Cognex In-Sight 7801C, In-Sight 7900, In-Sight 7802, In-Sight 7802C, In-Sight 7900C Reference Manual

...

®

In-Sight

7000 Gen2 Series

Vision System

Reference Guide

2018 April 24

Revision:5.6.0.90

Legal Notices

Legal Notices

The software described in this document is furnished under license, and may be used or copied only in accordance with

the terms of such license and with the inclusion of the copyright notice shown on this page. Neither the software, this

document, nor any copies thereof may be provided to, or otherwise made available to, anyone other than the licensee.

Title to, and ownership of, this software remains with Cognex Corporation or its licensor. Cognex Corporation assumes

no responsibility for the use or reliability of its software on equipment that is not supplied by Cognex Corporation.

Cognex Corporation makes no warranties, either express or implied, regarding the described software, its

merchantability, non-infringement or its fitness for any particular purpose.

The information in this document is subject to change without notice and should not be construed as a commitment by

Cognex Corporation. Cognex Corporation is not responsible for any errors that may be present in either this document or

the associated software.

Companies, names, and data used in examples herein are fictitious unless otherwise noted. No part of this document

may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose, nor

transferred to any other media or language without the written permission of Cognex Corporation.

Copyright © 2017 - 2018. Cognex Corporation. All Rights Reserved.

Portions of the hardware and software provided by Cognex may be covered by one or more U.S. and foreign patents, as

well as pending U.S. and foreign patents listed on the Cognex web site at: http://www.cognex.com/patents.

The following are registered trademarks of Cognex Corporation:

Cognex, 2DMAX, Advantage, AlignPlus, Assemblyplus, CheckitwithChecker, Checker, CognexVisionforIndustry,

CognexVSOC, CVL, DataMan, DisplayInspect, DVT, EasyBuilder, Hotbars, IDMax, In-Sight, LaserKiller, MVS-8000,

OmniView, PatFind, PatFlex, PatInspect, PatMax, PatQuick, SensorView, SmartView, SmartAdvisor, SmartLearn,

UltraLight, VisionSolutions, VisionPro, VisionView

The following are trademarks of Cognex Corporation:

The Cognex logo, 1DMax, 3D-Locate, 3DMax, BGAII, CheckPoint, CognexVSoC, CVC-1000, FFD, iLearn, In-Sight

(design insignia with cross-hairs), In-Sight2000, InspectEdge, Inspection Designer, MVS, NotchMax, OCRMax,

PatMaxRedLine, ProofRead, SmartSync, ProfilePlus, SmartDisplay, SmartSystem, SMD4, VisiFlex, Xpand

Portions copyright © Microsoft Corporation. All rights reserved.

Portions copyright © MadCap Software, Inc. All rights reserved.

Other product and company trademarks identified herein are the trademarks of their respective owners.

2

Regulations/Conformity

Regulations/Conformity

Note: For the most up-to-date CE declaration and regulatory conformity information, please refer to the Cognex

online support site: http://www.cognex.com/Support.

Safety and Regulatory

Manufacturer

FCC

KCC In-Sight 7600/7600C: Regulatory Model 1AAB: MSIP-REM-CGX-1AAB

NRTL TÜV SÜD AM SCC/NRTL OSHA Scheme for UL/CAN 61010-1.

CB TÜV SÜD AM, IEC/EN 61010-1. CB report available upon request.

EU RoHS Compliant to the latest applicable Directive.

Cognex Corporation

One Vision Drive

Natick, MA 01760 USA

In-Sight 7600/7600C: Regulatory Model 1AAB

In-Sight 7800/7800C: Regulatory Model 1AAB

In-Sight 7801/7801C: Regulatory Model 1AAB

In-Sight 7802/7802C: Regulatory Model 1AAB

In-Sight 7900/7900C: Regulatory Model 1AAB

In-Sight 7901/7901C: Regulatory Model 1AAB

In-Sight 7902/7902C: Regulatory Model 1AAB

In-Sight 7905/7905C: Regulatory Model R00063

FCC Part 15, Class A

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference; and (2) this device must accept any

interference received, including interference that may cause undesired operation. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at their own expense.

In-Sight 7800/7800C: Regulatory Model 1AAB: MSIP-REM-CGX-1AAB

In-Sight 7801/7801C: Regulatory Model 1AAB: MSIP-REM-CGX-1AAB

In-Sight 7802/7802C: Regulatory Model 1AAB: MSIP-REM-CGX-1AAB

In-Sight 7900/7900C: Regulatory Model 1AAB: MSIP-REM-CGX-1AAB

In-Sight 7901/7901C: Regulatory Model 1AAB: MSIP-REM-CGX-1AAB

In-Sight 7902/7902C: Regulatory Model 1AAB: MSIP-REM-CGX-1AAB

In-Sight 7905/7905C: Regulatory Model R00063: R-REM-CGX-R00063

3

Regulations/Conformity

China RoHS

Hazardous Substances 有害 物 质

Part Name

部件名 称

Regulatory

Model 1AAB

Regulatory

Model R00063

This table is prepared in accordance with the provisions of SJ/T 11364.

这个标 签 是 根据SJ / T 11364 的 规 定 准备的。

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement of GB / T26572 - 2011.

表示本 部 件 所有均质材 料 中 含 有的有害物 质 低 于GB / T26572 - 2011 的限量要 求 。

X: Indicates that said hazardous substance contained in at least one of the homogeneous materials used for this part is

above the limit requirement of GB / T26572 - 2011.

表示用 于 本 部件的至少 一 种 均 质材料中所 含 的 危害物质超 过 GB / T26572 - 2011 的 限 制要求。

Lead (Pb)铅Mercury (Hg)汞Cadmium

(Cd)

镉

X O O O O O

Hexavalent

Chromium

(Cr (VI))

六价铬

Polybrominated

biphenyls (PBB)

多溴联 苯

Polybrominated

diphenyl ethers (PBDE)

多溴二 苯 醚

For European Community Users

Cognex complies with Directive 2012/19/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 4 July 2012

on waste electrical and electronic equipment (WEEE).

This product has required the extraction and use of natural resources for its production. It may contain hazardous

substances that could impact health and the environment, if not properly disposed.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the natural

resources, we encourage you to use the appropriate take-back systems for product disposal. Those systems will reuse or

recycle most of the materials of the product you are disposing in a sound way.

The crossed out wheeled bin symbol informs you that the product should not be disposed of along with municipal

waste and invites you to use the appropriate separate take-back systems for product disposal.

If you need more information on the collection, reuse, and recycling systems, please contact your local or regional waste

administration.

You may also contact your supplier for more information on the environmental performance of this product.

4

Precautions

Precautions

Observe these precautions when installing the Cognex product, to reduce the risk of injury or equipment damage:

l The vision system is intended to be supplied by a UL or NRTL listed power supply with a 24VDC output rated for

at least 2A continuous, a maximum short circuit current rating of less than 8A, a maximum power rating of less

than 100VA and marked Class 2 or Limited Power Source (LPS). Any other voltage creates a risk of fire or shock

and can damage the components. Applicable national and local wiring standards and rules must be followed.

l To reduce the risk of damage or malfunction due to over-voltage, line noise, electrostatic discharge (ESD), power

surges, or other irregularities in the power supply, route all cables and wires away from high current wiring or

high-voltage power sources.

l Do not install Cognex products where they are directly exposed to environmental hazards such as excessive

heat, dust, moisture, humidity, impact, vibration, corrosive substances, flammable substances, or static electricity.

l Do not expose the image sensor to laser light; image sensors can be damaged by direct, or reflected, laser light.

If your application requires the use of laser light that may strike the image sensor, a lens filter at the

corresponding laser's wavelength is recommended. Contact your local integrator or application engineer for

suggestions.

l Changes or modifications not expressly approved by the party responsible for regulatory compliance could void

the user’s authority to operate the equipment.

l Service loops should be included with all cable connections.

l Cable shielding can be degraded or cables can be damaged or wear out more quickly if a service loop or bend

radius is tighter than 10X the cable diameter. The bend radius must begin at least six inches from the connector.

l This device is certified for office use only and if used at home, there can be frequency interference problems.

l This device should be used in accordance with the instructions in this manual.

l All specifications are for reference purpose only and may be changed without notice.

5

Table of Contents

Table of Contents

Legal Notices 2

Regulations/Conformity 3

China RoHS 4

For EuropeanCommunity Users 4

Precautions 5

Table of Contents 6

Symbols 8

Introduction 9

Support 9

Standard Components 9

Accessories 10

In-Sight Lenses, Lights and Covers 10

DataMan Lenses, Lights and Covers 16

External Lights 18

Cables 19

Mounting Brackets 20

I/O Modules 20

Connectors and Indicators 21

Installation 22

Install the Lens, Lighting and Cover 22

Install the C-Mount Lens and Cover (COV-7000-CMNT or COV-7000-CMNT-EX) 22

Install the C-Mount Lens and Cover (COV-7000-CMNT-LG) 24

Install the C-Mount Lens and Illumination 25

Install the Autofocus Lens and Illumination 30

Install the S-Mount/M12 Manual Focus Lens 36

Mount the Vision System 38

Install the Mounting Bracket (ISB-7000-7K) 39

Install the Mounting Bracket (ISB-7000-5K) 40

Working Distance and Field of View (S-Mount/M12 Lenses) 41

Connect the External Light Cable (Optional) 44

Connect the Ethernet Cable 44

Connect the Breakout Cable 45

Connect the CIO-MICRO I/O Module (Optional) 46

Connect the CIO-1400 I/O Expansion Module (Optional) 49

Replace the SD Card (Optional) 51

Replace the LED Ring Light (Optional) 52

Replace the M12 Autofocus Lens (Optional) 57

Remove the Illumination Accessory PCB 66

Specifications 68

7600/7800 Series Vision System Specifications 68

7900/7901/7902 Vision System Specifications 71

7905 Vision System Specifications 74

Acquisition Trigger Input 77

General-Purpose Inputs 78

6

Table of Contents

High-Speed Outputs 79

High-Speed Output Wiring 80

External Light Connector 81

Ethernet Cable 82

Breakout Cable 83

I/O Module Cable 84

Dimensions 85

7600/7800 Series, 7900/7901/7902 Vision System 85

7600/7800 Series, 7900/7901/7902 Vision System with Cover (COV-7000-CMNT) 86

7600/7800 Series, 7900/7901/7902 Vision System with Cover (COV-7000-CMNT-EX) 87

7600/7800 Series, 7900/7901/7902 Vision System with Illumination (ISLM-7000-xx) 88

7905 Vision System 89

7905 Vision System with Cover (COV-7000-CMNT) 90

7905 Vision System with Cover (COV-7000-CMNT-EX) 91

7905 Vision System with Cover (COV-7000-CMNT-LG) 92

7905 Vision System with Illumination (ISLM-7000-xx) 93

Mounting Bracket (ISB-7000-7K) 94

Mounting Bracket (ISB-7000-5K) 95

C-Mount Lens Clearance Dimensions 96

Cleaning/Maintenance 97

Clean the Housing 97

Clean the Image Sensor Window 97

Clean the Cover 97

7

Symbols

The following symbols indicate safety precautions and supplemental information.

WARNING: This symbol indicates the presence of a hazard that could result in death, serious personal injury or

electrical shock.

CAUTION: This symbol indicates the presence of a hazard that could result in property damage.

Note: Notes provide supplemental information about a subject.

Tip: Tips provide helpful suggestions and shortcuts that may not otherwise be apparent.

Symbols

8

Introduction

Introduction

The In-Sight®vision system is a compact, network-ready, stand-alone machine vision system used for automated

inspection, measurement, identification and robot guidance applications on the factory floor. All models can be easily

configured remotely over a network using an intuitive user interface.

Support

Many information resources are available to assist you in using the vision system:

l The In-Sight

l On-demand training: http://www.cognex.com/on-demand-training.aspx.

l The In-Sight online support site: http://www.cognex.com/Support/InSight.

Standard Components

Note:

l Cables are sold separately.

l If any of the standard components appear to be missing or damaged, immediately contact your Cognex

Authorized Service Provider (ASP) or Cognex Technical Support.

®

Explorer Help and EasyBuilder Help files, provided with In-Sight Explorer software.

Component Description

Vision System

Provides image acquisition, vision processing, job storage, Ethernet connectivity and discrete I/O. The

vision system has an 8GB SD card pre-installed.

9

Introduction

Accessories

The following components can be purchased separately. For a complete list of options and accessories, contact your

local Cognex sales representative.

In-Sight Lenses, Lights and Covers

The following In-Sight lenses, lights and covers are supported with the vision system.

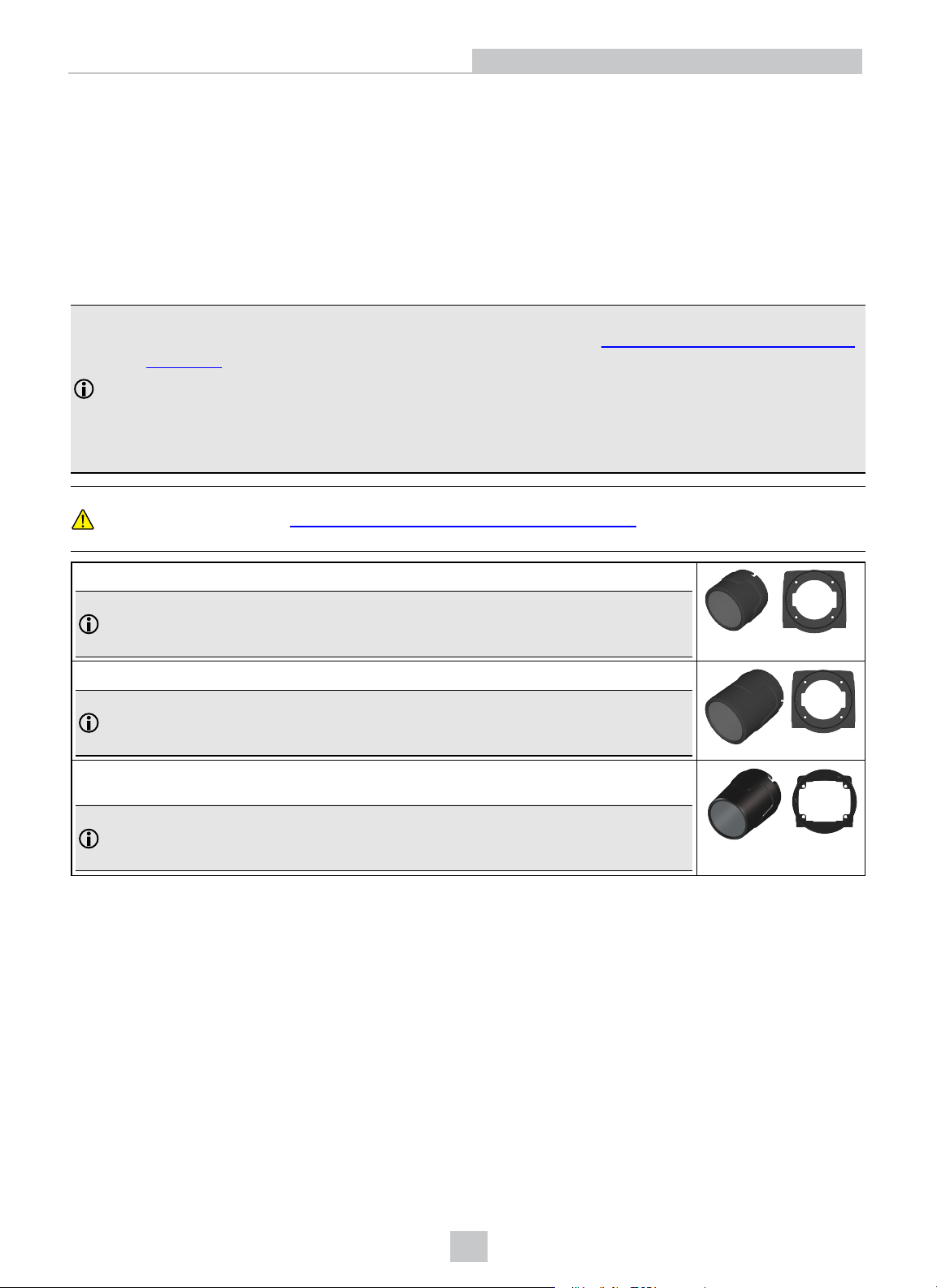

C-Mount Standard and Extended Covers

Note:

l When using a C-Mount lens, the following restrictions apply. Refer to C-Mount Lens Clearance Dimensions

on page96 for more information.

l Maximum thread length is 5.25mm.

l At infinity focus, the back focal length of the lens cannot be greater than 6.5mm in length unless the

back of the lens is smaller than 14.75mm diameter. If the back focal length is exceeded, a spacer

must be installed between the vision system and lens.

CAUTION: If installing a C-Mount cover, the illumination accessory (ISLM-7000-WHI) PCB should not be installed

to the vision system. Refer to Remove the Illumination Accessory PCB on page66 for steps to safely remove the

PCB and avoid damage to the vision system.

Standard C-Mount cover and adapter (COV-7000-CMNT).

Note: If using the COV-7000-CMNT cover, the maximum lens length is 41mm with a

bandpass filter, the maximum lens body diameter is 36.5mm and the maximum diameter

including locking screws is 47mm.

Extended C-Mount cover and adapter (COV-7000-CMNT-EX).

Note: If using the COV-7000-CMNT-EX extended cover, the maximum lens length is

62mm with a bandpass filter, the maximum lens body diameter is 36.5mm and the

maximum diameter including locking screws is 46.5mm.

Large C-Mount cover and adapter (COV-7000-CMNT-LG). This cover is only supported with

the In-Sight 7905 vision system.

Note: If using the COV-7000-CMNT-LG cover, the maximum lens length is 77mm with a

bandpass filter, the maximum lens body diameter is 55mm and the maximum diameter

including locking screws is 55mm.

10

Introduction

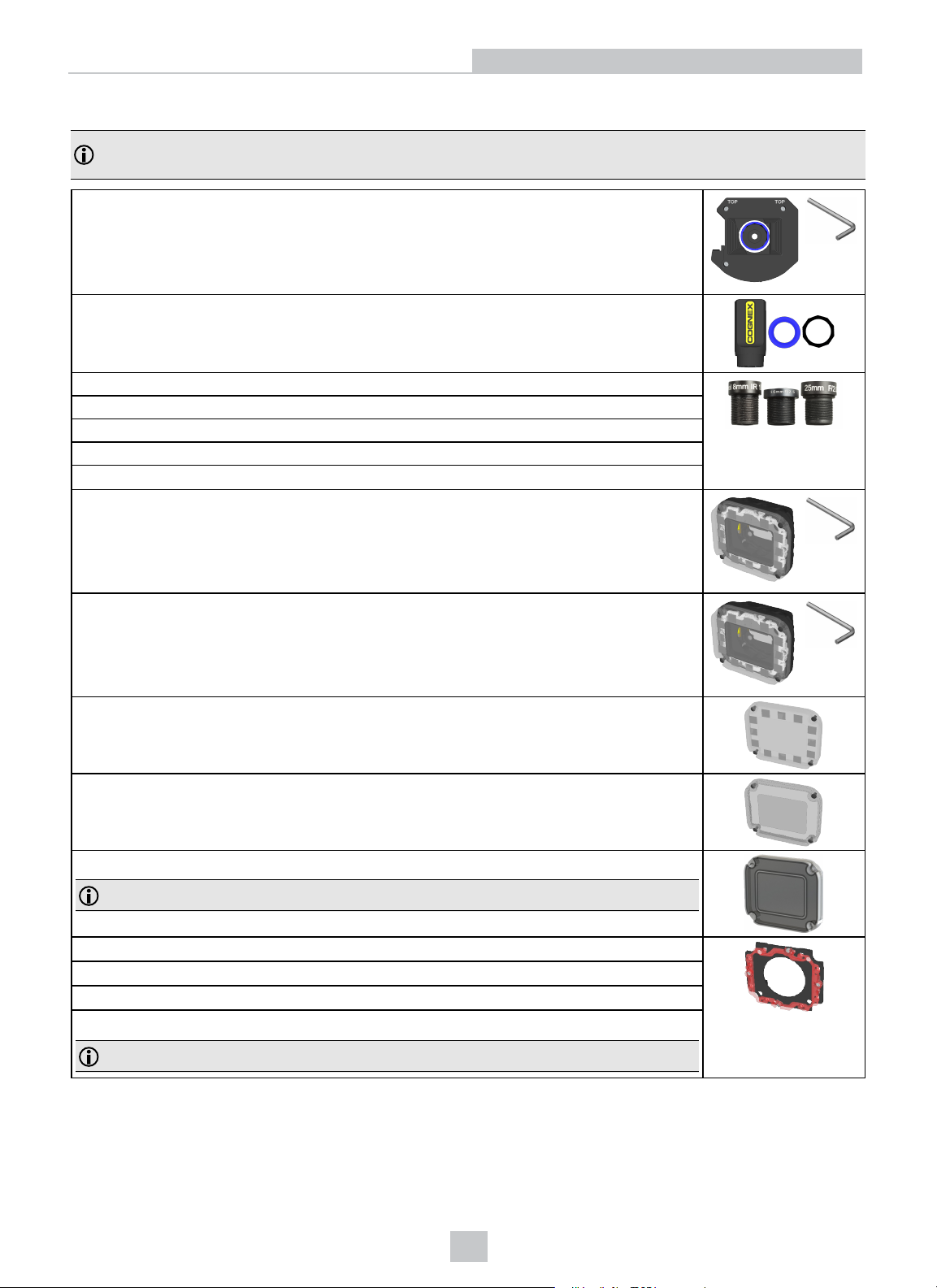

C-Mount Illumination Accessories

Note:

l When using a C-Mount lens, the following restrictions apply. Refer to C-Mount Lens Clearance Dimensions

on page96 for more information.

l Maximum thread length is 5.25mm.

l At infinity focus, the back focal length of the lens cannot be greater than 6.5mm in length unless the

back of the lens is smaller than 14.75mm diameter. If the back focal length is exceeded, a spacer

must be installed between the vision system and lens.

CAUTION: The following C-Mount lenses are supported with vision systems with a 1/1.8 inch image sensor and

using the illumination accessory (ISLM-7000-xx). If using a different C-Mount lens with the illumination accessory, it

must be 29.5mm in diameter or smaller. Maximum lens length is 38.5mm without a bandpass filter and 36mm with a

bandpass filter. Larger lenses will irretrievably damage the vision system.

9mm F1.4 aperture lens (LFC-9F1B)

12.5mm F1.4 aperture lens (LFC-12.5F)

16mm F1.4 aperture lens (LFC-16F1)

25mm F1.4 aperture lens (LFC-25F1)

35mm F1.6 aperture lens (LFC-35F1)

50mm F1.4 aperture lens (LFC-50F1)

Illumination accessory with white LED ring light, cover and hex wrench (ISLM-7000-WHI)

Illumination accessory with cover and hex wrench (ISLM-7000-00). Does not include an LED

ring light.

Diffuse cover (COV-7000-DF)

Clear cover (COV-7000-CLR)

Polarized cover (COV-7000-PL-FULL)

Note: When installing the cover, pull the red tab to remove the protective film.

Red LEDring light (ISL-7000-RD)

IR LED ring light (ISL-7000-IR)

Blue LED ring light (ISL-7000-BL)

White LED ring light (ISL-7000-WHI)

Note: For color vision systems, the white LEDring light should be used.

11

Red bandpass filter (ISF-7000-RDBP605) used with the corresponding red LEDring light

(ISL-7000-RD)

IR bandpass filter (ISF-7000-IRBP815) used with the corresponding IR LED ring light

(ISL-7000-IR)

Blue bandpass filter (ISF-7000-BLBP435) used with the corresponding blue LED ring light

(ISL-7000-BL)

Introduction

12

Introduction

S-Mount/M12 Autofocus Accessories

Note: The In-Sight 7905 vision system does not support this ISAF-7000-8mm autofocus module or any accessories

that require S-Mount/M12 lenses.

Autofocus module with 8mm lens (ISAF-7000-8mm)

Lens removal tool with replacement lens nuts (ISAF-7000-TOOL)

6mm M12 lens (LM12-06-01)

8mm M12 lens (LM12-08-01-F2.2)

12mm M12 lens (LM12-12-01-F2.3)

16mm M12 lens (LM12-16-01)

25mm M12 lens (LM12-25-01)

Illumination accessory with white LED ring light, cover and hex wrench (ISLM-7000-WHI)

Illumination accessory with cover and hex wrench (ISLM-7000-00). Does not include an LED

ring light.

Diffuse cover (COV-7000-DF)

Clear cover (COV-7000-CLR)

Polarized cover (COV-7000-PL-FULL)

Note: When installing the cover, pull the red tab to remove the protective film.

Red LEDring light (ISL-7000-RD)

IR LED ring light (ISL-7000-IR)

Blue LED ring light (ISL-7000-BL)

White LED ring light (ISL-7000-WHI)

Note: For color vision systems, the white LEDring light should be used.

13

Red bandpass filter (ISF-7000-RDBP605) used with the corresponding red LEDring light

(ISL-7000-RD)

IR bandpass filter (ISF-7000-IRBP815) used with the corresponding IR LED ring light

(ISL-7000-IR)

Blue bandpass filter (ISF-7000-BLBP435) used with the corresponding blue LED ring light

(ISL-7000-BL)

Introduction

14

S-Mount/M12 Manual Focus Accessories

Note:

l The In-Sight 7905 vision system does not support this S-Mount/M12 lenses or any accessories that require

S-Mount/M12 lenses.

l The DataMan clear cover accessory (DM300-CLCOV) is supported with In-Sight S-Mount/M12 manual focus

lenses and provides IP65 rating. For more information, refer to DataMan Lenses, Lights and Covers on

page16.

l The following S-Mount/M12 lenses are supported. If a different lens is used, the following restrictions apply:

l At infinity focus, the back focal length must be greater than 5.5mm.

l Close up, the back focal length of the lens cannot be greater than 13mm.

6mm M12 lens (LM12-06-01)

8mm M12 lens (LM12-08-01-F2.2)

12mm M12 lens (LM12-12-01-F2.3)

16mm M12 lens (LM12-16-01)

25mm M12 lens (LM12-25-01)

S-Mount/M12 adapter, lens locking cone and installation tool (ISLN-7000-SMNT)

Introduction

Note: The S-Mount accessory kit (ISLN-7000-SMNT) is required when installing

In-Sight S-Mount/M12 manual focus lenses.

15

Introduction

DataMan Lenses, Lights and Covers

The following DataMan accessories are also supported with the In-Sight vision system for S-Mount/M12 manual focus

lens configurations. DataMan lenses are only supported with DataMan lights and covers.

Note:

l The In-Sight 7905 vision system does not support this S-Mount/M12 lenses or any accessories that require

S-Mount/M12 lenses.

l The following S-Mount/M12 lenses are supported. If a different lens is used, the following restrictions apply:

l At infinity focus, the back focal length must be greater than 5.5 mm.

l Close up, the back focal length of the lens cannot be greater than 10 mm.

10.3mm M12 lens with locking (DM300-LENS-10) and 10.3 mm IR M12 lens with locking

(DM300-LENS-10-IR)

16mm M12 lens with locking (DM300-LENS-16)

25mm M12 lens with lens spacer and hex wrench (DM300-LENS-25) (also requires Extension kit)

Extension kit (DM300-EXT)

Clear cover (DM300-CLCOV)

Clear cover with white LED illumination (DM300-CLCOV-WHI)

Diffuse cover with red LED illumination (DM300-DLCOV-RE)

Diffuse cover with blue LED illumination (DM300-DLCOV-BL)

Diffuse cover with IR LED illumination (DM300-DLCOV-IR)

Polarized cover with red LED illumination (DM300-PLCOV-RE)

Diffuse cover, red illumination (assembled), ESD safe (DM300-DLCOV-RE-ESD)

16

Polarized red LED high-powered integrated light, ESD safe (DM360-HPIL-RE-P)

Non-polarized red LED high-powered integrated light (DM360-HPIL-RE)

High Power Illumination

Red narrow (DM30X-HPIA3-625)

Red wide (DM30X-HPIA3-625-W)

White narrow (DM30X-HPIA3-WHI)

White wide (DM30X-HPIA3-WHI-W)

Blue narrow (DM30X-HPIA3-470)

Blue wide (DM30X-HPIA3-470-W)

Infrared narrow (DM30X-HPIA3-IR)

Infrared wide (DM30X-HPIA3-IR-W)

Note:

l If using the following Cognex high-power lights with a DM30X-HPIA-xxx product ID:

l A spacer kit accessory (DMA-SPKIT-30X-00) is required when using the high power illumination

accessory. When the spacer is used, the field of view will be limited for wide-angled lenses.

Introduction

l A Fair-Rite ferrite (part number 0431167281) must be attached to the External Light cable to reduce

emissions.

Red narrow (DM30X-HPIA-625)

Red wide (DM30X-HPIA-625-W)

Red narrow with polarizer (DM30X-HPIA-625P)

White narrow (DM30X-HPIA-WHI)

White wide (DM30X-HPIA-WHI-W)

Blue narrow (DM30X-HPIA-470)

Blue wide (DM30X-HPIA-470-W)

Infrared narrow (DM30X-HPIA-IR)

Infrared wide (DM30X-HPIA-IR-W)

17

External Lights

External lights can be connected to the vision system's LIGHTconnector using the External Light cable.

Note:

l The vision system supports using either an external light or the illumination accessory (ISLM-7000-WHI), but

does not support using both lighting devices simultaneously.

l If using a Cognex IVSL-ODDM-S75, IVSL-YLW2X-xxx, IVSL-YLW300-xxx or IVSL-LX520-xxx external light,

a Fair-Rite ferrite (part number 0431167281) must be attached to the External Light cable to reduce

emissions.

l If daisy-chaining multiple Cognex IVSL-YLW2X-xxx or IVSL-YLW300-xxx external lights:

l The lights must be powered externally by a separate power supply.

l A Cognex control cable (CCB-FOV25-MAL-012) can be used to connect the vision system’s LIGHT

connector to the external light and a Cognex power cable (IVSL-5PM12-5) can be used to connect

the light to the separate power supply. Only the power and ground wires from the Cognex power

cable (IVSL-5PM12-5) should be connected to the remote power supply.

l If using a Cognex IVSL-LX520-xxx external light:

l The lights must be powered externally by a separate power supply.

l A Cognex control cable (CCB-FOV25-MAL-012) can be used to connect the vision system’s LIGHT

connector to the external light and a Cognex power cable (IVSL-5PM12-5) can be used to connect

the light to the separate power supply. Only the power and ground wires from the Cognex power

cable (IVSL-5PM12-5) should be connected to the remote power supply.

Introduction

l The following power cables must not be used with IVSL-LX520-xxx external lights: IVSL-5PM12-

J300, IVSL-5PM12-J500 and IVS-5PM12-J1000, IVSL-5PM12-J2000.

Ring light (CLRR-R7030G1CLR)

Back light (CLRB-F100100G1)

Coaxial Dual on Access Light (DOAL) (CLRO-K5050G1)

Spot light (CLRS-P14G1)

Dark-field light (CLRD-D120G1)

18

Brick light, narrow blue (IVSL-ODDM-S75-470)

Brick light, narrow red (IVSL-ODDM-S75-625)

Brick light, narrow white (IVSL-ODDM-S75-WHI)

Bar light, wide red (IVSL-YLW2X-625)

Bar light, narrow red, linear polarizer (IVSL-YLW2X-625P)

Bar light, narrow infrared (IVSL-YLW2X-850)

Bar light, narrow blue (IVSL-YLW300-470)

Bar light, wide blue (IVSL-YLW300-470 W)

Bar light, narrow red (IVSL-YLW300-625)

Bar light, wide red (IVSL-YLW300-625 W)

Bar light, narrow white (IVSL-YLW300-WHI)

Bar light, wide white (IVSL-YLW300-WHI W)

Bar light, blue (IVSL-LX520-470)

Bar light, red (IVSL-LX520-625)

Bar light, linear polarizer (IVSL-LX520-LP)

Cables

Introduction

Breakout cable, M12-12 to Flying Lead (CCB-PWRIO- xx) (straight, xx specifies

length: 5m, 10m, 15m)

Breakout cable, M12-12 to Flying Lead (CCB-PWRIO-xxR) (right-angled, xx specifies

length: 5m, 10m, 15m)

Ethernet X-coded M12-8 to RJ-45 cable (CCB-84901-2001-xx) (straight, xx specifies

length: 2m, 5m, 10m, 15m, 30m)

Ethernet X-coded M12-8 to RJ-45 cable (CCB-84901-2002) (right-angled, xx

specifies length: 2m, 5m, 10m)

External Light cable (CCB-M12LTF-xx) (xx specifies length: 0.5m, 1m, 2m, 5m)

External Light cable (IVSL-5PM12-J300, IVSL-5PM12-J500, IVSL-5PM12-J1000 and

IVSL-5PM12-J2000)

I/O Module cable M12-12 to DB15 (CCB-PWRIO-MOD-xx) (xx specifies length: 2m,

5m)

19

Mounting Brackets

Mounting bracket with M3x4 socket head screws and hex wrench (ISB-7000-7K). Also

has 1/4 - 20, M6 and flathead mounting holes. Mounting holes compatible with the

In-Sight 7000 series vision system.

Mounting bracket with Phillips flat head M3 screws and M4x4 screws (ISB-7000-5K).

Mounting holes compatible with the In-Sight 5000 series vision system.

I/O Modules

In-Sight CIO-MICRO I/O Module (CIO-MICRO-00)

Introduction

In-Sight 1400 I/O Expansion Module (CIO-1400)

20

Connectors and Indicators

Connector Function

PWR

Connector

LIGHT

Connector

ENET

Connector

Connects the Breakout cable, which provides connections to an external power supply, the acquisition

trigger input, general-purpose inputs, high-speed outputs, and RS-232 serial communications. For

more information, refer to Breakout Cable on page83. Alternately, this connector is used to attach the

I/O Module cable to a compatible In-Sight I/O module, which adds general-purpose discrete I/O. For

more information, refer to I/O Module Cable on page84.

Connects the vision system to an external lighting device. For more information, refer to External Light

Connector on page81.

Connects the Ethernet cable, which provides 10/100/1000 Ethernet connectivity. For more information,

refer to Ethernet Cable on page82.

Introduction

Indicator Function

Focus Metric

LEDs

TRIG Button

Indicates the image focus score (0 - 10) while in Live Video Mode within

In-Sight Explorer.

Manually triggers an image acquisition when the vision system is either:

l Online within In-Sight Explorer and the acquisition Trigger parameter

is set to Manual.

l Offline within In-Sight Explorer.

Power LED The green LED illuminates to indicate that the vision system is powered on.

SD Card Status

l Off: SDcard is not inserted.

LED

l Green: SD card is present and it is safe to remove the SD card after

removing power from the vision system.

l Yellow: The SD card is present, but it is not safe to remove it.

Pass/Fail LED and

Green or red when active. User configurable.

Indicator Ring

Network LED The yellow LED flashes to indicate network activity.

Error LED

TUNE Button

Red when active. User configurable.

Used as an Event Trigger within In-Sight Explorer to force a cell containing

an Event structure to run when the TUNEbutton is pressed.

21

Installation

Installation

This section describes the connection of the vision system to its standard components and accessories. For a complete

list of options and accessories, contact your Cognex sales representative.

Note: Cables are sold separately.

CAUTION: All cable connectors are “keyed” to fit the connectors on the vision system; do not force the connections

or damage may occur.

Install the Lens, Lighting and Cover

You can choose between a variety of different C-Mount and S-Mount/M12 lenses and covers to install to the vision

system. Refer to In-Sight Lenses, Lights and Covers on page10 and DataMan Lenses, Lights and Covers on page16 for

a complete list of options and accessories.

Install the C-Mount Lens and Cover (COV-7000-CMNT or COV-7000-CMNTEX)

Complete the following steps to install a C-Mount lens and cover (COV-7000-CMNT or COV-7000-CMNT-EX).

Note:

l When using a C-Mount lens, the following restrictions apply. Refer to C-Mount Lens Clearance Dimensions

on page96 for more information.

l Maximum thread length is 5.25mm.

l At infinity focus, the back focal length of the lens cannot be greater than 6.5mm in length unless the

back of the lens is smaller than 14.75mm diameter. If the back focal length is exceeded, a spacer

must be installed between the vision system and lens.

l If using the COV-7000-CMNT cover, the maximum lens length is 41mm with a bandpass filter, the maximum

lens body diameter is 36.5mm and the maximum diameter including locking screws is 47mm.

l If using the COV-7000-CMNT-EX extended cover, the maximum lens length is 62mm with a bandpass filter,

the maximum lens body diameter is 36.5mm and the maximum diameter including locking screws is

46.5mm.

CAUTION: If installing a C-Mount cover, the illumination accessory (ISLM-7000-WHI) PCB should not be installed

to the vision system. Refer to Remove the Illumination Accessory PCB on page66 for steps to safely remove the

PCB and avoid damage to the vision system.

1. Remove the rubber faceplate covering the image sensor window, if present.

2. Remove the protective film covering the threaded lens opening, if present.

3. Place the adapter on the faceplate of the vision system. Insert the four adapter screws and tighten; the maximum

torque is 0.90 Nm (8 in-lb).

4. Thread the lens into the vision system.

22

Installation

5. Attach the cover to the vision system. Rotate the cover clockwise approximately seven degrees to lock it.

23

Installation

Install the C-Mount Lens and Cover (COV-7000-CMNT-LG)

Complete the following steps to install a C-Mount lens and cover (COV-7000-CMNT-LG) to the In-Sight 7905 vision

system. This cover is only supported with the In-Sight 7905 vision system.

Note:

l When using a C-Mount lens, the following restrictions apply. Refer to C-Mount Lens Clearance Dimensions

on page96 for more information.

l Maximum thread length is 5.25mm.

l At infinity focus, the back focal length of the lens cannot be greater than 6.5mm in length unless the

back of the lens is smaller than 14.75mm diameter. If the back focal length is exceeded, a spacer

must be installed between the vision system and lens.

l If using the COV-7000-CMNT-LG cover, the maximum lens length is 77mm with a bandpass filter, the

maximum lens body diameter is 55mm and the maximum diameter including locking screws is 55mm.

CAUTION: If installing a C-Mount cover, the illumination accessory (ISLM-7000-WHI) PCB should not be installed

to the vision system. Refer to Remove the Illumination Accessory PCB on page66 for steps to safely remove the

PCB and avoid damage to the vision system.

1. Remove the rubber faceplate covering the image sensor window, if present.

2. Remove the protective film covering the threaded lens opening, if present.

3. Place the adapter on the faceplate of the vision system. Insert the four adapter screws and tighten; the maximum

torque is 0.90 Nm (8 in-lb).

4. Thread the lens into the vision system.

5. Attach the cover to the vision system. Rotate the cover clockwise approximately thirteen degrees to lock it.

24

Install the C-Mount Lens and Illumination

Complete the following steps to install a C-Mount lens and the illumination accessory (ISLM-7000-WHI).

CAUTION:

l Refer to C-Mount Illumination Accessories on page11 for lenses supported with the illumination accessory

(ISLM-7000-WHI). If using a different C-Mount lens with the illumination accessory, it must be 29.5mm in

diameter or smaller. Maximum lens length is 38.5mm without a bandpass filter and 36mm with a bandpass

filter. Larger lenses will irretrievably damage the vision system.

l Do not hot-plug the illumination accessory; verify the vision system is not receiving power when connecting

or disconnecting the illumination accessory. Failure to remove power during this procedure may result in

damage to the vision system and/or the illumination accessory.

l The vision system should be grounded, either by mounting the vision system to a fixture that is electrically

grounded or by attaching a wire from the vision system’s mounting fixture to frame ground or Earth ground. If

a ground wire is used, it should be attached to one of the four mounting points on the back plate of the vision

system; not to the mounting points on the front of the vision system.

l Tighten all of the illumination accessory screws in the following sequence.

Installation

1. Remove the rubber faceplate covering the image sensor window, if present.

2. Remove the protective film covering the threaded lens opening, if present.

3. Plug the PCB into the lighting connector on the vision system faceplate.

CAUTION: If uninstalling the PCB from the vision system, refer to Remove the Illumination Accessory PCB

on page66 for steps to safely remove the PCB and avoid damage to the vision system.

25

4. Install the spacer.

a. Place the spacer on top of the vision system with “TOP” oriented upward.

b. Verify seating of the gasket on the bottom of the spacer.

c. Insert the four M3 screws and use a 2mm hex wrench to torque screws to 0.34 Nm (3 in-lb). For the 7600,

7800, 7801, 7802, 7900, 7901 and 7902, use the M3 x 6mm screws. For the 7905, use the M3 x 8mm

screws.

Installation

5. Thread the lens into the vision system. Focusing of the C-Mount lens prior to light housing installation is required.

Note: If installing the autofocus accessory (ISAF-7000-8mm), refer to Install the Autofocus Lens and

Illumination on page30.

26

6. Install the light housing.

CAUTION:

l Do not hot-plug the LED ring light; verify the vision system is not receiving power when connecting or

disconnecting the LEDring light.

l A connector protrudes from the underside of the light housing. To prevent damage, it is

recommended the light housing not be removed from the box until ready to be assembled.

Note: If a different LEDcolor is required, refer to Replace the LED Ring Light (Optional) on page52.

a. Place the light housing with LEDring light on top of the spacer, with “TOP” oriented upward.

b. Verify seating of the gasket on the top of the spacer.

c. There are four captive screw access holes near the white circles on the LEDring light. Use a 2mm hex

wrench to torque the captive screws to 0.34 Nm (3 in-lb).

Installation

27

7. Optionally, install a bandpass filter to the light baffle.

Tip: Wear gloves when installing the filter to prevent leaving fingerprints on the surface of the filter.

a. Insert the filter in the light baffle so that it's held in place between the light baffle's filter retention tabs.

b. Push the filter down and snap it into place, ensuring the filter retention tabs are flush with the top surface

of the filter.

Installation

28

8. Install the light baffle.

a. Tilt the light baffle toward the light housing and maneuver the light baffle past the top of the LED ring light

structure.

b. Compress the light baffle and maneuver the bottom of the light baffle past the bottom of the LED ring light

structure until the light baffle snaps into place, with the keyed tabs sitting flush over each light housing

captive screw access hole.

Installation

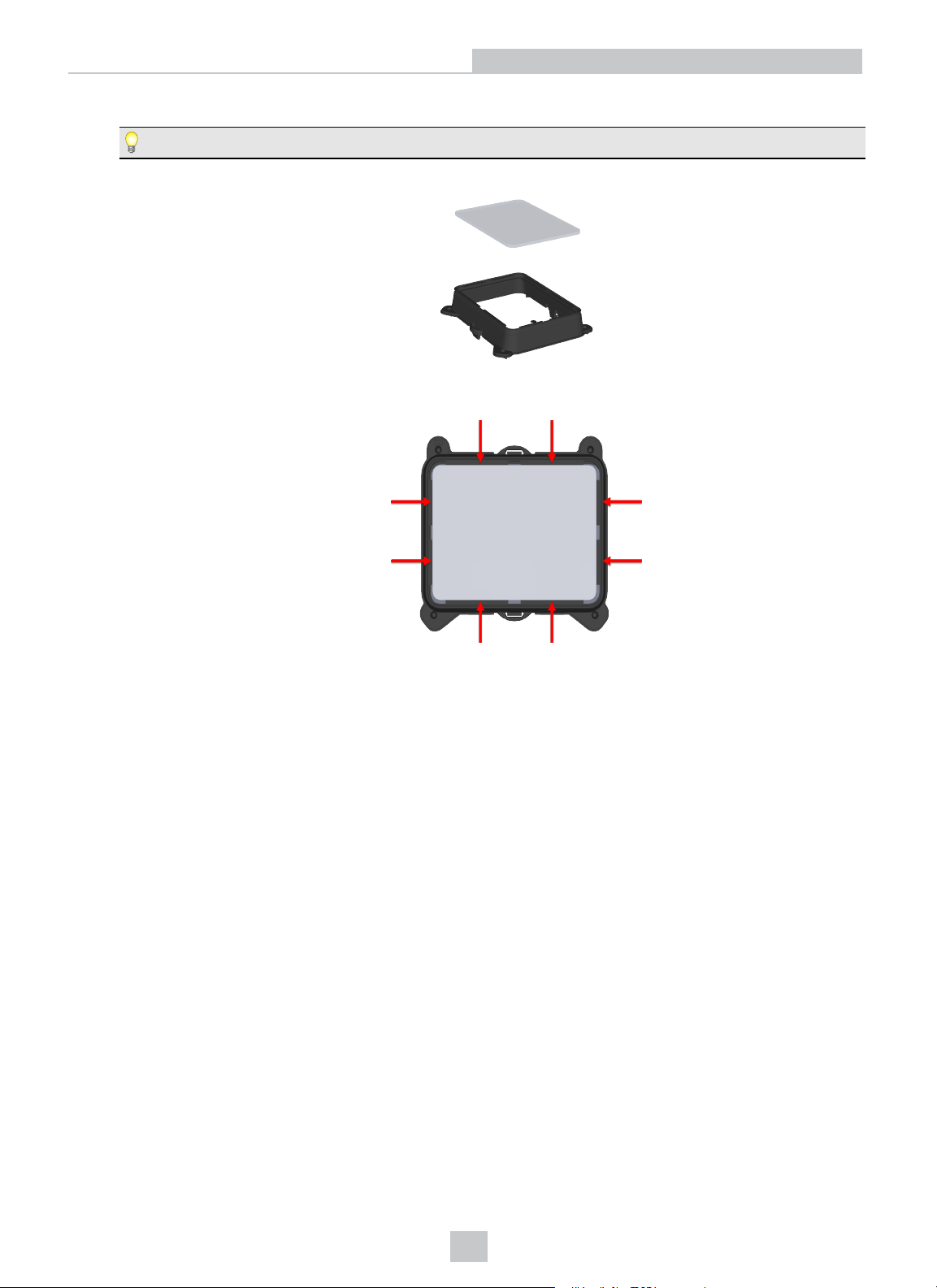

9. Install the cover.

a. Place the cover on the light housing.

b. Align the central clear region of the cover with the light baffle edges.

c. Insert the four M3 x 12mm screws and use a 2mm hex wrench to torque screws to 0.31 Nm (2.75 in-lb).

29

Installation

Install the Autofocus Lens and Illumination

Complete the following steps to install the autofocus accessory (ISAF-7000-8mm) and illumination accessory (ISLM7000-WHI).

Note:

l The In-Sight 7905 vision system does not support the autofocus accessory.

l The autofocus accessory has an 8mm M12 lens pre-installed. If a different lens is required, it should be

installed into the autofocus module before the autofocus module is installed to the vision system. Refer to

Replace the M12 Autofocus Lens (Optional) on page57 for more information.

l The illumination accessory (ISLM-7000-WHI) is sold separately. It is the only cover available for the

autofocus module and is required for IP67 rating.

CAUTION:

l When installing the illumination accessory (ISLM-7000-WHI):

l Do not hot-plug the illumination accessory; verify the vision system is not receiving power when

connecting or disconnecting the illumination accessory. Failure to remove power during this

procedure may result in damage to the vision system and/or the illumination accessory.

l The vision system should be grounded, either by mounting the vision system to a fixture that is

electrically grounded or by attaching a wire from the vision system’s mounting fixture to frame ground

or Earth ground. If a ground wire is used, it should be attached to one of the four mounting points on

the back plate of the vision system; not to the mounting points on the front of the vision system.

l Tighten all of the illumination accessory screws in the following sequence.

1. Remove the rubber faceplate covering the image sensor window, if present.

2. Remove the protective film covering the threaded lens opening, if present.

3. Plug the PCB into the lighting connector on the vision system faceplate.

CAUTION: If uninstalling the PCB from the vision system, refer to Remove the Illumination Accessory PCB

on page66 for steps to safely remove the PCB and avoid damage to the vision system.

30

4. Install the spacer.

a. Place the spacer on top of the vision system with “TOP” oriented upward.

b. Verify seating of the gasket on the bottom of the spacer.

c. Insert the four M3 screws and use a 2mm hex wrench to torque screws to 0.34 Nm (3 in-lb). For the 7600,

7800, 7801, 7802, 7900, 7901 and 7902, use the M3 x 6mm screws. For the 7905, use the M3 x 8mm

screws.

Installation

31

5. Install the autofocus module.

CAUTION: Do not hot-plug the autofocus module; verify the vision system is not receiving power when

connecting or disconnecting the autofocus module.

Note: If a different lens is required, it should be installed in the autofocus module before the autofocus

module is installed to the vision system. Refer to Replace the M12 Autofocus Lens (Optional) on page57 for

more information.

a. There are two alignment pins on the base of the autofocus module; seat the pins into the vision system

faceplate.

b. There are three captive screws in the autofocus module; partially thread the screws into the vision system

faceplate using a 1.5mm hex wrench.

c. Once threaded, torque the captive screws to 0.5 Nm (4.43 in-lb) using a torque screwdriver with a 1.5mm

hex torque bit capable of reaching 15mm into a 2.5mm diameter hole (for example, Wiha Tools 1.5mm

Hex Metric Torque Blade [SKU 28545] used with the Adjustable Torque Handle [SKU 28550]).

Installation

32

6. Install the light housing.

CAUTION:

l Do not hot-plug the LED ring light; verify the vision system is not receiving power when connecting or

disconnecting the LEDring light.

l A connector protrudes from the underside of the light housing. To prevent damage, it is

recommended the light housing not be removed from the box until ready to be assembled.

Note: If a different LEDcolor is required, refer to Replace the LED Ring Light (Optional) on page52.

a. Place the light housing with LEDring light on top of the spacer, with “TOP” oriented upward.

b. Verify seating of the gasket on the top of the spacer.

c. There are four captive screw access holes near the white circles on the LEDring light. Use a 2mm hex

wrench to torque the captive screws to 0.34 Nm (3 in-lb).

Installation

33

7. Optionally, install a bandpass filter to the light baffle.

Tip: Wear gloves when installing the filter to prevent leaving fingerprints on the surface of the filter.

a. Insert the filter in the light baffle so that it's held in place between the light baffle's filter retention tabs.

b. Push the filter down and snap it into place, ensuring the filter retention tabs are flush with the top surface

of the filter.

Installation

34

8. Install the light baffle.

a. Tilt the light baffle toward the light housing and maneuver the light baffle past the top of the LED ring light

structure.

b. Compress the light baffle and maneuver the bottom of the light baffle past the bottom of the LED ring light

structure until the light baffle snaps into place, with the keyed tabs sitting flush over each light housing

captive screw access hole.

Installation

9. Install the cover.

a. Place the cover on the light housing.

b. Align the central clear region of the cover with the light baffle edges.

c. Insert the four M3 x 12mm screws and use a 2mm hex wrench to torque screws to 0.31 Nm (2.75 in-lb).

35

Installation

Install the S-Mount/M12 Manual Focus Lens

Complete the following steps to install an In-Sight S-Mount/M12 manual focus lens. The S-Mount accessory kit (ISLN7000-SMNT) is required when installing In-Sight S-Mount/M12 manual focus lenses.

Note:

l The In-Sight 7905 vision system does not support this S-Mount/M12 lenses or any accessories that require

S-Mount/M12 lenses.

l The DataMan clear cover accessory (DM300-CLCOV) is supported with In-Sight S-Mount/M12 manual focus

lenses and provides IP65 rating. For more information, refer to DataMan Lenses, Lights and Covers on

page16.

1. Remove the rubber faceplate covering the image sensor window, if present.

2. Remove the protective film covering the threaded lens opening, if present.

3. Place the S-Mount adapter over the image sensor window.

4. Place the "In-Sight" end of the adapter tool on the adapter. Turn clockwise until tight.

5. Remove the adapter tool.

36

Installation

6. Thread the lens into the vision system. Focusing of lens prior to installation of the rubber lens-locking cone is

required.

7. Place the rubber lens-locking cone over the M12 lens until it snaps into place around the nose of the lens. When

installing, avoid rotating the M12 lens.

8. If using a lens cover accessory, attach the cover to the vision system.

37

Installation

Mount the Vision System

The vision system provides mounting holes for attachment to a mounting surface.

CAUTION: The vision system should be grounded, either by mounting the vision system to a fixture that is

electrically grounded or by attaching a wire from the vision system’s mounting fixture to frame ground or Earth

ground. If a ground wire is used, it should be attached to one of the four mounting points on the back plate of the

vision system; not to the mounting points on the front of the vision system.

1. Align the holes on the mounting surface with the mounting holes on the vision system.

2. Insert the M3 screws into the mounting holes and tighten using a 2.5mm hex wrench; the maximum torque is 0.90

Nm (8 in-lb).

Note: The maximum insertion depth of the M3 screws is 3.5mm in the rear housing and 3.75mm in the front

housing, plus the thickness of the mounting material used.

38

Installation

Install the Mounting Bracket (ISB-7000-7K)

Complete the following steps to attach the accessory mounting bracket (ISB-7000-7K) to the vision system.

CAUTION:

l The vision system should be grounded, either by mounting the vision system to a fixture that is electrically

grounded or by attaching a wire from the vision system’s mounting fixture to frame ground or Earth ground. If

a ground wire is used, it should be attached to one of the four mounting points on the back plate of the vision

system; not to the mounting points on the front of the vision system.

l When mounting the vision system to the mounting bracket, use the M3 screws supplied with the mounting

kit. If using the 1/4 - 20 or M6 screw holes on the mounting bracket to secure the vision system to a mounting

surface, the insertion depth of the screw should not exceed 7mm. Allowing the mounting screws to bottom in

the mounting hole can damage the vision system.

1. Align the mounting bracket with the mounting holes on the vision system.

2. Insert the M3 screws into the mounting holes and tighten using a 2.5mm hex wrench; the maximum torque is 0.90

Nm (8 in-lb).

39

Installation

Install the Mounting Bracket (ISB-7000-5K)

Complete the following steps to attach the accessory mounting bracket (ISB-7000-5K) to the vision system.

CAUTION:

l The vision system should be grounded, either by mounting the vision system to a fixture that is electrically

grounded or by attaching a wire from the vision system’s mounting fixture to frame ground or Earth ground. If

a ground wire is used, it should be attached to one of the four mounting points on the back plate of the vision

system; not to the mounting points on the front of the vision system.

l When mounting the vision system to the mounting bracket, use the Phillips head screws supplied with the

mounting kit. If using the M4 screw holes on the mounting bracket to secure the vision system to a mounting

surface, the insertion depth of the screw should not exceed 4mm. Allowing the mounting screws to bottom in

the mounting hole can damage the vision system.

1. Align the mounting bracket with the mounting holes on the vision system.

2. Insert the Phillips flat head screws into the mounting holes and tighten; the maximum torque is 0.56 Nm (5 in-lb).

40

Installation

Working Distance and Field of View (S-Mount/M12 Lenses)

The working distance is the distance from the vision system lens to the part that needs to be inspected; field of view is

what the vision system can see at that distance. As the working distance increases, so does the size of the field of view.

Note:

l The In-Sight 7905 vision system does not support this S-Mount/M12 lenses or any accessories that require

S-Mount/M12 lenses.

l The following charts show the design field of view of the In-Sight S-Mount/M12 accessory lenses and is fully

mapped onto the image sensor. Additional field beyond the design field of view may have vignetting. For

supported In-Sight lenses, refer to S-Mount/M12 Autofocus Accessories on page13 and S-Mount/M12

Manual Focus Accessories on page15.

41

Installation

42

Installation

43

Installation

Connect the External Light Cable (Optional)

The vision system's LIGHTconnector is used to connect the External Light cable to an external lighting device, providing

power and strobe control. The External Light cable can be connected to either a continuous or strobed lighting device.

For a list of supported accessories, refer to External Lights on page18.

1. Remove the protective cap from the LIGHT connector, if present.

2. Connect the External Light cable’s M12 connector to the vision system's LIGHT connector. For more information,

refer to External Light Connector on page81.

3. Connect the other end of the Light cable to an external lighting device (for example, a strobe light).

Connect the Ethernet Cable

CAUTION: The Ethernet cable shield must be grounded at the far end. Whatever this cable is plugged into

(typically a switch or router) should have a grounded Ethernet connector. A digital voltmeter should be used to

validate the grounding. If the far end device is not grounded, a ground wire should be added in compliance with

local electrical codes.

1. Connect the Ethernet cable’s M12 connector to the vision system’s ENET connector.

2. Connect the Ethernet cable’s RJ-45 connector to a switch/router or PC, as applicable.

44

Installation

Connect the Breakout Cable

CAUTION: To reduce emissions, connect the far end of the Breakout cable shield to frame ground.

Note:

l I/O wiring or adjustments to I/O devices should be performed when the vision system is not receiving power.

l Exposed wires can be cut short or wire ends trimmed, and the wires tied back using a tie made of non-

conductive material. Keep all bare wires separated from the +24VDC wire.

1. Verify that the 24VDC power supply being used is unplugged and not receiving power.

2. Optionally, connect the I/O wires to an appropriate device (for example, a PLC or a serial device). For more

information, refer to Breakout Cable on page83.

3. Attach the Breakout cable's +24VDC (Red wire) and GND (Black wire) to the corresponding terminals on the

power supply.

CAUTION: Never connect voltages other than 24VDC. Always observe the polarity shown.

4. Connect the Breakout cable's M12 connector to the vision system's PWR connector.

5. Restore power to the 24VDC power supply and turn it on if necessary.

45

Installation

Connect the CIO-MICRO I/O Module (Optional)

The vision system can access the CIO-MICRO I/O module's general-purpose input and output lines via an Ethernet

connection to the I/O module. Optionally, the I/O Module cable can be connected to access the I/O module's TRIGGER+,

TRIGGER-, HS OUT 0, HS OUT 1 and HS COMMON lines.

Note:

l When the vision system is connected to the I/O Module cable:

l Illumination accessories attached to the vision system faceplate or LIGHT connector are not

supported. If these illumination accessories are attached, the Breakout cable must be used to supply

power to the vision system and a connection to the I/O module established via Ethernet only.

l The vision system's IN 1, IN 2 / HS OUT 2, and IN 3 / HS OUT 3 lines are not supported.

l The I/O module's general-purpose outputs are configurable as NPN (current sinking) or PNP (current

sourcing) with 100mA maximum current and HS OUT 0 and HS OUT 1 are configurable as NPN (current

sinking) or PNP (current sourcing) with 50mA maximum current.

l The CIO-MICRO I/O module does not support 1000 BaseT pass-through operation. If 1000 BaseT operation

is required, you must connect a LAN cable from a Gigabit Ethernet switch to the I/O module’s LAN port and

connect the vision system’s Ethernet cable to the Gigabit Ethernet switch.

l I/O wiring or adjustments to I/O devices should be performed when the vision system is not receiving power.

I/O Port

Connects the I/O module to the vision system using the I/O Module cable, and provides

power, trigger and high-speed output signals to the vision system.

MODULE OK LED Illuminates after the I/O module has powered on, has booted up, and is ready to

communicate with the vision system.

COMM OK LED Blinks continuously until the vision system has established a successful connection to the

I/O module from In-Sight software. Once successfully connected and communicating

properly, the green LED is constantly illuminated.

PoE STATUS LED Not supported. When the vision system is connected to the I/O module's PoE port, the POE

STATUS LED may blink. This is normal and does not affect operation of the vision system.

PoE Port Connects the I/O module to the vision system, providing the vision system with Ethernet.

The green LED blinks when a network connection to the vision system is detected. The

orange LED blinks when network activity is detected.

46

Installation

LAN Port Connects the I/O module to an Ethernet network. The green LED blinks when a network

connection to the local area network is detected. The orange LED blinks when network

activity is detected.

Frame Ground Terminal Connects the I/O module to a frame ground.

RS-232 Port Connects the I/O module to an external serial device using an RS-232 (DB9) serial cable.

Provides RS-232 communications to the vision system.

High-Speed Output Status

LEDs (HS OUT 0 and HS

OUT 1)

Illuminates to indicate the high-speed output signal for the In-Sight vision system has

switched ON. The LEDs illuminate even if the I/O module’s high-speed terminals are not

connected to anything. In addition, the I/O module displays the last known state of the high-

speed output line; therefore the LEDs may be illuminated even if the vision system's I/O

module cable is disconnected from the I/O module.

Note: The I/O module's high-speed output terminals (labeled HS OUT 0 and HS OUT

1) correspond to the vision system’s built-in high-speed outputs when connected to

the I/O module cable. These signals are considered high-speed because they pass

directly through the I/O module without processing, which provides minimal delay.

I/O and Trigger Status

LEDs

Terminal Blocks

1. Connect the I/O module's power wires.

CAUTION: Never connect the I/O module to a power source other than 24VDC. Any other voltage creates a

risk of fire or shock and can damage the hardware. Do not connect the 24VDC power source to any

terminals other than the 24VDC + and – power terminals.

a. Verify that the 24VDC power supply being used is unplugged and not receiving power.

b. Use a screwdriver to loosen the I/O module's power terminals (labeled 24VDC + and –).

c. Insert the 24VDC + and – wires (16 - 22 AWG, solid or stranded wire) from the power supply into the

24VDC + and – terminals on the I/O module.

d. Tighten the screw terminals with the screwdriver to secure the wire leads in the terminal block; the

maximum torque is 0.1921 Nm (1.7 in-lb).

Illuminates to indicate that an input/output signal has switched ON.

Connects the I/O module to 24VDC power, trigger, external I/O, high-speed outputs and

common connections.

47

Installation

2. Connect a frame ground wire to the I/O module’s Frame Ground terminal. Connect the other end of the frame

ground wire to frame ground.

CAUTION: The shield ground connections of the RS-232 port, LAN port, PoE port, I/O port and Frame

Ground terminal are internally connected. The system grounding is designed to be at a zero ground

potential; this zero ground potential extends through the cable and to peripheral equipment (e.g. a vision

system, PLC, etc.). To ensure safe operating conditions, it is strongly recommended that all ground

connections are checked to ensure that a zero ground potential is met.

3. Connect the I/O module's I/O wires.

a. Determine how I/O devices will be connected to the I/O module’s input and output terminals.

b. Use a screwdriver to loosen the appropriate screw terminals.

c. Connect the input and output wires to the input and output terminals.

d. Connect the other end of the input and output wires to the corresponding I/O device.

e. Tighten the screw terminals with the screwdriver to secure the wire leads in the terminal block; the

maximum torque is 0.1921 Nm (1.7 in-lb).

4. To connect the vision system to a serial device, plug a RS-232 serial cable (DB9 male connector) into the I/O

module’s RS-232 port and connect the other end of the cable to the serial device. Tighten the connector screws

to secure it to the I/O module.

5. Connect to an Ethernet network.

a. Connect a LAN cable (RJ-45 connector) to the I/O module’s LAN port.

b. Connect the other end of the LANcable to a switch/router or PC, as applicable.

6. Connect the vision system's Ethernet cable.

a. Connect the Ethernet cable’s M12 connector to the vision system’s ENET connector.

b. Connect the Ethernet cable’s RJ-45 connector to the I/O module’s PoE port or to a switch/router, as

applicable.

7. Optionally, connect the I/O Module cable (CCB-PWRIO-MOD-xx) to the vision system to gain access to the I/O

module's TRIGGER+, TRIGGER-, HS OUT 0, HS OUT 1 and HS COMMON terminals.

a. Connect the I/O Module cable’s M12 connector to the vision system’s PWR connector.

b. Connect the I/O Module cable’s DB15 connector to the I/O module’s I/O connector.

c. Restore power to the 24VDC power supply and turn it on if necessary.

48

Connect the CIO-1400 I/O Expansion Module (Optional)

Note:

l When connected to the CIO-1400 I/O expansion module:

l HS OUT0 and HSOUT1 are configurable as NPN (current sinking) with 50mA maximum current

and the general-purpose outputs are configurable as NPN (current sinking) or PNP (current

sourcing) with 100mA maximum current.

l The vision system's IN 1, IN 2 / HS OUT 2, and IN 3 / HS OUT3 lines are not supported.

l I/O wiring or adjustments to I/O devices should be performed when the vision system is not receiving power.

Installation

Connector/Indicator Description

COMM OK LED (yellow) Illuminates to indicate that the vision system and I/O module are communicating

properly.

MODULE OK LED (yellow) Illuminates after the I/O module has initialized and is ready to communicate with the

vision system.

I/O and Trigger Status LEDs

Illuminates to indicate when an input/output has switched ON.

(yellow)

SENSOR Port Connects the I/O module to the vision system using the I/O Module cable, which

provides power, trigger, I/O and RS-232 signals to the vision system.

RS232 OUT Port Connects the I/O module to an RS-232 serial cable, which provides RS-232

communications between the I/O module and an external serial device.

Frame Ground Terminal

Connects the I/O module to a common frame ground.

1. Connect the I/O module's power wires.

CAUTION: Never connect the I/O module to a power source other than 24VDC. Any other voltage creates a

risk of fire or shock and can damage the hardware. Do not connect the 24VDC power source to any

terminals other than the 24VDC + and – power terminals.

a. Verify that the 24VDC power supply being used is unplugged and not receiving power.

b. Use a screwdriver to loosen the I/O module's power terminals (labeled 24VDC + and –).

c. Insert the 24VDC + and – wires (16 - 26 AWG, solid or stranded wire) from the power supply into the

24VDC + and – terminals on the I/O module.

d. Tighten the screw terminals with the screwdriver to secure the wire leads in the terminal block; the

maximum torque is 0.4 Nm (3.5 in-lb).

49

Installation

2. Connect a frame ground wire to the I/O module’s Frame Ground terminal. Connect the other end of the frame

ground wire to frame ground.

CAUTION: The shield ground connections of the RS232 OUT port, SENSOR port and Frame Ground

terminal are internally connected. The system grounding is designed to be at a zero ground potential; this

zero ground potential extends through the cable and to peripheral equipment (e.g. a vision system, PLC,

etc.). To ensure safe operating conditions, it is strongly recommended that all ground connections are

checked to ensure that a zero ground potential is met.

3. Connect the I/O module's I/O wires.

a. Determine how I/O devices will be connected to the I/O module’s input and output terminals.

b. Use a screwdriver to loosen the appropriate screw terminals.

c. Connect the input and output wires to the input and output terminals.

d. Connect the other end of the input and output wires to the corresponding I/O device.

e. Tighten the screw terminals with the screwdriver to secure the wire leads in the terminal block; the

maximum torque is 0.4 Nm (3.5 in-lb).

4. To connect the vision system to a serial device, plug an RS-232 serial cable (DB9 male connector) into the I/O

module’s RS232 OUT port and connect the other end of the cable to the serial device. Tighten the connector

screws to secure it to the I/O module.

5. Connect the I/O Module cable (CCB-PWRIO-MOD-xx) to the vision system.

a. Connect the I/O Module cable’s M12 connector to the vision system’s PWR connector.

b. Connect the I/O Module cable’s DB15 connector to the I/O module’s SENSOR port.

c. Restore power to the 24VDC power supply and turn it on if necessary.

50

Installation

Replace the SD Card (Optional)

The vision system is equipped with a Micro SD card slot and an 8GB SD card is pre-installed for saving job and image

files. Complete the following steps to replace the pre-installed SD card.

Note: The vision system supports SD cards formatted with a FAT32 file system.

CAUTION:

l Hot-plugging the SD card is not supported and may damage the SD card and/or lead to unexpected

behavior.

l IP67 protection requires that all cables are properly attached (or the provided connector plug installed), the

IP67-rated lens cover is properly installed and the Micro SD card cover is fastened in place.

l Observe ESD precautions when installing or removing an SD card or other accessories.

1. Remove power from the vision system.

2. Unscrew the screws in the Micro SD card cover and open the card slot.

3. Remove the existing SD card from the Micro SD card slot.

4. Insert the new SD card into the Micro SD card slot, ensuring the card is properly oriented.

5. Replace the SDcard cover, reinsert the screws and torque screws to 0.18 Nm (25 in-oz).

6. Restore power to the vision system.

51

Installation

Replace the LED Ring Light (Optional)

The illumination accessory (ISLM-7000-WHI) has a white LED ring light pre-installed. Complete the following steps to

replace the pre-installed LEDring light.

CAUTION:

l Do not hot-plug the illumination accessory; verify the vision system is not receiving power when connecting

or disconnecting the illumination accessory. Failure to remove power during this procedure may result in

damage to the vision system and/or the illumination accessory.

l Tighten all of the illumination accessory screws in the following sequence.

1. Remove power from the vision system.

2. Use a 2mm hex wrench to remove the four M3 x 12mm screws and remove the cover.

52

3. Remove the keyed light baffle.

Note: The following graphic includes an optional bandpass filter accessory installed to the light baffle. For

more information, refer to In-Sight Lenses, Lights and Covers on page10.

Installation

4. The LEDring light screw holes are indicated by a triangle symbol ►. Use a 2mm hex wrench to remove the four

M2.5 x 6mm screws and remove the LED ring light from the light housing.

53

5. Install the new LEDring light.

CAUTION: Do not hot-plug the LED ring light; verify the vision system is not receiving power when

connecting or disconnecting the LEDring light.

a. Place the new LEDring light inside the light housing, with "TOP" oriented upward.

b. Insert the four M2.5 x 6mm screws into the screw holes indicated by a triangle symbol ►.

c. Tighten the screws using a 2mm hex wrench; the maximum torque is 0.34 Nm (3 in-lb).

Installation

54

6. Install the light baffle.

a. Tilt the light baffle toward the light housing and maneuver the light baffle past the top of the LED ring light

structure.

b. Compress the light baffle and maneuver the bottom of the light baffle past the bottom of the LED ring light

structure until the light baffle snaps into place, with the keyed tabs sitting flush over each light housing

captive screw access hole.

Note: The following graphic includes an optional bandpass filter accessory installed to the light

baffle. For more information, refer to In-Sight Lenses, Lights and Covers on page10.

Installation

55

7. Install the cover.

a. Place the cover on the light housing.

b. Align the central clear region of the cover with the light baffle edges.

c. Insert the four M3 x 12mm screws and use a 2mm hex wrench to torque screws to 0.31 Nm (2.75 in-lb).

Installation

8. Restore power to the vision system.

56

Installation

Replace the M12 Autofocus Lens (Optional)

The autofocus accessory (ISAF-7000-8mm) has an 8mm M12 lens pre-installed. Complete the following steps to replace

the pre-installed M12 lens.

Note: The In-Sight 7905 vision system does not support this ISAF-7000-8mm autofocus module or any accessories

that require S-Mount/M12 lenses.

CAUTION:

l Do not hot-plug the illumination accessory; verify the vision system is not receiving power when connecting

or disconnecting the illumination accessory. Failure to remove power during this procedure may result in

damage to the vision system and/or the illumination accessory.

l Tighten all of the illumination accessory screws in the following sequence.

1. If the autofocus module is already installed to the vision system, you must first log onto the vision system using

In-Sight Explorer software and reset the focus position to 0. Refer to the In-Sight®Explorer Help file for more

information.

2. Remove power from the vision system.

3. Use a 2mm hex wrench to remove the four M3 x 12mm screws and remove the cover.

57

4. Remove the keyed light baffle.

Note: The following graphic includes an optional bandpass filter accessory installed to the light baffle. For

more information, refer to In-Sight Lenses, Lights and Covers on page10.

Installation

5. The light housing contains four captive screws that are accessible via captive screw access holes in the LEDring

light board. Use a 2mm hex wrench to loosen the four captive screws and remove the light housing.

CAUTION:

l Do not hot-plug the LED ring light; verify the vision system is not receiving power when connecting or

disconnecting the LEDring light.

l A connector protrudes from the underside of the light housing and can be damaged if placed on a

hard surface.

58

Installation

6. Use a 1.5mm hex wrench to loosen the three captive screws in the autofocus module and remove the autofocus

module from the vision system.

CAUTION: Do not hot-plug the autofocus module; verify the vision system is not receiving power when

connecting or disconnecting the autofocus module.

59

7. Remove the M12 lens from the autofocus module.

a. A lens tool is included with the lens toolkit accessory (ISAF-7000-TOOL). Place the lens tool directly on

the M12 lens, with the padded end of the tool pressed against the lens.

b. Holding the lens tool in place, remove the blue threaded lens nut on the underside of the autofocus

module.

CAUTION: Use light axial force on the lens tool when installing or removing the lens.

Installation

c. Remove the M12 lens from the autofocus module.

60

8. Install the new M12 lens.

a. An extra black lens nut is included with the lens toolkit accessory (ISAF-7000-TOOL). Thread this black

lens nut on the new M12 lens until snug.

b. Drop the new M12 lens into the module.

c. Quarter-turn the thread of the lens clockwise, to ensure the lens is seated in the lens carrier.

Installation

d. Once the lens is in the module, place the lens tool directly on the lens, with the padded end of the tool

pressed against the lens.

61

e. With the chamfer side of the blue lens nut facing the module, thread the blue lens nut on the lens and

finger-tighten until snug. The lens nut should be tight enough that it does not fall off due to vibration.

CAUTION: Use light axial force on the lens tool when installing or removing the lens.

Chamfer Side of Blue Lens Nut:

9. Install the autofocus module.

CAUTION: Do not hot-plug the autofocus module; verify the vision system is not receiving power when

connecting or disconnecting the autofocus module.

a. There are two alignment pins on the base of the autofocus module; seat the pins into the vision system

faceplate.

Installation

b. There are three captive screws in the autofocus module; partially thread the screws into the vision system

faceplate using a 1.5mm hex wrench.

c. Once threaded, torque the captive screws to 0.5 Nm (4.43 in-lb) using a torque screwdriver with a 1.5mm

hex torque bit capable of reaching 15mm into a 2.5mm diameter hole (for example, Wiha Tools 1.5mm

Hex Metric Torque Blade [SKU 28545] used with the Adjustable Torque Handle [SKU 28550]).

62

10. Install the light housing.

CAUTION:

l Do not hot-plug the LED ring light; verify the vision system is not receiving power when connecting or

disconnecting the LEDring light.

l A connector protrudes from the underside of the light housing and can be damaged if placed on a

hard surface.

Note: If a different LEDcolor is required, refer to Replace the LED Ring Light (Optional) on page52.

a. Place the light housing with LEDring light on top of the spacer, with “TOP” oriented upward.

b. Verify seating of the gasket on the top of the spacer.

c. There are four captive screw access holes near the white circles on the LEDring light. Use a 2mm hex

wrench to torque the captive screws to 0.34 Nm (3 in-lb).

Installation

63

11. Install the light baffle.

Note: The following graphic includes an optional bandpass filter accessory installed to the light baffle. For

more information, refer to In-Sight Lenses, Lights and Covers on page10.

a. Tilt the light baffle toward the light housing and maneuver the light baffle past the top of the LED ring light

structure.

b. Compress the light baffle and maneuver the bottom of the light baffle past the bottom of the LED ring light

structure until the light baffle snaps into place, with the keyed tabs sitting flush over each light housing

captive screw access hole.

Installation

64

12. Install the cover.

a. Place the cover on the light housing.

b. Align the central clear region of the cover with the light baffle edges.

c. Insert the four M3 x 12mm screws and use a 2mm hex wrench to torque screws to 0.31 Nm (2.75 in-lb).

Installation

13. Restore power to the vision system.

65

Installation

Remove the Illumination Accessory PCB

If the illumination accessory (ISLM-7000-WHI) must be uninstalled from the vision system, complete the following steps

to safely remove the PCB and avoid damage to the vision system.

CAUTION: Do not hot-plug the illumination accessory; verify the vision system is not receiving power when

connecting or disconnecting the illumination accessory. Failure to remove power during this procedure may result

in damage to the vision system and/or the illumination accessory.

1. Remove power from the vision system.

2. Use a 2mm hex wrench to remove the four spacer screws. Remove the spacer.

3. The vision system faceplate includes two lift points on either side of the PCB. Position an insulated extractor tool

(for example, Jonard Tools S-340 DIP/IC Extractor) under the edges of the PCB.

66

Installation

4. Once the extractor is engaged under the edges of the PCB, gently pull upward to disengage the PCB from the

internal connector and remove the PCB.

5. Verify the removal process did not damage mating components.

67

Specifications

Specifications

The following sections list general specifications for the vision system.

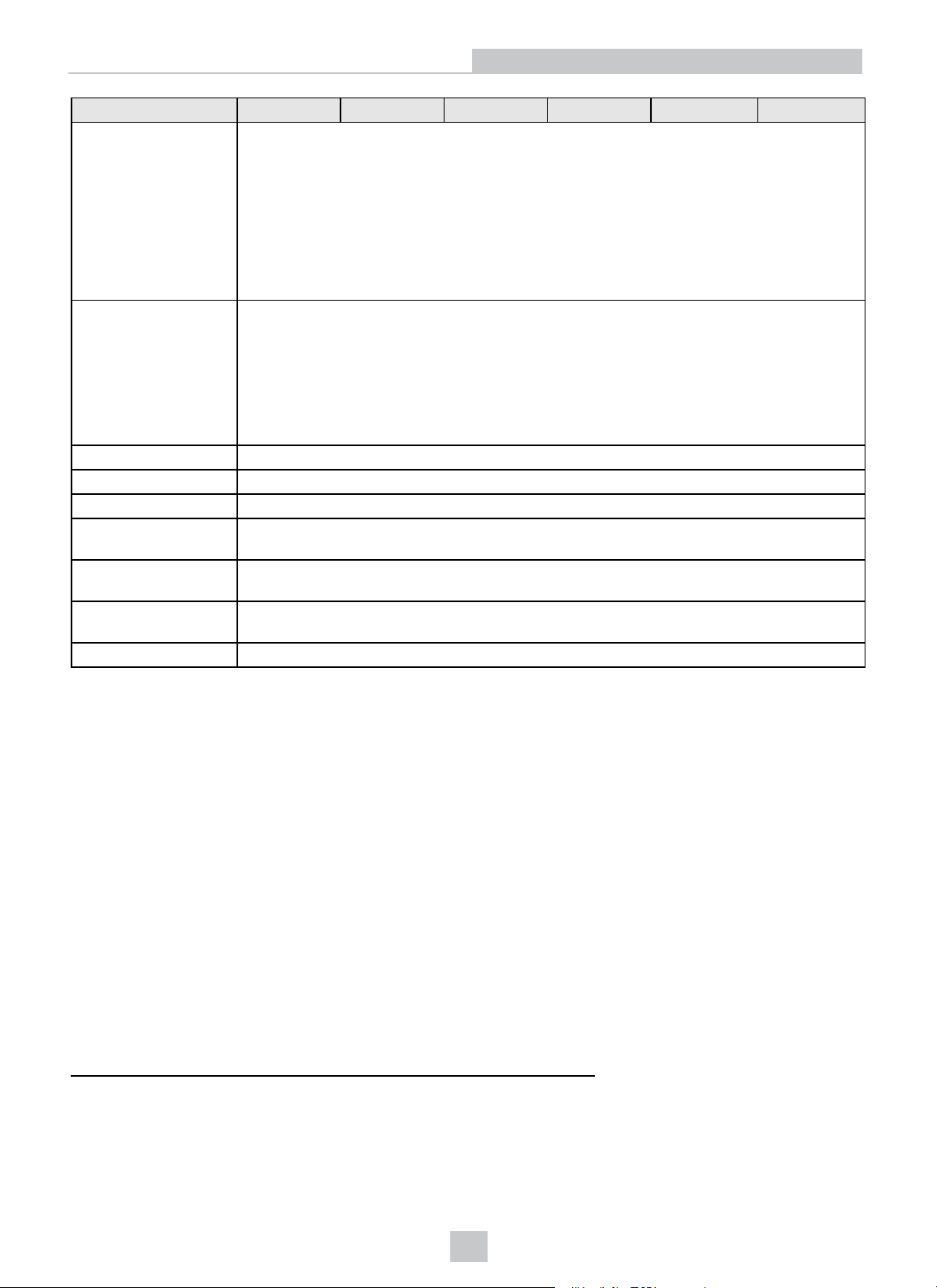

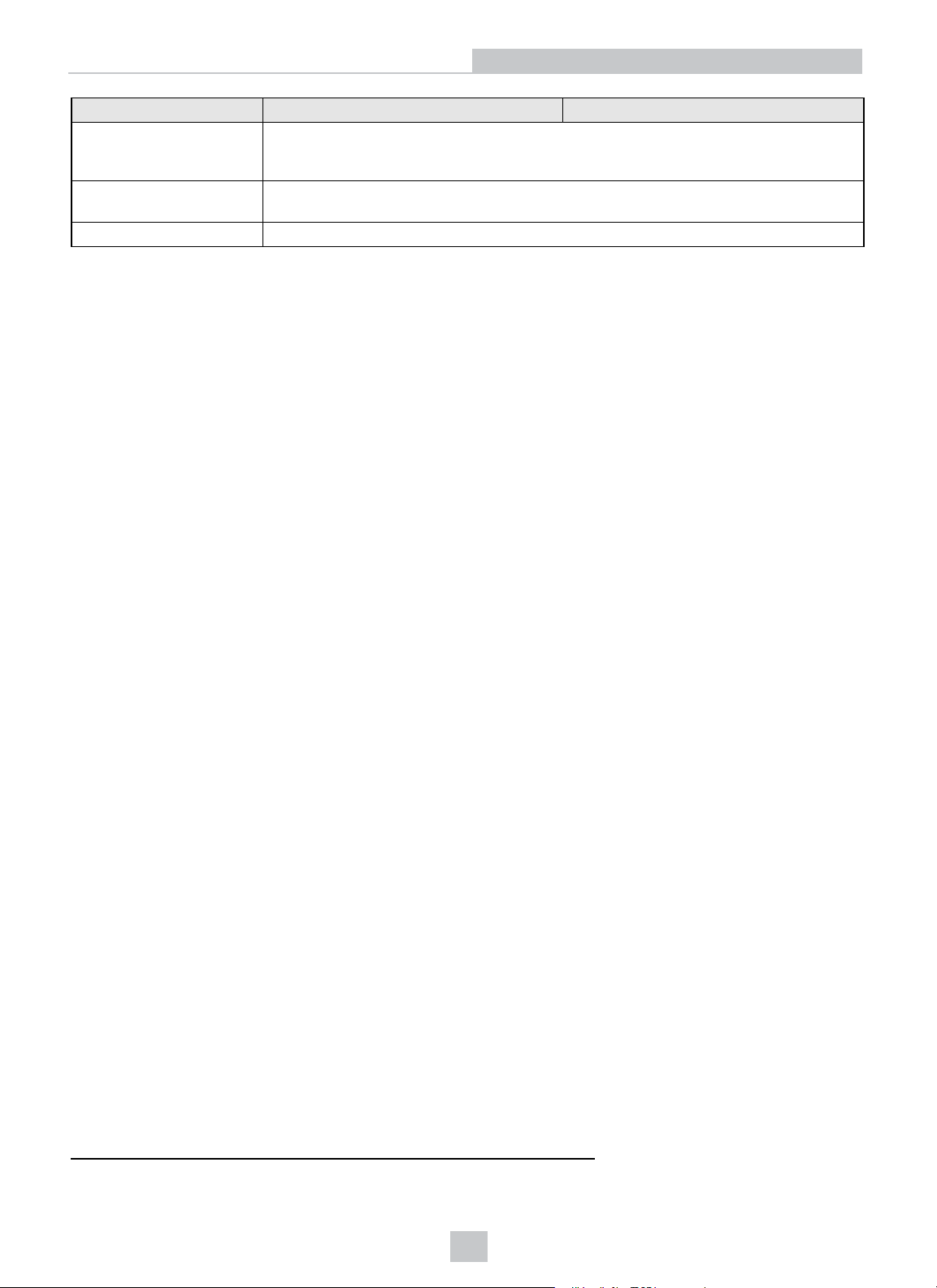

7600/7800 Series Vision System Specifications

Specifications 7600 7600C 7800 7800C 7801 7801C 7802 7802C

Minimum Firmware

Requirement

Job/Program Memory 7.2GB non-volatile flash memory; unlimited storage via remote network device.

Image Processing

Memory

SD Card 1 Micro SD card slot with an 8GB SD card pre-installed for saving job and image files. The

Sensor Type 1/1.8 inchCMOS, global shutter

Sensor Properties 800 x 600: 4.5mm diagonal, 4.5 x 4.5µm sq.

Maximum Image

Resolution (pixels)

Electronic Shutter

Speed

Acquisition Rapid reset, progressive scan, full-frame integration.

Bit Depth 256 grey

Frames Per Second

4

(FPS)

In-Sight

version

5.4.0

In-Sight

version

5.5.0

In-Sight

version

5.4.0

In-Sight

version

5.5.0

In-Sight

version

5.4.0

In-Sight

version

5.5.0

In-Sight

version

5.4.0

512MB SDRAM

vision system supports SD cards formatted with a FAT32 file system.

pixels

7.38mm diagonal, 4.5

x 4.5µm sq. pixels

1600 x 1200: 9mm

diagonal, 4.5 x 4.5µm

sq. pixels

640 x 480: 3.6mm diagonal, 4.5 x 4.5µm sq.

pixels

800 x 600: 9mm

diagonal, 4.5 x 4.5µm

sq. pixels

800 x 600

1

640 x 480 800 x 600 (Low Light

2

1280 x 1024 1600 x 1200

Mode)

800 x 600: 14µs to 550ms 17µs to 750ms 1600 x 1200: 20µs to

940ms

640 x 480: 14µs to 520ms 800 x 600 (Low Light

Mode): 20µs to 940ms

levels (8

bits/pixel)

800 x 600:

165 FPS

640 x 480:

217FPS

24-bit

color

800 x

600: 100

FPS

640 x

480: 135

FPS

256 grey

levels (8

bits/pixel)

800 x 600:

165 FPS

640 x 480:

217 FPS

24-bit

color

800 x

600: 100

FPS

640 x

480: 135

FPS

256 grey

levels (8

bits/pixel)

24-bit

color

256 grey

levels (8

bits/pixel)

76 FPS 45 FPS 1600 x

1200: 53

FPS

800 x 600

(Low Light

Mode): 53

FPS

In-Sight

version

5.5.0

3

24-bit

color

1600 x

1200: 33

FPS

800 x 600

(Low

Light

Mode): 45

FPS

1

The number of image sensor rows are configurable and can be set withinthe In-Sight Explorer software. Decreasing the number of rows will

increase the number of frames per second acquired by the vision system. Refer to the AcquireImage topic in the In-Sight®Explorer Help file for

more information.

2

The default resolutionis 800 x 600 pixels. The resolution can be configured as 640 x 480 pixelswithin the In-Sight Explorer software. Refer to

the In-Sight®Explorer Help file for more information.

3

The default resolutionis 1600 x 1200 pixels.The resolution can be configured as 800 x600 (Low Light Mode) within the In-Sight Explorer

software. When using800 x 600 (Low Light Mode), it providesincreased light sensitivityat a reduced resolution. Refer to the In- Sight®Explorer

Help file for more information.

4