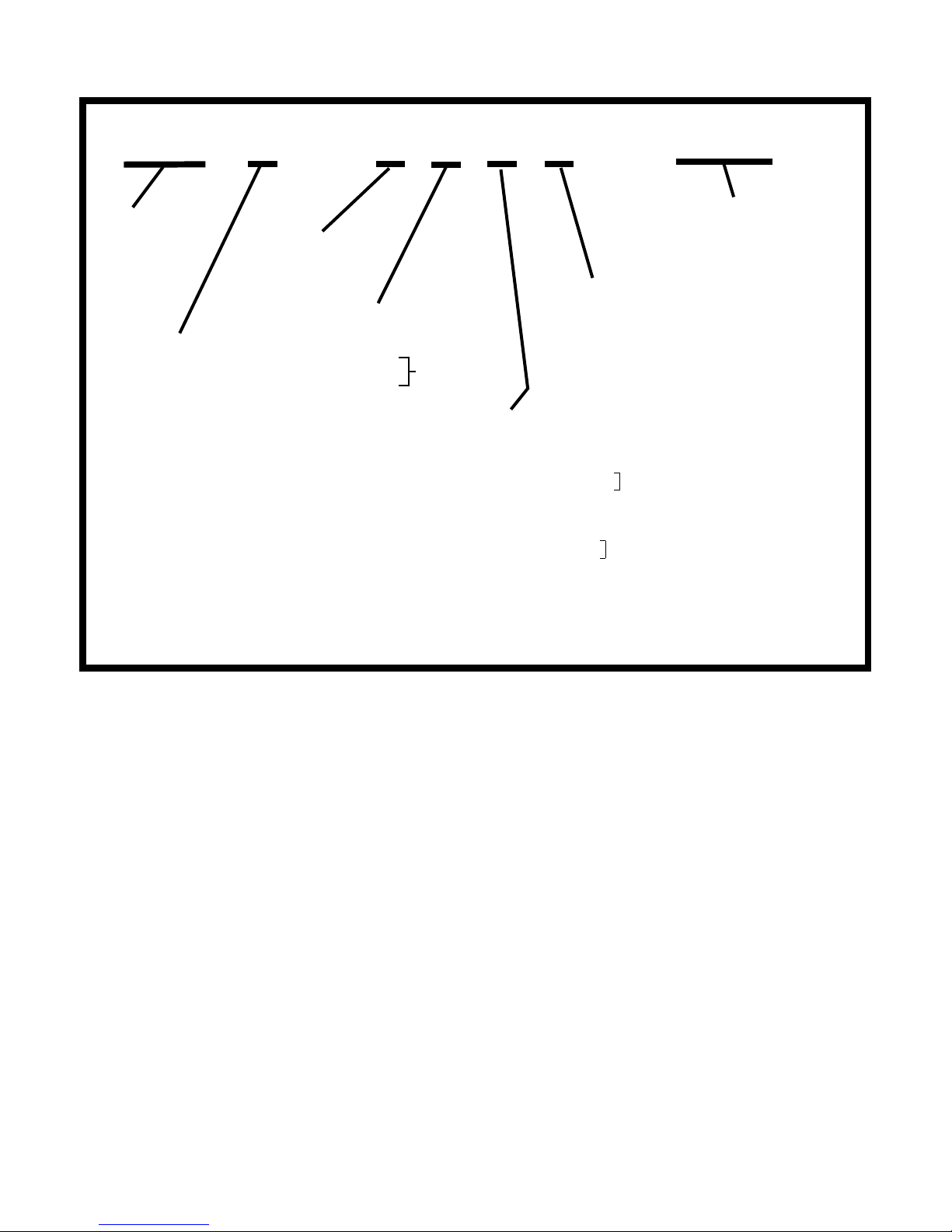

1.2 Mechanical Characteristics

A model number interpretation diagram ap-

pears in gure 4. This diagram shows the various

basic congurations of the Camera.

Dimensions for the Camera are shown in g-

ure 5. Figure 6 is a detailed dimensional illustration for the optional mounting block that provides

threaded 1/4-20 mounting holes. The Camera

consists of a main body casting and front casting

assembly.

Interconnections are via a 12-pin connector

located on the rear panel.

An adjustable CS-mount adapter threads

onto the front of the casting. It is secured from

turning by a nylon tipped hex-socket head setscrew.

The Camera can be mounted at any of three

places on its body:

1. By the CS mount directly to a microscope or

other similar device

2. By the top of the case — either with or without

the optional mounting block

3. By the bottom of the case — either with or

without the optional mounting block

Directly mounting to the top or bottom of the

housing requires removal of the two black button

head screws holding the outer housing cover in

place at that location (top or bottom). The optional Accessory Kit contains the mounting block

and a pair of 2-56 × 3/8 stainless steel screws to

attach it to the Camera.

If the Camera is to be mounted directly without use of the optional mounting block, a pair of

2-56 stainless steel screws of the required length

would have to be acquired. These are not supplied.

6X-1042D

3

3610 CAMERA

TECHNICAL REFERENCE

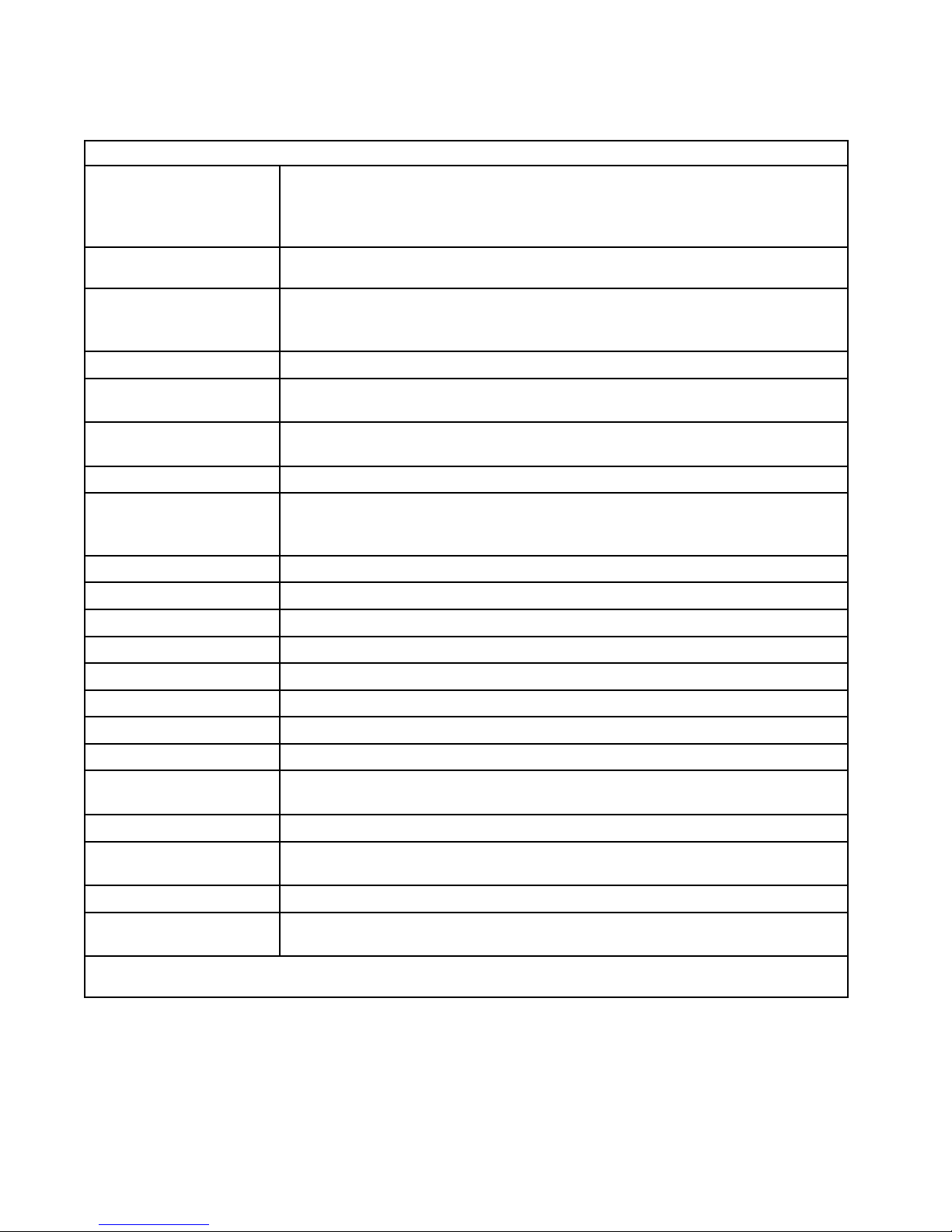

Table 1. Specications

ELECTRICAL

Interline transfer color CCD operating in eld mode

Format

Pixels 768 × 494 NTSC; 752 × 582 PAL

Pixel Cell Size

Resolution NTSC: 460 H × 350 TV lines; PAL: 450 X 415

Internal Clock

Sync

Frame Rate 30 fps (NTSC); 25 fps (PAL)

Sensitivity, Faceplate

White Balance Auto or manual white balance, 2500 to 9500 K

1/2 inch (6.45 × 4.84 mm)

1/3 inch (4.44 x 3.33 mm)

1/4 inch (3.33 × 2.5 mm)

1/2 inch: 8.40 (H) × 9.80 (V) µm NTSC ; 8.60 (H) × 8.30 (V) µm PAL

1/3 inch: 6.35 (H) × 7.40 (V) µm NTSC ; 6.50 (H) × 6.25 (V) µm PAL

1/4 inch: 4.75 (H) x 5.55 (V) µm NTSC ; 4.85 (H) x 4.65 (V) µm PAL

28.63636 MHz (NTSC)

28.375 MHz (PAL)

Internal crystal; or,

H & V drive, revert to crystal; (composite sync special order)

1/2 inch: 3 lux with full video, minimum gain

1/3 inch: 4 lux with full video, minimum gain

1/4 inch: 8.5 lux with full video, minimum gain

Gamma Choices of 10 gamma curves (8 power function, 2 linear)

Gain 0 to 32 dB gain control — either agc or menu selected manual adjustment

Shutter 1/60 (1/50 PAL) to 1/50,000 s, in nine steps (menu selected)

S/N 48 dB max; 22 dB S/N with 32 dB gain

Spectral Responses See gure 2

Integration 2 to 510 elds available using menu selection

Video Output Simultaneous composite and S-video (NTSC or PAL)

Lens Control

Serial Communications RS-232C, 19,200 baud (xed)

Power Input

Power Consumption 5 V: 2.5 W (500 mA) or 12 V: 4.2 W (350 mA)

Regulatory

5 volt camera: manual iris only

12 volt camera: manual iris, auto iris, or dc iris

5 V dc ±10 % or

12 V dc ±10 % (depending on model)

CE CISPRII class A plus EN61000-4 -3, EN61000-4 -6, EN61000-4 -8 interference immunity test

Continued on next page

4

6X-1042D

TECHNICAL REFERENCE

3610 CAMERA

Table 1. Specications (continued)

MECHANICAL

Dimensions 1 x 1 x 3 inch, less lens (see gure 5)

Weight 2.9 oz (82 g), less lens

Two 1/4-20 screws (accepts 0.200 deep screw) top or bottom mounting block,

Camera Mount

Lens Mount

Connectors Single 12-pin Hirose HR10A-10R-12PC

Temperature

Vibration, less lens Per MIL-STD-810(E), Method 514.4, categories 1, 4, 5, 8, 9, 10

Shock, less lens No damage to 30 g’s, 11 ms duration, no crash hazard to 75 g’s, 11 ms duration

or direct to top or bottom of camera body with two 2-56 inch screws,

or via CS mount direct to microscope or similar device

CS-mount, adjustable, or C-mount using 5 mm extension adapter

Lens can be moved up to 3-inch from main electronics

-20 to 70 °C operating

-30 to 85 °C non operating

end

6X-1042D

5

3610 CAMERA

2.0 INSTALLATION

In addition to the actual installation requirements, this section covers a number of other items

including proper shipping and handling of the

Camera.

2.2 Equipment Supplied

The equipment supplied depends on what

has been ordered. In its most basic form only the

following would be supplied (table 3):

TECHNICAL REFERENCE

1. The Camera itself (either NTSC or PAL version)

2. A CS-mount adapter, 0.335 width

3. Locking setscrew for adapter (4-40 x 5/32)

4. Graphical User Interface (GUI) available either

with the Camera on disk or downloaded from:

www.cohu-cameras.com/tech/tech.htm

The following items are provided if the option-

al accessory kit has been ordered (table 4):

1. Wrench, hex key (Allen) “L” type wrench, 1/16inch

2. 5 mm extender ring for use with C-mount

lenses

3. Mounting block (provides two 1/4-20 threaded

holes)

4. Screw, athead, 2-56 × 3/8 stainless (2 each)

1/4-inch Sensor

1/3-inch Sensor

5. Connector, plug, cable, 12-pin (mates with

rear panel connector)

The following items will also be supplied if

they were ordered:

1. Lens, for sensor imaging (for either 1/3-, 1/4-,

or 1/2-inch sensor), depending on version of

Camera

2. Power supply — depending on the version of

Camera:

6

1/2-inch Sensor

Figure 2. Sensor Response

Characteristics

6X-1042D

TECHNICAL REFERENCE

a. 5 V dc, 500 mA power supply (Cohu type

8470-5) or

b. 12 V dc, 350 mA power supply (Cohu type

8368-4)

Note that special-order Cameras and Camer-

as modied for special purposes may be shipped

with other items. The above listing are the basic

items for typical applications.

Table 3 lists the basic items supplied with a

Camera. Table 4 lists items supplied in an optional

accessory kit.

2.3 Equipment Required but Not

Supplied

If the following items were not ordered with

the Camera these will be required to make it operational:

3610 CAMERA

Figure 3. IR Cut Filter Response

Characteristics

1. CS- or C-mount lens suitable for the sensor

format/size in Camera

2. Power supply, 5 V dc, 500 mA output or 12 V

dc, 350 mA

3. Cable. Refer to one of these test cables as an

example for the construction of an interconnection cable to be used with the Camera:

a. See gure 8 for use with a 5 V dc (manual

iris) versions of Camera. This cable shows

connections for the H and V drive option.

b. See gure 9 for use with auto iris or dc

iris version of Camera (12 V dc operating

power).

c. See gure 10 for use with a 12 V dc Cam-

era optioned for freeze frame operation.

(Requires use of a manual iris lens.) This

cable shows connections for the H and V

drive option.

4. 1/4-20 mounting bolt(s) of the proper length if

the mounting block is to be used.

2.4 Cabling Requirements

A single 12-pin connector (gure 7) on the

rear panel provides all electrical connections to

the Camera. Table 6 lists the mating cable plug for

this rear panel connector. Use this plug to construct the cable for operating the camera.

Several test cables are shown in this manual.

They can be used as an example for wiring the

operating cable for a Camera.

Figure 8 shows the wiring arrangement for a

5 V dc (manual iris only) version of the Camera.

This cable provides for all operating capabilities of

a 5 V dc Camera.

A 12 V dc version of the Camera may require

a cable wired to either of two congurations. One

is for use when the Camera is internally cong-

ured for use with either an auto iris lens or a dc iris

lens. The other is for use when a 12 V dc Camera

is internally congured for freeze frame operation,

and/or external horizontal/vertical drive options.

1. Figure 9 shows the cable for use when a 12

V dc version of the Camera is congured for

either an auto iris lens or a dc iris lens.

2. Figure 10 shows cable wiring for use when

a 12 V dc Camera is internally congured for

either freeze frame operation or H and V drive.

Only a manual iris lens can be used when the

Camera is congured for either freeze frame

operation or H and V drive.

6X-1042D

7

3610 CAMERA

TECHNICAL REFERENCE

361 x — x x x x — ××××

SERIES

CCD

CAMERA

1 Internal crystal

2 H&V drive

POWER

1 5 V dc Power

2 12 V dc Power

* Revert to crystal 12 V dc Camera only

** Trigger designates the freeze frame mode

discussed in this manual

NOTE: Composite sync input is a special

order feature. It does not appear in this

model index diagram.

SYNC

*

IRIS

0 Manual Iris & Trigger

1 Auto Iris

4 Dc Iris

ACCESORIES

0 None

1 Test cable

2 Accessory kit

3 Test cable & accessory kit

12 Vdc

cameras

only

*

*

SENSOR

2 1/2-inch NTSC, S-video

3 1/3-inch NTSC, S-video

4 1/4-inch NTSC, S-video

5 1/2-inch PAL, S-video

6 1/3-inch PAL, S-video

7 1/4-inch PAL, S-video

12 V dc Camera only

12 V dc Camera only

LENS

0000 None

(Manual iris,

auto iris &

dc iris lenses

available)

This is a model number interpretation diagram. It should be used only for determining

the features of an existing model number — such as that labeled on a Camera.

Figure 4. Model Number Interpretation Diagram

Note that the pins 5, 6, 7, & 12 for a 12 V

dc Camera can be internally wired for any one of

three functions.

1. Auto iris lens

2. Dc iris lens

3. Freeze frame operation together with

H and V drive

The model number designates these differences for 12 V dc Cameras. See the

of gure 4.

IRIS section

2.5 Power Requirements

The Camera is available in two different

power congurations:

1. 5 V dc ±10% 500 mA (2.5 watt) power

2. 12 V dc ±10%, 350 mA (4.2 watt). Auto iris and

dc iris versions of the Camera are available

only in the 12 V dc version

8

6X-1042D

TECHNICAL REFERENCE

*

Optical path includes 0.031 (0.8) thick BK-7 flat glass and 0.213 (5.4) thick multilayer

quartz optical low-pass filter. Actual image plane is 0.81 (2.1) behind effective image plane.

3610 CAMERA

Locking Setscrew

(Nominal Position)

O

1.00

(25.40)

1.00

(25.40)

Adjustable CS-mount

Optical and Mechanical

Centerlines Same

Dimensions in inch and (mm)

(2 place)

Use 2-56 x 3/8 flathead stainless steel screw

Optional Mounting Block

1.125

(28.57)

0.335

(8.51)

Nominal

0.3175 (8.064)

0.492

(12.5)

0.55

(14)

Effective Image Plane

3.00 (76.2)

2.635

(66.93)

1.500 (38.10)

*

Mounting block

can fasten

top or bottom

0.50 (12.7)

1/4-20

(2 Place)

(0.20 max depth)

0.20

(5.1)

Figure 5. Dimensions, Model 3610 Camera

Figure 6. Dimensions, Optional Mounting Block

6X-1042D

9

Loading...

Loading...