Page 1

Horizon

®

USER’S MANUAL

®

Page 2

®

®

Horizon

Multi-media

Dry Imager

Starter Manual

Codonics® Catalog Number H-START-EN

Nov 21, 2005

Version 1 . 8.3

Codonics, Inc.

17991 Englewood Drive

Middleburg Heights, OH 44130 USA

440-243-1198 Phone

440-243-1334 Fax

Email info@codonics.com

www.codonics.com

Page 3

Copyright © 2005 by Codonics, Inc. All rights reserved, worldwide. Printed in the

U.S.A. Part Number 905-042-001.

No par t of thi s documen t may b e copied o r re produ ced in any form by any mean s

without prior written consent of Codonics, Inc., 17991 Englewood Dr.,

Middleburg Heights, Ohio 44130 U.S.A.

Although every effort has been made to ensure the accuracy of this document,

Codonics, Inc. assumes no responsibility for any errors that may appear.

Codonics, Inc. makes no commitment to update nor to keep current the

information contained in this document.

The Horizon imager is protected by the following patent number: US Patent No.

6,249,299 System for Printhead Pixel Heat Compensation. All other patents are

pending.

Horizon, DirectVista, ChromaVista, the Codonics logo, and “We bring the future into focus”

are registered trademarks, and Codonics, Variable Multiformatting, VMF, Fixed

Multiformatting, FMF, Medical Color Matching, MCM, SlideMaker, and Bracketing are

trademarks of Codonics, Inc.

Windows and Windows NT are registered trademarks of Microsoft Corporation.

PostScript is a registered trademark of Adobe Systems Incorporated.

Apple and Macintosh are trademarks of Apple Computer, Inc., registered in the U.S. and

other countries.

UNIX is a registered trademark of The Open Group.

Linux is a registered trademark of Linus Torvalds.

Zip is a registered trademark of Iomega Corporation.

StuffIt is a trademark of Aladdin Systems, Inc.

PKZIP is a registered trademark of PKWARE, Inc.

Intel is a registered trademark of Intel Corporation or its subsidiaries in the United States

and other countries.

All other registered and unregistered trademarks are the property of their respective

owners.

European Authorized Representative:

CEpartner4U

Esdoornlaan 13,

3951DB Maarn

The Netherlands

Tel.: +31 (0)6.516.536.26

Page 4

Contents

Preface

Manual Conventions .................................................................................... -vii

Bulleted Lists......................................................................................... -vii

Numbered Steps ................................................................................... -vii

Control Panel Navigation ..................................................................... -viii

Control Panel Keys .............................................................................. -viii

Control Panel Menu Options................................................................ -viii

Notes.................................................................................................... -viii

Cautions and Warnings........................................................................ -viii

Purpose and Scope ...................................................................................... -ix

Product Information ...................................................................................... -x

Disposal Requirements ................................................................................ -xi

Warnings and Limitations of Use................................................................. -xii

Location of Safety and Compliance Labels........................................... -xii

Voltage Warning................................................................................... -xiii

Laser Warning...................................................................................... -xiv

Temperature Warning ........................................................................... -xv

Compliance ........................................................................................... -xv

Serial Number, Configuration, Date Code, and Modification Codes.... -xvi

ESD Caution ....................................................................................... -xvii

Potential for Radio Frequency Interference on Imager Operation ...... -xvii

Potential for Radio and Television Interference ................................. -xviii

Safety Precautions ............................................................................... -xix

Location Precautions............................................................................ -xxi

Cleaning Precautions .......................................................................... -xxii

Media .................................................................................................. -xxii

File Transfer via FTP and LPR........................................................... -xxiv

Color Management............................................................................. -xxiv

Contents

Horizon Starter Manual iii

Page 5

Image Scaling .................................................................................... -xxiv

Hardware Variations............................................................................ -xxv

Indications for Use ..................................................................................... -xxv

Chapter 1: Setting Up the Imager

Preparing for Installation............................................................................. 1-1

Installing the Imager ................................................................................... 1-2

Connecting the Ethernet Cable .................................................................. 1-6

Powering On the Imager—First Time......................................................... 1-8

Cleaning the Platen Roller ................................................................... 1-9

Network Settings—Simple Network.......................................................... 1-10

Specifying the Imager’s IP Address ................................................... 1-11

Determining an IP Address.......................................................... 1-11

Specifying the Imager’s IP Address at the Control Panel ............ 1-12

Specifying IP Addresses for Other Devices on the Network .............. 1-14

Loading Media .......................................................................................... 1-15

Preparing the Imager for Shipment .......................................................... 1-15

iv Contents

Chapter 2: Basic Imager Operations

Horizon Imager Components...................................................................... 2-1

Powering the Imager On and Off................................................................ 2-3

Powering On the Imager ...................................................................... 2-3

Observing the Imager’s Operating Status in the Status Screen........... 2-4

Common Cassette Status Messages ............................................ 2-5

Color Ribbon Status....................................................................... 2-6

Powering Off the Imager ...................................................................... 2-7

Understanding the Control Panel ............................................................... 2-8

Control Panel Indicators....................................................................... 2-9

Alert and Fault Messages and the Fault Tone ................................... 2-10

Control Panel Display......................................................................... 2-10

Main Menu ................................................................................... 2-10

Page 6

Chapter 3: Media Handling and Storage

Overview..................................................................................................... 3-1

Supply Slots and Cassettes ................................................................. 3-1

Viewing the Status of a Supply Slot............................................... 3-3

Inserting or Changing Cassettes ................................................................ 3-4

Handling and Storing Media ....................................................................... 3-6

Break-Off Leaders (ChromaVista Only) ............................................... 3-6

Changing the Ribbon (ChromaVista).......................................................... 3-7

Ordering Media ......................................................................................... 3-10

Chapter 4: Printing from DICOM Applications

Introduction to DICOM ................................................................................ 4-1

DICOM Conformance Statement ......................................................... 4-2

Configuring the DICOM Application............................................................ 4-2

Sending a DICOM Print Job ....................................................................... 4-3

Specifying the Media Type and Size.................................................... 4-3

Using Job Settings Files with DICOM......................................................... 4-3

Categories of Job Settings................................................................... 4-4

Specifying a Job Settings File from a DICOM User Application........... 4-4

Hierarchy of Settings Used by the Horizon Imager .............................. 4-5

Contents

Chapter 5: Printing from Windows via PostScript

Introduction to PostScript ........................................................................... 5-2

Printing from Windows Applications ........................................................... 5-2

Notes About Changing PostScript Parameters.............................. 5-2

Changing Horizon PostScript Parameters—Windows 2000

and XP........................................................................................ 5-3

Chapter 6: Default Print Job Settings

Changing the Default Settings.................................................................... 6-2

Changing the Default Media Type and Size......................................... 6-2

Changing the Default User Settings..................................................... 6-3

Horizon Starter Manual v

Page 7

Chapter 7: Preventive Maintenance

Recommended Maintenance Schedule...................................................... 7-1

Horizon Cleaning Kits........................................................................... 7-2

Cleaning the Thermal Print Head and Platen Roller................................... 7-3

Cleaning the Pick Tires............................................................................... 7-7

Chapter 8: Film Calibration

Chapter 9: Troubleshooting

Sources of Status Information .................................................................... 9-1

Control Panel ....................................................................................... 9-1

Error Log .............................................................................................. 9-1

Online Help for Displayed Messages................................................... 9-1

Troubleshooting Tables .............................................................................. 9-2

Status Message Tables .............................................................................. 9-8

Common Cassette Status Messages................................................... 9-8

Color Ribbon Status ............................................................................. 9-9

Clearing a Sheet Jam ................................................................................. 9-9

Clearing a Jam from a Cassette......................................................... 9-12

Clearing a Jam from the Printing Area............................................... 9-14

Reinstalling Media Guides ................................................................. 9-17

Purging Print Jobs .................................................................................... 9-19

Contacting Technical Support .................................................................. 9-20

vi Contents

Appendix A: Specifications

Appendix B: System Job Settings Files

Index

Page 8

Preface

Manual Conventions

8

To access the

Main Menu

and scroll

through menu

options

Bulleted Lists

Bullets are used to display a list of nonprocedural items. For

example:

The control panel contains:

• A display panel

•Keys

•Indicators

Numbered Steps

The

8

in a procedure are numbered. For example:

1. Press the key.

The Main Menu displays on the control panel. The selector

arrow (X) automatically points to the first menu option.

2. To scroll through the menu options, press the and keys.

The selector arrow (

The bottom portion of the control panel display shows a

message associated with the currently selected menu option.

icon indicates the beginning of a procedure. The steps

MENU

S

X

) moves up and down through the list.

T

Preface

Horizon Starter Manual vii

Page 9

Control Panel Navigation

Menu paths

are used in some procedures instead of documenting

every step needed to navigate to a specific menu option. For

example:

From the Main Menu, select the following options:

Default Media

Grayscale

DV Film Blue

Control Panel Keys

Control panel keys are shown in small black ovals to resemble the

actual keys, for example, “Press the key.”

ENTER

Control Panel Menu Options

Control panel menu options are shown in bold type, for example,

“Select the

Gamma

menu option.”

Notes

Notes contain additional information related to a topic or

procedure. For example:

3

viii Preface

NOTE:

If your network is managed by a network administrator or an information technology

(IT) department, it would be considered a complex network. You should have the

responsible person perform any network-related administrative tasks.

Cautions and Warnings

Cautions alert you to actions or situations that could cause harm to

equipment or data. For example:

CAUTION

made by other users. Use caution when changing default settings.

Any changes you make to the imager default settings will also affect prints

Page 10

Warnings alert you to actions or situations that could result in

personal injury. For example:

WARNING With the imager cover open, touch only those internal components

that are colored green (except for the pick tires).

Purpose and Scope

3

Refer to this Starter Manual for procedures on how to perform the

most common imager operations, including:

•

Setting up the imager

•

Loading media

•

Sending print jobs from DICOM Print Service Class-compliant

applications running on imaging devices or image viewing

workstation

•

Changing the imager’s default image and sheet settings

•

Adjusting the appearance of printed images for user preference

•

Performing preventive maintenance

•

Performing film calibration

•

Troubleshooting common problems

NOTE:

This manual is current to the Horizon Imager v1.8.3 software. Some features and

functions described here may not apply to older versions of the software.

Preface

Horizon Starter Manual ix

Page 11

This Starter Manual is intended to be as simple and straightforward

as possible for the everyday user. If you need more detailed or more

technical information on a feature or topic, or wish to perform more

advanced operations, refer to the

Manual

User’s Manual

(Catalog no. HORIZON-MNLT) and the

(Catalog no. HORIZON-MNLU). The Technical

Manual serves as a companion document to this manual.

Product Information

For technical assistance with Codonics products, call the Codonics

“On Call” Technical Support System at one of the following

numbers:

Phone: +1.440.243.1198

Toll Free: 800-444-1198 (USA Only)

The “On Call” Technical Support System provides for around-theclock availability of qualified technical support personnel.

Horizon Imager Technical

Horizon Imager

You can also e-mail Technical Support at

xPreface

support@codonics.com

.

Page 12

Disposal Requirements

Disposal of this product shall be in accordance with all applicable

laws and regulations in effect at the locality at the time of disposal.

European Disposal Requirements

Codonics imagers and electronic accessory devices are not to be

discarded or recycled; rather they are to be returned to the

manufacturer. Contact Codonics directly or by the link provided for

the latest information concerning:

•

Identification of the country specific

Importer/Distributor/Producer

•

Product return and treatment of our electronic products

Manufacturer: Codonics Incorporated

17991 Englewood Drive

Middleburg Heights, OH 44130 USA

Phone: +1.440.243.1198

Fax: +1.440.243.1334

Email: WEEE@codonics.com

www.codonics.com

Preface

Codonics imagers and electronic accessory devices bearing this

symbol are subject to European Directive on Waste Electrical and

Electronic Equipment (WEEE) 2002/96/EC, amended by Directive

2003/108/EC. The EN 50419 symbol indicates separate collection

and return required.

Horizon Starter Manual xi

Page 13

Warnings and Limitations of Use

Location of Safety and Compliance Labels

The following figure shows the locations of the imager’s safety and

compliance labels.

Shock warning label

K

R

O

W

T

E

N

E

L

O

S

N

CO

S

P

Compliance label

ESD label

U

This equipment has been type tested and found to comply with the requirements in part 15 of FCC rules and Canadian Department of communications for a Class B

computing device. See instruction manual. Operation in a residential area may cause unacceptable interference to radio and TV reception requiring the operator to

take whatever steps are necessary to correct the interference.

Le pr sent appareil num rique n' met pas de bruits radio lectriques d passant les limites applicables aux appareils num r iques de la Classe B prescrites dans le

R glement sur le brouillage radio lectrique dict par le minist re des Comm unications du Canada.

This product is in conformity with the requirements of EC Council directive 93/42/EEC on the approximation of the laws of the Member States relating to medical

devices. This product satisfies the Class B limits of EN 55011 and CISPR 11.

CODONICS, INC.

17991 ENGLEWOOD DR.

MEDICAL ELECTRICAL EQUIPMENT

MIDDLEBURG HTS., OH 44130 U.S.A.

UL.2601-1, CAN/CSA C22.2 NO.601.1

MADE IN THE U.S.A.

Patents Pending, All Rights Reserved

AR: CEpartner4U, 2635 HL 33.NL

Tel: +31(0)6-516.536.26

31EB

COMPLIES WITH 21 CFR 1040.10 AND 1040.11

HORIZON MEDICAL PRINT IMAGER

EN 60601-1

100-120V, 50-60Hz, 6.0A

V, 50-60Hz, 3.0A

230

Laser warning

xii Preface

Hot surface warning label

label 1

Laser warning

C

L

A

S

S

2

L

A

O

SE

PE

R

N

R

A

AD

N

D

I

A

I

N

T

I

T

O

E

N

R

DO

W

L

O

H

N

CK

E

O

N

T

S

ST

D

E

AR

F

E

E

A

I

T

N

E

T

D

O

B

EAM

L

A

A

V

S

O

E

I

R

D

R

E

A

X

F

D

R

P

O

O

I

A

S

M

T

U

I

T

O

R

H

N

E

I

S

I

S

A

E

P

M

E

I

R

T

T

T

U

E

R

D

E

!

label 2

Page 14

Voltage Warning

The lightning flash with arrowhead symbol, within an equilateral

triangle, is intended to alert the user to the presence of uninsulated

“dangerous voltage” within the product’s enclosure that may be of

sufficient magnitude to constitute a risk of electric shock.

The exclamation point within an equilateral triangle is intended to

alert the user to the presence of important operating and

maintenance (servicing) instructions in the literature accompanying

this imager.

NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL. REMOVAL OF LABELS,

COVERS, OR ENCASEMENT FASTENERS VOIDS THE WARRANTY.

THIS APPARATUS MUST BE ELECTRICALLY GROUNDED.

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS

IMAGER TO RAIN OR MOISTURE.

Preface

EQUIPMENT IS NOT TO BE USED AS A COMPONENT OF A LIFE

SUPPORT SYSTEM. Life support devices or systems are devices or

systems that support or sustain life, and whose failure to perform

can be reasonably expected to result in a significant injury or death

to a person. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or system,

or to affect its safety or effectiveness.

Horizon Starter Manual xiii

Page 15

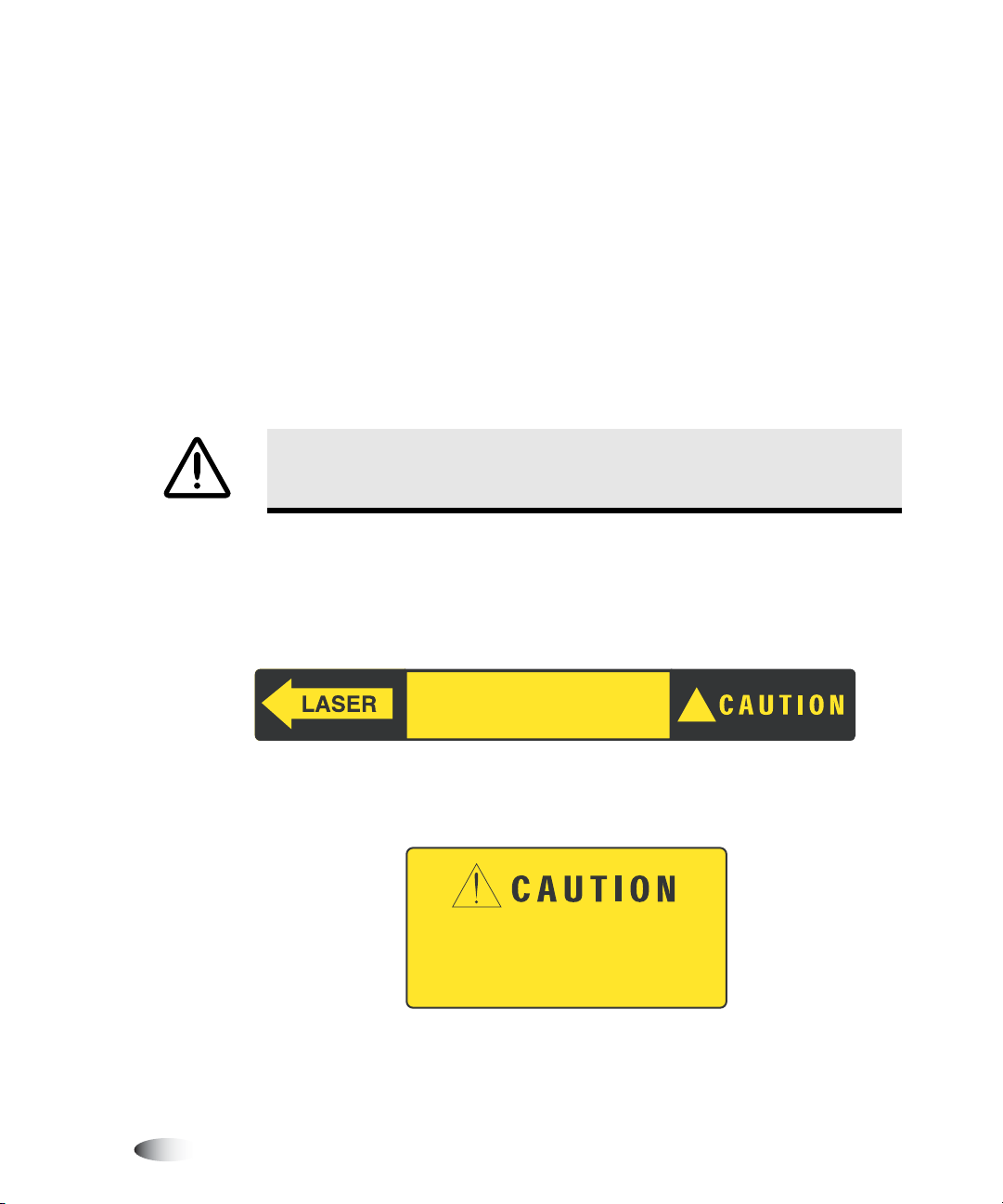

Laser Warning

The Horizon imager uses a laser to read barcode information on the

media cassettes. The laser module is a 670-nm, 1.26-mW device. As

such, it has been found to comply with the 21 CFR 1040.10 and

1040.11 and IEC 60825 laser standards as a low power Class 1

device.

For safety reasons, the laser is turned on only for a short time when

a cassette is inserted. Still, one should use caution and never stare

at the laser beam, should avoid exposure to the laser, and should

never override any of the interlocks and safety mechanisms. These

measures are taken for your protection.

WARNING Use of controls or adjustments to the performance of procedures

other than those specified in this manual may result in hazardous radiation

exposure.

The laser apertures are marked with a single label, shown below.

There are three apertures that correspond to the three cassette

locations, one for each, on the same side of the Horizon imager as

this label.

xiv Preface

AVOID EXPOSURE

LASER RADIATION IS EMITTED

FROM THIS APERTURE

!

Safety interlocks are marked by the following label. They are

located on the same side of the Horizon imager as this label.

CLASS 2 LASER RADIATION WHEN

OPEN AND INTERLOCKS DEFEATED

DO NOT STARE INTO BEAM

The locations of the two laser labels are shown in the figure on

page xii.

Page 16

Temperature Warning

Because the Horizon imager is a thermal print device, the surface

of the thermal print head heat sink gets hot. Avoid directly touching

any components not colored green when accessing the interior of

the imager if the imager has been printing. (During some

preventative maintenance tasks, you will be touching internal

components with cleaning pads or swabs.)

The temperature warning label is shown below.

Compliance

Codonics is in compliance with various regulations, of which details

are listed in Appendix A.

The Compliance label, which is affixed at the back of the imager, is

shown below.

Preface

CODONICS

EN 60601-1

Horizon Starter Manual xv

Page 17

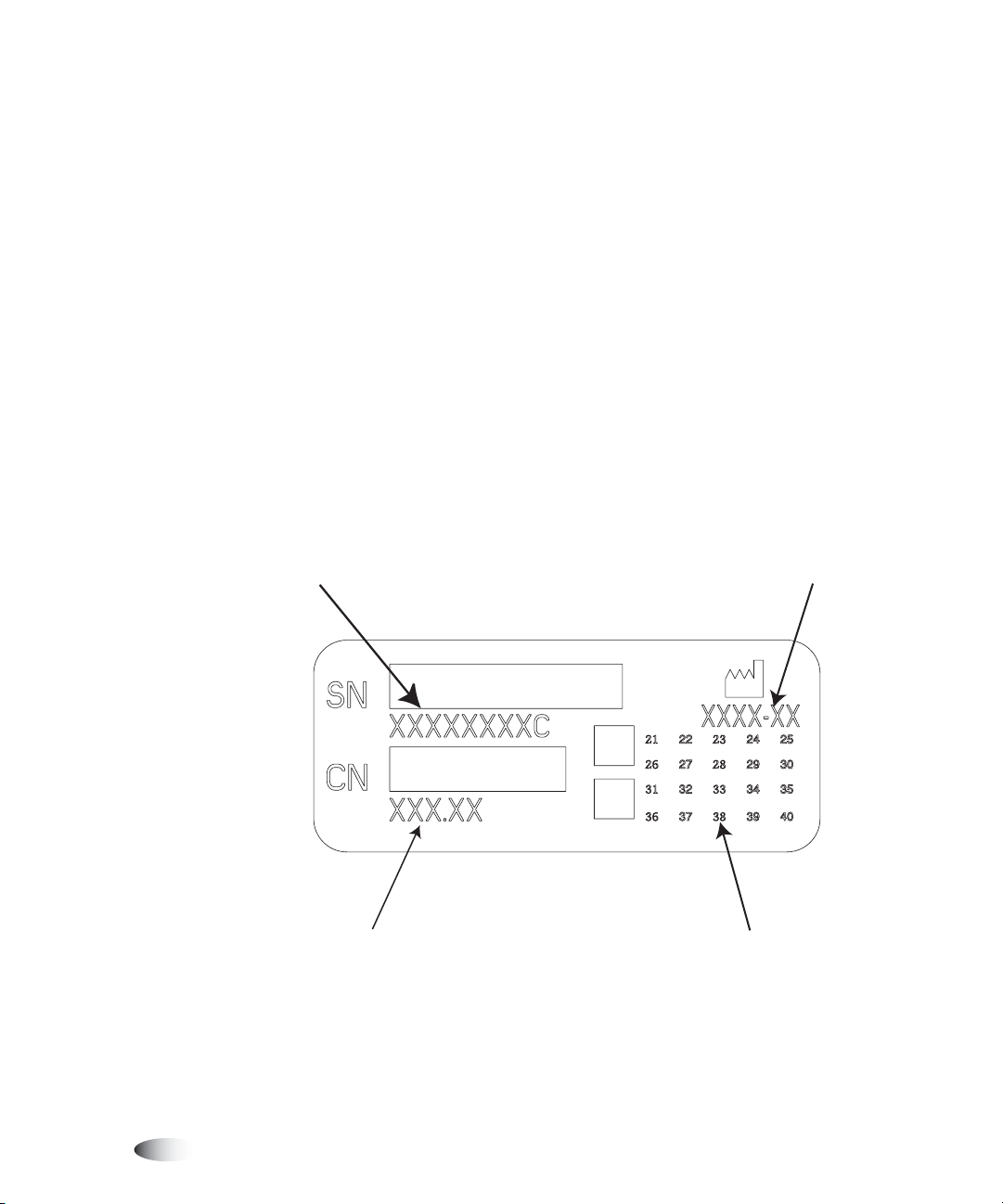

Serial Number, Configuration, Date Code,

and Modification Codes

The Serial number label is placed onto the Compliance label. It

includes the following information:

•

The serial number (SN), which uniquely identifies the unit.

•

The configuration number (CNFG), which details the build

configuration.

•

The modifications codes, which are to the right of the CNFG

number and are a series of 20 numbers. When any of these

numbers are blocked out, that identifies a modification that was

made to the unit.

•

The date code in YYYY-MM format below the factory date code

symbol.

Serial number Date code

xvi Preface

Configuration number Modification codes

Page 18

ESD Caution

Connections to other pieces of equipment are made at the rear of

the Horizon imager. These connectors are marked with a

precautionary ESD warning symbol, as shown below. Do not touch

any of the pins of these connectors. When making connections to

the imager, it is best done while the imager is plugged in but not

powered on. ESD may cause erratic behavior of the imager when

powered on. Should this occur, power to the imager may have to be

cycled. It is recommended that all staff involved in making

connections to the imager be aware of these ESD precautions.

NETWORK

CONSOLE

UPS

Potential for Radio Frequency Interference

on Imager Operation

Both portable and mobile RF communications equipment can affect

medical electrical equipment, including the Horizon imager. Keep

such RF communications equipment out of the immediate area.

Preface

Horizon Starter Manual xvii

Page 19

Potential for Radio and Television

Interference

The Horizon imager generates and uses radio frequency energy,

and if not installed and used properly, that is, in strict accordance

with the manufacturer’s instructions, may cause interference to

radio and television reception. It has been type tested and found to

comply with Class B emission limits for a computing device in

accordance with the specifications in Subpart J of Part 15 of FCC

Rules, which are designed to provide reasonable protection against

such interference when operating in a commercial environment.

Operation of the equipment in a residential area is likely to cause

interference, in which case the user, at his own expense, will be

required to take whatever measures may be appropriate to correct

the interference. If your imager does cause interference to radio or

television reception, you are encouraged to try to correct the

interference by one or more of the following measures:

•

Reorient the receiving antenna

•

Relocate the imager with respect to the receiver

xviii Preface

If necessary, you should consult Codonics technical support or an

experienced radio/television technician for additional suggestions.

You may find the following booklet prepared by the Federal

Communications Commission helpful:

Radio-TV Interference Problems

. This booklet is available from the

How to Identify and Resolve

U.S. Government Printing Office, Washington, D.C. 20402, Stock

No. 004-000-00345-4.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils

numériques de la Classe B prescrites dans le Réglement sur le

brouillage radioélectrique édicté par le ministére des

Communications du Canada.

Page 20

This product is in conformity with the protection requirements of

EC Council directive 89/336/EEC on the approximation of the laws

of the Member States relating to electromagnetic compatibility. This

product satisfies the Class B limits of EN 55011. A declaration of

conformity with the requirements of the Directive has been signed

by the Director of Quality Assurance and Regulatory Affairs.

Safety Precautions

•

Never connect this imager to any outlet or power supply that has

a voltage or frequency different than that specified on the rear of

the imager.

•

When servicing the imager, always power it off using the

(power) key at the control panel, then turn the rocker switch

in the back to the 0 (off) position, then unplug the imager.

•

Damage to the power cord may cause fire or shock hazard. When

unplugging the power cord, hold it by the plug only and remove

the plug carefully.

•

If the power cord needs to be replaced, replace it only with

another Codonics power cord manufactured specifically for your

imager’s power configuration.

•

If the imager is smoking or making unusual sounds, power off

and unplug the imager immediately.

•

Do not insert foreign objects of any kind into the imager; doing

so can constitute a safety hazard and cause extensive damage.

Preface

Horizon Starter Manual xix

Page 21

•

Do not place any liquid containers on the imager. If, for some

reason, liquid seeps into the imager, power off the imager and

unplug the power cord from the source outlet. If used without

corrective measures, the imager may be damaged.

•

Do not use the imager near flammable gases.

•

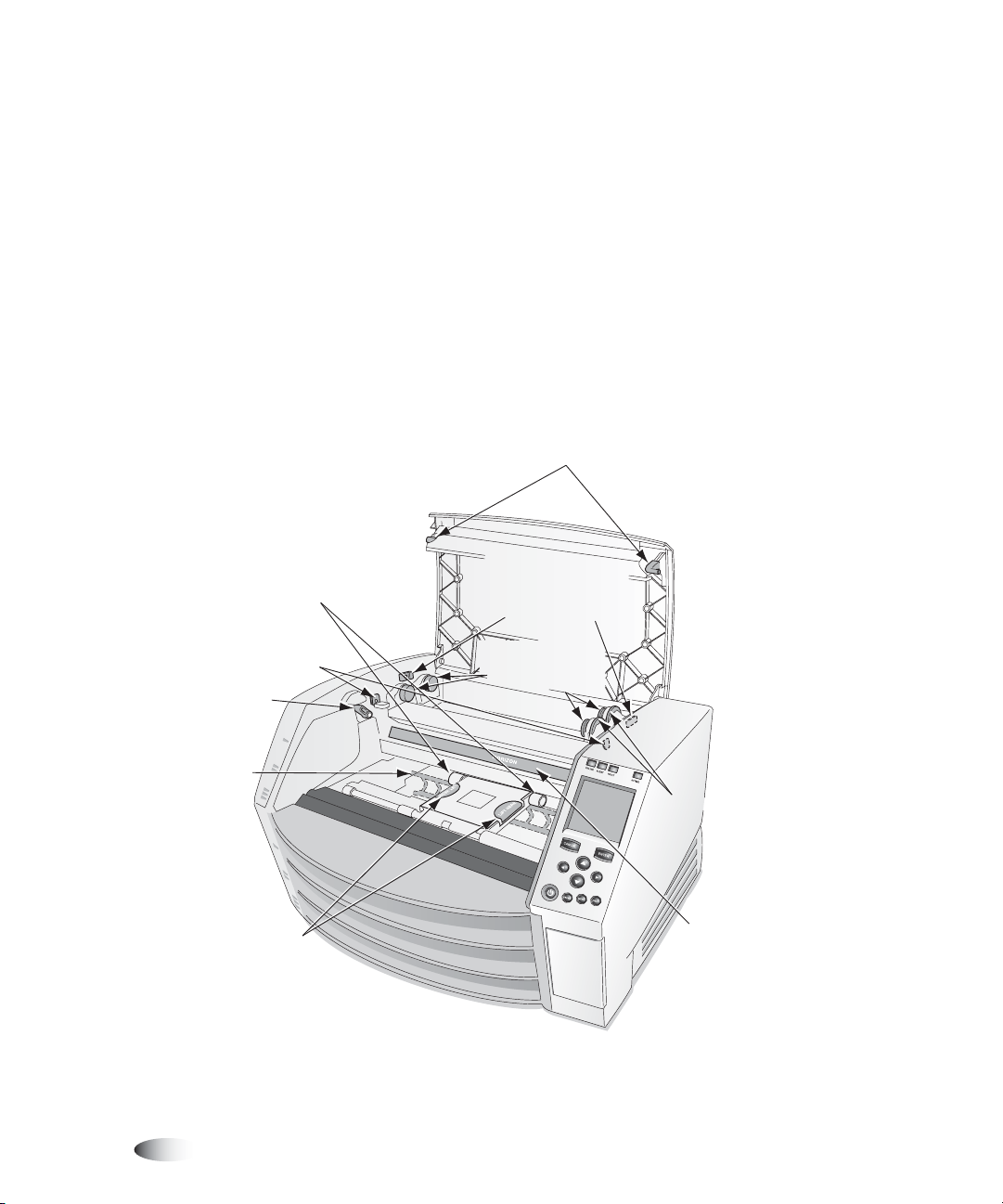

With the imager top cover open or the receive trays removed,

touch only those internal components that are colored green

(except for the pick tires). Remove rings, ties, jewelry, and other

items, and tie back hair, so that they do not fall into or get caught

in the imager.

Top cover releases

(DO NOT TOUCH except with

Pick Tires

Platen Roller Cleaning Wipe)

Upper fender releases

(down position)

Top cover

master release

Media

guides

Picker

(lift here)

Internal Components That Are Colored Green (called out in the

illustration) Are Safe to Touch (except for the pick tires)

Upper fender

releases

(up position)

Spring-loaded

spindles

Spool wheels

Diverter

xx Preface

Page 22

Location Precautions

•

The imager’s operating ambient temperature range is 15–30ºC

(59–86ºF), with a relative humidity of 10%–80%, non-condensing.

•

If the imager is moved quickly from an extremely cold place to a

warmer one, condensation is likely to form. Do not use the

imager if condensation has formed. Wait until the condensation

has evaporated. You can speed up the evaporation time by

moving the imager to a dryer location.

•

Ventilation slots and holes are provided on the sides and rear of

the imager. Place the imager on a hard level surface and locate it

at least 10 cm (4 in.) from walls to ensure proper ventilation.

CAUTION

•

Do not place imager in a high humidity or high dust area.

Airborne dirt particles can cause image quality problems. Avoid

placing the imager in areas where ventilation ducts, open doors,

or frequent passers-by might expose the imager and media to

high levels of debris.

Adequate ventilation is required for proper operation of the imager.

Preface

•

Do not locate the imager in hot-springs areas where hydrogen

sulfide and acidic ions are likely to be generated.

•

Do not locate the imager where there are oily fumes and vapors.

•

Do not locate the imager in direct sunlight.

•

Do not locate imager near sources of high RF energy.

•

Do not locate the imager where it might be subject to jarring or

vibrations, such as a table or desk in a high-traffic area. Jarring

and vibrations can affect the print quality of images.

Horizon Starter Manual xxi

Page 23

Cleaning Precautions

•

Many plastic components are used in the imager’s construction.

Coat flecking and deformation is likely to occur if the imager is

wiped with chemical dusters, benzene, thinners, insecticides, or

other solvents. Rubber and PVC materials left in contact with the

imager for extended times will cause damage. Never use

petroleum-based solutions or abrasive cleaners.

•

To clean the imager cover, first power off the imager using the

(power) key at the control panel, then turn the rocker switch

in the back to the 0 (off) position, then unplug the imager. Clean

the cover with a soft cloth slightly moistened with a mild soap

and water solution. Allow the cover to completely dry before

operating the imager again.

Media

•

For

ChromaVista® color prints, the consumed ribbon contains

facsimiles of any patient images printed to

sheets. Therefore, you must properly dispose of or destroy

consumed ribbon to ensure the confidentiality of patient images.

ChromaVista

color

xxii Preface

•

The optical density of reflective and transmissive prints have a

nominal range of: Dmin = 0.10 OD (reflective), 0.11 OD

(transmissive) to Dmax = 2.10 OD (reflective), 3.1 OD

(transmissive). Actual optical densities may vary based on media

variations and on the instrument being used to measure density.

For example,

Dmax than

DirectVista® Clear film may have a lower Dmin and

DirectVista

Blue film.

Page 24

•

The Horizon imager includes a built-in densitometer. The built-in

densitometer is designed to produce consistent prints by

compensating for variation from one film cassette to another and

one imager to another. For applications that require absolute

control of the maximum density, the results should be checked

against a bench-top commercial densitometer. The internal

densitometer can be calibrated to a desktop unit. See the

Imager Technical Manual

•

DirectVista

ChromaVista

media is optimized for grayscale prints, while

is optimized for color prints. If

for more information.

ChromaVista

Horizon

giving you satisfactory results with grayscale images, you may

want to consider using

•

Media variations between different production lots may produce

DirectVista

media for those applications.

subtle differences in image quality and color. These variations

most often occur in color ribbons and are characterized as a

slight color hue in grayscale images.

•

Codonics film media is designed to be viewed using a light box

suitable for viewing medical diagnostic images.

•

Codonics paper media is designed to be viewed under

cool-white, fluorescent light. Spectral differences and intensity

variations in the viewing light sources can change the apparent

color of images printed on paper.

is not

Preface

•

Printed images that are subject to prolonged exposure to

sunlight, ultraviolet light, or extreme heat may degrade in image

quality. (For example, printed sheets should not be stored in an

automobile on a sunny day.) Precautions should be used to avoid

prolonged direct exposure.

Horizon Starter Manual xxiii

Page 25

File Transfer via FTP and LPR

•

Different users who share a user name when transferring files to

the imager may cause unpredictable and erroneous printed

output. The imager associates information with the user name.

Each user should have a unique user name when connecting to

the imager via FTP and LPR.

Color Management

•

Image settings—including gamma, contrast, Dmax, saturation,

and MCM™ (Medical Color Matching™)—are intended to

compensate for differences that may occur between image

acquisition and image printing. These filters allow you to

accurately render the final printed image. You should use care

when applying these filters to avoid over compensation.

•

The Default User Settings set at the control panel will potentially

affect prints made by all users. Use caution when changing the

default settings.

xxiv Preface

Image Scaling

•

Scaling an image will filter the original image data and add or

remove information, which may affect the accuracy of the final

printed image. The amount of information added or removed will

also vary with the magnitude of the scale factor applied. This can

also affect the accuracy of the final printed image. You should be

aware of the properties and limitations of each scaling algorithm

and select the appropriate algorithm for the task.

Page 26

Hardware Variations

•

Components used in the imager may vary, causing differences in

image quality. The thermal process of producing a print utilizes

many components that are calibrated to provide consistency

between imagers. There are subtle differences between imagers

that can cause print variations. These differences usually apply to

thermal print head calibration. Other factors such as age, usage,

heat, mechanical wear, and shipping can affect image color and

quality.

Indications for Use

The Codonics, Inc., family of Horizon imagers produces

radiological quality, hardcopy output. They can produce color

prints on dye-diffusion film and paper, and grayscale prints on

direct thermal film and paper. They are designed to convert digital

image data from a host computer into hardcopy prints.

Preface

Film prints are suitable for diagnostic use when viewed on a light

box designed for such purposes. Color film prints, and color and

grayscale paper prints, have the quality, texture, and feel of

standard photographic materials. All Horizon imagers create prints

electronically, without optics, wet chemicals, or a separate fusing

process.

The exact media types and sizes supported will vary, depending on

the specific model purchased.

Horizon Starter Manual xxv

Page 27

Page 28

1

Setting Up the Imager

Preparing for Installation

To prepare for the Horizon imager installation, review the following

guidelines and requirements:

CAUTION

imager [approximately 66.7 kg (147 lbs) with receive trays and three full supply

cassettes installed].

•

Select a location for the imager that meets the requirements

described in “Location Precautions” on page xxi in the Preface.

•

It is recommended that you use a UPS (uninterruptible power

supply) to protect the imager from voltage spikes and power

outages.

•

Contact field service representatives of any imaging devices or

image viewing workstations that will be used with the imager, to

ensure that they are available during the imager’s installation to

assist with setup and help troubleshoot potential problems.

Make sure that the table or printer stand can support the weight of the

Setting Up the Imager

Horizon Starter Manual 1-1

Page 29

Installing the Imager

The Horizon imager comes stored in two boxes:

•

The imager is stored in the larger box.

•

The receive trays, power cord, manuals, technical briefs, and

other accessories are stored in the smaller box.

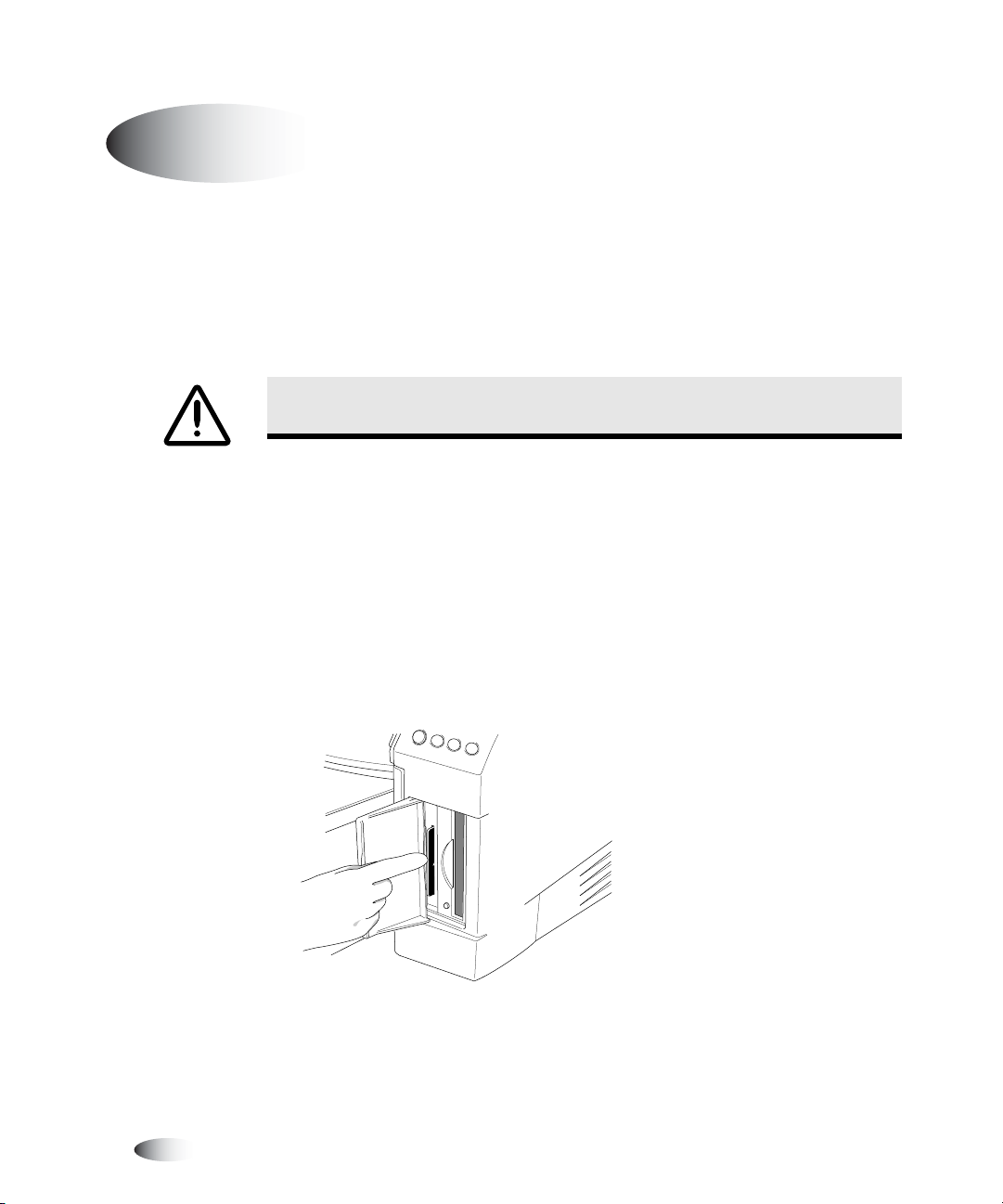

WARNING The imager is heavy. To avoid injury, use two people to unpack and

position the imager.

8

To install the

imager

1. Move the imager box close to the desired location.

2. Open the imager box and follow the instructions printed on the

box insert.

3. Lift the imager from the box and position it at the desired

location.

4. Open the Smart Card/Zip drive access door at the lower right

front of the imager and make sure that the Smart Card is fully

seated in its slot.

1-2 Setting Up the Imager

Page 30

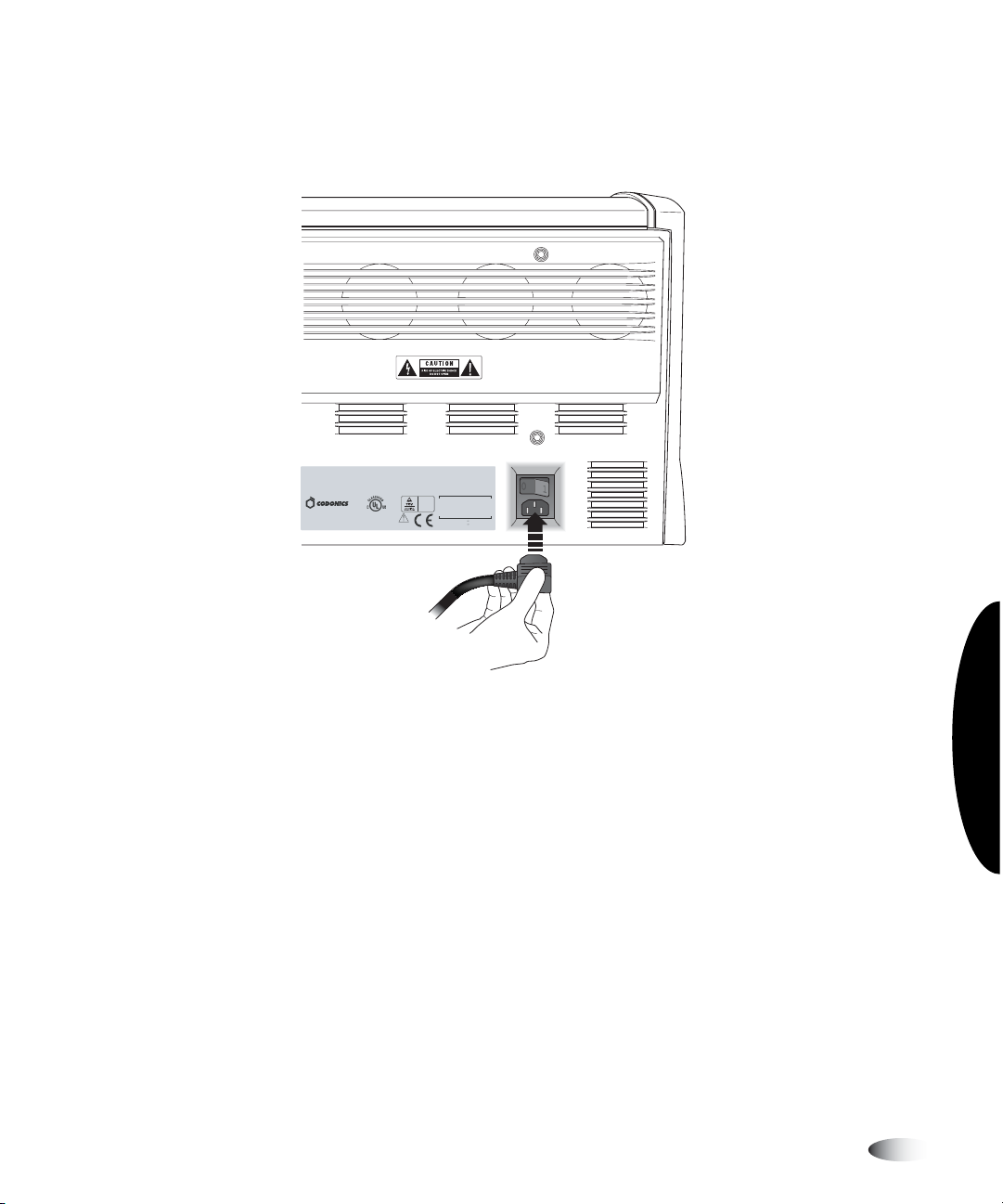

5. Retrieve the power cord from the Accessories box and plug its

right-angle connector into the power connection at the rear of

the imager.

This equipment has been type tested and found to comply with the requirements in part 15 of FCC rules and Canadian Department of communications for a Class B

computing device. See instruction manual. Operation in a residential area may cause unacceptable interference to radio and TV reception requiring the operator to

take whatever steps are necessary to correct the interference.

Le prsent appareil num rique n' met pas de bruits radio lectr iques d passant les limites applicables aux appareils numr iques de la Classe B prescrites dans le

Rglement sur le brouillage r adio lectr ique dict par le minist re des Comm unications du Canada.

This product is in conformity with the requirements of EC Council directive 93/42/EEC on the approximation of the laws of the Member States relating to medical

devices. This product satisfies the Class B limits of EN 55011 and CISPR 11.

CODONICS, INC.

17991 ENGLEWOOD DR.

MEDICAL ELECTRICAL EQUIPMENT

MIDDLEBURG HTS., OH 44130 U.S.A.

UL.2601-1, CAN/CSA C22.2 NO.601.1

MADE IN THE U.S.A.

Patents Pending, All Rights Reserved

AR: CEpartner4U, 2635 HL 33.NL

Tel: +31(0)6-516.536.26

31EB

COMPLIES WITH 21 CFR 1040.10 AND 1040.11

HORIZON MEDICAL PRINT IMAGER

EN 60601-1

100-120V , 50-60Hz, 6.0A

230

V , 50-60Hz, 3.0A

6. Plug the other end of the power cord into the UPS or electrical

outlet.

Horizon Starter Manual 1-3

Setting Up the Imager

Page 31

7. Open the top cover by pressing any of the green releases.

Left release

Master release

8. Remove any packing material inside the imager.

Right release

1-4 Setting Up the Imager

Page 32

9. Using a print head cleaning wipe included in the Accessory box,

gently clean the imager basement of any debris.

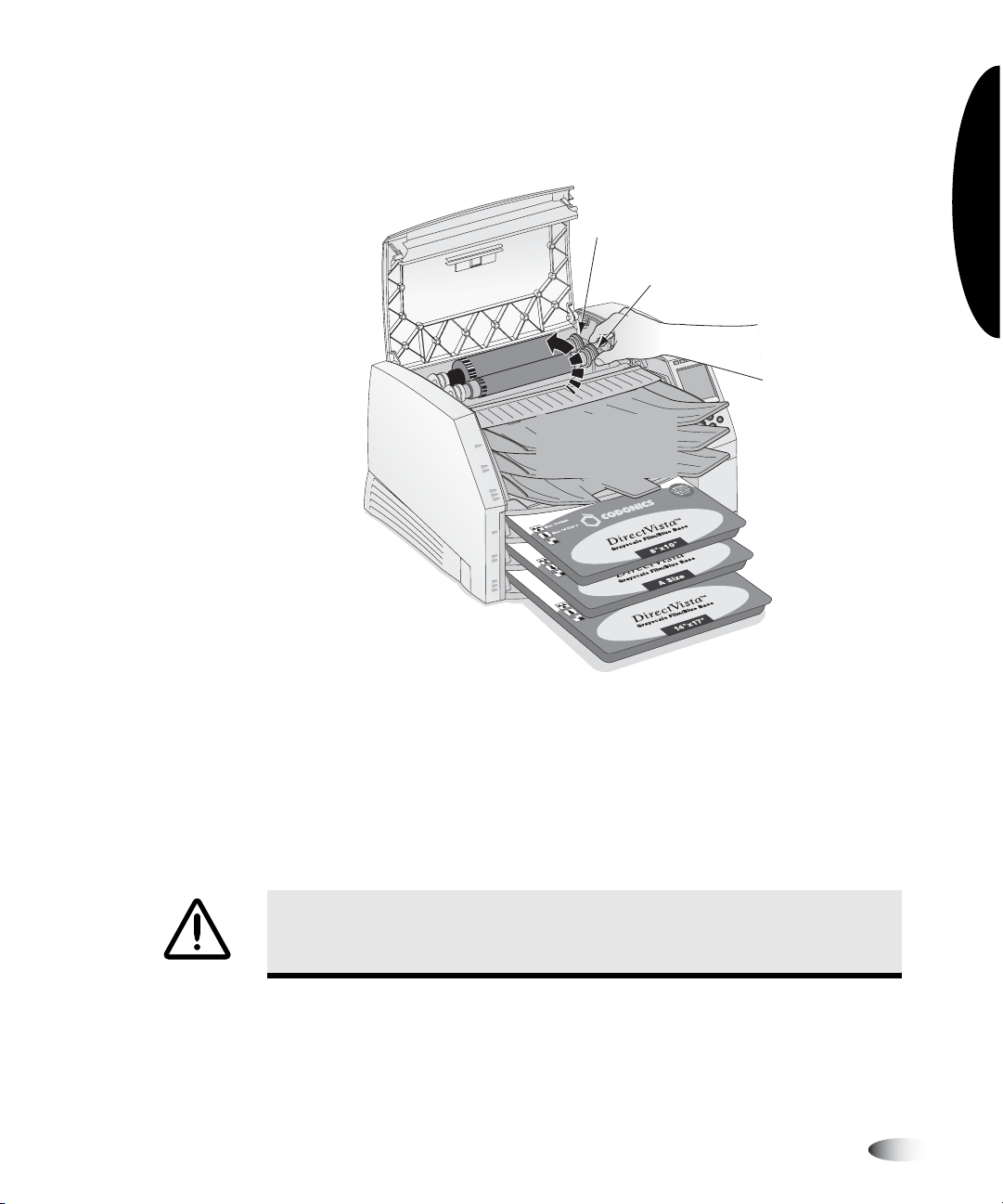

CAUTION

basement will damage the printed side of

Hide track

Cassettes

Cross-Section of Imager, Showing Location of Hide Track and Basement

(with receive trays and cassettes installed)

Do not scratch or nick the sheet metal. Scratches and nicks in the

ChromaVista

Receive trays

Basement

sheets.

Setting Up the Imager

3

10. Remove the receive trays from their box.

11. Using a platen roller wipe included in the Accessory box, clean

the receive trays of any dust or debris.

NOTE:

Save the imager box and all packing material. You must reinsert any packing

material and use the original box to ship the imager. Refer to “Preparing the Imager for

Shipment” on page 1-15 for more information.

Horizon Starter Manual 1-5

Page 33

12. Place the receive trays into the imager.

13. Close the top cover.

Receive trays

Connecting the Ethernet Cable

The Horizon imager supports the following network cables and

hubs:

1-6 Setting Up the Imager

Page 34

•

Category 5, RJ-45 [also referred to as unshielded twisted pair

(UTP)] network patch cables and crossover cables

•

10/100 Base-T Ethernet hubs

8

To connect the

Ethernet cable

to the imager

CAUTION

Make sure that the imager is powered off before connecting the Ethernet

cable. For information about powering the imager on and off, refer to “Powering the

Imager On and Off” on page 2-3.

1. Locate the Ethernet cable jack at the back of the imager and

insert the Ethernet cable.

Network

connector

NETWORK

E

L

ONSO

C

S

UP

This equipment has been type tested and found to comply with the requirements in part 15 of FCC rules and Canadian Department of communications for a Class B

computing device. See instruction manual. Operation in a residential area may cause unacceptable interference to radio and TV reception requiring the operator to

take whatever steps are necessary to correct the interference.

Le prsent appareil num rique n' met pas de bruits radio lectr iques d passant les limites applicables aux appareils numr iques de la Classe B prescrites dans le

Rglement sur le brouillage r adio lectr ique dict par le minist re des Comm unications du Canada.

This product is in conformity with the requirements of EC Council directive 93/42/EEC on the approximation of the laws of the Member States relating to medical

devices. This product satisfies the Class B limits of EN 55011 and CISPR 11.

CODONICS, INC.

17991 ENGLEWOOD DR.

MEDICAL ELECTRICAL EQUIPMENT

MIDDLEBURG HTS., OH 44130 U.S.A.

UL.2601-1, CAN/CSA C22.2 NO.601.1

MADE IN THE U.S.A.

Patents Pending, All Rights Reserved

AR: CEpartner4U, 2635 HL 33.NL

Tel: +31(0)6-516.536.26

31EB

COMPLIES WITH 21 CFR 1040.10 AND 1040.11

EN 60601-1

HORIZON MEDICAL PRINT IMAGER

100-120V , 50-60Hz, 6.0A

V , 50-60Hz, 3.0A

230

530-040-004 REV 02

Setting Up the Imager

CAUTION

Do not touch any of the connector pins.

2. Connect the other end of the Ethernet cable to the Ethernet hub

or to the workstation’s Ethernet jack.

Horizon Starter Manual 1-7

Page 35

NOTE:

When connecting the imager to only one workstation without the use of a hub, you

3

must use a special Ethernet cable, called a

connect the imager and the single workstation using two standard Ethernet patch cables and

a hub. This would allow for future expansion of the network.

crossover cable

. Optionally, you could still

Powering On the Imager—First Time

8

To power on

the imager

1. Press the power rocker switch to the 1 (on) position.

Power rocker switch

1-8 Setting Up the Imager

Page 36

3

2. Press the (power) key at the control panel.

NOTE:

Always use the key at the control panel to power on/off the imager. The power

rocker switch at the back of the imager should always be in the 1 (on) position, unless the

imager is being serviced or moved.

The control panel display shows startup messages as the imager

initializes. When the Status screen displays (shown below), the

imager is ready to receive images.

Supply

1: No cassette

2: No cassette

3: No cassette

Status OK

X

No sheets queued

Cleaning the Platen Roller

Clean the platen roller after powering the imager on for the first

time. Refer to “Cleaning the Thermal Print Head and Platen Roller”

on page 7-3.

Horizon Starter Manual 1-9

Setting Up the Imager

Page 37

Network Settings—Simple Network

This topic explains how to add the imager to a simple network. For

Horizon

3

adding the imager to a complex network, refer to the

Imager Technical Manual

NOTE:

If your network is managed by a network administrator or an information technology

(IT) department, it would be considered a complex network. You should have the

responsible person perform any network-related administrative tasks.

By

simple network

, we mean a local-area network (LAN) that is

.

connected to another LAN or wide-area network (WAN).

A simple network typically comprises several devices connected by

Ethernet UTP cable through an Ethernet hub. It could also be

simpler yet—a workstation or imaging device connected directly to

the Horizon imager using an Ethernet crossover cable.

not

View workstation

Simple Network with Ethernet Hub

1-10 Setting Up the Imager

Imaging device

Horizon imager

Ethernet hub

Page 38

Ethernet crossover cable

3

View workstation

Simple Network with Ethernet Crossover Cable

Horizon imager

In addition to the physical cabling connection, you must define an

IP (Internet Protocol) address for the imager.

Specifying the Imager’s IP Address

The required IP address uniquely identifies the imager on the

network.

Determining an IP Address

Make sure that device IP addresses within this network are unique.

NOTE:

If devices on this network do have to communicate with devices on other networks,

it is part of a complex network. For more information about configuring the Horizon imager

in a complex network, refer to the

Horizon Imager Technical Manual

IP addresses have the format x.x.x.x, where x is a value from 0 to

255. One series of IP addresses, 192.168.x.

x,

internet convention for self-contained networks. You assign the last

two parts in the address. So, you might assign the IP addresses as

follows:

.

has been reserved by

Setting Up the Imager

•

192.168.1.200

•

192.168.1.201

•

192.168.1.202

•

192.168.1.203

And so on.

to the Horizon imager

to an image viewing workstation on the network

to a second workstation

to an imaging device

Horizon Starter Manual 1-11

Page 39

3

3

3

Specifying the Imager’s IP Address at the Control Panel

NOTE:

For a simple network, you will only need to define the imager’s base IP address. You

can leave all other network settings for the imager at their default values.

NOTE:

For instructions on how to use the imager’s control panel and menus, refer to

Chapter 2.

NOTE:

After entering the base IP address, note that the imager will reboot once you exit the

menus so that the software can be properly updated with the new value.

8

To specify the

imager’s IP

address

1. At the imager’s control panel, press and hold the key, and

while holding it press the key.

MENU

W

The Main Menu with administrative options displays.

2. Use the and keys to move the selector arrow to

Settings

Load/Remove Ribbon...

Custom Job Settings...

Utilities...

Test Prints...

Print From Zip Disk...

Feature Management...

X

Network Settings...

Configure TCP/IP network

settings

S

.

T

Menu

Press MENU to exit menus

Network

1-12 Setting Up the Imager

Page 40

3. With the

Network Settings

option selected, press the key.

The Network Settings menu displays. Note that the current

settings are displayed in square brackets.

Network Settings

Network Settings

Speed [Auto Sense]...

XAddresses...

Reset Network Settings

Set network addresses of this

Imager.

Press MENU to exit menus

ENTER

3

4. Select the

Addresses

option, then press the key.

ENTER

The Network Addresses menu displays. Note that bold square

change

brackets are displayed around the first IP address octet

value of the Base IP Address. The bracketed portion of the

address is the portion that can currently be changed.

Network Addresses

Base IP Address:

[0].0.0.0

Gateway:

0.0.0.0

Subnet Mask:

255.255.255.0

Number of IP Addresses: 1

Set base IP address

Old value: 0.0.0.0

UP/DOWN to alter octet, LEFT/RIGHT

to change octets

Press MENU to exit menus

NOTE:

The Horizon imager can have more than one IP address assigned to it. For more

information about assigning multiple IP addresses, refer to the

Manual

.

Horizon Imager Technical

Setting Up the Imager

Horizon Starter Manual 1-13

Page 41

5. To change the first octet, press the or key until the

S

T

number you want is displayed.

Hold these keys to cycle through numbers.

3

3

6. To select the next octet, press the key. (Press the key to

X W

return to the previous octet.)

7. Repeat steps 5 and 6 until all four octets in the Base IP Address

have been defined. To save, press the key.

NOTE:

To exit the Network Addresses menu without saving your changes, press the

CANCEL

key. The previous menu in the hierarchy displays.

8. Press the or key to leave the Network Settings menu.

CANCEL

W

ENTER

A message states that the imager will automatically reboot when

you press the key to exit the Main Menu.

9. Press the key to acknowledge the message.

MENU

ENTER

10. When you are finished specifying the IP address and want to

exit the Main Menu, press the key.

MENU

Because the base IP address was defined, the imager reboots so

that it can be identified properly on the network.

NOTE:

You can reset the network settings to their default values at any time by selecting

Reset Network Settings

the

option in the Network Settings menu.

Specifying IP Addresses for Other Devices

on the Network

Just as you did for the Horizon imager, you must specify the IP

addresses for each of the other devices on the network. Refer to the

documentation or online help that comes with the device for

specific instructions.

For more information about IP addressing conventions, refer to the

Horizon Imager Technical Manual

1-14 Setting Up the Imager

.

Page 42

Loading Media

After setting the imager’s IP address, you can load media cassettes

and, optionally, load a ribbon to support color prints. For more

information about how to load media, refer to “Inserting or

Changing Cassettes” on page 3-4 and “Changing the Ribbon

(ChromaVista)” on page 3-7.

Preparing the Imager for Shipment

If you have to ship the imager for any reason, you must use the

original imager box and packing materials. If you do not have the

original box and packing materials, contact your Codonics

representative.

8

To prepare the

imager for

shipment

3

1. If a ribbon is in the imager, remove it. For more information,

refer to “Changing the Ribbon (ChromaVista)” on page 3-7.

2. Make sure the top cover is closed and the receive trays are

inserted.

NOTE:

The top cover must be closed

print head to park. If either the top cover is open or the receive trays are not inserted, the

imager will display a message indicating that it cannot be shut down until the condition is

corrected.

and

the receive trays must be inserted for the thermal

3. Power off the imager. For more information, refer to “Powering

Off the Imager” on page 2-7.

4. Remove the receive trays.

Horizon Starter Manual 1-15

Setting Up the Imager

Page 43

5. Open the top cover by pressing any of the green releases.

Left release

Master release

Right release

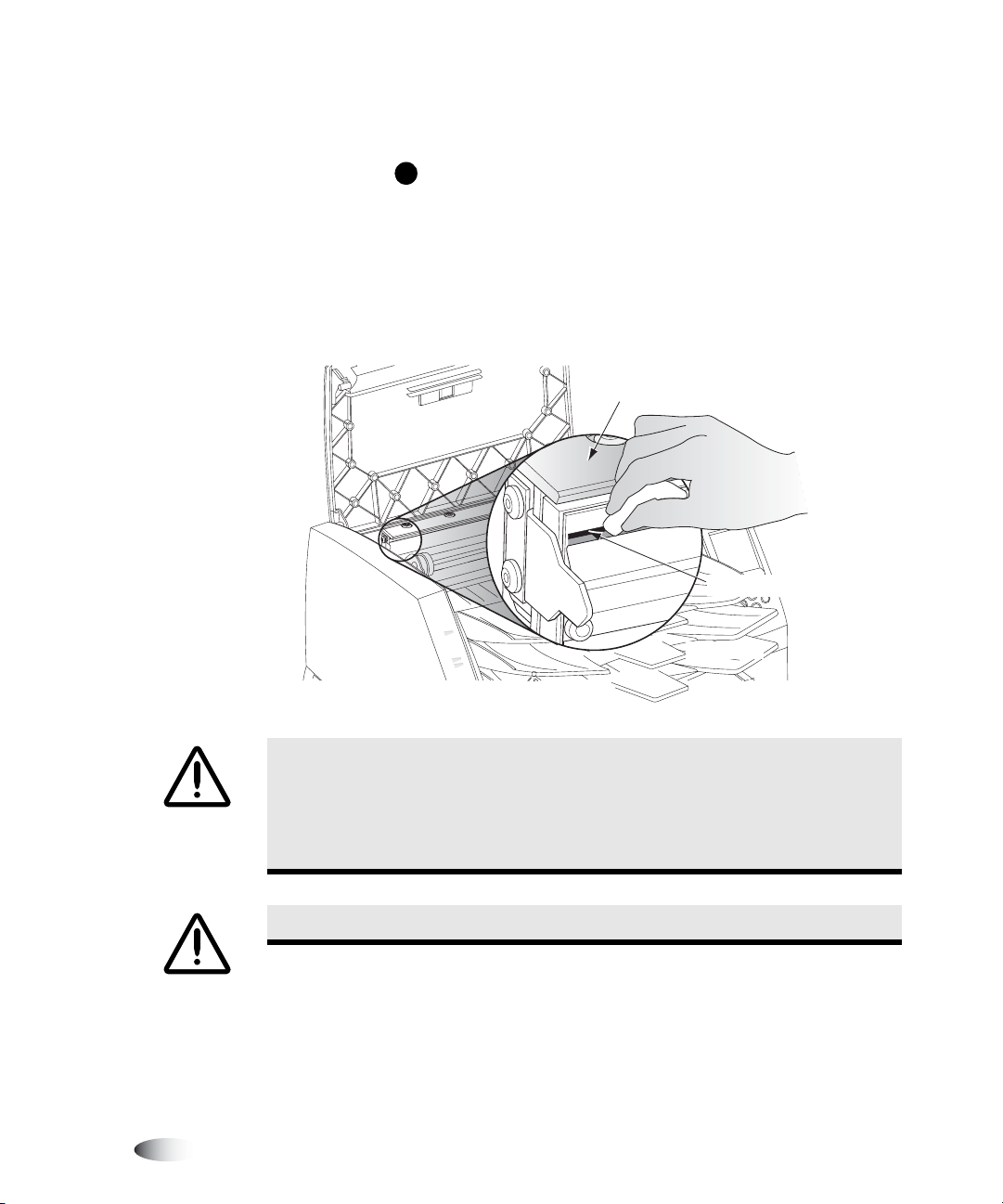

6. Make sure that the thermal print head has parked. The thermal

print head should be secure with no wobble.

Make sure thermal

print head is secure

and does not wobble

1-16 Setting Up the Imager

Thermal print head

Page 44

CAUTION

steps 2 and 3 to properly power off the imager so that it does park.

If the thermal print head is not parked, power on the imager, then repeat

7. Look down into the imager just in front of the thermal print

head and make sure that the ribbon carriage is fully down to the

bottom of the imager. (The ribbon carriage should have lowered

during power off.)

Thermal print head

3

Ribbon carriage

at bottom of imager

Cross-Section View of Imager

NOTE:

If the ribbon carriage is not fully down, you can use the foam stabilizer to push it

down. The stabilizer is shown in the first panel of the repacking illustration on the box insert.

The ribbon carriage does not move easily, but it is safe to apply moderate pressure to force

it all the way down.

CAUTION

damage the carriage.

Push the ribbon carriage down slowly. Forcing it down too quickly may

8. Replace the packing materials into the imager, close the top

cover, and repack the imager into its original box. Refer to the

box insert for illustrated instructions.

Horizon Starter Manual 1-17

Setting Up the Imager

Page 45

Page 46

2

Basic Imager Operations

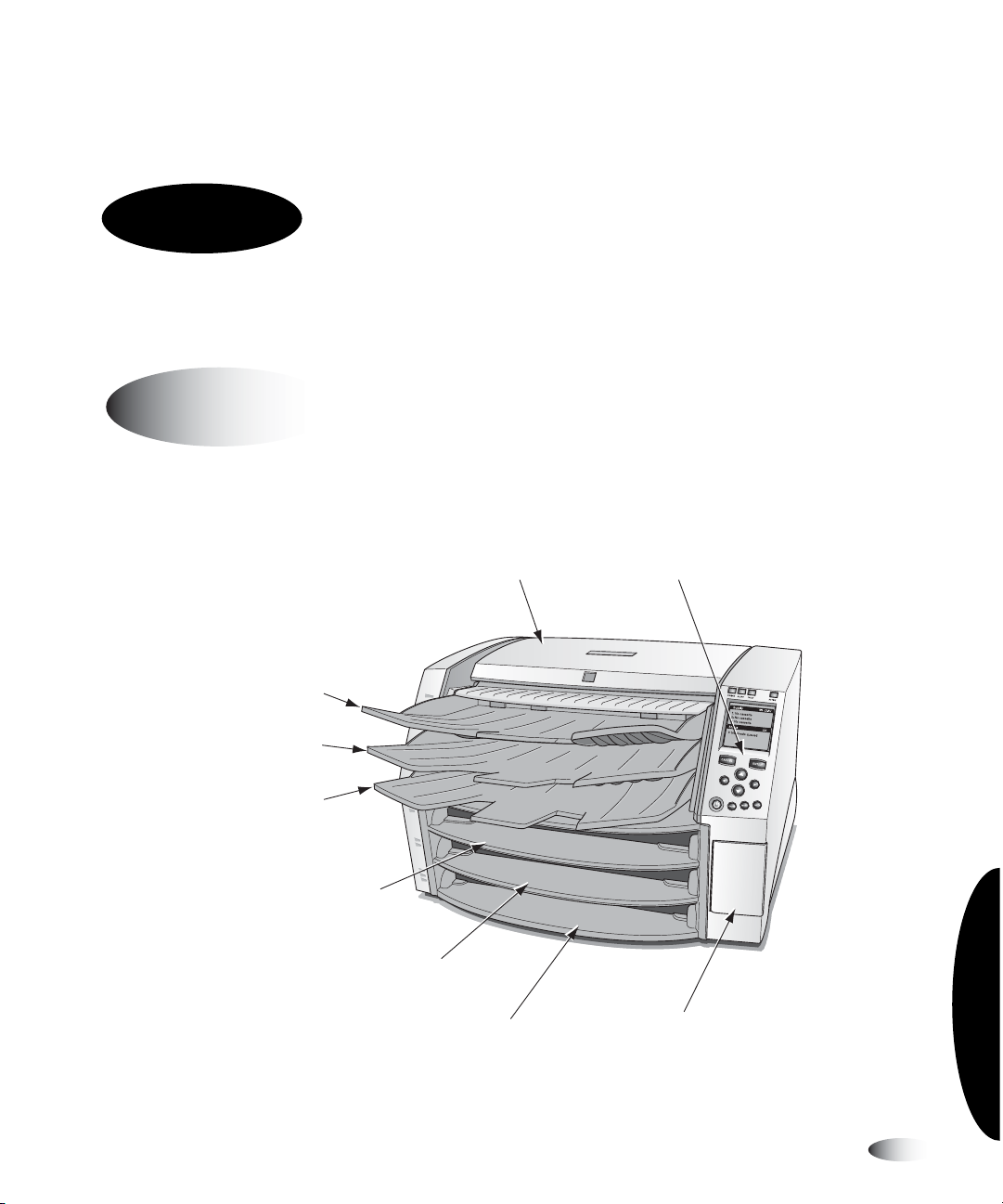

Horizon Imager Components

The following illustrations show the names and locations of the

main imager components.

Top cover Control panel

Receive tray 1

Receive tray 2

Receive tray 3

Supply slot 1

Names and Locations of the Imager’s Main Components—Front

Supply slot 2

Supply slot 3

Basic Imager Operations

Smart Card/

Zip drive panel door

Horizon Starter Manual 2-1

Page 47

KCONSOLE

R

O

W

T

E

N

S

P

U

This equipment has been type tested and found to comply with the requirements in part 15 of FCC rules and Canadian Department of communications for a Class B

computing device. See instruction manual. Operation in a residential area may cause unacceptable interference to radio and TV reception requiring the operator to

take whatever steps are necessary to correct the interference.

Le pr sent appareil num rique n' met pas de bruits radio lectr iques d passant les limites applicables aux appareils num r iques de la Classe B prescrites dans le

R glement sur le brouillage radio lectr ique dict par le minist re des Comm unications du Canada.

This product is in conformity with the requirements of EC Council directive 93/42/EEC on the approximation of the laws of the Member States relating to medical

devices. This product satisfies the Class B limits of EN 55011 and CISPR 11.

CODONICS, INC.

17991 ENGLEWOOD DR.

MEDICAL ELECTRICAL EQUIPMENT

MIDDLEBURG HTS., OH 44130 U.S.A.

UL.2601-1, CAN/CSA C22.2 NO.601.1

MADE IN THE U.S.A.

Patents Pending, All Rights Reserved

AR: CEpartner4U, 2635 HL 33.NL

Tel: +31(0)6-516.536.26

31EB

COMPLIES WITH 21 CFR 1040.10 AND 1040.11

HORIZON MEDICAL PRINT IMAGER

EN 60601-1

100-120V , 50-60Hz, 6.0A

V , 50-60Hz, 3.0A

230

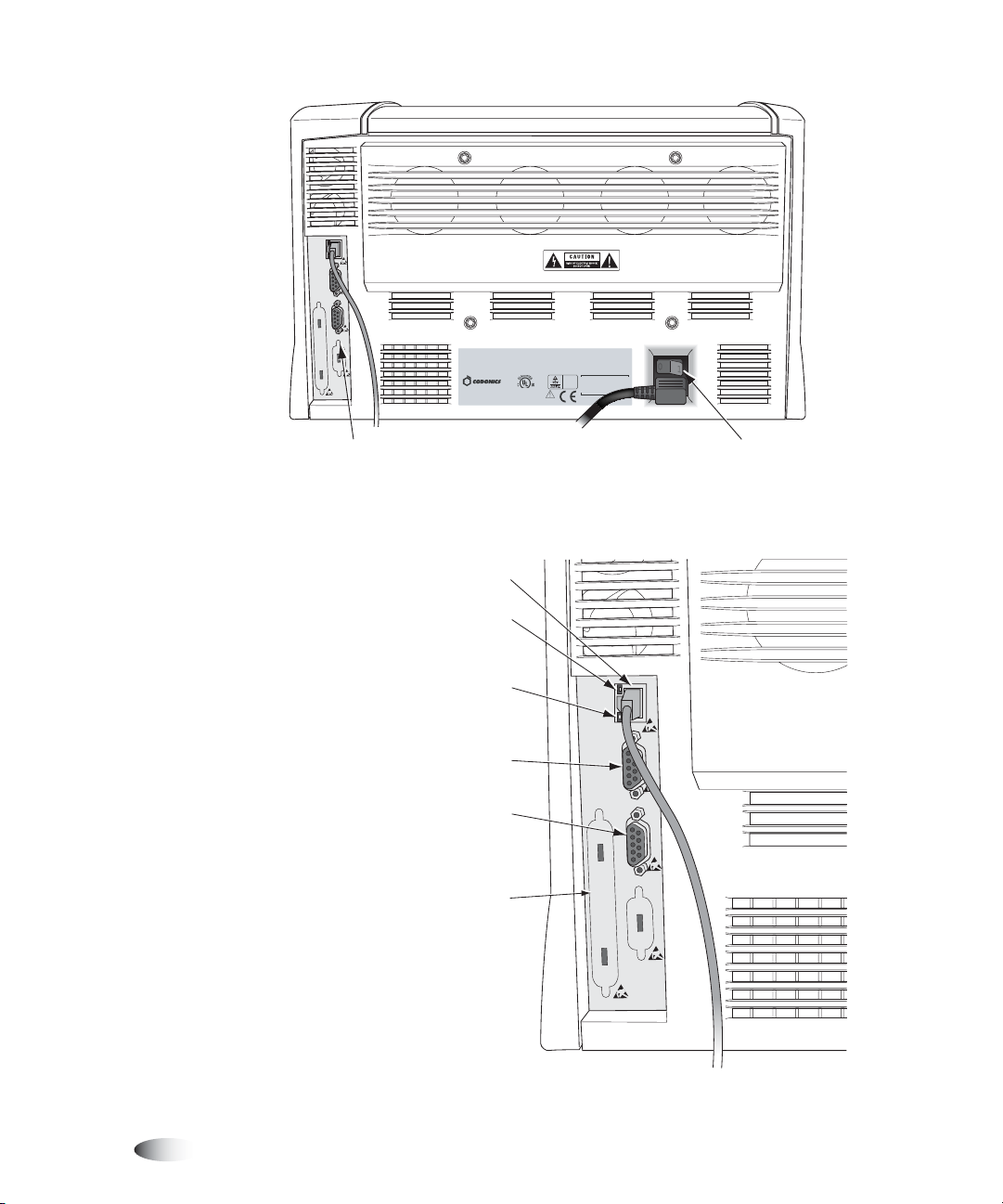

Power rocker switchConnectors

Names and Locations of the Imager’s Main Components—Rear

Network connector

Speed indicator:

On = 100 Mbps

Off = 10 Mbps

(for connection to UPS serial

Rear Connectors

2-2 Basic Imager Operations

Activity indicator:

On = Link

Flashing = Activity

Off = No link

Console

(Service only)

UPS

control cable)

Expansion slot

(for future use)

NETWORK

CONSOLE

UPS

Page 48

Powering the Imager On and Off

Powering On the Imager

8

To power on

the imager

3

Press the (power) key at the control panel.

The startup process takes 2 to 3 minutes. When the Status screen

displays, the imager is ready to receive images.

NOTE:

The

Horizon Imager Technical Manual

more detailed imager status information.

includes information about how to obtain

Horizon Starter Manual 2-3

Basic Imager Operations

Page 49

Observing the Imager’s Operating Status

in the Status Screen

The Status screen allows you to observe the imager status. The top

portion of the screen—the Supply window—displays the status of

the three supply cassettes and whether a color ribbon is installed.

The bottom portion of the screen—the Status window—displays

printing status messages and the imager’s operational state.

Supply window: Indicates

status of supply slots

Indicates that color ribbon

is installed and its status

Supply CMY

1: 8X10 DV Blue 53

2: A CV Paper 50

3: 14X17 DV Blue 76

Status OK

X

Sheets queued: 3

Status window: status

messages displayed here

When activity occurs, each

supply entry toggles with

activity status related to

cassette (processing, printing,

calibrating, media jam)

Number of sheets left in

cassette

Operational state (OK,

ALERT, or FAULT)

To get additional information about the currently selected status

message, press the key.

HELP

2-4 Basic Imager Operations

Page 50

Common Cassette Status Messages

The following table lists common cassette-related status messages.

Table 2-1. Cassette Status Messages

Message Explanation

Calibrating The imager is performing a calibration.

When performing a film calibration (when a DirectVista

grayscale film cassette is first inserted, or initiated manually

through the Main Menu), the “calibrating” message toggles

with supply information.

Checking cassette The imager is reading the supply cassette’s barcode, or waiting

to read the barcode (for example, if the top cover is open, the

barcode will not be read).

Media size, type,

and count

No cassette No cassette is loaded in the supply slot.

Printing The imager is printing from the indicated cassette.

Cleaning The imager is cleaning the picking system.

Indicates the type, size, and sheet count of the media cassette

inserted in the corresponding supply slot. For example,

14x17 DV Blue 53, indicating the cassette currently has 53

sheets of 14 x 17-in. DirectVista blue film.

Basic Imager Operations

Horizon Starter Manual 2-5

Page 51

Color Ribbon Status

The following table lists the color ribbon status indications.

Table 2-2. Color Ribbon Status Indications

Indication Explanation

Blank; the imager does not support ChromaVista color media.

CMY

OUT

WAIT

ERR

Ribbon loaded. Ribbon type indicated (for example, CMY for

cyan/magenta/yellow).

Ribbon loaded but the ribbon is spent.

Ribbon not loaded (and the imager does support ChromaVista

color media).

State of ribbon being determined.

Ribbon loaded but in an error condition.

2-6 Basic Imager Operations

Page 52

Powering Off the Imager

8

To power off

the imager

3

1. Press the (power) key at the control panel.

The Power menu displays.

Power

X

Power Off

Reboot

NOTE:

To cancel the power off , press the key again or the key.

2. Select the

Power Off

option.

CANCEL

Shutdown messages are displayed. When the shutdown

operation is complete, the imager powers off.

3

NOTE:

Always use the

rocker switch at the back of the imager should always be in the 1 (on) position, unless the

imager is being serviced or moved.

CAUTION

saved and will finish printing once the imager is powered on again. However, if the

imager is powered off using the rocker switch in the back or power is interrupted,

queued jobs may be lost.

If the imager is powered off using the key, unprinted queued jobs are

key at the control panel to power on/off the imager. The power

Horizon Starter Manual 2-7

Basic Imager Operations

Page 53

Understanding the Control Panel

Indicators

Refer to page 2-9

Display

Refer to page 2-10

Power key

Refer to page 2-3

2-8 Basic Imager Operations

Keys

Page 54

Control Panel Indicators

The following table describes the control panel indicators.

Table 2-3. Control Panel Indicators

Indicator Description

ONLINE (green) Indicates when imager is online (lit) or offline (off):

• When online, printing is enabled.

• When offline, printing is paused.

In both cases, the imager will continue to receive and

process print jobs.

ALERT (yellow) When lit, indicates a condition that requires operator

attention, but printing can continue.

An example of an alert condition is a queued job that

requires a supply cassette that is currently not loaded or

is empty, but other cassettes are not empty.

AULT (red) Indicates an imager fault condition that prevents the

F

imager from printing any job and requires operator

intervention. For example:

• A sheet is jammed

• No supply cassettes are loaded

• All supply cassettes are empty

ACTIVE (green) Has the following states:

• On: The imager is powered on but idle.

• Off: The imager is powered off.

• Flashing: The imager is actively receiving, processing,

or printing jobs; or powering on, off, or rebooting. If

jobs are paused, the A

CTIVE indicator will not flash.

Horizon Starter Manual 2-9

Basic Imager Operations

Page 55

Alert and Fault Messages and the Fault

Tone

When the imager needs attention or an error occurs, the

FAULT

indicator lights. Messages are displayed in the Status screen

ALERT

or

to help you respond to the condition.

If operator intervention is required, a Fault tone sounds. To stop the

Fault tone, press any control panel key.

For more information about alert and fault messages and how to

respond to them, refer to Chapter 9.

Control Panel Display

Main Menu

When the key is pressed, the

Menu to perform basic and frequently used imager operations.

use the and keys to

MENU

Selector arrow;

S

scroll the selector arrow

T

through the list.

Main Menu

XOpen Top Cover...

displays. Use the Main

Default Media...

Load/Remove Ribbon...

Utilities...

Test Prints...

Menu

2-10 Basic Imager Operations

Help message area

Access Imager internals to clean or

to change ribbon

Press MENU to exit menus

Page 56

If you press the key and, while holding it, press the key,

W

MENU

the Status screen shows additional administrative options in the

menus. You use these additional options to perform system

maintenance and setup tasks.

8

To exit the

Menu screens

Menu

Default User Settings...

Default Media...

XOpen Top Cover...

Load/Remove Ribbon...

Custom Job Settings...

Utilities...

Test Prints...

Print From Zip Disk...

Access Imager internals to clean

or to change ribbon.

Press MENU to exit menus

When finished, press the key. The Status screen is

MENU

Scroll indicator displays

when there are more menu

items available than can be

displayed at one time.

Black portion of scroll

indicator indicates where

the selected item is within

the complete list.

Use the and keys

to scroll the selector arrow

through the list.

S

T

displayed.

Horizon Starter Manual 2-11

Basic Imager Operations

Page 57

Page 58

3

Overview

Media Handling and Storage

Media Handling and

Storage

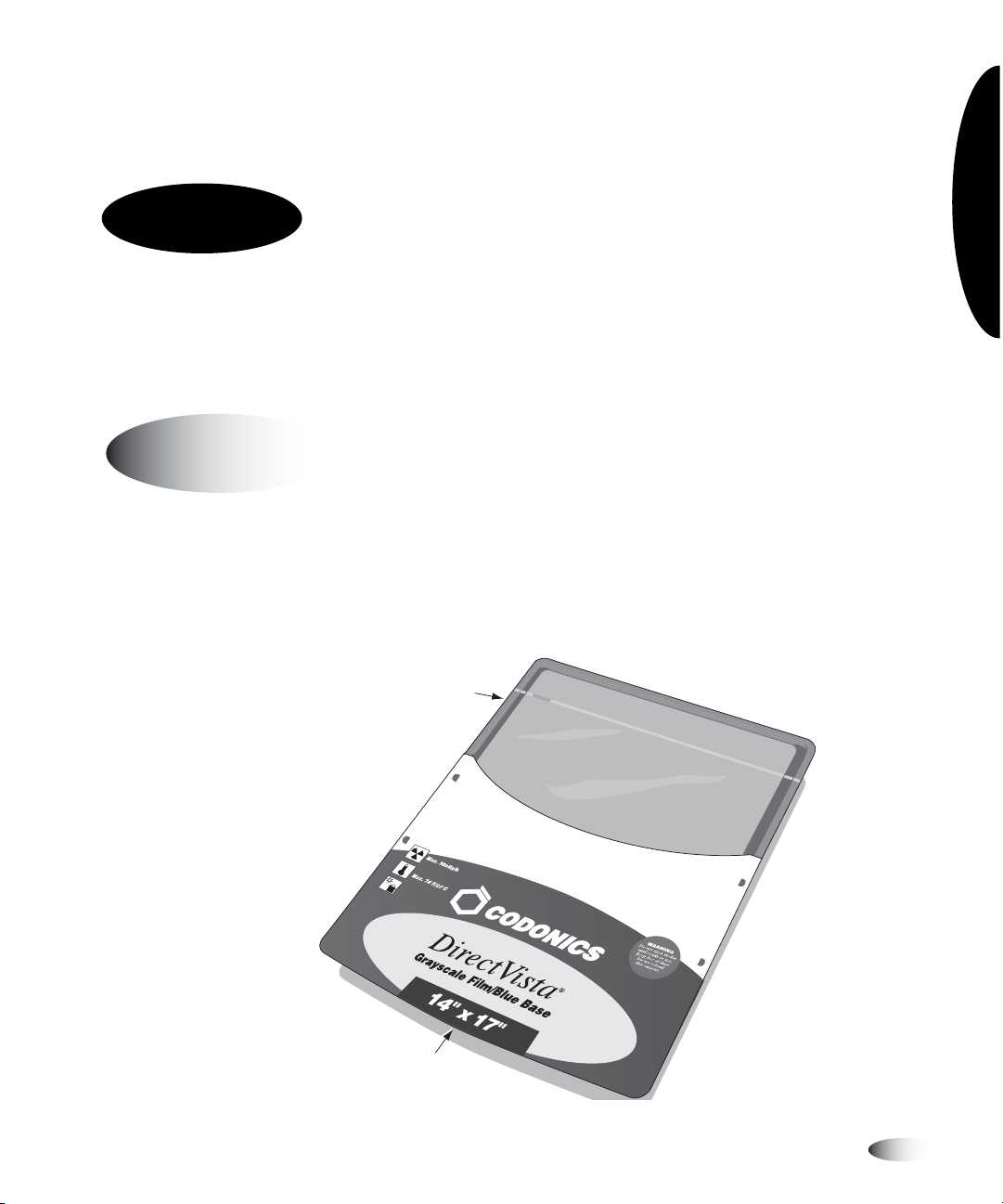

Supply Slots and Cassettes

Media used with the Horizon imager is prepackaged in

factory-sealed, disposable cassettes.

Barcode

(on side)

Cassette cover:

Do not remove

Horizon Starter Manual 3-1

Page 59

Each cassette contains a barcode that allows the imager to track

how many sheets remain in the cassette (this count will be

inaccurate if sheets have been manually added or removed, or the

cassette has been moved to a different imager).

In addition to the barcode itself, the cassette’s lot number and “Use

by” date are printed on the barcode label.

All cassettes can be loaded into any of the imager’s three supply

slots. By default, the printer ejects completed prints to the

corresponding receive tray.

CAUTION

or other unapproved media as damage, improper operation, or malfunction may

result. For information about the approved Codonics media types and sizes, and how

to order cassettes, refer to “Ordering Media” on page 3-10.

CAUTION

The cassette’s barcode information is essential for ensuring diagnostic image quality.

Compromising the cassette in any way jeopardizes the quality and reliability of the

imager.

3-2 Media Handling and Storage

Use only Codonics media. Do not use plain paper, office transparencies,

Do not refill a cassette. Do not tamper with or remove the barcode label.

Page 60

Viewing the Status of a Supply Slot

The Status screen shows the status of each supply slot, including

media type, size, and number of sheets remaining.

Supply CMY

1: 8X10 DV Blue 53

2: A CV Paper 100

3: 14X17 DV Blue 76

Status OK

X

3 sheets queued

Media Handling and Storage

Horizon Starter Manual 3-3

Page 61

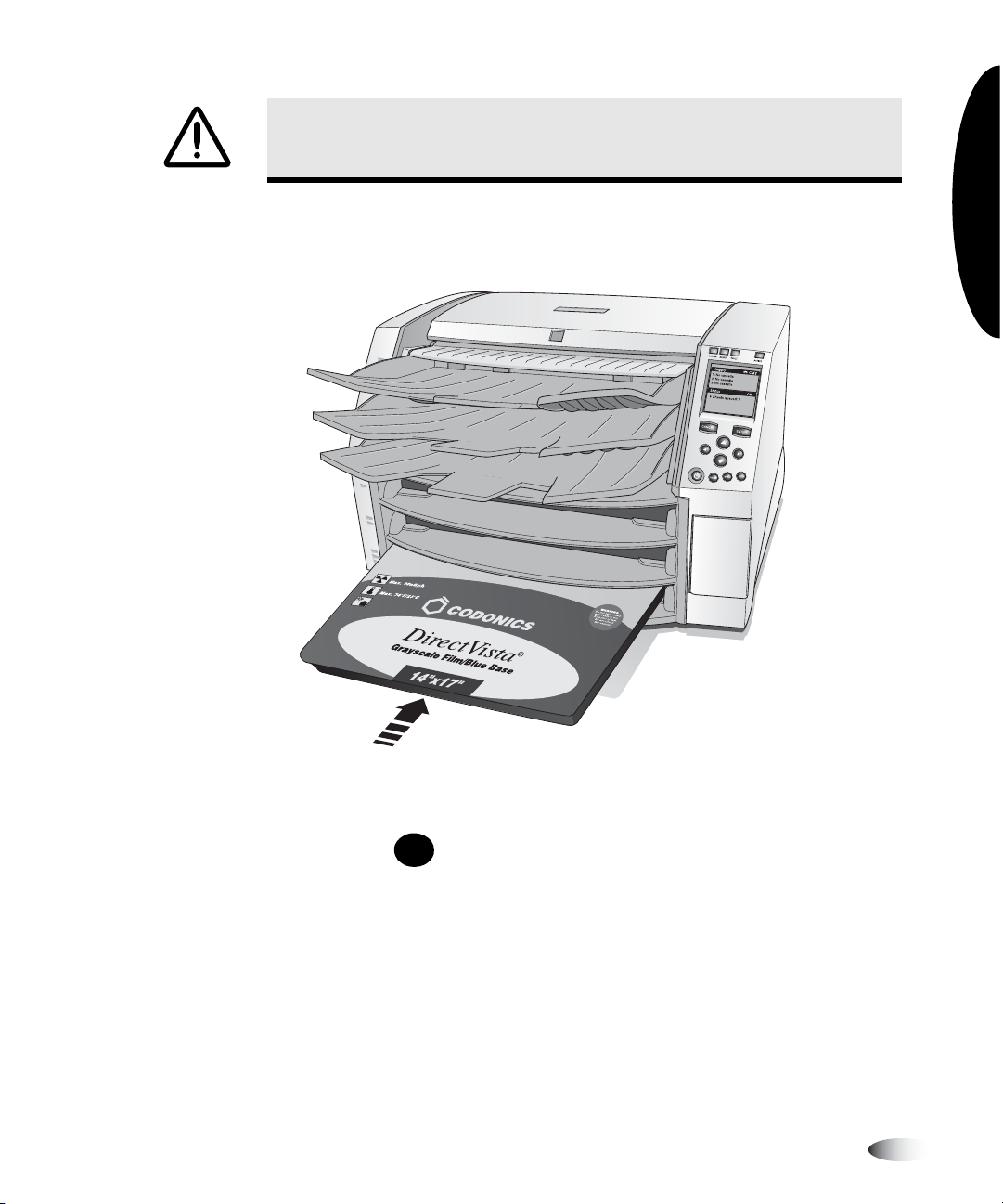

Inserting or Changing Cassettes

8

To change a

supply

cassette

1. Press the key, and wait until the

PAUSE

ONLINE

indicator turns off

and the Status screen indicates that the imager is paused.

If a sheet is currently being printed, the sheet will complete

printing before the imager enters the Paused state. While

paused, the imager can still receive and process jobs.

CAUTION

could affect the image quality of the printed sheet or cause a jam. Always pause the

imager first.

Do not remove or insert a cassette while a sheet is being printed, or you

2. Remove the cassette if one is currently in the supply slot you

want to use—lift the cassette up slightly and slide it from the

supply slot.

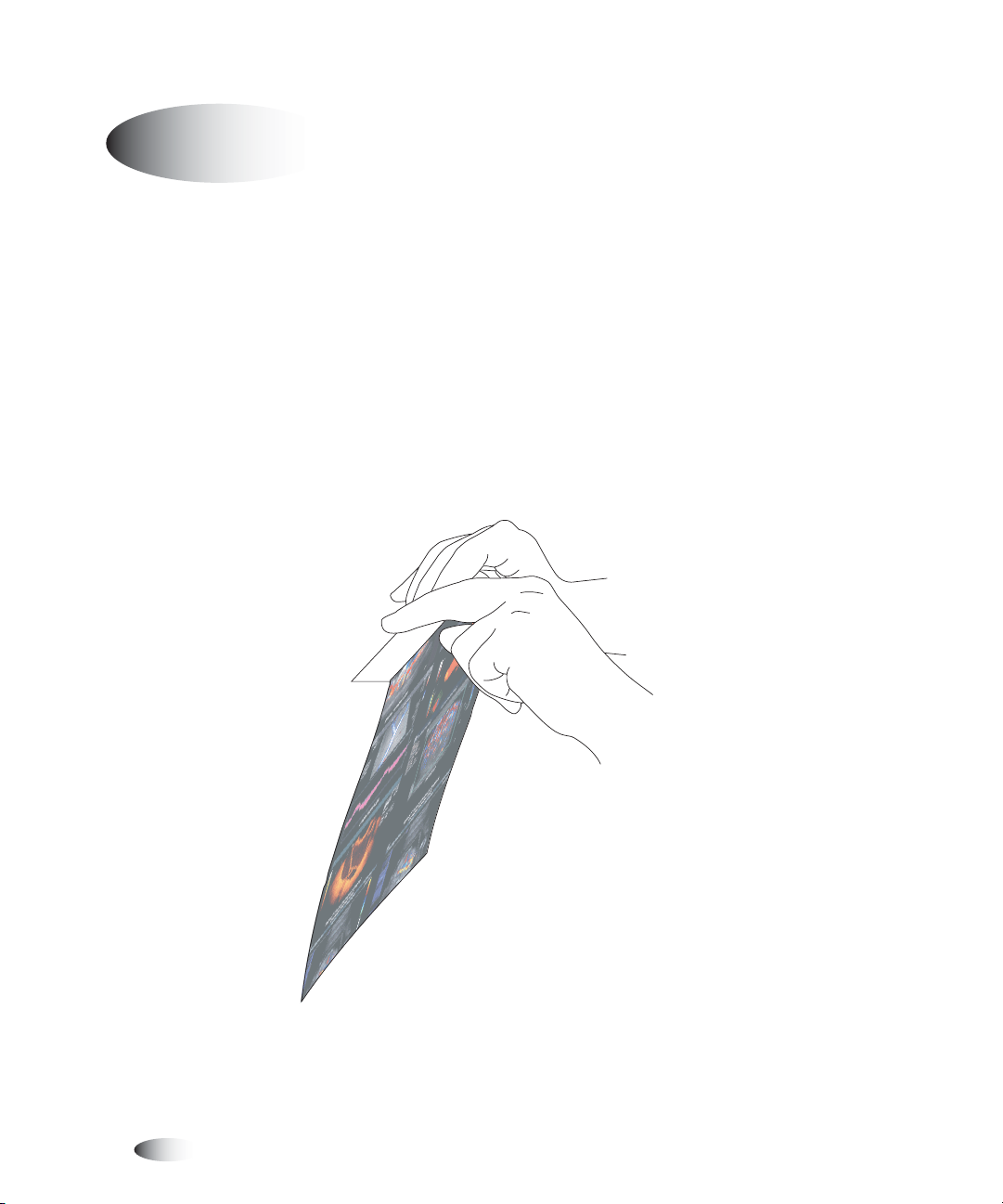

3. If inserting a new cassette, remove the clear wrapping from the

cassette. Use the pull strip to tear the clear wrapping.

Seam

3-4 Media Handling and Storage

Page 62

CAUTION

and other contaminants. Always hold and store the cassette with the open side up to

prevent the sheets from falling out.

Do not remove the printed cassette cover; it protects the media from dust

4. Insert the new cassette into the supply slot, with the cassette

label facing you and the barcode label to the left.

Media Handling and Storage

5. Slide the cassette into the supply slot until you feel the cassette

settle into the retaining detent.

6. Press the key to resume printing.

PAUSE

Horizon Starter Manual 3-5

Page 63

Handling and Storing Media

For best results, refer to the storage and handling instructions that

come with the media.

Break-Off Leaders (ChromaVista Only)

8

To remove the

break-off

leader

ChromaVista

and bottom to allow edge-to-edge printing:

On a completed print, bend the leader at the perforation line

fully one way, then fully the other way. The leader will break

away from the sheet.

color paper and film have break-off leaders at the top

3-6 Media Handling and Storage

Page 64

Changing the Ribbon (ChromaVista)

When the ribbon on the ribbon spools has been consumed and

needs to be changed:

•

The imager enters the Alert state.

•

A message indicating that a new ribbon needs to be loaded is

displayed in the Status window.

Media Handling and Storage

8

To change the

color ribbon

1. Press the key.

MENU

The Main Menu displays.

2. Select the

Load/Remove Ribbon

menu option.

After selecting this option:

•

The imager pauses, first completing the sheet if one is

currently printing.

•

The ribbon supply spool inside the imager rises.

•

After up to a minute to allow the thermal print head to cool,

the imager cover pops partially open.

3. Lift the cover all the way open, and locate the ribbon spools.

WARNING With the imager cover open, touch only those internal components

that are colored green (except for the pick tires, refer to the figure on page xx).

Remove rings, ties, jewelry, and other items, and tie back hair, so that they do

not fall into or get caught in the imager.

Horizon Starter Manual 3-7

Page 65

4. Remove the old ribbon, as shown in the following figure.

Spring-loaded

spindles

5. Load the new ribbon, as shown in the following figure.

Spring-loaded

spindles

3-8 Media Handling and Storage

Black (Supply)

Gray (Take-up)

Page 66

6. To take up any ribbon slack, rotate the top of the take-up spool’s

wheel (that is, the front wheel) towards the back of the imager,

as shown in the following figure.

Supply spool wheel

(Do not use this wheel)

Take-up spool wheel

Rotate take-up

spool toward

back

Media Handling and Storage

3

NOTE:

Do not use the supply spool (rear) wheel to take up ribbon slack. This would cause

spent ribbon to be reused.

7. When you are finished changing the ribbon, close the top cover.

After several seconds, the imager will leave the paused state and

resume printing.

CAUTION

using that ribbon. If you are required to ensure patient confidentiality and privacy, the

ribbon should be destroyed.

Used ribbon retains the negative of the color images that were printed

Horizon Starter Manual 3-9

Page 67

Ordering Media

The Horizon imager supports a variety of paper and film for both

grayscale and color prints. Not all Horizon imager configurations

support all media types and sizes. If your Horizon imager does not

support the media type and/or size you want to use, contact your

Codonics representative.

The following table shows the currently supported media size/type

combinations:

Media Type Size Catalog Number

3

DirectVista Paper A (8.5 x 11 in.)

A4 (210 x 297 mm)

11 x 14 in. (28 x 35 cm)

14 x 17 in. (35 x 43 cm)

DirectVista Film Blue 8 x 10 in.

11 x 14 in.

14 x 17 in.

DirectVista Film Clear 8 x 10 in.

11 x 14 in.

14 x 17 in.

ChromaVista Paper A

A4

ChromaVista Film A

A4

NOTE:

Some of the media type/size combinations listed here may not currently be

available.

A-DVP

A4-DVP

1114-DVP

1417-DVP

810-DVB

1114-DVB

1417-DVB

810-DVC

1114-DVC

1417-DVC

A-CVP

A4-CVP

A-CVC

A4-CVC

3-10 Media Handling and Storage

Page 68

4

Printing from DICOM

Applications

The printing procedures covered in this chapter assume that the

DICOM support option is installed in your Horizon imager and that

you are sending print jobs from a DICOM application.

NOTE:

If you are running DICOM Lite on the imager and see connection errors at the

3

Introduction to DICOM

console or workstation from which you are sending print jobs, you may require full DICOM.

Contact Codonics technical support for assistance (refer to “Contacting Technical Support”

on page 9-20).

DICOM (Digital Imaging and COmmunications in Medicine) is the

industry standard for transferring images and other medical

information. The Horizon imager is DICOM Print Service

Class-compliant.

Printing from DICOM

Applications

For more information about DICOM, visit the official web site—

medical.nema.org

of the Radiological Society of North America, Inc. (

. Additional information is available at the web site

www.rsna.org

Horizon Starter Manual 4-1

).

Page 69

DICOM Conformance Statement

The Horizon imager conformance statement is available on the

Codonics web site (

www.codonics.com

). It can also be mailed or

faxed to you on request.

Configuring the DICOM Application