Page 1

INTEGRATION GUIDE

CR8000 Decoded Scan Engine

INTEGRATION GUIDE VERSION: 10

RELEASE DATE: MARCH 2017

Configuration Guidewww.codecorp.com YouTube.com/codecorporation

Page 2

Code Reader™ 8000 Integration Guide

Copyright © 2012-2017 Code Corporation.

All Rights Reserved.

The software described in this manual may only be used in accordance with the terms of its license agreement.

No part of this publication may be reproduced in any form or by any means without written permission from Code. This includes electronic or mechanical

means such as photocopying or recording in information storage and retrieval systems.

NO WARRANTY. This technical documentation is provided AS-IS. Further, the documentation does not represent a commitment on the part of Code

Corporation. Code Corporation does not warrant that it is accurate, complete or error free. Any use of the technical documentation is at the risk of the user.

Code Corporation reserves the right to make changes in specifications and other information contained in this document without prior notice, and the reader

should in all cases consult Code Corporation to determine whether any such changes have been made. Code Corporation shall not be liable for technical or

editorial errors or omissions contained herein; nor for incidental or consequential damages resulting from the furnishing, performance, or

use of this material. Code Corporation does not assume any product liability arising out of or in connection with the application or use of any product

or application described herein.

NO LICENSE. No license is granted, either by implication, estoppel, or otherwise under any intellectual property rights of Code Corporation. Any use of

hardware, software and/or technology of Code Corporation is governed by its own agreement.

The following are trademarks or registered trademarks of Code Corporation:

CodeXML®, Maker, QuickMaker, CodeXML® Maker, CodeXML® Maker Pro, CodeXML® Router, CodeXML® Client SDK, CodeXML® Filter, HyperPage,

CodeTrack, GoCard, GoWeb, ShortCode, GoCode®, Code Router, QuickConnect Codes, Rule Runner®, Cortex, CortexRM, CortexMobile, Code, Code Reader,

CortexAG, Cortex Studio, CortexTools, Affinity®, and CortexDecoder.

All other product names mentioned in this manual may be trademarks of their respective companies and are hereby acknowledged.

The software and/or products of Code Corporation include inventions that are patented or that are the subject of patents pending. U.S. Patents:

6997387, 6957769, 7428981, 6619547, 6736320, 7392933, 7014113, 7240831, 7353999, 7519239, 7204417, 6942152, 7070091, 7097099, 7621453.

The Code reader software is based in part on the work of the Independent JPEG Group.

Code Corporation, 12393 S. Gateway Park Place, Suite 600, Draper UT 84020

www.codecorp.com

C005383_10 CR80XX Integration Guide

2

Page 3

Table of Contents

1 – CR8000 Introduction ...................................................................4

1.1 – Product Overview ............................................................4

1.2 – SKU Descriptions ............................................................4

2 – Mechanical Specifications ...........................................................5

2.1 – Decoded Scan Engine Components .................................5

2.2 – Decoded Scan Engine with Mounting

Bracket Components ......................................................5

2.3 – Scan Engine Components ................................................6

2.4 – Scan Engine with Mounting Tabs Components ................. 6

2.5 – Scan Engine Mechanical Specifications ...........................6

2.6 – Scan Engine with Mounting Tabs

Mechanical Specifications ...............................................7

2.7 – Decode PCB Mechanical Specifications ...........................7

2.8 – CR8000 Decoded Scan Engine with

Bracket Specifications .....................................................8

2.9 – Enclosure Specifications ..................................................9

3 – Optical Considerations .................................................................10

3.1 – Window Requirements .....................................................10

3.2 – Imager Field of View ........................................................11

4 – Electrical Specifications ...............................................................12

4.1 – System Requirements ......................................................12

4.2 – Electrical System Block Diagram ......................................12

4.3 – Host Interface Pinouts (CR8012 RS232) ..........................13

4.4 – Host Interface Pinouts (CR8011 USB) .............................13

4.5 – Host Interface Pinouts (CR8013 micro-USB) ...................13

4.6 – Electrical Control Signals

(CR8011 and CR8012 only) ............................................14

4.7 – Power Modes (CR8011 and CR8012 only) .......................14

4.8 – Power On (Boot) Timing Diagram

(CR8011 and CR8012 only) ............................................15

4.9 – Power Down Timing Diagram ........................................... 16

4.10 – Sleep to Wakeup Timing Diagram ...................................16

4.11 – Image Capture and Decode Timing Diagram .................. 17

4.12 – Flex Cable Diagram (Imager Board to Decoder

Board on All Models) ....................................................17

4.13 – Ribbon Cable Diagram (Decode board to Host

Interface on CR8011 and CR8012) ...............................18

4.14 – Electrical Characteristics

(DC) – Absolute Ratings (Min and Max) .........................19

4.15 – Electrical Characteristics

(DC) – Operating Conditions ..........................................19

4.16 – Decode PCB to Scan Engine PCB Connector .................20

4.17 – Decode PCB Expanded Illumination Connector ..............21

5 – Configuration ...............................................................................22

5.1 – Serial Commands ............................................................22

6 – Shipping Specifications ...............................................................23

7 – General Specifications .................................................................24

8 – Reading Range Specifications .....................................................25

9 – Warranty .....................................................................................26

10 – APPENDIX A: Development Kit User Guide ................................27

10.1 – CR8000 Development Board .........................................27

10.2 – Development Board Connections ...................................28

10.3 – Development Board Jumpers .........................................29

10.4 – Development Board Fuses .............................................30

11 – APPENDIX B: Optimizing for Low Power Applications .................31

11.1 – Configuration .................................................................32

11.2 – Communications from Sleep Mode ................................32

11.3 – Timing Specifications ..................................................... 33

C005383_10 CR80XX Integration Guide

3

Page 4

1 – CR8000 Introduction

1.1 – Product Overview

The Code Reader™ 8000 (CR8000) is a patented, high performance,

miniature barcode imaging engine. The CR8000 continues Code’s legacy

of dual optical fields - while most devices have a single field enhanced for

a specific application, the CR8000 has both a high density field for reading

the smallest of barcodes, and a wide angle field for reading oversized

barcodes giving you two readers in one.

The CR8000 includes Code’s Glare Reduction Technology. Barcodes printed

on shiny or reflective surfaces have typically been problematic for imagingbased barcode readers. Code has overcome this challenge with a patented

process that significantly reduces the reflections, thus making the barcodes

easily identifiable. In addition, the CR8000 supports the integration and

control of additional illumination blocks or elements. Example applications

that benefit from the expanded illumination are document scanning and

direct part marking.

For mechanical integration, a variety of mounting options are available

including tabs, blind through-holes, and mounting brackets for both the

Scan Engine and the decode board. The CR8000 communicates via RS232

or USB protocols.

Applications for the CR8000 include Medical Devices, ATMs, Price-Lookup,

Lottery, Age Verification, Direct Part Marking, Point of Sale, Self-Service

Kiosks and more.

1.2 – SKU Descriptions

The following table describes the options available for the CR8000

Scan Engine. Any SKU (Part Number) can be built using the following table:

SKU: CR8### - L## - MT## - D## - C###

CR801# L## MT# D# C###

Communications

Interface

1 = USB

(Ribbon Cable)

2 = RS232

(Ribbon Cable)

3 = USB

(micro-USB Cable)

Wide Field/High

Density Field Focus

00 = Standard Focus

WF: 115 mm; HD: 110 mm

Mounting Options Flex Cable

X = No Tabs

or Brackets

1= With Tabs;

No Bracket

(see Section 2.1)

2 = With Tabs and

Standard Bracket

(see Section 2.2)

X = No Flex Cable X = No Ribbon Cable

0 = Standard Flex Cable 800 = 2.0" Ribbon Cable

1 = Reverse Flex Cable

(for Bracket Mount)

2 = In-Line Flex Cable 802 = 12.0" Ribbon Cable

801 = 6.0" Ribbon Cable

Ribbon Cable

(CR8011/CR8012 only)

EXAMPLE: CR8000 USB with Standard Focus,Tabs,

Standard Flex, 2.0" Ribbon Cable.

SKU = CR8011-L00-MT1-D0-C800

Note: Additional Ribbon Cables, Flex Cables, and Focus options may

be available for your application. Please contact your Code representative

to discuss.

C005383_10 CR80XX Integration Guide

4

Page 5

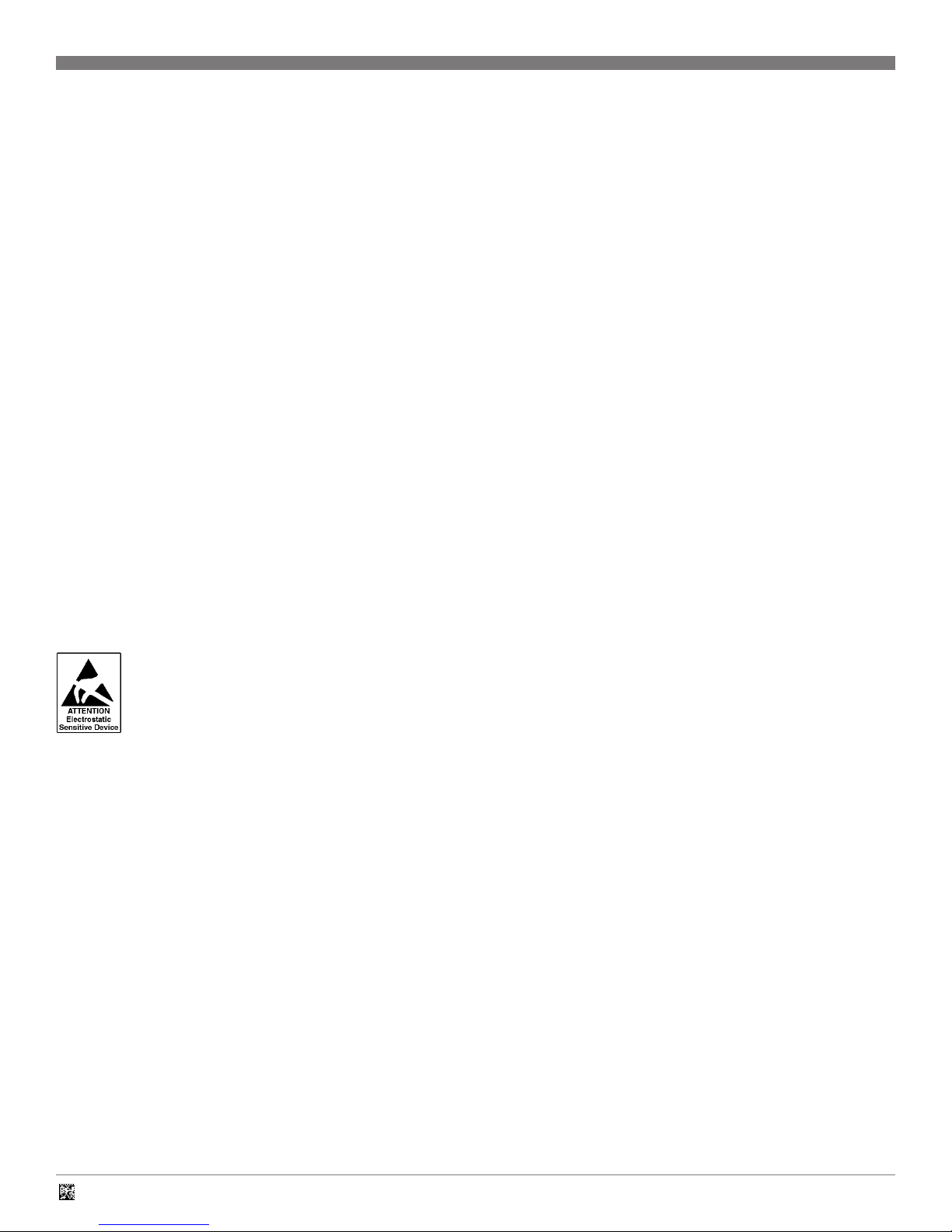

2 - Mechanical Specifications

The CR8000 is offered in multiple mechanical configurations. It can be

ordered as either an assembly or unassembled with or without Scan Engine

mounting tabs.

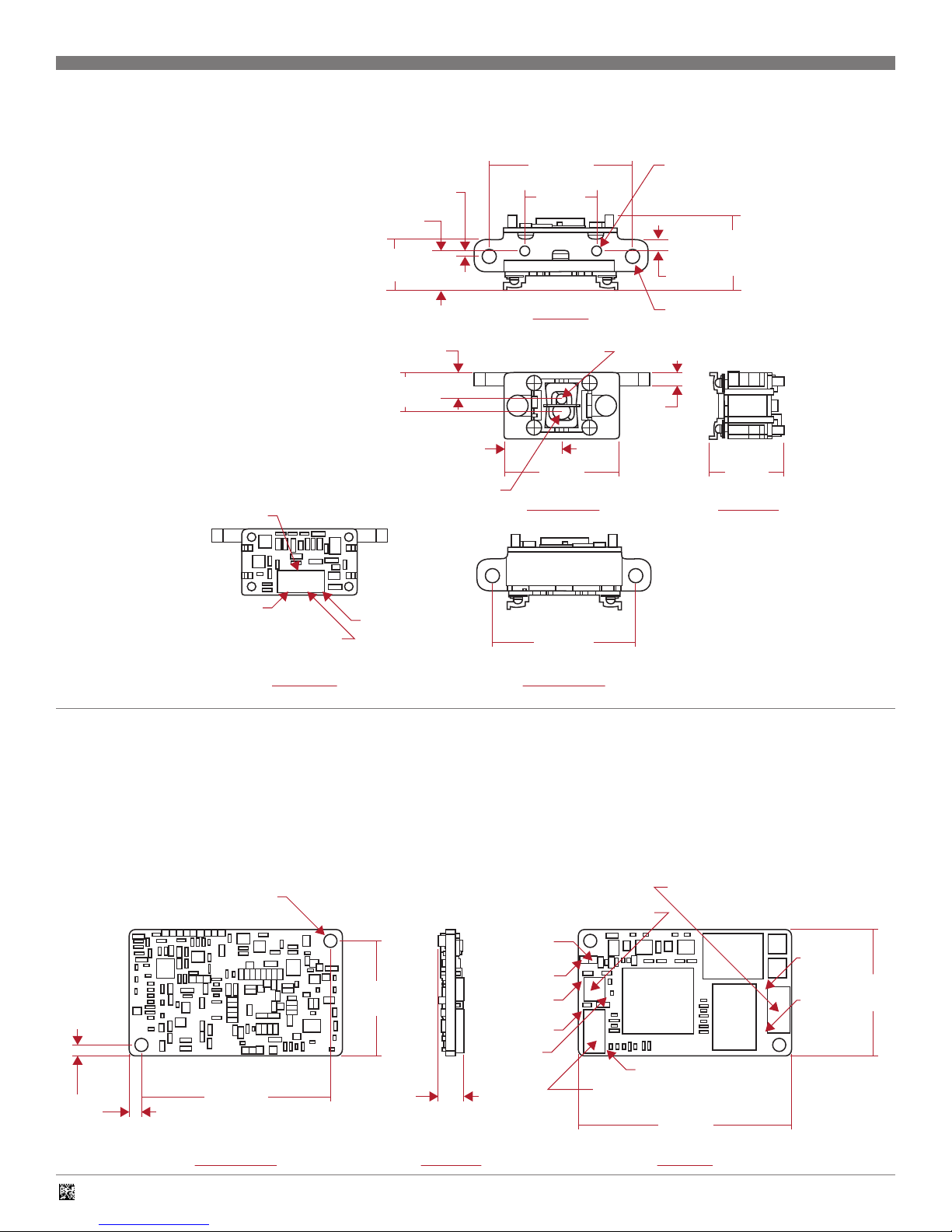

2.1 – Decoded Scan Engine Components

Fully Assembled Unit

1. CR8000 Decoded Scan Engine

3

Individual Components

2. Scan Engine (shown with tabs)

3. Decode Board

4. Decode Board to Scan Engine Flex Cable

(shown with Standard Flex Cable)

4

2.2 – Decoded Scan Engine with Mounting Bracket Components

Fully Assembled Unit

1. CR8000 Decoded Scan Engine

with Mounting Bracket

1

2

Individual Components

2. Scan Engine

3. Mounting Bracket (has multiple

possible configurations)

4. Decode Board

5. Decode Board to Scan Engine Flex

Cable (shown with Reverse Flex Cable)

C005383_10 CR80XX Integration Guide

3

1

2

5

4

5

Page 6

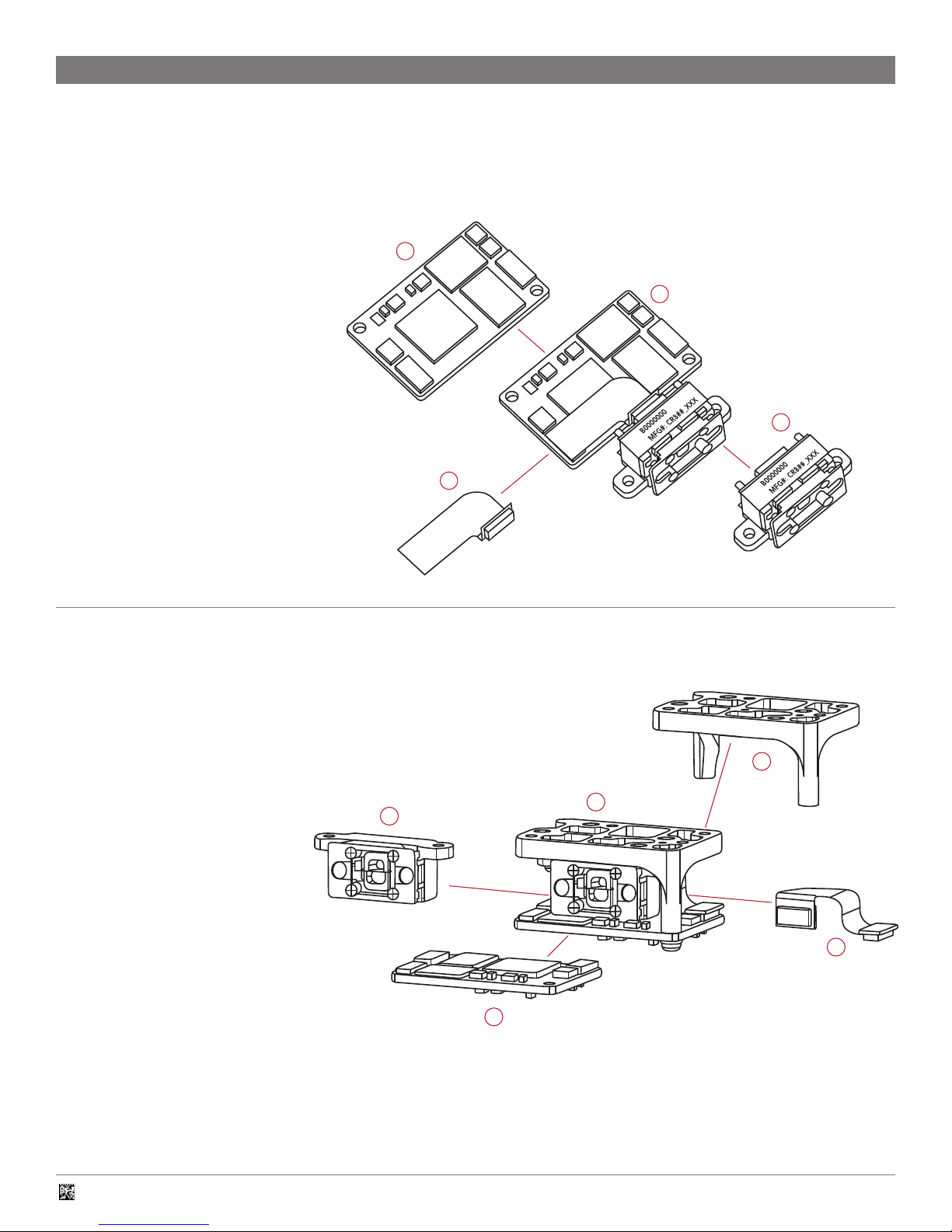

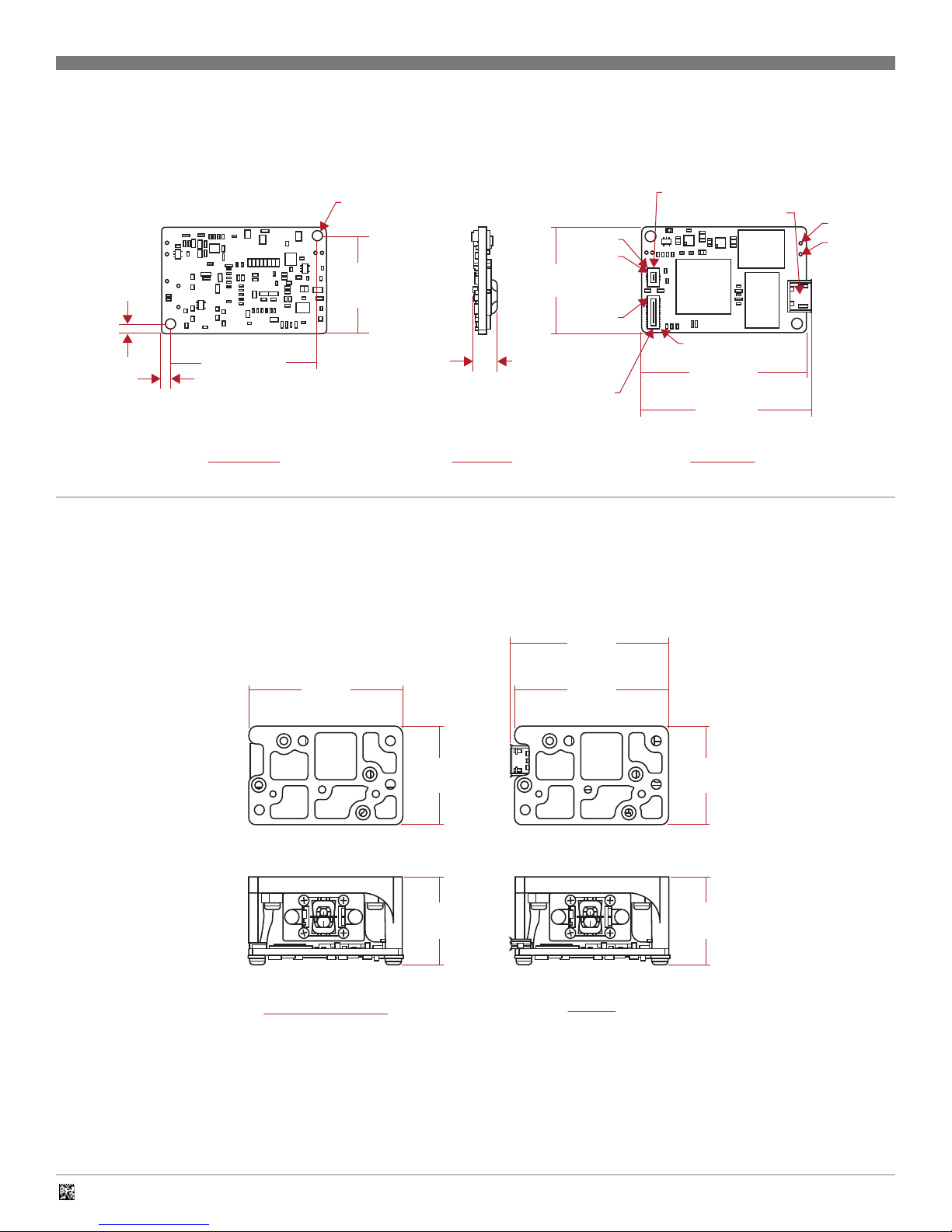

2.3 – Scan Engine Components

13.53

[.532]

SIDE VIEW

7.12

[.280]

13.00

[.512]

Ø1.65 [.065] X 3.00 [.128]

2 PLACES - HOLES ARE

PROVIDED FOR MOUNTING

WITH SELF-TAPPING SCREWS

TOP VIEW

11.90

[.468]

PIN 29

PIN 30

PIN 2

HIROSE CONNECTOR

P/N: DF40C-30DS-0.4V(51)

BACK VIEW

UNITS = MM [INCHES]

7.12

[.280]

13.00

[.512]

Ø1.65 [.065] X 3.00 [.128]

2 PLACES - HOLES ARE

PROVIDED FOR MOUNTING

WITH SELF-TAPPING SCREWS

TOP VIEW

11.90

[.468]

PIN 29

PIN 30

PIN 2

HIROSE CONNECTOR

P/N: DF40C-30DS-0.4V(51)

BACK VIEW

UNITS = MM [INCHES]

WITH SELF-TAPPING SCREWS

11.90

[.468]

PIN 29

PIN 30

PIN 2

BACK VIEW

2

1. Blue LED Targeting Lens

2. Red LED Illumination Lens

4

3

2

1

3. High Density Field Lens

4. Wide Field Lens

1

5. Self-Tapping Screw Holes

6. Printed Circuit Boards

2

7. Connector, Receptacle, 30 pin,

0.4 mm pitch

5

2.4 – Scan Engine with Mounting Tabs Components

2

1. Blue LED Targeting Lens

2. Red LED Illumination Lens

3. High Density Field Lens

4. Wide Field Lens

5. Mounting Tabs

6. Self-Tapping Screw Holes

7. Printed Circuit Boards

8. Connector, Receptacle, 30 pin,

0.4 mm pitch

2

1

2

5

4

3

6

2

6

5

7

6

1

7

2

5

6

8

7

2.5 – Scan Engine Mechanical Specifications

1. The Scan Engine has two holes available for

mounting with 2 self-tapping screws.

2. Please use #1-32 Trilobular® thread

forming screw or M1.8 Delta PT®

thread forming screw, with the following

dimensions:

Mininum Maximum

Thread Engagement 2.00 mm 2.50 mm

Length (B)

Torque N/A 1.5 Ibf-in

#1-32 OR

M1.8 SCREW

MOUNTING

SUBSTRATE

C8200 HOUSING

CR8000

(3.00)

Mounting Substrate

Thickness (A) + 2.00 mm

(Ø2.00)

(Ø1.65)

A

2.50 MAX

2.00 MIN

B

Mounting Substrate

Thickness (A) + 2.50 mm

20.58

[.810]

FRONT VIEW

13.53

[.532]

SIDE VIEW

HIROSE CONNECTOR

P/N: DF40C-30DS-0.4V(51)

11.90

[.468]

7.12

[.280]

TOP VIEW

PIN 2

PIN 30

PIN 29

BACK VIEW

Ø1.65 [.065] X 3.00 [.128]

2 PLACES - HOLES ARE

PROVIDED FOR MOUNTING

13.00

[.512]

UNITS = MM [INCHES]

C005383_10 CR80XX Integration Guide

6

Page 7

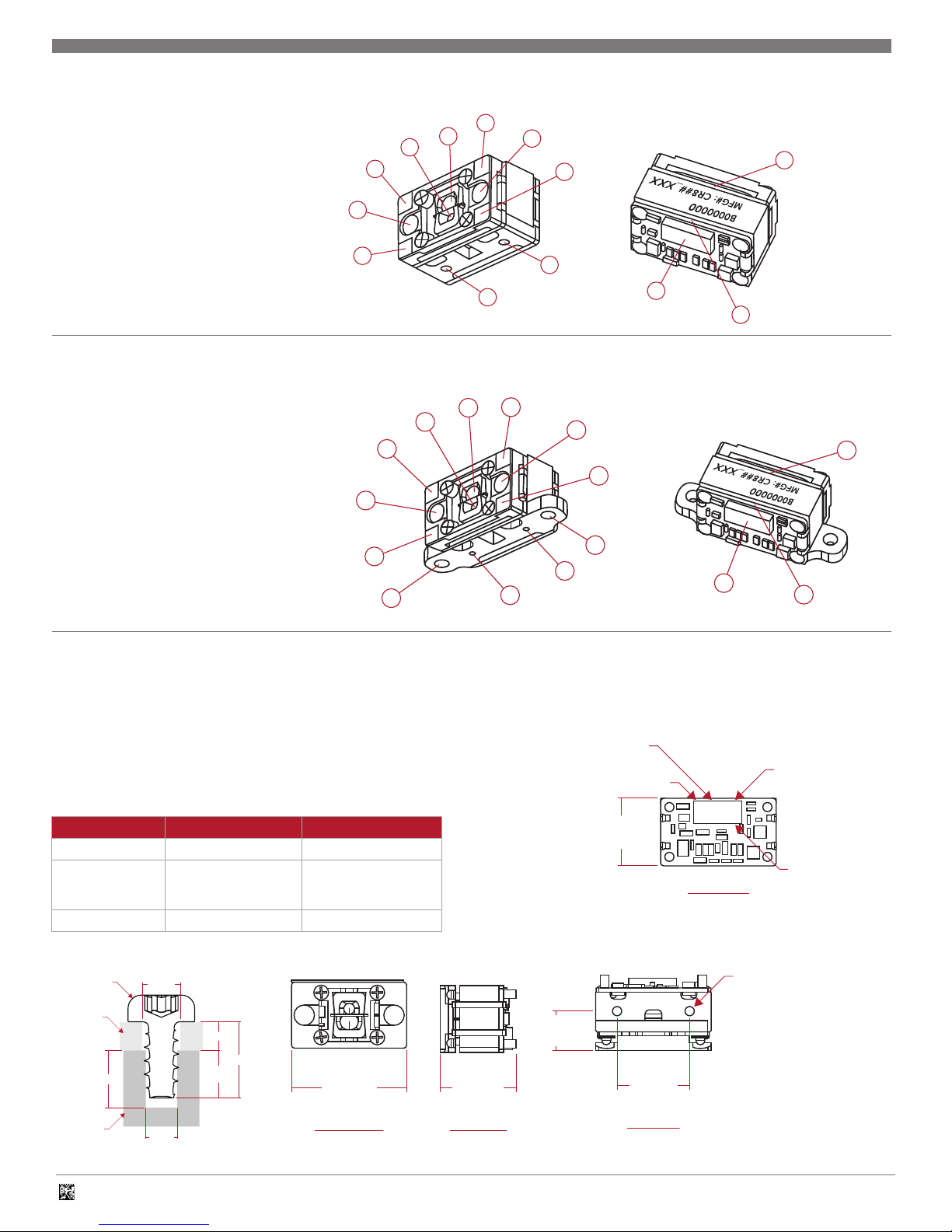

2.6 – Scan Engine with Mounting Tabs Mechanical Specifications

1. The CR8000 with Mounting Tabs has two

tabs with mounting holes as well as two

blind holes available for mounting with 2

self-tapping screws.

2. For the Mounting Tabs, please use M2.2

x 6 Phillips pan head screws. The design

does not require a washer, however, if one

is desired, Code recommends a flat washer,

No. 2 Screw Size, .19" OD,

.01"-.03" thick.

3. For the Blind Holes, please use M2.2 x 4.5

Phillips pan head, type AB, steel, zinc clear,

Trivalent self-tapping screws.

PIN 29

1.00

[.039]

7.12

[.280]

9.16

[.361]

4.75

[.187]

7.15

[.281]

[.405]

C

OF OPTICAL PATH

L

10.29

26.00

[1.024]

13.00

[.512]

TOP VIEW

C

OF OPTICAL PATH

L

20.58

[.810]

FRONT VIEW

E0000000

MFG#: CR8##_XXX

Ø1.65 [.065] X 3.00 [.128] 2 PLACES

HOLES ARE PROVIDED FOR MOUNTING

WITH SELF-TAPPING SCREWS.

13.53

[.532]

2.04

[.080]

CLEARANCE HOLE FOR

#2 OR M2 SCREW (2 PLACES)

2.45

[.096]

13.53

[.532]

SIDE VIEW

PIN 30

HIROSE CONNECTOR

P/N: DF40C-30DS-0.4V(51)

BACK VIEW

PIN 2

2.7 – Decode PCB Mechanical Specifications

1. The CR8000 Decode PCB has two holes available for mounting.

2. Please use M2.2 Phillips pan head screws with flat nylon washers, No.

2 Screw Size, 0.19" OD, 0.02" thick.

CR8011 and CR8012

2.54 [.100] CLEARANCE HOLE

2.25

[.089]

2 PLACES

34.50

[1.358]

HIROSE DF40C-10DS-0.4V(51)

22.75

[.896]

7.30

[.287]

[1.024]

BOTTOM VIEW

TP29

TP28

PIN 1

PIN 1

PIN 10

26.00

CONNECTOR FPC ZIF

P/N: FCI 10051922-1210ELF

PIN 30

HIROSE CONNECTOR

P/N: DF40C-30DS-0.4V(51)

39.00

[1.535]

UNITS = MM [INCHES]

PIN 12

PIN 1

25.00

[.984]

BOTTOM VIEW UNITS = MM [INCHES]

C005383_10 CR80XX Integration Guide

SIDE VIEW

TOP VIEW

7

Page 8

2.7 – Decode PCB Mechanical Specifications (continued)

CR8013

2.54 [.100]

CLEARANCE HOLE

2PLACES

PIN 1

PIN 10

25.00

[.984]

PIN 1

2.25

[.089]

2.25

[.089]

34.50

[1.358]

FRONT VIEW

22.75

[.896]

5.65

[.222]

HIROSE CONNECTOR

P/N: DF40C-30DS-0.4V(51)

SIDE VIEW

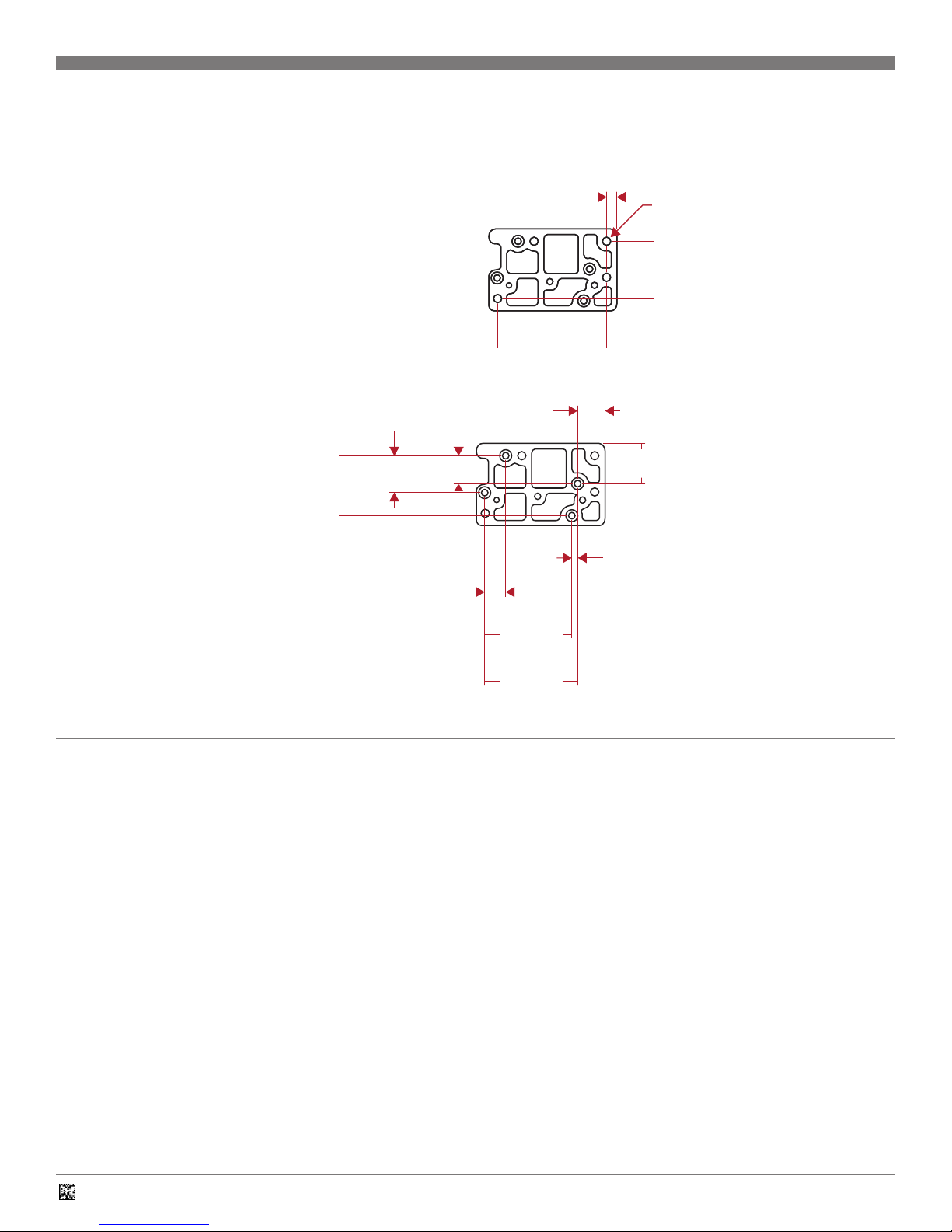

2.8 – CR8000 Decoded Scan Engine with Bracket Specifications

The CR8000 bracket has six holes for mounting the device: two unthreaded

holes and four threaded holes. This allows the use of

both self-tapping and machine screws in the target application.

Overall Dimensions

40.13

[1.580]

HIROSE DF40C-10DS-0.4V(51)

MICRO USB TYPE B

PIN 30

39.00

[1.535]

40.13

[1.580]

BACK VIEW

UNITS = MM [INCHES]

TP 31

TP 32

39.00

[1.540]

CR8011 and CR8012

25.00

[.980]

21.83

[.860]

39.00

[1.540]

25.00

[.980]

21.83

[.860]

CR8013

C005383_10 CR80XX Integration Guide

8

Page 9

2.8 – CR8000 Decoded Scan Engine with Bracket Specifications (continued)

Non-Threaded Mounting Holes

There are two 2.50 mm diameter non-threaded

mounting holes on the CR8000 bracket,

shown below.

3.24

3.24

[.128]

[.128]

33.09

33.09

[1.303]

[1.303]

2X 2.50 [.098]

2X 2.50 [.098]

± .07 THRU

± .07 THRU

17.35

17.35

[.680]

[.680]

Threaded Mounting Holes

There are four M2 threaded mounting holes

on the CR8000 bracket, shown below. We

recommend using a M2X5 machine screw

for mounting.

18.24

[.720]

11.23

[.440]

2.9 – Enclosure Specifications

1. The enclosure for the CR8000 should be sufficiently large enough

to accommodate the engine and allow air flow to maintain safe

temperatures. The enclosure should minimize infiltration by

airborne contaminants and foreign materials.

2. The CR8000 must not come in contact with water.

[.330]

6.27

[.250]

8.44

8.42

[.330]

12.22

[.480]

1.85

[.070]

26.24

[1.030]

28.09

[1.110]

3. The CR8000 is sensitive to Electrostatic Discharge (ESD) and must be

handled appropriately. Any individual that handles the CR8000 should

be grounded using a wrist strap and ESD protected work area and

work surface.

4. The warranty of the CR8000 is void if the recommendations above are

not followed when handling or integrating the device.

UNITS = MM [INCHES]

C005383_10 CR80XX Integration Guide

9

Page 10

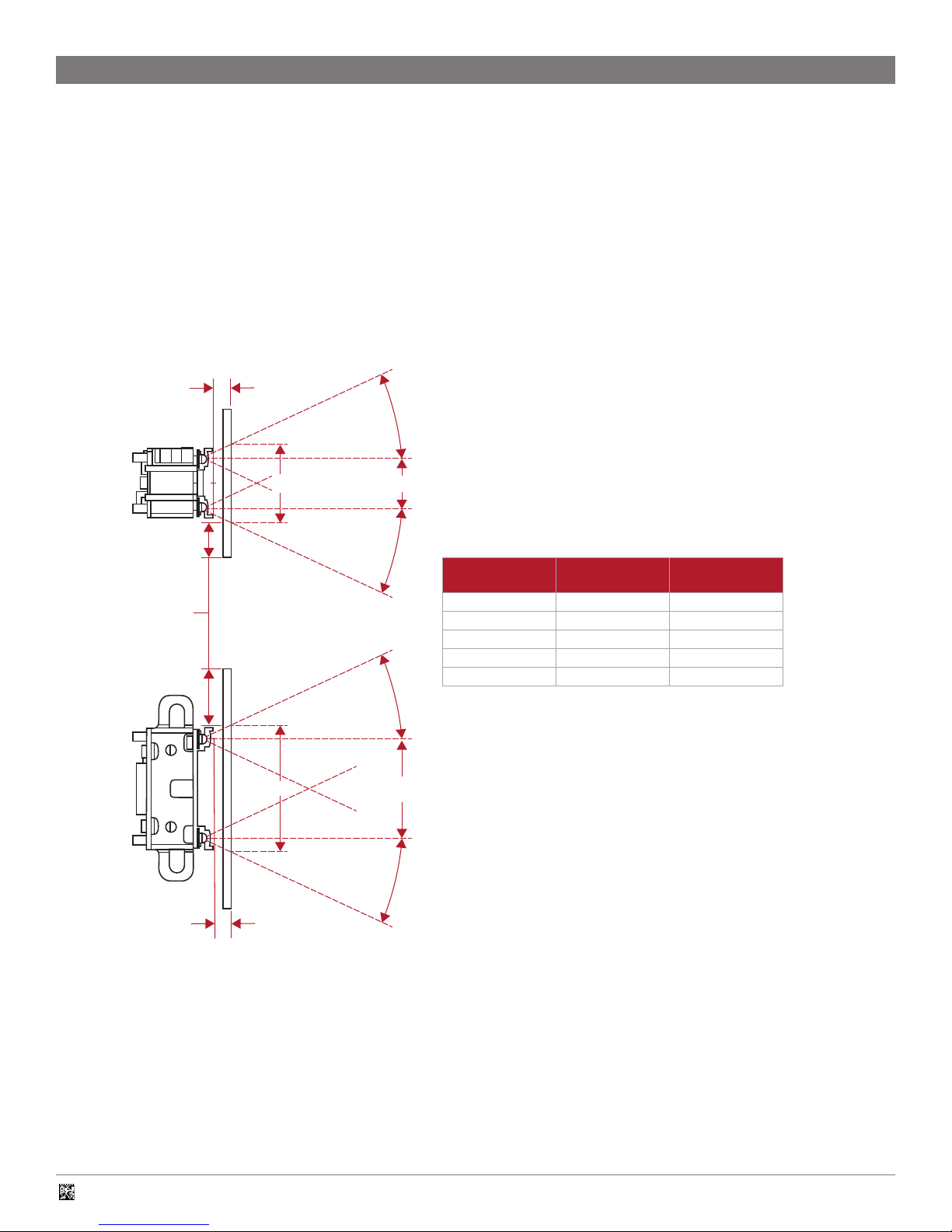

3 - Optical Considerations

3.1 – Window Requirements

When integrating the CR8000 into your device or application, it may be

necessary to install a window in front of the optics of the Scan Engine.

Although many different types of materials can be considered, Code makes

the following recommendations.

Placement: Contact to 0.5 mm away from the face of the Scan Engine,

parallel to engine face

Material: Optically clear acrylic

Thickness: 1 mm or less

CR8000 Field of Illumination Diagram

D

25.00˚

H

WINDOW SIZE MUST

EXCEED WIDTH

AND HEIGHT OF

ILLUMINATION ANGLE

8.69 (CENTER-TO-CENTER LED SPACING)

25.00˚

25.00˚

If your design constraints prevent the window from being mounted within

0.5 mm of the face of the engine, Code recommends an anti-reflective

(AR) coating be applied to both window surfaces (front and back). The AR

coating must have less than 3% reflectance from 400nm to 1000nm.

The window must be wide and tall enough so the surrounding enclosure

does not block any of the illumination from the LEDs. The following diagram

illustrates the field of illumination that must be unobstructed

by the edges of the window aperture.

Distance to

Window (D)

1 mm 19.58 mm 11.40 mm

2 mm 20.51 mm 12.33 mm

3 mm 21.44 mm 13.26 mm

4 mm 22.37 mm 14.20 mm

5 mm 23.31 mm 15.13 mm

*Window must exceed this width/height

Illumination

Width (W)*

Illumination

Height (H)*

W

D

C005383_10 CR80XX Integration Guide

16.87 (CENTER-TO-CENTER LED SPACING)

25.00˚

10

Page 11

3.2 – Imager Field of View

The CR8000 Decoded Scan Engine contains an imager with both Wide

Angle and High Density Fields. The Field of View for both Wide Angle

and High Density optics is shown below for Horizontal and Vertical

positioning of the imager:

CR8000 Field of View Diagram

HIGH DENSITY FOV

WIDE FIELD FOV

HIGH DENSITY FOV

16.75 ˚

16.75 ˚

15.00 ˚

10.00 ˚

10.00 ˚

25.00 ˚

WF

WIDE FIELD FOV

C005383_10 CR80XX Integration Guide

15.00 ˚

25.00 ˚

11

Page 12

4 - Electrical Specifications

4.1 – System Requirements

Power Supply: The CR8000 is powered from the host via the Vin and Gnd

pins. Vin must be within the range specified in Section 4.15 when measured

at the decoding board. Vin must be maintained with varying loads, such as

when the illumination is turned ON and OFF.

Host Ribbon Cable (FFC) (CR8011 and CR8012): The impedance of

the cable for the USB data lines should be 90 ohm differential. For 3.3V

operation, a Ribbon Cable of no more than 6.0" in length can be used with a

0.28 mm (0.011") trace width and 0.3 mm trace thickness.

Scan Engine to Decode Board Flex Cable (FPC): When leveraging a

non-bracketed design, care should be taken to alleviate bend stress on the

Flex Cable, which could lead to damage of that cable. The minimum bend

radius for this cable is 2.0 mm. Drawings can be provided upon request to

aid in design. Flex Cable length should not exceed 6.0".

4.2 – Electrical System Block Diagram

The CR8000 Decoded Scan Engine is a complete barcode scanning

system that can be easily integrated into any device.

The block diagram below shows the main components of the system

(CR8011/8012).

RIBBON CABLE (RS232/USB)

Power Sequencing: There is no special power sequence needed for the

CR8000 as long as the max and min voltage and current specifications are

met. However, if the voltage on a pin is greater than Vin, such as

when powering on, then current will flow from the pin to Vin through

the pull up resistors.

Thermal Requirements: The operating temperature range for the CR8000 is

-20ºC to 55 ºC (-4ºF to 131ºF) ambient air.

RS232 Polarit/NU

V

IN

GND

RXD/USB D-

TXD/NU

CTS/USB D+

RTS/NU

PwrDwn

nBeeper

nGoodRead

nWakeUp

nTrigger

NU = Not Used on USB Model

DECODE

PCBA

FLEX CABLE

Power

Illum. Control

I2C Bus

Image Control

Image Data

OPTICAL

ENGINE

C005383_10 CR80XX Integration Guide

12

Page 13

4.3 – Host Interface Pinouts (CR8012 RS232)

Pin Name Type Description Note

1 RS232 Polarity Input RS232 polarity control. When high, all RS232 signals have their normal polarity.

When low, all RS232 signals have inverted polarity.

2 Vin Power Power supply voltage input

3 Gnd Power Power supply and signal ground

4 RxD Input RS232 receive data, TTL level 1

5 TxD Output RS232 transmit data, TTL level 1

6 CTS Input RS232 Clear to Send, TTL level 1

7 RTS Output RS232 Request to Send, TTL level 1

8 PwrDwn Output Power down indicator; active high 1

9 nBeeper Output Feedback indicator (success, error, etc.); active low 1

10 nGoodRead Output Indicates a successful decode; active low 1

11 nWakeUp Input Bring the unit out of sleep state; active low 1,2

12 nTrigger Input Activate image acquisition, decode; active low 1

Notes: 1. Pin has a weak pull up to Vin.

2. If not actively controlling sleep mode, leave unconnected. Do not tie low.

4.4 – Host Interface Pinouts (CR8011 USB)

Pin Name Type Description Note

1 <unused> Input 1

2 Vin Power Power supply voltage input

3 Gnd Power Power supply and signal ground

4 D- Bidirectional USB D- signal

5 <unused> Output 1

6 D+ Bidirectional USB D+ signal

7 <unused> Output 1

8 PwrDwn Output Power down indicator; active high 1

9 nBeeper Output Feedback indicator (success, error, etc.); active low 1

10 nGoodRead Output Indicates a successful decode; active low 1

11 nWakeUp Input Bring the unit out of sleep state; active low 1,2

12 nTrigger Input Activate image acquisition, decode; active low 1

1

Notes: 1. Pin has a weak pull up to Vin.

2. If not actively controlling sleep mode, leave unconnected. Do not tie low.

4.5 – Host Interface Pinouts (CR8013 micro-USB)

Pin Name Type Description Note

1 Vin Power +5 VDC

2 D- Bidirectional USB D- signal

3 D+ Bidirectional USB D+ signal

4 ID Output On-the-GO (OTG) Host/Device ID 1

5 Gnd Power Power supply and signal ground

Notes: 1. Not supported.

C005383_10 CR80XX Integration Guide

13

Page 14

4.6 – Electrical Control Signals (CR8011 and CR8012 only)

The CR8000 is equipped with inputs and outputs that allow the user to

control the reader and get certain status information via hardware signals. A

brief description of each signal is given in this Section. For additional details

on the interaction and timing of these signals, refer to the Timing Diagrams

and Tables in the Sections that follow. To get more information on register

functions, refer to the Interface Configuration Document (ICD), available on

the Code website (www.codecorp.com).

Pin 8 - Power Down (output): The PwrDwn line is used to indicate the

operational state of the reader. PwrDwn will be asserted HIGH when the

CR8000 has switched to the sleep state. PwrDwn will transition back to the

LOW state when the CR8000 is not in the sleep state. The different power

modes are described in more detail in the Section 4.7.

Pin 9 – Beeper (output): The nBeeper line is used to indicate a successful

decode, completion of the boot process, errors, and certain other conditions

or events. nBeeper can be configured to transition to a LOW state for a

specified length of time or to output a series of pulses of a specified duration

on a successful decode or on certain error conditions. The duration of

this signal can be set with register 0x59. Default behavior for this signal is

one “beep” for a good decode, two “beeps” for a successful configuration

barcode read, and four beeps if a configuration was not applied successfully.

Pin 10 - Good Read (output): The nGoodRead line is used to indicate

a successful decode. Upon the completion of a successful scan and

decode, the nGoodRead line will be asserted LOW. The length of

nGoodRead assertion can be set with register 0x1EA.

Pin 11 – Wakeup (input): The nWakeUp line is used to change the state

of the reader from Sleep to Idle. Once the CR8000 has entered the sleep

state, it may be awakened by asserting nWakeUp with a LOW pulse. Note

that nWakeUp must be HIGH when the CR8000 enters the sleep state in

order for nWakeUp to awaken the CR8000 on assertion. Also note that when

the sleep state is not being used, this pin should be left open, not tied low.

Please note that the Sleep state is only valid for CR8012.

Pin 12 – Trigger (input): The nTrigger line is used to activate the reader.

To activate the CR8000, pull the nTrigger line LOW. This is normally used to

cause the reader to scan for a barcode.

Note: All output signals except USB D- and USB D+ are connected to

open drain buffers with a pull-up of 100 Kilo-ohm to Vin and a maximum

current capability of 50 mA. All input signals except USB D- and USB D+

are connected to a pull-up to Vin and to a buffer with a 50 mA maximum

current capability.

Note: When Vin is initially supplied, PwrDwn and the other outputs will

be LOW for a few milliseconds until the voltages on the board come up.

They will then transition to default HIGH due to pull-ups until the unit

is up and running. These signals should be ignored until the unit is fully

functioning. See startup timing diagram below for details.

4.7 – Power Modes (CR8011 and CR8012 only)

Boot Mode: The CR8000 enters boot mode upon application of Vin. The

PwrDwn pin will be HIGH (after power on delay) until the main app starts.

Active Mode: In Active Mode the unit is capturing images and initiating the

decode process and/or storing images. The unit transitions to Active Mode

from Idle Mode when a trigger event is received.

Idle Mode: In Idle Mode the unit is not actively capturing images. The

processor is fully functioning and communication can take place, upgrades

can be performed, and scripts can be run. Idle Mode is entered from Boot

Mode after power on, from Active Mode after a register defined timeout in

which there are no trigger events, and from Sleep Mode on receipt of a wake

up.

Sleep Mode (CR8012 only): The imager, illumination, and most of the

processor is powered down. The CPU wake up circuitry, the memory, and

the input/output buffers are powered. The unit enters the sleep state after

a register defined timeout of inactivity, which is defined in register 0x9F. On

receipt of a wake up on the nWakeUp pin, the processor restores the run

environment and enters Idle Mode.

C005383_10 CR80XX Integration Guide

14

Page 15

4.8 – Power On (Boot) Timing Diagram (CR8011 and CR8012 only)

The PwrDwn signal will transistion to HIGH

shortly after Vin is applied and will remain HIGH

until the main application starts.

VIN

nBeeper

nGoodRead

PwrDwn

TPU1 TPU3

TPU2

Parameter Symbol Min Typical Max Unit Note

Time from Power On to

Outputs as Default

Time from Power On to

PwrDwn transition to LOW

Time from end of TPU2 to

reader in Idle Mode

Notes: 1. This time can be longer on USB model due to USB enumeration time.

TPU1 10 msec

TPU2 9000 msec

TPU3 1000 msec 1

C005383_10 CR80XX Integration Guide

15

Page 16

4.9 – Power Down Timing Diagram

Power (Vin) can be removed at any time except

when the unit is performing an upgrade.

Removing power during an upgrade may

cause the unit to become unusable.

Outputs

Parameter Symbol Min Typical Max Unit Note

Time from Power Off to

all outputs low

5V

VIN

0V

5V

0V

TPD1

Outputs: PwrDwn, nGoodRead, nBeeper

TPD1 56 msec

4.10 – Sleep to Wakeup Timing Diagram

nWakeUp

TWUPW

PwrDwn

TSU

TWU

Signal Description Min Typical Max Unit

Twupw nWakeUp pulse width 10 20 msec

Tsu Time between nWakeUp asserted and

outputs valid

Twu Time between nWakeUp asserted and

CR8000 ready

5 5 10 msec

120 msec

C005383_10 CR80XX Integration Guide

16

Page 17

4.11 – Image Capture and Decode Timing Diagram

Image acquisition and decoding can be started from either the nTrigger line

(CR8011 or CR8012) or via a communications channel command. The

time required to capture an image can vary depending on the size of image

selected, the confirmation time register (0xE3), and where the imager is in

the capture cycle. The time to decode an image can depend on the image

nTrigger

TRIGGER ACCEPTED

IMAGE CAPTURE COMPLETE

TTMIN

TTCT

Image Capture and Decode Timing

Parameter Symbol Min Typical Max Unit Note

Time from Trigger Accepted to

Image Capture Complete

Minimum Trigger duration TTmin TTcT 2

Trigger Confirmation Time TTcT 0 2

Notes: 1. Maximum image size.

2. Trigger must be asserted for Trigger Confirmation Time;

3. Trigger Confirmation Time defaults to zero and is adjustable as referenced above (register E3).

Tic 25 50 msec 1

quality, complexity of the barcode, etc. The maximum time spent trying to

decode an image defaults to 320ms and can be controlled by a register

(2C). To get more information on register functions, refer to the Interface

Configuration Document (ICD), available on the Code website (www.

codecorp.com).

IC

T

31

msec 3

4.12 – Flex Cable Diagram (Imager Board to Decoder Board on All Models)

Code Flex Cables have the following characteristics:

1: Fabricated to the following specifications:

• IPC-6013 (Generic Performance Specification

for Printed Boards)

• IPC-SM-839 (Pre and Post Solder Mask Application

Cleaning Guidelines)

• IPC-SM-840 (Qualification and Performance of

Permanent Polymer Coating for Printed Boards)

• IPC-2615 (Printed Board Dimensions and Tolerances)

• IPC-A-600 (Acceptability of Printed Boards)

2: Stiffener area material is FR-4 natural material with finished

thickness 0.8 mm +/- 0.13 mm

3: Flex area material is polyimide with finished thickness

0.254 mm +/- 0.05 mm

4: Both sides silkscreened in Haven 421 WF-1 or equivalent

5: RoHS and UL 94V0 compliant

6: Vias plated shut

7: Connectors are Hirose Part Number DF40C-30DP-0.4V(51)

8: Cable length should not exceed 152.4 mm (6.0")

Three Flex Cables are available with the following SKUs:

SKU Type

D0 Standard Flex

D1 Reverse Flex

D2 In-Line (Centerline) Flex

23.70

[.933]

9.00

[.354]

5.00

[.196]

9.00

[.354]

5.00

[.196]

Standard Flex

UNITS = MM [INCHES]

18.00

[.708]

C005383_10 CR80XX Integration Guide

17

Page 18

4.12 – Flex Cable Diagram (Imager Board to Decoder Board on All Models) (continued)

UNITS = MM [INCHES]In-line (Centerline) Flex

29.00

[1.141]

9.00

[.354]

9.00

[.354]

7.57

[.298]

17.57

[.691]

52.30

[2.050]

19.00

[.748]

Reverse Flex

17.90

[.704]

9.00

[.354]

9.00

[.354]

5.00

[.196]

4.13 – Ribbon Cable Diagram (Decode Board to Host Interface on CR8011 and CR8012)

Our Ribbon Cables have the following characteristics:

1: Bottom contact on CR8000 mating end

2: 12 pin

3: 0.5 mm pitch

4: 0.3 mm thickness with stiffener

Our Ribbon Cables have contacts on the same side of each end. Please

take this into account with respect to the control signals when designing the

mating connector pinout on the host interface.

The Development Kits, CR80XX-DKX, use a Ribbon Cable with opposite

side contacts.

3.3V operation of the CR8000 is only possible with 6.0" or

shorter Ribbon Cable.

Three Ribbon Cables are available with the following SKUs and lengths:

SKU Length

C800 50.8 mm (2.0")

C801 152.4 mm (6.0")

C802 304.8 mm (12.0")

3.556

[.14]

.305

[.012]

C005383_10 CR80XX Integration Guide

CABLE LENGTH

6.00

[.236]

.28

[.011]

.50

[.020]

5.50

[.217]

.356

[.014]

6.50

[.256]

UNITS = MM [INCHES]

18

Page 19

4.14 – Electrical Characteristics (DC) – Absolute Ratings (Min and Max)

Parameter Symbol Min Max Unit Note

DC Supply Voltage Vin -0.5 5.5 V

DC Input Voltage Vi -0.5 5.5 V

DC Output Voltage Vo -0.5 5.5 V

Output source or sink current Io 50 mA

4.15 – Electrical Characteristics (DC) – Operating Conditions

Parameter Symbol Min Typical Max Unit Note

RS232

DC Supply Voltage, RS232 Vin 3.3 5.5 V

High level input voltage Vih 0.7 x Vin V

Low level input voltage Vil 0.8 V

High level output voltage Voh Vin 1

Low level output voltage Vol 0.55 V

Sleep current is 1 mA 3,4

USB

DC Supply Voltage, USB Vin 4.75 5.25 V

USB high level input voltage Vusbih 2.0 V

USB low level input voltage Vusbil 0.8 V

USB static output high Vusboh 2.8 3.6 V

USB static output low Vusbol 0.3 V

RS232 and USB

Output leakage current ioz 10 uA

Active operating current ia 345 mA 2,5

Idle operating current ii 75 mA

Maximum current available to

expand illumination circuitry

ixi 200 mA 6

Notes: 1. 100 Kilo-ohm pull-up to Vin on open drain output; actual voltage will depend on

external impedance connected to pin.

2. Depends on the brightness level of the illumination LEDs.

3. Assumes inputs and outputs are tri-stated or high. If pulled low, current through pull up

resistors will need to be added.

4. The USB model does not support sleep mode.

5. Continuous scan.

6. Current limited by constant current rating of ferrite.

C005383_10 CR80XX Integration Guide

19

Page 20

4.16 – Decode PCB to Scan Engine PCB Connector

Pin Name Type Description Note

1 Vin Power Vin power to Optical Engine

2 Vin Power Vin power to Optical Engine

3 1.8V Power 1.8V power to Optical Engine

4 1.8V Power 1.8V power to Optical Engine

5 Gnd Power Power and signal ground

6 ExtClk Output External clock to imager

7 Gnd Power Power and signal ground

8 PixClk Input Pixel clock

9 Gnd Power Power and signal ground

10 FrameValid Input Vsync from imager

11 LineValid Input Hsync from imager

12 Gnd Power Power and signal ground

13 Dout4 Input Imager pixel data 4

14 Dout5 Input Imager pixel data 5

15 Dout6 Input Imager pixel data 6

16 Dout7 Input Imager pixel data 7

17 Dout8 Input Imager pixel data 8

18 Dout9 Input Imager pixel data 9

19 Dout10 Input Imager pixel data 10

20 Dout11 Input Imager pixel data 11

21 nImagerReset Output Imager reset, active low

22 ImagerStandby Output Imager standby

23 Sdata Input/Output I2C bus data line

24 Sclk Output I2C bus clock line

25 Gnd Power Power and signal ground

26 IllumPwm0 Output PWM illumination signal

27 TargetLed Output Targeting LED control signal

28 1.8VImagerEnable Output Imager 1.8V enable

29 5VEnable Output Optical Engine 5V enable

30 2.8VEnable Output Optical Engine 2.8V enable

C005383_10 CR80XX Integration Guide

20

Page 21

4.17 – Decode PCB Expanded Illumination Connector

The board connector is a Hirose DF40C-10DS-0.4V(51) and mates to a

cable containing a Hirose DF40C-10DP-0.4V(51) connector.

Pin Name Type Description Note

1 Vin Power Power supply voltage input

2 Vin Power Power supply voltage input

3 Illumination IO 0 Bidirectional Illumination Communications Line, UART

Port4 TX TTL Level, I2C SDA

4 Illumination IO 1 Bidirectional Illumination Communications Line, UART

Port4 RX TTL Level, I2C SCL

5 Illumination PWM 1 Output Illumination PWM output

6 Illumination IO 2 Bidirectional Illumination Communications Line, GPIO

7 Illumination IO 3 Bidirectional Illumination Communications Line, GPIO

8 Illumination IO 4 Bidirectional Illumination Communications Line, Boot

Select Signal

9 Gnd Power Power supply and signal ground

10 Gnd Power Power supply and signal ground

Notes: 1. 10 Kilo-ohm pull-up to 3.3V.

1

1

1

C005383_10 CR80XX Integration Guide

21

Page 22

5 - Configuration

5.1 – Serial Commands

The CR8000 engine can be configured by scanning barcodes or by

sending serial commands. The following is an overview of the serial

command functionality. The details are documented in the Interface

Configuration Document (ICD), which is available on the Code

website (www.codecorp.com).

Serial commands can be sent in two formats. The default format is

referred to as a packetized command. A packetized command contains

the following structure and are valid values for each component of the

packetized command:

Prefix: 0xEE 0xEE 0xEE 0xEE

Command Type: Single ASCII character representing command

Data Size: Byte value in range [0,240], which indicates size

of Data (in bytes)

Datum/Data: Any byte value in the range [0,255]

Reserved: 0x00

CRC14: Two consecutive bytes, each in range [0,127], representing a

check digit for the packet being sent.

The complete list of commands and valid data options are listed in the ICD.

The below is an example of the sequence of hex values that would cause the

reader to beep:

0xEE 0xEE 0xEE 0xEE 0x23 0x01 0x03 0x00 0x4E 0x71

This sends the reader the ‘#’ command with a value of 3, which will cause

the reader to beep three times.

A simpler method is referred to as text commands. In order to

eliminate inadvertent commanding of the reader, text commands

are disabled by default. Text commands can be enabled by sending

the following sequence:

;>PA1 0x0d

This sets register 0x41 to 1, which enables text commands to be sent. The

following sequence could also be sent, which will enable text commands but

suppresses echo and responses:

;>PA7 0x0d

Once text commands are enabled you can execute commands by

sending only the command. No packet is required. For example,

the same packetized beep command described above in text

command format would be:

#%03 0x0d or #0x03 0x0d

The reader will convert %xx characters to the ASCII values represented by

the xx. In the example above %03 is also 0x03 or the ETX ASCII character.

The reader will respond with an appropriate response after

a command is received (if responses are enabled).

The complete documentation of the available commands, reader responses

and registers are documented in the Interface Configuration Document

(ICD), available at www.codecorp.com

C005383_10 CR80XX Integration Guide

22

Page 23

6 – Shipping Specifications

The CR8000 engines are shipped in bulk packaging in a 10-unit box.

Each unit is individually packaged in an ESD safe bag and separated by

cardboard dividers. The Flex Cables are packaged in an ESD safe bag and

placed in a cardboard divider.

A label with up to 10 unit serial numbers is affixed to the outside

of the box.

The box dimensions are 9.0" (190 mm) W x 8.0" (170 mm) D x 3.0" (105

mm) H and the box is sealed with an ESD caution label.

10124512 10045123 20014541 20001425 20145136

20000145 20001564 10101010 54875643 10011001

C005383_10 CR80XX Integration Guide

23

Page 24

7 – General Specifications

Physical Characteristics Specification

CR8000 Dimensions 0.81" W x 0.53" D x 0.47" H

CR8000 with Tabs Dimensions 1.25" W x 0.53" D x 0.47" H

Decode PCB 1.54" W x 0.98" D x 0.30" H

CR8000 with Tabs Weight 0.10 oz. (3.0g )

CR8000 and Decode PCB Weight 0.17 oz. (5.0 g)

CR8000 Reader without Tabs Weight 0.09 oz. (3.0 g)

Physical Characteristics Specification

Field of View High Density Field: 30° horizontal by 20° vertical

Focal Point High Density Field: 100 mm

Sensor CMOS 1.2 Megapixel

Optical Resolution High Density Field: 960 x 640

Pitch ± 60° (from front to back)

Skew ± 60° from plane parallel to symbol (side-to-side)

Rotational Tolerance ± 180°

Print Contrast 25% (1D symbologies) or 35% (2D symbologies)

Target Beam Single, blue targeting bar

Ambient Light Immunity Sunlight: Up to 9,000'-candles/96,890 lux

Shock Withstands multiple drops of 6' (1.8 meters) to

Power Requirements Reader @ 5vdc: Typical=303 mA; Idle=57 mA;

Memory Capacity 128MB Flash ROM, 32MB RAM

Communication Interfaces TTL-RS232, USB 2.0, (Generic HID, HID Keyboard,

(20.58 mm W x 13.53 mm D x 11.9 mm H)

(31.7 mm W x 13.53 mm D x 11.9 mm H)

(39.0 mm W x 25.0 mm D x 7.5 mm H)

Wide Field: 50° horizontal by 33.5° vertical

Wide Field: 115 mm

(1280 x 960) gray scale

Wide Field: 960 x 640

absolute dark/light reflectance differential, measured at

650nm

concrete in an enclosed housing

Sleep=less than 2 mA

Virtual Com Port); micro-USB connection available

User Environment Specification

Operating Temperature -20° to 55° C / -4° to 131° F

Storage Temperature -30° to 65° C / 22° to 150° F

Humidity 5% to 95% non-condensing

1D Barcodes Codabar, Code 11, Code 32, Code 39, Code 93, Code 128,

Stacked 1D Barcodes PDF417, Micro PDF417, Codablock A & F

2D Barcodes Data Matrix, QR Code, Micro QR Code, Aztec Code,

Proprietary 2D Barcodes GoCode® (Additional License Required)

Image Output Options Formats: JPEG, PGM, Raw (Uncompressed)

Field Selection High-Density or Wide Field

Programming Toolset JavaScript

C005383_10 CR80XX Integration Guide

Interleaved 2 of 5, GS1 DataBar (RSS), Hong Kong 2 of 5,

Maxtrix 2 of 5, MSI Plessey, Pharmacode, Plessey, Straight

2 of 5, Telepen, Trioptic, UPC/EAN/JAN

Maxicode, Han Xin (Chinese Simplified) Code

24

Page 25

8 – Reading Range Specifications

The following table summarizes the reading distances for the specified

barcodes with both the Wide Area Field and the High Density Field enabled

and active for decoding.

Test Barcode Min Inches (mm) Max Inches (mm)

3 Mil Code 39 3.1" (80 mm) 4.0" (102 mm)

7.5 Mil Code 39 1.3" (33 mm) 7.2" (182 mm)

10.5 Mil GS1 Databar 0.8" (20 mm) 8.7" (220 mm)

13 Mil UPC 1.1" (28 mm) 11.0" (280 mm)

5 Mil Data Matrix 1.7" (43 mm) 4.5" (115 mm)

6.3 Mil Data Matrix 1.3" (33 mm) 5.9" (150 mm)

10 Mil Data Matrix 0.8" (20 mm) 7.1" (180 mm)

20.8 Mil Data Matrix 1.1" (28 mm) 13.5" (343 mm)

Note: working ranges are a combination of both the wide and high density fields. All samples were high quality barcodes and were read along a

physical center line at a 10° angle. Default AGC settings were used. Accuracy = +/- 10%.

C005383_10 CR80XX Integration Guide

25

Page 26

9 - Warranty

The CR8000 carries a one year limited warranty as described herein.

Limited Warranty. Code warrants each Code product against defects in materials

and workmanship under normal use for the Warranty Coverage Term applicable

to the product as described at www.codecorp.com/legal/warranty/term.php. If

a hardware defect arises and a valid warranty claim is received by Code during

the Warranty Coverage Term, Code will either: i) repair a hardware defect at no

charge, using new parts or parts equivalent to new in performance and reliability;

ii) replace the Code product with a product that is new or refurbished product with

equivalent functionality and performance, which may include replacing a product

that is no longer available with a newer model product; or ii) in the case of failure

with any software, including embedded software included in any Code product,

provide a patch, update, or other work around. All replaced products become the

property of Code. All warranty claims must be made using Code’s RMA process.

Exclusions. This warranty does not apply to: i) cosmetic damage, including but

not limited to scratches, dents, and broken plastic; ii) damage resulting from

use with non-Code products or peripherals, including batteries, power supplies,

cables, and docking station/cradles; iii) damage resulting from accident, abuse,

misuse, flood, fire or other external causes, including damage caused by unusual

physical or electrical stress, immersion in fluids or exposure to cleaning products

not approved by Code, puncture, crushing, and incorrect voltage or polarity;

iv) damage resulting from services performed by anyone other than a Code

authorized repair facility; v) any product that has been modified or altered; vi)

any product on which the Code serial number has been removed or defaced. If

a Code Product is returned under a warranty claim and Code determines, in

Code’s sole discretion, that the warranty remedies do not apply, Code will contact

Customer to arrange either: i) repair or replace the Product; or ii) return the

Product to Customer, in each case at Customer’s expense.

Non Warranty Repairs. Code warrants its repair/replacement services for ninety

(90) days from the date of shipment of the repaired/replacement product to the

Customer. This warranty applies to repairs and replacements for: i) damage

excluded from the limited warranty described above; and ii) Code Products on

which the limited warranty described above has expired (or will expire within such

ninety (90) day warranty period). For repaired product this warranty covers only

the parts that were replaced during the repair and the labor associated with such

parts. Non Warranty Repairs. Code warrants its repair/replacement services for

ninety (90) days from the date of shipment of the repaired/replacement product to

the Customer. This warranty applies to repairs and replacements for: i) damage

excluded from the limited warranty described above; and ii) Code Products on

which the limited warranty described above has expired (or will expire within such

ninety (90) day warranty period). For repaired product this warranty covers only

the parts that were replaced during the repair and the labor associated with such

parts.

No Extension of Term of Coverage. Product that is repaired or replaced, or for

which a software patch, update, or other work around is provided, assumes the

remaining warranty of the original Code Product and does not extend the duration

of the original warranty period.

responsible for shipping and insurance charges for shipping Code Product to

Code’s designated RMA facility and repaired or replaced product is returned with

shipping and insurance paid by Code. Customer is responsible for all applicable

taxes, duties, and similar charges.

Transfer. If a customer sells a covered Code Product during the Warranty

Coverage Term, then that coverage may be transferred to the new owner by written

notification from the original owner to Code Corporation at:

CodeOne Service Center

12393 South Gateway Park Place, Suite 600

Draper, UT 84020 USA

Limitation on Liability. Code’s performance as described herein shall be Code’s

entire liability, and the Customer’s sole remedy, resulting from any defective

Code product. Any claim that Code has failed to perform its warranty obligations

as described herein must be made within six (6) months of the alleged failure.

Code’s maximum liability related to its performance, or failure to perform, as

described herein shall be limited to the amount paid by Customer for the Code

product that is subject to the claim. In no event will either party be liable for any

lost profits, lost savings, incidental damage, or other economic consequential

damages. This is true even if the other party is advised of the possibility of such

damages.

EXCEPT AS MAY BE OTHERWISE PROVIDED BY APPLICABLE LAW, THE

LIMITED WARRANTIES DESCRIBE HEREIN REPRESENT THE ONLY

WARRANTIES CODE MAKES WITH RESPECT TO ANY PRODUCT. CODE

DISCLAIMS ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED,

ORAL OR WRITTEN, INCLUDING WITHOUT LIMITATION IMPLIED WARRANTIES

OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT.

THE REMEDIES DESCRIBED HEREIN REPRESENT CUSTOMER’S EXCLUSIVE

REMEDY, AND CODE’S ENTIRE RESPONSIBILITY, RESULTING FROM ANY

DEFECTIVE CODE PRODUCT.

CODE SHALL NOT BE LIABLE TO CUSTOMER (OR TO ANY PERSON OR

ENTITY CLAIMING THROUGH CUSTOMER) FOR LOST PROFITS, LOSS OF

DATA, DAMAGE TO ANY EQUIPMENT WITH WHICH THE CODE PRODUCT

INTERFACES (INCLUDING ANY MOBILE TELEPHONE, PDA, OR OTHER

COMPUTING DEVICES), OR FOR ANY SPECIAL, INCIDENTAL, INDIRECT,

CONSEQUENTIAL OR EXEMPLARY DAMAGES ARISING OUT OF OR IN ANY

MANNER CONNECTED WITH THE PRODUCT, REGARDLESS OF THE FORM

OF ACTION AND WHETHER OR NOT CODE HAS BEEN INFORMED OF,

OR OTHERWISE MIGHT HAVE ANTICIPATED, THE POSSIBILITY OF SUCH

DAMAGES.

Software and Data. Code is not responsible for backing up or restoring any of

software, data, or configuration settings, or reinstalling any of the foregoing on

products repaired or replaced under this limited warranty.

Shipping and Turn Around Time. The estimated RMA turn-around time from

receipt at Code’s facility to shipment of the repaired or replaced product to

Customer is ten (10) business days. An expedited turn-around time may

apply to products covered under certain CodeOne Service Plans. Customer is

C005383_10 CR80XX Integration Guide

26

Page 27

10 – APPENDIX A: Development Kit User Guide

SPK1

J1 C1

U1

C2

U2

C3

J2

J3

POLARITY

BOOT

SELECT

D1

RX

J4

TX

TX

RX

TRIGGER

10.1 – CR8000 Development Board

Development Kit Overview

The CR8000 development kit includes everything needed to integrate

the CR8000 (specifically the CR8011 or CR8012) Scan Engine into a

target design. We provide a complete Scan Engine, development breakout

board and all documentation required to quickly evaluate and integrate the

CR8000.

Scan Engine

The development kit comes with a complete CR8000 Decoded Scan Engine

with Bracket which includes the imager and decoder board integrated into a

single assembly. Please see Section 2.2 for details

on this assembly.

Development Board

The development board is the main user interface to the CR8000 kit. It

provides access to all features of the CR8000 Scan Engine including the

debug and development resources available.

Interface

J23 and J24 connect to the CR8000 decoder board. J23 connects

to the host interface connector and J24 connects to the expanded

illumination connector.

J23

J19

CR8000

J20

SW1

WAKE UP

SW2

TRIGGER

J22

EXPANDED

ILLUMINATION

J21

J25

VPI Engineering

C005425_02.pcb

J24

RX

D–

LED0

D+

LED1

RTS

TX

CTS

J7

J8

J5

J6

3 2 1

J9

POLARITY

J10

RX

J 11

TX

J12

CTS

J13

RTS

J14

LED0

J15

BEEPER

J16

LED1

J17

WAKE UP

J18

TRIGGER

F1

Scan Interface

J1 interfaces to a RJ-50 connector that carries both USB and RS-232

signals to an external interface. The connector also provides a trigger signal

to activate the CR8000 remotely.

Indicators

The development board includes a speaker (SPK1) for audible indication as

well as a bi-color LED (D1) for visual indication.

Configuration Jumpers

A group of jumpers allow the development board to re-configure and access

different features of the CR8000. J7 and J8 configure auxiliary serial port

features that appear on J2 and J3. J5 configures serial port polarity, and J6

in conjunction with SW2 controls which boot mode the CR8000 enters upon

powering up. Finally, the CR8000 host port configuration can be changed

via the jumper block J9-J18.

Auxiliary Headers

J2 and J3 provide auxiliary and debug serial communications to the

CR8000, and J19 provides access to all of the expanded illumination I/O.

20 May 2010

Trigger/Wake Up Switches

SW1 and SW2 allow the user to trigger a barcode read and wake the unit

up from Sleep Mode, respectively. If the unit is in a sleep state when the

trigger is pushed, the CR8000 will automatically wake up before performing

a barcode read.

C005383_10 CR80XX Integration Guide

27

Page 28

10.2 – Development Board Connections

SPK1

SPK1

SPK1

CR8000 Connections

The CR8000 connects to the development board

via J23 and J24.

RJ50 System Header

The majority of system communication goes

through the RJ50 System Header. The RJ-50

cable provides power to the development kit and

is available in RS232 or USB version. There is

also the ability to trigger through

this connection.

U1

J1 C1

U1

J1 C1

POLARITY

SELECT

D1

J3

POLARITY

SELECT

D1

RX

J4

TXTXRX

J3

BOOT

RX

J4

TXTXRX

BOOT

LED0

LED1

RTS

TRIGGER

CTS

RX

LED0

D+

LED1

RTS

TX

TRIGGER

CTS

RX

D–

D+

TX

J7

J8

D–

J5

J6

J7

J8

J5

J6

3 2 1

3 2 1

J9

J10

J 11

J12

J13

J14

J15

J16

J17

J18

J9

J10

J 11

J12

J13

J14

J15

J16

J17

J18

POLARITY

RX

TX

CTS

RTS

LED0

BEEPER

LED1

WAKE UP

TRIGGER

F1

POLARITY

RX

TX

CTS

RTS

LED0

BEEPER

LED1

WAKE UP

TRIGGER

F1

C2

U2

C3

J2

C2

U2

C3

J2

J23

CR8000

J21

J25

SW1

WAKE UP

SW2

TRIGGER

J22

J20

J19

J23

CR8000

SW1

WAKE UP

SW2

TRIGGER

J22

J20

J19

VPI Engineering

C005425_02.pcb

EXPANDED

ILLUMINATION

J24

J21

J25

VPI Engineering

C005425_02.pcb

EXPANDED

ILLUMINATION

J24

20 May 2010

20 May 2010

Auxiliary and Debug Serial Headers

J2 and J3 provide auxiliary communications to

the CR8000 for development and test purposes.

J2 is a serial console interface

to the Linux kernel operating on the

CR8000 engine, and J3 is attached

to RS232 Port 4.

U1

J1 C1

J3

POLARITY

SELECT

D1

RX

J4

TXTXRX

BOOT

LED0

LED1

RTS

TRIGGER

CTS

RX

D–

D+

TX

J7

J8

J5

J6

3 2 1

J9

POLARITY

J10

RX

J 11

TX

J12

CTS

J13

RTS

J14

LED0

J15

BEEPER

J16

LED1

J17

WAKE UP

J18

TRIGGER

F1

C2

U2

C3

J2

J23

CR8000

J21

J25

SW1

WAKE UP

SW2

TRIGGER

J22

J20

J19

VPI Engineering

C005425_02.pcb

EXPANDED

ILLUMINATION

J24

20 May 2010

C005383_10 CR80XX Integration Guide

28

Page 29

10.2 – Development Board Connections (continued)

SPK1

SPK1

Illumination Expansion Header

The CR8000 provides extra I/O for control of

third party illumination boards. The Illumination

Expansion Header (J19) allows user

development of these boards from a simple

J1 C1

low-density connector. The following table defines

the pin-out of J19:

Pin Description

1 Vin

2 Vin

3 Illumination IO 0/RS232 Port 4 TX

4 Illumination IO 1/RS232 Port 4 RX

5 Illumination PWM 1

6 Illumination IO 2

7 Illumination IO 3

8 Illumination IO 4

9 Gnd

10 Gnd

10.3 – Development Board Jumpers

Interface Header

The jumper block of J9-J18 configures the

signals between the CR8000 and RJ-50

connector. This is done by shorting pins 1-2 or

2-3 on each jumper. Refer to the table below for

configuring these pins for each interface:

Jumper RS232 Kit USB Kit

J9 1-2 1-2

J10 1-2 2-3

J11 1-2 1-2

J12 1-2 2-3

J13 1-2 1-2

J14 1-2 1-2

J15 1-2 1-2

J16 1-2 1-2

J17 1-2 1-2

J18 1-2 1-2

U1

U1

J1 C1

POLARITY

SELECT

D1

U2

C3

J2

D1

RX

J4

TXTXRX

J3

BOOT

J3

POLARITY

BOOT

SELECT

TRIGGER

RX

J4

TXTXRX

J7

J8

RX

D–

LED0

D+

LED1

RTS

TX

CTS

J5

J6

LED0

LED1

RTS

TRIGGER

CTS

3 2 1

J7

J8

RX

D–

D+

TX

J5

J6

3 2 1

J9

J10

J 11

J12

J13

J14

J15

J16

J17

J18

J9

J10

J 11

J12

J13

J14

J15

J16

J17

J18

POLARITY

RX

TX

CTS

RTS

LED0

BEEPER

LED1

WAKE UP

TRIGGER

F1

C2

U2

C3

J2

C2

J19

POLARITY

RX

TX

CTS

RTS

LED0

BEEPER

LED1

WAKE UP

TRIGGER

J19

F1

J23

CR8000

CR8000

J20

SW1

WAKE UP

SW2

TRIGGER

J23

J20

J22

EXPANDED

ILLUMINATION

SW1

WAKE UP

SW2

TRIGGER

J22

J21

J25

VPI Engineering

C005425_02.pcb

20 May 2010

J24

J21

J25

VPI Engineering

C005425_02.pcb

EXPANDED

ILLUMINATION

J24

20 May 2010

C005383_10 CR80XX Integration Guide

29

Page 30

10.3 – Development Board Jumpers (continued)

SPK1

SPK1

Serial Polarity and Boot Select Jumpers

J5 selects whether or not the primary RS-232

data are inverted, and the combination of J6 and

SW2 will select the boot mode the kit comes up

in. The RS-232 data will be inverted if J5 has

pins 2-3 bridged, and will remain non-inverted if

the jumper is left in the default position of 1-2.

J3

POLARITY

SELECT

D1

RX

J4

TXTXRX

BOOT

RX

LED0

D+

LED1

RTS

TX

TRIGGER

CTS

D–

J7

J8

J5

J6

3 2 1

J9

POLARITY

J10

RX

J 11

TX

J12

CTS

J13

RTS

J14

LED0

J15

BEEPER

J16

LED1

J17

WAKE UP

J18

TRIGGER

CR8000

J19

F1

J1 C1

Boot

J6 SW2 Description

C2

U1

U2

C3

J2

Mode

1 1-2 Open Normal Mode - Reader Application

2 1-2 Depressed Upgrade Mode - Linux Application to upgrade

Reader Application

3 2-3 Open Factory Restoration Mode

4 2-3 Depressed U-Boot Upgrade Mode - Upgrade Linux OS

and Filesystem

J23

J20

SW1

WAKE UP

SW2

TRIGGER

J22

EXPANDED

ILLUMINATION

J21

J25

VPI Engineering

C005425_02.pcb

20 May 2010

J24

Serial Debug Jumpers

The serial debug jumper block of J4, J7 and J8

determine whether or not RS232 Port 4 is routed

to J3, and allows a user to tap off of the debug port

on J2. J7 and J8 are shorted to

connect CR8000 RS232 Port 4 to J3.

J1 C1

U1

POLARITY

SELECT

D1

J4

J3

BOOT

RX

TXTXRX

TRIGGER

RX

LED0

LED1

RTS

TX

CTS

D–

D+

J7

J8

J5

J6

3 2 1

J9

POLARITY

J10

RX

J 11

TX

J12

CTS

J13

RTS

J14

LED0

J15

BEEPER

J16

LED1

J17

WAKE UP

J18

TRIGGER

F1

C2

U2

C3

J2

J23

CR8000

J21

J25

SW1

WAKE UP

SW2

TRIGGER

J22

J20

J19

VPI Engineering

C005425_02.pcb

EXPANDED

ILLUMINATION

J24

20 May 2010

C005383_10 CR80XX Integration Guide

30

Page 31

10.4 – Development Board Fuses

There are two fuses on the CR8000 development

board. Both are used to protect the input voltage

line, VIN, but for different connection options.

The standard cables provide VIN through the

RJ-50 connector, J1. The fuse that protects the

circuit when using that connection is F2, and that

is the fuse that most often opens. F2 is located

on the back side of board, under the RJ-50

connector, J1.

If power is supplied through the Expanded

Illumination header, J19, the fuse that protects

the circuit is F1, which is located on the front side

of the board, next to J19.

Both fuses have the same part number:

• Code P/N: V005953

• Description: Fuse, 0.75 Amp 0603

• Manufacturer: Littelfuse

• Manufacturer P/N: 0467.750NR

C005383_10 CR80XX Integration Guide

31

Page 32

11 – APPENDIX B: Optimizing for Low Power Applications

Achieving low power consumption with the CR8000 requires that certain

setup and configuration values be programmed into the Scan Engine, as

well as certain protocols that need to be followed to wake up from sleep

11.1 – Configuration

Register 0x9F controls the duration between a completed read operation

and when the unit goes to sleep. It should be written with a small,

non-zero value to minimize the idle time between scan completion

and the CR8000 entering sleep mode.

11.2 – Communications from Sleep Mode

The host needs to assert the nWakeUp pin and wait for the PwrDwn pin

to be negated before the host can communicate with the CR8000. By

programming register 0x9F and performing this operation, the time that the

CR8000 remains awake can be minimized.

Long-Term Communication

The following timing diagram shows the general

process for waking up and communicating with

the CR8000 on a long-term basis. This includes

configuration and performing firmware upgrades

on the engine. Please refer to Section 12.3 for all

appropriate timing values.

1. Host asserts nWakeUp for at least

Twupw, and is optionally held low until

communication with the CR8000 is finished

2. After Twu, CR8000 negates PwrDwn

3. After Tcmddelay, host writes register 0x9F

with 0x80000000 to disable sleep timer

4. Host communicates with CR8000

5. Host writes register 0x9F with appropriate

value to enable sleep timer

Note: There are several timeouts the CR8000

uses for various modes. To fine tune the total

timeout of Idle and Sleep modes, reference

registers 0x9F, 0x2C, and 0x32 in the ICD.

nWakeUp

PwrDwn

Data

mode. This appendix describes these operations. This applies to the

RS232 interface model only.

TWUPW

TSU

TWU

TCMDDELAY

DATAWR REG 0X9F WR REG 0X9F

Wake-Up Communication Timing Diagram

C005383_10 CR80XX Integration Guide

32

Page 33

11.2 – Communications from Sleep Mode (continued)

Rapid Scanning and Returning to Sleep

The following diagram shows the timing diagram

for scanning a barcode when the unit is in sleep

mode. When register 0x9F is minimized, the unit

will consume the minimum amount of power

possible. Please refer to Section 12.3 for all

appropriate timing values.

1. Host asserts nWakeUp

2. After Twu, CR8000 negates PwrDwn

3. After Tcmddelay, host can assert nTrigger

4. Output signals are invalid during

setup time Tsu

5. CR8000 decodes barcode and

asserts nGoodRead

6. CR8000 transmits data to host

7. After CR8000 transmits data, engine goes to

sleep after TTimeouT period programmed in

register 0x9F

nWakeUp

TWUPW

PwrDwn

TWU

nTrigger

nGoodRead

TSU

Data

Wake-Up Barcode Read Timing Diagram

11.3 – Timing Specifications

TCMDDELAY

TDECODE

TGRPW

TTIMEOUT

DATA

Signal Description Min Typical Max Unit

Twupw nWakeUp pulse width 10 20 msec

Twu Time between nWakeUp asserted and

Tsu Time between nWakeUp asserted and

Tcmddelay Time between CR8000 ready and when

Tdecode Time between nTrigger asserted and

Tgrpw nGoodRead pulse width See Note 1

TTimeouT Time between data transfer and sleep state See Note 2 msec

Notes: 1. Tgrpw is programmable using command register 0x1EA.

2. TTimeouT is programmable using command register 0x9F.

CR8000 ready

5 5 10 msec

outputs valid

0 1 msec

nTrigger can be asserted

100 msec

nGoodRead asserted (decode time)

120 msec

C005383_10 CR80XX Integration Guide

33

Loading...

Loading...