IN-SIGHT 2000

VISION SENSORS

THE GLOBAL LEADER

IN MACHINE VISION AND INDUSTRIAL BARCODE READING

Cognex,® the leading supplier of machine vision

and industrial barcode reading solutions.

With over 3 million systems installed in facilities

around the world and over forty years of experience,

Cognex is focused on industrial machine vision

and image-based barcode reading technology.

Deployed by the world’s top manufacturers, suppliers

and machine builders, Cognex products ensure

that manufactured items meet the stringent quality

requirements of each industry.

Cognex solutions help customers improve

manufacturing quality and performance by eliminating

defects, verifying assembly and tracking information

at every stage of the production process. Smarter

automation using Cognex vision and barcode reading

systems means fewer production errors, which equates

to lower manufacturing costs and higher customer

satisfaction. With the widest range of solutions and

largest network of global vision experts, Cognex is the

best choice to help you Build Your Vision.™

$811

MILLION

2020 REVENUE

GLOBAL OFFICES IN

20+ COUNTRIES

3,000,000+

SYSTEMS SHIPPED

OVER 40

YEARS IN THE BUSINESS

500+

CHANNEL PARTNERS

Visit www.cognex.com/machine-vision

2

THE NEED FOR

AUTOMATED INSPECTION

Increased throughput, higher quality, and lower

costs are key drivers for automated inspection in

manufacturing. Manual inspection can be slow,

prone to errors, and often impossible considering

the product size, lighting conditions, or line speed.

Given these factors, companies in a wide range of

industries rely on vision sensors to perform simple

pass/fail inspections that help ensure products

and packaging are error-free and meet strict

quality standards. Cognex vision sensors provide

easy and reliable inspections thanks to powerful

vision tools, integrated lighting, modularity, and an

easy-to-use setup environment.

3

IN-SIGHT 2000 SERIES

VISION SENSORS

The power, ease-of-use, and flexibility

to solve any error-proofing application

Cognex In-Sight® 2000 series vision sensors

combine the power of In-Sight vision systems

with the simplicity and aordability of an industrial

sensor. Ideal for error-proong applications,

these vision sensors set new standards for value,

ease of use, and exibility thanks to a powerful

combination of proven In-Sight vision tools,

simple setup, and a modular design featuring

eld-changeable lighting and optics.

▪ Intuitive EasyBuilder® interface allows

even novice users to achieve reliable

inspection performance in nearly any

production environment

▪ Proven, reliable Cognex In-Sight vision tools

▪ Compact, modular design with eld-

changeable, integrated optics and lighting

▪ Autofocus lens eliminates the need to

manually refocus or adjust the mounting

height of the sensor during line changeovers

▪ Single-cable Power over Ethernet (PoE)

models simplify installation

4

Visit www.cognex.com/InSight2000

IN-SIGHT

2D VISION SOFTWARE

In-Sight Explorer

IN-SIGHT 2D VISION SOFTWARE

All In-Sight 2D products, from vision sensors to vision systems, are congured with the powerful, yet intuitive

In-Sight Explorer software. The easy-to-use interface walks you step by step through the setup process and

provides the power and exibility of the vision spreadsheet for more dicult applications. In-Sight Explorer also

oers the widest range of built-in communication protocols that interface directly to any PLC, robot, or HMI on the

factory network.

EasyBuilder

The EasyBuilder conguration environment

guides users through a step-by-step setup

process allowing both novice and experienced

operators to congure vision applications quickly

and easily on vision sensors and vision systems.

Easy-to-deploy HMI

Cognex In-Sight sensors and systems oer multiple

runtime visualization options, including VisionView

— available as a ready-to-deploy LCD touch

panel and as a PC application — and a platform

independent Web HMI that runs in any internet

browser. Both VisionView and the Web HMI allow

users to view inspection images and results and to

modify setup parameters.

Spreadsheet

Access to the spreadsheet provides

ultimate application development exibility

without programming.

Visit www.cognex.com/explorer

5

POWERFUL IN-SIGHT VISION TOOLS

The EasyBuilder interface provides access to a selection of powerful vision tools:

Location

Pattern, edge, and circle tools

locate (or xture) the part so

other vision tools can use this

as a reference to complete

their inspections.

Counting

Counting patterns and edge

features conrm the correct

number of items are present on a

conveyer or in a package.

Brightness, contrast, pattern,

pixel count, edge, and circle

tools determine the presence or

absence of a part.

OCR*

Uses Cognex’s OCRMax

auto-tune feature to quickly and

easily read high-quality characters

on a variety of surfaces.

MeasurementPresence/absence

Distance, angle, and circle

diameter measurements verify

a part’s features are the correct

size and in the correct position

and orientation.

Blob*

Determines the presence or

absence of non-uniform objects.

Image Filters*

More than 25 unique image ltering

tools including binarize, edge

magnitude, and stretch which can

be used as a pre-processing step for

subsequent vision tools.

*Available on IS2000-230 and IS20001-230 models.

6

ELECTRONICS

OK NG

OK NG

The presence of a

rubber gasket attached

to a molded plastic

part is veried before

an automated nal

assembly step.

The presence of a ducial

is used to verify that an

integrated circuit has been

soldered onto the PCB in

the correct orientation.

OK NG

The dial on a thermostat

is checked to conrm that

it is in the correct position,

which helps to ensure

proper installation.

7

AUTOMOTIVE

OK NG

A fuel lter assembly

is checked for the

presence of an O-ring

installed in the proper

location before nal

packaging.

OK NG

OK NG

A wheel hub bearing is

checked for the presence

of quality control (QC)

marks before moving

to the next stage of

assembly. The absence

of the QC marks indicates

that the hub bearing has

not yet been inspected.

A fuel bowl gasket is

inspected to verify that

all 13 through holes have

been punched out. A

missing hole will cause

the part to fail.

8

FOOD AND BEVERAGE

OK NG

OK NG

In-Sight vision sensors

allow you to perform

multiple inspections

with each image. In this

example, a bottle passes

in front of the sensor, and

both ll level and cap

assembly are validated

before the product is

packaged.

A color pixel count tool

veries that the correct fruit

snack avor is present to

ensure that it is packaged

in the correct order.

OK NG

Inspections on a juice box

verify that the date/lot code

has been printed, conrm

the safety seal is intact,

check for the presence of a

straw, and conrm that the

aps are fully secured.

9

CONSUMER PRODUCTS

OK NG

OK NG

The distance between

the two halves of an

enclosure is measured to

verify that the electrical

plug has been assembled

correctly. An open plug

will cause a failure in the

downstream packaging

equipment.

A pattern counting tool

is used in this example

to inspect the carton and

to verify that the correct

number of staple strips

have been added.

10

OK NG

A package of light bulbs

is inspected to conrm

that all 4 bulbs are

present and that none of

the bulbs are broken.

HEALTH AND PHARMACEUTICALS

OK NG

OK NG

A lotion bottle is checked

to conrm that the pump

dispenser is in the locked

position before the bottle

is packed into a carton.

A shampoo bottle is

inspected to conrm

that the cap and bottle

colors match.

OK NG

A blister pack is

inspected to verify that

all the capsules are

present after sealing.

11

Modular Design

In-Sight 2000 series models include an integrated lens and LED illumination that eliminate the need for costly external

lighting. Lenses and lighting are eld-interchangeable to adjust to dierent application requirements. The In-Sight 2000

Mini has a smaller form factor making it ideal for mounting in tight spaces.

In-Sight 2000

In-Sight 2000 Mini

A Model for Any Application

Available in both monochrome and color image models, and with dierent combinations of vision tools, the

In-Sight 2000 series lets you choose the level of capability you need. Whatever your inspection application,

there’s an In-Sight 2000 vision sensor model that’s right for the job.

12

IN-SIGHT 2000 MODELS

2000-110 2000-120 2000-130 2000-230 2001-230

User Interface

1/3" CMOS Imager, Global Shutter Monochrome and Color

S-Mount/M12 Lenses

640 x 480 (standard)

Image Modes

640 x 480 (2x magnication)

800 x 600 (2x magnication)

1280 x 960

Lighting

Standard Diffuse white LED ring light

Options Red, blue and IR LED ring lights and lens lters, and polarized light cover

Maximum Acquisition Speed

1

2

ü ü ü ü ü

û ü ü ü ü

û û ü ü ü

û û û û ü

40 fps

Relative Processing Speed 1x 2x

Location Tools

Inspection Tools

Measurement &

Counting Tools

Advanced Features

Pattern

Edge, Circle

Pattern

Pixel Count

Brightness & Contrast

Edges

Distance, Angle & Diameter

Patterns & Edges

OCR

Blob Detection

Image Filters

ü ü ü ü ü

û û ü ü ü

ü ü ü ü ü

û

û ü ü ü ü

û û ü ü ü

û û ü ü ü

û û ü ü ü

û û û ü ü

û û û ü ü

û û û ü ü

Data Output Pass/Fail Pass/Fail, Numeric

General Protocols TCP/IP, UDP, FTP, Telnet, RS-232C

Communications

& I/O

Industrial Protocols

Connectors (1) Industrial M12 Ethernet, (1) M12 Power & I/O

Inputs & Outputs (1) Acquisition trigger, (1) General purpose input

Dimensions

Mechanical

Weight 200 g (7.05 oz)

Material and Protection Painted aluminum, IP65-rated housing

Power 24 VDC ±10%, 48 W (2.0 A) maximum when the illumination is on

Operating

PoE Conguration Available No

Temperature 0 °C to 40 °C (32 °F to 104 °F)

1

Available in select regions. Ask your Cognex sales representative for more information.

2

Maximum framerate with minimum exposure; no vision tools; and 640 x 480 image with 2x Image Magnication enabled (for 2000-120/130/230 models).

3

Limited to Measurement & Counting Tools only.

4

(7) general purpose inputs and (8) general purpose outputs when using optional CIO-1400 I/O Expansion Module.

In-Sight Explorer EasyBuilder, Cognex VisionView PC Software,

and VisionView 900 HMI touchscreen panel

Standard: Autofocus (liquid lens) 6.2 mm or manual focus 8 mm

Optional: Manual focus 3.6 mm, 6 mm, 12 mm, 16 mm, 25 mm

75 fps (mono)

55 fps (color)

Grayscale and color

3

OPC UA, EtherNet/IP with AOP, PROFINET Class B, iQSS, SLMP, SLMP Scanner,

CC-Link IE Field Basic, Modbus TCP

4

, (4) General purpose outputs

In-line conguration: 92 mm (3.61 in) x 60 mm (2.38 in) x 52 mm (2.05 in)

Right-angle conguration: 61 mm (2.42 in) x 60 mm (2.38 in) x 52 mm (2.05 in)

40 fps (mono)

24 fps (color)

4

13

IN-SIGHT 2000 MINI MODELS

2000-110 Mini 2000-120 Mini 2000-130 Mini 2000-230 Mini 2001-230 Mini

User Interface

1/3" CMOS Imager, Global Shutter Monochrome Monochrome and Color

S-Mount/M12 Lenses Autofocus (liquid lens) 6.2 mm or 16 mm

Image Modes

640 x 480 (standard)

640 x 480 (2x magnication)

800 x 600 (2x magnication)

1280 x 960

1

ü ü ü ü ü

û ü ü ü ü

û û ü ü ü

û û û û ü

Standard Modular red LEDs Modular red (mono) and white (color) LEDs

White, blue &

Lighting

Options

IR LED lights,

band-pass lters &

polarizing lter

Maximum Acquisition Speed

2

40 fps

Relative Processing Speed 1x 2x

Location Tools

Inspection Tools

Measurement &

Counting Tools

Advanced Features

Pattern

Edge, Circle

Pattern

Pixel Count

Brightness & Contrast

Edges

Distance, Angle & Diameter

Patterns & Edges

OCR

Blob Detection

Image Filters

ü ü ü ü ü

û û ü ü ü

ü ü ü ü ü

û

û ü ü ü ü

û û ü ü ü

û û ü ü ü

û û ü ü ü

û û û ü ü

û û û ü ü

û û û ü ü

Data Output Pass/Fail Pass/Fail, Numeric

General Protocols TCP/IP, UDP, FTP, Telnet, RS-232C

Communications

& I/O

Industrial Protocols

Connectors (1) Industrial M12 Ethernet, (1) M12 Power & I/O

Inputs & Outputs (1) Acquisition trigger, (1) General purpose input

Dimensions

Mechanical

Weight 142 g (5 oz)

Material and Protection Painted aluminum, IP65-rated housing

Power 24 VDC ±10%, <3.0 W or Class 1 Power over Ethernet (PoE)

Operating

PoE Conguration Available

û ü ü ü ü

Temperature 0 °C to 40 °C (32 °F to 104 °F)

1

Available in select regions. Ask your Cognex sales representative for more information.

2

Maximum framerate with minimum exposure; no vision tools; and 640 x 480 image with 2x Image Magnication enabled (for 2000-120/130/230 models)

3

Limited to Measurement & Counting Tools.

4

(7) general purpose inputs and (8) general purpose outputs when using optional CIO-1400 I/O Expansion Module.

5

PoE models cannot use a 24 VDC power supply and vice versa.

In-Sight Explorer EasyBuilder, Cognex VisionView PC Software,

and VisionView 900 HMI touchscreen panel

White, blue & IR LED lights, band-pass lters,

polarizing lter, and polarized light cover

75 fps (mono)

55 fps (color)

Grayscale

3

OPC UA, EtherNet/IP with AOP, PROFINET Class B, iQSS, SLMP, SLMP Scanner,

CC-Link IE Field Basic, Modbus TCP

4

, (4) General purpose outputs

In-line conguration: 43.1 mm (1.69 in) x 22.4 mm (0.88 in) x 64 mm (2.51 in)

Right-angle conguration: 43.1 mm (1.69 in) x 35.8 mm (1.40 in) x 49.3 mm (1.94 in)

5

40 fps (mono)

24 fps (color)

Grayscale

and color

4

14

Flexible Mounting Configurations

In-Sight vision sensors can be congured for in-line and right-angle mounting installation. This modular body design

provides maximum exibility to mount in tight spaces, simplies wiring and optical paths, and minimizes the need to

design new mechanical xtures.

Field of View Options

In-Sight 2000 vision sensors support a wide variety of modular lens options, making it easy to choose the correct

conguration for your work cell. Simply choose the desired working distance and the minimum eld of view

to determine the appropriate lens. This will minimize the amount of time spent choosing and troubleshooting

accessories for the application.

In-Sight 2000 In-Sight 2000 Mini

15

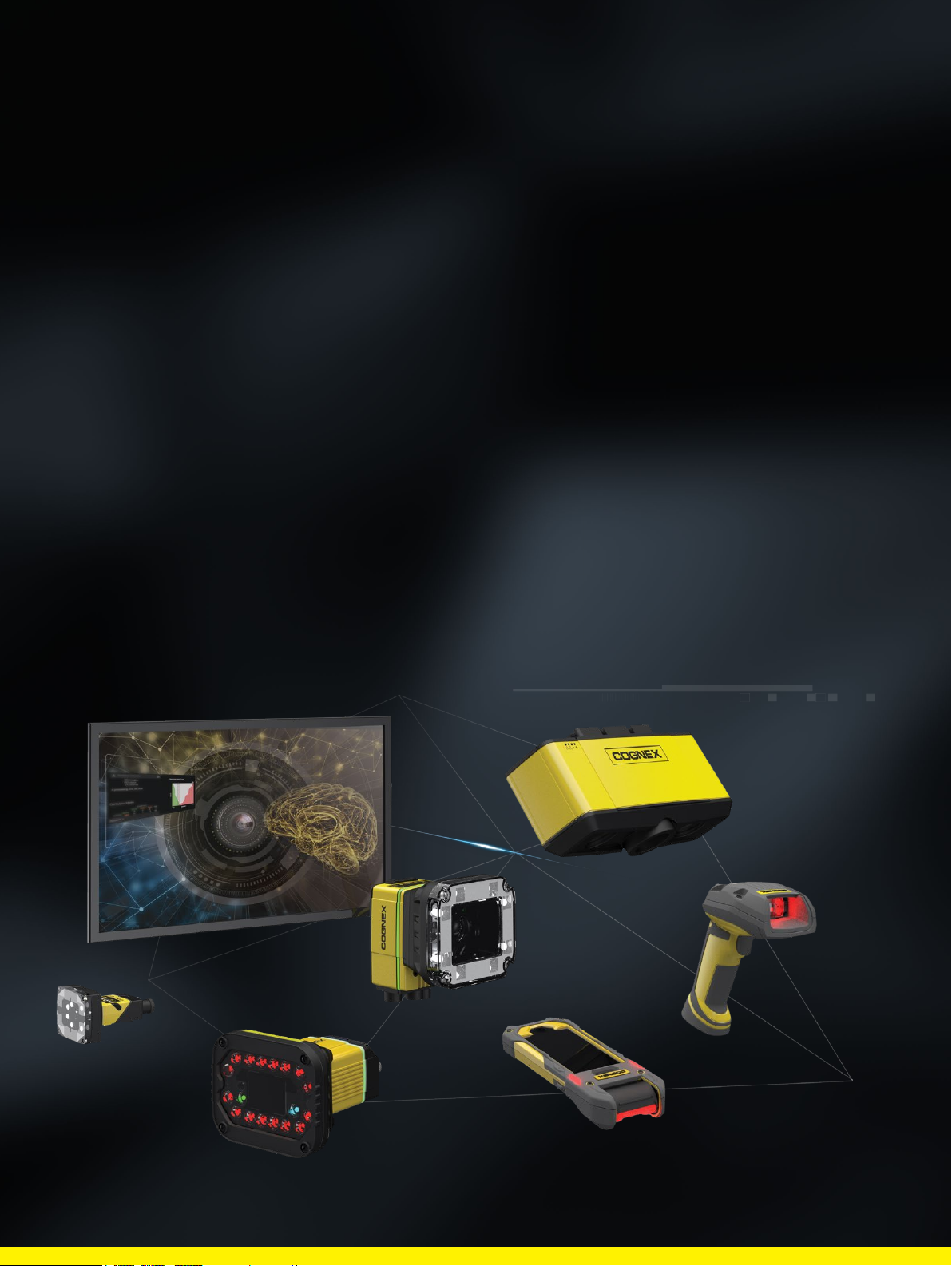

BUILD YOUR VISION

2D VISION SYSTEMS

Cognex machine vision systems are unmatched in their ability to inspect,

identify and guide parts. They are easy to deploy and provide reliable,

repeatable performance for the most challenging applications.

www.cognex.com/machine-vision

3D VISION SYSTEMS

Cognex In-Sight laser prolers and 3D vision systems provide ultimate

ease of use, power and exibility to achieve reliable and accurate

measurement results for the most challenging 3D applications.

www.cognex.com/3D-vision-systems

VISION SOFTWARE

Cognex vision software provides industry leading vision technologies,

from traditional machine vision to deep learning-based image analysis,

to meet any development needs.

www.cognex.com/vision-software

BARCODE READERS

Cognex industrial barcode readers and mobile terminals with patented

algorithms provide the highest read rates for 1D, 2D and DPM codes

regardless of the barcode symbology, size, quality, printing method or surface.

www.cognex.com/barcodereaders

Companies around the world rely on Cognex vision and barcode

reading to optimize quality, drive down costs and control traceability.

Corporate Headquarters One Vision Drive Natick, MA 01760 USA

Regional Sales Oces

Americas

North America +1 844-999-2469

Brazil +55 11 4210 3919

Mexico +800 733 4116

Europe

Austria +49 721 958 8052

Belgium +32 289 370 75

France +33 1 7654 9318

Germany +49 721 958 8052

Hungary +36 800 80291

Ireland +44 121 29 65 163

Italy +39 02 3057 8196

Netherlands +31 207 941 398

Poland +48 717 121 086

Spain +34 93 299 28 14

Sweden +46 21 14 55 88

Switzerland +41 445 788 877

Turkey +90 216 900 1696

United Kingdom +44 121 29 65 163

Asia

China +86 21 6208 1133

India +9120 4014 7840

Japan +81 3 5977 5400

Korea +82 2 530 9047

Malaysia +6019 916 5532

Singapore +65 632 55 700

Taiwan +886 3 578 0060

Thailand +66 88 7978924

Vietnam +84 2444 583358

www.cognex.com

© Copyright 2021, Cognex Corporation. All information in this document is subject to change without notice. All Rights Reserved. Cognex, In-Sight,

EasyBuilder, and VisionView are registered trademarks of Cognex Corporation. Build Your Vision and In-Sight Explorer are trademarks of Cognex

Corporation. All other trademarks are property of their respective owners. Lit. No. SG-EN-03-2021

Loading...

Loading...