COHU 3220 Series Installation Manual

3220 SERIES ANALOG

ENVIRONMENTAL CAMERA

INSTALLATION MANUAL

RS-232

RS-422

Technical Manual 6X-1082a

Figure 1. Model 3220 NTSC or PAL Camera

March 25, 2008

3220 CAMERA

INST

CAUTION

Do not power the 24 V ac version of

this camera directly from a Variac. It

will blow up the power supply.

ALLA

TION MANUAL

2

Figure 2. Camera Version with Pigtail Cable

(Model 3221 or Model 3223)

Also available without factory wired pigtail cable to allow for direct

connections to internal terminals

(Model 3222 or Model 3224)

Two other manuals related to this camera are available:

1. Manual 6X-1084. The setup GUI - for conguring camera

characteristics

2. Manual 6X-1085. The protocol - for use by programmers to

write software for controlling camera functions

6X-1082a

INSTALLATION MANUAL

1.0 GENERAL DESCRIPTION

This introduction briey describes the overall

characteristics of the Model 3220 Camera (gure

1) related to its installation. Complete specications

can be found on the CD supplied with this camera.

Electrical Characteristics

1.1

The 3220 provides a highly sensitive CCD

camera in an environmental housing.

The 3220 is available with either NTSC or PAL

video output, depending on the model. Operating

power is either 12 V dc or 24 V dc/ac — again de-

pending on the model.

It has an integrated camera module with 3.3

mm to 99 mm zoom lens.

Data communications with the camera can be

either RS-232 or RS-422 for control of DSP func-

tions.

It has a day/night feature that increases sensi-

tivity by reverting from color to monochrome output

in low light conditions. This feature can be made to

operate automatically or by manual control when

desired.

A model number interpretation diagram ap-

pears in gure 4. That diagram shows the various

basic congurations of the 3220.

1.1.1 Initial Setup Software

3220 CAMERA

Figure 3. Camera Front View

An integral sun shield over the camera module

housing minimizes heat build up that could result

from direct sun light on the camera module housing.

The mounting base (gure 5) for the 3220 has

a two-hole pattern on a sliding “T” slot type bar for

attachment to a suitable base.

A 3220 can be mounted on any one of ve me-

chanical congurations. The model number denes

the mounting equipment supplied as part of the

3220. Table 1 lists the mounting items supplied for

each of the mounting congurations available with a

3220.

Graphical User Interface (GUI) software is

available for setting the address and performing

eld tests and setups for each camera. This is

included on a CD provided with the camera. The

reference manual for this GUI is technical manual

6X-1084 which is also included on the CD.

1.1.2 Camera Firmware Protocol

The protocol for a programmer to develop

software for controlling the camera is available on

the CD provided with the camera. Refer to technical

manual 6X-1085.

Mechanical Characteristics

1.2

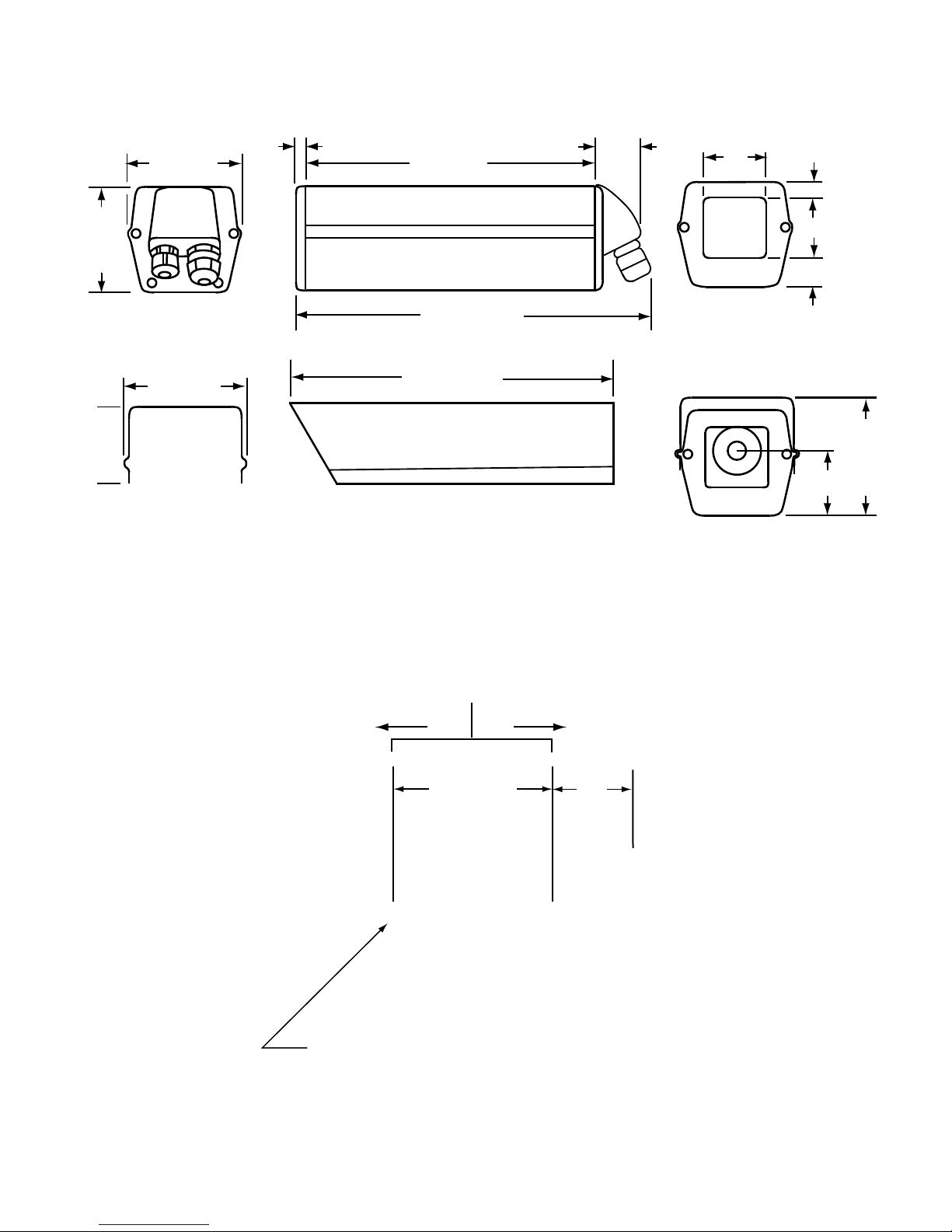

Dimensions are shown in gure 5. The 3220

consists of an IP66 environmentally sealed camera

module. This housing is not pressurized with an

inert gas such as dry nitrogen.

6X-1082a

2.0

INSTALLATION

This section covers the general requirements

of installing the 3220 including cabling and power

requirements. In addition to the actual installa-

tion requirements, this section covers a number of

other items including static discharge protection and

proper shipping and handling of the 3220.

Unpacking and Receiving Inspection

2.1

This item was thoroughly tested and carefully

packed in the factory. Upon acceptance by the car-

rier, they assume responsibility for its safe arrival.

Should you receive this item in a damaged condi-

tion, apparent or concealed, a claim for damage

must be made to the carrier.

If a visual inspection shows damage upon

receipt of this shipment, it must be noted on the

3

3220 CAMERA

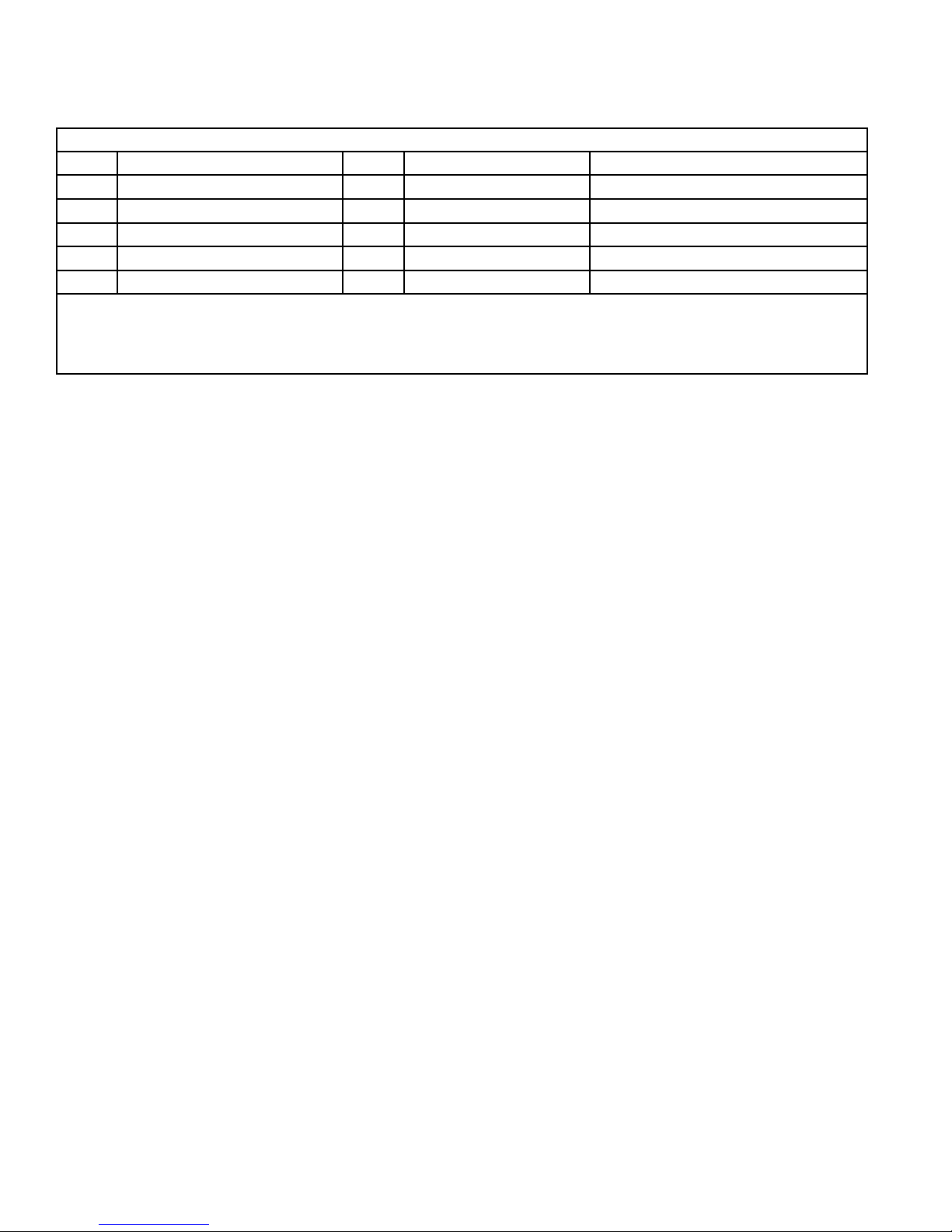

SERIES

POWER

Camera in IP66 Rated

Unpressurized

Housing

1 12 V dc with interface cable

2 12 V dc

3 24 V ac/dc with interface cable

4 24 V ac/dc

MOUNT

3 NTSC

7 PAL

Not

Assigned

WALL (Wall Mount)

PEDD (Pedestal Mount)

CEIL Ceiling Mount)

POLE (Pole Mount)

HDWM (Heavy Duty Wall Mount)

VIDEO

FORMAT

**

**

*

*

*

***

***

322 x—x000 xxxx

WALL (Wall Mount) is included

with all models

Wired to environmental connector on a pigtail

An HDWM (Heavy Duty Wall Mount) is included

with the POLE mount configuration

INST

ALLA

TION MANUAL

Figure 4. Model Number Interpretation Diagram

freight bill or express receipt and the notation signed

by the carrier’s agent. Failure to do this can result in

the carrier refusing to honor the claim.

When the damage is not apparent until the unit

is unpacked, a claim for concealed damage must be

made. Make a mail or phone request to the carrier

for inspection immediately upon discovery of the

concealed damage. Keep all cartons and packing

materials.

Since shipping damage is the carrier’s respon-

sibility, the carrier will furnish you with an inspection

report and the necessary forms for ling the con-

cealed-damage claim.

please contact the Customer Service Department

for a Return Authorization (RA) Number.

2.2

handled, the following precautions should be fol-

lowed:

To return the product to the factory for service,

Static Discharge Protection

In the event that a disassembled 3220 is being

4

ment, especially solid state devices, are susceptible

to damage from static discharge. The relative sus-

ceptibility to damage for semiconductors varies from

low with TTL to high with CMOS. Most other semiconductors fall between TTL and CMOS in suscep-

tibility to static discharge. As a minimum, therefore,

observe the following practices when working inside

this or any other electronic equipment:

CAUTION

This 3220 contains sensitive devices that can be

damaged by static discharge. Use appropriate static

control methods when working inside the 3220.

Components used in modern electronic equip-

1. Use conductive sheet stock on the work bench

surface.

2. Connect the sheet stock to ground through a 1

megohm or greater value resistor.

3. Use a wrist strap connected to ground through a

1 megohm or greater value resistor when working at

the bench.

6X-1082a

INSTALLATION MANUAL

MOUNT

DESIGNATION

MOUNT

DESCRIPTION

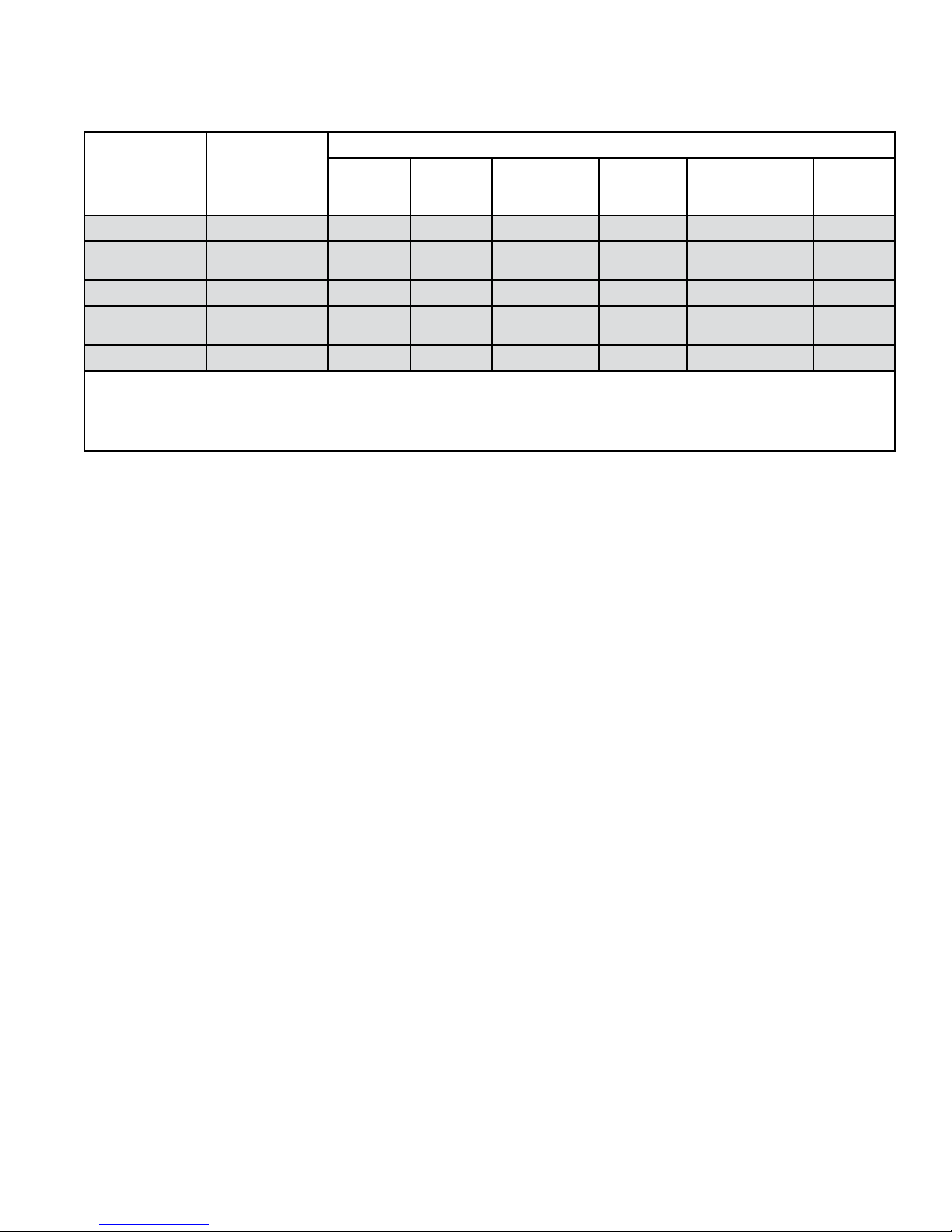

Table 1. Mounting Congurations

ITEMS SUPPLIED

3220

CAMERA

WALL

MOUNT

PEDESTAL

MOUNT

CEILING

MOUNT

3220 CAMERA

HEAVY DUTY

WALL MOUNT

POLE

MOUNT

WALL

PEDD

CEIL

HDWM

POLE

Note: Read the table horizontally. A dot “•” designates an item supplied for each mounting conguration. As an example,

for the CEIL (Ceiling Mount) three items are supplied: a 3220 camera , a wall mount, and a ceiling mount.. Notice in

the Wall Mount column that it is always supplied with a camera. It is required only for a WALL mount installation, but

can be used if desired as an alternate mounting method if the need arises.

4. Maintain relative humidity of the room above 30

percent. This may require a room humidier. Working

on circuits with relative humidity below 30 percent

requires extraordinary procedures not listed here.

5. Use antistatic bags to store and transport an ex-

posed chassis, circuit boards, and components. Use

new antistatic bags. Old, used bags lose their static

protection properties.

Wall Mount

Pedestal

Mount

Ceiling Mount

Heavy Duty

Wall Mount

Pole Mount

• •

• • •

• • •

• • •

• • • •

mating connector is supplied for the system inter-

connection cable. These are 18-pin MS type metal

connectors. Figure 29 shows this connector kit.

Two hex (Allen) wrenches are also supplied

with the camera. One is for removing housing

screws to gain access to the interior of the camera

and the other hex wrench is for the ball head adjust-

ment on the basic WALL mount.

This list serves as a reminder of the mini-

mum acceptable practices. Be sure that all static

discharge devices at the work bench are properly

installed and maintained. Standard grounding mats

and wrist straps purchased for use at work benches

are supplied with leads having current limiting resis-

tors for safety. Never substitute with a grounding

lead not having the resistor.

Equipment Supplied

2.3

The basic conguration consists of the camera

and a wall mount arm. The housing is tted with an

integral sun shield assembly that covers the camera

module housing. This sun shield minimizes heat

buildup inside the camera by shielding it from the

direct rays of the sun.

If either a model 3221 or model 3223 has been

supplied (9-inch pigtail cable attached to camera) a

2.3.1

Mounting Hardware Supplied

Several assortment of nuts, bolts, at washers,

and locking washers may be provided depending on

which mounting conguration has been selected.

1. The standard wall (WALL) mount supplied with all

cameras is shipped with a 1/4-20 x 1/2 inch bolt and

a locking washer.

2. Pedestal, ceiling, heavy duty wall mounts, and

pole mounts are shipped with hardware kit 84988 — which supplies various bolts and washers to

choose from when attaching a camera to the mount

being used.

The pole mount is also shipped with an ad-

ditional hardware kit for attaching the clamp to the

pole and for attaching the heavy duty wall mount to

the clamp. See gure 26.

6X-1082a

5

3220 CAMERA

Table 2. Mounting Hardware Kit 8498-8

ITEM DESCRIPTION QTY PART NUMBER WHERE USED

1 1/4-20 x 1/2 Hex Head Screw 2 2010730-006 Pedestal Mount

2 1/4-20 x 5/8 Hex Head Screw 2 2010730-005 Ceiling Mount

3 1/4 Spring Lock Washer 2 2010732-002 Pedestal Mount; Ceiling Mount

4 1/4 Flat Washer 2 2010731-002 Pedestal Mount; Ceiling Mount

5 1/4-20 x 1/2 Flat Head Screw 2 0310010-091 Heavy Duty Wall Mount

Notes: All dimensions in inches. This kit provides the hardware necessary to attach a 3220 series camera to a

Heavy Duty Wall Mount, a Ceiling Mount, or a Pedestal Mount. This hardware must be used in place of the metric

hardware included with these mounts. (The two athead screws in item 5 are required for the Pole mount option,

too, since it uses the Heavy Duty Wall Mount as part of its assembly.)

2.5

2.3.1 Mounting Hardware Not Supplied

No hardware is supplied for securing a wall,

ceiling, or pedestal mount to their mounting surface.

However, the pole mount does not require any

additional hardware to mount it to a pole. It can be

clamped to a pole with two threaded rods that are

supplied in its hardware kit.

Two versions of the camera have slightly dif-

ferent cabling requirements. With one version the

system interconnection cable plugs into a camera

connector. With the second version the system interconnection cable must be directly wired to inter-

nal terminals inside the camera.

INST

Cabling Requirements

ALLA

TION MANUAL

Equipment Required but Not Supplied

2.4

As a minimum the 3220 requires a source of

operating power, a monitor on which to view the

scene, an interconnection cable, and a computer

running Graphical User Interface (GUI) software for

control of the 3220 if this is desired.

During maintenance and setup operations us-

ing either a laptop or desktop PC it is likely that a

USB to RS-232 converter will be required.

Typically PC’s have had only an RS-232 port

— and rarely an RS-422 port.

However, newer PC’s and laptops no longer

have an RS-232 port and instead rely on USB and

other newer type ports.

With these computers, a USB to RS-232 con-

verter will be required. Be aware that some of these

converters do not provide reliable RS-232 com-

munications If problems are experienced determine

whether it is the converter.

If it is desired to use the RS-422 feature of the

camera it will then be necessary to add an RS-232

to RS-422 converter.

Or a USB to RS-422 converter could be used

directly but these are not common devices.

2.5.1 Model 3221 and 3223 Cameras

For the model 3221 and model 3223 versions

of the camera, system interconnections are made

to the connector on a permanently attached 9-inch

“pigtail” cable. A connector (gure 29) is provided to

mate with this pigtail connector.

Figure 6 through gure 15 show typical cables

available for use with the pigtail connector.

2.5.2 Model 3222 and 3224 Cameras

For the model 3222 and model 3224 versions

of the camera, system interconnections are made

directly to terminals inside the camera (gure 16

and gure 17).

2.5.3 Customer Supplied Cable

A high quality multiconductor shielded cable

must be used with this camera both to minimize EMI

radiation and to reduce susceptibility to interference.

The cable must have an overall shield with at

least 95 percent coverage.

Data wiring must be twisted pairs similar to that

used in CAT-5e cable. A data ground wire must be

used.

6

6X-1082a

INSTALLATION MANUAL

3.66 (93)

2.44 (62)

3.66 (93)

3.27 (83)

3.46 (88)

8.15 (255)

6.3 (160)

1.42

(36)

0.43

(11)

10.0 (254)

1.87

(47.5)

0.87 (22)

1.87 (47.5)

0.53 (13.5)

1.90

(48)

Dimensions in inches and (mm)

Sunshield

(installed on camera)

Sunshield

Sunshield

L

C

See photo below for bottom mounting dimensions

2.75 (69.8)

1/4-20

(Typical two places)

Note: 1/4-20 bolts must not protrude more that

5/16 inch past bottom of camera

1.50

(38.1)

0.63 (16)

0.63 (16)

Note: Mounting bracket slides 0.63 inches

right or left from centered position shown

3220 CAMERA

Figure 5. Dimensions, Model 3220 Series Cameras

6X-1082a

7

3220 CAMERA

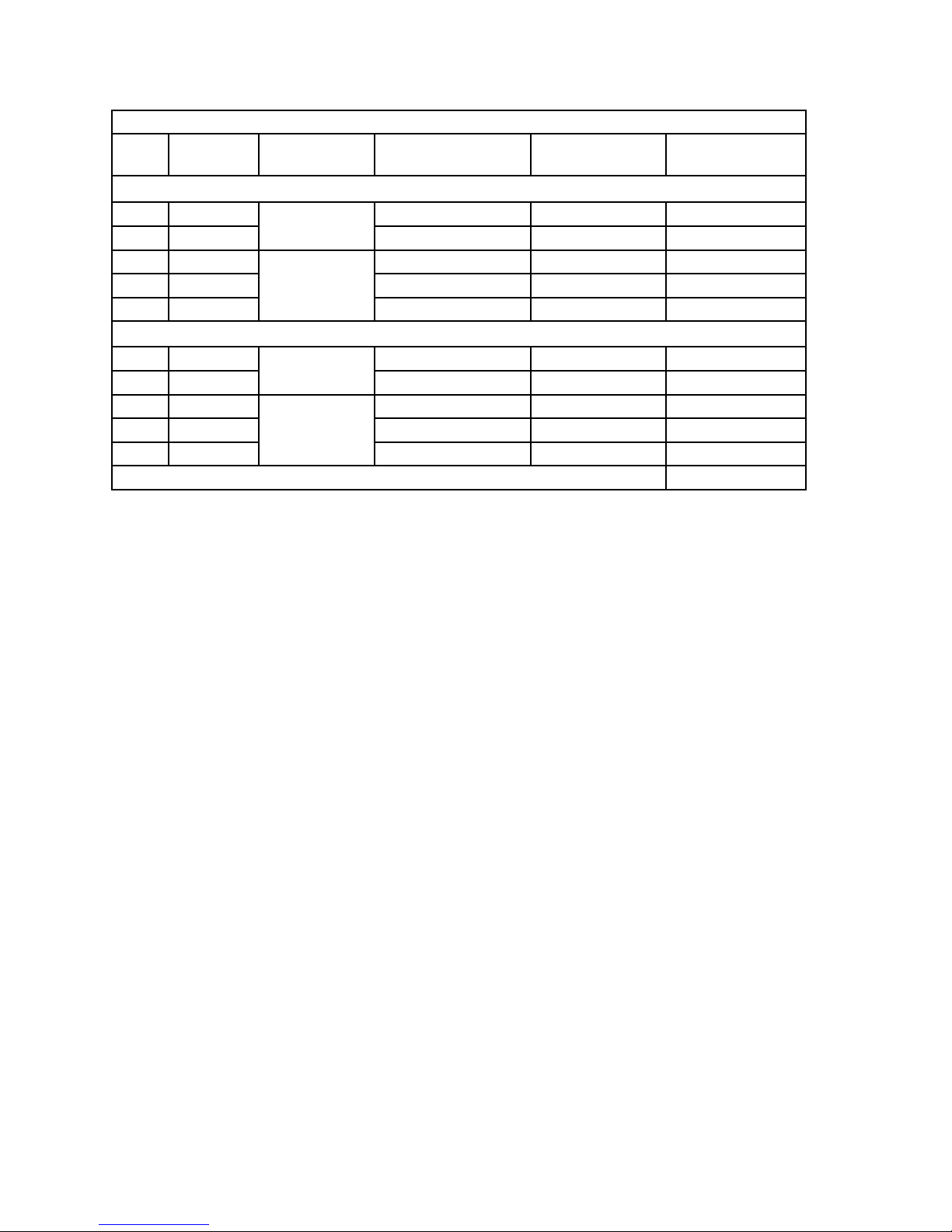

ITEM CABLE

1

2 CA-253B BNC stripped leads D9 female

3 CA-254A

4 CA-254B BNC stripped leads 232/422 converter

5 CA-254M BNC stripped leads RJ-45

6 CA-292A

7 CA-292B BNC stripped leads D9 female

8 CA-293A

9 CA-293B BNC stripped leads 232/422 converter

10 CA-293M BNC stripped leads RJ-45

CA-253A

INST

Table 3. System Interconnection Cable Characteristics

TYPE

DATA

TYPE

VIDEO

CONNECTION

POWER

CONNECTION

12 V dc

RS-232

RS-422

stripped leads stripped leads stripped leads

stripped leads stripped leads stripped leads

24 V ac / 24 V dc

RS-232

RS-422

stripped leads stripped leads stripped leads

stripped leads stripped leads stripped leads

ALLA

TION MANUAL

DATA

CONNECTION

Coaxial cable must be 75 ohm RG-59/U and

not have any type of iron conductors. Belden 8241F

is a typical good coax.

Power wiring must be of sufcient size to main-

tain proper operating voltage at the camera. Power

wires can be paralleled to reduce voltage drop.

2.5.2 Pigtail Connector Pinout

Table 5 lists pin functions on the pigtail connec-

tor for various versions of the model 3221 and 3223

cameras.

2.5.3 System Interconnection Cables

Eight system interconnection cables are available for use with the model 3221 and 3223 cam-

eras.

Table 3 lists these cables and describes their

characteristics.

The major breakdown between cables types is

whether they are for 12 or 24 volt cameras.

Each of these two groups is then further sub-

divided into whether a camera is to use RS-232 or

RS-422 communications.

The nal determination is whether the cable

should have stripped leads for all the eld instal-

lation connections or whether certain connectors

and/or data converters should be provided with the

cable.

2.6

Power Requirements

Two versions of the 3220 are available in rela-

tion to power input requirements:

1. The model 3221 and model 3222 operate from 12

V dc +/- 10 percent;

2. The model 3223 and model 3224 operate from

either 24 V ac or 24 V dc +/- 10%.

Power consumption is less than 4 watts when

the internal heater is off and less than 20 watts

when the thermostat turns the heater on.

CAUTION

Do not power the 24 V ac version of

this camera directly from a Variac. It

will blow up the power supply.

8

6X-1082a

Loading...

Loading...