Page 1

INSTALLATION INSTRUCTIONS

US Version

CL 5000AT II.U.S.version 8PP_Layout 1 20/09/2013 10:44 Page 1

Page 2

6

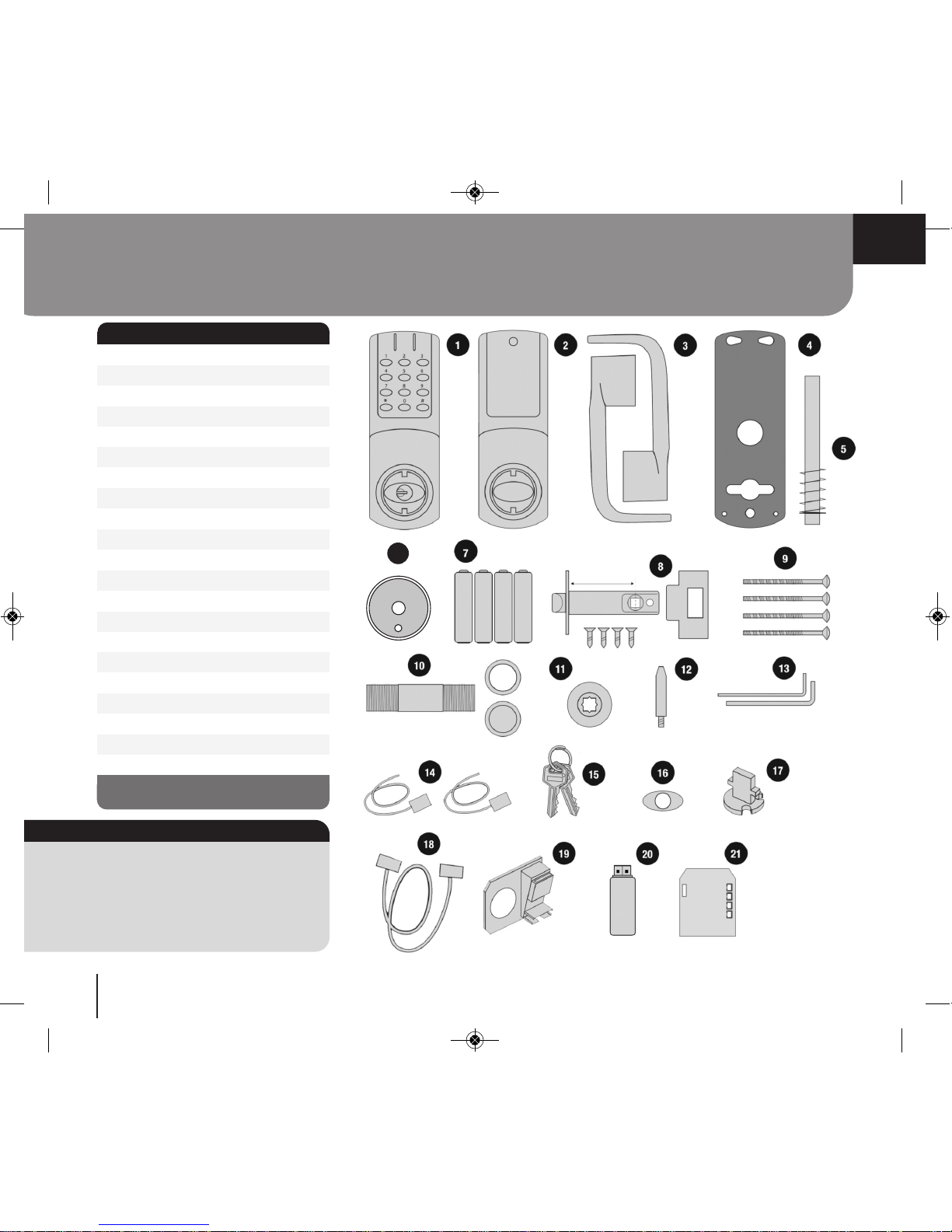

Box Contents

Please check the contents

of the box are correct

• Hammer/mallet

• Stanley knife

• Power drill

• Drill bits -

10mm (3/8”), 25mm (1”)

and 54mm (21/8”)

2

1 Front Plate

2 Back Plate

3 Lever Handles

4 Gasket x 2

5 Sprung Spindle

6 Fire Cup

7 1.5v AA Batteries (x4)

8 Mortice Latch, Strike and 4 Screws

9 Fixing Bolts x 4 (Inc spare)

10 Cable Tube and Ring Nut and Cap

11 Alignment Insert

12 Latch Support Post

13 Allen Keys

14 Cable Connections for REM1 and REM2

15 Front Plate Cylinder Keys

16 Front Plate Cylinder Cover

17 Classroom Function Tailpiece

18 Data Transfer Cable (optional)

19 USB Connector (optional)

20 USB Stick (optional)

21 PCB for Audit Trail (optional)

This box should also contain an Installation Template

and Programming and Operating Instructions.

• Philips screwdriver

• Pliers (for cutting bolts)

• Chisel 25mm (1”)

• Adhesive tape, pencil,

bradawl, tape measure

70mm (2

3

/4”)

Key Description

Tools Required

CL 5000AT II.U.S.version 8PP_Layout 1 20/09/2013 10:44 Page 2

Page 3

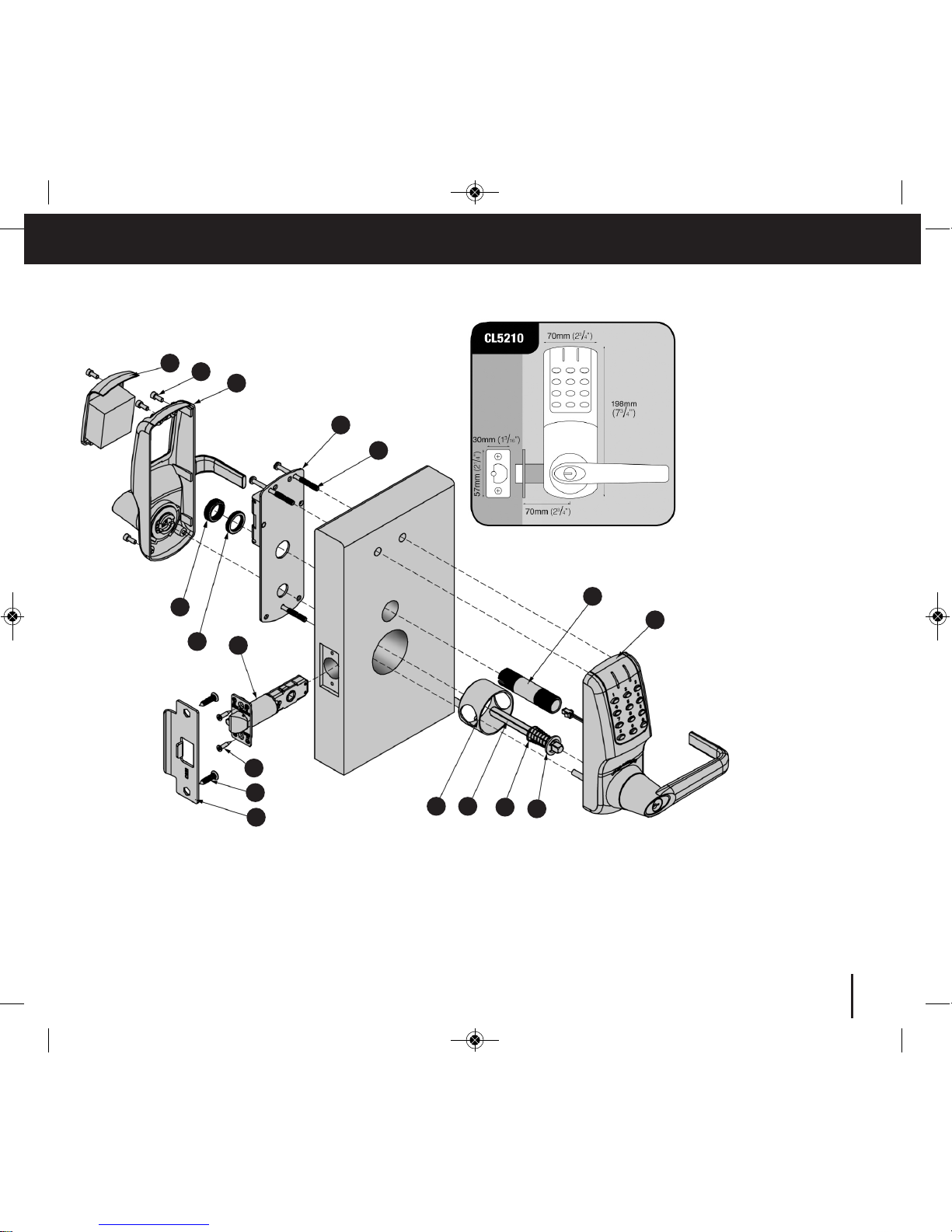

16

17

15

14

13

12

11

1

2

3

4

5

6

7

8

9

10

CL5210 LATCH

FUNCTION

Outside handle turns freely

without operating the

latchbolt. When the code is

entered the Blue LED

flashes, and the handle will

retract the latchbolt. The

latch automatically locks

the door when closed.

The key will open the door

without the code.

3

1 Washer

2 Spindle Spring

3 Spindle

4 Fire Cup

5 ‘T’ Type Strike

6 Screw

7 Countersunk Head Screw

8 Latch

9 Ring Nut

10 Threaded Tube Cap

11 Front Plate

12 Threaded Cable Tube

13 Fixing Bolts x 3

14 Inside Plate

15 Back Plate

16 Fixing Bolts x 4

17 Battery Cover

CL 5000AT II.U.S.version 8PP_Layout 1 20/09/2013 10:44 Page 3

Page 4

You should familiarise yourself with the operation of the lock

and check that all parts work properly.

Remove the battery cover from the back plate and install the 4 x

AA cells supplied.

Connect the cables from the front plate and back plate. A BEEP

should be heard when you do this. If no BEEP is heard then

check that the batteries are correctly installed.

Place the long spindle in the front plate socket and using finger

grip only, test that the spindle is easily moved 80

o

in both

directions. Leave socket in the centred position.

Enter the factory Master Code #1234.

The Blue LED should flash and the spindle should not turn as

before. After 5 seconds the Red LED should flash and the

spindle should turn easily again. This confirms that the clutch

engaged correctly when the code was entered.

N.B. When the Master Code is entered 3 times consecutively

without performing a programming function, a penalty time of

10 seconds is activated.

Disconnect the cables.

REMOTE RELEASE OPTION

Cables are provided for the REM 1 and REM 2 terminals on the circuit board

(Fig 1).

OPERATIONS CHECK SPECIAL FIXING NOTE

4

AUDIT TRAIL OPTION

If the CL5210AT is ordered, it will be supplied with parts 18,19, 20 and 21

from the contents list. The Data Transfer Cable (18) will be fixed to the PCB

in position 5, see Fig 1 below.

Note : To upgrade a standard CL5210 lock to one with Audit Trail

functionality, an upgrade kit (P5000 AT KIT) can be purchased, which

includes parts 18,19, 20 and 21.

FIG 1

1. Battery

2. Remote 1

3. Remote 2

4. Clutch/Actuator

5. Data Cable Connector

(AT option only)

REM 1 is for connection to a reception desk push button or a door intercom

system. Pressing the button will cause the Blue LED to flash on the lock and

release the lock for the pre-set time.

REM 2 is for connection to a fire alarm system so as to release a door in an

emergency. This allows rooms, wards, offices to be easily checked to ensure

that no person is trapped or overlooked during an emergency or a practice fire

drill. When activated REM 2 will maintain the unlocked condition for 30

minutes, and the Red LED will flash and BEEP during this time. The lock will

automatically lock again after 30 minutes. If necessary Program 11 can be

used to re-lock before the end of the 30 minutes.

REM 1 and REM 2 do not require additional power.They are normally open

contacts requiring a momentary or maintained signal to close.

CL 5000AT II.U.S.version 8PP_Layout 1 20/09/2013 10:44 Page 4

Page 5

5

Take time to be precise

and nish the job

quicker.

Installation holes must be

drilled in exactly the

correct positions and

precisely at right angles to

the door surface. Lock

components must be

vertically and horizontally

accurate in relation to each

other and to the door.

WEDGE THE DOOR

FIRMLY TO PREVENT

MOVEMENT WHILST

DRILLING AND

CHISELLING.

1 Lightly mark a height line on the edge and both faces of the door to indicate the top of the lock when fitted.

Crease the template along one of the dotted lines (60mm (2

3

/8”) or 70mm (23/4”) latch) and tape it to the

door with the top in line with the height line. Mark the holes to be drilled. Mark the centre line of latch on

to the door edge. Apply the template to the other side of the door precisely against the height line and the

centre line of latch mark. Mark the holes to be drilled again. (See diagram A).

2 Keeping the drill level and straight, drill a 25mm (1”) hole in the centre of the door edge to accept the latch.

Put the latch into the hole and holding it square to the door edge, draw around the faceplate. Starting with

the top and bottom cuts, chisel a rebate to allow the latch faceplate to fit flush with the door edge. Remove

the latch.

3 Keeping the drill level and straight, drill the holes in the door face. Drill from both sides of the door to

increase accuracy and to avoid damage to the other side when a drill goes right through.

4 Insert the fire cup into the 54mm (2

1

/8”) hole. N.B. open side of the fire cup to face code side with small

bolt through hole at the bottom.

CL5210

Template

INSTALLATION OF CL5210 LOCK

CL 5000AT II.U.S.version 8PP_Layout 1 20/09/2013 10:44 Page 5

Page 6

9 Remove the 4 socket head bolts from the back plate (2 are found

under the battery cover). This will release the inside fixing plate.

10 Cut the fixing bolts to correct length. Measured from beneath the

bolt head, the length should be the door thickness, plus

approximately 15mm (

1

/2”) to the nearest cutting point of the bolt.

N.B. Always cut the bolts at one of the cutting points so as not to

damage a thread. Use the cutting edges of pliers to crimp

strongly several times around the selected cutting point. The

surplus end should break off quite easily.

11 Put the spindle into the latch with the spring on the front plate

side of the door.

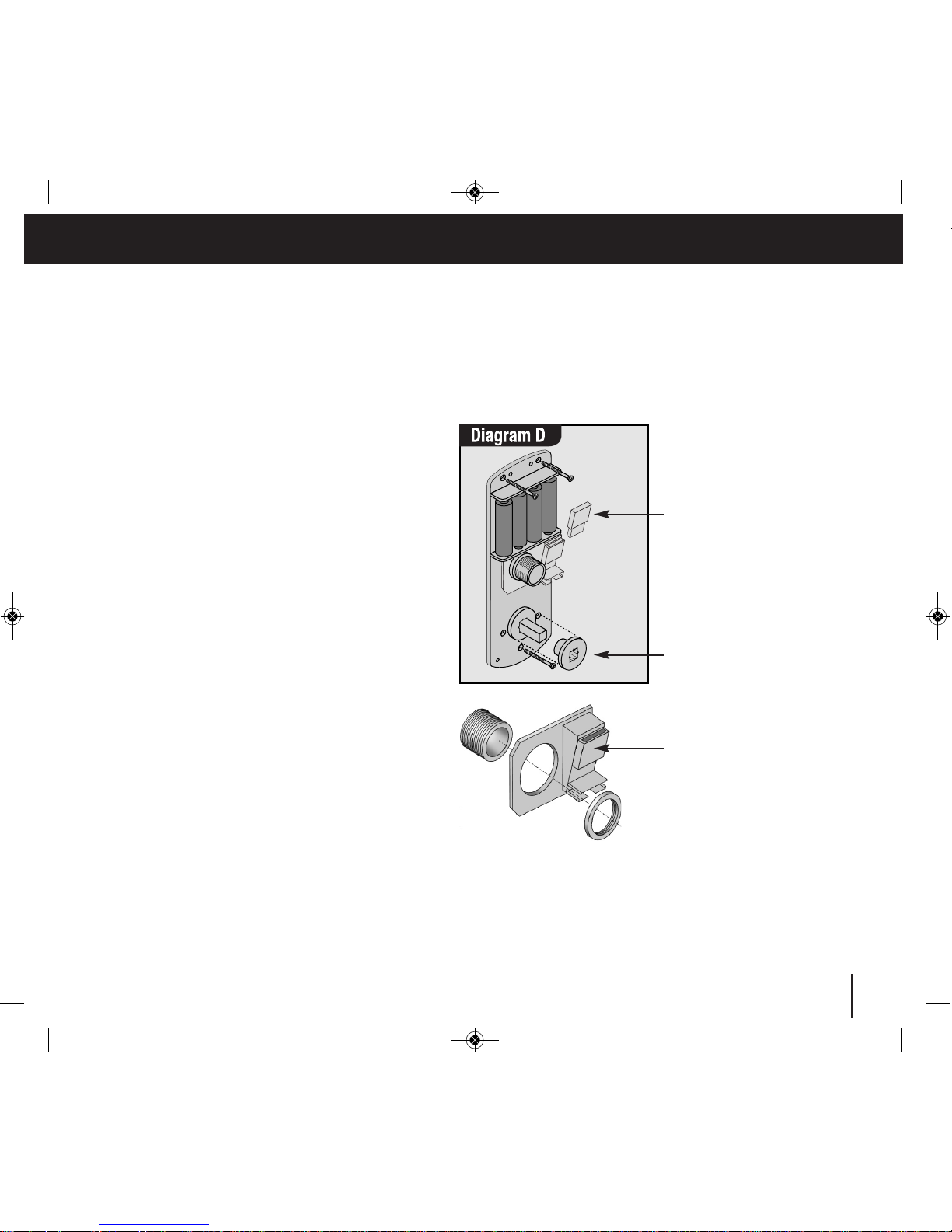

12 Apply the front plate over the spindle, passing the cable tube

through the door and the latch support post through the latch.

Place the fixing plate over the cable tube and spindle. If installing

the Audit Trail Option take the USB Connector (19) and place

over the cable tube, securing in place with double sided tape.

Screw the ring nut onto the cable tube until finger tight. Fit the

alignment insert over the spindle. Screw the fixing bolts through

to the front plate. (See diagram D on page 7).

13 Check that the spindle turns freely, and the latch retracts and

projects smoothly, with the alignment insert in place. If it is tight,

loosen the fixing bolts slightly and adjust the position of the

fixing plate until the spindle will turn freely. Tighten the fixing

bolts. Test the spindle again. Do not over-tighten the bolts as this

may cause the door to distort and affect the lock function.

REMOVE THE ALIGNMENT INSERT.

5 Reinsert the latch and fix the screws, with the bevel towards the door

frame. (See diagram B)

6 Fit the latch support post on the inside of the front plate, in outer hole

Side A for a left hand hung door and in outer hole B for a right hand

hung door. (See diagram C below).

6

7 Screw the cable tube into the front plate, passing the cable through the

tube. For doors less than 45mm (1

3

/4”) thick screw the tube all the way

to the end of the thread. For doors more than 45mm (1

3

/4”) leave an

appropriate amount of thread showing. Example: For a 60mm (2

3

/8”)

thick door leave 15mm (

1

/2”) of thread showing.

8 Fit the self-adhesive gaskets to the front and back plates. The gaskets

provide friction against the door so that it is not necessary to overtighten the fixing bolts to provide stability.

B

Diagram C

A

INSTALLATION OF CL5210 LOCK CONTINUED

CL5210 nside

front plate

CL 5000AT II.U.S.version 8PP_Layout 1 20/09/2013 10:44 Page 6

Page 7

7

14 Connect the cables, storing any excess cable within the

door. Screw end cap onto cable tube. Then install the

batteries.

15 Fit the back plate over the fixing plate using the 4 socket

head screws.

16 Fit the cylinder cover and outside handle to the front plate.

17 Fit the inside handle to the back plate.

18 The inside handle will now retract the latchbolt. The

outside handle will turn freely without retracting the latch.

Enter the factory Master Code #1234. The Blue LED will

flash and the outside handle will now retract the latch.

19 FITTING THE STRIKE PLATE

Position the strike plate on the doorframe so that the

aperture lines up with the flat of the latchbolt, and NOT the

plunger. Mark the positions of the fixing screws and draw

around the aperture of the strike plate. Chisel out the

aperture to 15mm

(1/2”) deep to receive the latchbolt. Fix

the strike plate to the surface of the frame using only the

top fixing screw. Gently close the door and check that the

latchbolt enters the aperture easily, and is held without too

much ‘play’. When satisfied, draw around the outline of

the strike plate, remove it and cut a rebate to enable the

strikeplate to lie flush with the surface. Re-fix the strike

plate using both screws.

N.B. The plunger beside the latchbolt deadlocks it to

protect against manipulation or ‘shimming’. The strike

plate must be accurately installed so that the plunger

CANNOT enter the aperture when the door is closed, even

when it is slammed shut.

Alignment insert MUST

be removed before

completing installation.

Optional USB Connector (19).

Optional USB Stick (20).

CL 5000AT II.U.S.version 8PP_Layout 1 20/09/2013 10:44 Page 7

Page 8

CODELOCKS LTD UK

Tel: +44 (0) 1635 239645

Fax: +44 (0) 1635 239644

sales@codelocks.co.uk

Helpline, service & spares

FREEPHONE 0800 393 405

CODELOCKS INC US

Tel: +1 714 979 2900

Fax: +1 714 979 2902

sales@codelocks.us

www.codelocks.us

II-CL5000US-v2:0913

5OOO

www.codelocks.us

ANSI/BHMA

A156.2

A156.25

CL 5000AT II.U.S.version 8PP_Layout 1 20/09/2013 10:44 Page 8

Loading...

Loading...