Page 1

SERVICE MANUAL

MODE PERFORMANCE250 DV/DVP

CODE ZL-012601-01

CODE ZL-012701-01

Address:Via Svizzera,12/14,Castel Goffredo Mantova 46042 Italy

Website: www.coef.it

Page 2

INDEX

COVER-------------------------------------------------------------------------------------------------.1

INDEX--------------------------------------------------------------------------------------------------.2

1.0 SPECIFICATIONS---------------------------------------------------------------------3

2.0 CHANNELS AND DIGITAL VALUES---------------------------------------------4

3.0 ASSEMBLY SKETCH AND PART LIST--------------------------------------------6

4.0 WIRE CONNECT DIAGRAM-------------------------------------------------------9

5.0 PCB COMPONENT LOCATION DRAWING------------------------------------10

6.0 ELECTRONIC MAINTENANCE--------------------------------------------------11

7.0 ORDINARY MAINTENANCE-----------------------------------------------------12

8.0 EXTRAORDINARY MAINTENANCE-----------------------------------------12

9.0 TROUBLE SHOOTING------------------------------------------------------------.13

COSTOMER SUPPORT REQUEST FORM-------------------------------------15

2

Page 3

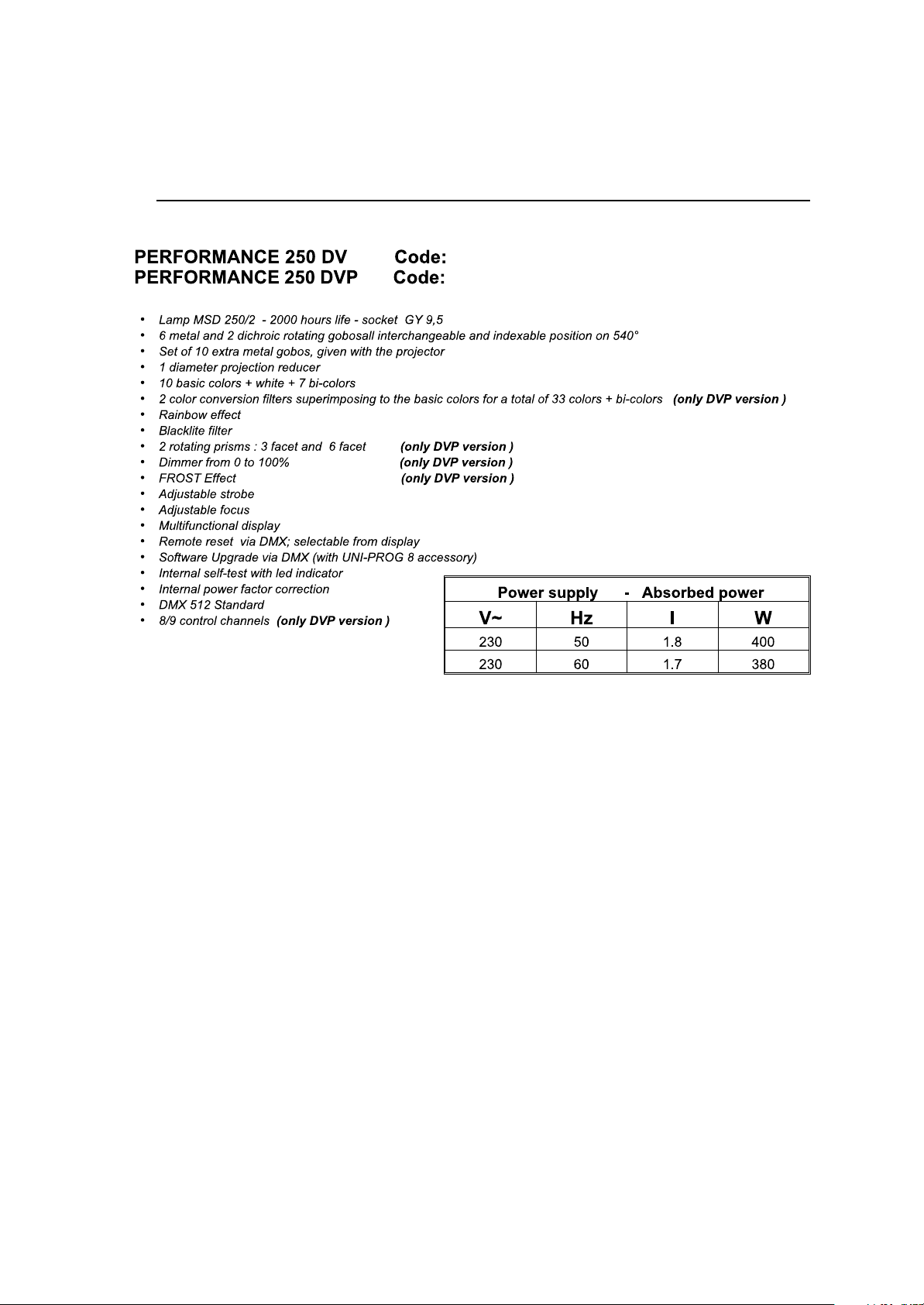

1.0 SPECIFICTION

ZL-012701-01

ZL-012601-01

3

Page 4

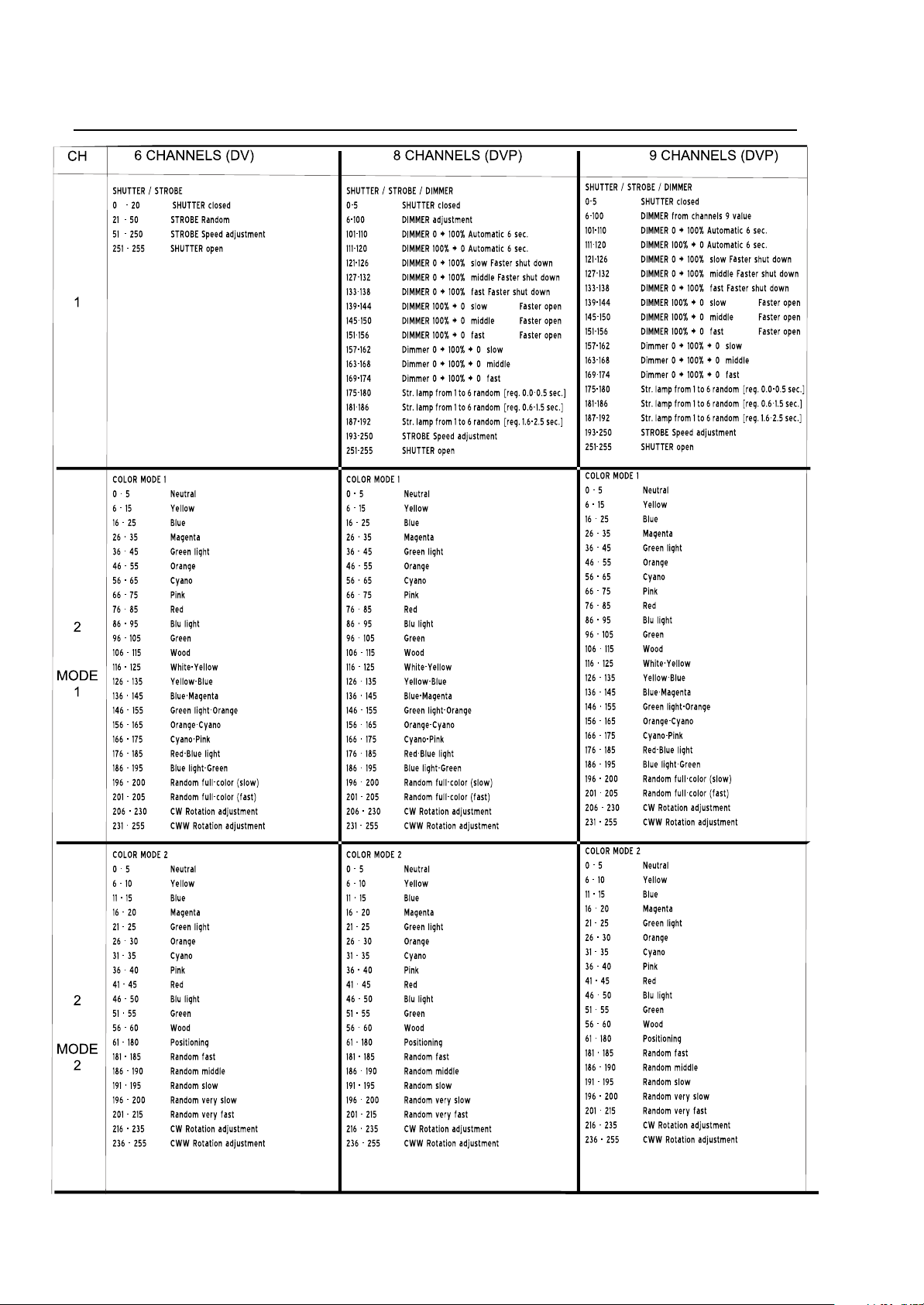

2.0 CHANNELS

AND

DIGITAL

VALUES

next

4

Page 5

continue

5

Page 6

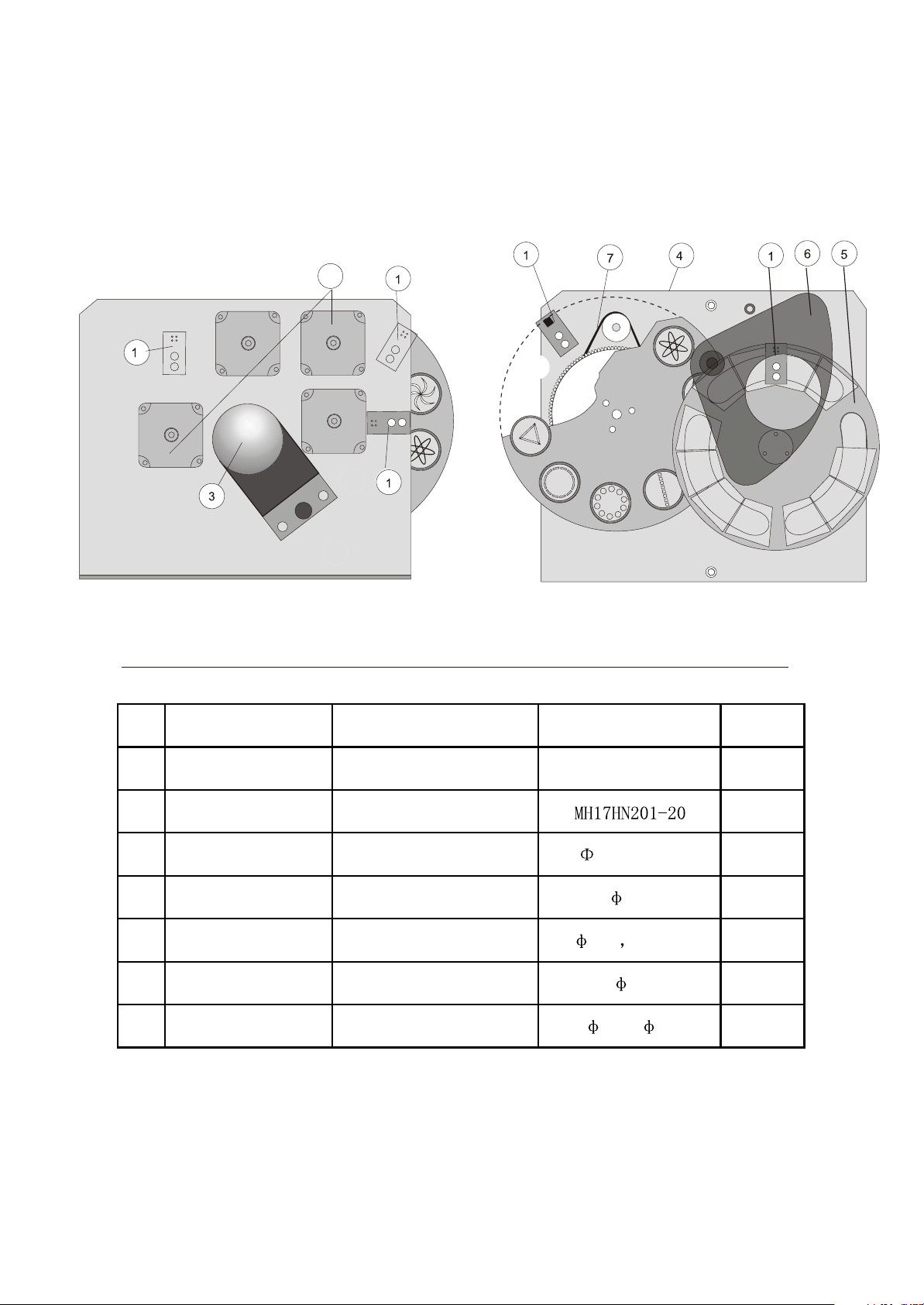

1

R/N P/N PART NAME DESCRIPTION QUA

1 126-0326000000 lampholder GY9.5 L=400mm 1

2 022-1014022254 transformer

100V-250V2*(28V

2A)

12V 1.8A

1

3 119-2523000600 ballast 230VAC50/60HZ 3A 1

4 013-4000412505 capacitor

40 F 250V

1

5 088-5001063400 ignitor 4-5KV,5A HQCD-7 1

6 370-5012301033 elliptic reflector

85.8* 26*44.3

1

7 083-0230000000 fan

119*119mm

230VAC/50/60HZ

1

8 088-5012601538 main pcb loaded 261×141mm 1

9 619-0126010000 objective lens assembly

75 400°

1

10 605-0000000019 step motor 5

11 626-0126010000 mirror assembly 125x175x1.2 ,R62.5 1

12 575-1009061900 focus adjustment 9*61mm 3

13 066-1080000000 thermal switch

80

1

14 626-0127012000 anti-heat filter(DV only) 153.5*80 1

13

3.0 ASSEMBLY SKETCH AND PARTS LIST

5

3

6

1

14

8

11

10

12

9

2

7

4

6

Page 7

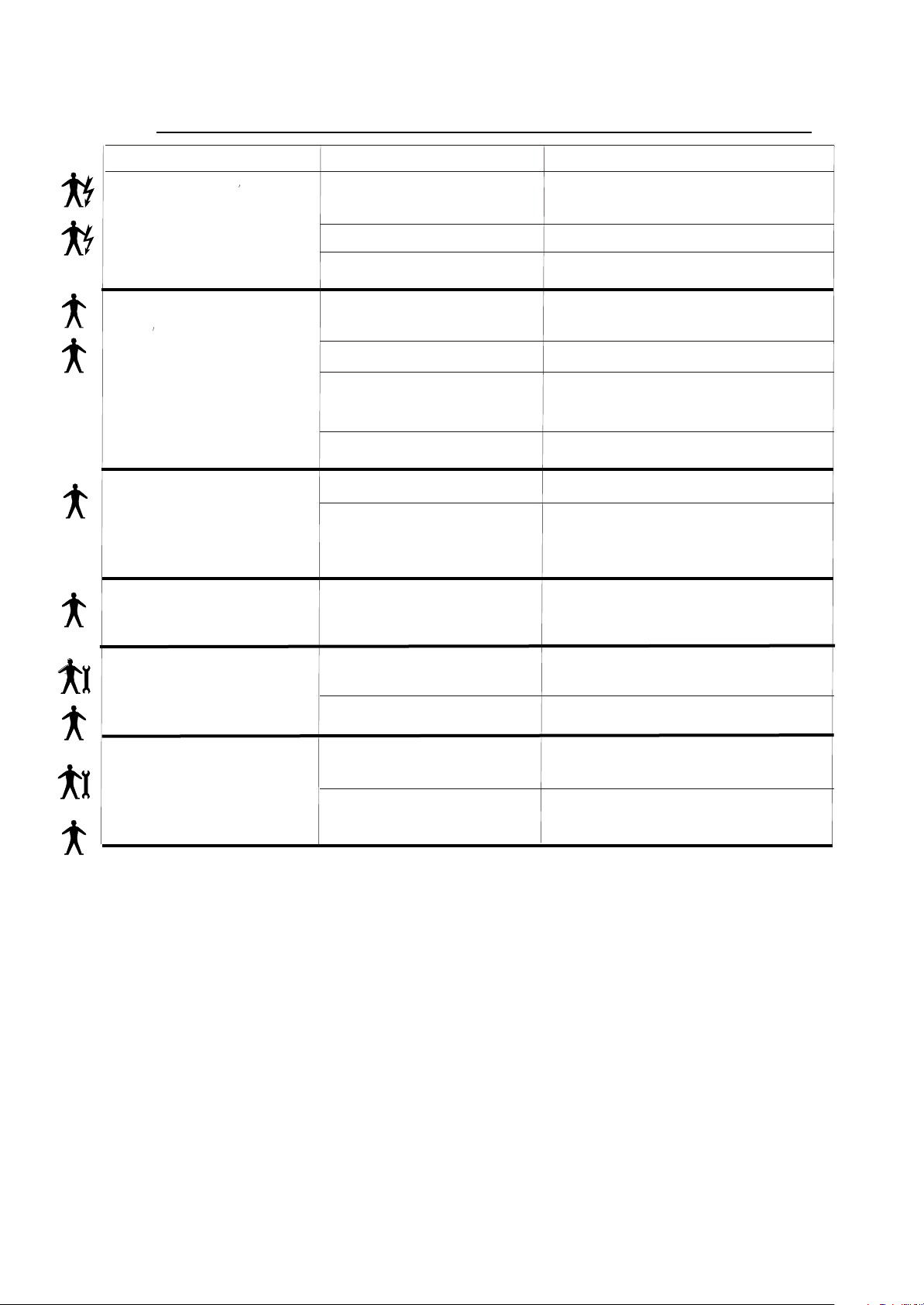

3.1 ASSEMBLY SKETCH AND PARTS LIST

R/N P/N PART NAME DESCRIPTION QUA

1 852-0740003500 OR-ring

3.53 57

1

2 622-0126010000 prism wheel assembly

151

1

3 605-0000000023 step motor MH17HN201-20 2

4 088-5020600490 optical sensor pcb assembly 26.7*26.76mm 4

5 618-0126010000 gobos wheel assembly

152

1

6 616-0126010000 focus lens assembly

49.8 1120°

1

7 852-0580003500 OR-ring

3.53 74

1

8 610-5012301000 shutter/strobe/dimmer blade 0.5mm 2

9 611-0126010000 color wheel assembly

138

1

10 624-5012601000 anti-heat filter assembly 70*164*1.2 1

(DVP ONLY)

4

21

3

54

7

4

8

9

4

6

5

3

12

10

6

Part list

7

Page 8

3.2 ASSEMBLY SKETCH AND PARTS LIST

R/N P/N PART NAME DESCRIPTION QUA

1 088-5020600490 optical sensor pcb loaded 26.7*26.76mm 4

2 605-0000000023 step motor 2

3 616-0126010000 focus adjustment assembly

49.8 1120°

1

4 618-0126010000 gobo wheel assembly

152

1

5 611-5012301000 color wheel assembly

138 11PCS

1

6 626-0127011000 shutter/strobe blade assembly

28

1

7 852-0580003500 OR-ring

3.53 74

1

(DV ONLY)

2

Part list

8

Page 9

4.0 WIRE CONNECT DIAGRAM

9

Page 10

5.0 PCB COMPONENT LOCATION DRAWING

10

Page 11

6.0 ELECTRONIC MAINTAENCE

This section is dedicated in detail to the electronic connection between the card and the mechanical

components,assembled in the projector .These informations will be absolutely necessary when the mechanical

unit has to be removed from the projector for maintence and/or repair.

The connections are made using handy connectors and are detailed where you can find indications about the

connection beteween a specific connector and specific component of the mechanical unit. This includes the motors

and the sensors of the various effects wheels(color,gobosprisms,,shutter etc.)

WARNING! An improper use of this documentation made by not specifically qualified staff

can damage irremediably theelectronic and/or mechanical components of the projector

11

Page 12

7.0

ORDINARY MANTENANCE

WARNING switch off the projector before operating

8.0 EXTRAORDINARY MAINTENANCE

To make an extraordinary maintenance, it is necessary thepresence of a generic or qualified mechanicaloperator,according to the type of the needed intervention.To make it

simple, we advice to completely extract the mechanical part of the PER-FORMANCE

250DV/DVP from its box: look figure where you can see the hexa-gonal screws (A&B)4 for

DV model and 3 for DVP model; the focus bracket screws(C)that have to removed,so that

you can extract the whole mechanical part,supportIng the motors and the various heels

(Effects, color, gobos). In this way it will be much more easy to observe

the different particulars that have to be cleaned and, at the same time,

The whole mechanical structure mounted with all its components shown.

You must particularly take care of the sensors which are really fundamental in the unit working.

The sensors are absolutely necessary when a general reset of the projector is needed. If this function

is not correctly executed, it will totally compromise the regular working of the projector, at least for

the group referred to the sensor itself.

The same situation eill occur in the case of the gobos wheel or the effects wheel.

The section shutter/strobe/dimmer does not use sensors during the reset positioning but it is conditioned by a mechanical beat of the shutter shovels.

You must carefully clean also the moving zoom lens. After several working hours dust and grease

will be stored on this lens, carried inside the projector by air flow.

12

Page 13

9.0

PROBLEM CAUSE ACTION

TROUBLE SHOOTING

The Projector doesn t switch on

The projector switches on but

doesn t answer to commands

Defecting projection

Projectionb with halo

-The power supply is not present

-The lamp is not working

The thermal switch is active Just to wait for little of time

-Wrong DMX configuration

-Defective cables

-Defective control unit

LED A is off Check the control unit&DMX cable

-The lens is broken

-Dust or grease stored on the all

parts of projector

-

- Dust or grease stored on the all

parts of projector

Check if the luminous indicator is lighted

or not.

Replace the lamp.

Make sure that the projector is correctly

configurated.

Replace or repair the DMX CABLE

Check the control unit by means of other

working projectors

Technical aid is required.

Check that the lens are not broken

Remove dust or grease stored on lenses

Carefully clean the optical group lenses

and the projector components

The color or other effects does

not coincide to the selected

value.

The PAN movement does not

coincide to the selected value

-Position senser dirty with dust or

grease

- Defective motor

- Electronic board

- Position senser dirty with dust or

grease

- Defective Motor

- Electronic board

Carefully clean the optical group lenses

and the projector components.

Technical aid is required.

Carefully clean the optical group lenses

and the projector components

Technical aid is required

13

Page 14

COSTOMER SUPPORT REQUEST FORM

If you have any technical problem/malfunction and you need support, please fill in the

following form and send it by fax or e-mail directly to International Technical and Service

Department

The fax number is +086 0755 8209 0203 the e-mail address is sales@coef.itFor a better

problem comprehension you should fill in all the fields requested

Thank you.

Company name:

Contact person : fax:

tel: e-mail

Product indentification

Product name code number ( * ) serial number

Time in use before fault:

Date of shipment to distributor:

Date of shipment to end user:

Operating conditions:

Mains supply voltage(volt): main supply frequency(hertz):

Ambient temperature(¢J) : Operating position:

Lamp type and manufacturer

Used in: disc, theatre, rental, other

Detailed description of product problem/requirement

Loading...

Loading...