Coffee Queen Crema Compact, Crema Digital 3 group, Crema Digital 4 group, Crema Digital 2 group Service Manual

Rev.041004

Compact

Digital 2 groups

Digital 3 - 4 groups

Crema Compact Digital

Your retail dealer

Service manual

Coffee Queen Espressomachines

S / GB

2.

1. Table of contents sida 2

2. Orientation 3

3. Introduction 4

4. Contemplated use and warnings 5

5. Technical description -

5.1 Overview of the espresso coffee machines Crema Comp/Dig 5

5.2 Operating Principles 6

5.3 Operation for espresso machine model Crema Compact/Digital 6

6. Safety precautions 6

7. Installation - Location - Start up -

7.1 Precautions for installation 7

7.2 Locations and connections 8

7.3 Start up 8

7.4 P semi-automatic version operation On-Off 8

7.5 Digital automatic version dose programming 9

7.6 Failure message 10

7.7 Automatic cleaning of the groups 11

8. User instructions 12

8.1 Normal operating values 12

8.2 How to make espresso coffee 13

8.3 How to make cappuccino 13

9. Maintenance -

9.1 Daily cleaning 14

9.2 Weekly cleaning 14

9.3 Instructions for regenerating descaling filter 15

10. Faults and routine repairs 16- 19

11. Shut-down and dismantling 19

12. Technical Data 20

13. Spare part list 21-22

14. Exploded view 23-27

15. Flow diagram (comp machines) 28

15. Flow diagram (dig machines) 29

16. Electrical diagram 30

1. Table of contents Crema Compact och Crema Digital

3.

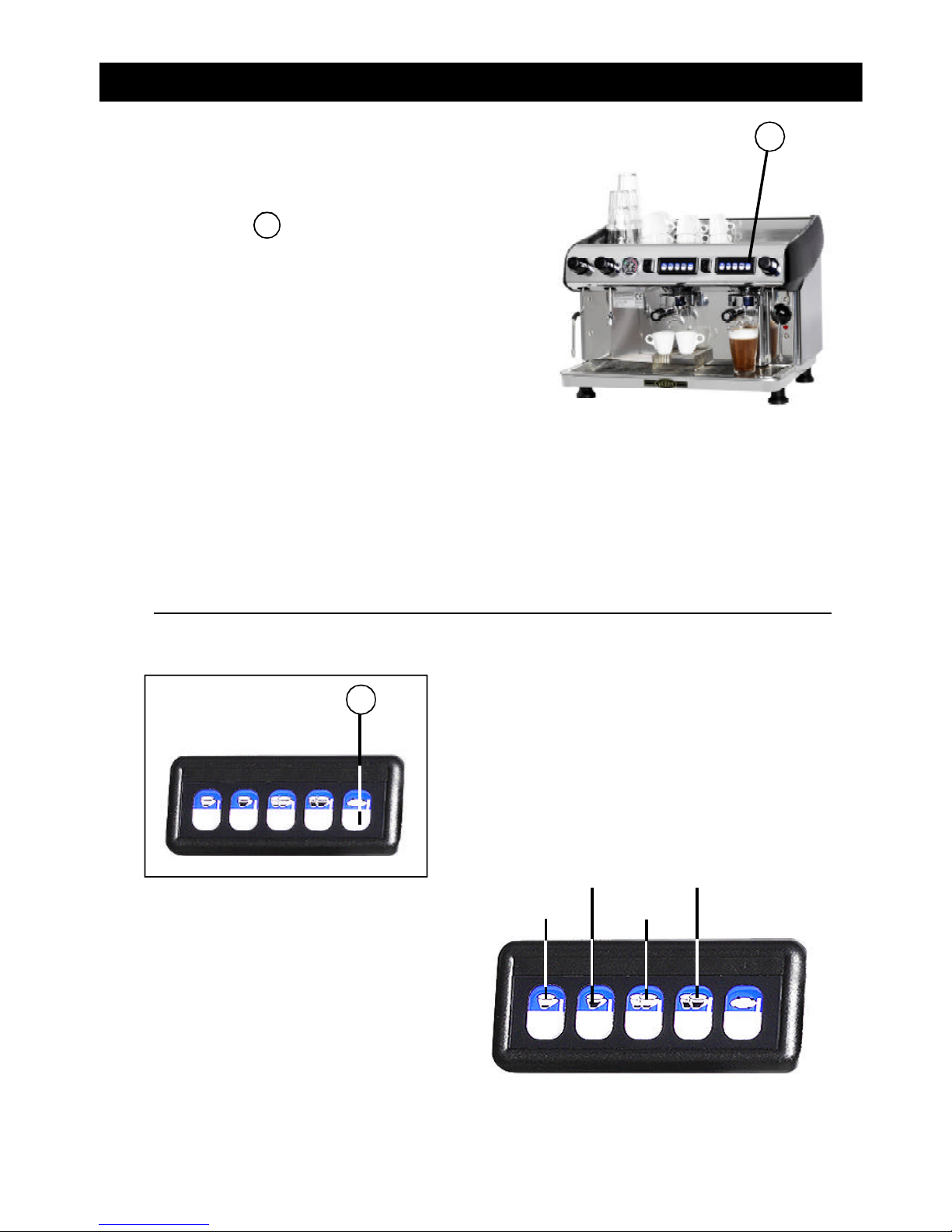

1. Steam pipe

2. Tap handgrip (steam)

3. Manometer

4. Tap handgrip (hotwater)

5. Brew switch (manual)

6. Push-button pad

7. Tap handgrip (steam)

8. Main switch

9. Indication light

10. Drip tray

11. Outlet (hotwater)

12. Handgrip for filterholder

13. Rubber spacer (for automatic cleaning).

14. 1 cup filter

15. 2 cup filter

16. Handle (steam pipe)

12

1514

13

2. Orientation

4

5

3

6

7

10

8

9

12

11

2

1

16

1

4.

Save; your manual and instructions:

The manual is dedicated the user and/or an authorized personel. It will give you information how to use the

machine in a correctly way, desirable maintenance and a good safety and security for the user.

The manufacturer is not responsible for personnel damage or environment damage, caused by the

machine, if it has been used in a way, which is different from what prescribes in these instructions.

This manual must always be available to the user and/or maintenance technician, who must be

informed of the correct

use of the machine and of possible hidden risks. It must be kept in a dry, clean place.

The information given in this manual does not replace the safety instructions and technical data for

installation and

operating directly affixed to the machine and packaging.

This manual is to be considered as part of the machine and must be kept for future reference until same is

dismantled.

Should you lose it or require further information, contact your area agent or the manufacturer.

This manual reflects the state of the art at the current time and cannot be considered inadequate merely

because it is updated

later on the basis of new developments.

The manufacturer also reserves the right to modify the manual without the duty of updating earlier issues,

except in exceptional

basis of new developments.

If the machine is used incorrectly or in ways, other than described in this manual it will render any

guarantee or

manufacturer´s responsibility condition null and void; it should only be used by a responsible adult.

3. Introduction: Crema Compact och Digital

5. Technical description Crema Compact och Digital

5.1 Overview of the espresso coffee machines Crema Compact och

Digital

Automatic coffee machines

Crema Compact och Crema Compact Take Away

Espresso coffee machine with microprocessor controlled electronic measured dosage and digital

programming from the push-button pad. Available in 2-group models. Automatic boiler filling is standard. Filter

for mixed use either with ground coffee or with coffee pod upon request. The machines is delivered with a

Turbo Creme Milk-frothingnozzle and descaling filter.

Crema Digital/2-4 Take Away

Espresso coffee machine with microprocessor controlled electronic measured dosage and digital

programming from the push-button pad. Available in 2-3-4 group models. Automatic boiler filling is standard.

Filter for mixed use either with ground coffee or with coffee pod upon request. The machines is delivered with

a Turbo Creme Milk-frothing nozzle and descaling filter.

Semi automatic coffee machines

Crema Compact On-Off och Crema Grande On-Off

Semi-automatic espressomachine with unmeasured brewing and push-button pad.

Delivered with; automatic level regulation of boiler.

Filter for mixed use either with ground coffee or with coffee pod upon request and descaling filter.

5.

The espresso coffee machine is an appliance for delivering steam/hot water for the professional preparation

of coffee or for obtaining water and/or steam.

Its long lasting, non-toxic components are easily accessible for proper cleaning and maintenance.

The user must be an adult. The machine must not be used by children or unsuitable people.

The user must comply with the safety regulations in force in the country of installation, as well as

with the rules dictated by common sense, and ensure that routine maintenance is carried out regularly and

correctly.

The installer, the user and the maintenance technician must inform the manufacturer of possible faults or

wear which could affect the system´s original safety.

The installer must check that the environmental conditions are suitable, so as to guarantee safety and

hygiene for the operators and users. The various manufacturers are responsible for the commercial

components fitted to the machine; the customer is responsible for the people authorized to use the machine.

Do not expose the machine to the weather (sun, rain, etc. ).

Long machine stoppages at temperatures as below 0ºC (zero degrees celsius) can cause damage or

breakage to the piping boiler ; thus total emptying is recommended.

4. Contemplated use and warnings

6.

5.3 Operation for espresso machine model Crema Compact och Digital

Water system diagram

The water used for production of coffee does not come from the boiler. It is supplied directly from the water

net, through the heat exchangers inside the boiler. The hot water and steam surrounding the heat

exchangers, give the water inside the right temperature. This is shown in the water system diagram

Wiring diagram

The machine is connected to the power supply network by means of the electric cord supplied. See p. 35.

The main switch

The machine is fitted with a two-position power switch:

- Position 0: no power supply to the internal components.

- Position 1: power supply to the operational electric components and to the heating element.

5. Technical description Crema Compact och Digital

Do not tamper with the machine´s components or pull on the electric power cord to unplug it.

Never clean the inside of the machine with the power ON or with the plug connected and do not use

detergents or jets of water in any case.

The operator must not touch the machine with damp or wet hands or feet, or use it with bare feet.

Allthough the machine is earthed, we recommend the use of a wooden foot-board and a centralized lifesaving system to prevent the risk of electric schocks as much as possible.

Grinder shall only be used for coffee beans. All other usage could be dangerous and must seems like a

wrong and defective way to handle the machine.

The manufacturer is not responsible for damage which is caused by improper, unreasonable and/or incorrect

usage of machine.

Warning: Do not try to put in spoons, knife´s or other kitchen / housekeeping tools in the grinder

when machine is operating or in use.

6. Safety precautions

5. Technical description Crema Compact och Digital

5.2 Operating Principles

An espresso coffee machine is basically made up of the following elements:

Boiler

Is used to contain the hot water and steam.. Made of copper to get a equal temperature over the year.

Brewing group and heat exchanger

The brewing group is the component which, when attached to the filterholder, brews and delivers the

beverages when supplied with hot water. (Containing the filter and the ground coffee or coffee pod).

The heat exchangers, one for each group, are immersed in the water and are used for fast heating of the

fresh water from the network to the optimal temperature and to prevent thermal imbalances within the system.

Heat source

This is normally provided by an electric heating element immersed in the boiler and/or by an external gas

burner , which heat the water and provide the steam.

Electric pump

This device is used to raise the pressure of the network, which is normally inadequate for the purpose, to a

pressure of 9 bars which is ideal for making the best coffee.

Steam taps

This allow steam to be delivered to give the indispensable ”froth” to the milk used for preparing cappuccino,

for heating water and punches and for preparing chocolate drinks.

Water tap

It allows water to be delivered for preparing hot drinks, tea and tisanes.

Control instruments

Manometers: show the current pressure in the boiler and in Dig. models the pump´s operating

pressure.

Pressure switchest: control the pressure and switching ON/OFF the heat sources to keep the boiler water

temperature constant.

Level gauge: shows the water level in the boiler.

7.1 Precautions for installation

The manufacturer has obviously taken every possible precaution to guarantee user safety, but the different

installation and/or transport conditions could give rise to uncontrollable or unpredictable conditions; so it is

always necessary to assess hidden hazards and to consider the following suggestions:

- The packing elements (cardboard, cellophane,metal staples, etc.) can cut, wound or cause

accidents if not handled

carefully or if used incorrectly; do not leave them accessible to children or unsuitable people.

- Any fault or defect should be promptly notified to the personnel who are qualified and authorized to

carry out installation and maintenance.

- An earthing connection is mandatory as is the system´s conformity with the regulations in force in

the country of installation. The manufacturer accepts no responsibility for accidents due to noncompliance with the regulations.

- The use of extensions or flying connections is prohibited. The working environment is heavily

exposed to water and damp which prevent the natural conditions for insulating the system.

- The machine must only be installed by authorized, qualified personnel.

- Check the condition of the components and, should defects or faults arise, stop the installation and ask

for their replacement.

- Ensure that the power supply voltage (see rating plate) is the same as that of the mains supply network

to be used in the place of installation.

- The customer must provide for the machine´s power supply, protecting the line with a suitable safety

cut-out (life-saver).

- It is important to place the machine on a flat surface! Adjust the machine feets and check with a

spirit level.

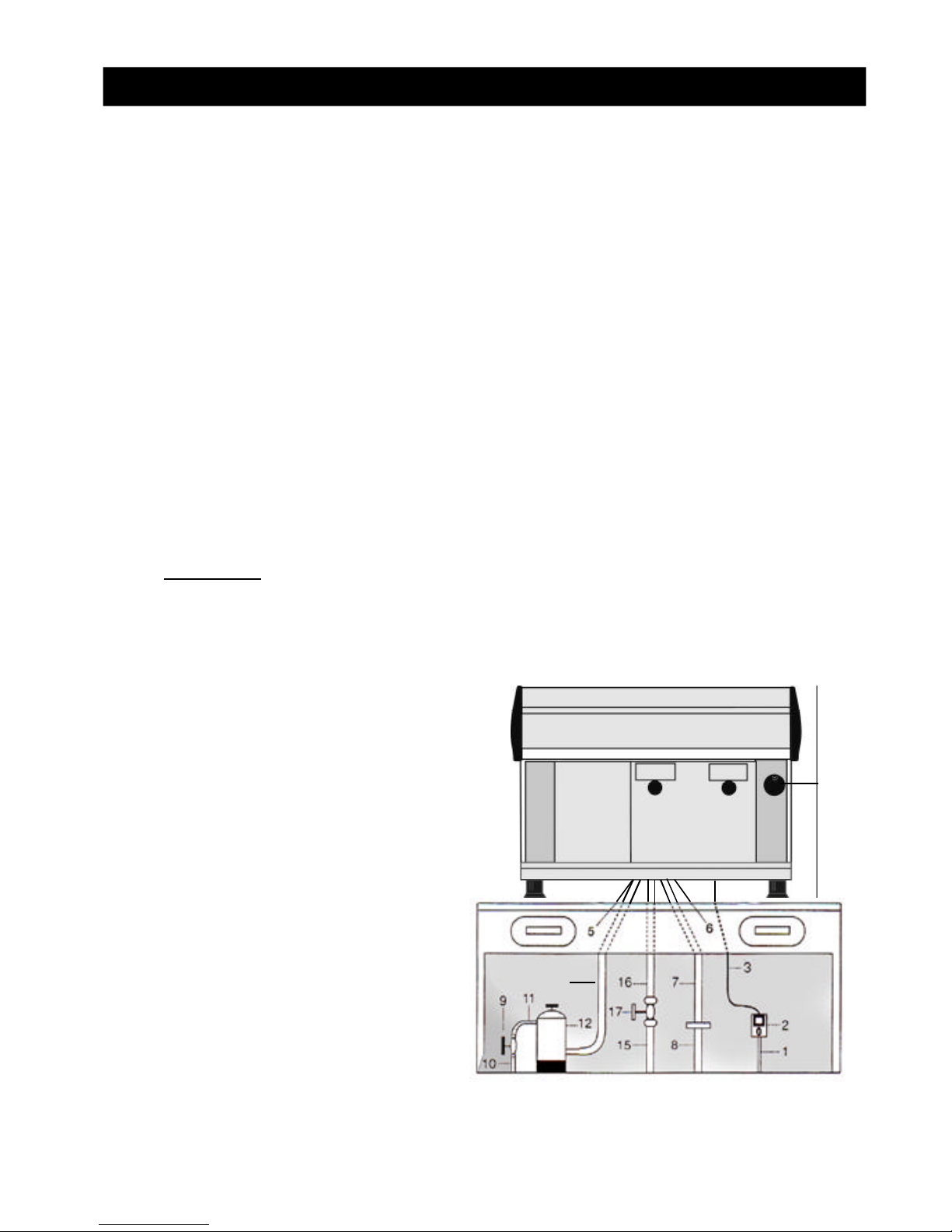

Fig. 1 Installation

1 - Mains electric power supply.

2 - Mains line switch.

3 - Power supply cord.

4 - Main switch.

0-off

1-power supply to controls

5 - Water inlet union.

6 - Drain tray

7 - Drain pipe

8 - Main drain pipe

9 - Water mains tap

10 - Water mains supply line

11 - Hose from water mains to descaling filter

12 - Descaling filter

13 - Hose from descaling filter to water inlet

15 - Pipe from gas tap to gas regulator

16 - Gas supply pipe

17 - Gas tap

7.

7. Installation - Location - Start up Crema Compact och Digital

13

FIG 1

4

8.

7. Installation - Location - Start up Crema Compact och Digital

7.2 Locations and connections

Before installing the machine it is advisable to check the efficiency of the water mains (pos. 10 fig. 1), of the

electrical connections (pos. 1 fig. 1) and of the gas mains ( for gas heated machines). An electric cut out

(pos. 2 fig. 1) with fuses rated for the machine´s electrical input is needed for the machine to be properly

connected.

Attention: the earth connection (yellow/green wire) is mandatory.

Finally the efficiency of the main drain pipe must be checked before it is connected to the machine´s drain

pipe (pos. 7 fig. 1).

Hydraulic connections: - Water inlet: pipe3/8 union int D 10/12 mm.

- Drain: pipe int D 16/17 mm.

Locate the machine on the shelf and find a suitable position for the water softener (pos. 12 fig. 1).

- Connect the softener to the tap (pos. 9) using the pipe (pos. 11 fig 1).

- Connect the pipe (pos. 13) to the water inlet (pos. 12).

Connect pipe (pos. 7) to the drain tray (pos. 6) and then to the main drain pipe (pos. 8).

- Place a recipient under the water softener´s discharging pipe ( see regeneration instructions page 10 ).

- Open tap and run the water through for a few minutes to clean the softener.

The pump is equipped with a inlet filter which prevents unwanted particles from the system of water mains,

to damage the machine.

Check and clean the filter every month.

Make the electrical connections, connecting the power supply cord (pos. 3) to the mains line switch (pos. 2).

If the machine is fitted with a gas system, connect it to the pipe (pos. 16 fig. 1) using the tap (pos.17) and

adjust it as instructed.

7.3 Start up

- Make sure that the water tap to the machine is open and that the softener´s tap are turned to the

left!

- Turn ON main switch. The machine is fitted with water level control and boiler will be filled automatically

with water.. Machine is also equiped with a element defence and must not be filled up before starting up the

machine. Before starting machine, make sure that the water is on.

Filling of water stop automatically after 120 seconds. Turn OFF the machine with the main switch (pos.

4) and turn it ON again after 5 seconds. The filling of water will start again. Se chap. 7.6 page 9.

When the water in the boiler reach the right level, the machine stops filling water. Push ON the right button

for each group to fill up the heat exchangers. When the water is coming out from the groups in a even

stream, turn OFF with the same button.

The water will now heats up and the pressure in boiler accumulates to 1 bar. Meanwhile the water is heating

up, place the filter holders in there groups so that the filter holders leaves varm. After brewing allways leave

filterholders with coffee grounds in there groups. It is a better way to make coffee if filterholders are varm.

After a while you hear a ”ventilated sound” . This is normal. When the pressure are approx. 1 bar and the

groups and filterholders are varm. The machine is ready to use.

7.4 P semi-automatic version operation On-Off.

Press the switch located above the selected group to start delivery. When the required quantity has been

delivered, press the switch again to stop it.

9.

7. Installation - Location - Start up Crema Compact och Digital

(A)

1

Ordinary espresso Double espr

Ordinary longo Double longo

Recommended quantity of water

when programming the doses:

Ordinary espresso 7cl.

Ordinary longo 9cl.

Double espr 10cl.

Double longo 15cl.

1

Fig. 2

7.5 Digital automatic version dose programming:

To program the doses: (fig. 2).

1. Press button 1 on push-button pad in approx. 8 seconds.

The Indicator lamps above the other buttons will be

switched on.

2. Now place the empty filterholder in the group (A).

- Choose button and press.

Hot water will now starts flow.

When the water has reached the required level in the cup.

Stop the filling by press at the same button

once again.

3. The settings is now stored in the memory of push-button pad.

- And the lamp above the button you stored will be switched off.

4. The other buttons can be programmed in the same way.

If it should take to long time between programming of the other doses.

All remaining indicator lamps will be switched off;

Then do the programming again as chapter 1.

The indicator lamp above the button which not is programmed will be lighting.

5. When you are satisfyed with programming of doses on the first group. Go further to the second group.

10.

7. Installation - Location - Start up Crema Compact och Digital

7.6 Failure message

Finite brewtime for each group are 240 seconds.

If you reach this time indicator lamp start blinking and the group will beblocked.

If the flowmeter operate incorrect, the indic. lamp above the button you pressed will start blinking.

If this should happen you can´t get any doses when machine is brewing.

Still you can do a manuel brewing, by using button 1.

On Model Digital, by using the manuel brew switch (pos. 5page 3).

To avoid flooding or overflow: The autom water system is equipped with a safety device.

If the water level control solenoid valve remains open for more than 120 seconds; it is automatically

switched off and the fault is signalled by indic. lamps are blinking on all the push-button pads.

To restart, the machine power must be removed for at least 5 seconds, and then start

the machine again.

If failure message repeats, please contact authorized personnel or your retail dealer.

Loading...

Loading...