Operators Manua

l

O

p

FFEE PR

670MAC

y

A

f

2

W

arrant

y

T

(1)

y

y

a

y.

T

y

any

.

his product is guaranteed to be free from defects in materials and workmanship for two (2) years

from date of retail purchase in USA or Canada and one

cover the batter

maintenance. This warrant

n authorized factory repair facilit

he foregoing warranty is exclusive and in lieu of all other warranties of merchantability, fitness for

purpose and an

one to assume for it any other obligation or liability in connection with its product and will not be

liable for consequential damages

or damage resulting from misuse, neglect, accident or improper installation or

does not apply to any product which has been repaired or altered outside

other type, whether express or implied. AgraTronix neither assumes nor authorizes

year overseas. This warranty does not

ll information, illustrations and specifications in this manual are based

on the latest in

ormation available at the time of publication. The right is

eserved to make changes at any time without notice.

roduct Warranty and Repair Progra

m

Preh

g

n

.

s

n

.

1

r

3

T

g

3

f

.

Operation

perating Conditions

Contents

age

perational Messages

perating Procedure

Normal Operatio

To Display Temperature in the Cell

To Average Test Result

To Adjust Calibratio

Moisture Limit Guidelines

alibration Consideration / Limits

To Clear Calibration

To Select a Different Language

To Select a New Grain Scale or Function

To Turn on Backlight and Turn Off Tester

eatin

.........................................................................................

........................................................................... 4

.......................................................

..............................................................................

.......................................................................

............................................................................. 1

ervice

To Replace Batteries

To Clean the Teste

..........................................................................

.............................................................................. 1

.............................................

roubleshootin

ecord the Serial Number

arrying Case

otes

...................................................................................................

All information, illustrations and specifications in this manual are based

on the latest in

reserved to make changes at any time without notice

.....................................................................................

ormation available at the time of publication. The right is

.........................................................................14

...................................................................

5

Operation

S

p

g

˚F (16˚C)

a

t

.

g

y

z

.

S

g

below limi

above limi

)

e

4

PERATING CONDITION

Test cell and grain MUST be free of any conden

ation or surface moisture. Moisture on grain or

n test cell will cause high readings. Very hot or

ool grain will pick up moisture when it warms

or cools. The

queeze moisture from high moisture grains,

uch as corn, into the bottom of the test cell.

ecause grains are irregularly shaped and may

ot always pack the same way in the test cell,

minor variations in readings may occur. To

nhance accuracy, always take three (3) succes

ive readings of the total sample being tested

nd average the results. Empty and refill the

tester with new

ach test.

ressure cap of the tester can

rain from the sample between

The tester is most accurate when grain and tester are between 60

and 90˚F

(32˚C). The unit will, however, operate at temperatures between 33˚F (1˚C) and 120˚F

49˚C). For best results, grain temperature should not be below 40˚F (4˚C) or above

10˚F (43˚C). If the grain temperature is 20˚F (11˚C) more or less than the temper

ture of the unit, preheat the tester per instructions on page 5. Condensation on the

grain or test cell is best avoided by having the tester and grain at about the sample

emperature

The environment to which a grain sample is exposed can appreciably change its

moisture content. Exposed to the open air,

moisture in onl

a few minutes. If a sample is to be held for even a short time before

rain can gain or lose 1% to 2% indicated

being tested, it should be placed into a tightly closed, air-tight container, such as a

iplock bag or jar

PERATIONAL MESSAGE

Symbol Definition

YSTEM BATTERY LOW

ystem battery needs replacin

ISTURE BELOW LIMIT

ISTURE ABOVE LIMIT

ERROR (---

----------------------------------

ture is

ture is

Electronic Failur

t

t

Operation

G

f

:

(A)

(B)

A

f

W

f

.

4

fl

(A). (

)

.

n

PERATING PROCEDURE – PREHEATIN

IMPORTANT: If the temperature of the grain sample is 20˚F (11˚C) more or less than

the temperature o

PREHEATING PROCEDURE

.

emove cap

Press ON-OFF button (C) to turn on tester. The display (D) will show ALWAYS

VERAGE 3 TESTS for approximately 7 seconds, then will show ALFALFA (initial

operation) or the name o

.

hen the grain to be tested has been selected using the SELECT arrows (E), fill

the test cell (B) even to the top o

.

eplace cap loosely DO NOT TIGHTEN.

the unit, preheat the tester and test as follows

and inspect test cell

to be sure that it is clean and empty

the last grain tested.

the cell with sample to be tested

.After 30 seconds, empty test cell and immediately refill with fresh grain.

6. Replace cap (A) and tighten until pressure-indicator screw (F) is

top of cap

Use finger-flush test as illustrated in Figure 1.

ush with the

Immediately press TEST button (G). The words TESTING will be displayed for

bout 10 seconds, while the tester compensates for temperature. The moisture

and temperature will then be displayed for about 10 seconds

- Test Butto

Operation

–

(A)

(B)

y.

(C)

The displ

(D)

w

y

w

d.

W

ll (B)

f

ested.

4

.

(A)

fl

S

(G)

.

y

.

:

A

p

y

PERATING PROCEDURE

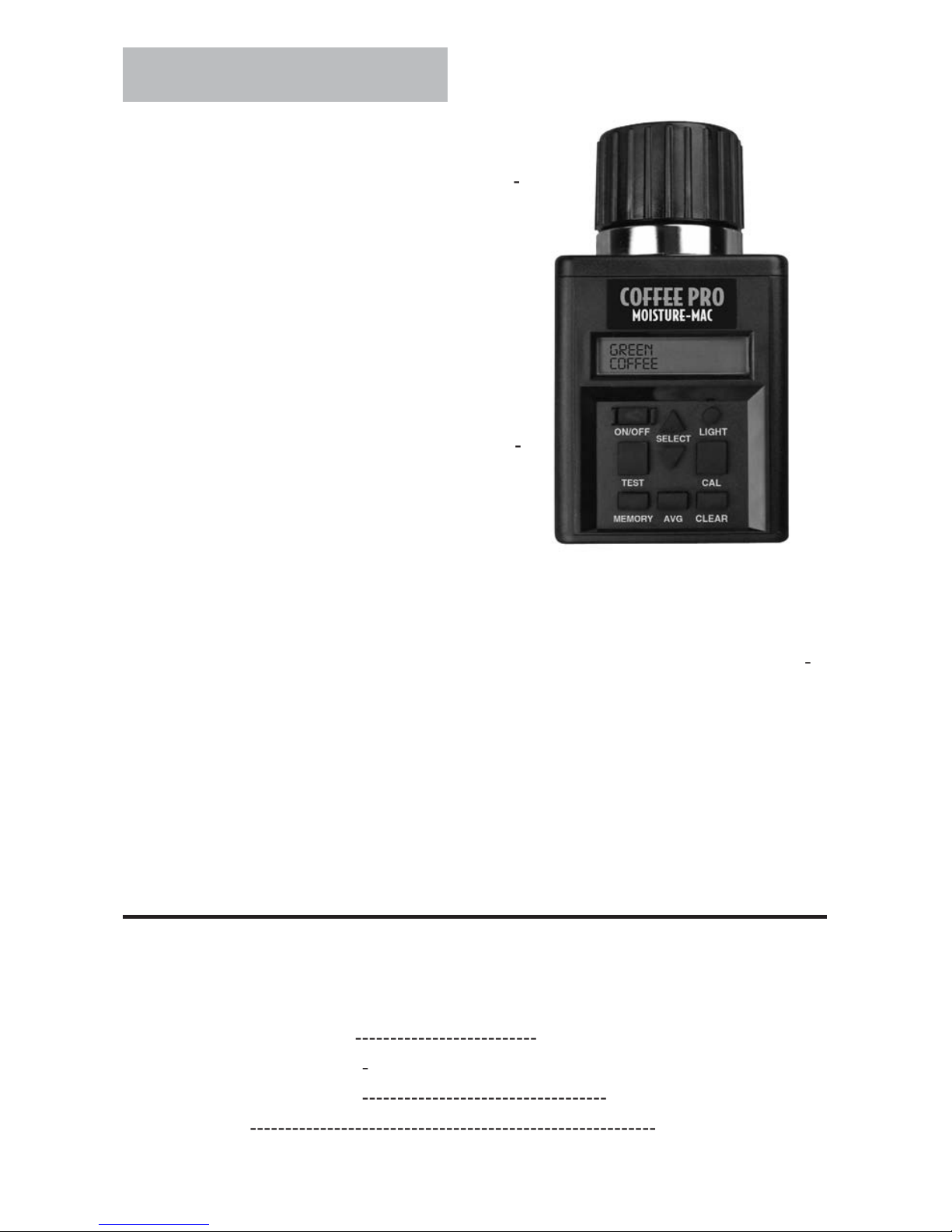

NORMAL OPERATION

.

emove cap

test cell

s clean and empt

and inspect

to be sure that it

Press ON-OFF button

turn on tester.

to

ay

ill show ALWAYS AVERAGE

TESTS for approximatel

7 seconds, then will sho

REEN COFFEE (initial opera

tion) or the name of the last

rain teste

3.

hen the grain to be tested

as been selected using the

ELECT arrows (E), fill the

test ce

the cell with sample to be

o

even to the top

t

.

tightening pressure cap, turn on

tester and allow to warm up for 30

econds before

ttempting first test

.

eplace cap

and tighten until

ressure-indicator screw (F) is

ush with the top of cap (A). (Use

Finger-Flush test as illustrated.)

- Ca

- Test Cell

- ON-OFF Button

- Displa

- Select Arrows

- Pressure-Indicator Screw

- Test Button

6. Immediately press TE

bout 10 seconds, while the tester compensates for temperature. The moisture

and temperature will then be displayed for about 10 seconds

7. The tester will then return to displaying the name of the last grain tested. Empt

the test cell and refill with a fresh sample and test again

NOTE

ample collected and average the results.

T button

. The words TESTING will be displayed for

TO

DISPLAY TEMPERATURE IN THE CEL

L

To display th

S

W

(B). Th

ill b

˚

y

.

t

t

TO

S

W

g

g

g

grain’

.

A

VG button (B) to display the average of all

.

%

.

e temperature in the cell, press either the up or

down arrow on the

ELECT button (A) to index forward or

backward through the grain (function) menu until the word

TEMPERATURE is displayed.

hen TEMPERATURE is displayed, press TEST

utton

displayed in both F

displa

ed for a few seconds then will return to the

e current temperature in cell w

and C˚. Temperature will be

e

ain grain menu

Operation

OTE:

f the tester and grain are differen

emperatures, the mass of the metal

ester will quickly warm or cool the grain.

herefore, the temperature reading is the cell temperature, no

ecessarily the temperature of the grain before being put in the cell.

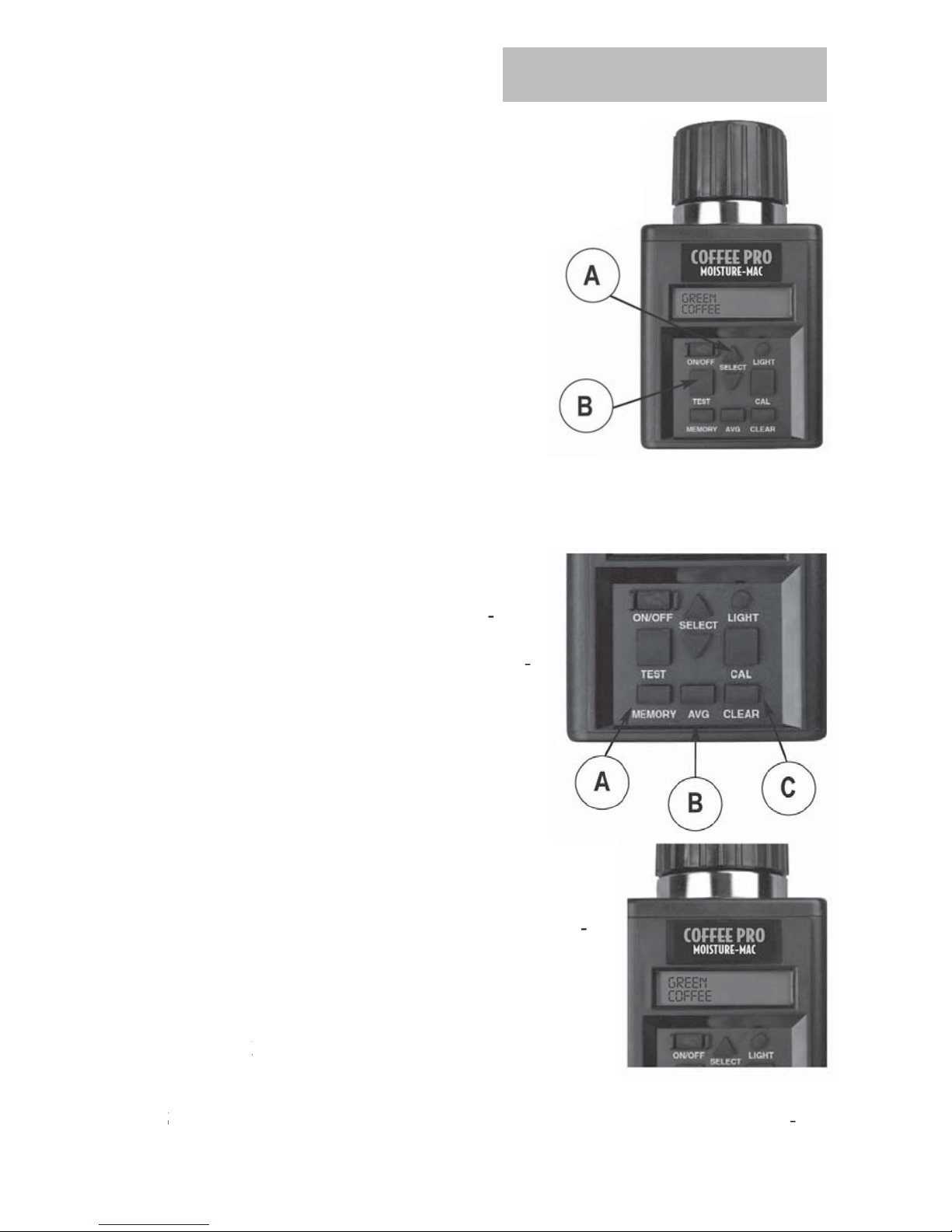

AVERAGE TEST RESULT

hen testing grain, the test result is dis

layed for about ten seconds. During the

eriod that the test moisture % and tempera

ture is displayed, press the MEMORY button

A). The tester will acknowledge that it has

ntered the reading into memory, by display-

ng the current average and then the number

of stored readin

s. Up to 20 readings can be

tored into memory. If the maximum number

of readin

s has been reached, the tester will

ot allow any more readings to be stored.

OTE: Averaging is stored for one grain only. When

test for a new grain is performed, existing avera

ng data for the previous grain is erased when the

new

s averaging data is taken. Averaging data is

retained even if batteries are removed

Press the

results entered for the grain being tested

3.

played. Then press the CLEAR button (C) and the tester will then display 0.0

0 ). This indicates that the averaging has been cleared

Operation

ON

s

t

t

.

t

.

.

T

s

t

O

.

.

(C)

.

O

Adjustment can NOT be made to factor

n

s

O

lid

ill

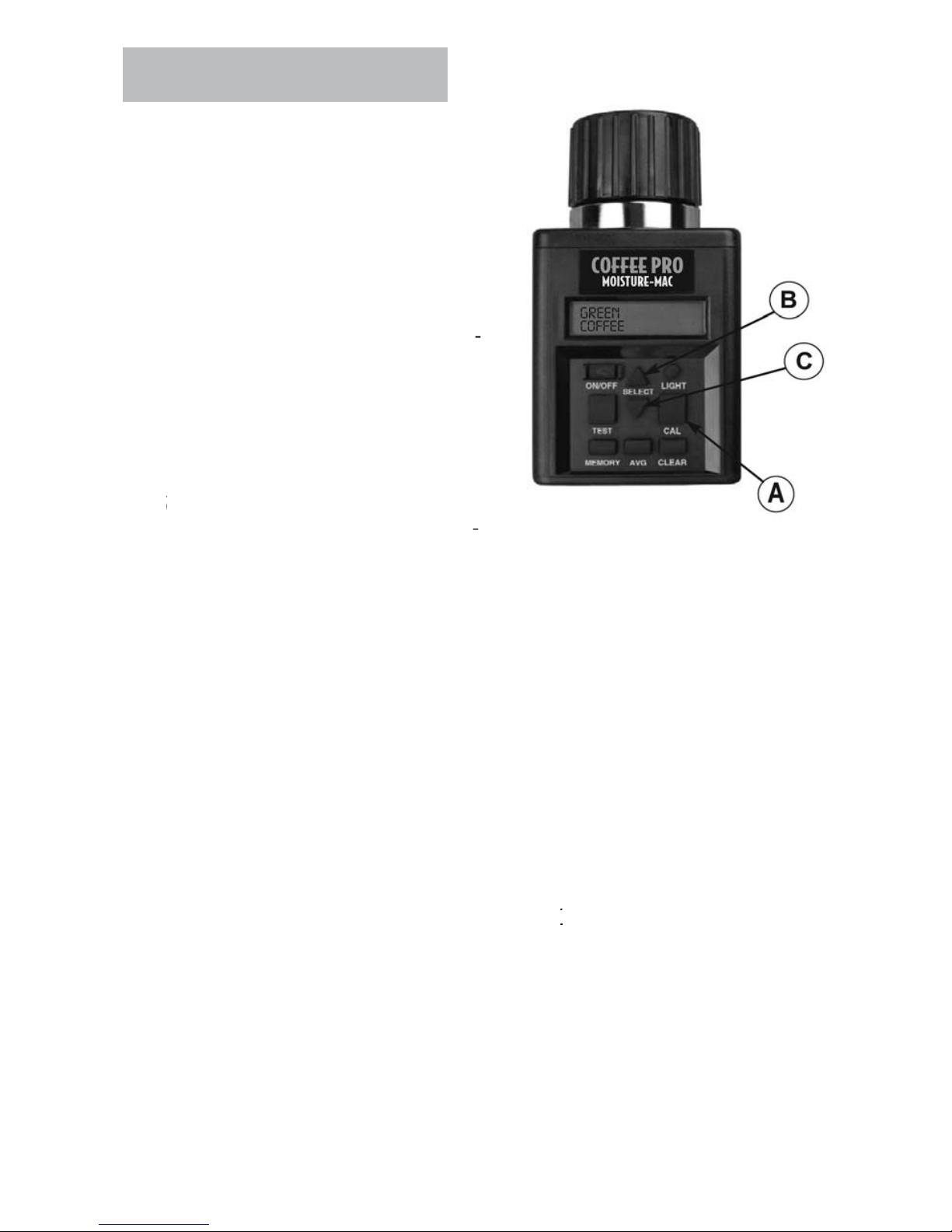

TO ADJUST CALIBRATI

MPORTANT: Always obtain three (3) test

esults from the grain elevator for the

ample being compared. Average these

hree (3) results. Compare this average with

he average of three (3) tests by the

oisture tester

ach grain scale can be individually ad

justed up to 5.0% by increments of 0.1%

o more closely match the results of an

vator tester

irst select the grain to be adjusted

you wish to adjust to. Once valid moi

ure appears, press the CAL button (A).

N

TE:

alibration of given grain cannot be perormed

nless a valid moisture test has been perormed

nce CAL button (A) is pressed, tester will now display the obtained moisture

eading and the current offset applied to that moisture range

ress the UP arrow (B) to raise the adjustment amount or press the DOWN

rrow

to lower. The tester will add or subtract up to 5.0% by increments of

.1% to the current moisture range

After the adjustment amount has been selected, press the CAL button (A) to

eturn to grain tester mode.

N

TE:

calibratio

o produce moisture readings in a tester that show

BELOW LIMIT” or “ABOVE LIMIT” readings.

RTANT:

IMP

This tester incorporates Multi-Point Calibration for each grain. Therefore, once a

va

test is taken and an adjustment is made, the adjustment w

oisture range of the sample tested.

only affect the

DISPLAY READIN

G

S

e

w

)

%

%

E

0%

40.0%

ISTURE LIMIT GUIDELINE

Specifications and design subject to chang

ithout notice

Operation

REEN COFFEE

PARCHMENT COFFE

OTE:

ear either the high or the low limit of the unit (listed above), the tester is programmed to close

own its range of operating limits.

Moisture Range

w Limit

9.0

.

oisture Range

igh Limit

5.0

Operation

0

T

w

id

:

flect

Teste

ces

,

y

pp

g

f

(

f

y

g

a

-

y

g

g

y

g

s

y

y

(High Moi

y

y

f

ALIBRATION CONSIDERATION / LIMITS

ypically the moisture tester will be consistent

ith most elevator testers over a broad range of

moisture levels. However, there are some things

to cons

tester calibration.

er when thinking about your moisture

OTE

may not match a given elevator tester. None of

the testers exactly match the actual weighted

moisture of an

difference between moisture testers and various U.S.D.A. a

s not a constant value. A correction at one moisture level may not be valid for a

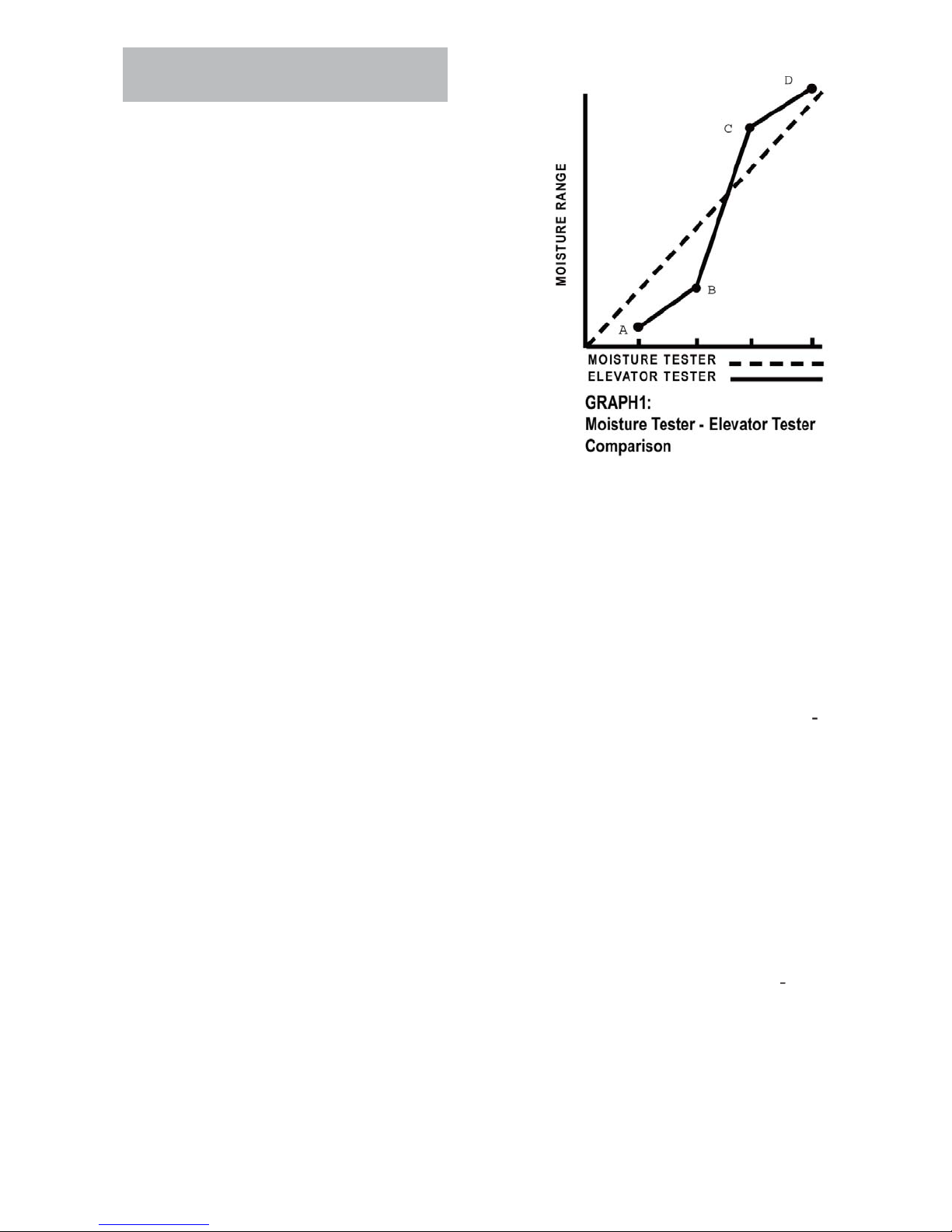

different moisture level. Graph 1 shows how the moisture tester mi

an elevator tester over a broad range of moisture levels. The moisture tester, and

most elevator testers (shown in graph by solid line) will closely match those o

moisture tester

get away

elevator tester and moisture tester not onl

moisture tester readin

tor tester. For example, in Graph 1, the area between B and C represents the mid

range moisture. Moisture tester readings match elevator tester readings in this area

with an accurac

the low moisture ran

readings, and are LOWER than elevator tester readings. The area beween C and D

represents the hi

elevator tester readings than the

are HIGHER than elevator tester readin

raph provided is for illustration

purposes only and does not re

ctual test data.

r Differen

rom mid-range into the high and low moisture levels, differences between

: Your moisture tester unit

given grain. There is no national standard for elevator testers. The

shown by dashed line) for that range, as illustrated. However, as we

higher than elevator tester to a reading lower than the elev

of plus or minus 0.5 percent. The area between A and B represents

e. Moisture tester readings differ more from elevator tester

h moisture range. Moisture tester readings again differ more from

did at mid-range moistures, but now the readings

roved elevator testers

ht compare to

become greater, but may switch from a

s.

the

alibration Requirements: Graph 1 illustrates that moisture tester readings closely

match elevator tester readings for mid-range moisture levels.

ration purposes only and does not reflect actual test data.)Calibration changes

required for grain in this moisture range will be small, if an

ry (Low Moisture Range) or very wet

to calibrate

our grain in both testers. Record the calibration correction required. It will be valid

or all testing in that moisture range for that grain.

our moisture tester unit against the elevator tester using a sample of

1

Graph is for illu

. However, if grain is ver

sture Range), it may be necessary

TO C

LEAR CALIBRATI

ON

r

lib

C

ed.

.

TO S

f

T

(

.

W

(B)

(A)

in l

f

.

4

. Select grain to clea

Press CAL button (A), tester will then

splay last ca

ration that was made.

Operation

3. Press

LEAR button (B).

both lines if the calibration has been

r

TE:f you press the CAL button

––––

nd tester displays 0.0% on

oth lines, then no calibration

––––

as been made for this grain

ELECT A DIFFERENT LANGUAGE

.At start up, the tester will always display the name of the last grain tested in the

current language selected. (English is the de

ault language from the factory.)

.

button (A) to index forward or backward

through the grain

function) menu until the

word LANGUAGE is displayed

3.

hen LANGUAGE is displayed, press TEST

button

. The current language selected

will be displayed. Press either the up or

down arrow on the SELECT button

ndex forward or backward through the

gra

o

anguage menu until your choice

language is displayed. The seven (7)

anguages (as displayed) are: ENGLISH,

PANISH, GERMAN, FRENCH, ITALIAN,

SWEISH and PORTUGUESE

. Press TEST button (B) again to return to the main grain menu, which wil now be

displayed in the new language.

to

Operation

2

)

At start up, the tester will display AL

WAYS

y

g

.

t

f

O

er

m

.

R

.

O

ibility in low

g

t

see

T

hed.

TO SELECT A NEW GRAIN SCALE

R FUNCTION

AVERAGE 3 TESTS for approximatel

seconds, then will display the name of the

rain tested, such as GREEN COFFEE

last

up or down arrow on the SELECT button (A)

o index forward or backward through the

rain (function) menu. The grains are listed

in alphabetical order followed by other tester

unctions.

N

TE:

test

p or down to get desired function.

ush TEST button (B) to peror

hat function

TO TURN ON BACKLIGHT AND TURN OFF TESTE

ress LIGHT button (A)

ress again to turn off backlight.

N

TE:

ester will automatically turn itself off

minutes after the last button has been

pus

he backlighting feature is designed

o improve display vis

ht conditions. In bright ligh

li

onditions, the backlighting cannot

n.

1

TO CHEC

K BATTERY POWER LEVELS AND REPLACE BATTERIE

S

Th

pplied with

f

kligh

.

A

TTERY LOW

l

y

kligh

ill

At any time, select BA

TTERY from

y

y

A

TTERY LOW message

he b

10%

r

y is fresh and

y needs replacing,

klight b

r

y can be used to

e

y location.

TO C

y

.

:

A

.

e tester is su

alkaline batteries. The le

owers the bac

t circuit. The

two 9 volt

t battery (A)

right battery (B) powers the system

The tester will flash a B

essage if system battery needs re

acing when unit is turned on. It will

not sa

this for the backlight battery.

In the event that the backlight battery

s low, the bac

t w

not work.

.

ain menu and press TEST to

displa

the percentage available for

both batteries.

Service

The tester system functions will

operate if no backlight batter

is

nstalled or if it is low.

. SYSTEM B

will be presented when unit is turned ON and

t

attery is

or less usable.

TE:If the backlight batte

e bac

atte

perate the system by moving it to th

LEAN THE TESTER

Remove cap and wipe out inside of the tester with a dr

- Light Battery

- System Battery

- Main Menu

- Test Button

- Select Button

paper towel

TE

rain may become lodged in threads of cap and

hould be removed with a small blade.

Troubleshooting

)

.

.

w

(

.

.

g

y

(S

).

TTERY LOW, the test results may be

r

y.

ymptom A: Unit does not power up or loses power occasionally (or backlighting

oes not operate.

Solution 1: Press ON-OFF button for shorter time. Do NOT hold button down

olution 2: Check batteries for 0% or higher. Replace as necessary

olution 3: Battery contacts may be making poor contact. Remove batteries

nd pull metal contacts up from bottom of compartment and above height of

lastic knob using needle-nose pliers. See illustration belo

mptom B: Unit is inaccurate.

olution 1: Temperature of the grain and unit

may be more than 20˚F

11˚C) different. Follow

reheat procedure (page 5)

olution 2: If grain is at an extreme temperature,

et grain settle to reach room temperature. Retest

rain

olution 3: Grain and/or test cell may have

eveloped surface moisture from rapid change

n temperature of the grain sample. Allow grain

nd tester to stabilize near room temperature.

Inspect for visible moisture on

test cell. Dr

test cell with soft cloth or blow

dryer, if necessary. Retest grain.

rain and inside

ee page 6

olution 4: If the tester displays SYSTEM

naccurate. Replace batte

Serial Number

W

g

f

__________________________________

_

________________________________________

V

.

y

.

A

o

®

g

y

.

RECORD SERIAL NUMBER

TE: The tester serial number is located on the bottom of the unit.

rite your model number, serial number and date of purchase in the space provided

elow. Your dealer needs this information when ordering parts and when filin

warranty claims.

Date o

Purchase

erial No. _______________________________________

odel No.

(To be filled in by purchaser)

ARRYING CASE

The carr

ing case is constructed of padded vinyl to

protect the tester

zipper bottom and Velcr

sealin

flap permit operation with tester

in carr

ing case

rder Part No. 06053

elcro is a registered trademark of VELCRO Industries

Notes

16

peradores Manuales

O

009

FFEE PR

Marzo 2

qp g p j

arantìa

(2)

a

p

.

y

y

n

T

ó

.

Este producto esta garantizado para estar libre de defectos en los materiales utilizados y su acabado

por dos

o cubre la batería ò daño resultante de uso erróneo, negligencia, accidente o mantenimiento e inst

lación inapropiada. Esta garantía no aplica a ningún producto que haya sido reparado o alterado una

autorización de re

La garantía declarada es exclusiva del resto de de las garantías de mercantibilidad, apropiadas para

el propósito

cualquier obligación o responsabilidad con respecto a su producto

sabilizara por daños.

años a partir de la fecha de compra en USA ò Canadá y un (1) año en ultramar. Esta garantía

aración e instalación de fabrica

cualquier tipo, explicito o tácito. AgraTronix tampoco adopta ni autoriza a otro a asumir

consecuentemente no se respo

oda información, ilustración y especificación en este manual son

basados en la ultima informaci

n disponible a la hora de la publicación.

e reserva el derecho de realizar cambios sin previo aviso

a

arantia de Producto y Programa de Mantenimient

o

o

o

f

o

o

l

a

a

edad

.

1

o

r

.

r

3

.

ipo

.

3

n

p

Functionamient

ondiciones de manej

Contenidos

Pagin

ecados de manejo

Procedimiento de

Precalentamient

Operación norma

Mostrar Temperatura en la célul

Promedio de los resultados de la prueb

Ajustar calibración

Pauta limite de hum

onsiderar calibración / limites

alibración nítida

eleccionar un idioma diferente

Seleccionar una función de la escala del gran

etroiluminado y apagado del medido

................................................................................ 4

uncionamient

..............................................................................

...........................................................

.................................................................................

.......................................................................

.................................................................................

...................................

ervicio

ambiar baterías.................................................................................

Limpiar el medido

...............................................................................1

1

Localización y resolución de problemas

egistrar el número de serie

orta equ

otas

...................................................................................................

Toda información, ilustración y especificación en este manual so

basados en la ultima información disponible a la hora de la publicación.

Se reserva el derecho de realizar cambios sin

.......................................................................................

...................... 14

...............................................................

revio aviso.

5

Funcionamiento

JO

e

e

e

)

ca

O

y

did

a.

u

n

(3) l

Vaci

did

p

y

did

.

g

.

NDICIONES DE MANEJ

l medidor de célula y grano DEBE estar libre de

ualquier condensación o humedad superficial.

umedad en el grano o en el medidor de célula

ausará lecturas de idas y venidas. El grano

caliente o frío absorberá humedad cuando

mu

e caliente o refresque. La funda de presión del

me

a, variaciones en la lectura de menor importa

muestra total aprobada y tomar un promedio.

de la muestra entre cada

or puede exprimir humedad de granos

ltamente humedecidos, como una mazorca, en

l fondo del medidor de célul

orqué los granos son de forma irregular y no

iempre encajan por igual en el medidor de cél

ia pueden ocurrir. Para aumentar la precisión

empre tome tres

ar y rellenar el me

ecturas sucesivas de la

or con un nuevo grano

rueba.

l medidor es más exacto cuando el grano y el medidor están entre 60˚F (16˚C)

0˚F (32˚C). La unidad sin embargo, funcionará con temperaturas entre 33˚F (1˚C) y

20˚F (49˚C). Para obtener mejores resultados, la temperatura del grano no debe es

tar por debajo de 40˚F (4˚C) o sobre 110˚F (43˚C). Si la temperatura del grano es 20˚F

(11˚C) más o menos que la temperatura de la unidad, precalentar el medidor según

nstrucciones en la pagina 5. Condensación en el grano o medidor de célula es mejor

vitarse teniendo el me

or y el grano con temperaturas casi iguales

medioambiente al cual se expone una muestra de grano puede cambiar apre-

iablemente su contenido de humedad. Expuesto al aire libre el grano puede perder

o

anar de 1 a 2% de humedad en solo unos pocos minutos. Si una muestra va a

ometerse por un corto periodo antes de ser probada, debería ser colocada en un

nvase bien cerrado, hermético, como una bragueta o recipiente

RECADOS DE MANE

Símbolo Definición

SISTEMA BATERIA DESCARG

-------------------------------

ecesita reemplazars

HUMEDAD BAJO LIMITE

HUMEDAD SOBRE LIMITE

ERROR (---

----------------------------------------------------------

a humedad esta bajo el límit

La humedad esta sobre el límit

lla electróni

Funcionamiento

Tornillo del Indicador de

ón

a

O

o

did

OC

O

.

fl

ada

4

.

é

(A). (

)

y

.

PROCEDIMIENTO DE FUNCIONAMIENTO - PRECALENTAMIENT

IMPORTANTE: Si la temperatura de la muestra del grano es 20˚F (11˚C) más

enos que la temperatura de la unidad, precalentar el me

or y revise como sigue.

PR

EDIMIENTO DEL PRECALENTAMIENT

1. Remueva la tapa (A) e inspeccione el medidor de célula (B) asegúrese que esta

impio y vacío

. Presione el botón ON-OFF (C) para girar el probador. La exhibición (D) dem-

strará SIEMPRE PROMEDIO DE 3 PRUEBAS por aproximadamente 7 segundos,

después demostrará la ALFALFA (operación inicial) o el nombre del grano pasado

probado.

uando el grano a ser examinado haya sido seleccionado usando el SELECT

3.

echa (E), llene el medidor de célula (B) aún al tope de la célula con la muestra a

r examin

.

.

espués de 30 segundos, vacíe el medidor de célula e inmediatamente rellene

.

R

on grano fresco.

6. Reemplace la tapa (A) y apret

y nivele con la tapa

hasta que el indicador de presión atornille (F)

Use el dedo como nivel según se ilustra en la Figura 1.

7. Inmediatamente presione el botón TEST (G). La palabra PROBANDO aparecerá

or 10 segundos, mientras el medidor compensa la temperatura. La humedad %

la temperatura aparecerán por cerca de 10 segundos

Presi

G - Botón de Prueb

Funcionamiento

o

a

F

S

o

cador de

a

JO

c

)

acío

ón (D)

á

S

ado ha sido seleccionado

ada.

)

A

y

.

é

ille (F) nivel

t

l nivel

)

y

.

e

.

:

y

ROCEDIMIENTO DE MANE

PERACIÒN NORMAL

Remueva la tapa (A) e inspe

cione el medidor de célula (B

asegúrese que esta limpio y

.

v

Presione el botón ON-OFF

C) para girar el probador. La

exhibici

IEMPRE PROMEDIO DE 3

PRUEBA

ente 7 segundos, después

emostrará la CAFE VERDE

operación inicial) o el nombre

el grano pasado probado.

demostrar

por aproximada

uando el grano a ser ex

min

sando SELECT flecha (E),

lene el medidor de célula (B)

aún al tope de la célula de

tra a ser examin

Sólo para prueba inicial

ntes de apretar la tapa de presión,

gire el medidor

permita calendar

nos 30 segundos antes de intentar

a primer prueba

Reemplace la tapa (A) y apret

hasta que el indicador de presión

atorn

e con el tope de la

A - Casquill

B - Pruebe la Célul

- Botón ON-OF

D - Exhibición

eleccione las Flechas

E F - T

rnillo del Indi

- Botón de Prueb

Presión

apa (A). (Use dedo para examinar

e

como se indica en la Figura.

Inmediatamente presione el botón TEST (G). La palabra PROBANDO aparecerá

por cerca de 10 segundos, mientras el medidor compensa la temperatura. La

humedad %

la temperatura aparecerán luego por cerca de 10 segundos

El medidor retornará mostrando el nombre del grano de la ultima muestra. V

el medidor de célula y rellene una muestra fresca y pruebe nuevamente

NOTA

promedie los resultados.

í

Funcionamiento

a

g

a

TEMPERATURA

ó

˚ y C˚

á

incipal del g

.

g

g

O

A

acene

lecturas

T

A: Solo almacena el promedio de un grano.

VG para mostrar el promedio

VG. El promedio actual se mostrará.

.

MOSTRAR TEMPERATURA EN LA CÈLULA

Para indicar la temperatura en la célula, presione cualquier

Hacia arriba o hacia abajo permitiendo al botón SELECT (A)

Para adelantarlo o atrasarlo a través del

función) menú hasta que la palabr

se muestre.

uando TEMPERATURA se muestre, presione el

n (B) TEST la temperatura actual en la célula

bot

se mostrará en F

. Temperatura se mostrará.

Por escasos segundos luego volver

pr

rano

turas diferentes, la masa del medidor de metal

rápidamente calentara o refrescará al

anto, la lectura de la temperatura es la temperatura de la célula, no necesariamente

la temperatura del

rano antes de colocarse en la célula.

rano

al menú

rano. Por

PR

MEDIO DE LOS RESULTADOS DE LA

PRUEB

. Cuando examine el grano, el resultado de la

rueba lo muestra por 10 segundos. Durante

l periodo que el medidor de humedad % y

a temperatura se muestra, presione el botón

A) MEMORY. El medidor reconocerá que ha

ncorporado la lectura en la memoria, most

rando el promedio actual y luego el numero

de su almacenamiento. Sobre 20 lecturas

ueden ser almacenadas en la memoria.

Si el numero máximo de lecturas ha sido

lcanzado, el medidor no permitirá que se

m

n mas

.

NO

uando una prueba para un grano se desarrolla, existe

romedio de datos previos y se borra cuando se toma

n nuevo promedio. El promedio es retenido aún si las

ilas son retiradas.

e todos los resultados ingresados por los granos que

stán siendo examinados.

3.

resionar el botón CLEAR (C) y el probador mostrara 0.0% ( 0 ). Esto indica que

l promedio ha sido retirado

Funcionamiento

O

:

t

s

edad.

r

).

s

lida de h

y

(B)

C

.

q

SO

.

j

á

ARA AJUSTAR LA CALIBRACIÒN

IMP

RTANTE

iempre obtenga tres (3) pruebas de la

oma de grano para la muestra que esta

iendo comparada. El promedio de esas (3)

uestras. Compare ese promedio con el

promedio de las (3) pruebas del medidor de

m

ada escala de grano se puede ajustar

individualmente hasta 5.0% por incre

entos de 0.1% para acercarse e igualar

los resultados de una toma

del medido

rimero seleccione el grano para ser

ajustado.

Examine el grano seleccionado, usando la muestra deseas ajustarlo también.

na vez que aparezca la humedad validada, presione el CAL botón (A

TA: La calibración de grano no puede ser realizado a meno

ue se haya realizado una prueba va

umedad.

Una vez CAL botón (A) es presionada, el medidor no mostrará la lectura de la

humedad obtenida

resione hacia arriba

flecha (

) para bajar. El medidor sumará o restará hasta 5.0% por incrementos de

la actual contrarrestará a ese rango de humedad.

para levantar la cantidad ajustada o presione abajo

.1% por rangos actuales de humedad.

Después de que la cantidad ajustada ha sido seleccionada, presione la CAL botón

A) para volver a la modalidad de medidor de grano

TA: El ajuste de calibración no puede ser realizado por la fábrica para producir

lecturas de humedad en un medidor

“

BRE LIMITE”

ue muestra LECTURAS DE “BAJO LIMITE” o

IMPORTANTE:

ste medidor incorpora la calibración de Multi-Puntos para cada grano. Por

tanto, una vez que se tome una prueba válida se hace un a

surtir

efecto en el rango de humedad de la muestra examinada.

uste, el ajuste solo

MOSTRANDO LECTURAS E INDICACIONES

U

)

prog

o

d

d

e

E

0%

0%

0%

0%

DE LÍMITE DE H

Especificaciones y diseños sujetos a cambios

sin previo aviso

MEDAD

Funcionamiento

Humeda

ajo Limite

umeda

obre Limit

AFE VERD

.......................

AFE PERGAMINO .................... 10.

TA:

ramado para caer en los rangos de los límites de funcionamient

.....................

...................40.

Funcionamiento

0

S

ÒN

Típ

OTA:

y

e

de

y

did

did

ó

f

did

l

j

y

ascenso en esa área con una exac

did

e

did

o

)

lib

did

:

did

d

o

NSIDERACIÒN DE LOS LÌMITE

DE LA CALIBRACI

icamente el medidor de humedad será

onsecuente con la mayoría de las pruebas por

ncima de los rangos de humedad, sin embargo

ay otras cosas a considerar cuando se piensa

n medidores de calibración de humedad.

N

no reflejan datos actuales d

ruebas.

iferencias de medición de tu medidor

umedad:puede no igualar el medidor de

scenso.Ningùn medidor iguala con precisión

l peso actual de humedad de un grano dado.No hay un estándar nacional para un

medidor de ascenso.La diferencia entre un medidor de humedad

os medidores de ascenso no son un valor constante.Una corrección en el nivel de

umedad no será validada por un nivel de humedad. El gráfico 1 muestra que el

medidor de humedad puede compararse a un medidor de ascenso con rango amplio

n niveles de humedad. El me

muestran en s

unteada) por ese rango, tal cual se ilustra, sin embargo, como se consiguió alejarse

del rango medio en el alto

e ascenso y el me

medidor de humedad lectura más alto que el medidor de ascenso para una lectura

más ba

representa la humedad de rango medio. El medidor de humedad lectura la subida

ntre A y B representa el rango mas bajo de humedad. La lectura del medidor de hu

medad discrepa otra vez con el me

n el rango medio, pero ahora las lecturas son más altas que el medidor de ascenso.

a que el medidor de ascenso. Por ejemplo en el gráfico 1, el área entre B

l medidor de

lidas líneas) se acercaran al medidor de humedad (mostrada en línea

ionan e ilustran metas

RAPH1

e

or de humeda

– medidor de ascens

omparaciòn

varios U.S.D.A.

or de humedad y los me

y bajo nivel de humedad las di

or de humedad no son grandes, puede que el interruptor de

titud de más o menos 0.5%. El área

or de ascenso lecturando lo que ellos hicieron

ores de ascenso(se

erencias entre el medidor

equerimientos de calibración: El graficó 1 ilustra la lectura del medidor de hum

ad cercana a la lectura del me

medi

Los cambios de calibración solicitados por el grano en el rango de humedad, deben

er pequeñas, si hubiesen. Sin embargo, si el grano es muy seco (bajo rango de

umedad) puede que sea necesario ca

ontra del medidor de ascenso usando una muestra o tu grano en ambas pruebas.

egistre la calibración de la corrección requerida. Será válido para toda prueba en

sa gama de humedad para ese grano.

el gráfico ilustra solo el propósito y no refleja fechas de pruebas actuales

1

or de ascenso para niveles de humedad de rango

rar la unidad del me

or de humedad en

ALIBRACIÒN NÌTID

A

r

ces e

e

o

á

)

p

ó

eccionada será e

ó

é

,

y

.

4

g

.

. Seleccione el grano para despeja

Presione el botón de la CAL (A), pro

r enton

xhibirá la calibración

asada que fue hecha.

. Presione el botón CLEAR (B).

El probador entonces exhibirá 0.0%

ara ambas líneas si se ha despejado

a calibración.

Funcionamiento

OTA:

i usted presiona el botón de

la CAL y el probador exhib

.0% en ambas líneas,

espués no se ha hech

ninguna calibración para este grano.

PARA SELECCIONAR UNA DIVERSA LENGUA

. En empiece para arriba, el probador exhibirá siempre el nombre del grano

asado probado en la lengua actual seleccionada. (El inglés es la lengua del

defecto de la f

brica.

. Para seleccionar una nueva lengua, presione hacia arriba o hacia abajo la flecha

en el botón SELECT (a) para poner en un índice adelante o al revés a través del

enú del grano (función) hasta que se

exhiba la

.

uando se exhibe la IDIOMA, presione

el bot

l

arriba o hacia abajo la flecha en el bot

alabra IDIOMA.

n de TEST (b). La lengua actual

xhibida. Presione hacia

n

SELECT (a) para poner en un índice

adelante o al rev

s a través del menú de la

engua del grano hasta que su opción de

a lengua se exhiba. Las siete (7) idiomas

según lo exhibido) son: INGLES

ESPANOL, ALEMAN, FRANCES, ITALIANO,

SUECO

PORTUGUES

. Presione el botón de TEST (b) otra vez para

volver al menú principal del

en la nueva lengua

rano, que el wil ahora se exhiba

Funcionamiento

2

O

)

g

i

S

n

.

usar otras funciones

e

a

je

.

.

cas del co

A

a

ELECCIONAR UNA ESCALA DE GRANO NUEV

(O FUNCIÒN

. En empiece para arriba, el probador exhibirá

IEMPRE PROMEDIO DE 3 PRUEBAS por

aproximadamente 7 se

irá el nombre del grano pasado probado, por

ejemplo CAFE VERDE.

. Para seleccionar una escala de grano la flecha

arriba o abajo de

adelante o atrás a través del grano (función)

enú. Los granos son colocados en orde

alfabéticos seguido del medidor de funciones

: Para

incluidas en el medidor empuj

ELECT botón (A) arriba o abajo par

onseguir la función deseada, empu

otón (B) para realizar la función.

undos, después exh

ELECT botón (A) coloque

. Presione LIGHT botón (A)

. Presione nuevamente y apague la contraluz

:

e diseñan para mejorar la

isibilidad de la muestra en

ondiciones de baja luz

ue el contraluz no puede

pague el medidor presione ON-OFF botón

B). El medidor se encenderá automátic

ente y se apagará 2 minutos después de

ser activado.

1

racterísti

ntraluz

A

ueba

REVISAR NIVEL DE PODER EN LAS BATERÌAS Y SU REEMPLAZ

O

a

.

ecesita

í

a batería de co

cue

e

ú

ST

.

4

i

ja.

á

.

s

a

ón

OR

A: El grano puede alojarse en las ranuras de la tapa y debe ser quitado

.

1. El medidor es alimentado con dos

terías alcalinas de 9 voltios. L

batería izquierda (A) alimenta el

circuito contraluz. La batería (B)

erecha alimenta al sistema

2. El medidor destellará BATERIA BAJA

i el sistema de baterías n

remplazarse cuando la unidad esta

prendida. Pero no lo hará para la

bater

a de contraluz. En caso que

l

ntraluz se en

ntr

baja, la contraluz no trabajará.

Service

3. Cada vez que seleccione BATERIAS

del men

principal y presione TE

ostrará el porcentaje disponible de

ambas baterías

. Las funciones del sistema del med

dor funcionaran, si la batería no esta

colocada o si esta ba

. SISTEMA BATERIA DESCARG se mostrar

cuando la unidad esta ON y la batería

esta 10% o menos, utilizable

TA: Si la batera de contraluz e

resca y el sistema necesita reemplazarse,

a batería de contraluz puede ser usada par

ncender el sistema moviéndolo a la ubicaci

el sistema de la batería.

- Batería Ligera

- Bateria del Sistema

- Menú Principal

- Botón de Pr

- Seleccione el Botón

LIMPIAR EL MEDID

uite la tapa y limpie el medidor con una toalla de papel seca.

on una hoja pequeña

3

Localización y resolución de problemas

.

á

.

.

i

m

r

ibl

e

p

.

á

ntoma A:La unidad no levanta o pierde energía ocasionalmente (o no funcionan).

olución 1: Presione el botón ON-OFF corto tiempo. NO sujete el botón hacia

ajo.

olución 2: Revisé las baterías para 0% o rango superior. Reemplace de ser

ecesario

olución 3: Los contactos de batería pueden hacer escaso contacto. Remueva

as baterías y jale hacia arriba el contacto de metal de la parte inferior del

compartimiento sobre altura de pl

stico usando

tes. Vea la ilustración abajo

ntoma B: La unidad es imprecisa

olución 1:

a temperatura del grano y de la un

dad puede ser más que 20˚F (11˚C) diferente. Siga

procedimiento de precalentamiento (pagina 5).

olución 2: Si el grano se encuentra con te

eratura extrema, Asiente el grano para alcanzar

temperatura ambiente. Reexamine el grano.

olución 3: Grano y/o medidor de célula puede

aber desarrollado humedad por rápidos cambios

n la temperatura de la muestra del grano. Pe

mite al grano y medidor estabilizar la temperatura

mbiente. Examine para ver si hay humedad vis

n el grano y dentro del medidor de célula. Secar

l medidor de célula con paño suave o secador de

e

elo, de ser necesario. Reexamine el grano. (Ver

àg. 6)

olución 4: Si visualiza en el medidor BATERÌA

, los resultados de la prueba pueden ser inex-

ctos, Reemplace la batería.

olución 5: La unidad puede requerir ser r

calibrada en fábrica. Vuelva a su distribuidor de

Farmex

ara reparación o sustitución

íntoma C: La unidad lee HUMEDAD BAJO EL LÌMITE o HUMEDAD SOBRE EL

olución 1: El grano puede estar muy húmedo muy o seco para la prueba.

Revise los limites de humedad en las indicaciones de la P

iones de funcionamiento.

gina 9 de las Instruc

OTA: Pagina 9 limites son solo indicaciones.

Numero de Serie

E

ú

j

í

_

)

V

.

p

g

did

y

®

l

e

3

REGISTRO DEL NÙMERO DE SERI

TA: El número de serie del medidor esta ubicado en la parte inferior de la unidad.

Escriba su n

proporcionado aba

mero de modelo, número de serie, y fecha de compra en el espacio

o. Tu Distribuidor necesita esta información cuando ordenas

repuestos y cuando demandas los documentos de garant

echa de Compra __________________________________

erie No. _______________________________________

odelo No. ________________________________________

(Para ser llenado por el comprador

PORTA EQUIPO

orta equipo es construido de vinilo rellenado para

El

prote

er el me

or.

a.

Una cremallera,

un sello hermético Velcro

ermiten funcionar el medidor con

porta equipo.

e

mero de Part

de la Orden 0605

elcro es una marca registrada de industrias VELCRO

Loading...

Loading...