®

™

EP-1000

Series

Instant Dry

Imager

User’s Manual

Codonics® Catalog Number 1000-MNLU

December 9, 2004

Version 1.1

Codonics, Inc.

17991 Englewood Drive

Middleburg Heights, OH 44130 USA

440-243-1198 Phone

440-243-1334 Fax

Email info@codonics.com

www.codonics.com

$PQZSJHIUªCZ$PEPOJDT*OD"MMSJHIUTSFTFSWFEXPSMEXJEF 1SJOUFEJOUIF

64"1BSU/VNCFS

/PQBSUPGUIJTEPDVNFOU NB ZCFDPQJFEPSSFQSPEVDFEJOBOZGPSNCZBOZNFBOT

XJUIPVUQSJPSXSJUUFODPOTFOUPG$PEPOJDT*OD &OHMFXPPE %S

.JEEMFCVSH )FJHIUT0IJP 64"

"MUIPVHIFWFSZFGGPSUIBTCFFONBEFUPFOTVSFUIFBDDVSBDZPGUIJTEPDVNFOU

$PEPOJDT*ODBTTVNFTOPSFTQPOTJCJMJUZGPSBOZFSSPSTUIBUNBZBQQFBS

$PEPOJDT*ODNBLFTOPDPNNJUNFOUUPVQEBUFOPSUPLFFQDVSSFOUUIF

JOGPSNBUJPODPOUBJOFEJOUIJTEPDVNFOU

$PEPOJDTUIF$PEPOJDTMPHPi8FCSJOHUIFGVUVSFJOUPGPDVTwBOE$ISPNB7JTUB

BSFSFHJTUFSFEUSBEFNBSLTBOE&1.FEJDBM$PMPS.BUDIJOHBOE.$.BSF

USBEFNBSLTPG$PEPOJDT *OD

8JOEPXTBOE8JOEPXT/5BSFSFHJTUFSFEUSBEFNBSLTPG.JDSPTPGU$PSQPSBUJPO

"MMPUIFSSFHJTUFSFEBOEVOSFHJTUFSFEUSBEFNBSLTBSFUIFQSPQFSUZPGUIFJS

SFTQFDUJWFPXOFST

&VSPQFBO"VUIPSJ[FE3FQSFTFOUBUJWF

$&QBSUOFS6

&TEPPSOMBBO

%#.BBSO

5IF/FUIFSMBOET

5FM

Contents

Preface

Manual Conventions ..................................................................................... vii

Bulleted Lists.......................................................................................... vii

Numbered Steps .................................................................................... vii

Display Panel Indicator Lights and Buttons ........................................... viii

Notes and Tips ...................................................................................... viii

Cautions and Warnings ......................................................................... viii

Technical Assistance ..................................................................................... ix

Warnings and Limitations of Use ................................................................... ix

Potential for Radio and Television Interference ....................................... ix

EP-1000 Warnings ................................................................................... x

EP-1000 Precautions ............................................................................. xii

Contents

Never Insert Any Foreign Object into the Imager............................. xii

Protect Against Dew Formation ....................................................... xii

Operating Temperature and Humidity Ranges ................................ xii

Unsuitable Locations ....................................................................... xii

Unsuitable Materials for the Imager ................................................ xiii

Thermal Print Head Abrasion ......................................................... xiii

Product Cautions ............................................................................ xiii

Packaging ....................................................................................... xiii

Labeling................................................................................................. xiv

Limitations of Use................................................................................... xv

Overview.......................................................................................... xv

Media ............................................................................................... xv

Grayscale Management................................................................... xv

Error Handling.................................................................................. xv

Hardware Variations ........................................................................ xv

EP-1000 Instant Dry Imager User’s Manual

iii

EP-1000 Series Disposal ...................................................................... xvi

EP-1000 Series Specifications ................................................................... xvii

Chapter 1: Introduction

Chapter 2: Setting Up the EP-1000

Finding a Location for the EP-1000 ............................................................ 2-2

Unpacking the EP-1000.............................................................................. 2-3

Loading the Ribbon Cartridge..................................................................... 2-5

Connecting a Parallel Cable ....................................................................... 2-9

Connecting a USB Cable.......................................................................... 2-10

Loading Paper .......................................................................................... 2-11

Handling Paper................................................................................... 2-11

Storing Paper ..................................................................................... 2-11

Loading the Paper Tray ...................................................................... 2-12

Installing the Dust Covers......................................................................... 2-16

About Imager Initialization ........................................................................ 2-17

Making a Test Print................................................................................... 2-17

Chapter 3: Operating the EP-1000

Indicator Lights and Control Buttons .......................................................... 3-1

Canceling Multiple Copy Printing................................................................ 3-3

Chapter 4: Maintenance

Properly Maintaining the EP-1000 ............................................................................... 4-1

Cleaning the EP-1000...................................................................................................... 4-2

iv

Contents

Chapter 5: Troubleshooting

Interpreting the Indicator Lights .................................................................. 5-1

Troubleshooting Common Problems .......................................................... 5-3

Clearing a Paper Jam ................................................................................. 5-6

Clearing a Paper Jam from the Ribbon Cartridge Area ....................... 5-7

Clearing a Paper Jam from the Front Area........................................... 5-9

Clearing a Paper Jam from the Back Area ......................................... 5-10

Repairing a Torn Ribbon .......................................................................... 5-11

Cleaning the Thermal Print Head ............................................................. 5-12

Appendix A: Hazardous Material Information

Materials of Construction ............................................................................ A-1

Manufacturing ............................................................................................. A-2

Contents

EP

-1000

Instant Dry Imager User’s Manual

v

Preface

Manual Conventions

8

To unpack the

Imager

Bulleted Lists

Bullets are used to display a list of nonprocedural items. For

example:

The control panel contains:

•

A display panel

•

Keys

•

Indicators

Numbered Steps

The

8

in a procedure are numbered. For example:

1. Open the shipping carton.

2. Carefully remove the top foam with the accessories.

3. Lift the imager out of the carton.

icon indicates the beginning of a procedure. The steps

Preface

EP-1000 Instant Dry Imager User’s Manual

vii

Display Panel Indicator Lights and Buttons

Display panel indicator light and button names are in bold.

Notes and Tips

Notes contain additional information related to a topic or

procedure. For example:

3

NOTE:

Save the packaging in case you need to ship the EP-1000.

Cautions and Warnings

Cautions alert you to actions or situations that could cause harm to

equipment or data. For example:

CAUTION

scratches on your prints.

Warnings alert you to actions or situations that could result in

personal injury. For example:

WARNING Before you begin cleaning the EP-1000, turn off the EP-1000 and

unplug it.

Touching the dye patches could contaminate the ribbon, resulting in

viii

Preface

Technical Assistance

For technical assistance with Codonics products, call the Codonics

“On Call” Technical Support System at one of the following

numbers:

Phone: 440-243-1198

Toll Free: 800-444-1198

The “On Call” Technical Support System provides for around-theclock availability of qualified technical support personnel.

You can also e-mail Technical Support at

support@codonics.com

Warnings and Limitations of Use

Potential for Radio and Television

Interference

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radiofrequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of the equipment

in a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at his or

her own expense.

.

Preface

If your imager does cause interference to radio or television

reception, you are encouraged to try to correct the interference by

one or more of the following measures:

EP

-1000

Instant Dry Imager User’s Manual

ix

•

Reorient the receiving antenna.

•

Relocate the imager with respect to the receiver.

•

Move the imager away from the receiver.

If necessary, you should consult your sales representative or an

experienced radio/television technician for additional suggestions.

You may find the following booklet prepared by the

Communications Commission helpful:

Resolve Radio-TV Interference Problems

How to Identify and

. This booklet is available

Federal

from the U.S. Government Printing Office, Washington, D.C. 20402,

Stock No. 004-000-00345-4.

EP-1000 Warnings

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

The lightning flash with arrowhead symbol, within an equilateral

triangle, is intended to alert the user to the presence of uninsulated

“dangerous voltage” within the product’s enclosure that may be of

sufficient magnitude to constitute a risk of electric shock.

The exclamation point within an equilateral triangle is intended to

alert the user to the presence of important operating and

maintenance (servicing) instructions in the literature accompanying

this imager.

•

NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

•

THIS APPARATUS MUST BE EARTHED.

•

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS

IMAGER TO RAIN OR MOISTURE.

x

Preface

•

EQUIPMENT IS NOT TO BE USED AS A COMPONENT OF A LIFE

SUPPORT SYSTEM. Life support devices or systems are devices

or systems which support or sustain life, and whose failure to

perform, can be reasonably expected to result in a significant

injury or death to a person. A critical component is any

component of a life support device or system whose failure to

perform can be reasonably expected to cause the failure of the

life support device or system, or to affect its safety or

effectiveness.

•

EQUIPMENT IS NOT TO BE USED IN A PATIENT VICINITY. The

EP-1000 Series Imagers must be located at least 1.83 m (6 ft) from

the patient treatment or examination area (bed, exam table, etc.)

at all times to avoid inadvertent patient contact with the

apparatus.

•

EQUIPMENT IS TO BE USED AS SPECIFIED UNDER THE TOPIC

“EP-1000 PRECAUTIONS.”

•

ALWAYS UNPLUG THE ENTIRE SYSTEM FROM THE POWER

SOURCE PRIOR TO CLEANING THE THERMAL PRINT HEAD.

EP

-1000

Instant Dry Imager User’s Manual

xi

Preface

EP-1000 Precautions

Never Insert Any Foreign Object into the Imager

Foreign objects of any kind inserted into this imager constitute a

safety hazard and can cause extensive damage. The imager will not

print on materials not specifically designed for it. Feeding standard

office overhead transparency material into the imager will not work

and can damage the print mechanism.

Protect Against Dew Formation

In extremely cold regions, if the imager is moved quickly from an

extremely cold place to a warmer one, dew is likely to form. If dew

has formed, printing is not possible.

Operating Temperature and Humidity Ranges

The imager’s operating intake air temperature range is 59–86°F

(15–30°C), and the operating humidity range is 30–85%

noncondensing.

Unsuitable Locations

Do not place imager in high humidity or high dust areas. Airborne

dirt particles can cause image quality problems. Avoid placing the

imager in areas where ventilation ducts, open doors, or frequent

passers-by might expose the imager and media to high levels of

debris.

Avoid hot-springs areas where hydrogen sulfide and acidic ions are

likely to be generated. Avoid places where imager is likely to

contact oily fumes and vapors. Avoid direct sunlight.

xii

Preface

Unsuitable Materials for the Imager

Many plastic components are used in the imager’s construction.

Coat flecking and deformation is likely to occur if the imager is

wiped with chemical dusters, benzene, thinners, insecticides or

other solvents. Rubber and PVC materials left in contact with the

imager for extended times will cause damage. Never use

petroleum-based solutions or abrasive cleaners.

Thermal Print Head Abrasion

The thermal print head will wear. When it is abraded, it becomes

difficult to print fine details. In such a case it is necessary to replace

the thermal print head. Contact your service representative for

assistance.

Product Cautions

This product will not cause any special health or safety hazard

when used as intended. Spent media can be disposed in accordance

with local, state, or federal regulations.

Packaging

Use the original packaging when shipment of the product is

necessary. This packaging has been designed to minimize possible

damage during shipment.

Preface

EP

-1000

Instant Dry Imager User’s Manual

xiii

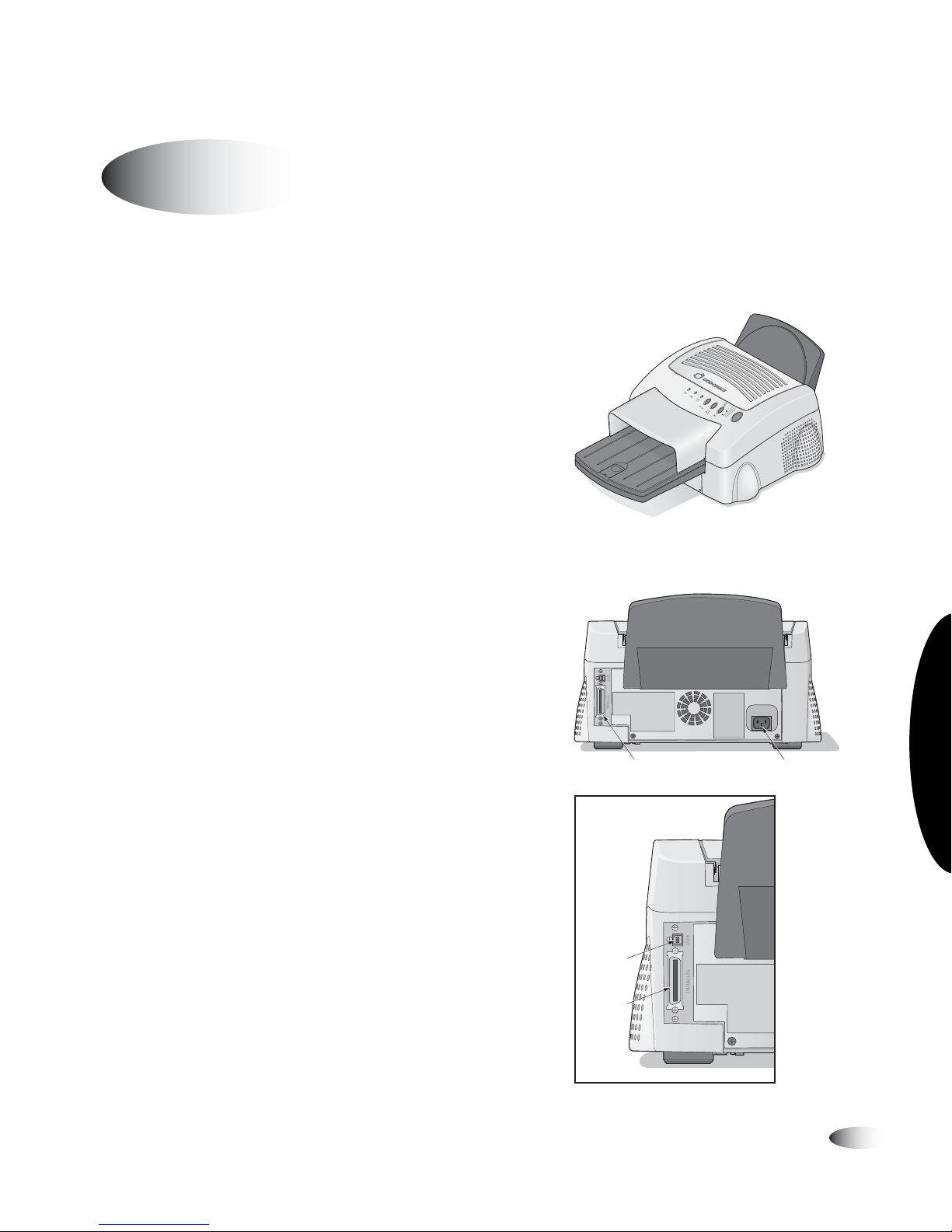

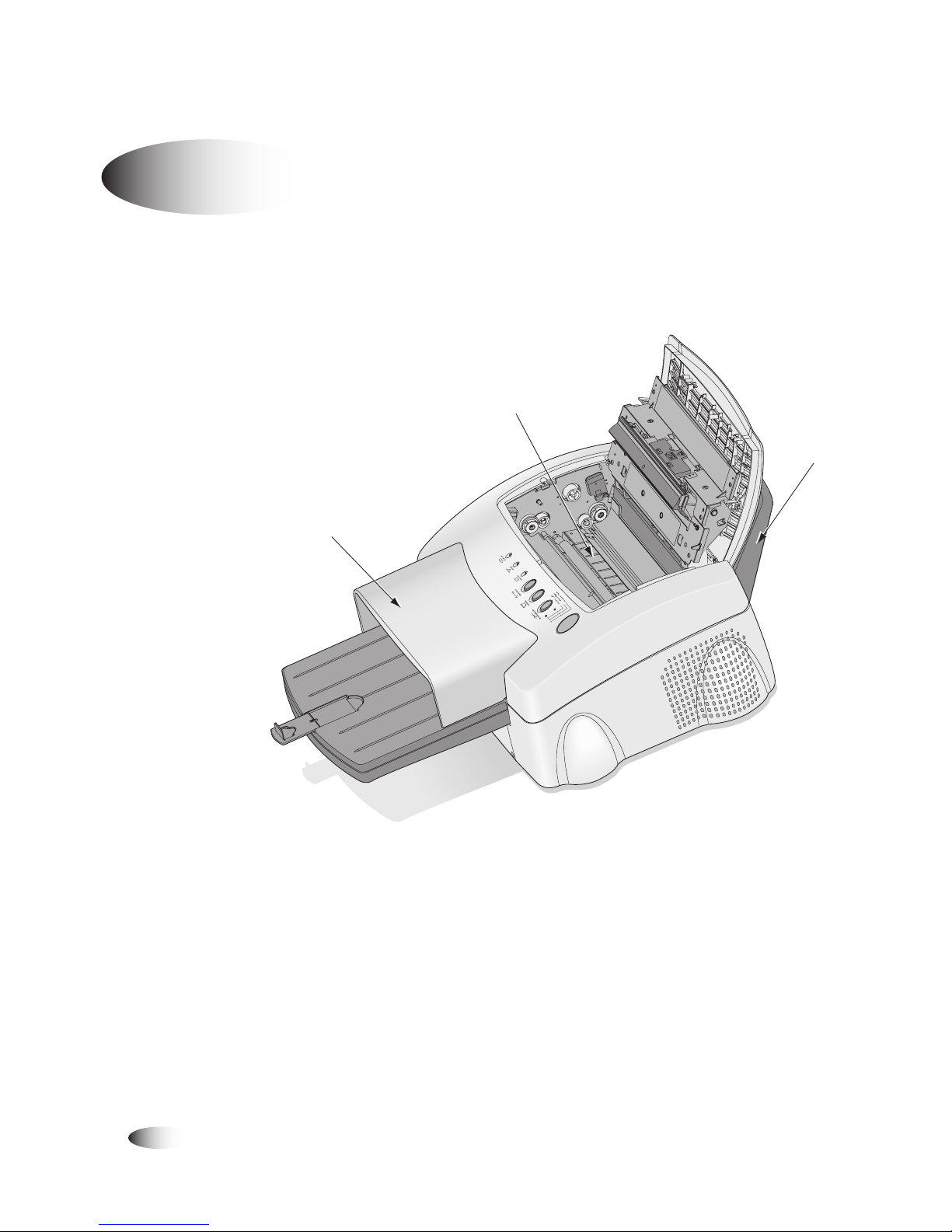

Labeling

The locations of the EP-1000 labels are shown in the following

illustration.

CODONICS, INC.

17991 ENGLEWOOD DR.

MIDDLEBURG HTS., OH 44130 U.S.A.

MADE IN THE U.S.A.

100-120V~, 50/ 60Hz, 2.9A

CAUTION: BEFORE CONNECTING READ INSTRUCTIONS

LISTED

I.T.E.

9C72

Patents Pending, All Rights Reserved

CAUTION

RISK OF ELECTRIC SHOCK

Sequential serial

number

Configuration code

(version)

DO NOT OPEN

Serial label

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference

(2) This device must accept any interference

including interference that may cause

received,

undesired operation.

This Class A digital apparatus complies with

Canadian ICES-003.

Cet appareil numerique de la classe A est conforme

a la norme NMB-003 du Canada.

MODEL / MODLE EP-1000

COLOR / DRY MEDICAL IMAGER

Date of manufacture

(e.g., "2004-08")

xiv

Preface

Limitations of Use

Overview

This section describes imager and media usage considerations that

can affect output results and quality.

Media

•

Media variations between different production lots may produce

subtle differences in image quality.

•

Printed images that experience prolonged exposure to heat,

sunlight, or ultraviolet light may degrade in image quality.

Precautions should be used to avoid prolonged direct exposure.

Grayscale Management

Grayscale image management filters—including gamma, contrast,

and film type—are intended to compensate for differences that may

occur between image acquisition and image printing. These filters

allow the user to accurately render the final printed image. Care

should be used when applying these filters to avoid over

compensation.

Error Handling

The imager will discard invalid, unsupported, and corrupt images

and not print the page.

Hardware Variations

Components used in the imager may vary causing differences in

image quality. The thermal process of producing a print utilizes

many components that are calibrated to provide consistency

between imagers. All imagers contain subtle differences that can

cause print variations. These differences usually apply to thermal

print head calibration. Other factors such as age, usage, heat,

mechanical wear, and shipping can affect image quality.

EP

-1000

Instant Dry Imager User’s Manual

xv

Preface

EP-1000 Series Disposal

Disposal of this product shall be in accordance with all applicable

laws and regulations in effect at the locality at the time of disposal.

For further information, refer to Appendix A.

xvi

Preface

EP-1000 Series Specifications

Print Technology: Dye Sublimation.

Spatial Resolution: 314 dpi (12.36 pixels/mm).

Color Resolution: 16.7 million colors. 256 levels each of

cyan, magenta, and yellow.

Density Range: Up to 2.55 OD Dmax.

Imager and Cassette

Color Registration: Less than 0.1 mm average.

Interfaces: Centronics-type 36-pin connector

(IEEE 1284) and USB 1.1.

Compatibility: Drivers available for Windows 2000

and XP.

Image Correction: Gamma, contrast, and Medical Color

Matching™ (MCM™) selectable in drivers.

Memory: 23 MB RAM memory, three image planes

of 2508 x 3134 pixels.

Cassettes: One dual A or A4 media cassette included

with imager, 50-sheet capacity.

Media Sizes: A or A4 ChromaVista

®

paper. CMY Donor

ribbon.

Power: 120 V~, 50/60 Hz; 2.7 A/210 W (printing),

0.35 A/21 W (idle), 30-130 W (head

preheating)

Dimensions and Weight: Height:10.75 in. (27.2 cm).

Width:17.0 in. (43.3 cm).

Depth:28.5 in. (72.0 cm).

Weight:28.7 lbs (13 kg).

Back Panel

po

w

e

r

fa

ul

t

m

e

d

i

a

O

n

e

NLI

t

w

U

o

N

r

S

k

E

B

p

a

r

a

l

l

e

l

P

R

I

N

T

I

N

T

E

R

F

A

C

E

Preface

Power cordConnectors

Regulatory: US FDA 510(k), UL, FCC.

Environment: Operating

Temperature: 63–86°F (17–30°C)

Storage: -8–123°F

Operating

Humidity: 30-80% R.H.

Use Environment: The imager must be located at least

1.83 m (6 ft) from the patient treatment or

examination area (bed, exam table, etc.) at

all times to avoid inadvertent patient

contact with the apparatus.

(-22.2–51.6°C)

EP

USB port

Parallel port

-1000

Instant Dry Imager User’s Manual

xvii

1

Introduction

The Codonics EP-1000 Instant Dry Imager is a thermal dye-difusion

device with superior printing speed. It has a resolution of 314 pixels

per inch and prints a three-color page in about 90 seconds. Printed

images are high-contrast and long-lasting.

The EP-1000 is a Medical Hardcopy Device as defined in

21CFR892.2040. It is suitable for use with Medical Ultrasound,

Nuclear, MRI (magnetic resonance imaging), CT (computed

tomography), and other color imaging modalities.

The standard EP-1000 comes equipped with industry-standard

Parallel (IEEE 1284) and Universal Serial Bus (USB 1.1) interfaces.

Print drivers are available for Windows 2000 and Windows XP

operating systems. An optional Ethernet converter is available to

enable printing over a local area network (LAN), although custom

drivers may be needed. See your Codonics sales representative for

more information.

Introduction

The EP-1000 accepts A- or A4-size

covers a large imageable area:

•

A-size paper: 2508 pixels (8.0 in.; 203.2 mm) wide by 2954 pixels

(9.4 in.; 239.3 mm) long

•

A4-size paper: 2508 pixels (8.0 in.; 203.2 mm) wide by

3134 pixels (10 in.; 253.9 mm) long

ChromaVista

EP-1000 Instant Dry Imager User’s Manual

color paper, and

1-1

EP-1000 Instant Dry Imager

power

fa

ul

t

m

e

di

a

O

NLINE

n

e

tw

U

o

r

S

k

B

p

a

r

a

l

l

e

l

P

RINT

INTERFA

CE

EP-1000 Back Panel

1-2

Introduction

Power cordConnectors

2

Setting Up the EP-1000

This section explains how to set up the EP-1000. The steps are:

1. Finding an appropriate location for the EP-1000

2. Unpacking the EP-1000

3. Loading the ribbon cartridge

4. Connecting the imager cable

5. Connecting the power cord and powering on the EP-1000

6. Loading paper

7. Installing the dust covers

8. Making a test print

The software for the EP-1000, which enables you to take full

advantage of the EP-1000’s capabilities, is on the CD-ROM that ships

with the EP-1000. After you set up the EP-1000, you should install

the appropriate print driver.

Special drivers may be provided to interface to certain OEM

equipment. Contact your Codonics sales representative or Codonics

Technical Support.

EP-1000 Instant Dry Imager User’s Manual

2-1

Setting Up the EP-1000

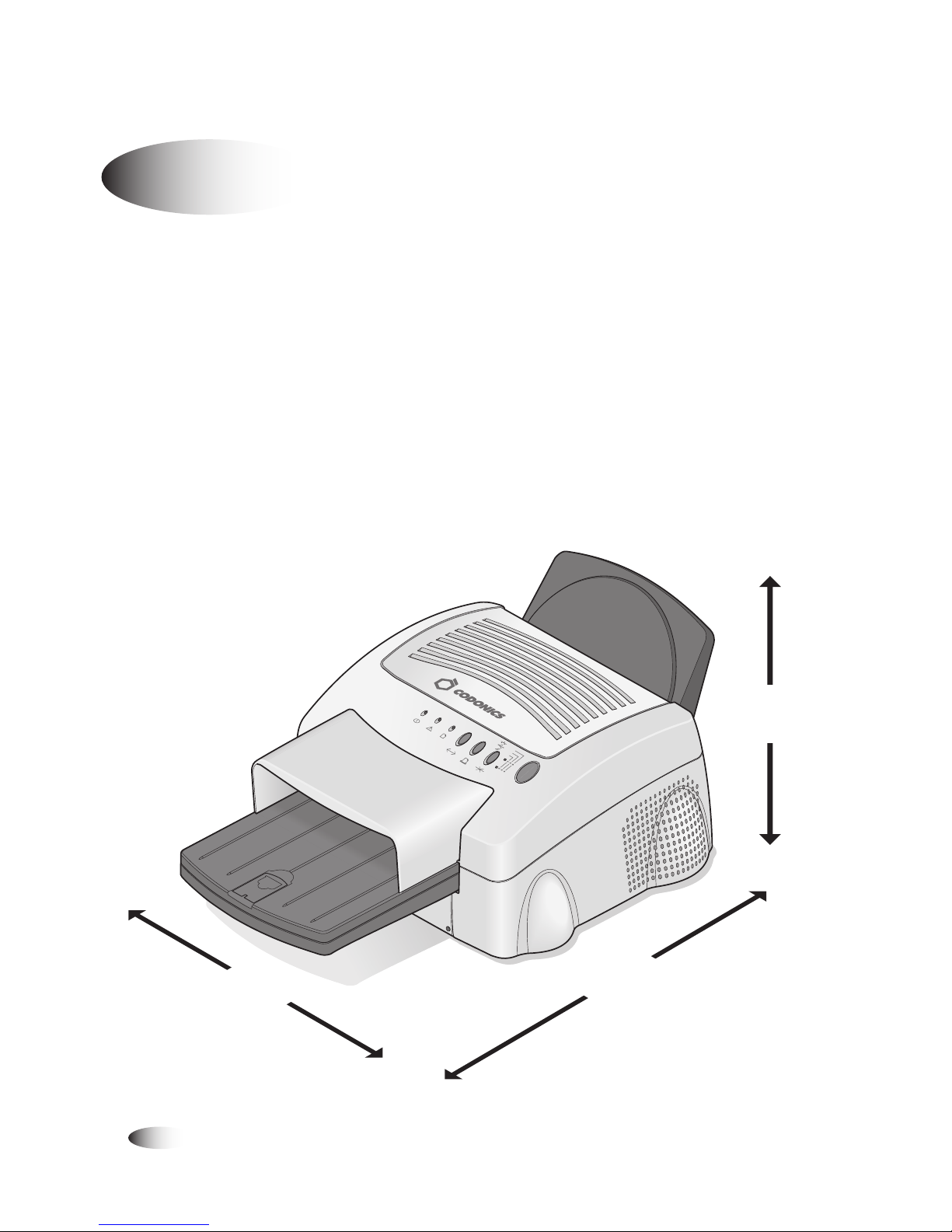

Finding a Location for the EP-1000

Keep the following guidelines in mind when selecting a site for the

EP-1000.

•

Allow 2 in. (5 cm) on the left and right sides, and 15.8 in. (40 cm)

above for air flow and cooling. The back of the EP-1000 may be

placed flush against a wall.

•

Avoid placing the EP-1000 in areas where ventilation ducts, open

doors, or frequent passers-by might expose it to debris. Airborne

dirt particles can cause image quality problems.

The space requirements for the EP-1000 are shown below.

2-2

21.0 in.

(53.4 cm)

Introduction

powe

r

f

a

u

lt

m

e

di

a

O

NLINE

n

e

tw

U

o

rk

S

B

p

a

r

a

ll

e

l

PRINT

INTERFA

CE

Allow 15.8 in.

(40 cm) to open

the top door

Allow 32.3 in. (82 cm)

to remove the paper tray

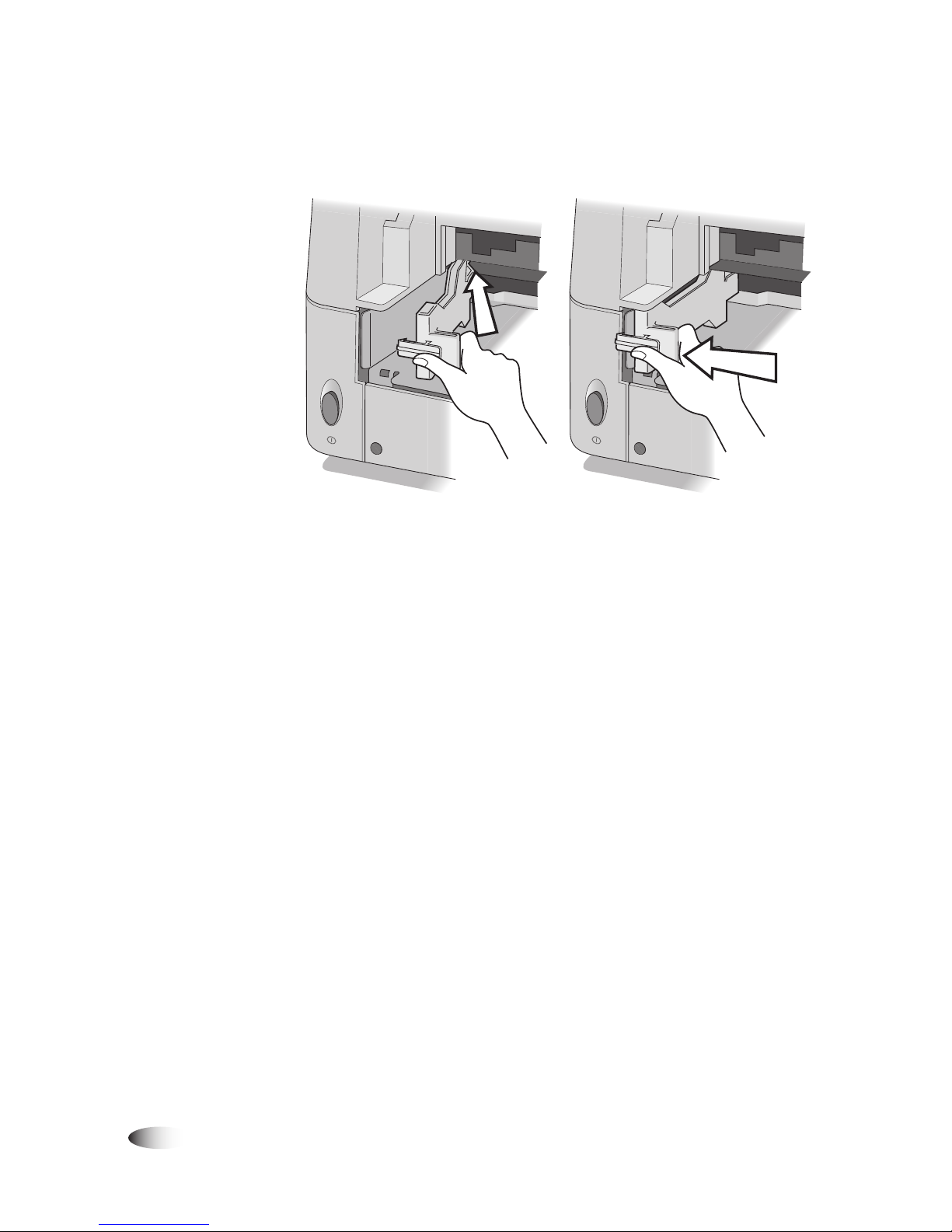

Unpacking the EP-1000

8

To unpack the

Imager

3

1. Open the shipping carton.

2. Carefully remove the top foam with the accessories.

3. Lift the imager out of the carton.

4. Remove the EP-1000 from the plastic sheet, and place the

EP-1000 at the desired location.

NOTE:

Save the packaging in case you need to ship the EP-1000.

5. Remove the shipping inserts on the paper tray inserting slot.

Setting Up the EP-1000

POWER

Hold the tab

EP

POWER

Pull the shipping insert

to the center

-1000

Instant Dry Imager User’s Manual

2-3

3

NOTE:

When you do not use the EP-1000 for a long period, make sure to attach the shipping

inserts on the slot, as shown below, or the rollers may be deformed.

POWER

Push toward the inner part Hook the shipping

POWER

insert on the printer

2-4

Introduction

Loading the Ribbon Cartridge

The ribbon cartridge fits easily in the EP-1000. There is only one

way to correctly load the ribbon cartridge.

8

To load the

ribbon

cartridge

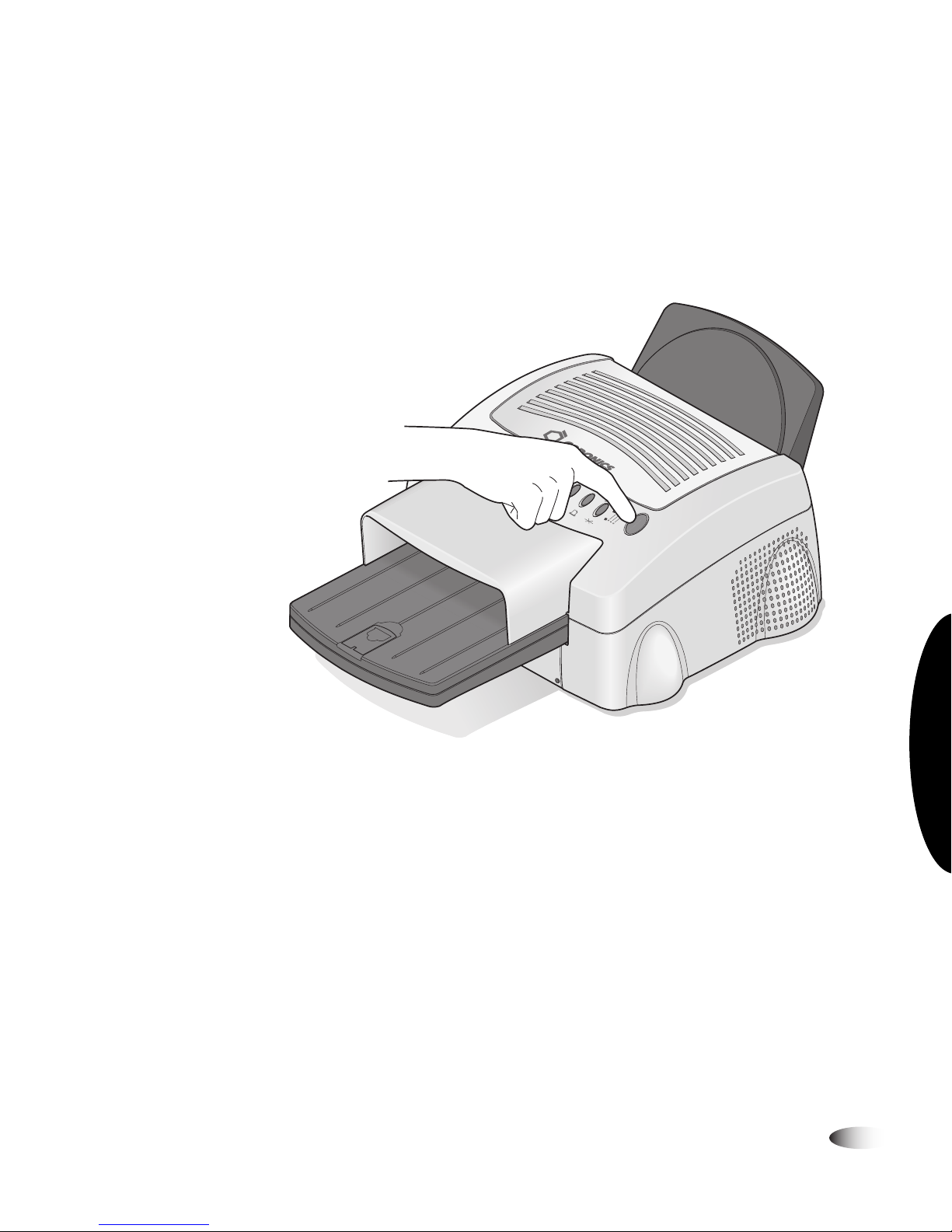

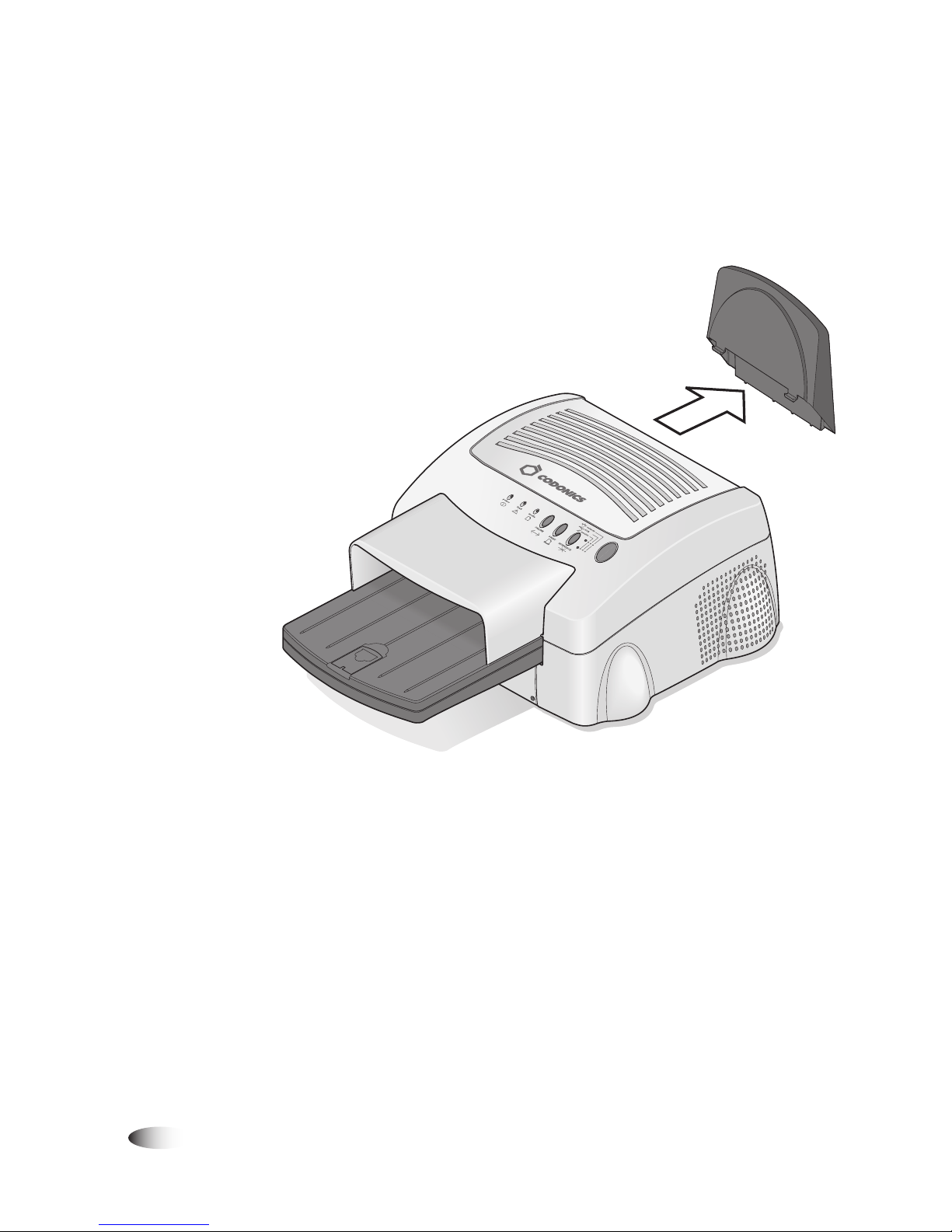

1. Press the

Open

button to open the top cover.

power

fa

ul

t

m

e

di

a

O

NLINE

n

e

tw

U

o

rk

S

B

p

a

r

a

ll

e

l

P

RINT

INTERFA

CE

Setting Up the EP-1000

EP

-1000

Instant Dry Imager User’s Manual

2-5

2. If necessary, push the old ribbon cartridge to the left and lift it

up to remove it.

2-6

Introduction

CAUTION

Images remain on the ribbon after printing. If you are working with

confidential documents, you may need to consider alternate ways of disposing of the

ribbon to maintain security.

3. Remove the old ribbon from the ribbon carrier.

3

NOTE:

Do not discard the ribbon carrier.

4. Remove the new ribbon from its packaging.

CAUTION

scratches or artifacts on your prints.

Touching the dye patches could contaminate the ribbon, resulting in

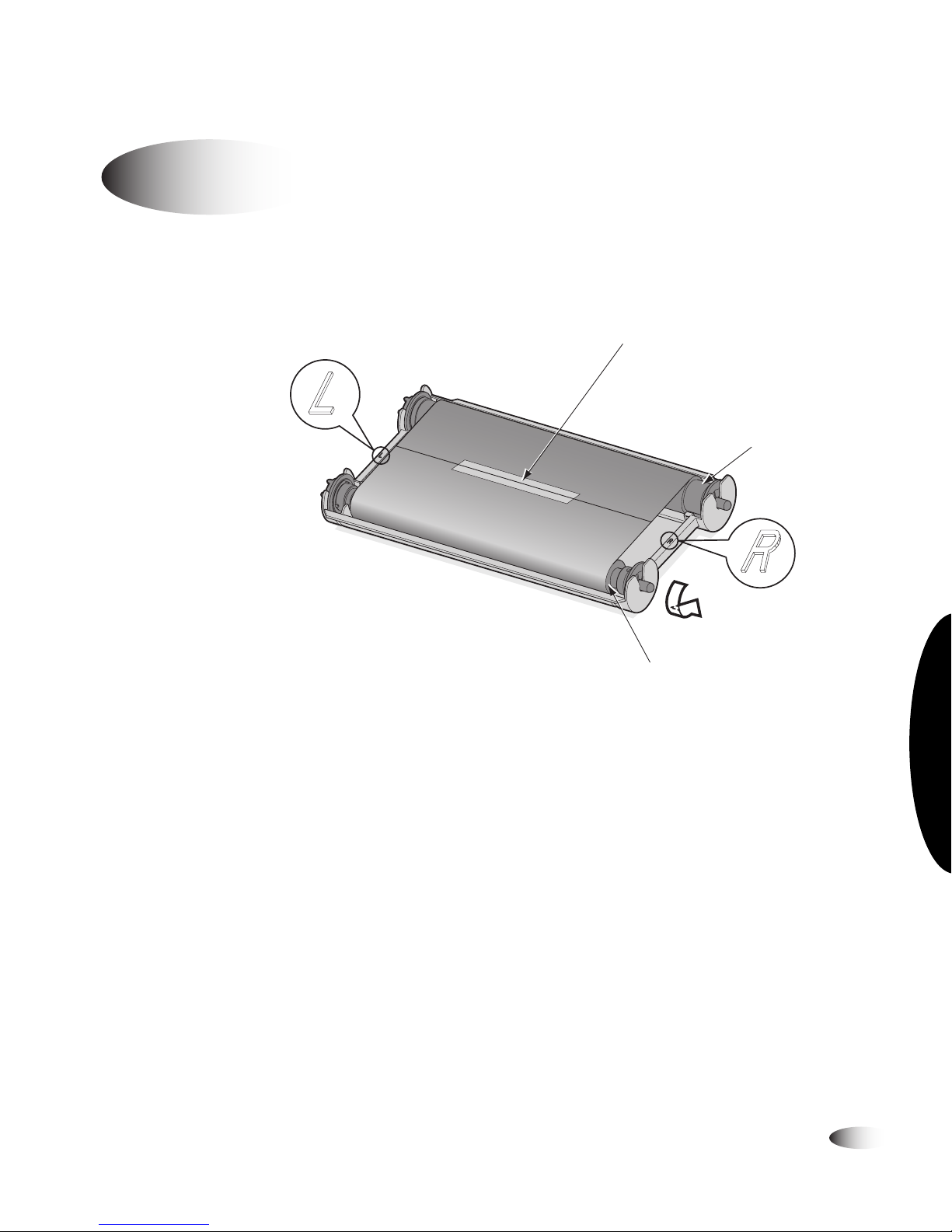

5. Set the new ribbon on the ribbon carrier as shown below.

Spool

Ribbon

Setting Up the EP-1000

EP

Handle

Ribbon carrier

-1000

Instant Dry Imager User’s Manual

2-7

6. Grasp the ribbon cartridge by the handle, and slide the spool

onto the two hubs on the left side.

Hubs

7. Push the ribbon cartridge against the hubs on the left until it can

engage the two holders on the right.

Holders

8. Turn the thick spool in the direction shown by the arrow

(above), until the ribbon is taut.

9. Close the top cover.

2-8

Introduction

Connecting a Parallel Cable

8

To co nne ct a

parallel

(Centronics)

cable

1. Make sure that your computer is turned off.

2. Connect the female end (no pins) of the cable to the EP-1000

parallel port.

Parallel

port

Power cord

connector

Setting Up the EP-1000

3. Connect the 25-pin end of the cable to the computer’s parallel

port.

4. Connect the power cord.

5. Press the

6. Press the

7. Press the

8. Press the

The

Parallel

Power

Online

Interface

Online

button to power on the EP-1000.

button to set the EP-1000 to offline mode.

button so that the

Parallel

light flashes.

button to set the EP-1000 to online mode.

light comes on steady (stops flashing).

EP

-1000

Instant Dry Imager User’s Manual

2-9

Connecting a USB Cable

8

To co nne ct a

USB cable

1. Make sure that your computer is turned off.

2. Connect and secure the USB cable to the USB port.

USB

port

Power cord

connector

3. Connect the power cord.

2-10

Introduction

4. Press the

5. Press the

6. Press the

7. Press the

The

USB

Power

Online

Interface

Online

button to power on the EP-1000.

button to set the EP-1000 to offline mode.

button so that the USB light flashes.

button to set the EP-1000 to online mode.

light comes on steady (stops flashing).

Loading Paper

Handling Paper

Follow these guidelines when you handle the paper:

•

Hold the paper by the edges to avoid fingerprints.

•

Do not load more than 50 sheets of paper in the paper tray.

•

Do not use wet or damaged paper.

Storing Paper

Follow these storage instructions to ensure the highest image

quality:

•

Store opened paper at temperatures below 77°F (25°C). Avoid

exposure to temperatures higher than 86°F (30°C).

•

Avoid storing a loose stack of paper out of its wrapper.

Setting Up the EP-1000

EP

-1000

Instant Dry Imager User’s Manual

2-11

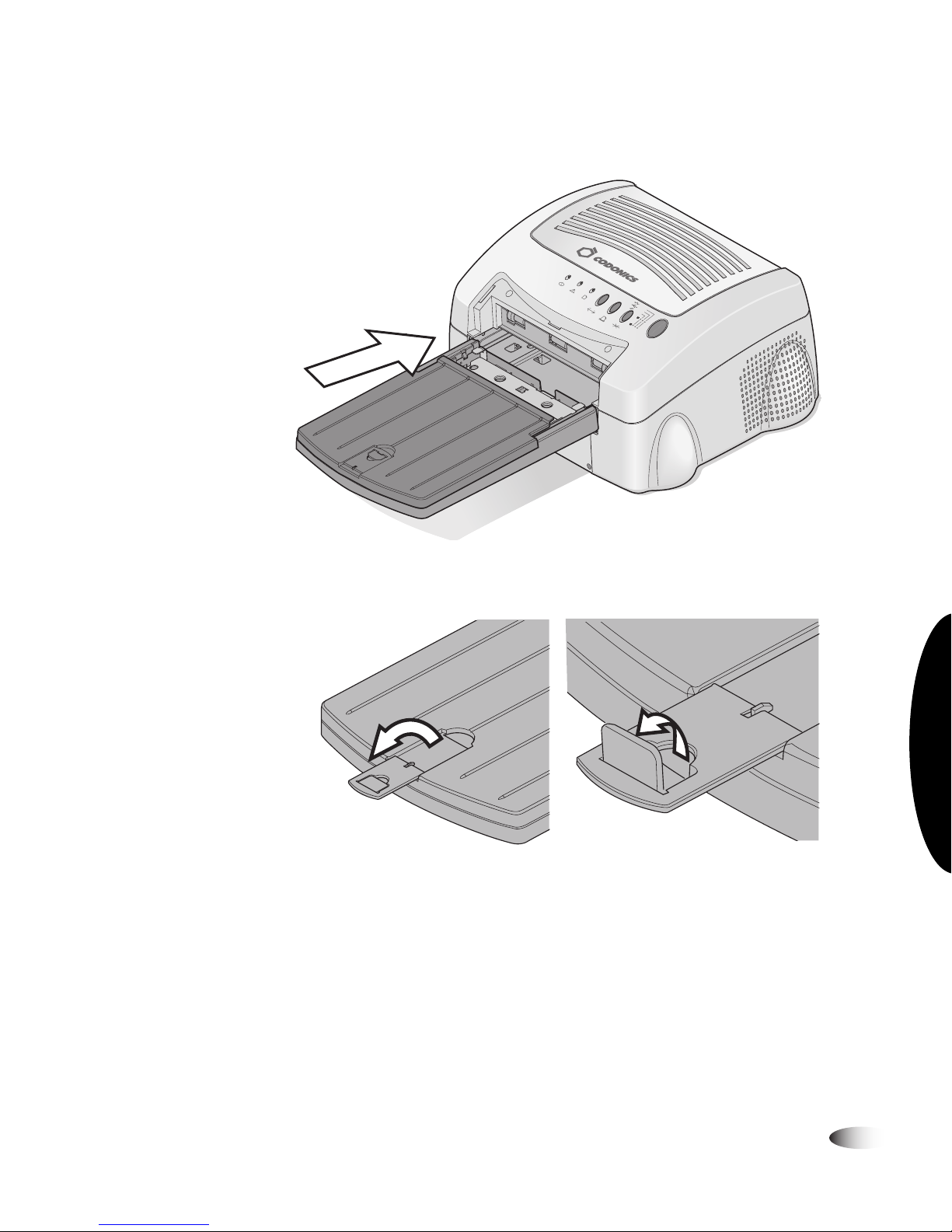

Loading the Paper Tray

The paper tray adjusts to the size of the paper you are loading. Do

not force paper that is too long or too wide into the tray.

3

8

To load the

paper tray

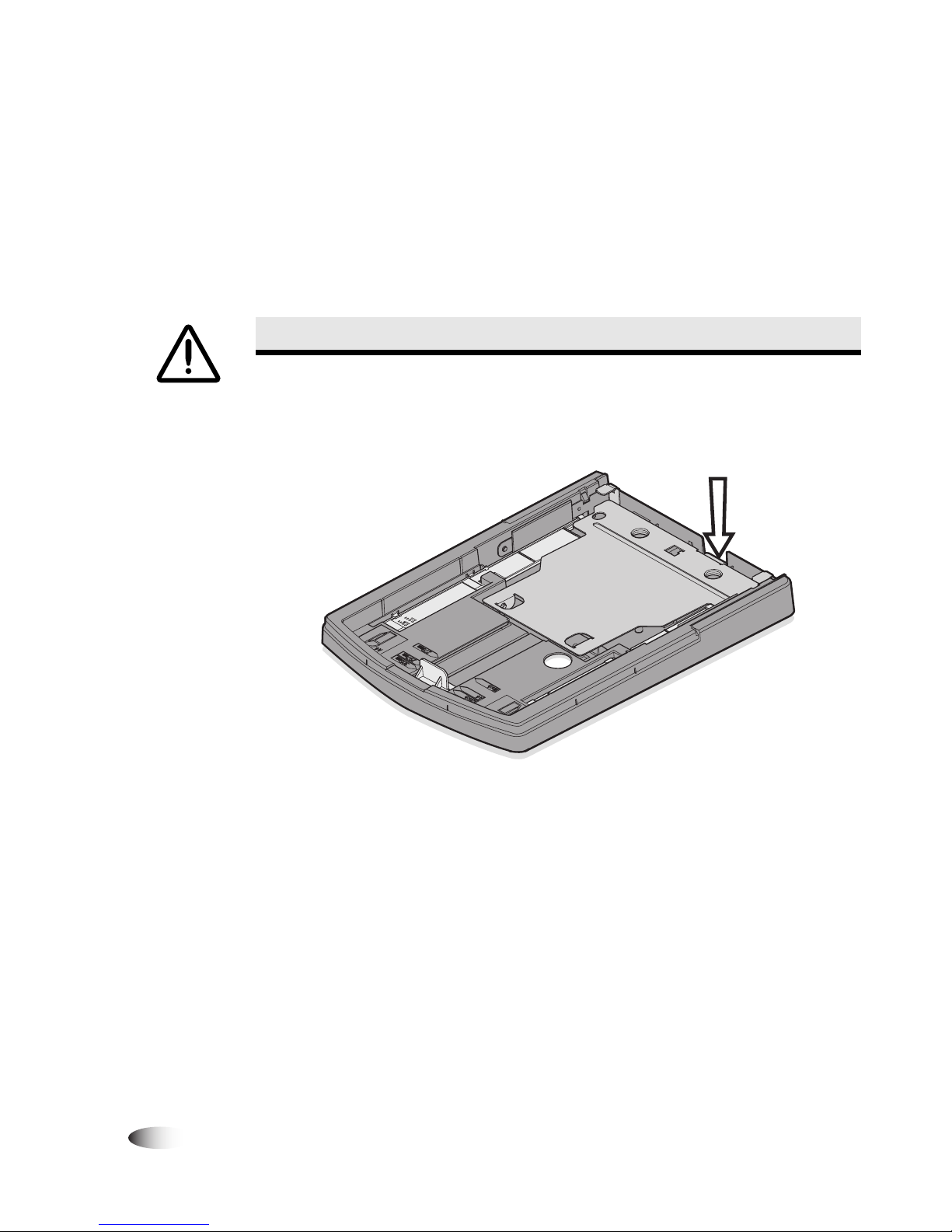

NOTE:

EP-1000 is shipped from the factory. Remove this spacer when using the EP-1000.

A spacer for protection during transport is attached inside the paper tray when the

CAUTION

Use only the tray designed for the EP-1000.

1. Pull down the plate lever of the paper tray until you hear a click.

2-12

Introduction

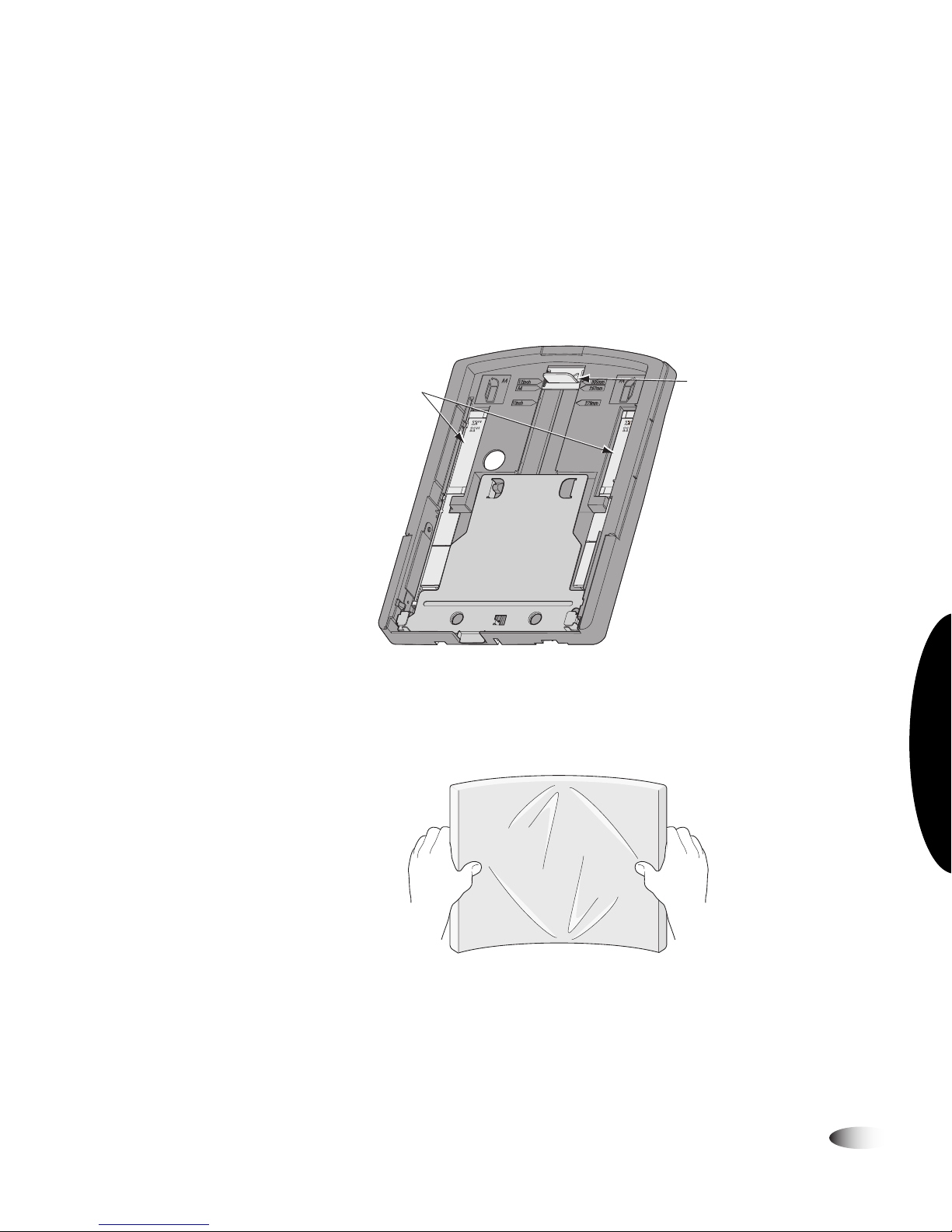

2. If necessary, adjust the paper tray to fit the paper you are

loading:

•

Move the paper width adjuster to the correct position for

either A- or A4-size paper.

•

Slide the paper length adjuster to the correct position for the

length of the paper you are loading. Make sure that the

paper length adjuster is locked into position.

3

Paper width

adjustor

3. Loosen the paper in the package.

NOTE:

pages well before unpacking.

Paper sheets may become stuck together during storage or shipping. Loosen the

Paper length

adjustor

Setting Up the EP-1000

Loosen the paper

before unpacking

EP

-1000

Instant Dry Imager User’s Manual

2-13

4. Remove the paper from the package.

CAUTION

Handle the paper by the edges to avoid fingerprints on the top sheet.

5. Place the paper in the tray with the printing side (glossy side)

facing up, making sure that the front corners of the stack are

under the metal tabs.

3

NOTE:

One package includes 50 sheets of paper. Do not exceed the 50-sheet capacity of

the paper tray.

6. Set the clear cover onto the paper tray.

2-14

Introduction

7. Install the paper tray in the EP-1000.

8. Raise the stopper.

power

f

a

ul

t

me

d

i

a

ON

net

LINE

work

USB

p

a

rallel

PR

INT

INTERFACE

Setting Up the EP-1000

EP

-1000

Instant Dry Imager User’s Manual

2-15

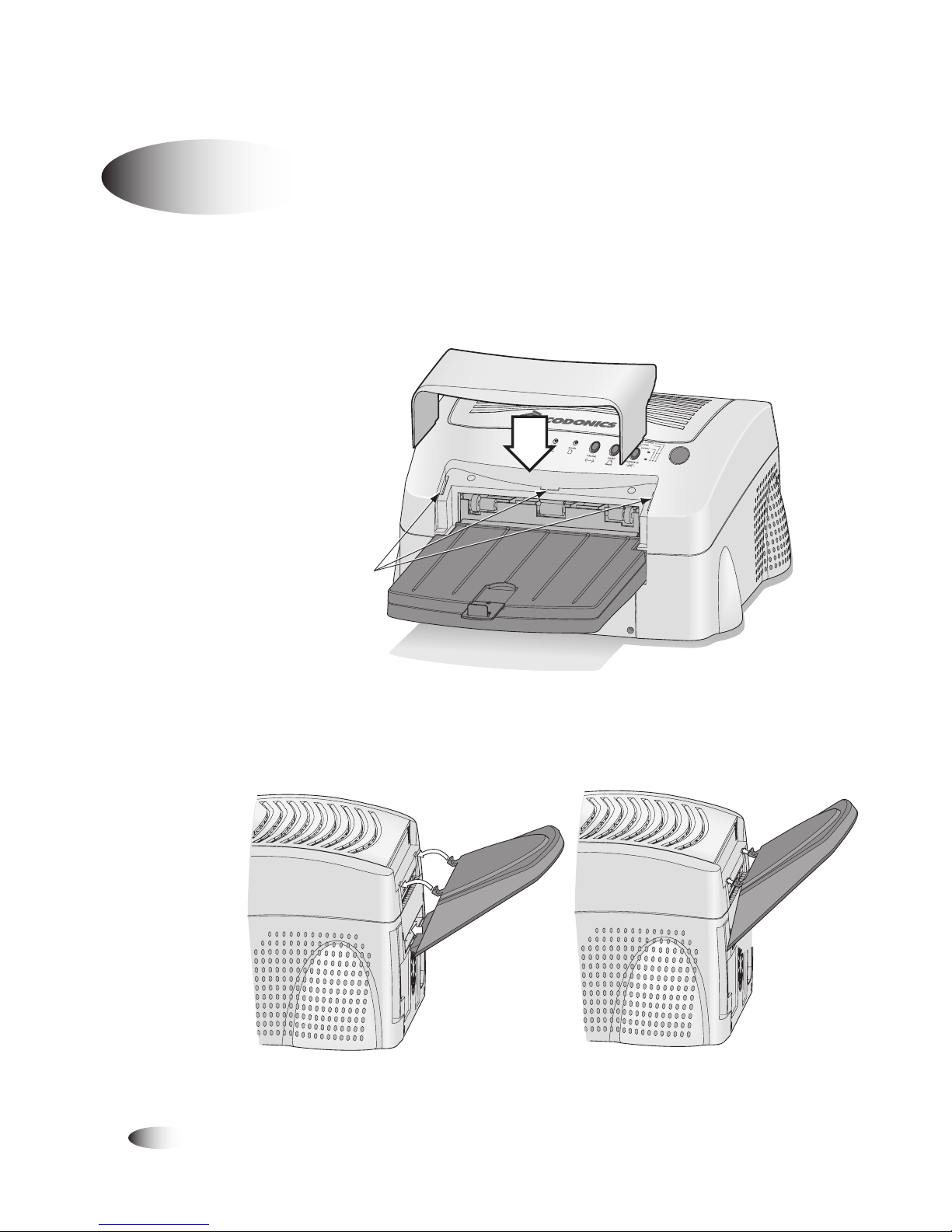

Installing the Dust Covers

Install the dust covers on the front and back of the EP-1000.

For the front cover,

install the cover as shown below (insert the

cover into the groove).

Groove

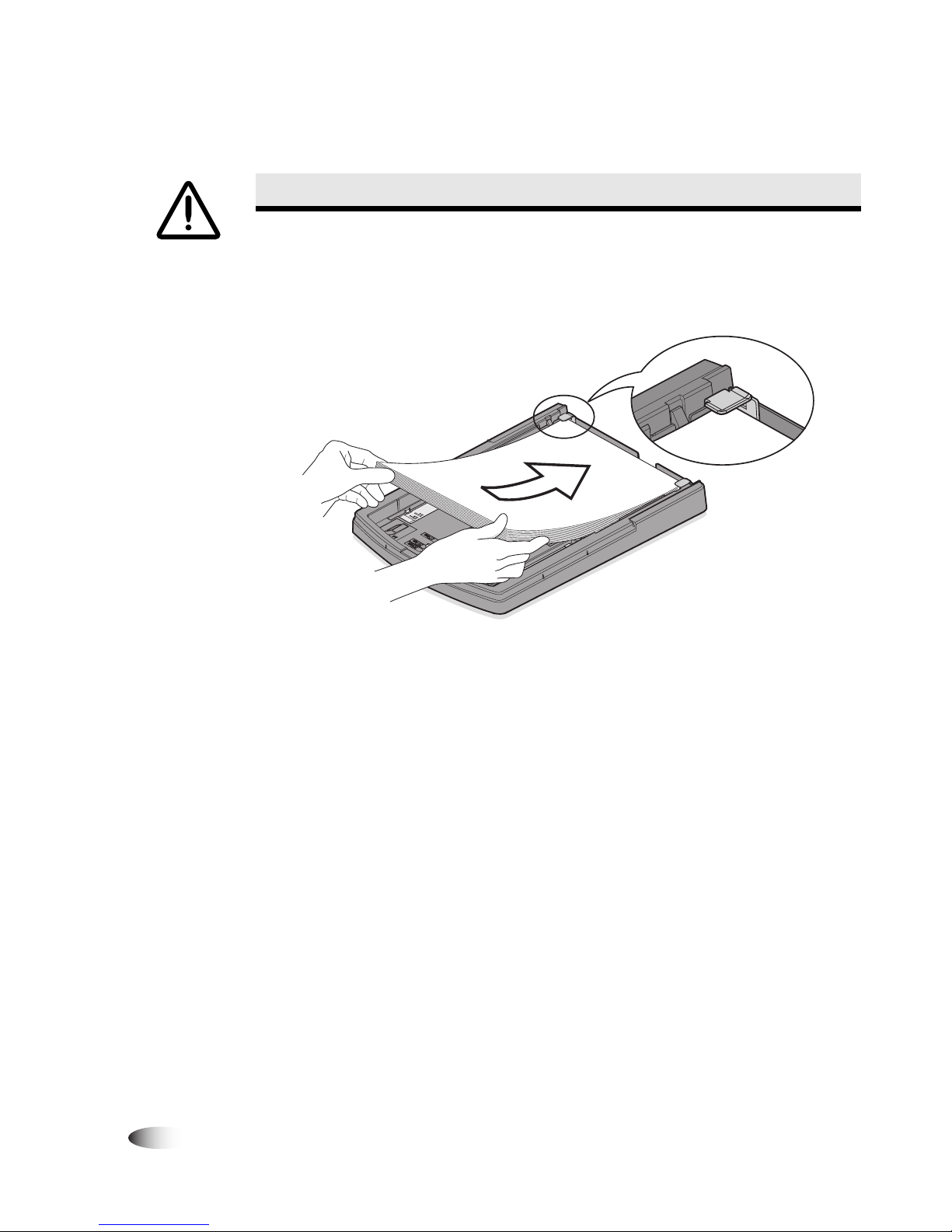

For the back cover,

insert the bottom of the dust cover on the back

slit of the EP-1000. Then, hook the dust cover on the EP-1000.

2-16

Introduction

About Imager Initialization

When you power on the EP-1000, it initializes (starts up and

performs a self-check) in a few seconds. During this time, the Fault,

Media, Parallel

, and

USB

lights flash.

If the EP-1000 fails to initialize, none of the lights on the display

panel will flash. Power off the EP-1000, then power it back on.

If the lights do not flash after powering on again, power off both

the EP-1000 and the host computer. Disconnect all cables from the

EP-1000 except the power cable. Power on the EP-1000 again. If the

lights on the display panel still do not flash, call Codonics Technical

Support for service.

Making a Test Print

8

To make a test

print

Making a test print verifies proper EP-1000 setup and operation,

and confirms print quality.

1. Press the

2. Press the

Power

Print

button while holding the

button.

Online

button.

The test print prints.

3. After printing, press the

4. Select the desired interface, then press the

Online

button.

Online

button again.

The imager is now ready for normal printing.

An example test print is shown on the next page.

Setting Up the EP-1000

EP

-1000

Instant Dry Imager User’s Manual

2-17

2-18

Introduction

Operating the EP

3

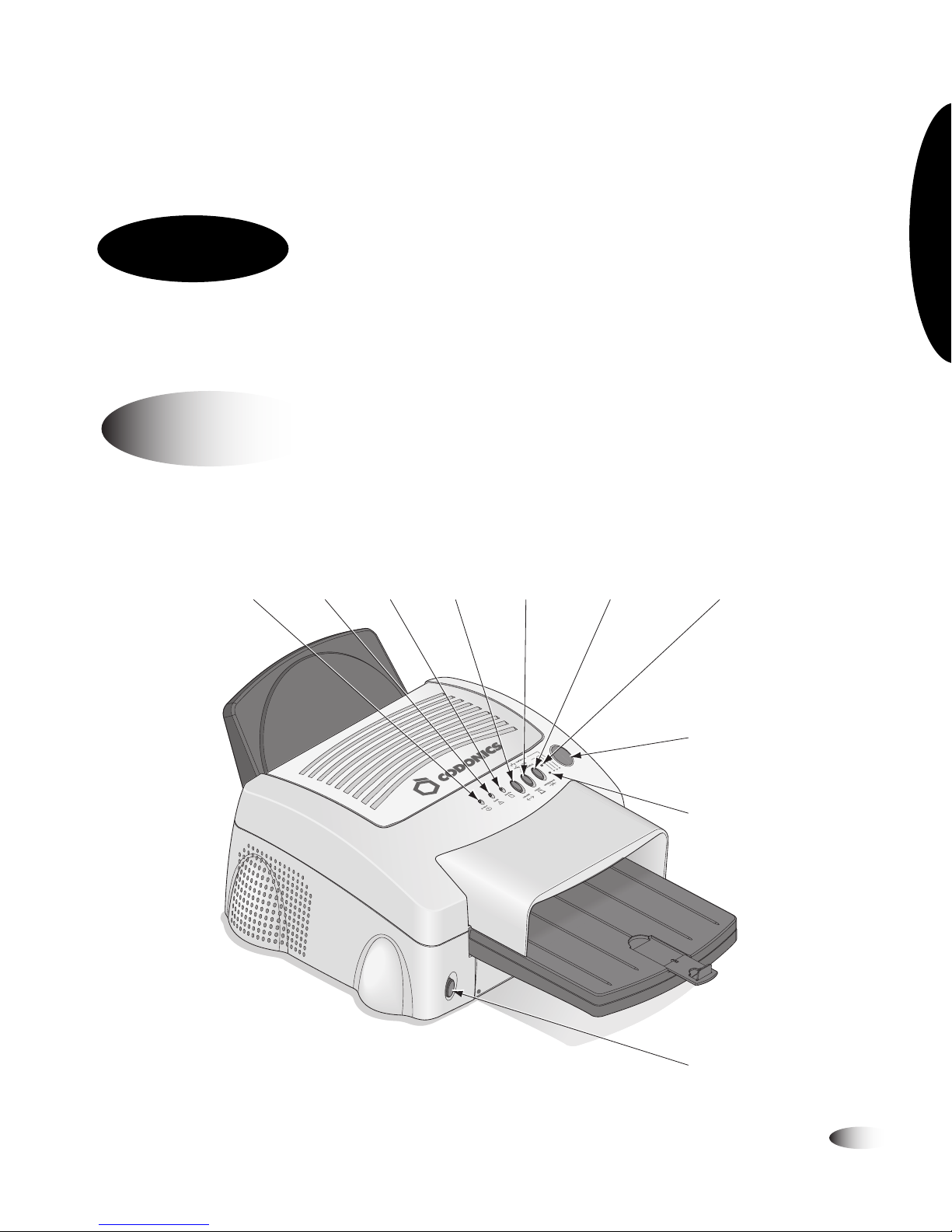

Indicator Lights and Control Buttons

Power

light

Operating the EP-1000

The indicator lights and control buttons on the EP-1000’s display

panel are shown below.

Fault

light

Media

light

Online

button

Print

button

Interface

select button

Parallel light

-1000

EP-1000 Instant Dry Imager User’s Manual

Open top

cover button

USB light

Power button

3-1

Table 3-1 and Table 3-2 describe the functions of the indicator

lights and control buttons.

Table 3-1. Display Panel Indicator Lights

Indicator Light Description

Power Lights green when the EP-1000 is turned on.

Fault Lights red when a fault occurs. The light remains on until all the

faults are resolved.

When the Fault light comes on steadily, you may be able to

correct the problem yourself.

Media Lights red when a fault concerning print paper occurs.

Parallel Lights green when the Parallel port is selected.

USB Lights green when the USB port is selected.

Table 3-2. Display Panel Control Buttons

Button Description

Power Press to turn the power on or off. When power is on, the Power

light comes on.

Online Press to toggle the imager online and offline. In online mode,

you can control the EP-1000 through the computer.

Print Press to reprint a valid job that is still in the image buffer. This

button is not available when image data has not been sent or

the EP-1000 is online.

Interface Press to select either the Parallel or USB port. The indicator

light for the selected interface flashes. This button is disabled

when the EP-1000 is online.

Open Press to open the top cover. You will need to open the top

cover when loading the ink ribbon or clearing a paper jam.

CAUTION

Do not open the top cover during printing. Doing so may cause print faults

or damage the EP-1000.

3-2

Operating the EP

-1000

Canceling Multiple Copy Printing

Operating the EP

When printing two or more copies of one image, you can use

continuous printing. The number of the copies can be set by the

print driver.

To cancel continuous printing, press the

seconds until the

Fault

(in green),

Parallel

Print

, and

button for a few

USB

lights flash.

After completing the current sheet, continuous printing is canceled.

-1000

EP

-1000

Instant Dry Imager User’s Manual

3-3

4

Maintenance

Properly Maintaining the EP-1000

To keep the EP-1000 in good working condition:

•

Keep the EP-1000 clean. Keep the surrounding area vacuumed

and litter-free.

•

Protect the EP-1000 from tobacco smoke, dust, sand, and liquid

spills.

Maintenance

EP-1000 Instant Dry Imager User’s Manual

4-1

Cleaning the EP-1000

To help ensure good performance and high-quality output, make

sure the operating environment is clean and dust free.

Clean the EP-1000 regularly as described below.

WARNING Before you begin cleaning the EP-1000, turn off the EP-1000 and

unplug it.

•

Wipe the covers, the paper tray area, and the paper tray with

water and a damp, lint-free cloth. This eliminates dust buildup

and prevents dirt from getting into the EP-1000.

CAUTION

Do not use alcohol cleaning pads to clean the cabinet.

•

Clean the area around and under the EP-1000 to prevent dirt from

Never use abrasives or harsh chemicals to clean any part of the EP-1000.

getting into it.

4-2

Maintenance

5

Interpreting the Indicator Lights

Troubleshooting

The indicator lights become red when a problem has occurred. You

must resolve any problems before you can print. The following

table explains how to interpret the condition of the indicator lights.

Troubleshooting

EP-1000 Instant Dry Imager User’s Manual

5-1

Table 5-1. EP-1000 Indicator Lights Indications

Problem

Status Power Fault Media Parallel USB

Normal Status:

Power OFF

Initializing

Online (USB)

Online (Parallel)

Offline (USB)

Offline (Parallel)

Transferring data

Printing

{ { { { {

}~~~~

} { } { }

}{}}{

} { { { ~

}{{~{

} { } ~ ~

}{}}}

Light Indications

Cancelling multiple copy printing

Fault Status:

Overheat condition

Door open

Out of media (paper)

Out of media (ink)

Paper illegal

Paper jam or mechanical error

Paper size does not match image size

{ = LED off ~ = Green flashing } = Green on z = Red on

} ~ } ~ ~

} ~ {

}zz

} { z

}{z

} z z

}z{

} z z

5-2

Troubleshooting

Troubleshooting Common Problems

Table 5-2 lists common problems you might encounter while

operating the EP-1000, their possible causes, and solutions.

Table 5-2. EP-1000 Troubleshooting Chart

Problem Possible Causes Solutions

Fault light off,

Media light red

Fault light red,

Media light off

Fault light red,

Media light red

The supply spool in the ribbon cartridge

is empty.

The ink ribbon is used up.

The paper tray is empty or the paper

tray is not set

A paper jam occurred.

A mechanical fault occurred.

The paper is not loaded properly.

The top cover is open.

The paper size in the tray is not the

same as the size specified by the print

driver.

Install a new ribbon in the ribbon carrier.

Refer to “Loading the Ribbon Cartridge”

on page 2-5.

Install a new ribbon in the ribbon carrier.

Refer to “Loading the Ribbon Cartridge”

on page 2-5.

Load the paper tray. Refer to “Loading

the Paper Tray” on page 2-12.

Clear the paper path. Refer to “Clearing

a Paper Jam” on page 5-6.

Remove the paper tray and ribbon

cartridge. Power off the EP-1000, then

power it on again.

Load the proper paper into the tray.

Close the top cover.

Set the print driver setting to the paper

size in the tray, or change the paper in

the tray to match the print driver setting.

Troubleshooting

EP-1000 does not power

on.

The power is not on.

The cables and the power cord are not

connected securely.

EP

Check that the power switch is pressed

securely and that the power cable is

properly connected.

Check that the cables and the power

cord are connected securely.

-1000

Instant Dry Imager User’s Manual

5-3

Table 5-2. EP-1000 Troubleshooting Chart (Continued)

Problem Possible Causes Solutions

Printing takes much

longer than usual.

Nothing happens when a

print job is sent.

The image file size may be larger than

usual and, therefore, takes longer to

process.

The EP-1000 is too warm (the Fault

light flashes green).

The job is processing.

The communication settings may be

incompatible with the host computer.

Wait a few minutes.

Wait until the temperature inside the

EP-1000 falls.

If the temperature does not fall, power

off the EP-1000. Consider moving the

EP-1000 to a location where the

temperature is lower.

Wait to see if the job is still processing.

During data transfer, the Parallel and

USB light come on steady.

• Print a file that you successfully

printed previously.

• If that does not work, check the

communication settings to make

sure they are compatible with the

host computer.

• Disconnect the imager cable, then

make a test print.

White or colored lines and

scratches appear on

prints.

5-4

Troubleshooting

There may be a problem with the print

connections.

• If the test print works, reconnect the

imager cable, make sure the correct

port is selected at the display panel,

and try printing from the host

computer.

• If the problem persists, contact

Codonics Technical Support.

Dust or dirt has caused contamination. • Check that the paper in the paper

tray is clean and streak free.

• Check that the ribbon is clean.

• Clean the thermal print head. Refer

to “Cleaning the Thermal Print Head”

on page 5-12.

• If the problem persists, contact

Codonics Technical Support.

Table 5-2. EP-1000 Troubleshooting Chart (Continued)

Problem Possible Causes Solutions

White or multicolored

Dust or dirt has caused contamination. • Clean the EP-1000 and the

spots appear on prints.

Smudges, smears,

fingerprints, or other

Fingerprints or other oils have

contaminated the paper or ribbon.

irregular-shaped and

colored areas appear on

prints.

Paper does not feed There is a problem with the paper load

or tray.

The EP-1000 does not

respond when you press

buttons.

Imager conditions (for example, the

state of the top cover or paper tray) are

not correct for enabling imager

operation.

surrounding area.

• Move the EP-1000 away from room

ventilation ducts or open doors.

Replace the contaminated paper or

ribbon with a new supply. Handle paper

and ribbon carefully. Refer to “Handling

Paper” on page 2-11 and “Loading the

Ribbon Cartridge” on page 2-5.

• Remove sheets with irregularities.

• Check that the tray is correctly

adjusted for the size paper installed.

• Reduce the size of the stack of paper

in the paper tray.

• Make sure that the top cover is

closed.

• Remove and reinstall the paper tray.

• Restart the EP-1000. Check that the

Power light comes on.

Troubleshooting

EP

-1000

Instant Dry Imager User’s Manual

5-5

Clearing a Paper Jam

Paper and ribbon may occasionally jam in the EP-1000. Jams are

typically identified when the

occur in the following locations:

Fault

light comes on red. Jams may

Front area

Ribbon cartridge

area

Back area

5-6

Troubleshooting

Clearing a Paper Jam from the Ribbon

Cartridge Area

8

To clea r a

paper jam

from the

ribbon

cartridge area

1. Power off the EP-1000.

2. Open the top cover.

power

fa

ul

t

m

e

di

a

ONLINE

n

et

w

U

o

r

S

k

B

p

a

r

a

ll

e

l

P

RINT

INTERFA

CE

Troubleshooting

EP

-1000

Instant Dry Imager User’s Manual

5-7

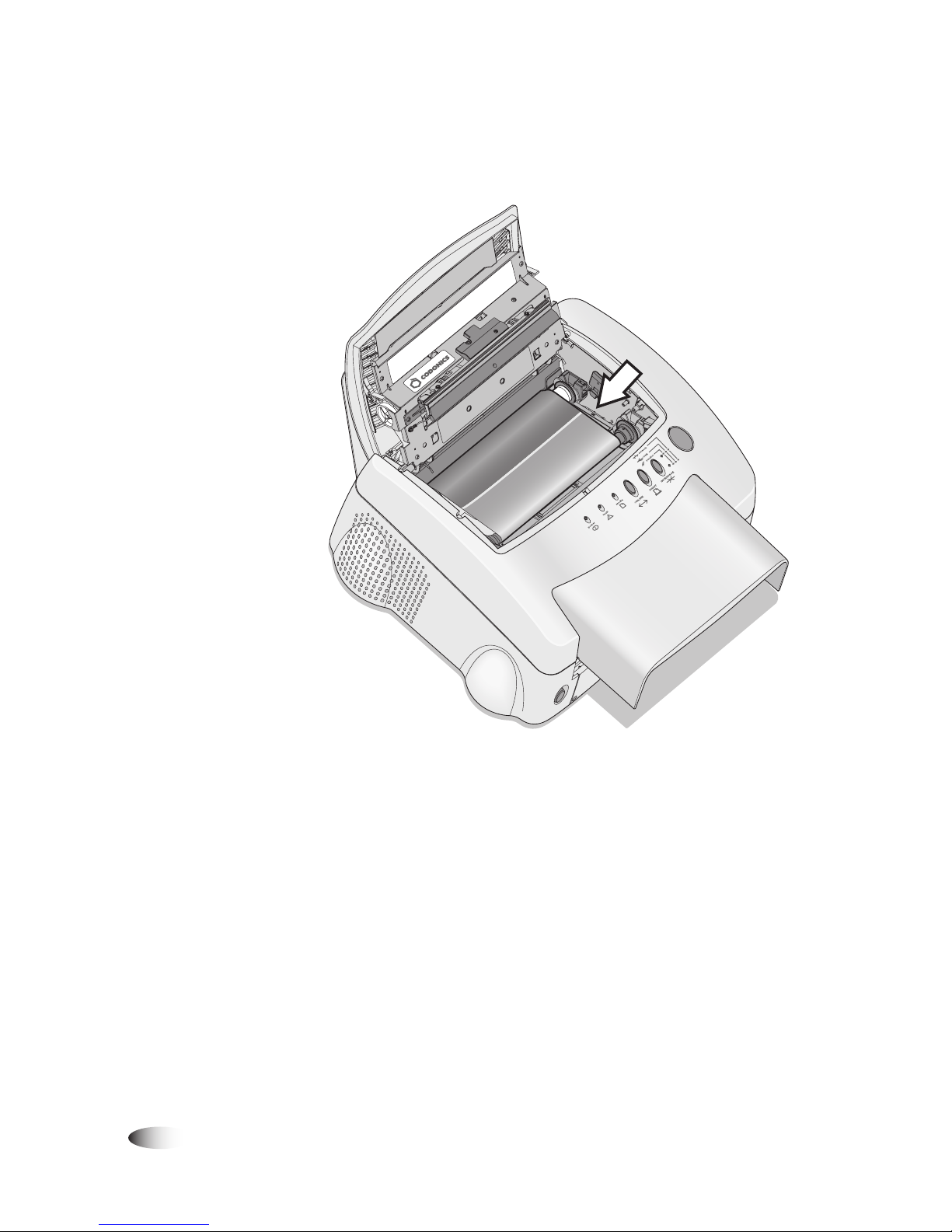

3. Remove the ribbon cartridge. Push the ribbon cartridge to the

left and lift it up to remove it.

4. Pull out the jammed paper.

5. Install the ribbon cartridge, and close the top cover.

6. Discard any partially-fed paper from the paper tray.

5-8

Troubleshooting

Clearing a Paper Jam from the Front Area

8

To clea r a

paper jam

from the front

area

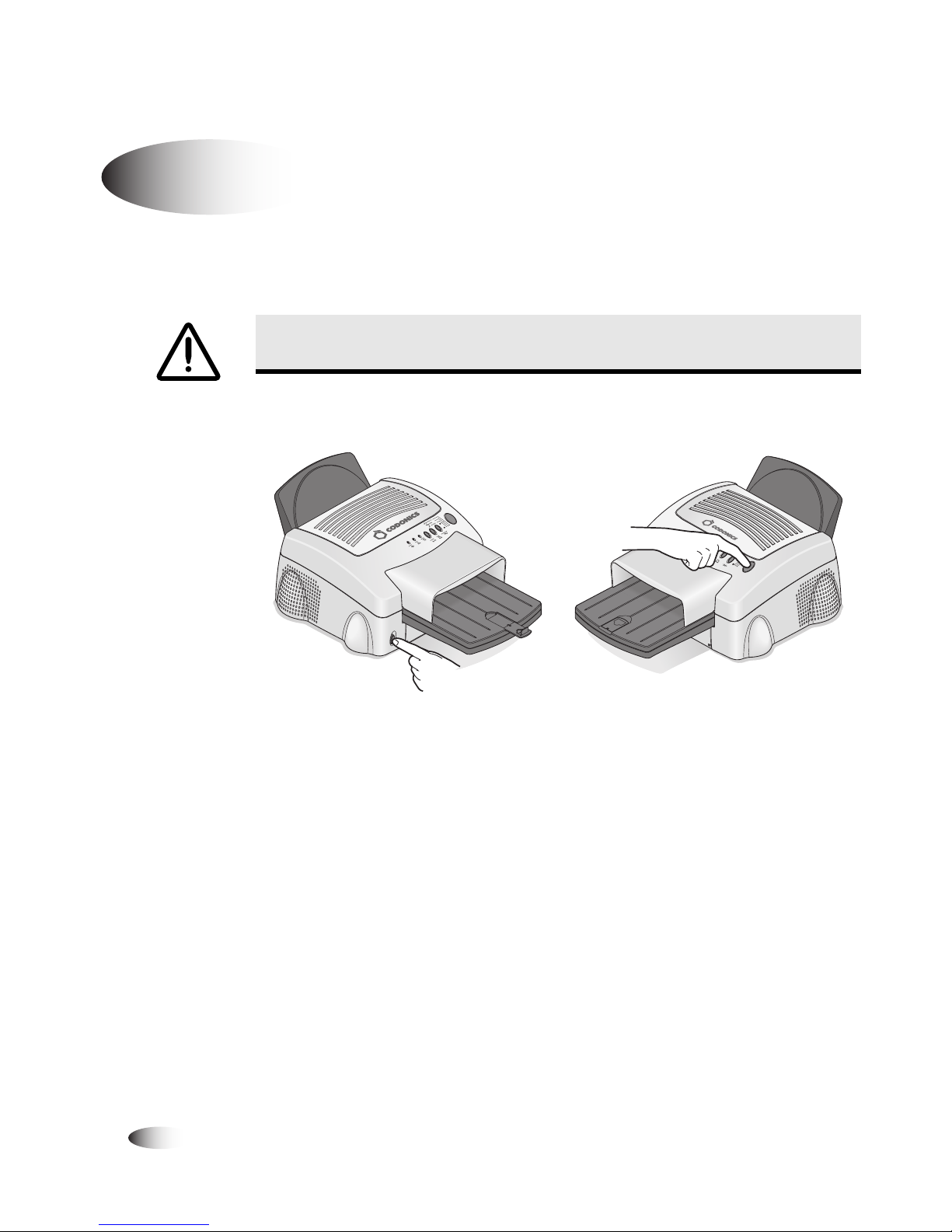

1. Power off the EP-1000.

2. Completely remove the paper tray and the front dust cover.

3. Reach in and pull out the partially-fed paper.

4. Install the tray and the front dust cover in the imager.

CAUTION

Do not put partially-fed paper back into the paper tray.

5. Discard any partially-fed paper from the paper tray.

Troubleshooting

EP

-1000

Instant Dry Imager User’s Manual

5-9

Clearing a Paper Jam from the Back Area

k

8

To clea r a

paper jam

from the bac

area

1. Power off the EP-1000.

2. Remove the back dust cover.

3. Remove the jammed paper.

4. Install the back dust cover.

5. Discard the jammed paper.

5-10

Troubleshooting

Repairing a Torn Ribbon

8

To repair a

torn ribbon

1. Position the ribbon cartridge with the torn ribbon on a clean

surface as shown below.

Office tape

Supply spool

Takeup spool

Troubleshooting

2. Place a piece of office tape on the center of the ribbon.

3. Wind the takeup spool counterclockwise so that the office tape

is not seen and the ribbon is straight.

4. Install the repaired ribbon cartridge in the EP-1000.

EP

-1000

Instant Dry Imager User’s Manual

5-11

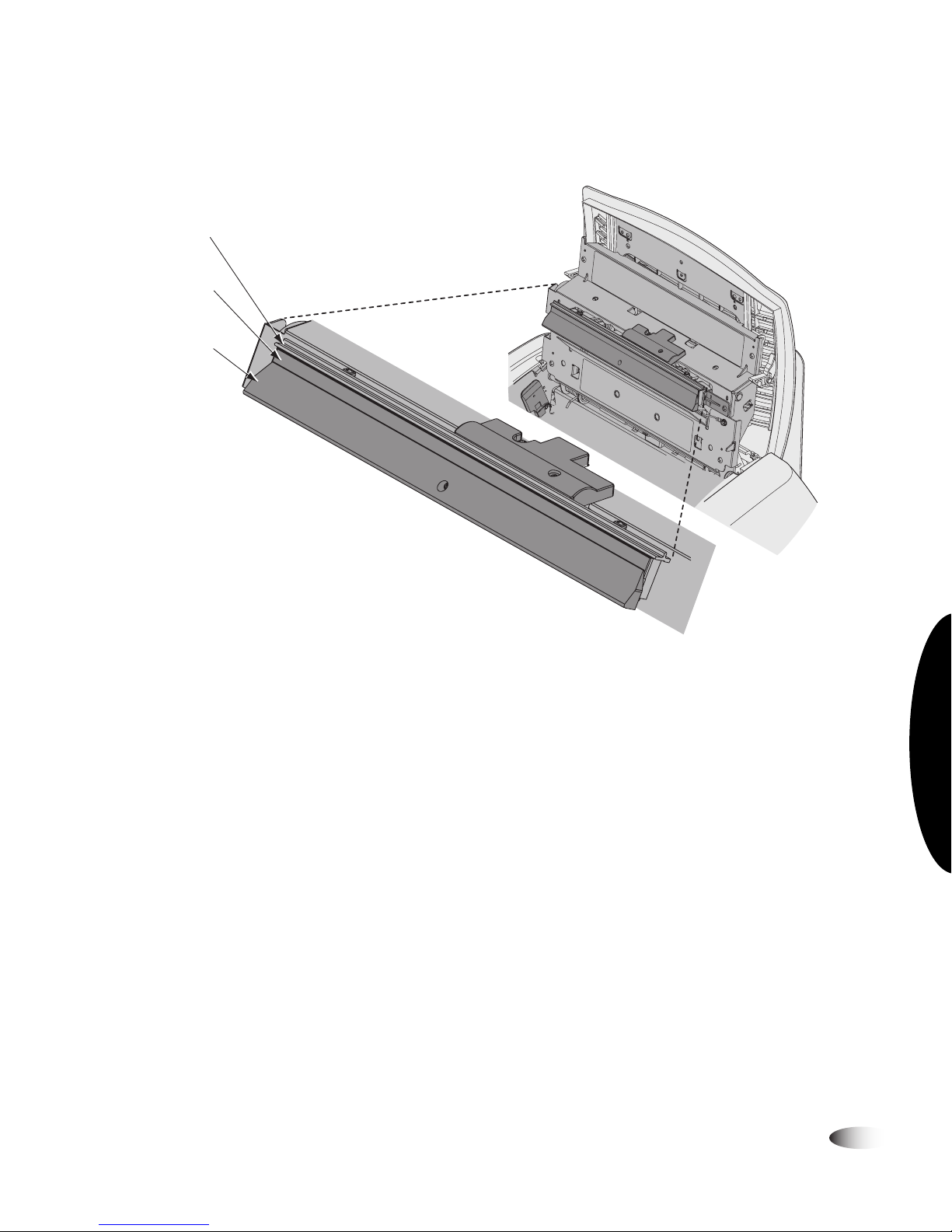

Cleaning the Thermal Print Head

Cleaning the thermal print head helps to eliminate lines, streaks,

and other artifacts on your prints.

8

To clean the

thermal print

head

CAUTION

Never rub or wipe anything across the thermal print head except when

cleaning it.

1. Power off the EP-1000, and open the top cover.

p

o

w

e

r

f

au

lt

m

e

d

i

a

O

n

e

N

t

wo

L

U

IN

r

S

k

E

B

p

a

r

al

le

l

P

R

I

N

T

IN

T

E

R

F

A

C

E

2. Use a Codonics print head cleaning wipe to clean the thermal

print head, and wipe along the heater line four times:

•

Wipe the full length of the area (always in one direction).

•

Use a clean part of the cloth for each wipe.

•

Apply firm, even pressure.

5-12

Troubleshooting

Guide bar

Heater line

Cover head

•

Wipe only the areas shown in the following figure.

3

3. Allow the wiped area to dry for about 2 minutes.

4. Close the top cover, and power on the imager.

5. Make a test print. If image artifacts are visible on the test print,

repeat this cleaning procedure.

NOTE:

It may be necessary to repeat the cleaning procedure several times to remove all

artifacts. If you cannot remove the artifacts, call Codonics Technical Support for service.

Troubleshooting

EP

-1000

Instant Dry Imager User’s Manual

5-13

A

Materials of Construction

Hazardous Material

Information

Codonics has set very stringent standards for evaluating products to

ensure the marketing of regulatory compliant products worldwide.

We do not intentionally add, nor are we aware, that the products or

packaging contain the following materials:

•

Mercury, except as used in lamp applications (for example,

scanning lamps, Backlit LCDs).

•

Cadmium, except as used as thick film inks on printed circuit

boards.

•

Hexavalent Chromium, except as used as thick film inks on

printed circuit boards, as chromate conversion coatings on metal

surfaces, and as a photoresist on glass panels of cathode ray

tubes.

•

Polybrominated diphenyl ethers and polybrominated biphenyls.

•

Bioavailable arsenic (small amounts of arsenic used in glass,

LEDs, and semiconductors are not considered to be bioavailable).

•

Bioavailable crystalline silica (small amounts of crystalline silica

are used in certain paints, coatings, and filler materials).

•

Polychlorinated biphenyls (PCBs).

EP-1000 Instant Dry Imager User’s Manual

A-1

Hazardous Material

Information

•

Asbestos.

•

Organic tin (not used in tin lead solder applications).

•

Ozone-depleting substances such as chlorofluorocarbons, methyl

chloroform, and carbon tetrachloride.

WARNING This thermal imager contains lead. Disposal of lead may be

regulated due to environmental considerations. For disposal or recycling

information, please contact your local authorities or the Electronics Industry

Alliance (www.eiae.org).

Manufacturing

During manufacturing operations that produce Codonics products

(including packaging), no ozone depleting substances (such as

chlorofluorocarbons, methyl chloroform, and carbon tetrachloride)

are used.

A-2

Hazardous Material Information

Loading...

Loading...