Page 1

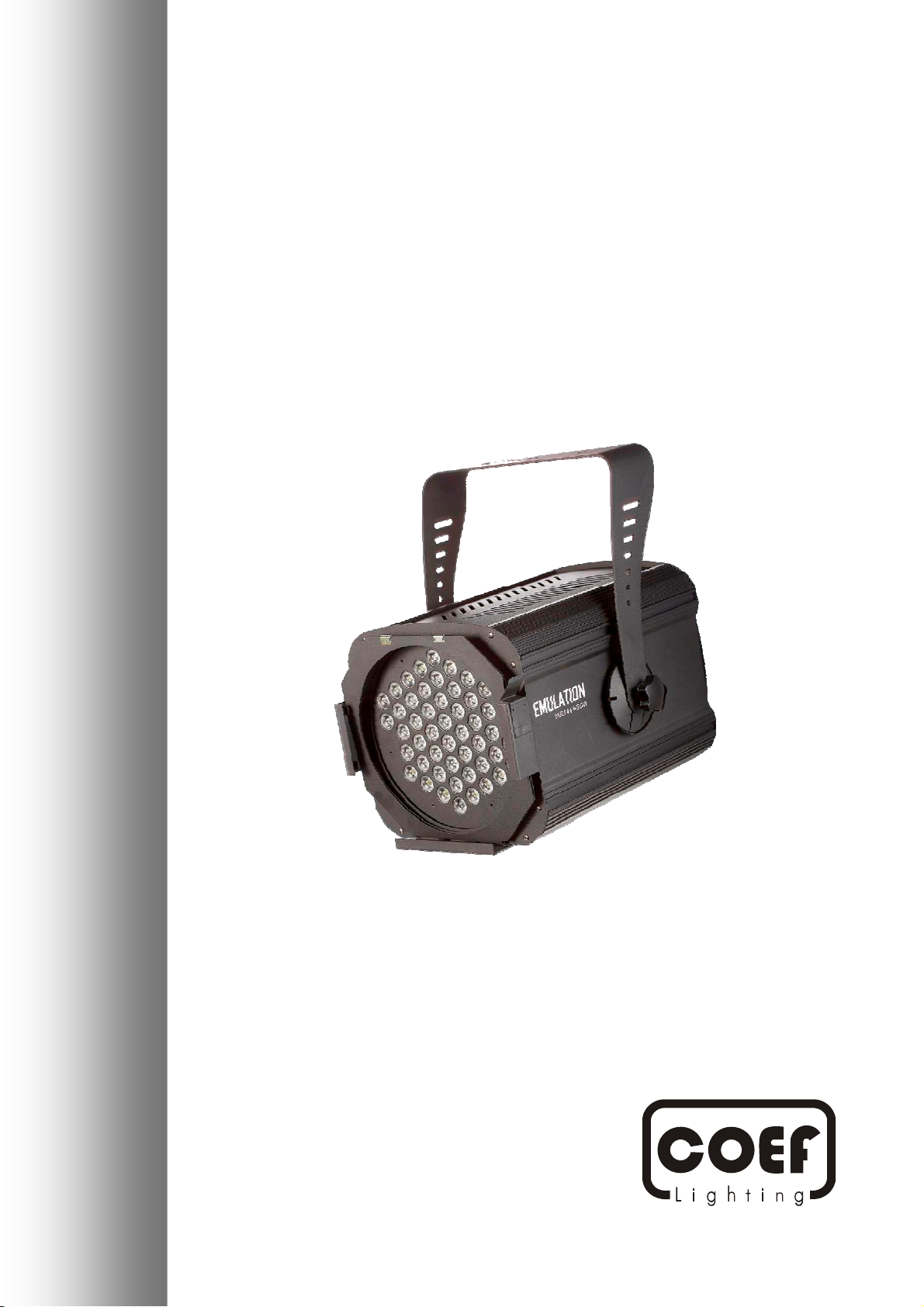

OPERATION MANUAL

EMULATION WRGB

Document No: OM-L2010-001-R01

Page 2

COEF EMULATION WRGB

TABLE OF CONTENTS

GENERAL NOTES

DECLARATION OF CE CONFORMITY ------------------------------------------------------------------------------------------------------ 3

ADVICES FOR A CORRECT INSTALLATION----------------------------------------------------------------------------------------------3

GENERAL WARRANTY CONDITIONS------------------------------------------------------------------------------------------------------- 4

PACKING CONTENTS---------------------------------------------------------------------------------------------------------------------------- 4

WIRING BASICS------------------------------------------------------------------------------------------------------------------------------------ 4

1. INTRODUCTION -------------------------------------------------------------------------------------------------------------------------------- 5

2. OPERATION-------------------------------------------------------------------------------------------------------------------------------------- 5

2.1 DMX TABLE ----------------------------------------------------------------------------------------------------------------------------- 6

2.2 BACK PANEL --------------------------------------------------------------------------------------------------------------------------- 6

2.3 MENU STRUCTURE ------------------------------------------------------------------------------------------------------------------ 7

3. APPLICATIONS EXAMPLE ------------------------------------------------------------------------------------------------------------------ 8

3.1 MANUAL DMX ADDRESSING ----------------------------------------------------------------------------------------------------- 8

3.2 AUTO ID (DMX) ADDRESSING---------------------------------------------------------------------------------------------------- 8

3.3 MANUAL DMX AND AUTO ID ADDRESSING I-------------------------------------------------------------------------------- 8

3.4 MANUAL DMX AND AUTO ID ADDRESSING II------------------------------------------------------------------------------- 8

4. TROUBLESHOOTING ------------------------------------------------------------------------------------------------------------------------- 9

5. TECHNICAL SPECIFICATIONS ------------------------------------------------------------------------------------------------------------ 9

PAGE 2

Page 3

COEF EMULATION WRGB

DECLARATION OF CE CONFORMITY

We Manufacturer IAG Sanecore Science & Technology Industry Park, Jiuwei Village, Xixiang Town, Shenzhen, China,

518102 Declare that the product EMULATION WRGB is in conformity with 89/336 EEC-EMC directive and with the

actual required safety standards in accordance with LVD 73/23 EEC

Shenzhen, 01 August 2010

ATTENTION: carefully read the directions of this manual. Exclusively follow the safety rules in force and do not carry

out assembly and/or maintenance operations without taking all precautions as indicated in the different sections or without the necessary specialization.

This manual must always accompany the equipment, therefore it must be available and readable at any moment if necessary. Also in case of sale, rent, change of place and/or ownership, these documents shall be enclosed with the relative equipment.

ADVICES FOR A CORRECT INSTALLATION

This equipment is designed to an exclusively Professional use.

1) Make sure that all the fastening parts of the spotlight are in good condition. Regulate the proportions of the fastening accessories (screws, bushes, nuts, supports, etc.) in order to be slightly over-dimensioned as compared to the

actual requirements.

2) The installation must always be secured with a secondary safety attachment, e.g. an appropriate catch net. The

secondary safety attachment must be constructed in a way that no part of the installation can fall down if the main

attachment fails.

3) Carefully check the contents of the packaging and the completeness of the components. If any of the parts listed

hereunder is missing, please contact your Dealer immediately.

4) Do not install the projector outside where the influence of atmospheric factors could damage the unit working

(rain, wind, intense heat etc.) or indoor if there is a high percentage of humidity.

5) Do not clean the projector using water jets or immersion in different liquids. Scrupulously follow the indications

given in the chapter MAINTENANCE.

6) Make the electric connections and the installation / replacement of the lamp after having disconnected the power

supply and after had positioned the power switch to OFF. The apparatus is classified as belonging to Class 1 type

of protection against electric shocks. Its connection to an earthed mains unit is compulsory. The equipment must

be protect by an degusted magneto-thermal switch. You are recommended to equip the system with aptly dimensioned differential switches.

7) Do not touch in any case the internal and external parts of the projector without previous authorization of the constructor and make modifications only by the intervention of qualified staff.

8) If the bulb explodes, the particular design of the apparatus prevents the splinters from going outside the projector.

All the parts, therefore, shall be complete and perfectly assembled. The lenses, if visibly damaged, shall be replaced by original spare parts.

9) Minimum distance from illuminated objects:

by the light beam are located at least 1 meters from the projector objective.

10) Minimum distance from inflammable materials: 0.5 meters

The projector must be positioned in such a way that objects struck

PAGE 3

Page 4

COEF EMULATION WRGB

11) MAX ambient temperature: 60° C.

12) MAX external surface temperature:

13) Don’t look directly the lamp trough the lens.

14) We recommend not to look at the lamp without wearing a proper protection; also ensure that the covers are assembled to the equipment.

15) Inside the equipment there are high temperatures and tension/current values which might be very dangerous. It is

necessary to disconnect the equipment from the mains before removing its protection covers and wait for 30 minutes at least before touching any part inside.

16) Do not switch on the equipment if its lamp is not inserted.

17) Leave sockets and air outlets free from encumbrances and clean them periodically (see “Maintenance” section).

18) Do not leave the packaging elements (polystyrene, nylon, metal parts, etc.) unattended; they might be dangerous

for children.

This manual has been organized in order support the user, the installer or the maintenance operator of the described

unit with those necessary in formations for a correct use of the installation and working procedures of the same unit.

The various procedures will be just signaled by indicators (when necessary) evidencing the operation dangers and the

necessity of technical support.

80° C.

GENERAL WARRANTY CONDITIONS

• The guarantee is valid for a period of 12 months from the date of equipment delivery.

• The guarantee is not valid in case a wrong voltage or frequency is selected.

• The parts which are proved to have manufacturing defects are also covered by the guarantee.

• The external parts of the equipment, its removable elements and lamps are excluded from the guarantee; for

these parts we recommend to follow the directions supplied by their manufacturers.

• The guarantee is not valid in case of tampering or repairs carried out by non-authorized personnel.

• The replacement of the equipment during the validity of the guarantee is not provided for.

• The transport freights from and to the manufacturer for repairs under guarantee are at Customer’s charge.

• When applying for the repair, always mention the serial number and the model of the equipment.

PACKING CONTENTS

• Complete EMULATION CTC unit

• This user manual

• 1 AC Power cord

WIRING BASICS

Connection with the mains

Connect the device to them mains with the power plug. The occupation of the connection cables as follows:

European Standard

Cable Pin International

Brown Live L

Blue Neutral N

Yellow Earth E

Cable Pin International

Black Live L

White Neutral N

Green Earth G

American Standard

∗ The earth must be connected !

PAGE 4

Page 5

COEF EMULATION WRGB

DMX-512 connection/ connection between fixtures

The wires must not come into contact with each other, otherwise the fixtures will not work

at all, or will not work properly.

Please note, the starting address depends upon which controller is being used.

Only qualified shield cable (Belden 9841 or Belden 9842 is recommended) and 3-pin XLR plugs and connectors in order to connect the controller with the fixture or one fixture with another.

Occupation of the XLR connection:

DMX Output

XLR mounting socket

1: Ground

2: Signal (-)

3: Signal (+)

If you are using controllers with this occupation, you can connect the DMX output of the controller directly with the DMX

input of the first fixture in the DMX chain. If you wish to connect DMX controllers with other XLR outputs, you need to

use adapter cables.

Building a serial chain:

Connect the DMX output of the first fixture in the DMX chain with the DMX input of the next fixture. Always connect on

output with the input of the next fixture until all fixtures are connected.

Caution:

At the last fixture, the DMX cable has to be terminated with a terminator. Solder a 120Ω resistor between signal (+) and

signal (-) into 3-pin XLR plug and plug it in the DMX output of the last fixture.

DMX input

XLR mounting plug

1: Ground

2: Signal (-)

3: Signal (+)

1. INTRODUCTION

EMULATION WRGB is a spotlight with true color mixing for 16 millions of color and optional projection angle, it’s a per-

fect fixture to extent the color change function than conventional PAR 64 spotlight.

With the ground breaking design, EMULATION WRGB offer following advanced features:

• Four optics are available on request: 45º, 60º, 90º.

• 200 lm high power 3W white LED.

• Universal power supply

• Constant voltage/ current drive control.

• Speed of ventilation fan adjust by temperature changing

• Automatic recovery protection from over load, over temperature.

• Automatic/ manual DMX addressing. (AUTO ID Function)

• High tech and patented material offer the best ventilation.

2. OPERATION

The setup of EMULATION WRGB is very easy via related keypads with necessary information shows on the display.

Also with two LEDs indicating the operation status. Please refer to following instructions.

PAGE 5

Page 6

COEF EMULATION WRGB

2.1 DMX TABLE

CHANNEL NO. FUNCTION CHANNEL NO. FUNCTION

Channel 1 White dimmer 0 - 100% Channel 7 1 - 10, white sound active

Channel 2 White strobe 1 - 30Hz Channel 7 11 - 20, R/G/B sound active

Channel 3 Red dimmer 0 - 100% Channel 7 21 - 70, Program - 1

Channel 4 Green dimmer 0 - 100% Channel 7 71 - 120, Program - 2

Channel 5 Blue dimmer 0 - 100% Channel 7 121 - 170, Program - 3

Channel 6 R/G/B Strobe 1 - 30Hz Channel 7 171 - 255, white & RGB sound active

Channel 7 0 = dimmer Channel 8 Master

2.2 BACK PANEL

DMX IN

AUTO ID LINK

DMX OUT

AUTO ID is very useful function that device doesn’t need to address DMX channel manually. Since the first device

setup the DMX address, rest of devices archived their own unique ID automatically. Benefit is less installation time, and

DMX address conflict free.

For using AUTO ID devices only or mix with NOT AUTO ID devices, please refer to the chapter “Applications Exam-

ple”.

PAGE 6

Page 7

2.3 MENU STRUCTURER

COLOR CHANGE

DMX 8 CHANNEL

(INITIAL DISPLAY)

COEF EMULATION WRGB

Note 1:

The LED display will blink twice after pressing

ENTER key, that’s means the setup is complete.

Note 2:

The function of “NOT ID 001 ON” is using in the

system mix with AUTO ID and NON AUTO ID

devices. Please refer to the next page

“Application Examples”.

COLOR CHANGE

DMX AUTO ID OFF

(SETTING UP DMX AUTO ADDRESSING FUNCTION)

UP/DOWN

ENTER

DMX AUTO ID ON

ENTER

(IF DMX AUTO ID IS ON, DMX MANU ID WILL BE REMAIN 000)

COLOR CHANGE

DMX MANU ID 001

(SETTING

UP

DMX ADDRESS MANUALLY)

COLOR CHANGE

NOT ID 001 ON

(SETTING

UP MIXED AUTO ID AND NON AUDO ID DEVICES, )

COLOR CHANGE

SOUND OFF

(ACTIVATING AUTO COLOR CHANGE FUNCTION BY SOUND)

DMX AUTO ID OFF

ENTER

(USING UP/DOWN KEY TO SELECT DMX START ADDRESS)

UP/DOWN

ENTER

UP/DOWN

ENTER

COLOR CHANGE

DMX AUTO ID ON

COLOR CHANGE

DMX MANU ID 000

COLOR CHANGE

DMX MANU ID 001

COLOR CHANGE

NOT ID 001 OFF

COLOR CHANGE

SOUND ON

UP + 1

DOWN –1

COLOR CHANGE

DMX MANU ID 512

COLOR CHANGE

DMX MANU ID 001

COLOR CHANGE

AUTO DEMO OFF

(ACTIVATING DEMO FUNCTION)

COLOR CHANGE

MANU COLOR OFF

UP/DOWN

COLOR CHANGE

MANU COLOR ON

(SETTING UP COLOR MANUALLY)

MENU

UP/DOWN

ENTER

COLOR CHANGE

AUTO DEMO ON

MANU COLOR ON

COLOR WHITE 000

MANU COLOR ON

COLOR RED 000

MANU COLOR ON

COLOR GREEN 000

MANU COLOR ON

COLOR BLUE 000

(HIGHER DMX LEVEL, MEANS HIGHER INTENSITY)

UP + 1

DOWN - 1

UP + 1

DOWN - 1

UP + 1

DOWN - 1

UP + 1

DOWN - 1

MANU COLOR ON

COLOR WHITE 255

MANU COLOR ON

COLOR RED 255

MANU COLOR ON

COLOR GREEN 255

MANU COLOR ON

COLOR BLUE 255

PAGE 7

Page 8

3. APPLICATIONS EXAMPLE

3.1 MANUAL DMX ADDRESSING

COEF EMULATION WRGB

DMX MANU ID 001

Channel 1-8

DMX Controller

DMX MANU ID 009

Channel 9-16

3.2 AUTO ID (DMX) ADDRESSING

DMX AUTO ID ON

Channel 1-8

DMX Controller

DMX AUTO ID ON

Channel 9-16

3.3 MANUAL DMX AND AUTO ID ADDRESSING I

DMX MANU ID 017

Channel 17-24

DMX AUTO ID ON

Channel 17-24

DMX MANU ID 025

Channel 25-32

DMX AUTO ID ON

Channel 25-32

DMX AUTO ID OFF

DMX Manu ID 09

NOT ID 001 ON

Channel 9-16

DMX Controller

Example

Channel 1-8

NON AUTO ID

Device

3.4 MANUAL DMX AND AUTO ID ADDRESSING II

DMX AUTO ID OFF

DMX Manu ID 09

NOT ID 001 ON

Channel 9-16

DMX AUTO ID OFF

DMX Manu ID 33

NOT ID 001 ON

Channel 33-40

DMX Controller

Example

Channel 1-8

NON AUTO ID

Device

DMX AUTO ID ON

Channel 17-24

DMX AUTO ID ON

Channel 17-24

DMX AUTO ID ON

Channel 41-48

DMX AUTO ID ON

Channel 25-32

Example

Channel 25-32

NON AUTO ID

Device

PAGE 8

Page 9

COEF EMULATION WRGB

4. TROUBLESHOOTING

To ensure the reliability of the spotlight it should be kept clean. It is recommended that the fan should be clean every 15

days with compressed air and in case of more resistant dirt with one soft brush.

Shall any malfunction occurred, please try following solutions.

PROBLEM

The spotlight does not start Check the power connections

The spotlight does not respond to the controller

The spotlight does not work or work not properly.

Color does not match the assigned channel. Check the DMX channel related color.

Check the DMX cable connections, DMX address, Auto ID

and signal indication LED status. Make sure that they are

all proper addressed.

Check the DMX cable connections and DMX address.

Make sure that the spotlight is not in the demo or sound

activated mode.

POSSIBLE SOLUTION

5. TECHNICAL SPECIFICATIONS

Power Supply:

Power Consumption:

LED Power:

LED Source:

Luminous flux:

100-240V/AC, 50/60HZ

100W

144W

12 * 3W W-LED

36 * 3W RGBLED

W/3W=200 lum/ 6500°K

R/3W=70 lum /620nm G/3W=140 lum/ 520nm

B/3W=30 lum/ 465nm

Optional Optics:

Maximum Ambient Temperature:

Maximum Housing Temperature:

Chassis Material:

Protection:

DMX Channel

Dimension (L * W * H):

Weight:

45º/ 60º/ 90º

0°C to 60°C

80ºC

Die cast aluminum body

IP20

8 Channel

294mm * 362mm * 344.5mm

4.5Kg

PAGE 9

Page 10

COEF EMULATION WRGB

PAGE 10

Page 11

®

Sanecore Science & Technology Industry Park, Jiuwei Village, Xixiang Town, ShenZhen, China 518102

Tel: +86 755 2748 3618 Fax: +86 755 2997 5508 email: sales@coef.it http://www.coef.it

All rights reserved © 2010 COEF. COEF is a member of the International Audio Group.

Loading...

Loading...