Page 1

http://www.coef.it

e-mail:info@coef.it

Realized by PC CAD & VIDEO

Printed in October 2005

Page 2

http://www.coef.it -

e-mail: info@coef.it

Tutti i diritti di riproduzione, diffusione del presente manuale sono riser-

vati a

COEF.

Le descrizioni ed illustrazioni fornite nella presente pubblicazione non

sono impegnative.

si riserva il diritto di apportare in qualsiasi momento tutte le

COEF

modifiche che riterrà opportune.

Il presente manuale non può essere ceduto in visione a terzi senza spe-

cifica autorizzazione scritta dalla COEF

.

All rights for reproduction of this catalogue are reserved for COEF

.

Descriptions and illustrations are not binding.

COEF reserves the right to make all necessary modifications at any

time. This manual can not be inspected by third party, without written autorization by COEF

.

Les droits de reproduction de ce catalogue sont entiérement réservés à

la Société COEF.

Les descriptions et les illustrations fournies dans ce manuel n’engagent

acunement notre Société.

se réserve le droit d’apporter, à tout moment, les modifica-

COEF

tions qu’elle jugera utiles.

Ce manuel nepeut être remis à des tiers sans l’autorisation préalable de

la Société COEF.

Alle Rechte vorbehalten. Nachdruck verboten.

Die indiesem Handbuch enthaltenen Beschreibungen und Abbildungen

sind nicht verbindilich.

Die Firma COEF behält sich das Recht auf Änderungen zu jedem

Zeitpunkt vor.

Diese Bedienungsanleitung darfohne schriftliche Genehmigung der Fir-

ma COEF

dritten Personen nicht zugänglich gemacht werden.

Pag. 2 http://www.coef.it - info@coef.it

Page 3

Page 4

1.0 HOW TO USE THE MANUAL

1.1 TECHNICAL NOTES

This manual has been organized in order support the user, the installer or the maintenance operator of the de

scribed unit with those necessary informations for a correct use of the installation and working procedures of the

same unit. The various procedures will be just signalled by indicators (when necessary) evidencing the operation

dangers and the necessity of technical support. Please find here below a list of symbols and relative meaning.

OPERATOR: Not particulary qualified staff, that can operate when no specific knowledge is required.

COEF OPERATOR: Technical staff, qualified and trained by the constructor, for repair and extraordi-

nary operations.

MECHANICAL OPERATORS: Staff employed in the ordinary mechanical maintenance.

SPECIALIZED MECHANICAL OPERATOR: Qualified staff employed in extraordinary authorized in-

stallations and repairs.

ELECTRIC OPERATORS: Staff employed in the ordinary electric maintenance.

SPECIALIZED ELECTRIC OPERATORS:Qualified staff employed in extraordinary authorized instal-

lations and repairs.

DANGER SIGNAL: Generic danger signal and electric shock danger signal.

-

MP250 Fresnel Code:ZL-012401-01

MSD 250/2 lamp - 250 W - 2.000 hours life - 8.000 °k

•

•

540° PAN - 270° TILT

•

16 bit movement resolution

•

PAN and TILT automatic repositioning

•

80 colors + white + bi-colors

•

2 Conversion filters 3200° k / 5600° k

•

Rainbow effect adjustable in speed

•

Black light filter

•

Linear dimmer from 0% to 100%

•

Mechanical shutter

•

Adjustable strobe

•

Frost linear effect

•

Multifunctional display

•

Remote reset via DMX, selectable from display

•

Remote ON/OFF lamp via DMX, selectable from display

•

Software Upgrade via DMX (UNI-PROG 8 optional available)

•

Internal self-test with led indication

•

Internal power factor correction - absorbed power 1,8 A.

•

DMX 512 Standard

•

8/9 control channels

Pag. 4 http://www.coef.it - info@coef.it

Page 5

Page 6

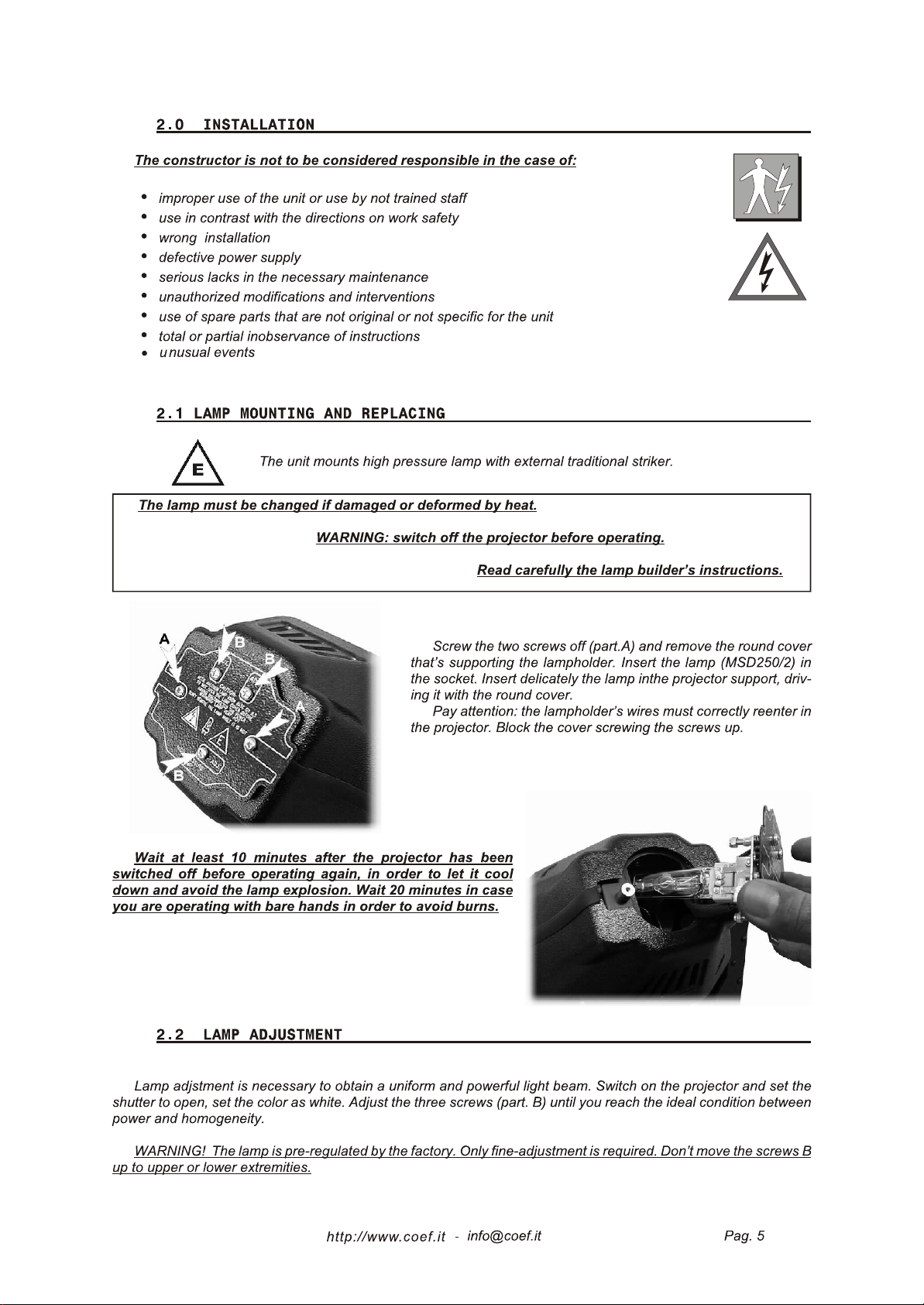

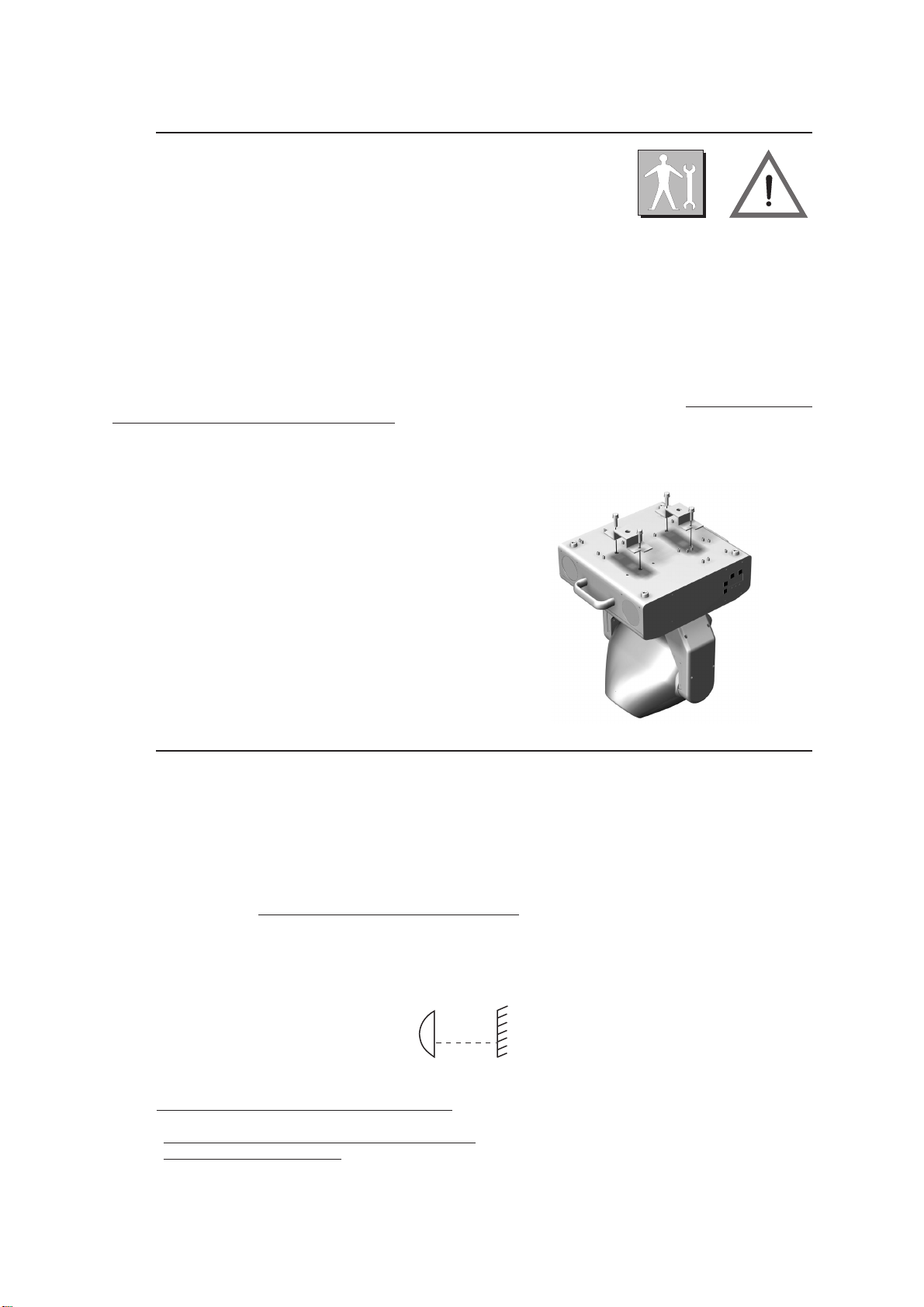

2.3 PROJECTOR INSTALLATION

To fix the MP250 Fresnel is necessary, when the installation has to be on a raised-from-the ground support, to

block the fixing bracket of the unit by means of a screw provided with nut and locknut measuring not less than

M10X50, to insert in the central pre-arranged hole on the fixing bracket.

In order to guarantee a necessary security and in respect of the actual safety rules concerning the projectors’ installation, it is compulsory to install a safety-chain (or steel cable), equipped with spring clips, to connect the MP250

Fresnel‘s body to the fixing structure.

ATTENTION: the safety-chain must be properly installed and fixed to the supporting structure, in a way that an

incidental giving in of the main bracket would leed to the shortest possible fall of the projector. After such an intervention the safety-chain must be replaced.

ATTENTION: COEF is not responsible for installations not correctly made or made without respecting the

above indications: those installations are considered dangerous.

2.4 ADVICES FOR A CORRECT INSTALLATION

The following conditions have to be respected for a correct operation:

1) Do not install the projector outside where the influence of atmospheric factors could damage the unit work-

ing (rain, wind, intense heat etc.).

2) Do not clean the projector using water jets or immersion in different liquids. Scrupulously follow the indica-

tions given in the chapter MAINTENANCE.

3) Make the electric connections and the installation / replacement of the lamp after haved disconnected the

power supply and after haved positioned the power switch to OFF

4) Do not touch in any case the internal and external parts of the projector without previous authorization of the

constructor and make modifications only by the intervention of qualified staff.

5) Make sure that the projector is correctly fixed on the support as indicated in par.2.3.

1,5 m

6) Minimum distance from illuminated objects:

struck by the light beam are located at least 1,5 metres from the projector objective.

7) Minimum distance from inflammable materials:

8) MAX ambient temperature:

40° C.

The projector must be positioned in such a way that objects

.

0.3 meters

Pag. 6 http://www.coef.it - info@coef.it

Page 7

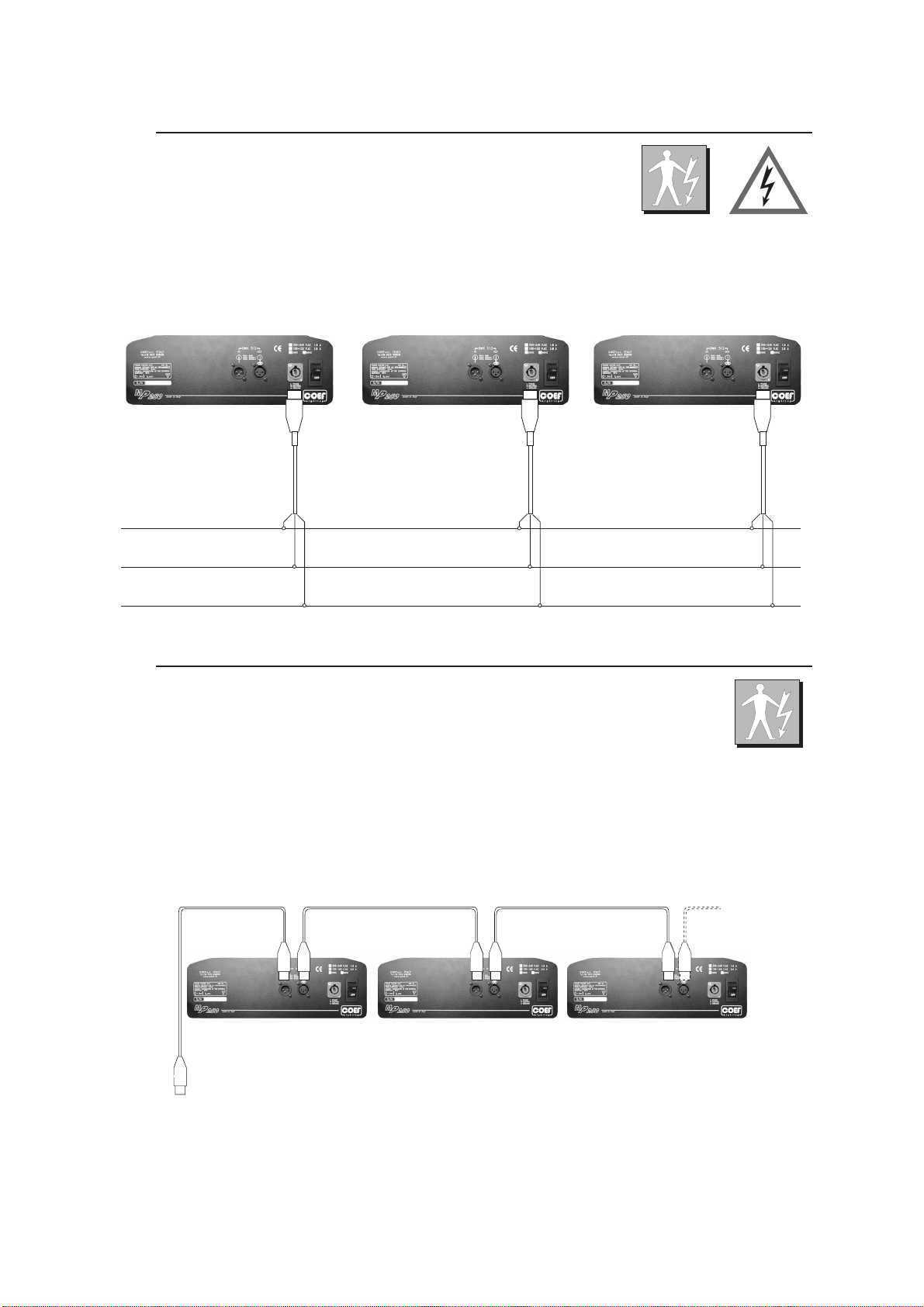

3.0 POWER SUPPLY CONNECTIONS

Supply the projector by connecting it as indicated in picture

Power supply: 220-240 V. 50-60 Hz. with Voltage and frequency as indicated on the rear of the projector.

Power absorbed: 430 VA 1,8 A. with nominal voltage.

Power factor: 0.97 Phase advancer : 50 uF.

PHASE

GROUND

NEUTRAL

3.1 DMX 512 CONNECTIONS

Connect the projector to the control unit by means of a RG58 or RG59 coaxial cable supplied with 3 Pin XRL

Cannon plugs and connectors. Respect, according to the indications on the panel, the input and the output of the

DMX 512 signal.

FROM CONTROL UNIT

http://www.coef.it - info@coef.it Pag. 7

Page 8

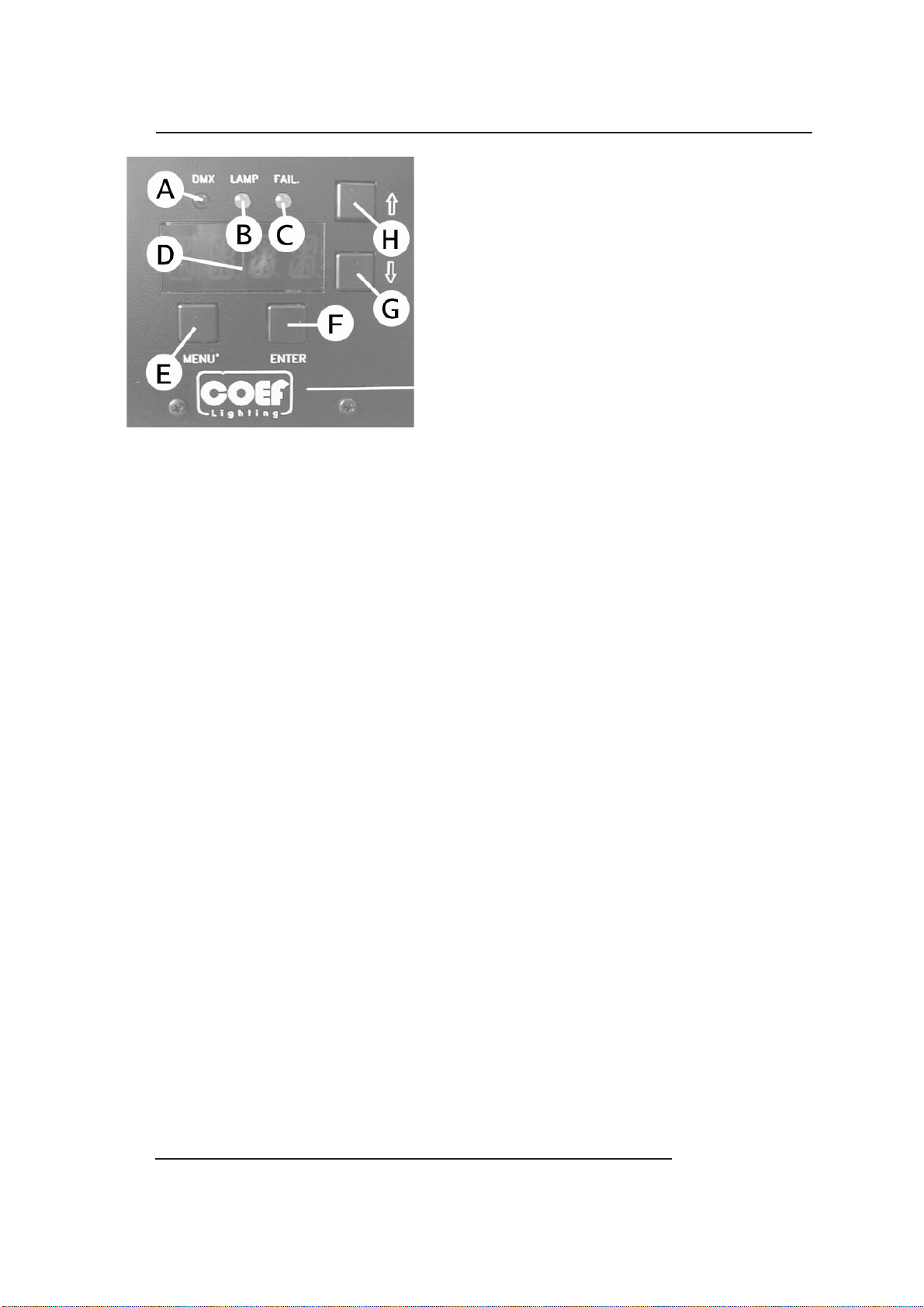

4.0 SPECIAL FUNCTIONS AND PROJECTOR ASSIGNMENT

On the front panel of MP250 Fresnel you'll find a section

for the additional functions and for setting the projector.

Following the picture, you can see all the offered possibili

ties in detail.

All operations are to be carried out with the E, F, G, H buttons, respectively indicated as MENU, ENTER, DOWN and

UP.

The display D will inform you about the selected functions.

The 3 A, B, and C leds will allow you to know:

A = reception of the DMX line.

B = lamp ON.

C = errors indicated on the ERR table.

On switching the projector on, the display will indicate the type of projector and the version of control software

which have been installed. To this purpose, please remember that this type of projector belongs to a new generation

of projectors, designed with the possibility of updating the software version through the normal DMX connection by

means of a programmer deliberately created: UNI-PROG 8.

After the indication MSTR HOME, the projector carries out the RESET and gets ready to be controlled from the

connected console.

The display will indicate 1 as default value. This means that the first channel occupied by the projector will respond to the values sent to channel 1 by the DMX line. This also means that according to the total number of channels assigned to the projector by means of the CH89 function, MISC menu (see Table 4.1 Menu/Fuctions), we shall

be able to check the MP250 Fresnel with the 1 to X channels (8 or 9 according to how the setting is) of the DMX line.

This enables us to make MP250 Fresnel (which we are installing) completely independent from control or integral

with any other installed projector.

-

General Rules:

Refer to the Table of Section 4.1 in the following page.

By each pressure, Button MENU (E) permits to go backwards by one level.

GandH(DOWN and UP) buttons select functions and sub-functions.

Button F (ENTER) enters the function and confirms a control.

By pressing Button MENU (E) and buttons UP and DOWN (H and G) you can select the menu you have to modify.

Once the wished menu is reached, press Button F (ENTER) to confirm your selection and enter the function.

Press G or H to enter the sub-functions if available.

Always confirm your selection with ENTER.

Press MENU to go out of the function and press again to go back to the starting level.

Example: We installed our projector on the ceiling and for this reason we want the visualization of the display to

be correct.

•

Press MENU

•

Press H (UP) 11 times up to “MISC”

•

Press ENTER the Display will show “RSET”

•

Press H (UP) twice up to “DSPL”

•

Press ENTER the Display will show “ONOF”

•

Press H (UP) once up to “STRV”

•

Press ENTER the Display will show “STND”; this is the actual configuration state.

•

Press H (UP) once up to R.E.V..; the blinking point indicate the available configuration.

•

Press ENTER ...... The Display visualization as been rotated to 180°.

•

Press MENU 4 times to return to starting MENU.

The indication of the display will automatically come back after 120 sec. and inform on the set starting channel

DMX. If we are now in a sub-function, this automatic device will not assume control.

Pag. 8 http://www.coef.it - info@coef.it

Page 9

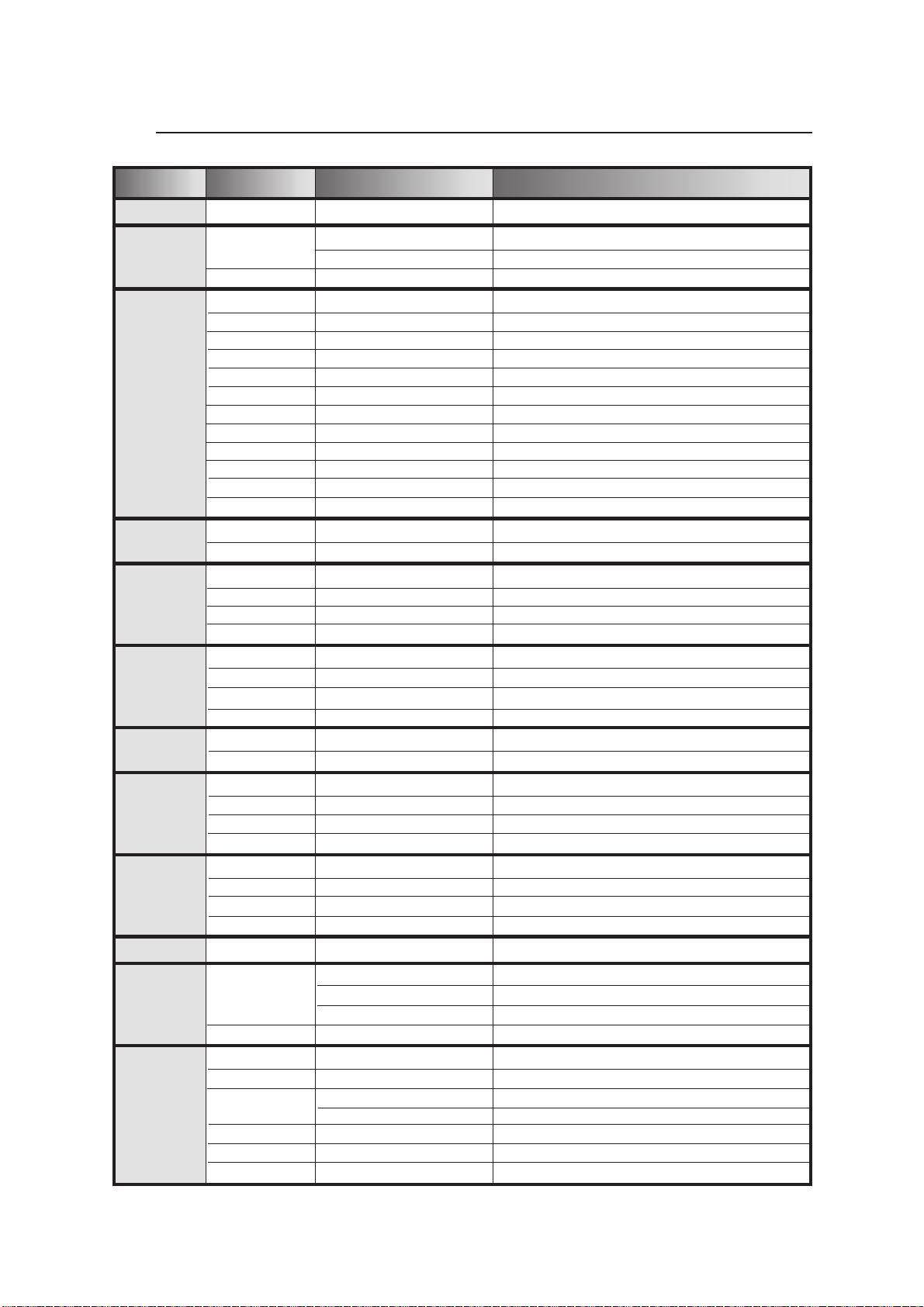

4.1 MENU, FUNCTION & SUB-FUNCTION

MENU FUNCTION SUB-FUNCTION DESCRIPTION

DMX (*) 1 / 255 DMX start channel

TIME

ERR

SHUT

COL1

COL2

LAMP

MACH

EOK

E110

E210

E220

E230

E240

E250

E260

E510

E260

W310

W410

HOME

TEST

HOME

TEST

CSHUT

MODE

HOME

TEST

CSHUT

MODE

SHOW - KH, H

RESET - GO?

SHOW - KH, H

(*) OFF / ON

(*) MOD1 / MOD2

(*) OFF / ON

(*) MOD1 / MOD2

Lamp working hours (KH=thousands H=hours)

Lamp working hours reset (confirm by ENTER)

Projector working hours (KH=thousands H=hours)

NO ERROR

EEPROM failure

Malfunction of the SHUTTER motor

Malfunction of the COLOR 1 motor/sensor

Malfunction of the COLOR 2 motor/sensor

Malfunction of the FROST effect motor/sensor

Malfunction of the PAN motor/sensor

Malfunction of the TILT motor/sensor

Malfunction of the PAN Encoder

Malfunction of the TILT Encoder

Checksum Setup not valid

Lamp working hours for more than 1900 hours.

HOME SHUTTER

TEST SHUTTER

HOME COLOR 1

TEST COLOR 1

Color change in black-out position

Color switching or linear wheel motion.

HOME COLOR 2

TEST COLOR 2

Color change in black-out position

Color switching or linear wheel motion.

FROST

PAN

TILT

SCH da CH1 a CH9 0 / 255 DMX value for the indicated channel

LAMP

MISC

HOME

TEST

HOME

TEST

STRV

ENCO

HOME

TEST

STRV

ENCO

ONOF

CDMX

RSET

RDMX

DSPL

SWPT

CH 8/9

VER

(*) STND / REV

(*) ON / OFF

(*) STND / REV

(*) ON / OFF

ON

OFF

AUTO

(*) NO / YES

(*) YES / NO

(*) ON / OFF

(*) STND / REV

(*) STND / SWAP

(*)CH8/CH9

HOME GOBOS rotation

TEST GOBOS rotation

HOME PAN movement

TEST PAN movement

Switch movement direction ( DX / SX)

ON/OFF the automatic repositioning of the PAN

HOME TILT movement

TEST TILT movement

Switch movement direction (UP / DOWN)

ON/OFF the automatic repositioning of the TILT

LAMP ON

LAMP OFF

LAMP OFF after 1 hour of no change on DMX

LAMP switching on by DMX control

MASTER HOME (Starting RESET)

MASTER HOME via DMX control

Display on / Display off

180° rotation of the visualization display

Channel control switch PAN / TILT

Pojector control (8 or 9 channels)

Show the installed software version

http://www.coef.it - info@coef.it Pag. 9

Page 10

5.0 CHANNELS AND DIGITAL VALUES

CH

8 CHANNELS 9 CHANNELS

SHUTTER / STROBE / DIMMER

0-5 SHUTTER closed

6-100 DIMMER Adjustment

101-110 DIMMER 0 > 100% Automatic 6 sec.

111-120 DIMMER 100% > 0 Automatic 6 sec.

121-126 DIMMER 0 > 100% slow Faster shut down

127-132 DIMMER 0 > 100% middle Faster shut down

133-138 DIMMER 0 > 100% fast Faster shut down

1

139-144 DIMMER 100% > 0 slow Faster open

145-150 DIMMER 100% > 0 middle Faster open

151-156 DIMMER 100% > 0 fast Faster open

157-162 Dimmer 0 > 100% > 0 slow

163-168 Dimmer 0 > 100% > 0 middle

169-174 Dimmer 0 > 100% > 0 fast

175-180 Strobe lamp from 1 to 6 random [reg. 0.0-0.5 sec.]

181-186 Strobe lamp from 1 to 6 random [reg. 0.6-1.5 sec.]

187-192 Strobe lamp from 1 to 6 random [reg. 1.6-2.5 sec.]

193-250 STROBE Speed adjustment

251-255 SHUTTER open

COLOR 1 MODE 1

0 - 5 Neutral

6 - 15 Yellow

16 - 25 Blue

26 - 35 Magenta

36 - 45 Green light

46 - 55 Orange

56 - 65 Cyano

66 - 75 Pink

76 - 85 Red

86 - 95 Blu light

96 - 105 Green

106 - 115 Wood

116 - 125 White-Yellow

126 - 135 Yellow-Blue

136 - 145 Blue-Magenta

146 - 155 Green light-Orange

156 - 165 Orange-Cyano

166 - 175 Cyano-Pink

176 - 185 Red-Blue light

186 - 195 Blue light-Green

196 - 200 Random full-color (fast)

201 - 205 Random full-color (slow)

206 - 230 CW Rotation adjustment

231 - 255 CCW Rotation adjustment

2

COLOR 1 MODE 2

0 - 5 Neutral

6 - 10 Yellow

11 - 15 Blue

16 - 20 Magenta

21 - 25 Green light

26 - 30 Orange

31 - 35 Cyano

36 - 40 Pink

41 - 45 Red

46 - 50 Blu light

51 - 55 Green

56 - 60 Wood

61 - 180 Positioning

181 - 185 Random fast

186 - 190 Random middle

191 - 195 Random slow

196 - 200 Random very slow

201 - 215 Random very fast

216 - 235 CW Rotation adjustment

236 - 255 CCW Rotation adjustment

SHUTTER / STROBE / DIMMER

0-5 SHUTTER closed

6-100 DIMMER from channel 9 value

101-110 DIMMER 0 > 100% Automatic 6 sec.

111-120 DIMMER 100% > 0 Automatic 6 sec.

121-126 DIMMER 0 > 100% slow Faster shut down

127-132 DIMMER 0 > 100% middle Faster shut down

133-138 DIMMER 0 > 100% fast Faster shut down

139-144 DIMMER 100% > 0 slow Faster open

145-150 DIMMER 100% > 0 middle Faster open

151-156 DIMMER 100% > 0 fast Faster open

157-162 Dimmer 0 > 100% > 0 slow

163-168 Dimmer 0 > 100% > 0 middle

169-174 Dimmer 0 > 100% > 0 fast

175-180 Strobe lamp from 1 to 6 random [reg. 0.0-0.5 sec.]

181-186 Strobe lamp from 1 to 6 random [reg. 0.6-1.5 sec.]

187-192 Strobe lamp from 1 to 6 random [reg. 1.6-2.5 sec.]

193-250 STROBE Speed adjustment

251-255 SHUTTER open

COLOR 1 MODE 1

0 - 5 Neutral

6 - 15 Yellow

16 - 25 Blue

26 - 35 Magenta

36 - 45 Green light

46 - 55 Orange

56 - 65 Cyano

66 - 75 Pink

76 - 85 Red

86 - 95 Blu light

96 - 105 Green

106 - 115 Wood

116 - 125 White-Yellow

126 - 135 Yellow-Blue

136 - 145 Blue-Magenta

146 - 155 Green light-Orange

156 - 165 Orange-Cyano

166 - 175 Cyano-Pink

176 - 185 Red-Blue light

186 - 195 Blue light-Green

196 - 200 Random full-color (fast)

201 - 205 Random full-color (slow)

206 - 230 CW Rotation adjustment

231 - 255 CCW Rotation adjustment

COLOR 1 MODE 2

0 - 5 Neutral

6 - 10 Yellow

11 - 15 Blue

16 - 20 Magenta

21 - 25 Green light

26 - 30 Orange

31 - 35 Cyano

36 - 40 Pink

41 - 45 Red

46 - 50 Blu light

51 - 55 Green

56 - 60 Wood

61 - 180 Positioning

181 - 185 Random fast

186 - 190 Random middle

191 - 195 Random slow

196 - 200 Random very slow

201 - 215 Random very fast

216 - 235 CW Rotation adjustment

236 - 255 CCW Rotation adjustment

Pag. 10 http://www.coef.it - info@coef.it

Page 11

COLOR 2 MODE 1

CH

0 - 5 Neutral

6 - 15 Violet

16 - 25 Emerald

26 - 35 Pink

36 - 45 Purple

46 - 55 Red

56 - 65 Cyano

66 - 75 Blue

76 - 85 Yellow

86 - 95 Cream

3

96 - 105 Conversion 3200° k

106 - 115 Conversion 5600° k

8 CHANNELS 9 CHANNELS

116 - 125 Bicolor Neutral-Violet

126 - 135 Bicolor Violet-Emerald

136 - 145 Bicolor Emerald-Pink

146 - 155 Bicolor Purple-Red

156 - 165 Bicolor Red-Cyano

166 - 175 Bicolor Cyano-Blue

176 - 185 Bicolor Yellow - Cream

186 - 195 Bicolor Cream - Conversion 3200°k

196 - 200 Random unit color (lento)

201 - 205 Random unit color (veloce)

206 - 230 CW Rotation adjustment

231 - 255 CCWRotation adjustment

COLOR 2 MODE 2

0 - 5 Neutral

6 - 10 Violet

11 - 15 Emerald

16 - 20 Pink

21 - 25 Purple

26 - 30 Red

31 - 35 Cyano

36 - 40 Blue

41 - 45 Yellow

46 - 50 Cream

FROST EFFECT

0 - 10 NO Frost filter

4

11 - 241 Reg. Frost effect

242 - 255 Frost filter to 100%

PAN MOVEMENT

5

PAN MOVEMENT FINE ADJUSTMENT

6

TILT MOVEMENT

7

TILT MOVEMENT FINE ADJUSTMENT

8

9

51 - 55 Conversion filter 3200° k

56 - 60 Conversion filter 5600° k

61 - 180 Posizionamento

181 - 185 Random full color (veloce)

186 - 190 Random full color (medio)

191 - 195 Random full color (lento)

196 - 200 Random full color (lentissimo)

201 - 215 Random full color (velocissimo)

216 - 235 CW Rotation adjustment

236 - 255 CCWRotation adjustment

FROST EFFECT

0 - 10 NO Frost filter

11 - 241 Reg. Frost effect

242 - 255 Frost filter to 100%

PAN MOVEMENT

PAN MOVEMENT FINE ADJUSTMENT

TILT MOVEMENT

TILT MOVEMENT FINE ADJUSTMENT

DIMMER

0 - 10 DIMMER CLOSED

11 - 250 DIMMER Adjustment

251 - 255 DIMMER OPEN

WARNING :position CHANNEL1 ata valuebetween 6and 100,

in order to control DIMMER with this channel.

SPECIAL ACTION

When the lamp control via DMX (CDMX) and the RDMX function have been activated in the configuration menu, it’s possible,

by a combination of the channels values, to control the lamp switch ON/OFF or to allow the projector MASTER RESET.

Lamp ON via DMX: (CDMX=YES)

CHANNEL 2 = value 0

CHANNEL 3 and CHANNEL 4 = value0>255>0

Lamp OFF via DMX: (CDMX=YES)

CHANNEL 2 = value 255

CHANNEL 3 and CHANNEL 4 = value0>255>0

MASTER RESET: (RDMX=YES)

CHANNEL 1 = value 0

CHANNEL 2 and CHANNEL 3 = value0>255>0

http://www.coef.it - info@coef.it Pag. 11

Page 12

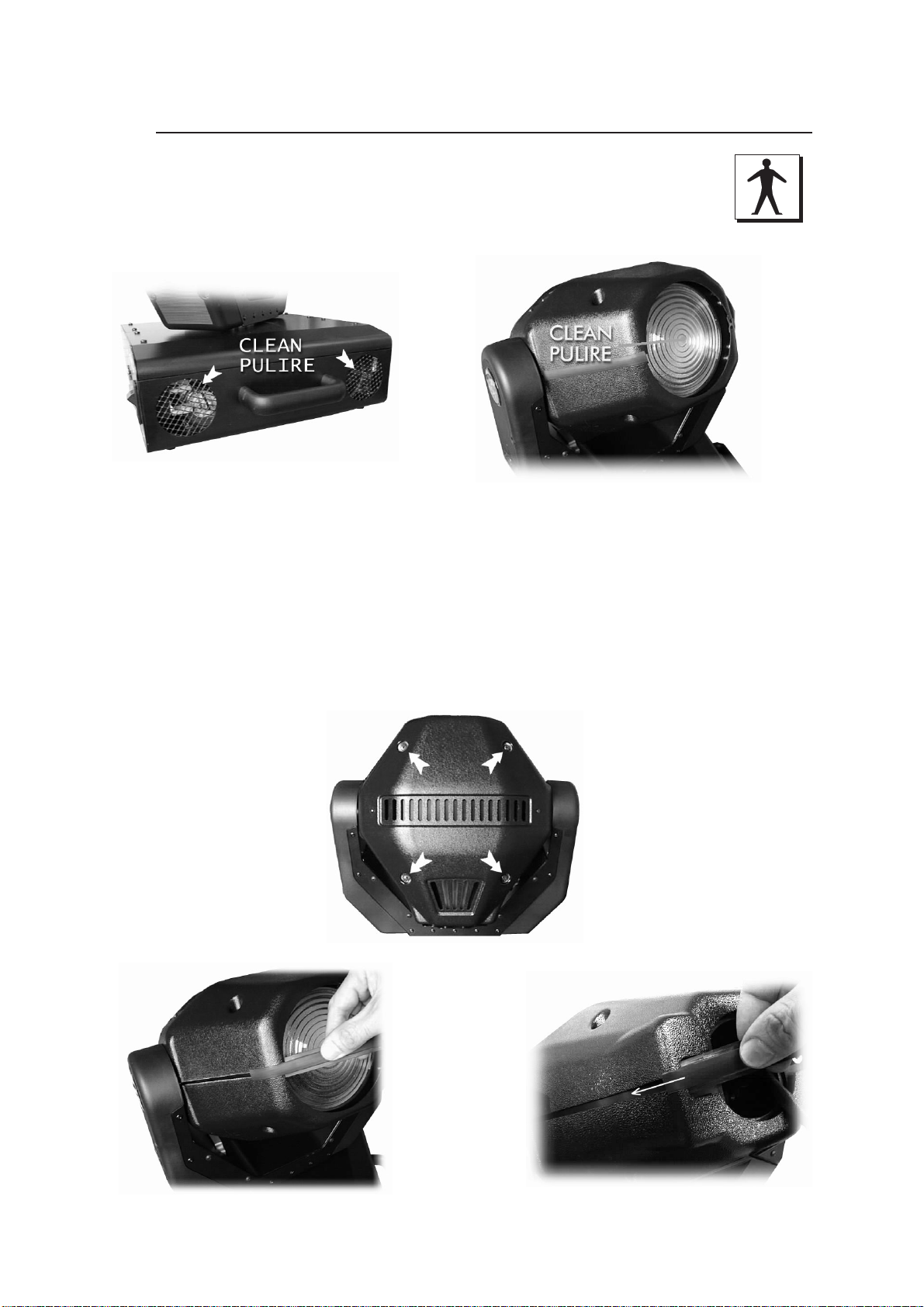

6.0 ORDINARY MAINTENANCE

The ordinary maintenance is fundamental for the perfect efficiency of MP250 Fresnel, in order

to prevent any functional defect as a reduced light beam or irregularities in the movement of the projector or of other rotating parts.

The parts which need more maintenance are shown in the figures. In order to free them from

dust or grease, clean them with a soft cloth and normal products for windows cleaning.

To let you operate more easily, we advice you to remove the two top covers of MP250 and the two basis covers.

In order to put again the cover to its place, operate as shown below:

A) Positionate the top cover on the MP250 FRESNEL projector.

B) Screw down the frontal screws (objective); not yet those on the back (lamp).

C) Insert the 2 rubber front parts, guiding them to the end of their position.

D) Remove the lamp cover and insert the two remaining rubber packings, guiding them to the

end of their position.

E) Block carefully the four screws.

Pag. 12 http://www.coef.it - info@coef.it

Page 13

6.1 EXTRAORDINARY MAINTENANCE

To make an extraordinary maintenance, it is necessary the presence of a generic or qualified mechanical operator, according to the type of the needed intervention.To let you operate more easily, we advice you to remove the

two top covers of MP250 Fresnel and the two basis covers. In this way it will be much more easy to observe the

components to maintain and/or replace. In the following figures it’s possible to observe the different parts that have

to be cleaned and, at the same time, the whole mechanical structure mounted with all its components is shown.

You must particularly take care of the sensors which are

really fundamental in the unit working.

The sensors are absolutely necessary when a general reset of the projector is needed. If this function is not correctly

executed, it will totally compromise the regular working of the

projector, at least for the group referred to the sensor itself.

Es : when there’s an irregular reset of the color wheel, all

the setted colors will not correspond to the colours listed in the

chapter about DMX digital values.

The section shutter/strobo doesn’t use sensors during the

reset positioning but it’s conditioned by a mechanical beat of

the shutter shovels.

http://www.coef.it - info@coef.it Pag. 13

Page 14

6.2 ELECTRONIC MAINTENANCE

This section is dedicated in detail to the electronic connections between the card and the mechanical compo

nents, assembled in the projector. These informations will be absolutely necessary when the mechanical unit has to

be removed from the projector for maintenance and/or repair.

The connections are made using handy connectors and are detailed where you can find indications about the

connection between a specific connector and a specific component of the mechanical unit. This includes the motors

and the sensors of the various effects wheels ( color 1, color 2, shutter etc.).

WARNING!

irremediably the electronic and/or mechanical components of the projector.

An improper use of this documentation made by not specifically qualified staff can damage

-

Pag. 14 http://www.coef.it - info@coef.it

Page 15

7.0 TROUBLESHOOTING

PROBLEM CAUSE ACTION

The projector doesn’t switch on

The projector switches on but

doesn’t answer to commands

Defecting projection

Projection with halo

- The power supply is not present

- The lamp is not working

- Wrong DMX configuration

- The (A) Led is not blinking

- Defective cables

- Defective control unit

- The lens is broken

- Dust or grease stored on lens

- Not aligned Lamp

- Dust or grease stored on the all

parts of projector.

Check if the luminous indicator is lighted

or not.

Replace the lamp.

Make sure that the projector is correctly

configurated.

Check the Fuse F3(1A) on the main board

Replace or repair the DMX cable.

Check the control unit by means of other

working projectors.

Technical aid is required.

Ceck that the lens are not broken.

Remove dust or grease stored on lens

Lamp adjustment (see 2.2 chapter)

Carefully clean the projector components

(see “Maintenance” chapter)

The color or other effects doesn’t

coincide to the selected value.

The PAN movement doesn’t coincide to the selected value

The projector does not carry out

the automatic repositioning of the

PAN or TILT movements.

- Position sensor dirty with dust or

grease

- Defective Motor

- Electronic board

- Position sensor dirty with dust or

grease

- Defective Motor

- Electronic board

- ENCO OFF in the PAN/TILT configuration menu

Carefully clean the projector components

(see “Maintenance” chapter)

Technical aid is required.

Carefully clean the projector components

(see “Maintenance” chapter)

Technical aid is required.

Set ON ENCO Function of PAN/TILT configuration MENU (cap. 4.1)

Technical aid is required.

http://www.coef.it - info@coef.it Pag. 15

Page 16

Page 17

10.0 DIMENSIONS

9.0

Pag. 17 http://www.coef.it - info@coef.it

Page 18

11.0 PART ASSEMBLY

10.0

http://www.coef.it - info@coef.it Pag. 18

Page 19

Pag.19 http://www.coef.it - info@coef.it

Page 20

Pag.19 http://www.coef.it - info@coef.it

Page 21

http://www.coef.it - info@coef.it Pag. 18

10.0

11.0 ASSEMBLAGGIO PARTI

Page 22

Pag. 17 http://www.coef.it - info@coef.it

9.0

10.0 DIMENSIONI

Page 23

Page 24

Intervento di assistenza tecnica.

der ai canali del PAN e del TILT.

Vedi tabella cap. 4.1 per abilitare l’enco-

Intervento di assistenza tecnica

zione)

parti del proiettore(vedi capitolo manutenEffettuare una accurata pulizia di tutte le

Intervento di assistenza tecnica

zione)

parti del proiettore(vedi capitolo manutenEffettuare una accurata pulizia di tutte le

http://www.coef.it - info@coef.it Pag. 15

movimento PAN o TILT

e sottofunzione ENCO a OFF

- Configurazione menu PAN o TILT

- Scheda elettronica

- Motore difettoso

- Cinghia rotta

- Sensori di posizione sporchi

- Scheda elettronica

- Motore difettoso

- Cinghia rotta

- Sensori di posizione sporchi

sizionamento automatico per il

Il proiettore non esegue il ripo-

stati

TILT non segue i valori impoIl movimento del PAN o del

spondono al valore impostato

Il colore o altri effetti non corri-

zione)

parti del proiettore(vedi capitolo manutenEffettuare una accurata pulizia di tutte le

Regolare la lampada

ti.

Rimuovere la polvere e/o grasso sulle len-

Controllare che la lente non sia rotta.

Intervento di assistenza tecnica.

proiettori funzionanti.

Controllare l’unità di pilotaggio con altri

Sostituire i cavi o riparare.

Controllare F3(1A) sulla scheda madre

Assegnare il valore DMX per il proiettore

la Lampada.

Vedi tabella cap.4.1 perconfigurare in ON

Sostituire la lampada.

te le parti del proiettore

- Strati di grasso e/o polvere su tut-

- Posizione lampada non regolata

lenti

- Strati di grasso o polvere sulle

- La lente è rotta

- Unità di pilotaggio difettosa

- Cavi di collegamento difettosi

lo frontale

- Non lampeggia LEDA sulpannel-

- Configurazione DMX errata

dal menu LAMP

- La lampada è configurata in OFF

- Lampada non funzionante

Proiezione con alone

Proiezione difettosa

sponde ai comandi

Il proiettore siaccende ma non ri-

terruttore di accensione.

-

Verificare l’accensione della spia sull’in

- Mancanza di alimentazionedi rete

DIFETTO CAUSA RIMEDIO

Il proiettore non si accende

7.0 PROBLEMI

Page 25

Pag. 14 http://www.coef.it - info@coef.it

eseguite delle operazioni di manutenzione straordinaria e/o riparazioni.

qualificato, può danneggiare in modo irrimediabile le parti elettroniche e/o meccaniche del proiettore su cui vengono

Un uso improprio di questa documentazione, od effettuato da personale non espressamente

ATTENZIONE!

pora i motori e i sensori delle ruote dei vari effetti ( colore 1, colore 2, otturatore ecc. ).

spondenza di un determinato connettore ad una determinata parte componente della piastra meccanica, che incor-

I collegamenti effettuati attraverso comodi connettori vengono dettagliati nella figura dove è indicata la corri-

sa scheda elettronica, vengano rimosse dall’interno del proiettore per manutenzione e/o riparazione.

all’interno del proiettore. Queste informazioni risultano indispensabili nel caso in cui le piastre meccaniche, o la stes-

Questa sezione è dedicata al dettaglio dei collegamenti elettronici tra la scheda e le parti meccaniche montate

6.2 MANUTENZIONE ELETTRICA/ELETTRONICA

Page 26

http://www.coef.it - info@coef.it Pag. 13

meccanica delle palette d’oscuramento.

zionamento in fase di reset ma è condizionata da una battuta

La sezione otturatore/strobo, non usa sensori per il posi-

nel canale DMX per ottenere il colore desiderato.

dichiarate nel capitolo dedicato ai valori digitali da impostare

impostati risulteranno non corrispondenti alle caratteristiche

Es: ad un reset irregolare della ruota colore, tutti i colori

associato al sensore stesso.

del proiettore stesso, almeno per quanto riguarda il gruppo

mente, pregiudica in modo totale il funzionamento regolare

rale del proiettore, funzione che se non eseguita corretta-

I sensori sono indispensabili nel momento del reset gene-

parecchiatura.

rivestono un ruolo fondamentale nel funzionamento dell’ap-

Una particolare attenzione andrà dedicata ai sensori che

con tutte le sue parti.

punti indicati come punti di pulizia e nello stesso tempo potremo avere una vista d’insieme della meccanica montata

più semplice osservare le varie parti da manutenere e/o sostituire. Nelle figure a seguire è possibile osservare i vari

due coperchi della testa del MP250 Fresnel e le due piastre di copertura della base. In questo modo risulterà molto

uno qualificato, a seconda del tipo di intervento da eseguire. Per semplicità di intervento consigliamo di rimuovere i

Per eseguire una manutenzione straordinaria è richiesto l’intervento di un manutentore meccanico semplice o di

6.1 MANUTENZIONE STRAORDINARIA

Page 27

Pag. 12 http://www.coef.it - info@coef.it

E) Bloccare con cura le 4 viti del coperchio.

dandoli sino alla loro posizione.

D) rimuovere il coperchio portalampada ed infilare le due parti in gomma rimanenti per la parte posteriore guiC) infilare dalla parte anteriore le 2 parti in gomma frontali partendo dal foro della lente

B) avvitare solo le 2 viti di fissaggio della parte frontale (obiettivo); lasciare libere le due posteriori (lampada).

A) appoggiare il coperchio sulla testa dell’MP250 FRESNEL

Per rimontare il coperchio seguire le fasi descritte:

4 viti di fissaggio con un cacciavite a croce medio.

Nel casoin cui debba essere rimosso il coperchio della testa dell’MP250 FRESNEL, sarà sufficente rimuovere le

alla loro pulizia con un panno morbido e normali prodotti per la pulizia dei vetri.

Nelle figure vengonoevidenziate le parti più sottoposte ad accumulare polveri e grassi. Procedere

nosa del fascio oppure il movimento irregolare del proiettore o di altre parti rotanti.

fetta efficenza l’apparecchiatura ed evitare l’insorgere di difetti come ad esempio la scarsa resa lumi-

-

La manutenzione ordinaria sui proiettori MP250 Fresnel è indispensabile per mantenere in per

6.0 MANUTENZIONE ORDINARIA

Page 28

nale.

preso tra 6 e 100 per controllare il DIMMER con questo caATTENZIONE: posizionare il CANALE 1 ad un valore com-

http://www.coef.it - info@coef.it Pag. 11

CANALE 2 e CANALE 3 = Valore0>255>0

CANALE 1 = Valore 0

MASTER RESET: (RDMX=YES)

CANALE 3 e CANALE 4 = Valore0>255>0

CANALE 2 = Valore 255

Spegnimento della lampada via DMX: (CDMX=YES)

CANALE 3 e CANALE 4 = Valore0>255>0

CANALE 2 = Valore 0

Accensione della lampada via DMX: (CDMX=YES)

MASTER RESET al proiettore.

verso una combinazione di valori nei canali, controllare sia l’accensione e lo spegnimento della lampada oppure far eseguire un

Se nel MENU configurazioni è stato abilitato il controllo della lampada via DMX (CDMX) e la funzione RDMX, è possibile, attra-

COMANDI SPECIALI

251 - 255 DIMMER Aperto

11 - 250 Regolazione DIMMER

0 - 10 DIMMER Chiuso

DIMMER

REGOLAZIONE FINE MOVIMENTO TILT

MOVIMENTO TILT

REGOLAZIONE FINE MOVIMENTO PAN

MOVIMENTO PAN

242 - 255 Filtro FROST 100%

11 - 241 Regolazione Effetto FROST

0 - 10 Escluso

EFFETTO FROST

236 - 255 Rotazione in senso anti-orario regolabile

216 - 235 Rotazione in senso orario regolabile

201 - 215 Casuale colori pieni (velocissimo)

196 - 200 Casuale colori pieni (lentissimo)

191 - 195 Casuale colori pieni (lento)

186 - 190 Casuale colori pieni (medio)

181 - 185 Casuale colori pieni (veloce)

61 - 180 Posizionamento

56 - 60 Conversione 5600° k

51 - 55 Conversione 3200° k

231 - 255 Rotazione in senso anti-orario regolabile

206 - 230 Rotazione in senso orario regolabile

201 - 205 Casuale colori pieni (lento)

196 - 200 Casuale colori pieni (veloce)

186 - 195 Bicolore Panna-Conversione 3200°k

176 - 185 Bicolore Giallo -Panna

166 - 175 Bicolore Celeste Blu

156 - 165 Bicolore Rosso-Celeste

146 - 155 Bicolore Viola-Rosso

136 - 145 Bicolore Smeraldo-Rosa

126 - 135 Bicolore Violetto-Smeraldo

116 - 125 Bicolore Bianco-Violetto

9

REGOLAZIONE FINE MOVIMENTO TILT

8

MOVIMENTO TIL

7

REGOLAZIONE FINE MOVIMENTO PAN

6

MOVIMENTO PAN

5

242 - 255 Filtro FROST 100%

11 - 241 Regolazione Effetto FROST

4

0 - 10 Escluso

EFFETTO FROST

46 - 50 Panna

41 - 45 Giallo

36 - 40 Blu

31 - 35 Celeste

26 - 30 Rosso

21 - 25 Viola

16 - 20 Rosa

11 - 15 Smeraldo

6 - 10 Violetto

0 - 5 Neutro

COLORE 2 MODE 2

106 - 115 Conversione 5600° k

3

96 - 105 Conversione 3200° k

86 - 95 Panna

76 - 85 Giallo

66 - 75 Blu

56 - 65 Celeste

46 - 55 Rosso

36 - 45 Viola

26 - 35 Rosa

16 - 25 Smeraldo

6 - 15 Violetto

0 - 5 Neutro

COLORE 2 MODE 1

CH

8 CANALI 9 CANALI

Page 29

Pag. 10 http://www.coef.it - info@coef.it

236 - 255 Rotazione in senso anti-orario regolabile

216 - 235 Rotazione in senso orario regolabile

201 - 215 Casuale colori pieni (velocissimo)

196 - 200 Casuale colori pieni (lentissimo)

191 - 195 Casuale colori pieni (lento)

186 - 190 Casuale colori pieni (medio)

181 - 185 Casuale colori pieni (veloce)

61 - 180 Posizionamento

56 - 60 Wood

51 - 55 Verde scuro

46 - 50 Blu chiaro

41 - 45 Rosso

36 - 40 Rosa

31 - 35 Celeste

26 - 30 Arancio

21 - 25 Verde chiaro

16 - 20 Magenta

11 - 15 Blu scuro

6 - 10 Giallo

0 - 5 Neutro

COLORE 1 MODE 2

231 - 255 Rotazione in senso anti-orario regolabile

206 - 230 Rotazione in senso orario regolabile

201 - 205 Casuale colori pieni (lento)

196 - 200 Casuale colori pieni (veloce)

186 - 195 Bicolore Blu chiaro-Verde scuro

176 - 185 Bicolore Rosso-Blu chiaro

166 - 175 Bicolore Celeste-Rosa

156 - 165 Bicolore Arancio-Celeste

146 - 155 Bicolore Verde chiaro-Arancio

136 - 145 Bicolore Blu scuro-Magenta

126 - 135 Bicolore Giallo-Blu scuro

116 - 125 Bicolore Bianco-Giallo

106 - 115 Wood

96 - 105 Verde scuro

86 - 95 Blu chiaro

76 - 85 Rosso

66 - 75 Rosa

56 - 65 Celeste

46 - 55 Arancio

36 - 45 Verde chiaro

26 - 35 Magenta

16 - 25 Blu scuro

6 - 15 Giallo

0 - 5 Neutro

COLORE 1 MODE 1

236 - 255 Rotazione in senso anti-orario regolabile

216 - 235 Rotazione in senso orario regolabile

201 - 215 Casuale colori pieni (velocissimo)

196 - 200 Casuale colori pieni (lentissimo)

191 - 195 Casuale colori pieni (lento)

186 - 190 Casuale colori pieni (medio)

181 - 185 Casuale colori pieni (veloce)

61 - 180 Posizionamento

56 - 60 Wood

51 - 55 Verde scuro

46 - 50 Blu chiaro

41 - 45 Rosso

36 - 40 Rosa

31 - 35 Celeste

26 - 30 Arancio

21 - 25 Verde chiaro

16 - 20 Magenta

11 - 15 Blu scuro

6 - 10 Giallo

0 - 5 Neutro

COLORE 1 MODE 2

2

231 - 255 Rotazione in senso anti-orario regolabile

206 - 230 Rotazione in senso orario regolabile

201 - 205 Casuale colori pieni (lento)

196 - 200 Casuale colori pieni (veloce)

186 - 195 Bicolore Blu chiaro-Verde scuro

176 - 185 Bicolore Rosso-Blu chiaro

166 - 175 Bicolore Celeste-Rosa

156 - 165 Bicolore Arancio-Celeste

146 - 155 Bicolore Verde chiaro-Arancio

136 - 145 Bicolore Blu scuro-Magenta

126 - 135 Bicolore Giallo-Blu scuro

116 - 125 Bicolore Bianco-Giallo

106 - 115 Wood

96 - 105 Verde scuro

86 - 95 Blu chiaro

76 - 85 Rosso

66 - 75 Rosa

56 - 65 Celeste

46 - 55 Arancio

36 - 45 Verde chiaro

26 - 35 Magenta

16 - 25 Blu scuro

6 - 15 Giallo

0 - 5 Neutro

COLORE 1 MODE 1

251-255 OTTURATORE aperto

193-250 Regolazione velocità STROBO

187-192 Lampi da1a6random [reg. 1.6-2.5 sec.]

181-186 Lampi da1a6random [reg. 0.6-1.5 sec.]

175-180 Lampi da1a6random [reg. 0.0-0.5 sec.]

169-174 Dimmer 0 > 100% > 0 veloce

163-168 Dimmer 0 > 100% > 0 medio

157-162 Dimmer 0 > 100% > 0 lento

151-156 DIMMER 100% > 0 veloce Apertura istantanea

145-150 DIMMER 100% > 0 medio Apertura istantanea

139-144 DIMMER 100% > 0 lento Apertura istantanea

133-138 DIMMER 0 > 100% veloce Chiusura istantanea

127-132 DIMMER 0 > 100% medio Chiusura istantanea

121-126 DIMMER 0 > 100% lento Chiusura istantanea

111-120 DIMMER 100% > 0 Automatico in 6 sec.

101-110 DIMMER 0 > 100% Automatico in 6 sec.

6-100 DIMMER con valore impostato canale 9

0-5 OTTURATORE chiuso

OTTURATORE / STROBO / DIMMER

8 CANALI 9 CANALI

251-255 OTTURATORE aperto

193-250 Regolazione velocità STROBO

187-192 Lampi da1a6random [reg. 1.6-2.5 sec.]

181-186 Lampi da1a6random [reg. 0.6-1.5 sec.]

175-180 Lampi da1a6random [reg. 0.0-0.5 sec.]

169-174 Dimmer 0 > 100% > 0 veloce

163-168 Dimmer 0 > 100% > 0 medio

157-162 Dimmer 0 > 100% > 0 lento

151-156 DIMMER 100% > 0 veloce Apertura istantanea

145-150 DIMMER 100% > 0 medio Apertura istantanea

139-144 DIMMER 100% > 0 lento Apertura istantanea

133-138 DIMMER 0 > 100% veloce Chiusura istantanea

1

127-132 DIMMER 0 > 100% medio Chiusura istantanea

121-126 DIMMER 0 > 100% lento Chiusura istantanea

111-120 DIMMER 100% > 0 Automatico in 6 sec.

101-110 DIMMER 0 > 100% Automatico in 6 sec.

6-100 Regolazione DIMMER

0-5 OTTURATORE chiuso

OTTURATORE / STROBO / DIMMER

CH

5.0 CANALI E VALORI DIGITALI

Page 30

http://www.coef.it - info@coef.it Pag. 9

Mostra la versione del software installato.

Controllo proirttorea8o9canali

Scambia i canali attribuiti a PAN e TILT

Inverte di 180° la visualizzazione del Display

Display visibile / Display spento

Abilita MASTER HOME via DMX

Esegue il MASTER HOME (RESET INIZIALE)

Controllo accensione della lampada via DMX

Lampada spenta dopo 1 ora di inattività DMX

Lampada spenta

Lampada accesa

Consente o esclude il riposizionamento automatico

Cambia la direzione di movimento (Alto / Basso)

Esegue il test movimento TILT

Esegue HOME movimento TILT

Consente o esclude il riposizionamento automatico

Cambia la direzione di movimento ( DX / SX)

Esegue il test movimento PAN

Esegue HOME movimento PAN

Esegue il test Effetto FROST

Esegue HOME Effetto FROST

(*)CH8/CH9

(*) STND / SWAP

(*) STND / REV

(*) ON / OFF

(*) YES / NO

(*) NO / YES

AUTO

OFF

ON

(*) ON / OFF

(*) STND / REV

(*) ON / OFF

(*) STND / REV

VER

CH 8/9

SWPT

DSPL

RDMX

RSET

CDMX

ONOF

ENCO

STRV

TEST

HOME

ENCO

STRV

TEST

HOME

TEST

HOME

MISC

LAMP

SCH da CH1 a CH9 0 / 255 Visualizza il valore DMX sul canale prescelto

TILT

PAN

FROST

Commutazione del colore o movimento lineare

Cambio colore con otturatore chiuso al cambio

Esegue il test COLORE 2

Esegue HOME COLORE 2

Commutazione del colore o movimento lineare

Cambio colore con otturatore chiuso al cambio

Esegue il test COLORE 1

Esegue HOME COLORE 1

Esegue il test OTTURATORE

Esegue HOME OTTURATORE

Accensione della lampada oltre le 1900 ore

Checksum Setup non valido

Malfunzionamento Encoder TILT

Malfunzionamento Encoder PAN

Malfunzionamento motore/sensore TILT

Malfunzionamento motore/sensore PAN

Malfunzionamento motore/sensore Eff. FROST

Malfunzionamento motore/sensore COLORE 2

Malfunzionamento motore/sensore COLORE 1

Malfunzionamento motore OTTURATORE

EEPROM guasta

Nessun errore

Ore di funzionamento della macchina (migliaia e ore)

Resetta le ore della lampada (conferma con ENTER)

Ore di funzionamento della lampada (migliaia e ore)

(*) MOD1 / MOD2

(*) OFF / ON

(*) MOD1 / MOD2

(*) OFF / ON

SHOW - KH, H

RESET - GO?

SHOW - KH, H

MODE

CSHUT

TEST

HOME

MODE

CSHUT

TEST

HOME

TEST

HOME

W410

W310

E520

E510

E260

E250

E240

E230

E220

E210

E110

EOK

MACH

LAMP

COL 2

COL 1

SHUT

ERR

TIME

DMX (*) 1 / 255 Imposta il canale di partenza

FUNZIONE SOTTOFUNZIONE DESCRIZIONE

MENU

4.1 MENU, FUNZIONI E SOTTOFUNZIONI

Page 31

Pag. 8 http://www.coef.it - info@coef.it

Se ci troviamo in una sottofunzione questo automatismo non interverrà.

postato.

-

L’indicazione del display ritornerà automaticamente dopo 120 sec. ad informare sul canale di partenza DMX im

Pulsante ENTER ...... il Display ha ruotato di 180° la visualizzazione.

•

Pulsante H (UP) 1 volta fino a R.E.V.. I punti sono lampeggianti ed indicano la possibile configurazione.

•

Pulsante ENTER indicazione Display “STND”; questo è lo stato attuale di configurazione

•

Pulsante H (UP) 1 volta fino a “STRV”

•

Pulsante ENTER indicazione Display “ONOF”

•

Pulsante H (UP) 2 volte fino a “DSPL”

•

Pulsante ENTER indicazione Display “RSET”

•

Pulsante H (UP) 11 volte fino a “MISC”

•

Pulsante MENU

•

corretta.

Es: Abbiamo installato il proiettore a soffitto e per questo motivo vogliamo che la visualizzazione del display sia

Premere MENU per uscire dalla funzione e premerlo ancora per ritornare al livello di partenza.

•

Confermare la scelta sempre con ENTER.

•

PremereGoHperaccedere a sottofunzioni se presenti.

•

funzione.

Una volta raggiunto il menu desiderato, premere il pulsante F (ENTER) per confermare la scelta ed accedere alla

•

modifiche.

Premendo il pulsante MENU (E) ed i pulsanti UP e DOWN (H e G) si potrà scegliere il menu a cui apportare le

•

Il pulsante F (ENTER) entra nella funzione e conferma un comando.

I pulsanti G e H (DOWN e UP) selezionano le funzioni e le sottofunzioni.

il pulsante MENU (E) ad ogni pressione, permette di ritornare indietro di un livello.

Riferirsi alla tabella del capitolo 4.1 nella pagina seguente.

Regole generali:

proiettori installati.

rendere l’ MP250 Fresnel che stiamo installando, completamente indipendente al controllo oppure solidale ad altri

MP250 Fresnel con i canali dall’1 all’ X (8o9aseconda dell’impostazione) della linea DMX. Questo ci permette di

al proiettore per mezzo della funzione CH89 menu MISC (vedi tabella 4.1 Menu/Funzioni), potremo controllare l’

ai valori inviati sul canale 1 della linea DMX. Questo vuol dire che a seconda del numero totale dei canali assegnati

Il display come valore di default indicherà 1; ciò significa che il il primo canale occupato dal proiettore, risponderà

ad esso collegata.

Con l’indicazione MSTR HOME il proiettore esegue il RESET e si predispone adessere controllato dalla console

programmatore appositamente realizzato: l’ UNI-PROG 8.

tati con la possibilità di aggiornare la versione software attraverso il normale collegamento DMX per mezzo di un

to. A tale proposito si ricorda che questo tipo di proiettore appartiene ad una nuova generazione di proiettori, progetAll’accensione del proiettore, il display indicherà il tipo di proiettore e la versione del software di controllo installa-

C = errori specificati nella tabella ERR.

B = lampada ACCESA.

A = ricezione della linea DMX.

I 3 led A, B,eC, ci permetteranno di conoscere:

Il display D ciinformerà inmerito allefunzioni desiderate.

UP.

H indicati rispettivamente come MENU, ENTER, DOWN e

Tutte le operazioni si effettuano tramite i pulsanti E, F, G,

sibilità offerte.

-

Seguendo la figura vediamo in dettaglio tutte le varie pos

cessorie.

sezione dedicata al settaggio del proiettore e alle funzioni ac-

Nel pannello frontale dell’ MP250 Fresnel troviamo una

4.0 CODIFICA E FUNZIONI SPECIALI

Page 32

http://www.coef.it - info@coef.it Pag. 7

FROM CONTROL UNIT

512.

Cannon 3 Pin XRL. Rispettare, secondo la serigrafia riportata sul pannello, gli ingressi e le uscite del segnale DMX

Collegare il proiettore e l’unità di controllo con un ottimo cavo schermato bipolare, corredato di spine e prese

NEUTRAL

GROUND

PHASE

3.1 COLLEGAMENTO DMX 512

Fattore di potenza: 0.97 Rifasamento:50uF.

Potenza assorbita: 430 VA 1,8 A alla tensione nominale

Alimentazione: 220-240 V. 50-60 Hz. a secondo delle indicazioni poste sulla targhetta del proiettore

Alimentare il proiettore collegandolo come indicato in figura

3.0 COLLEGAMENTO ALIMENTAZIONE DI RETE

Page 33

0.3

Pag. 6 http://www.coef.it - info@coef.it

ambiente non deve superare i 40° C.

per un migliore ed affidabile funzionamento del proiettore, la temperatura

1,5 mt.

il proiettore deve essere posizionato in modo tale che gli oggetti

8) Massima temperatura ambiente:

mt.

7) Distanza minima prescritta per i materiali infiammabili da ogni punto del corpo dell’apparecchio:

colpiti dal fascio luminoso siano distanti almeno 1,5 metri dall’obiettivo del proiettore stesso.

6) Distanza minima degli oggetti illuminati:

5) Assicurarsi del corretto fissaggio del proiettore alla struttura di sostegno come indicato al capitolo 2.3.

del fabbricante e senza che le modifiche vengano eseguite da personale qualificato.

4) Non manomettere in alcun modo le parti interne ed esterne del proiettore senza preventiva autorizzazione

mentazione e con l’interruttore di accensione in posizione OFF.

3) Eseguire i collegamenti elettrici e la installazione / sostituzione della lampada in assenza di tensione di alisamente a quanto indicato nel capitolo MANUTENZIONE.

2) Non eseguire la pulizia del proiettore con getti di acqua o immersione in altri liquidi, ma attenersi scrupolomento dell’apparecchiatura stessa (pioggia, vento, sole intenso ecc. ).

1) Non installare il proiettore all’esterno dove è possibile l’influenza di agenti atmosferici dannosi al funziona-

Per un corretto funzionamento dell’apparecchiatura rispettare le seguenti condizioni:

2.4 UNA CORRETTA INSTALLAZIONE

zioni, e quindi considerate pericolose.

ATTENZIONE: COEF non risponde di installazioni scorrette od effettuate senza il rispetto delle suddette indica-

chiatura. Dopo tale intervento, la fune di sicurezza deve essere sostituita.

modo che, in caso di cedimento delle staffe di fissaggio principali, si realizzi la minor caduta possibile dell’apparec-

la fune di sicurezza dovrà essere installata e montata a regola d’arte alla struttura di sostegno, in

Importante:

po macchina dell’ MP250 Fresnel alla struttura di ancoraggio.

parecchiature, è obbligatorio installare una catena di sicurezza (o cavo d’acciaio) con moschettoni che collega il cor-

Per garantire una sicurezza essenziale e nel rispetto delle attuali norme di sicurezza per l’installazione delle ap-

base dell’MP250 Fresnel.

M8X20, da inserire nei fori predisposti sulle staffe di fissaggio ed avvitati negli appositi inserti filettati presenti nella

sostegno sollevata da terra, bloccare le staffe di fissaggio fornite a corredo del proiettore, con i relativi bulloni

Per il fissaggio dell’ MP250 Fresnel è indispensabile, quando l’installazione è prevista su di una attrezzatura di

2.3 MONTAGGIO DELL’APPARECCHIATURA

Page 34

http://www.coef.it - info@coef.it Pag. 5

estremo inferiore o superiore della loro corsa.

La lampada è pre-regolata in fabbrica. Regolare solo finemente. Non portare le viti al punto

ATTENZIONE!

Regolare le 3 vitia croce(part. B)fino araggiungere la condizione ideale tra potenza del fascio ed omogeneità.

proiettore ed impostare il canale otturatore aperto e quello del colore su “bianco”.

La regolazione della lampada è indispensabile per ottenere un fascio luminoso uniforme e potente. Accendere il

2.2 REGOLAZIONE LAMPADA

scottature.

globalmente 20 minuti, se si opera a mani nude, per evitare

venire la possibilità di esplosione della lampada. Attendere

spegnimento per consentire il raffreddamento parziale e pre-

Prima di intervenire, attendere almeno 10 minuti dopo lo

pada al proiettore.

Riavvitare le due viti per fissare di nuovo il coperchio della lam-

sizione naturale.

facendo attenzione che il cavo di collegamento ritorni nella sua poquindi la lampada montata nel corpo del proiettore con molta cura

evitando il contatto della lampada con la pelle delle mani. Inserire

del portalampada. Inserire la lampada nello zoccolo con cautela,

Rimuovere le due viti a croce (part. A) che fissano il coperchio

Leggere attentamente le istruzioni d’uso fornite dal costruttore della lampada.

ATTENZIONE: disconnettere l’alimentazione al proiettore prima dell’operazione.

La lampada deve essere sostituita se è stata danneggiata o deformata dal calore

tradizionale esterno.

L’apparecchio monta una lampada ad alta pressione con accenditore

2.1 MONTAGGIO O SOSTITUZIONE LAMPADA

•

eventi eccezionali

•

inosservanza totale o parziale delle istruzioni

•

utilizzo di ricambi non originali o non specifici per il modello

•

modifiche o interventi non autorizzati

•

gravi carenze nella manutenzione prevista

•

difetti di alimentazione

•

installazione non corretta

•

uso contrario alla direttive in materia di sicurezza sul lavoro

•

uso improprio dell’ apparecchiatura o da parte di personale non addestrato

Il Fabbricante si ritiene sollevato da eventuali responsabilità in caso di:

2.0 INSTALLAZIONE

Page 35

8/9 canali controllabili; funzione programmabile

•

DMX 512 Standard

•

Rifasamento interno - assorbimento 1,8 A.

•

Autotest interno con led indicatore

•

Software Upgrade via DMX (con accessorio UNI-PROG 8)

•

ON/OFF lampada via DMX; funzione programmabile

•

Reset remoto via DMX; funzione programmabile

•

Display multifunzione

•

Effetto Frost lineare

•

Strobo regolabile

•

Otturatore meccanico

•

Dimmer lineare da 0% al 100%

•

Filtro Wood

•

Effetto Rainbow regolabile in velocità

•

2 filtri conversione 3200 k° e 5600 k° sovrapponibili ai colori base

•

80 colori + bianco + bicolori

•

Riposizionamento automatico PAN e TILT

•

Risoluzione movimento a 16 bit

•

540° PAN - 270° TILT

•

Lampada MSD 250/2 - 250 W - 2.000 ore vita - 8.000 °k

•

Pag. 4 http://www.coef.it - info@coef.it

SEGNALE DI PERICOLO: Segnalazione di pericolo generico e segnalazione di parti sotto ten-

MP250 Fresnel Codice:ZL-012401-01

1.1 CARATTERISTICHE TECNICHE

sione.

razioni straordinarie autorizzate.

OPERATORI ELETTRICI SPECIALIZZATI: Personale qualificato addetto alla installazione o alle ripa-

MANUTENTORI ELETTRICI: Personale addetto alla manutenzione ordinaria di natura elettrica.

razioni straordinarie autorizzate.

OPERATORI MECCANICI SPECIALIZZATI: Personale qualificato addetto alla installazione o alle ripa-

MANUTENTORI MECCANICI: Personale addetto alla manutenzione ordinaria di natura meccanica.

razioni di riparazione o interventi straordinari.

OPERATORE COEF: Personale tecnico qualificato e responsabilizzato dal costruttore, per tutte le ope-

richiesta una conoscenza specifica.

OPERATORE : Personale non espressamente qualificato in grado di eseguire operazioni dove non è

vento tecnico. Di seguito vengono rappresentati questi simboli con il loro significato.

-

necessario) da segnali indicatori che evidenzieranno sia le pericolosità dell’operazione che le necessità di un inter

di funzionamento dell’apparecchiatura stessa. Le varie procedure verranno appositamente segnalate (dove sarà

scritta, venga supportato da quelle informazioni indispensabili per un uso corretto delle procedure di installazione e

-

Questo manuale è organizzato in modo tale che l’utente, l’installatore o il manutentore dell’apparecchiatura de

1.0 COME USARE IL MANUALE

Page 36

Page 37

Pag. 2 http://www.coef.it - info@coef.it

dritten Personen nicht zugänglich gemacht werden.

ma COEF

Diese Bedienungsanleitung darfohne schriftliche Genehmigung der Fir-

Zeitpunkt vor.

Die Firma COEF behält sich das Recht auf Änderungen zu jedem

sind nicht verbindilich.

Die indiesem Handbuch enthaltenen Beschreibungen und Abbildungen

Alle Rechte vorbehalten. Nachdruck verboten.

la Société COEF.

Ce manuel nepeut être remis à des tiers sans l’autorisation préalable de

tions qu’elle jugera utiles.

COEF

se réserve le droit d’apporter, à tout moment, les modifica-

acunement notre Société.

Les descriptions et les illustrations fournies dans ce manuel n’engagent

la Société COEF.

Les droits de reproduction de ce catalogue sont entiérement réservés à

COEF.

zation by

time. This manual can not be inspected by third party, without written autoriCOEF reserves the right to make all necessary modifications at any

Descriptions and illustrations are not binding.

.

COEF.

All rights for reproduction of this catalogue are reserved for COEF

cifica autorizzazione scritta dalla

Il presente manuale non può essere ceduto in visione a terzi senza spe-

modifiche che riterrà opportune.

COEF

si riserva il diritto di apportare in qualsiasi momento tutte le

sono impegnative.

Le descrizioni ed illustrazioni fornite nella presente pubblicazione non

COEF.

vati a

Tutti i diritti di riproduzione, diffusione del presente manuale sono riser-

e-mail: info@coef.it

http://www.coef.it -

Page 38

Stampato in Settembre 2005

http://www.coef.it

e-mail:info@coef.it

Realizzato da PC CAD & VIDEO

MANUALE ISTRUZIONI

•

MP250 fresnel

Loading...

Loading...