Page 1

Advantage RFID

Thermal Printer HF

(13.56 Mhz)

User Guide

105-132-01 Rev A

*105-132-01*

Page 2

Copyright © 2004, Cognitive.

Cognitive™ and Advantage™ are trademarks of Cognitive. Microsoft

®

and Windows™ are

trademarks of Microsoft Corporation. Other product and corporate names used in this

document may be trademarks or registered trademarks of other companies, and are used only

for explanation and to their owner’s benefit, without intent to infringe.

All information in this document is subject to change without notice, and does not represent a

commitment on the part of Cognitive. No part of this document may be reproduced for any

reason or in any form, including electronic storage and retrieval, without the express

permission of Cognitive. All program listings in this document are copyrighted and are the

property of Cognitive and are provided without warranty.

To contact Cognitive:

Cognitive Solutions, Inc.

4403 Table Mountain Drive

Suite A

Golden, CO 80403

E-Mail: info@cognitive.com

Telephone: +1.800.525.2785

Fax: +1.303.273.1414

Page 3

Table of Contents

RFID and the Advantage RFID Thermal Printer..................................... 1

What is RFID?..................................................................................... 1

Active Versus Passive RFID Tags....................................................... 2

RFID Frequencies ............................................................................... 3

Uses for HF RFID................................................................................ 3

RFID Standards................................................................................... 3

Drivers and Label Software..................................................................... 4

Installing Printer Drivers from the Companion CD............................... 4

Setup......................................................................................................... 7

Printer Requirements .......................................................................... 7

Communications ........................................................................... 7

Power (US) ................................................................................... 7

Environment.................................................................................. 7

Controls, Indicators, and Connectors .................................................. 8

Connecting Power and Cables............................................................ 9

Releasing the Print Mechanism......................................................... 10

Loading a Ribbon (Thermal Transfer Only) ....................................... 11

Loading Print Media .......................................................................... 13

Performing the Self Test.................................................................... 15

Printing Standard Labels and Tags...................................................... 18

Using Label Software ........................................................................ 18

Using CPL Programming................................................................... 18

Creating a Text File..................................................................... 19

Sample Label.............................................................................. 22

Using Third-Party and Proprietary Applications................................. 22

Printing from Microsoft Word ...................................................... 22

Printing from Proprietary Applications......................................... 27

Page 4

Printing RFID Tags ................................................................................ 28

RFID Tag Overview........................................................................... 28

Using Label Software ........................................................................ 30

Using CPL Programming................................................................... 30

Creating a Text File..................................................................... 30

Stored Formats ........................................................................... 32

Sample RFID Tag ....................................................................... 34

Using Third-Party and Proprietary Applications................................. 34

Maintenance and Calibration ................................................................ 35

Maintenance...................................................................................... 35

Calibration ......................................................................................... 36

Programming ......................................................................................... 37

Programming Overview..................................................................... 37

Programming Rules .................................................................... 38

RFID Command Name Structure................................................ 38

RFID Command Structure Example............................................ 39

RFID Commands............................................................................... 40

RF ID_GET ................................................................................. 41

RF HOST .................................................................................... 42

RF VAR_CLEAR......................................................................... 43

RT ............................................................................................... 44

WT .............................................................................................. 45

WTLOCK .................................................................................... 46

RF_TYPE.................................................................................... 48

RF_IDNUM ................................................................................. 49

RF_BLKSZ.................................................................................. 50

RF LOCATION............................................................................ 51

!RFID ? ....................................................................................... 52

!RFID CONFIRM......................................................................... 53

!RFID HOST ............................................................................... 54

!RFID LEDFLSH ......................................................................... 55

!RFID LEDTIME.......................................................................... 56

!RFID MARK ............................................................................... 57

Page 5

!RFID RDAFTWT ........................................................................ 58

!RFID RETRY ............................................................................. 59

!RFID SSONCMD ....................................................................... 60

!RFID TAGTYPE......................................................................... 61

!RFID TIMEOUT ......................................................................... 62

!RFID TXAFTER ......................................................................... 64

!RFID VOID................................................................................. 65

Troubleshooting .................................................................................... 66

Isolating Problems............................................................................. 66

Run a Printer Self Test................................................................ 66

Print a Proven Label Format ....................................................... 66

Print a Label Format Written on Your System............................. 66

Check the Label Format Header Line ......................................... 67

Comment Out Portions of the Nonworking Label Format............ 67

Common Issues ................................................................................ 67

Labels Skipping or Printer Feeding Blank Labels ....................... 67

READY Light is Red.................................................................... 68

Setting Up an Ethernet Printer .................................................... 68

Printer Drivers............................................................................. 69

Serial Communication................................................................. 69

Parallel Communication .............................................................. 69

Printing Too Light........................................................................ 69

Upgrade From Blazer Printer ...................................................... 70

Technical Support Contact Information ............................................. 71

Appendix A – Specifications................................................................. 72

Appendix B – Certified RFID Tags........................................................ 73

Page 6

Chapter

1

RFID and the Advantage RFID Thermal Printer

Cognitive’s Advantage barcode label printers provide an integrated

solution for traditional barcode labeling and writing a radio frequency

identification (RFID) tag. Using an RFID label, the printer can

simultaneously write RFID data and print a barcode label. The printer

will also perform either operation independently. The Advantage prints

both thermal and thermal transfer labels and tags in a host and

network system or in a standalone keyboard or scanner input device

system.

Today’s businesses face increasing pressure to provide goods and

services quickly, accurately, and at the lowest possible cost. From the

component level, through manufacturing, throughout the supply chain,

and onto the shelves, managers attempt to control loss, shortage,

spoilage, and other factors that impact profitability. RFID is a

technology that allows real-time tracking and inventory control.

What is RFID?

Simply put, RFID is a method of remotely storing and retrieving

information using devices called RFID tags. An RFID tag is a small

object, such as an adhesive sticker, that can be attached to or

incorporated into a product. The stored information may consist of a

serial number or other data that identifies a person or object.

Copyright © 2004, Cognitive. 1

Page 7

RFID AND THE ADVANTAGE RFID PRINTER

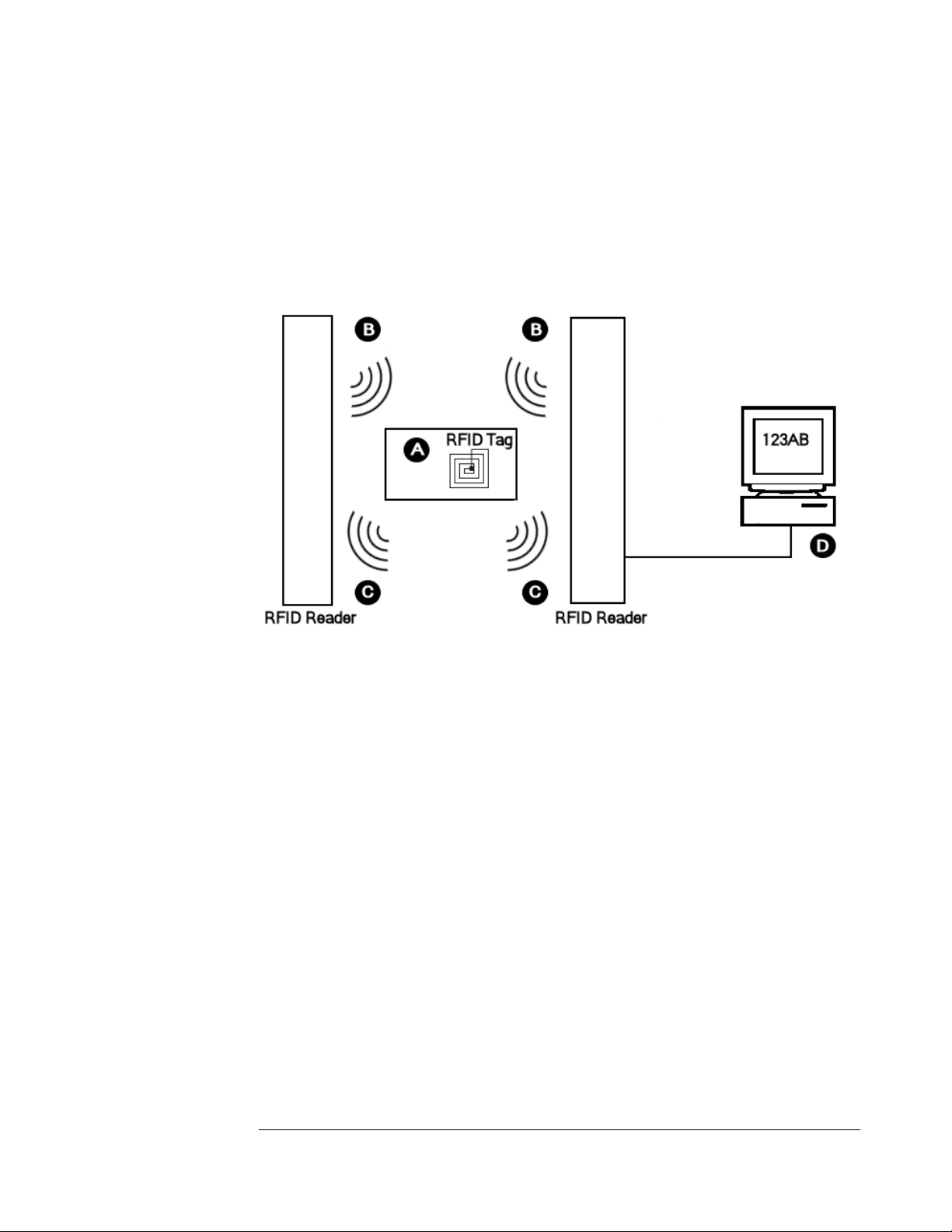

Refer to Figure 1-1, RFID Overview. The RFID tag contains an antenna

(A) that allows the tag to receive and respond to radio-frequency queries

from an RFID reader. The reader transmits radio waves (B). The radio

waves are reflected back from the RFID tag (C) and converted into

digital information. This information is then passed on to computers (D)

that can make use of the data.

Figure 1-1. RFID Overview

Active Versus Passive RFID Tags

RFID tags can be either active or passive.

Passive RFID tags do not have their own power supply. A small

electrical current is induced in the antenna by the RFID reader. This

provides enough power for the tag to send a response. The device,

lacking a power supply, is quite small. The smallest such devices

commercially available measure 0.4 mm × 0.4 mm, and are thinner

than a sheet of paper. Passive tags have practical read ranges that vary

from about 10 mm up to about 5 meters.

Active RFID tags have a power source, and can have longer ranges and

larger memories than passive tags. Active tags also often have the

ability to store additional information sent by the transceiver. Presently,

the smallest active tags are about the size of a coin. Many active tags

have practical ranges of tens of meters, and a battery life of up to

several years.

Copyright © 2004, Cognitive. 2

Page 8

RFID AND THE ADVANTAGE RFID PRINTER

RFID Frequencies

RFID tags operate at a specific frequency and both the reader and the

tag must be tuned to the same frequency to transfer information. The

Advantage RFID Thermal Printer is designed for RFID tags that

operate at 13.56 Megahertz. This frequency is referred to as High

Frequency, or HF.

Uses for HF RFID

HF RFID tags are used in a variety of industries and situations

including library book or bookstore tracking, pallet tracking, building

access control, baggage tracking, and apparel item tracking. Highfrequency tags are widely used in identification badges, replacing earlier

magnetic stripe cards. These badges need only be held within a certain

distance of the reader to authenticate the holder. RFID tags are also

used in payment systems that allow customers to pay for items without

using cash. Hospitals are using RFID tags for patient identification and

pharmaceutical management.

RFID Standards

RFID devices have been in use since World War II. The United

Kingdom used RFID devices to differentiate between English aircraft

and German aircraft. Widespread use of RFID technology has been

hampered by a lack of international standards for RFID devices and

technology that is not advanced enough for RFID to be cost effective.

A number of international standards have been adopted for specific

applications. These include tracking animals and freight containers.

Other standards initiatives are under way. The International

Organization for Standardization (ISO) is working on standards for

tracking goods in the supply chain using high-frequency tags (ISO

18000-3) and ultra-high frequency tags (ISO 18000-6). EPCglobal, a

joint venture set up to commercialize Electronic Product Code

technologies, has its own standards process that was used to create bar

code standards. EPCglobal intends to submit EPC protocols to ISO so

that they can become international standards.

Copyright © 2004, Cognitive. 3

Page 9

Chapter

2

Drivers and Label Software

Printer drivers are software tools that translate information from an

external system into an acceptable format for the printer. Older DOSbased systems do not require special drivers. Other systems may use a

generic text driver to communicate with the printer. The companion CD

contains drivers for the Microsoft Windows operating system. You can

also download current drivers from the Cognitive website at

http://www.cognitive.com.

Installing Printer Drivers from the Companion CD

1. Insert the Companion CD into your CD drive. If the CD does

not start automatically, do the following:

a. Click the Start button.

b. Click Run.

c. In the Open: text box, type D:/autorun.exe, where D is the

letter assigned to your CD drive.

2. Click the Software button at the top of the screen.

3. Click the Printer Drivers button.

Copyright © 2004, Cognitive. 4

Page 10

DRIVERS AND LABEL SOFTWARE

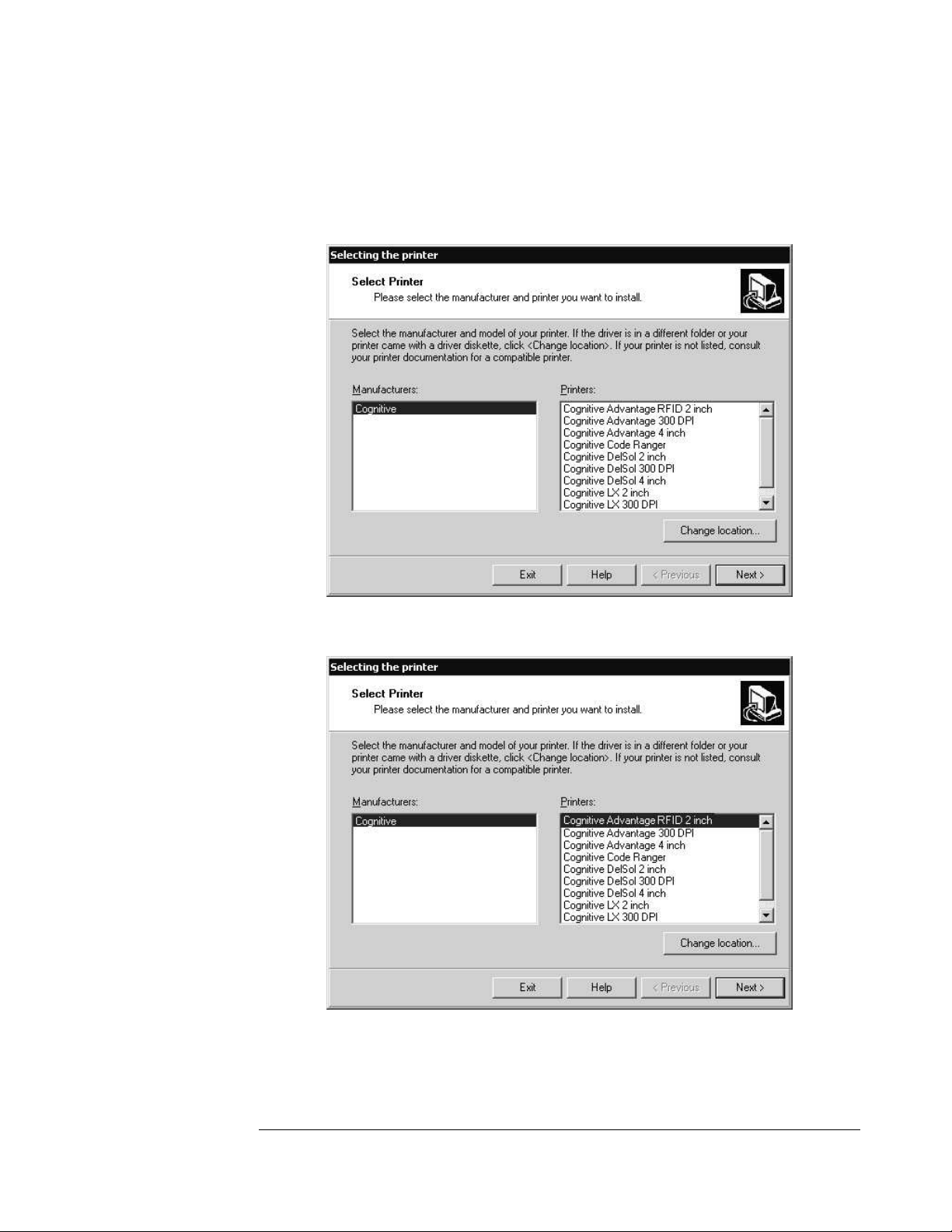

4. Click the hyperlink for your operating system. The Welcome

window appears.

5. Click Next. The Selecting the Printer window appears.

6. Choose your printer from the Printers: list.

7. Click Next. The Options window appears.

Copyright © 2004, Cognitive. 5

Page 11

DRIVERS AND LABEL SOFTWARE

8. Choose the port that the printer is connected to from the

Available ports: list. Keep the default (LPT1) if you are not

sure how the printer is connected.

9. Click Finish. The proper files will be copied to your computer

and the installation wizard will close. This may take several

minutes.

The Advantage RFID Thermal Printer driver is now installed and

available for use.

Copyright © 2004, Cognitive. 6

Page 12

Chapter

3

Setup

Setting up the Advantage RFID Thermal Printer is simple. This chapter

describes printer requirements, printer controls, loading thermal

transfer ribbon and loading print media. The printer self test is also

described.

Printer Requirements

The Advantage RFID Thermal Printer has the following operational

requirements.

Communications

Serial – Standard RS-232 null modem •

•

USB Option – USB to serial cable

•

Ethernet option – Standard 10Base-T Ethernet cable

Power (US)

•

Class 2 transformer

•

Input: 120VAC, 60Hz, 107W

•

Output: 19VAC 4.0A

Environment

•

Operating mode: 41ºF to 104ºF (5ºC to 40ºC)

•

Storage: -4ºF to 122ºF (-20ºC to 50ºC), 25-85% non-condensing

relative humidity

Copyright © 2004, Cognitive. 7

Page 13

SETUP

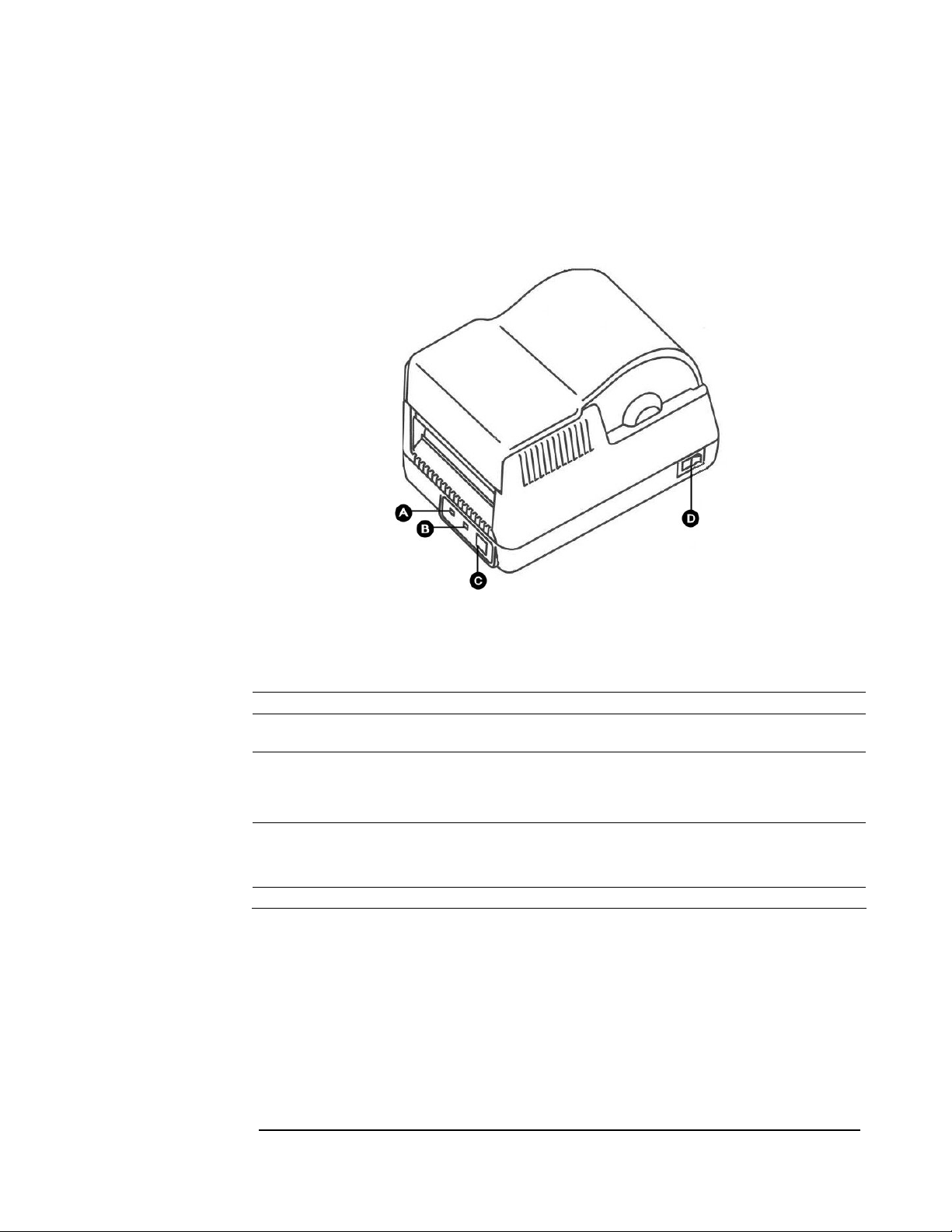

Controls, Indicators, and Connectors

Controls and indicators for the Advantage RFID Thermal Printer are

conveniently located on the front panel and right side of the unit.

Figure 3-1. Advantage RFID Thermal Printer Front View

Device Primary Function Use

A - POWER indicator Shows power status ON – printer on and ready to print

OFF – no power applied

B - READY indicator Shows printer status GREEN – printer ready to accept data

RED – printer error, empty media roll, or paused

operation during batch mode processing

OFF – no power applied

C - FEED button Advances print media Press to advance media

D - ON/OFF switch Controls printer power Press to turn printer on and off

Press and hold while turning unit on to initiate self

test and print current configuration

Copyright © 2004, Cognitive. 8

Page 14

SETUP

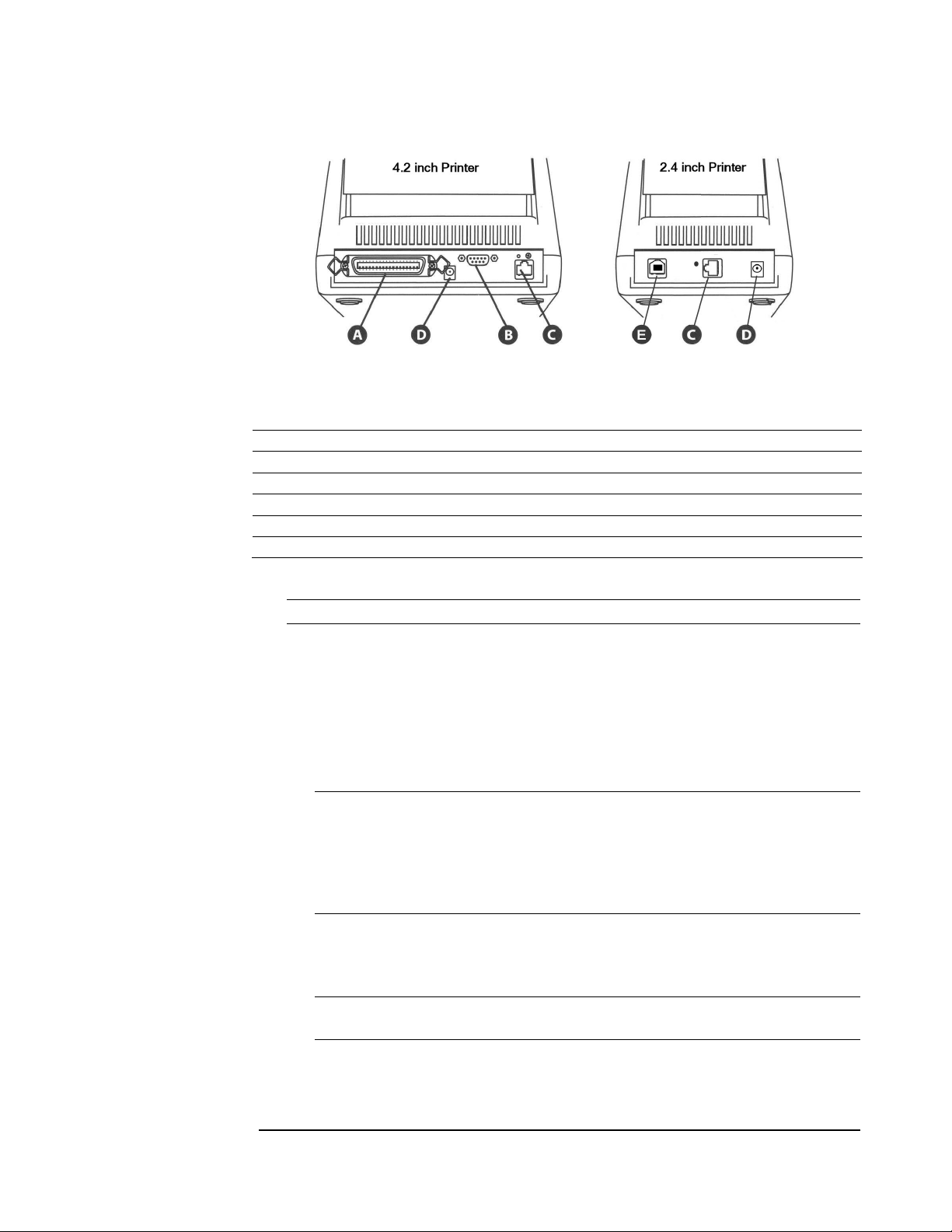

Figure 3-2. Advantage RFID Thermal Printer (Rear View) Connections

and Power

Connector Use

A - Parallel port (optional) Parallel data communications port

B - Serial port (RS232) Serial data communications port

C - Ethernet connector (optional) Ethernet communications port for network connectivity

D - POWER connector Connection for power adapter

E – Universal Serial Bus (USB) port USB communications port

NOTE: Printer port options are dependent upon printer model.

Connecting Power and Cables

The following steps describe how to connect power and data cables.

1. Connect a data cable (parallel, serial, USB, or Ethernet) to the

connector on the back of the printer.

NOTE: A null modem cable is required for serial connections. Do NOT use

a standard serial cable.

For parallel connections, use a standard, non-bidirectional (Centronix

cable. The parallel port must be configured as an LPT port, not an ECP

port.

2. Connect the cable from the power supply to the power connector

on the back of the printer.

IMPORTANT!

Use only the 19VAC power supply provided with the printer.

®

)

Copyright © 2004, Cognitive. 9

Page 15

SETUP

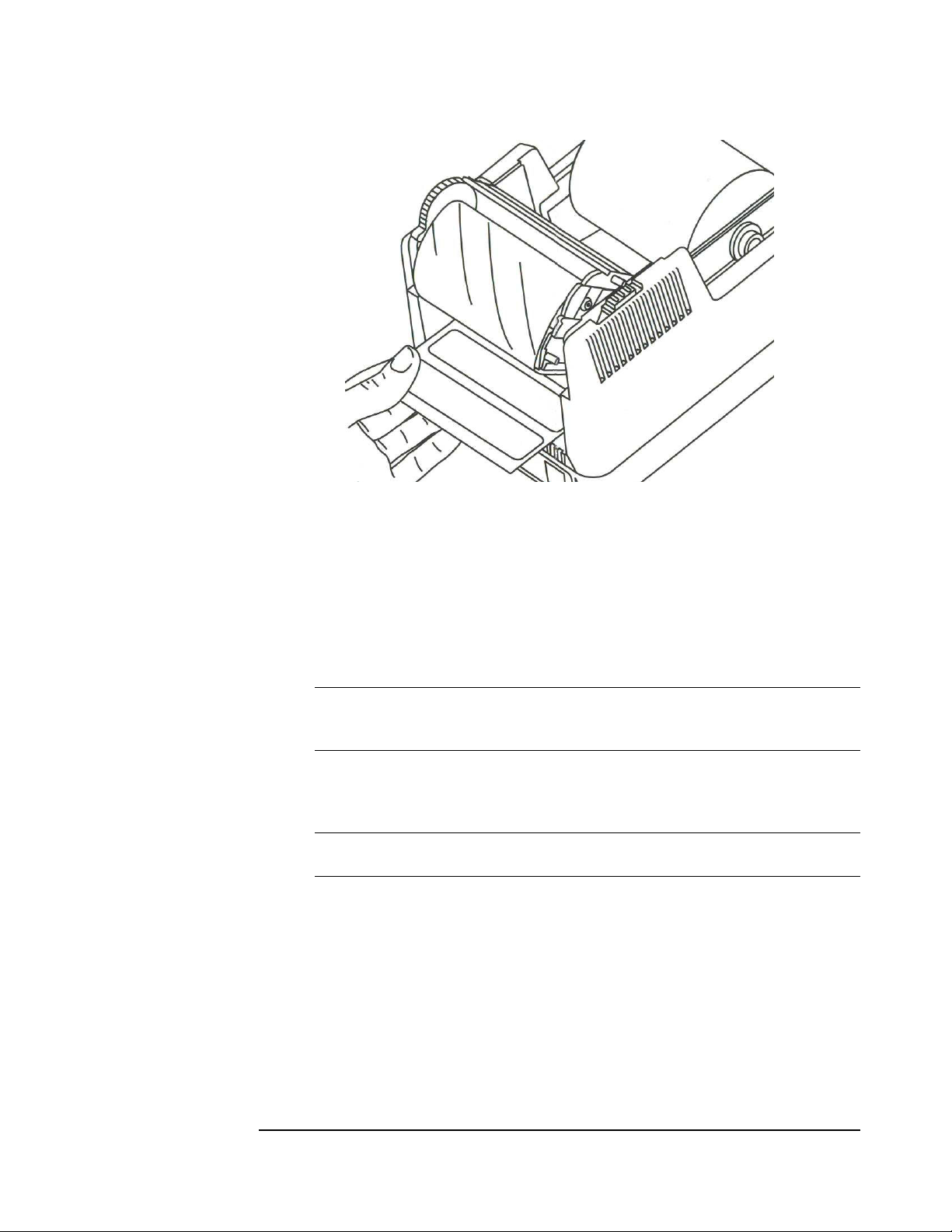

Releasing the Print Mechanism

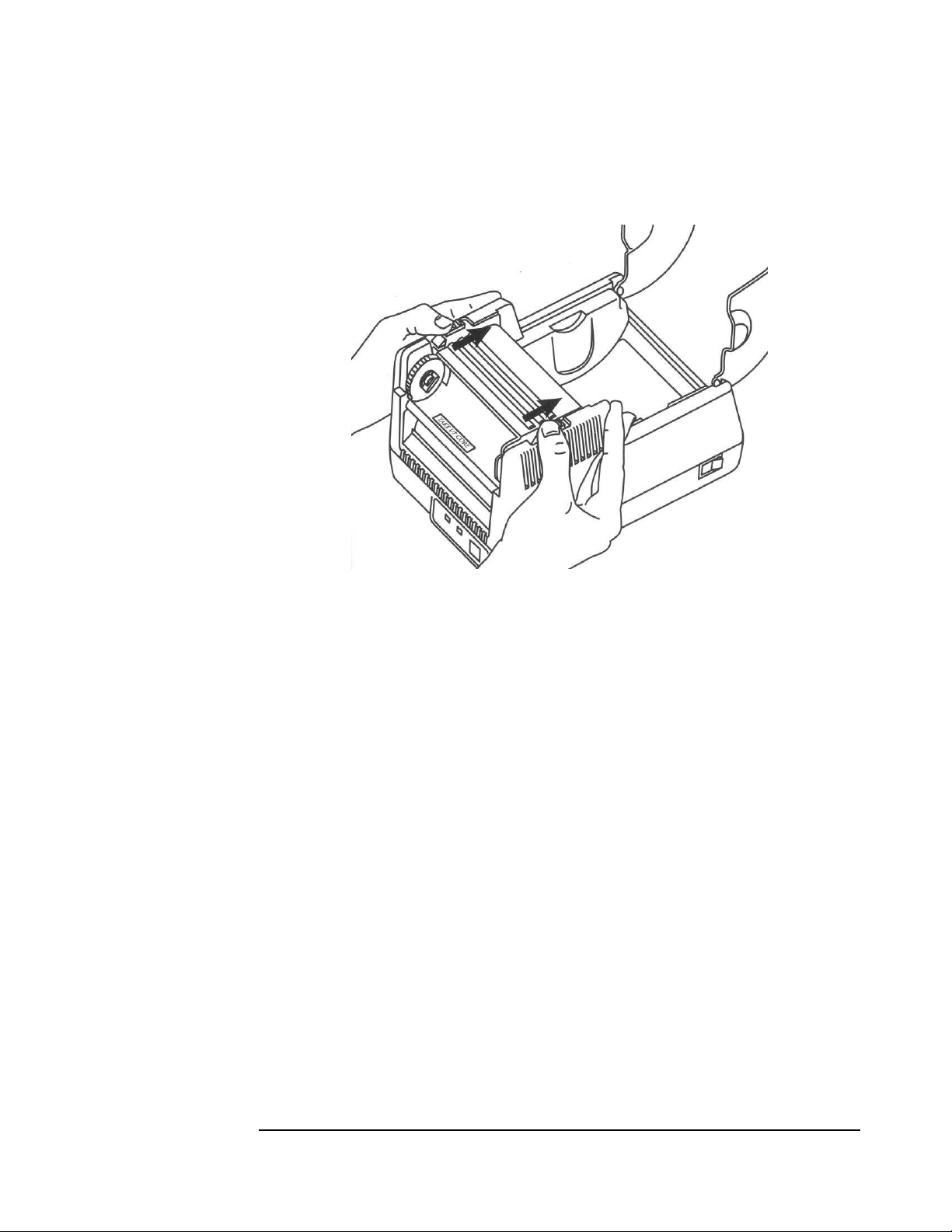

Refer to the figure below to release the print mechanism.

Figure 3-3. Releasing the Print Mechanism

1. Open the dust cover.

2. Refer to Figure 3-3. Slide the black latches towards the rear of

the unit to release the print mechanism.

3. Raise the printhead mechanism in preparation for loading the

print media and/or ribbon. This also provides access to the

printhead for cleaning purposes.

Copyright © 2004, Cognitive. 10

Page 16

SETUP

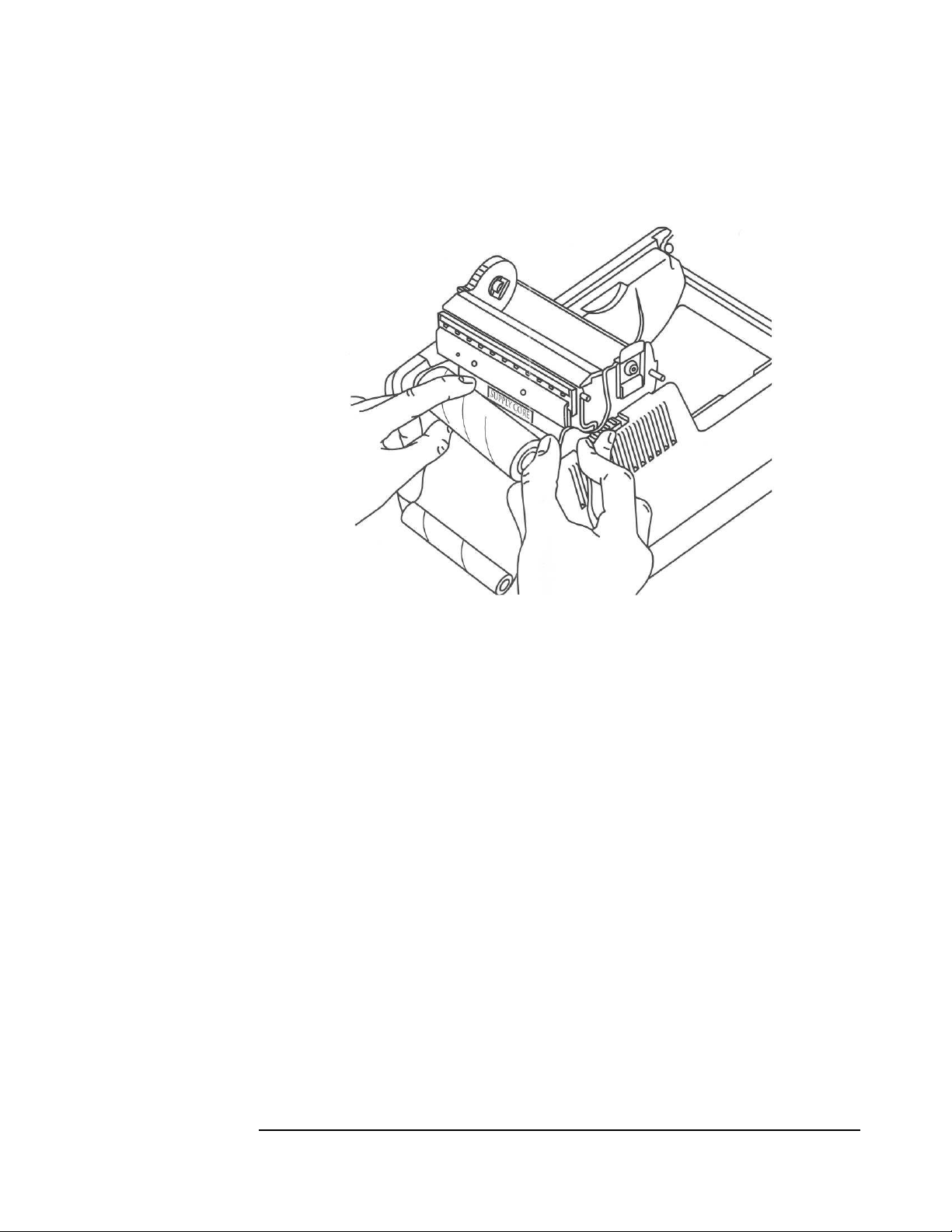

Loading a Ribbon (Thermal Transfer Only)

Refer to the figure below to load thermal transfer ribbon.

Figure 3-4. Loading Thermal Transfer Ribbon

1. Release the print mechanism.

2. Unwind a few inches of the new ribbon from the supply core.

3. Pull gently on the supply core mount flexible arm and insert the

ribbon supply roll.

Copyright © 2004, Cognitive. 11

Page 17

SETUP

Figure 3-5. Loading Thermal Transfer Ribbon (continued)

4. Refer to Figure 3-5. Turn the ribbon take-up core to align the

slotted end with the take-up mount.

5. Gently push the flexible arm out and snap the take-up core into

place.

NOTE: The printer automatically takes up the slack in the ribbon.

6. Lower the print mechanism and press down firmly to secure the

latches.

NOTE: The latches click into place when properly closed. The READY light

turns green indicating that the printer is ready for use.

Copyright © 2004, Cognitive. 12

Page 18

SETUP

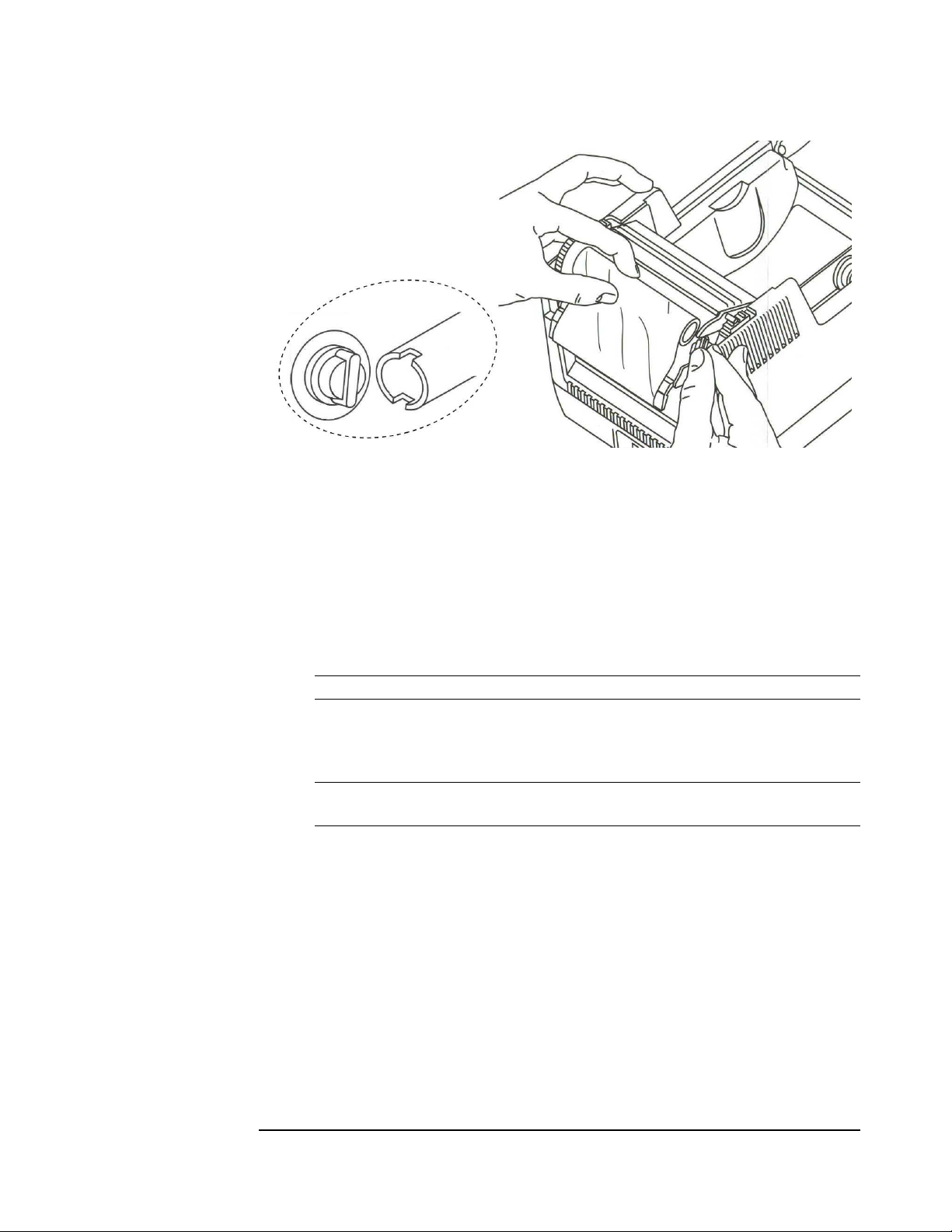

Loading Print Media

Refer to the figures and instructions below to load print media.

Figure 3-6. Loading Print Media onto the Spindle

1. Release the print mechanism.

2. Lift out the media spindle.

3. Load the media onto the spindle, keeping the black media

guide to the right of the media roll.

IMPORTANT!

The label surface must face UP as it passes under the print mechanism.

The label roll must be left justified on the label spindle.

Copyright © 2004, Cognitive. 13

Page 19

SETUP

Figure 3-7. Feeding Media Under the Print Mechanism

4. Place the loaded media spindle into the printer with the black

guide to the right.

5. Feed the media under the open print mechanism.

NOTE: The media spindle should fit securely with the black guide pressed

against the media roll. The label roll must be left justified on the label

spindle.

6. Lower the print mechanism and press down firmly to secure

the latches.

NOTE: The latches click into place when properly closed. The READY light

turns green indicating that the printer is ready for use.

Copyright © 2004, Cognitive. 14

Page 20

SETUP

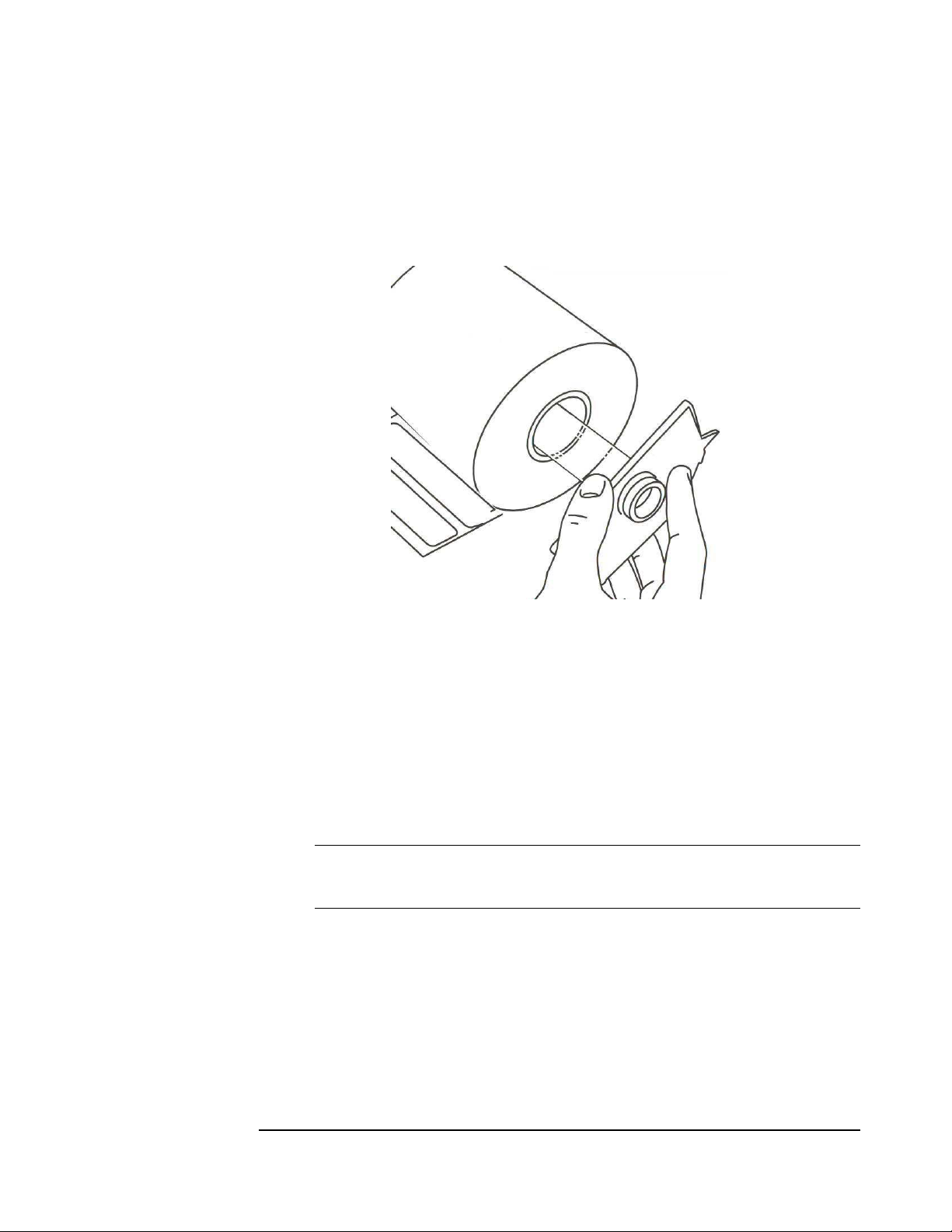

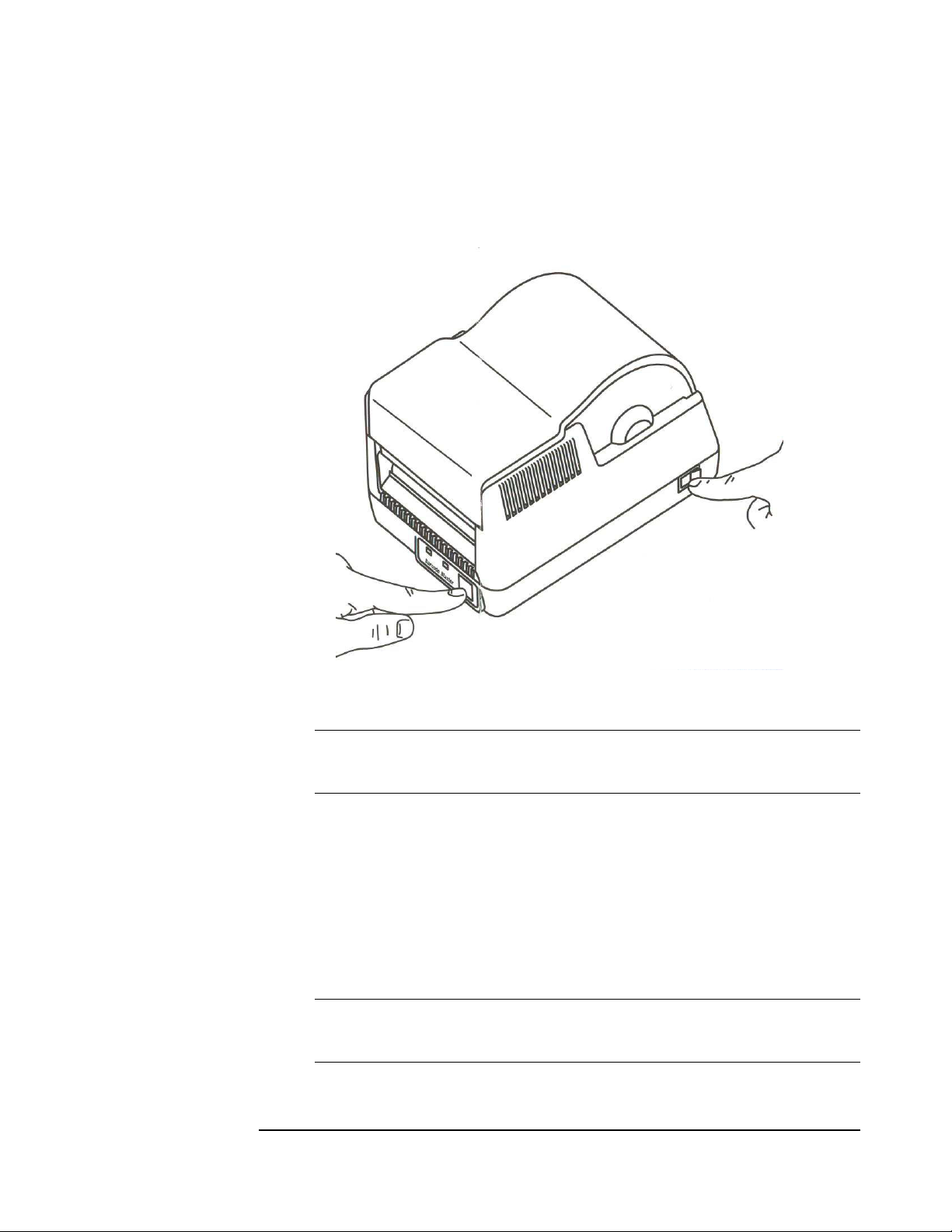

Performing the Self Test

The self test checks the printer’s overall operability. Refer to the figures

and instructions below to perform the printer self test.

Figure 3-8. Performing the Printer Self Test

IMPORTANT!

The printer should be loaded with media, connected to AC power, and

turned off.

1. Press and hold the FEED button.

2. Turn the printer ON while holding the FEED button.

3. Release the FEED button when the self test starts to print.

4. Turn the printer off and then on again to return to normal

printing operation.

IMPORTANT!

After performing the self test, the printer is in hexadecimal dump mode and

cannot print normally until you cycle the power.

Copyright © 2004, Cognitive. 15

Page 21

SETUP

The output from the self test is described in the table below.

Setting Description Example

S/N Printer serial number S/N: A123456789

F/W Firmware version F/W: 195-150-320

REVISION and BUILD Firmware revision and build number REVISION: 3.20 BUILD = 08

DATE Date and time of the self test DATE: AUG 19 2004 11:05:40

INCHES PRINTED Total inches printed INCHES PRINTED: 000000801

TEXT BUF Size and overflow value for the text

buffer

COMM Communications port configuration

values (Baud, Parity, Data Bits, Stop

Bits)

XON/XOFF Indicates the status of XON/XOFF

handshaking

FEEDBACK Shows the status of VARIABLE

USER_FEEDBACK

DARKNESS Darkness setting of printer. FACT is

Factory setting (not user modifiable).

VAR is the variable, user modifiable

setting.

MEDIA ADJUSTMENT Adjusts print contrast on object leading

edges for optimum print quality.

P-H TEMP, P-H VOLTS Printhead temperature and voltage P-H TEMP: 181(30) P-H VOLTS: 211

POWER UP PITCH Print density in dots per inch at power

up

DEFAULT WIDTH Default label width (approximate), in

hundredths of an inch

SHIFT LEFT Distance the image is shifted to the

left, in hundredths of an inch

TEXT BUF: Size=64512 Ovf=256

COMM: 9600,N,8,1

XON/XOFF: ON

FEEDBACK: Off

DARKNESS: FACT=34 VAR=0

MEDIA ADJUSTMENT: 300

POWER UP PITCH: 200

DEFAULT WIDTH: 224

SHIFT LEFT: 0

LABEL PRESENTATION When ON, Printer will advance and

reverse the distance specified below

for each label printed.

FORWARD With PRESENTLABEL ON, the

distance that a label is advanced, in

hundredths of an inch

REVERSE With PRESENTLABEL ON, the

distance that a label is retracted, in

hundredths of an inch

PRINT SPEED Displays the current printing speed

setting.

INDEX Displays index configuration, including

FEED_TYPE mode, gain, tx, rx, top of

form, filter, and current index value

Copyright © 2004, Cognitive. 16

LABEL PRESENTATION: ON

FORWARD (1/100 inches): 8

REVERSE (1/100 inches): 8

PRINT SPEED: HIGH

INDEX: GAP .3.2.36.01.0000.053.217

Page 22

SETUP

Setting Description Example

RECALIBRATE If a label travels the No Media Timeout

distance without seeing an index

mark, the printer will attempt to

recalibrate the printer if

RECALIBRATE: ON. If

RECALIBRATE: OFF, the printer will

error out with a red ready light.

PRINT MODE DT indicates direct thermal printing,

TT indicates thermal transfer printing

and AUTO indicates automatic print

mode switching. In AUTO mode, the

printer will check for the presence of a

ribbon when it is turned on or when

you lower the printhead. If it detects a

ribbon it will set itself for TT mode,

otherwise it will automatically select

DT mode.

ERROR REPORT LEVEL Displays current setting for error

reporting

NO MEDIA TIMEOUT Distance (in inches) the label travels

before the printer either attempts to

recalibrate, or errors out with a red

ready light. (Gap indexing mode only)

EMULATION MODE Displays status of Blazer Emulation

Mode. A value of 0 sets the default

print pitch to its highest value.

IMAGE BUFFER Available free space in the image

buffer

RECALIBRATE: ON

PRINT MODE: DT (AUTO)

ERROR REPORT LEVEL: 0

NO MEDIA TIMEOUT: 0

EMULATION MODE: 0

IMAGE BUFFER: 1903911 bytes free

MEM SLOT 3 Amount of space in Flash RAM for

stored objects

MAC ADDRESS Hardware address of the printer 00:E0:70:00:00:00

IP ADDRESS Network address 255.255.0.0

GATEWAY Network gateway address 0.0.0.0

SNMP TRAP IP Address for the network SNMP trap 0.0.0.0

LPD Displays status of LDP protocol LPD: ON

Telnet Displays status of Telnet protocol Telnet: ON

BootP Displays status of BootP/DHCP BootP: OFF

RTEL Displays status of RTEL protocol RTEL: ON

Ethernet TXTBFR Displays the size of the text and

overflow buffers

MEM SLOT 3: 3670016 bytes installed

Ethernet TXTBFR: Size=8192 Ovf=1514

Copyright © 2004, Cognitive. 17

Page 23

Chapter

4

Printing Standard Labels and Tags

The Advantage RFID Thermal Printer prints both direct thermal and

thermal transfer labels and tags in a host or network environment. The

Advantage RFID Thermal Printer also has the capability to program

and read RFID tags placed within special media as well as print on

certain areas of that media.

Sources for printed label and tag data include the following:

• Label software

• CPL programming

• Third party applications or interfaces

Using Label Software

A version of NiceLabel labeling software, designed specially for

Cognitive printers, is included on the Companion CD. This software

provides label printing and label design capabilities. Refer to the

NiceLabel help files for information on how to use this product with

your Cognitive printer.

Using CPL Programming

A common method of printing labels is CPL programming. Commands

and data are sent to the printer through a generic text printer driver.

The commands prepare the printer to receive the label, establish print

position and characteristics, and terminate printing operation. Data is

passed as ASCII text and may be printed on the label, encoded in an

RFID device, or both.

Copyright © 2004, Cognitive. 18

Page 24

PRINTING LABELS AND TAGS

Creating a Text File

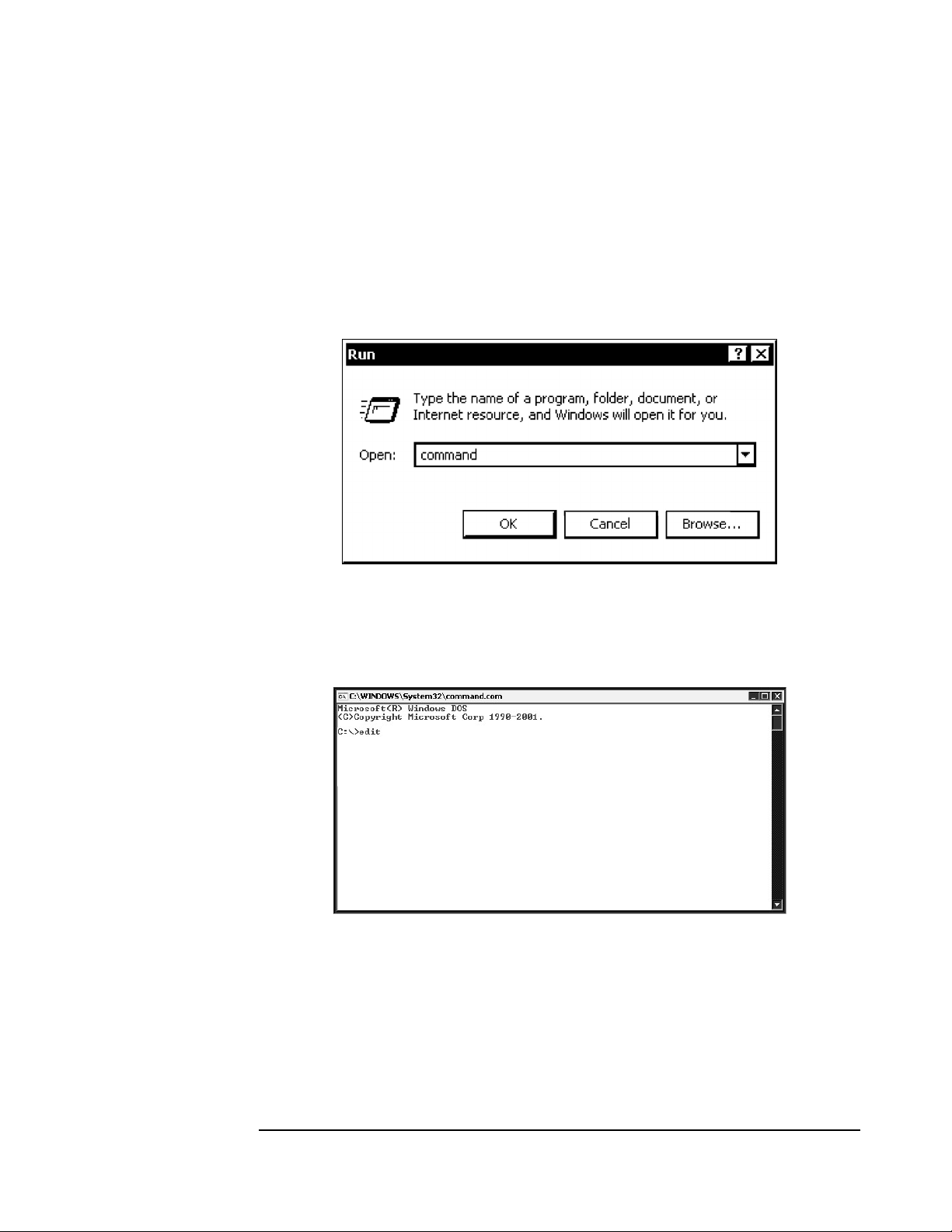

Use the following instructions with Windows-based computers.

1. Click Start.

2. Choose Run.

3. In the Open: text box, type command.

4. Click OK. The Command window appears.

5. In the Command window, at the prompt, type edit and press

ENTER. The DOS Editor window appears.

Copyright © 2004, Cognitive. 19

Page 25

PRINTING LABELS AND TAGS

6. In the DOS Editor window, type the commands and data to

be sent to the printer.

NOTE: If you are using a printer with a serial port (COM port), it may be

necessary to save the file and print directly from the Command window.

Refer to If using a printer with a serial port.

7. On the File menu, choose Print.

8. In the Print dialog, verify that the Complete document option

is selected. Then, click OK. The label is sent to the printer.

9. On the File menu, click Exit.

10. At the prompt, type exit. The Command window closes.

If using a printer with a serial port:

1. In the Command window, at the prompt, type exit. The

Command window closes.

2. On the File menu, choose Save.

Copyright © 2004, Cognitive. 20

Page 26

PRINTING LABELS AND TAGS

3. In the Save As dialog, type a name for the file. Then, click

OK.

NOTE: The file name must be eight characters or less. The name cannot

contain spaces or symbols.

4. On the File menu, click Exit. This returns you to the

Command window.

5. At the prompt, type mode com1 9600,N,8,1. Press ENTER.

6. At the prompt, type copy filename com1. Replace filename

with the file name that you used in step three. Press ENTER.

7. The label prints on the printer.

8. At the prompt, type exit. The Command window closes.

Copyright © 2004, Cognitive. 21

Page 27

PRINTING LABELS AND TAGS

Sample Label

This is a sample label and the programming used to create it.

! 0 100 100 1

WIDTH 224

PITCH 200

DRAW_BOX 20 0 200 30 2

TEXT 2 20 0 TEST LABEL

BARCODE CODE39 20 70 40 1234567894567

END

Using Third-Party and Proprietary Applications

Labels are frequently printed from commercial software or proprietary

applications.

Printing from Microsoft Word

The instructions below describe how to create both simple and complex

labels using Microsoft Word software. The instructions assume the

following conditions:

• You have a basic understanding of Microsoft software and the

Windows operating system.

• Cognitive printer drivers are installed correctly.

• The printer is connected, powered on, and ready to print.

NOTE: Examples shown here were created using Microsoft Windows XP

and Microsoft Word 2002.

Selecting a Printer

To configure the software for a Cognitive printer:

1. Open Microsoft Word.

Copyright © 2004, Cognitive. 22

Page 28

PRINTING LABELS AND TAGS

2. Press CTRL+P or, on the File menu, choose Print. The

Print dialog appears.

3. Select a Cognitive printer.

4. Click Close to close the Print dialog.

Copyright © 2004, Cognitive. 23

Page 29

PRINTING LABELS AND TAGS

Setting Label Size

Set the printer driver for the label size.

1. On the File menu, click Page Setup. The Page Setup dialog

appears.

2. Set all margins to 0.

3. Click the Paper tab.

Copyright © 2004, Cognitive. 24

Page 30

PRINTING LABELS AND TAGS

4. Set the correct width and height for your label. The example

shows a 2.4” wide by 1” tall label.

5. Click OK and, if necessary, Fix to reset the margins. The

Word document should look similar to the figure below.

Copyright © 2004, Cognitive. 25

Page 31

PRINTING LABELS AND TAGS

Creating a Label and Barcode

Design the label as you would any Word document. Use the following

steps to design a barcode.

1. Select the desired font.

2. Enter the numbers for the barcode. A barcode will not display

on the screen, but is printed on the label.

3. Set the height of the barcode by adjusting the font size. Use

trial and error to adjust the size correctly.

Printing a Label

Make sure that the printer is connected to the computer and powered

on. Ensure that the media is loaded correctly. Use the following steps to

print the label:

1. Press CTRL+P or, on the File menu, choose Print. The

Print dialog appears.

2. Verify that the Cognitive printer is selected.

3. Click OK.

Copyright © 2004, Cognitive. 26

Page 32

PRINTING LABELS AND TAGS

Printing from Proprietary Applications

There are a variety of applications that are industry or function specific.

Some of these require a generic text printer driver. Others have built-in

printer drivers. Refer to your software documentation or contact the

software vendor to determine the appropriate method for printing labels

with proprietary software.

Copyright © 2004, Cognitive. 27

Page 33

Chapter

5

Printing RFID Tags

Printing RFID tags may include printing information on the tag,

writing data to the tag, reading data from the tag, or a combination

these actions. While tags may differ in appearance and storage capacity,

programming the tag properly depends on understanding how the

Advantage RFID Thermal Printer writes to and reads from the RFID

tag.

NOTE: Cognitive highly recommends the use of Cognitive-certified RFID tags

with the Advantage RFID Thermal Printer. Refer to Appendix B, Certified Tags.

RFID Tag Overview

Each RFID tag contains a small microchip used to store data. RFID

programming commands are used to transfer data from a label format

or other data source into the tag. Several important concepts must be

understood when writing data to an RFID tag.

Data is stored in blocks.

Each block stores a specific number of characters. Use the RF_BLKSZ

variable or the specification sheet for the RFID tag to determine this

number.

Refer to Figure 5-1, Data Blocks. With a block size of 4, the RFID tag

will store 4 characters in each block. Therefore, a data string that

contains 18 characters occupies 5 blocks. The WT command places a

NULL character at the end of each stored data string. In this example,

data is stored in blocks 0 through 4.

Copyright © 2004, Cognitive. 28

Page 34

PRINTING RFID TAGS

Figure 5-1. Data Blocks

The write tag (WT) command ASCII string is limited to 63

characters.

Each WT command ASCII string is limited to a maximum of 63

characters. For a 256 byte RFID tag, a maximum of four WT commands

containing 63 characters of data may be used.

NOTE: It is the user’s responsibility to track the 63 character maximum. If more

than 63 characters are included in a WT command, the command will fail.

The read tag (RT) command stores data in a user-specified

location.

The RT command retrieves data from an RFID tag and stores the data

in a location that the user identifies. The location is identified with a

number between 1 and 99. The user may store the result of a maximum

of 32 separate RT commands.

The RT command reads up to a specified ending block or until a

null character is encountered.

The RT command reads data from the RFID chip beginning at the block

specified in the command parameter. The command will continue to

read up to the block specified in the command parameters OR until a

null character is encountered. The RT command will not read past the

null character.

Again, refer to Figure 5-1. Reading blocks 0-3 returns “COGNITIVE

PRINTE”. Reading blocks 0 through 4 returns “COGNITIVE

PRINTERS”. Finally, reading blocks 0 through 5 returns the same

string as reading blocks 0 through 4.

Copyright © 2004, Cognitive. 29

Page 35

PRINTING RFID TAGS

Using Label Software

A version of NiceLabel labeling software, designed specially for

Cognitive printers, is included on the Companion CD. This software

provides label printing, label design, RFID write and RFID read

capabilities. Refer to the NiceLabel help files for information on how to

use this product with your Cognitive printer.

Using CPL Programming

RFID commands have been added to the CPL programming language.

These new commands allow you to read and write data as well as print

information on the tag. Commands and data are sent to the printer

through a generic text printer driver. The commands prepare the

printer to receive the tag, establish print position and characteristics,

and terminate printing operation. Data is passed as ASCII text and

may be printed on the label, encoded in an RFID device, or both.

Creating a Text File

Use the following instructions with Windows-based computers.

1. Click Start.

2. Choose Run.

3. In the Open: text box, type command.

4. Click OK. The Command window appears.

Copyright © 2004, Cognitive. 30

Page 36

PRINTING RFID TAGS

5. In the Command window, at the prompt, type edit and press

ENTER. The DOS Editor window appears.

6. In the DOS Editor window, type the commands and data to

be sent to the printer.

NOTE: If you are using a printer with a serial port (COM port), it may be

necessary to save the file and print directly from the Command window. Refer

to Stored Formats.

7. On the File menu, choose Print.

8. In the Print dialog, verify that the Complete document option

is selected. Then, click OK. The label is sent to the printer.

Copyright © 2004, Cognitive. 31

Page 37

PRINTING RFID TAGS

9. On the File menu, click Exit.

10. At the prompt, type exit. The Command window closes.

Stored Formats

Stored formats are tag formats that are saved as a text file. This file can

be reused to create tags without having to retype all of the required

commands.

Use the following instructions with Windows-based computers.

1. Click Start.

2. Choose Run.

3. In the Open: text box, type command.

4. Click OK. The Command window appears.

5. In the Command window, at the prompt, type edit and press

ENTER. The DOS Editor window appears.

Copyright © 2004, Cognitive. 32

Page 38

PRINTING RFID TAGS

6. In the DOS Editor window, type the commands and data to

be sent to the printer.

7. On the File menu, choose Save.

8. In the Save As dialog, type a name for the file. Then, click

OK.

NOTE: The file name must be eight characters or less. The name cannot

contain spaces or symbols.

9. On the File menu, click Exit. This returns you to the

Command window.

10. At the prompt, type mode com1 9600,N,8,1. Press ENTER.

11. At the prompt, type copy filename com1. Replace filename

with the file name that you used in step three. Press ENTER.

12. The label prints on the printer.

Copyright © 2004, Cognitive. 33

Page 39

PRINTING RFID TAGS

13. At the prompt, type exit. The Command window closes.

Sample RFID Tag

This is a sample RFID tag and the programming used to create it.

! 0 100 1200 1

W 100

VARIABLE DARKNESS 100

DELIMIT $

RF VAR_CLEAR

WT 0 "Cognitive Solutions RFID 1-800-525-2785"

WT 16 "PAT ID:354647"

RF ID_GET

RT 0 10 "A" 11

RT 16 31 "A" 21

T 2 (0,90,1,1) 150 280 PATIENT: COGNITIVE

SOLUTIONS

T 1 (0,90,1,1) 120 280 ADM:8/8/2004

T 1 (0,90,1,1) 90 280 DOB 8/9/1973

B CODE128(2:3)- 30 260 70 354647

T 1 (0,90,1,1) 60 280 SSN: 523-43-8798

T 1 (0,90,1,1) 30 280 DR: John Doe MD

T 1 (0,90,1,1) 10 380 www.cognitive.com

RF HOST $RF_IDNUM$

RF HOST "$RF 11$"

RF HOST "$RF 21$"

END

Using Third-Party and Proprietary Applications

There are a variety of applications that are industry or function specific.

Some of these require a generic text printer driver. Others have built-in

printer drivers. Refer to your software documentation or contact the

software vendor to determine the appropriate method for printing labels

with proprietary software.

Copyright © 2004, Cognitive. 34

Page 40

Chapter

6

Maintenance and Calibration

The Advantage RFID Thermal Printer is designed to provide

exceptional service with a minimum of preventive maintenance.

Maintenance

Printer maintenance should be performed with each media roll.

Figure 6-1. Performing Printer Maintenance

1. Open the print mechanism.

2. Clean the printhead (A), drive roller (B), and the index

sensors (C and D) with a soft, lint-free cloth saturated with 99

percent isopropyl alcohol.

Copyright © 2004, Cognitive. 35

Page 41

MAINTENANCE AND CALIBRATION

3. Press the FEED button to clean all sides of the roller

CAUTION!

Incorrectly cleaning the printer will cause permanent damage and void the

printer’s warranty. Cognitive recommends using a certified cleaning pen for

all your printer’s cleaning requirements, P/N 60-14-00-0002.

Calibration

Calibration is the process of configuring the printer with a specific set of

parameters. Calibrate the printer when the following occurs:

• Print media type changes

• Printer skips labels

• Printer feeds blank labels

NOTE: Do NOT calibrate Blazer model printers.

To calibrate the printer, type the following commands in the DOS

Editor or Notepad:

! 0 0 0 0

VARIABLE INDEX SETTING 0

VARIABLE FEED_TYPE GAP

VARIABLE INDEX SETTING CALIBRATE

VARIABLE WRITE

END

Programming notes:

First line must use zeros with a space between each.

Second line, for a Direct Thermal printer, use index setting 0.

Third line, feed type will be GAP or BAR depending on the type of label used.

On the File menu, choose Print to send this file to the printer. The

printer READY light will flash and a label may be ejected. The printer

will not print on the label.

Wait for the READY light to turn solid green. Turn the printer OFF and

then ON.

Copyright © 2004, Cognitive. 36

Page 42

Chapter

7

Programming

The Advantage RFID Thermal Printer, like other Cognitive printers, is

programmable using ASCII commands. Additional commands have

been added to support the RFID functionality. This chapter provides an

explanation of the new RFID commands used by the Advantage RFID

Thermal Printer.

Programming Overview

Most Cognitive printers use the same command language, which has

become an industry standard. RFID commands are broken into three

types:

• RFID Standard Commands – Standard commands that are

inserted into a label format

• RFID Variable Commands – Variables used with other

commands and inserted into a label format

The format for creating a printer variable is:

<Delimiter>RF_VAR<Delimiter>

<Delimiter> is defined according to Cognitive’s CPL

command language.

NOTE: In this document, the dollar sign ($) character is used as the delimiter

character.

• RFID Setup/Debug Commands – Commands used with a

serial interface to the printer and sent individually for setup

or debug information

Copyright © 2004, Cognitive. 37

Page 43

PROGRAMMING

Programming Rules

Use blank spaces exactly as shown in the command descriptions,

examples, and syntax. Blank spaces are the delimiters between

parameters. Omitting a necessary space may result in incorrect

programming or a failure to recognize commands.

In CPL-RFID programming, the RFID specific directives are casesensitive and must be fully spelled-out.

Certain CPL-RFID commands operate outside of the standard label

formatting. The commands that start with the !RFID command verb

need not be placed between a header line and an END command.

RFID Command Name Structure

RFID commands described in this chapter will use the following

conventions:

RFID Command Name

Function Purpose of the command

Explicit Form Proper sequence for using the command and its

parameters

Parameters Variables or conditions that may be required or

used with the command

Command Type Category of the RFID command

Copyright © 2004, Cognitive. 38

Page 44

PROGRAMMING

RFID Command Structure Example

The following listing is an example of RFID command usage.

! 0 100 1200 1

DELIMIT $

RF VAR_CLEAR

WT 0 "COGNITIVE SOLUTIONS RFID xxxxxx"

WT 16 "PATIENT ID:xxxxxx"

RF HOST "RFID TAG WRITTEN"

RF ID_GET

RT 0 10 "A" 11

RT 16 31 "A" 21

RF HOST “$RF_IDNUM$”

RF HOST "$RF 11$"

RF HOST "$RF 21$"

END

Copyright © 2004, Cognitive. 39

Page 45

PROGRAMMING

RFID Commands

Use the following commands to program RFID features of the

Advantage RDIF printers.

Standard

Commands

Variable

Definitions

Setup/Debug

Commands

RF ID_GET RF_TYPE !RFID ?

RF HOST RF_IDNUM !RFID CONFIRM

RF VAR_CLEAR RF_BLKSZ !RFID HOST

RT RF LOCATION !RFID LEDFLSH

WT !RFID LEDTIME

WTLOCK !RFID MARK

!RFID RDAFTWT

!RFID RETRY

!RFID SSONCMD

!RFID TAGTYPE

!RFID TIMEOUT

!RFID TXAFTER

!RFID VOID

Copyright © 2004, Cognitive. 40

Page 46

PROGRAMMING

RF ID_GET

Function This command is defined as "RFID Function", ID

GET. This command retrieves the current RFID

tag's unique identification number and returns it to

the host.

Explicit Form

RF ID_GET

Parameters None

Response This command will automatically transmit the

detected ‘Tag_ID’s numeric value to the Host

Machine via the printer’s serial port.

Command Type RFID Standard Command

Example To Printer:

! 0 0 0 0

DELIMIT $

RF ID_GET

RF HOST "Here the Variables:"

RF HOST "$RF_TYPE$"

RF HOST "$RF_IDNUM$"

RF HOST "$RF_BLKSZ$"

END

From Printer:

TAG_ID: E0:07:00:00:01:F3:06:10

Here the Variables:

[ISO15693]

[E0:07:00:00:01:F3:06:10]

[4]

Copyright © 2004, Cognitive. 41

Page 47

PROGRAMMING

RF HOST

Function This command instructs the Printer to transmit the

specified ASCII string to the Host Machine using

the serial port. When used in conjunction with the

printer "Delimit" command in a label format,

certain variable values can also be returned to the

host.

Explicit Form

RF HOST "ASCII-string-to-send-to-host"

Parameters The data placed inside the " " can be either a

variable such as RF TYPE or other ASCII data.

Response The Static or Derived Variable valued string is

transmitted to the Host Machine via the printer’s

serial port.

Command Type RFID Standard Command

Example To Printer:

! 0 0 0 0

DELIMIT $

RF ID_GET

RF HOST "Here the Variables:"

RF HOST "$RF_TYPE$"

RF HOST "$RF_IDNUM$"

RF HOST "$RF_BLKSZ$"

END

From Printer:

TAG_ID: E0:07:00:00:01:F3:06:10

Here the Variables:

[ISO15693]

[E0:07:00:00:01:F3:06:10]

[4]

Copyright © 2004, Cognitive. 42

Page 48

PROGRAMMING

RF VAR_CLEAR

Function This command instructs the Printer to clear and

reset all of the internal RFID Read-Tag DataHandler Variables. After executing this command,

no ‘RF nn’ Variables are defined

Explicit Form

RF VAR_CLEAR

Parameters None

Response None

Command Type RFID Standard Command

Example To Printer:

! 0 0 0 0

DELIMIT $

RF VAR_CLEAR

RT 0 3 "A" 33

RF HOST "$RF 33$"

END

From Printer:

123-1234-123

NOTE: By using this command in the example above

the result sent to the Host Machine is guaranteed to be

that from the ‘RT …33’ command within the label and

not from a previous ‘RT …. 33’ processed earlier.

Copyright © 2004, Cognitive. 43

Page 49

PROGRAMMING

RT

Function Read Tag. This command retrieves RFID-tag data

from the tag currently positioned over RFID

Reader/Writer H/W.

Explicit Form

Parameters

RT ss ee “fmt” vv

ss

Starting block to begin reading octets

(bytes)

ee

Ending block. Stop on this block after

reading the contents.

“fmt”

Format of the data being read. Use A for

ASCII.

vv

Storage index number used for

subsequent retrieval action (0-99)

Response No specific response

Command Type RFID Standard Command

Example To Printer:

! 0 0 0 0

DELIMIT $

RF VAR_CLEAR

RT 0 3 "A" 33

RF HOST "$RF 33$"

END

From Printer:

123-1234-123

Copyright © 2004, Cognitive. 44

Page 50

PROGRAMMING

WT

Function Write Tag. This command stores the quoted data to

the RFID-Tag currently positioned over RFID

Reader/Writer H/W. The data will begin storage at

the ss Tag-block and extend to and Zero pad any

unused bytes within the ending block.

Explicit Form

Parameters

WT ss “data”

ss

Starting block to begin reading octets

(bytes)

“data”

Collection of data octets to be written to

the RFID tag. The size of "data" must

be in the range of 1-255 octets.

Response No specific response

Command Type RFID Standard Command

Example To Printer:

! 0 100 800 0

DELIMIT $

WT 0 "123-1234-123"

WT 4 "John Q. Public"

WT 10 "Cardiac Care Unit"

RT 0 3 "A" 33

RF HOST "$RF 33$"

END

From Printer:

123-1234-123

NOTE: In this initial Adv-LX RFID Printer, the SkyetekM1 Reader/Writer Module limits individual Read or

Write transfers to/from the RFID-Tags to 64-bytes

maximum. CPL command lines are naturally limited to

256-bytes. Therefore, 4 separate 64-byte WT

commands must be executed to fill a 256-byte RFIDTag,

Copyright © 2004, Cognitive. 45

Page 51

PROGRAMMING

WTLOCK

Function Write and Lock Tag. The command permanently

writes data to a tag. As with the WT command, the

user is responsible for maintaining the 63 byte

requirement. Approximately 15 seconds, with no

retries, is required to write lock a full blank tag.

NOTE: This command will overwrite any non-locked

portion of a tag. Attempting to overwrite a locked

portion of the tag will result in a failure.

Explicit Form

Parameters

WTLOCK ss “data”

ss

Starting block to begin reading octets

(bytes)

“data”

Collection of data octets to be written to

the RFID tag. The size of "data" must be

in the range of 1-255 octets.

EXCEPTION: data="<null>" locks the

specified starting block (nn).

Command Type RFID Standard Command

Copyright © 2004, Cognitive. 46

Page 52

PROGRAMMING

Example To Printer:

! 0 100 800 0

DELIMIT $

WTLOCK 0 "123-1234-123"

WT 4 "John Q. Public"

WT 10 "Medical Mumbo Jumbo"

RT 0 3 "A" 33

RF HOST "$RF 33$"

END

From Printer:

123-1234-123

NOTE: Individual Read or Write transfers to/from the

RFID-Tags are limited to 64 bytes maximum. CPL

command lines are naturally limited to 256 bytes.

Therefore, 4 separate 64-byte WT commands must be

executed to fill a 256-byte RFID-Tag,

Copyright © 2004, Cognitive. 47

Page 53

PROGRAMMING

RF_TYPE

Function This is an RFID reserved and internal variable

contains the last RFID-Tag’s Type. This variable is

often used in conjunction with the RF HOST

command.

Explicit Form

$RF_TYPE$

Parameters None

Response The printer’s parser will replace any Static or

Derived Variables with valued string associated

with variable and then attempt to execute the CPL

or CPL-RFID command

Command Type RFID Standard Command

See also

RF HOST

Example To Printer:

! 0 0 0 0

DELIMIT $

RF ID_GET

RF HOST "Here the Variables:"

RF HOST "$RF_TYPE$"

RF HOST "$RF_IDNUM$"

RF HOST "$RF_BLKSZ$"

END

From Printer:

TAG_ID: E0:07:00:00:01:F3:06:10

Here the Variables:

[ISO15693]

[E0:07:00:00:01:F3:06:10]

[4]

Copyright © 2004, Cognitive. 48

Page 54

PROGRAMMING

RF_IDNUM

Function This command is defined as "Reference Find" ID

Number. This command returns the unique tag

identification number and is often used in

conjunction with the RF HOST command.

Explicit Form

$RF_IDNUM$

Parameters None

Response The Printer’s parser will replace any Static or

Derived Variables with valued string associated

with variable and then attempt to execute the CPL

or CPL-RFID command.

Command Type RFID Standard Command

See also

RF HOST

Example To Printer:

! 0 0 0 0

DELIMIT $

RF ID_GET

RF HOST "Here the Variables:"

RF HOST "$RF_TYPE$"

RF HOST "$RF_IDNUM$"

RF HOST "$RF_BLKSZ$"

END

From Printer:

TAG_ID: E0:07:00:00:01:F3:06:10

Here the Variables:

[ISO15693]

[E0:07:00:00:01:F3:06:10]

[4]

Copyright © 2004, Cognitive. 49

Page 55

PROGRAMMING

RF_BLKSZ

Function This command is defined as "Reference Find", Block

Size. The command returns the block size for a

specific tag type. This variable is often used in

conjunction with the RF HOST command to return

the tag block size to the host.

Explicit Form

$RF_BLKSZ$

Parameters None

Response The printer’s parser will replace any Static or

Derived Variables with valued string associated

with variable and then attempt to execute the CPL

or CPL-RFID command.

Command Type RFID Variable Command

See also

RF HOST

Example To Printer:

! 0 0 0 0

DELIMIT $

RF ID_GET

RF HOST "Here the Variables:"

RF HOST "$RF_TYPE$"

RF HOST "$RF_IDNUM$"

RF HOST "$RF_BLKSZ$"

END

From Printer:

TAG_ID: E0:07:00:00:01:F3:06:10

Here the Variables:

[ISO15693]

[E0:07:00:00:01:F3:06:10]

[4]

Copyright © 2004, Cognitive. 50

Page 56

PROGRAMMING

RF LOCATION

Function This command is defined as "Reference Find",

Variable at Location #. The command returns the

value that was stored in a printer variable with the

RT command where nn is an argument to be

specified.

Explicit Form

Parameters

$RF nn$

nn

Range of 0 through 99. A maximum

of 32 locations may be in use at any

one time. Each location can store a

maximum of 63 characters.

Response The printer’s parser will replace any Static or

Derived Variables with valued string associated

with variable and then attempt to execute the CPL

or CPL-RFID command.

Command Type RFID Variable Command

Example To Printer:

! 0 0 0 0

DELIMIT $

RF VAR_CLEAR

RT 0 3 "A" 33

RF HOST "$RF 33$"

END

From Printer:

123-1234-123

Copyright © 2004, Cognitive. 51

Page 57

PROGRAMMING

!RFID ?

Function This command queries the printer for a summary of

the existing printer settings for RFID functionality.

Explicit Form

!RFID ?

Parameters None

Response See example below.

Command Type RFID Setup/Debug Command

Example From Printer:

Setup/Config Parameters:

Assigned Tag Type: ISO15693

Mark/OverRide State: OFF

VOID Stamp Message: <NoStampMsg>

LED Flash Control: ON

LED Flash Duration: 250 MSecs

SelecTag before Cmd: ON

TxPowerRF after Cmd: ON

ReadTag after Write: ON

Confirm Commands: OFF

Retry Command: 2 Times

Base Cmd Timeout: 10 MSecs

Select Tag Timeout: 70 MSecs

Read Tag Timeout: 16 MSecs

Write Tag Timeout: 32 MSecs

Lock Tag Timeout: 26 MSecs

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). Attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result are ignored without indication.

Copyright © 2004, Cognitive. 52

Page 58

PROGRAMMING

!RFID CONFIRM

Function Controls the transmission of a ‘Success’ or ‘Failure’

indication at the very end of any CPL-RFID

command’s execution.

Explicit Form

Parameters

!RFID CONFIRM on/off

ON

When the setting is ON, the printer will

return RFID:SUCCESS or RFID

:FAILURE for every command issued to

the printer.

OFF

When set to OFF, no messages are sent

to the host.

Response In the case of transitioning to the CONFIRM ON

state, the Printer will response by transmitting a

command Success to the Host Machine.

Conversely, in the case of transitioning to the

CONFIRM OFF state, the Printer will have no

specific response resulting from the execution of

this command.

Command Type RFID Setup/Debug Command

Example To Printer:

!RFID CONFIRM ON

From Printer:

[RFID:SUCCESS]

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). Attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result are ignored without indication.

Copyright © 2004, Cognitive. 53

Page 59

PROGRAMMING

!RFID HOST

Function This command instructs the Printer to transmit the

specified ASCII string to the Host Machine using

the serial port. When used in conjunction with the

printer "Delimit" command in a label format,

certain variable values can also be returned to the

host.

Explicit Form

RF HOST "ASCII-string-to-send-to-host"

Parameters The data placed inside the " " must be ASCII data.

Data length must be between 0 and 240 characters.

Response The static string is transmitted to the Host

Machine by way of the printer’s serial port.

Command Type RFID Standard Command

Example To Printer:

!RFID HOST “Setting RFID Power-Up Defaults”

!RFID CONFIRM OFF

From Printer:

Setting RFID Power-Up Defaults

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). So, attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result in being completely and

unabashedly ignored without indication.

Additionally, only static valued strings will print with this

command. Delimited variable substitution is an intralabel-format function only. For example, variables such

as “$RF_IDNUM$” may not be used.

Copyright © 2004, Cognitive. 54

Page 60

PROGRAMMING

!RFID LEDFLSH

Function Controls the transmission of a ‘Success’ or ‘Failure’

indication to the LED display during and at the

very end of any CPL-RFID command’s execution.

Explicit Form

Parameters

!RFID LEDFLSH ON/OFF/ACCUM

ON

Flashes LED (Green for Success) or (Red

for Failure) after any CPL-RFID

command completion

OFF

Does NOT flash any LED after CPLRFID command completions. The LED

normally remains OFF during a labelformat execution until the printer is

ready for the next label or command

where LED is set Green

ACCUM

Does NOT flash any LED until after the

entire label- format has completed

execution. If all CPL- RFID commands

completed successfully, the LED is

flashed GREEN and OFF three times.

If any CPL-RFID command failed, the

LED is flashed RED and OFF three

times.

Response No specific response

Command Type RFID Setup/Debug Command

Example To Printer:

!RFID LEDFLSH OFF

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). Attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result are ignored without indication.

Copyright © 2004, Cognitive. 55

Page 61

PROGRAMMING

!RFID LEDTIME

Function Regulates the interval of LED illumination and

LED OFF time used in generation of an LED Flash

on ‘Success’ or ‘Failure’.

Explicit Form

Parameters

!RFID LEDTIME nn

nn

Determines the LED illumination

interval. Range is 0 to 65535.

Response No specific response

Command Type RFID Setup/Debug Command

Example To Printer:

!RFID LEDTIME 100

!RFID ?

From Printer:

Setup/Config Parameters:

Assigned Tag Type: ISO15693

Mark/OverRide State: OFF

VOID Stamp Message: <NoStampMsg>

LED Flash Control: ON

LED Flash Duration: 250 MSecs

SelecTag before Cmd: ON

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). Attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result are ignored without indication.

Copyright © 2004, Cognitive. 56

Page 62

PROGRAMMING

!RFID MARK

Function This command sets whether or not to print a

defined mark on a label that fails to write expected

data to an RFID tag.

Explicit Form

Parameters

!RFID MARK ON/OFF

ON

When the setting is ON, the printer will

mark a label that fails a RT, WT, or

WTLOCK command.

Response No specific response

Command Type RFID Setup/Debug Command

Example To Printer:

!RFID MARK OFF

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). Attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result are ignored without indication.

Copyright © 2004, Cognitive. 57

Page 63

PROGRAMMING

!RFID RDAFTWT

Function This command initiates an integrity test following a

WT command. Data is read and undergoes a byteby-byte comparison with the initial data. The

comparison occurs before the WT command is

returned as successful or failed.

Explicit Form

Parameters

!RFID RDAFTWT ON/OFF

ON

Byte-by-byte comparison with initial

data is performed.

OFF

No comparison is performed.

Response No specific response

Command Type RFID Setup/Debug Command

Example To Printer:

!RFID RDAFTWT OFF

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). Attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result are ignored without indication.

Copyright © 2004, Cognitive. 58

Page 64

PROGRAMMING

!RFID RETRY

Function This command sets the number of retries that the

printer will perform on a RT, WT, or WTLOCK

command. To enter the retry loop, the printer must

fail a specific command after reading the tag

identification and type.

Explicit Form

Parameters

!RFID RETRY nn

nn

Number of retries allowed. There are no

range limitations.

Response No specific response

Command Type RFID Setup/Debug Command

Example To Printer:

!RFID RETRY 1

!RFID ?

From Printer:

Setup/Config Parameters:

Assigned Tag Type: ISO15693

| | |

Confirm Commands: OFF

Retry Command: 1 Times

Base Cmd Timeout: 10 MSecs

Select Tag Timeout: 70 MSecs

Read Tag Timeout: 16 MSecs

Write Tag Timeout: 32 MSecs

Lock Tag Timeout: 26 MSecs

Copyright © 2004, Cognitive. 59

Page 65

PROGRAMMING

!RFID SSONCMD

Function This command controls the automatic execution of

a Select-Tag command prior to the Host Command

to RT, WT, or WTLOCK an RFID tag.

Explicit Form

Parameters

!RFID SSONCMD ON/OFF

ON

Causes automatic Select-Tag command

executions before any RT, WT or WTLOCK

command.

OFF

No automatic Select-Tag command

occurs

Response No specific response

Command Type RFID Setup/Debug Command

Example To Printer:

!RFID SSONCMD OFF

!RFID ?

From Printer:

Setup/Config Parameters:

Assigned Tag Type: ISO15693

| | |

LED Flash Duration: 250 MSecs

SelecTag before Cmd: ON

TxPowerRF after Cmd: ON

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). Attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result are ignored without indication.

Copyright © 2004, Cognitive. 60

Page 66

PROGRAMMING

!RFID TAGTYPE

Function This command verifies a tag type. Enter the tag

type and verify the change with the !RFID ?

command.

Explicit Form

Parameters

!RFID TAGTYPE ISO/TI/PHILPS

ISO

Sets the industry standard ISO-15693

tag type

TI

Sets Texas-Instrument’s ‘Tag-it HF’ tag

type.

PHILPS

Sets Philips ‘I-Code1 (SL1)’ tag type.

Response No specific response

Command Type RFID Setup/Debug Command

Example To Printer:

!RFID TAGTYPE ISO

!RFID ?

From Printer:

Setup/Config Parameters:

Assigned Tag Type: ISO15693

Mark/OverRide State: OFF

VOID Stamp Message: <NoStampMsg>

LED Flash Control: ON

| | |

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). Attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result are ignored without indication.

Copyright © 2004, Cognitive. 61

Page 67

PROGRAMMING

!RFID TIMEOUT

Function This command sets the time delay, in milliseconds,

to wait before considering a command a failure.

NOTE: The parameters are part of a calculation and do

not translate into exact execution time differences.

Explicit Form

Parameters

!RFID TIMEOUT bb,ss,rr,ww,ll

bb

Base Time Out – Specifies the time

delay in milliseconds. The range of this

parameter is 0 through 65535.

ss

Base Time Out – Specifies the time

delay in milliseconds. The range of this

parameter is 0 through 65535.

rr

Read Time Out – Specifies the time

delay in milliseconds. The range of this

parameter is 0 through 65535.

ww

Write Time Out – Specifies the time

delay in milliseconds. The range of this

parameter is 0 through 65535.

ll

Lock Time Out – Specifies the time

delay in milliseconds. The range of this

parameter is 0 through 65535.

Command Type RFID Setup/Debug Command

Copyright © 2004, Cognitive. 62

Page 68

PROGRAMMING

Example To Printer:

!RFID 20,,,,50

!RFID ?

From Printer:

Setup/Config Parameters:

| | |

Base Cmd Timeout: 20 Msecs

Select Tag Timeout: 70 Msecs

Read Tag Timeout: 16 MSecs

Write Tag Timeout: 32 MSecs

Lock Tag Timeout: 50 Msecs

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). Attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result are ignored without indication.

Copyright © 2004, Cognitive. 63

Page 69

PROGRAMMING

!RFID TXAFTER

Function This command controls the state of the hardware’s

RF carrier transmission after any Host Command

to read, write or write and lock an RFID-Tag

Explicit Form

Parameters

!RFID TXAFTER ON/OFF

ON

Causes hardware to keep RF carrier

transmission ON after CPL-RFID TagInterface command completion.

OFF

Causes hardware to turn RF carrier

transmission OFF after CPL-RFID TagInterface command completion

Response No specific response

Command Type RFID Setup/Debug Command

Example To Printer:

!RFID TXAFTER OFF

!RFID ?

From Printer:

Setup/Config Parameters:

Assigned Tag Type: ISO15693

| | |

LED Flash Duration: 250 MSecs

SelecTag before Cmd: ON

TxPowerRF after Cmd: OFF

| | |

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). Attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result are ignored without indication.

Copyright © 2004, Cognitive. 64

Page 70

PROGRAMMING

!RFID VOID

Function This command instructs the printer to use this

specified ASCII string to stamp or print on failing

RFID-Tags if and only if !RFID MARK ON is

selected.

Explicit Form

!RFID VOID “ASCII-String-to-Stamp-BadTags”

Parameters

“ASCIIString-toStamp-BadTags”

Text string to stamp or print on

failed tags. String must be 0-240

characters in length.

Command Type RFID Setup/Debug Command

Example To Printer:

!RFID VOID “<<<BAD RFID TAG>>>”

!RFID MARK ON

!RFID ?

From Printer:

Setup/Config Parameters:

Assigned Tag Type: ISO15693

Mark/OverRide State: ON

VOID Stamp Message: <<<BAD RFID TAG>>>

LED Flash Control: ON

LED Flash Duration: 250 MSecs

SelecTag before Cmd: ON

| | |

NOTE: All CPL-RFID Configuration-Setup Commands

are processed outside the context of a standard CPL

Label-Format (i.e. CPL beginning with a header-line ‘! 0

100 nnn 1’ and ending with ‘END’). Attempts to use

CPL-RFID Configuration-Setup Commands within a

Label-Format result are ignored without indication.

Copyright © 2004, Cognitive. 65

Page 71

Chapter

8

Troubleshooting

The Advantage RFID Thermal Printer is a dependable printer that

requires little user maintenance. When problems occur, it is important

to determine if hardware or programming is the cause.

Isolating Problems

Programming issues can often make the problem appear hardware

related. Use the following steps to determine the source of the problem.

Run a Printer Self Test

If the printer will not print a self-test label, the problem is most likely a

hardware problem. The printer will not respond to incoming data if it

will not print a self-test label.

Print a Proven Label Format

If you have a known-good label format, try printing it before

troubleshooting new label formats. If the proven format will not print,

look for a communication problem. If the proven format does print, you

will have eliminated most of the possible hardware-related problems.

Print a Label Format Written on Your System

Sometimes the host operating system or text editor produces data that

is incompatible with the printer. Creating a simple label format using

the host system and sending the format to the printer helps isolate this

problem. Something like this will do:

CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

! 0 100 20 1

STRING 8X8 10 10 HELLO

END

Copyright © 2004, Cognitive. 66

Page 72

PROGRAMMING

If the printer will not print this label but does print labels that were

prepared on another system, your system may not be compatible with

the printer. The most common cause of this is improper end-of-line

termination.

NOTE: Hex dump mode allows you to see every character that reaches the

printer. Use of hex dump mode can help resolve some programming problems.

Check the Label Format Header Line

When a particular label format will not print or is cut off at the bottom,

the trouble is frequently in the header line. Check the header line before

continuing. Especially check that the header line begins with the proper

mode character and specifies the correct number of dot rows. When

programming portable printers, the header line should be preceded by

the wake-up string.

Comment Out Portions of the Nonworking Label Format

You can usually isolate a bad printer command by placing a "C" before

selected command lines. Begin by commenting out the most complex

lines, then try printing the format again. If the problem persists, try

commenting out every line between the header line and the END

statement, then add lines one at a time to see which lines are at fault.

After you have isolated the portion of the format that does not work,

examine the code for errors or test the code by itself in a simpler format.

When examining label formats, look for instances where the letters "O"

or "I" have been incorrectly entered for the numbers 0 and 1. These are

very common typographical errors.

Common Issues

The following issues are based on technical support records of user

questions.

Labels Skipping or Printer Feeding Blank Labels

Label skipping can frequently be corrected by performing a printer

calibration. Refer to Chapter 6, Maintenance and Calibration for the

calibration procedure.

Copyright © 2004, Cognitive. 67

Page 73

PROGRAMMING

READY Light is Red

Make sure that the printhead is latched down tightly on both sides.

If the printer feeds out multiple blank labels, it will need to be

calibrated. Refer to Chapter 6, Maintenance and Calibration, for

calibration instructions.

Make sure that you have the correct power supply for your printer.

Blaster and Advantage model printers use a 19VAC output power

supply; Del Sol and Solus model printers have a 24VAC output power

supply. The output voltage is printed on the power supply.

Setting Up an Ethernet Printer

First, connect the printer to a PC via the parallel or serial port (see

parallel or serial port setup). Do NOT connect the Ethernet cable at this

time.

Type in the following commands from a Dos Editor or from Notepad on

your computer:

! 0 0 0 0 (Must use zero; space between each character)

VARIABLE ETHERNET IP xxx,xxx,xxx,xxx

VARIABLE NETMASK xxx,xxx,xxx,xxx

VARIABLE GATEWAY xxx,xxx,xxx,xxx

VARIABLE ETHERNET RESET

END

Send this file to the printer by going to File->Print. The printer will not

print anything, but the ready light will blink off and on. When you have

a solid Green ready light, cycle the power on the printer.

NOTE: If using a Unix/Linux system, you will need to create a text file in an

editor, then print or copy the file to the printer.

Next, disconnect the parallel or serial cable and connect the Ethernet.

You should now be able to ping the printer.

NOTE: The parallel or serial cable and the Ethernet cable should NOT be