Page 1

Dimensions

Features

■ Code Free Entry Mode by turning

the slotted button 90 degrees

after entering the code

(models 505, 515, 525 only)

■ Inside handle always retracts the

latch for exit

■ Weather resistant

■ Vandal resistant, with stainless

steel buttons, and clutch

protection if the outside handle

is forced

■ Reversible handles

■ Easy code change as often

as required

■ Fits doors between 35mm and

60mm thick without modification

Features - Model 525 only

■ Split follower lock enables inside

handle to retract latch and

deadbolt simultaneously,

satisfying ‘means of escape’

requirements for exit at all

times. Prevents accidental lock-ins

■ Deadbolt thrown by key to lock

out code users after work hours

■ Key will retract the latchbolt

giving access for admin functions

■ Double Euro-profile cylinder with

3 keys. Any Euro-profile cylinder

may be used

■ On multiple door installations

consideration should be given to

having all cylinders keyed alike,

with restricted key issue, for

ease of management

1

2

3

4

5

6

7

8

9

0

C

178mm

35 — 60mm

Model 500/505

For use with existing lock

1

2

3

4

5

6

7

8

9

0

C

60mm

Model 510/515

With tubular latchbolt

1

2

3

4

5

6

7

8

9

0

C

72mm

235mm

55mm

84mm

Model 520/525

With full ‘Panic Function’

mortice lock & cylinder

2.07.02

INSTALLATION

INSTRUCTIONS

USHbutton 500 series

P

CODELOCKS LTD

Tel 01635 268029 Fax 01635 268031

sales@codelocks.co.uk

www.codelocks.co.uk

Helpline, service & spares

FREEPHONE 0800 393405

Page 2

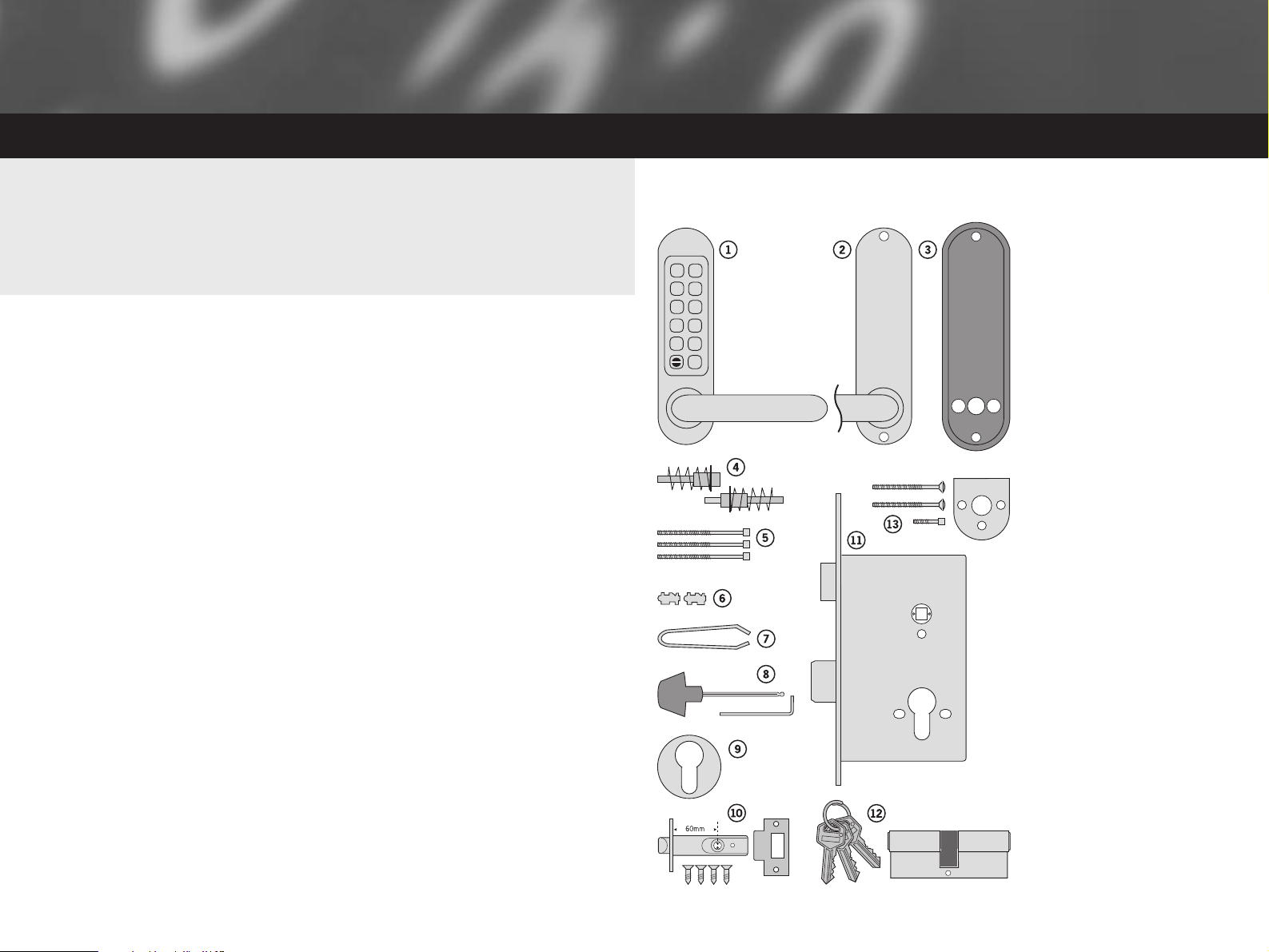

1 Front plate and handle

2 Back plate and handle

3 Neoprene seals x2

4 Two-part spindle with springs

(patent pending)

5 Fixing bolts x2 (1x spare)

6 Spare code tumblers x2

7 Tweezers for code changing

8 Allen keys x2

9 Key way escutcheons

10 Mortice latch, strike & 4 screws

11 2 bolt mortice lock and strike

12 Double Europrofile cylinder & 3 keys

13 Adaptor kit for mortice locks

with horizontal fixings

■ Installation template

■ Code change instructions

■ Code card

■ Power drill

■ Drill bit 20mm

16mm

12mm

■ Phillips screwdriver

■ Chisel 22mm

■ Chisel 25mm

■ Hammer/mallet

■ Stanley knife

■ Adhesive tape, pencil, bradawl

tape measure

PUSHBUTTON 500 SERIES

Check that the contents of your box are correct according to the model.

BOX CONTENTS

Model 500/505 Model 510/515 Model 520/525

✱✱ ✱

✱✱ ✱

✱✱ ✱

✱✱ ✱

✱✱ ✱

✱✱ ✱

✱✱ ✱

✱✱ ✱

2 pairs – 1 pairs

– ✱ –

––✱

––✱

✱ ––

– ✱✱

✱✱ ✱

✱✱ ✱

✱✱ ✱

✱✱ ✱

––✱

✱✱ ✱

– ✱✱

––✱

– ✱✱

– ✱✱

– ✱✱

– ✱✱

TOOLS REQUIRED

On models 505, 515 and 525

note the slotted turn within the

bottom left hand button. If the

slot is in the vertical position it

signifies that a code is needed

each time to operate the lever

handle. Enter the code from

the code card and the lever

handle should turn fully to 35

degrees, and then spring back

to horizontal. Enter the code

again, turn the slot to the

horizontal position and the

lock will be in code-free

access mode. Return the slot

to the vertical position and

after one further free turn the

lock will be in code control

mode again.

Turn the front plate over and

note that the red tipped

tumblers inside correspond to

the code. The code may be

entered in any sequence, i.e.

1370 may be entered as

3710 or any other sequence

of those numbers. There are a

total of 2047 codes available

on the 500, 510 and 520

locks, any of which may be

entered in any order. There

are 1023 codes available on

the 505, 515 and 525.

If you intend to change the

code you should do it, if

convenient, before installing

the lock – see the Code

Change Instructions in the

separate sheet.

CHECK

OPERATION OF

THE CODED

FRONT PLATE

1

6

7

2

3

8

4

9

5

0

C

Page 3

MODEL 500/505 INSTALLATION INSTRUCTIONS

The model 500/505 is intended to replace the conventional door furniture fitted

to an existing mortice latch, or an existing mortice lock which has both a spring

latch and a deadbolt. The square follower should be 8mm square. Any lock and

key mechanism is retained to operate the deadbolt. The latchbolt will only

operate by code, and NOT by key.

A mortice lock case should have holes for fixing bolts to pass through on either

side of the square latch follower and sometimes, additionally, a hole below the

follower. See figure 1 and confirm that your lockcase is compatible with the

500/505 lock plates.

IF YOUR LOCKCASE HAS A

HOLE BELOW THE

FOLLOWER (FIGURE 1 ‘A’),

PROCEED AS FOLLOWS:

step 1

Hold one of the black

neoprene seals against the

door, perfectly vertically, with

the large hole accurately over

the follower. Mark the top and

bottom holes on the door

face, and repeat the

procedure on the other side

of the door. Remove the lock.

At both points drill a 12mm

hole through the door. Drill

from both sides for greater

accuracy and to avoid

splintering out of the door

face. Check that the existing

spindle hole is at least 18mm

diameter. Replace the lock.

8mm latch follower

'A'

Through fixing hole

below the follower

FIGURE 1 – lockcase

'B'

Through fixing holes

either side of the follower

step 2

Take the 2-part spindle, with

the springs in place. Note that

one has a RED coloured face,

and the other a BLUE face. If

your door is hinged on the

right, viewed from outside,

then fit the BLUE spindle into

the latch follower on the

outside, with the colour on

TOP. Fit the RED spindle to

the inside, again with the

colour on TOP. For a left hand

hung door fit the spindles the

other way around, with the

colours on TOP.

step 3

Check that the lever handles

are correctly fitted for the

hand of door. To change the

hand of a lever handle, loosen

the grub screw with the small

Allen key, reverse the lever

handle and fully tighten the

grub screw.

step 4

Cut two of the black socket

head screws to the required

length for your door.

Approximate overall length

should be door thickness plus

25mm, to allow about 10mm

of threaded bolt to enter the

outside plate.

step 1

Hold one of the black

neoprene seals against the

door, perfectly vertically, with

the large hole accurately over

the follower. Mark the top hole

and the holes on either side

of the follower, and then

repeat the procedure on the

other side of the door.

Remove the lock.

Drill the 3x 12mm holes from

both sides for greater

accuracy, and to avoid

splintering out of the door

face. Check that the existing

spindle hole is at least 18mm.

step 5

Apply the front and back

plates, with the neoprene

seals in position, against the

door, over the protruding

ends of the spindle.

step 6

Fix the two plates together

using the socket head bolts,

starting with the top fixing.

Ensure that the two plates are

truly vertical and then tighten

the bolts using the ‘T’ shaped

Allen key. Do not use

excessive force.

step 7

Before closing the door,

enter the code and ensure

that the latchbolt will retract

when the lever handle is

depressed. Now check the

operation of the inside lever

handle. If there is any binding

of the handles or latch then

loosen the bolts slightly and

reposition the plates slightly

until the correct position is

found, and then re-tighten

the bolts.

IF YOUR LOCKCASE ONLY

HAS HOLES ON EITHER

SIDE OF THE FOLLOWER

(FIGURE 1 ‘B’), PROCEED

AS FOLLOWS:

step 2

Take the 2-part spindle, with

the springs in place. Note that

one has a RED coloured face,

and the other a BLUE face. If

your door is hinged on the

right, viewed from outside,

then fit the BLUE spindle into

the latch follower on the

outside, with the colour on

TOP. Fit the RED spindle to

the inside, again with the

colour on TOP. For a left hand

hung door fit the spindles the

other way around, with the

colours on TOP.

Page 4

step 4

Take the adaptor kit, item 13

on the contents page. Cut the

two M5 countersunk head

bolts to length to suit the

door thickness; i.e. door

thickness plus a maximum of

10mm (no more than 5mm

should enter the front plate).

Hold the front plate, with a

neoprene seal, against the

door over the protruding

spindle. From the other side

of the door, with the other

neoprene seal in position, fix

the adaptor plate to the front

plate. Before tightening up the

fixings make sure that there is

an equal gap all around

between the plate and the rim

of the neoprene seal to allow

the back plate housing to fit

over the adaptor plate. Do not

use excessive force.

step 5

Be sure that the handle is

fixed to the back plate, and

then remove the plate which

covers the handle spring.

Cut one of the long black

socket head screws to the

required length for your door.

Approximate overall length

should be door thickness plus

25mm, to allow about 10mm

of threaded bolt to enter the

front plate. Use this screw,

with the ‘T’ shaped Allen key,

to fix the back plate to the

front plate through the TOP

holes. Using the 20mm socket

head screw fix the back plate

through the BOTTOM holes to

the adaptor plate. Do not use

excessive force.

step 6

Before closing the door,

enter the code and check

that the latchbolt retracts

when the lever handle is

depressed. Now check the

operation of the inside lever

handle. If there is any binding

of the handles or latch then

loosen the top and bottom

bolts and reposition the plates

slightly until the correct

position is found, and then

re-tighten the bolts.

step 3

Check that the lever handles

are correctly fitted for the

hand of door. To change the

hand of a lever handle, loosen

the grub screw with the small

Allen key, reverse the lever

handle and fully tighten the

grub screw.

MODEL 510/515 INSTALLATION INSTRUCTIONS

The model 510/515 has a tubular, deadlocking, mortice latch and may be used

as a new installation on a door, or where an existing latch is to be replaced.

step 1

Lightly mark a height line on

the edge and both faces of the

door, and on the door jamb, to

indicate the top of the lock

when fitted.

Crease the template along the

dotted line, and tape it to the

door with the top in line with

the height line.

Mark the 2x 12mm and the

1x 20mm holes. Mark the

centre of the door edge on the

Centre Line of Latch. Remove

the template and apply it to

the other side of the door,

aligning it accurately with the

first Centre Line of Latch mark.

Mark the 3 holes again.

step 4

Put the latch into the hole and,

holding it square to the door

edge, draw around the

faceplate. Remove the latch

and score the outline with a

Stanley knife to avoid splitting

when chiselling. Chisel a

rebate to allow the latch to fit

flush to the surface.

step 2

Keeping the drill level and

square to the door, drill a hole

to accept the latch.

step 3

Keeping the drill level and

square to the door, drill the

12mm and 20mm holes from

both sides of the door to

increase accuracy and to avoid

splintering out the door face.

step 5

Fix the latch with the wood

screws, with the bevel

towards the door frame.

step 6

Take the 2-part spindle, with

the springs in place. Note that

one has a RED coloured face,

and the other a BLUE face. If

your door is hinged on the

right, viewed from outside,

then fit the BLUE spindle into

the latch follower on the

outside, with the colour on

TOP. Fit the RED spindle to

the inside, again with the

colour on TOP. For a left hand

hung door fit the spindles the

other way around, with the

colours on TOP.

step 7

Check that the lever handles

are correctly fitted for the

hand of door. To change the

hand of a lever handle, loosen

the grub screw with the small

Allen key, reverse the lever

handle and fully tighten the

grub screw.

Page 5

MODEL 520/525 INSTALLATION INSTRUCTIONS

Model 520/525 is a complete locking unit with all the parts necessary for a

new installation, or the total replacement of an existing lock.

IMPORTANT The mortice lock provided (fig. 2) has features which are not found in most other locks

and so it is recommended that you familiarise yourself with them as follows:

A. When necessary the hand

of the latchbolt can be

changed by removing the

three screws holding the

faceplate to the lockcase

and reversing the latchbolt.

B. Put the key in the cylinder

and insert it centrally into

the lockcase. Fix it in

position with the long bolt

through the faceplate. It

should now be possible to

project and retract the

deadbolt with the key, and

also to retract the latchbolt.

C. The square latchbolt

follower is in 2 parts: the

inside ‘panic function’

follower will retract the

latchbolt and also the

deadbolt when it is

projected. The effect of

this is to ensure that it is

not possible to accidentally

lock someone in a room

because the deadbolt is

projected. The outside

follower will always retract

the latchbolt whenever the

lever handle is depressed

after a correct code is

entered, but it will

not

retract the deadbolt.

The hand of the ‘panic

function’ is determined as

follows: the grub screws

on the split follower facing

the code side must be

removed. This prevents

the outside handle

retracting the deadbolt.

NEVER remove grub

screws from both sides at

the same time.

All door locks should be

installed with a degree of

precision to ensure that all

components are horizontally

and vertically accurate in

relation to each other, and in

relation to the door.

Do not install the lock where

it will involve cutting into a

joint between the door stile

and a mid-rail.

step 8

Fitting the strike plate.

NB: The plunger beside the

latchbolt deadlocks it to

protect against manipulation

or ‘shimming’. The strike plate

must be accurately installed

so that the plunger CANNOT

enter the aperture when the

door is closed, even if it is

slammed shut.

Position the strike plate on

the door frame so that it lines

up with the flat of the

latchbolt, and NOT the

plunger. Mark the positions of

the fixing screws, and draw

around the aperture of the

strike plate. Chisel out the

aperture 15mm deep to

receive the latchbolt. Fix the

strike plate to the surface of

the frame using only the top

fixing screw. Gently close the

door and check that the

latchbolt enters the aperture

easily, and is held without too

much ‘play’. When satisfied,

draw around the outline of the

strike plate, remove it and cut

a rebate to enable the

faceplate to lie flush with the

surface. Re-fix the strike plate

using both screws.

step 9

Apply the front and back

plates, with the neoprene

seals in position, against the

door, over the protruding

ends of the spindle.

step 10

Fix the two plates together

using the socket head bolts,

starting with the top fixing.

Ensure that the two plates

are truly vertical and then

tighten the bolts using the ‘T’

shaped Allen key. Do not use

excessive force.

step 11

Before closing the door,

enter the code and ensure

that the latchbolt will retract

when the lever handle is

depressed. Now check the

operation of the inside lever

handle. If there is any binding

of the handles or latch then

loosen the bolts slightly and

reposition the plates slightly

until the correct position is

found, and then re-tighten

the bolts.

Page 6

step 12

Before closing the door,

enter the code and check that

the latchbolt will retract when

the lever handle is depressed.

Now check the operation of

the inside lever handle. If there

is any binding of the handles

or the latch then loosen the

bolts and reposition the plates

slightly until the correct

position is found, and then

re-tighten the bolts.

step 13

Fit the double Euro-profile

cylinder and secure it with

the long screw through the

faceplate. Fit the cylinder

escutcheons.

step 14

Check that the deadbolt will

project and retract by key,

and that the key will also

retract the latchbolt.

Check that the inside lever

handle WILL retract the

deadbolt simultaneously with

the latchbolt.

Check that the outside lever

handle WILL NOT retract the

deadbolt.

step 15

Mark a vertical line on the door

jamb half the door thickness

away from the door stop. This

gives the centre line of the

strike plate. Align the Strike

Plate Template with the height

line, with the arrow heads

aligned with the centre line.

Mark the fixing holes, and draw

around the apertures for the

latchbolt and the deadbolt.

Chisel out the latch aperture to

12mm deep, and the deadbolt

aperture to 22mm deep.

Fix the strike plate with the top

screw only and gently close the

door. Ensure that the latchbolt

enters its aperture easily and

holds the door without too much

‘play’. When satisfied, draw

around the final position of the

strike plate, remove it, and cut a

rebate to allow it to fit flush to

the surface. Re-fix the strike with

both screws.

step 9

Check that the lever handles

are correctly fitted for the

hand of door. To change the

hand of a lever handle, loosen

the grub screw with the small

Allen key, reverse the lever

handle and fully tighten the

grub screw.

step 10

Apply the front and back

plates, with the neoprene

seals in position, against the

door, over the protruding

ends of the spindle.

step 11

Fix the two plates together

using the socket head bolts,

starting with the top fixing.

Ensure that the two plates are

truly vertical and then tighten

the bolts using the ‘T’ shaped

Allen key. Do not use

excessive force.

step 5

Drill the holes from both sides

of the door to improve

accuracy and to avoid

splintering out the door face.

step 4

Fold the template accurately

along the dotted line and tape it

to the door face with the top in

line with the height line, and the

fold on the door edge. Mark the

centres of all the holes to be

drilled. Remove the template

and repeat the procedure on the

other face of the door.

step 3

Apply tape to the 16mm drill

bit at 90mm from the tip to

act as a depth guide when

drilling the mortice holes.

Ensure the drill is level and

parallel to the door face and

drill the holes as indicated on

the template. Remove the

remaining wood with a chisel

to leave a clean mortice hole

which accepts the lockcase

without forcing. With the lock

in the mortice make sure that

the forend is parallel with the

door edge and mark the

outline of the forend plate.

Cut the outline with a Stanley

knife to avoid splitting out

when chiselling. Chisel a

rebate sufficient to accept the

forend flush with the surface.

22mm bolt throw

Bolt through fixings

for lever furniture

Grub screws

Split follower

Bolt through fixings

for escutcheons

Easy to reverse

key action latchbolt

FIGURE 2

520/525 lockcase

step 1

Lightly mark a height line on

the edge and both faces of the

door, and the door jamb, to

indicate the top of the lock

when fitted. Mark a line down

the centre of the door edge,

extending above the height line

and 300mm below it.

step 2

Hold the template against the

edge of the door with the top

in line with the height line, and

with the arrows in line with the

‘Centre of Door Edge’ line.

Mark the positions of the

fixing screws, and the holes

to be drilled for the mortice.

step 8

Take the 2-part spindle, with

the springs in place. Note that

one has a RED coloured face,

and the other a BLUE face. If

your door is hinged on the

right, viewed from outside, then

fit the BLUE spindle to the latch

follower on the outside, with

the colour on TOP. Fit the RED

spindle to the inside, again with

the colour on TOP.

For a left hand hung door fit the

spindles the other way around,

with the colours on TOP.

step 6

Install the lockcase in the door.

step 7

Cut two of the black socket

head bolts to the required

length for your door.

Approximate overall length

should be door thickness plus

25mm to allow about 10mm of

threaded bolt to enter the

outside plate.

Loading...

Loading...