Page 1

INSTRUCTION MANUAL

CODE 119/92

FOR ASYNCHRONOUS ROWAN SINGLE-PHASE MOTORS with

T ACHOMETER

CONFORMITY

EMC

REV. 6 - Date 21/10/09

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Motori, azionamenti, accessori e servizi per l'automazione

Via Ugo foscolo, 20 - CALDOGNO - VICENZA - ITALIA

Tel.: 0039 0444 - 905566 - Fax: 0039 0444 - 905593

E-mail: info@rowan.it - WEB-SITE: www.rowan.it

Page 2

INDEX

page

C119/92 Series - Technical characteristics - Standard Conformity 3

Overall dimensions - Working principles 4

Circuit silkscreen, trimmers, micro-switches, leds - terminal board 5

Description of trimmers, microswitches, displays 6

Standard set-up, Characteristics of single-phase motors and power absorbed by brake and fan,

Instructions for the connection of Rowan single - phase motors, Motor service board connection

7

Brake connection, instructions for connection and start-up , E.M.C. standard 8

Connection diagrams, Examples of control terminal board connection 9

Instructions for maintenance of Rowan motors 11-12

Instructions for the replacement of previous drives 13-14

Block diagram 15

Warning !

- ROWAN ELETTRONICA s.r.l. declines any responsibility for any inaccuracies contained in this manual, due to

printing and/or transcription errors. ROWAN ELETTRONICA s.r.l. reserves the right to make any variations that it

considers necessary for better functioning of the product, without prior notification.

- Regarding the data and characteristics mentioned in the manual, a maximum tolerance of 10% has been allowed,

if not otherwise indicated.

- The product guaranty is considered ex-works and is valid 6 months from the date of leaving ROWAN ELETTRONICA

s.r.l.

- The electrical equipment could create dangerous situations for the safety of both personnel and objects; the user

is responsible for the installation of the equipment and for the conformity of the installation with the regulations in force.

- The diagrams contained in this manual are mere examples and should be perfected by the customer according

to their specific needs.

- The equipment must be installed only by qualified personnel, after having read and understood this manual. In

case of doubt, the supplier should be contacted.

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 3

CODE 119/92

DRIVE FOR ASYNCHRONOUS ROWAN SINGLE-PHASE MOTORS

with TACHOMETER

POWER RANGES

This drive is produced in two sizes on the same base:

- C119/92 for the command of Rowan single.phase motors up to 1HP. Provided with 10A protection

fuse.

- C119/92/2 for the command of Rowan single-phase motors up to 2HP. Provided with 20A

protection fuse.

TECHNICAL CHARACTERISTICS

-

product

- Standard supply voltage: 230Vac ±10% 50/60Hz.

- Environmental temperature limit: -5°C +40°C.

- Stocking temperature from -25°C to +70°C.

- Working humidity limit from 5 to 95% (without condensation).

- Preset for ROWAN single-phase motors 2 - 4 - 6 pole, with 10Vdc at 1400rpm (20V at 2800rpm)

tachometer.

- Input/output signals galvanically insulated from high voltage and connectable to PLC, programmable

logics, interface drives, etc.

- Input for tachometer with precision rectifier for functioning in both rotational sense.

- Motor revolution control adjustable through potentiometer (connected at 2 or 3 wires) or 0 /+10Vdc

signal.

- Motor torque limitation internally adjustable through trimmer, or externally through potentiometer

or 0 / +10Vdc signal.

- Input for pure contact (or NPN open collector transistor) for static run/stop command(12Vdc 2mA).

- Internal regulations through trimmer for:

> acceleration/deceleration ramp

> max speed

> minimum speed

> max torque

> minimum torque

> stability (anti-oscillation trimmer)

- Signalling by led illumination of the following functions:

> power on

>tachometer generator presence

> motor run

- Driving circuit protection with 0.5 A fuse (power protection to be performed externally).

- Cage-clamp terminal strip (in type 119/92 2 Hp power terminal strips are screw-clamp type).

- Standard open version with metal support and poly-carbonate cover, protection level IP 20

STANDARD CONFORMITY

Drive Code 119/92 is in conformity with the general IEC EN 60204-1 standard corresponding to the

essential safety requirement of the "Machinery Directive 89/392/CEE", modified by the CEE

Directive 91/368 - 93/44 - 93/68. In particular, regarding the Electro-magnetic Compatibility (EMC)

in industrial environment, drive Code 119/92 is in conformity to the product CEI EN 61800-3

standard, for "VARIABLE SPEED ELECTRICAL DRIVES" if connected to the network through a

filtering device as indicated by diagrams on page 9 and installed as written on page 8.

Ask Rowan El. for choosing the correct anti E.M.I. Filter (ELECTROMAGNETIC INTERFERENCE).

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 4

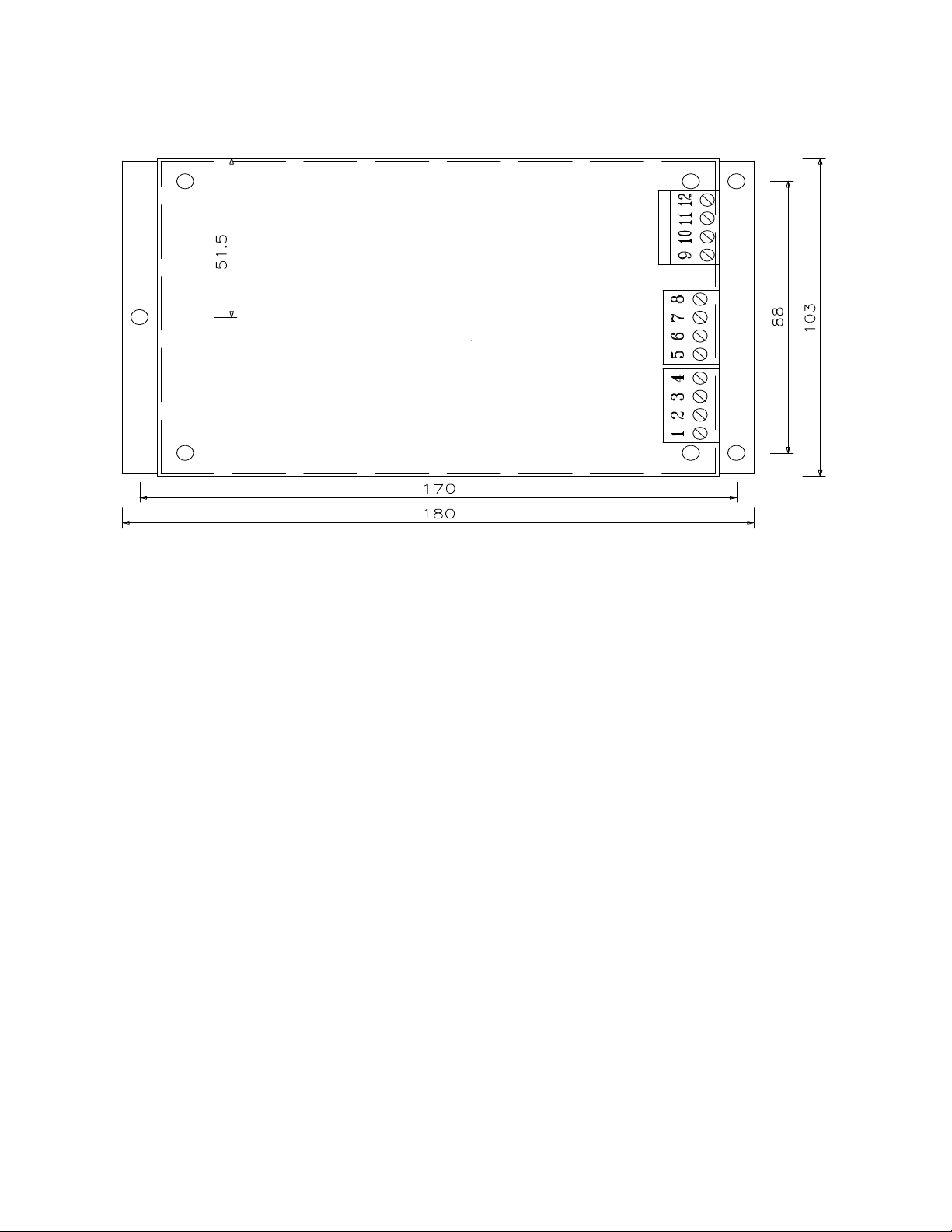

OVERALL DIMENSIONS in mm

Height:

Code 119/92 = 65 mm Code 119/92 - 2HP = 95 mm

WORKING PRINCIPLES

Drive code119/92 is a single-phase voltage regulator with tachometer feedback using controlled

diodes (SCR) driven by a system at phase partialization.

The voltage supplying the motor results from an analog process mantaining constant rotations by

means of the differential control between the real speed reference taken from the tachymeter generator

and the one set by the potentiometer or external analog voltage. The coupling with the asynchronous

single-phase high slip Rowan motor gives a variable speed system extremely silent (Absence of

typical PWM whistle) and uniform, from zero to the maximum motor rounds. The application of

controlled diodes on the power part gives reliability against extravoltages or over-currents. In addition,

it is possible to adjust the acceleration/deceleration ramp upon the application needs; the controlled

acceleration ramp works for moving braking loads or irreversible systems only.

Drive code 119/92 gives the possibility to control the speed/torque of the Rowan single-phase motor;

the torque regulation can be done by limiting the maximum voltage on the motor through internal

trimmer P1 or, externally, through potentiometer or 0/+10Vdc signal; for a more precise control of the

motor torque, it is necessary to let the code 119/92 communicate with other devices working at current

closed loop (ex. code 199/92 or code 268).

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 5

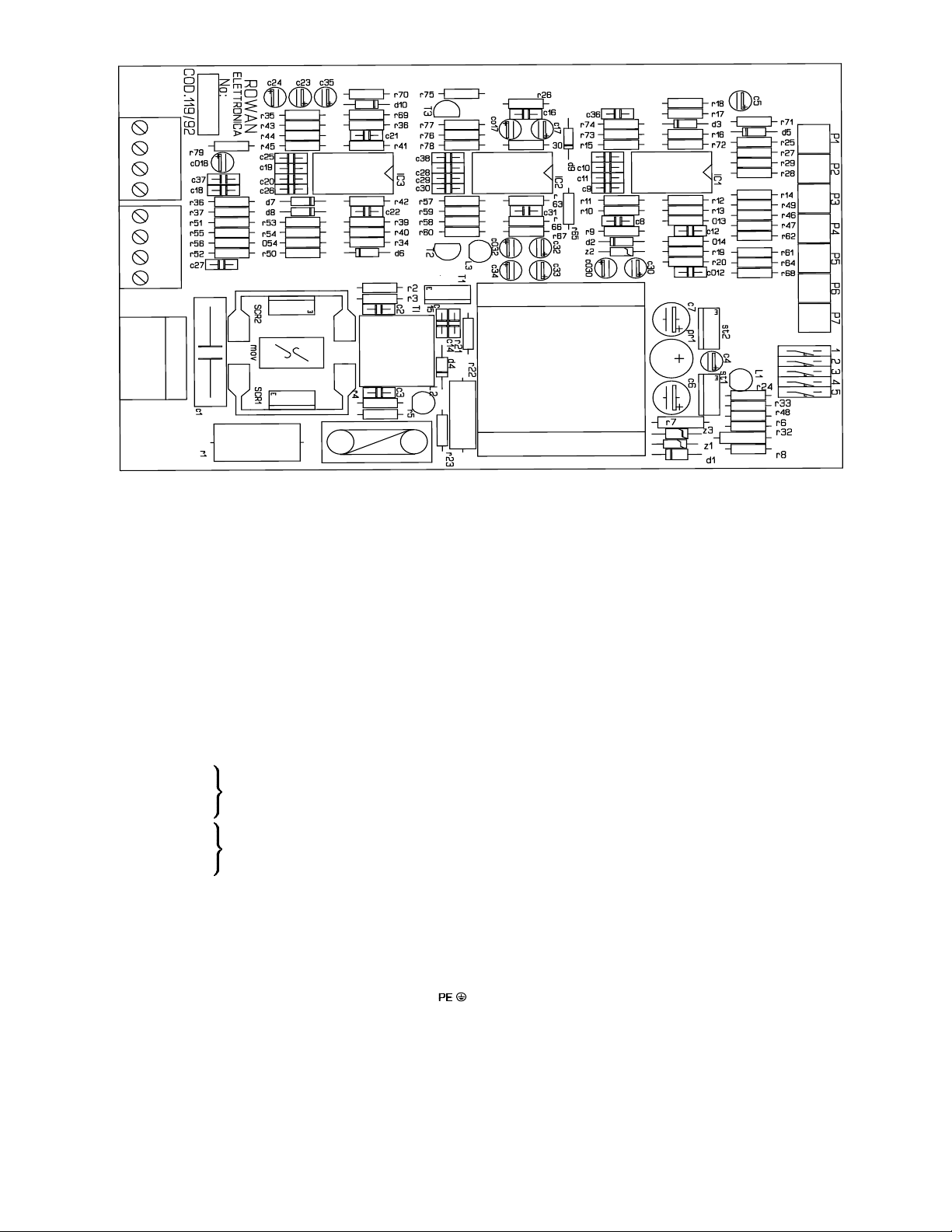

CIRCUIT SILKSCREEN - TRIMMERS, MICRO-SWITCHES, LEDS

DESCRIPTION OF CONNECTION TERMINAL BOARD

1 - 6 -7 ZERO VOLT for input/output signals.

1 - 2 A.R. contact connection (static run consent) or NPN open collector transistor; when open, assents

1 - 3 torque limitation 0 / +10VDC signal input:

1 - 4 +10VDC 3mA reference voltage output for speed and torque (max. 3kohm load) regulation external

1 - 5 speed regulation 0 / +10VDC signal input:

1 = extreme

3 = cursor torque limitation external potentiometer connection

4 = extreme (active with S1 open) R = 10kohm

4 = extreme

5 = cursor speed regulation external potentiometer connection

6 = extreme (active with S3 open) R = 10kohm

For connection of the 2 wire potentiometer (R = 10kohm) close microswitch S3 and use only terminals 5 - 6.

7 - 8 tachogenerator type 20VDC / 2800 rpm input

9 - 10 regulated output for powering starting and power windings of single phase Rowan motor (max 230VAC 8A

acceleration ramp motor rotation up to maximum set speed and causes RUN led illumination. Closed, it

removes voltage from the motor and set acc./dec. ramp to zero.

0VDC = minimum torque / +10VDC maximum torque

potentiometers.

0VDC = zero turns / +10VDC = max speed

for code 119/92 up to 1HP and max 230VAC 15A for code 119/92/2 - 2HP).

11 - 12 power supply 230 VAC ±10% 50/60 Hz. -

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

GROUND CONNECTION.

Page 6

DESCRIPTION OF TRIMMERS

P1 max torque limitation if adjusted counter-clockwise, it limits max voltage to motor windings (active with

microswitch S2 closed).

P2 minimum torque if adjusted clockwise, it increases min voltage to motor windings (active with microswitch

S2 closed).

P3 acceleration/deceleration ramp min 20 mSec, max 8 Sec.

P4 max speed regulates motor max speed with speed regulation potentiometer at maximum and in any case with

input on terminal 5 = +10VDC. Turned clockwise, it increases speed.

P5 min speed regulates motor min speed with speed regulation potentiometer at minimum and in any case with

input on terminal 5 = 0VDC. Turned clockwise, it increases speed.

P6 stability: to be regulated clockwise to stabilise any oscillations in the control of speed if regulation of trimmer

P7 was not sufficient (proportional / integral action).

P7 stability: to be regulated in a counter-clockwise direction to stabilise any oscillations in the control of speed

(integral action).

DESCRIPTION OF MICROSWITCHES

S1 open: activates external torque limitation from potentiometer or from 0+10VDC signal connected to terminal 3

closed: activates board internal torque limitation from trimmer P1

S2 open: cuts out torque limitation

closed: activates torque limitation

S3 open: in case of 3 wire speed regulation potentiometer connection

closed: in case of 2 wire speed regulation potentiometer connection

S4 open: in case of connection to 2 pole motor

closed: in case of connection to 4 pole (or 6 pole) motor. In case of 6 pole motor recalibrate maximum speed

with P4 until the tachogenerator generates a maximum voltage of 6 VDC.

S5 open: in case of maximum precision in controlling speed (minimum shift from loadless to loaded)

closed: enchances prompter response in speed change transients to the detriment of precision (greater shift

from loadless to loaded)

DESCRIPTION OF DISPLAYS

L1 POWER ON: indicates power supply flowing through the board and driving circuit.

L2 RUN: when on indicates that motor rotation has been enabled with the opening of run consent contact (AR)

at terminals 1 - 2. It illuminates in proportion to the voltage to motor windings.

L3 TACHOMETER GENERATOR PRESENCE: when on indicates that motor is rotating and that tachometer

generator voltage is available at terminals 7 -8. Tachometer generator voltage is directly proportional to motor

speed and assumes a value of approximately 20VDC at 2800 tpm.

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 7

STANDARD SET-UP

ROTOM

CEM

PH WK

moNI

A

.DNOCHCNUAL

Fu desaercni(

tadedeeneuqrot

)trats

NAF

REWOP

W

EKARB

REWOP

W

36 51.0 11.0 6.1 )61(21 01 02

17 52.0 81.0 9.1 )52(02 61 02

08 5.0 73.0 1.3 )13(52 81 52

09 1 57.0 6 )05(04 05 03

119/92 drives come out of Rowan labs ready tested and set-up for:

- 4-pole motors with speed regulation by 3-wire potentiometer (min. 0 rpm - max. 1300 rpm);

- torque limitation not active;

- acc/dec ramp: 2 Sec.;

- microswitch S4 closed (all other microswitches open).

SINGLE-PHASE MOTORS CHARACTERISTICS AND POWER ABSORBED BY BRAKE AND COOLING FAN

The capacitor within parentheses increases starting torque by

approx. 20% but cannot be used for continual service; its use is

recommended only for intermittent movements.

The maximum current of Rowan single-phase motors is to be

calculated to an approximate value by multiplying the rated value

by 1.5. The same current can be used during the starting phase

or in cycles that require the use for a period equivalent to a

maximum of 20% of the entire work cycle.

INSTRUCTIONS FOR THE CONNECTION OF SINGLE PHASE ROWAN MOTORS

LAUNCHING WINDING

POWER WINDING

TERMINALS OR CONNECTOR

FOR BRAKE CONNECTION

SERVICE TERMINAL BOARD

POWER TERMINAL BOARD

MOTOR SERVICE BOARD CONNECTION

1-2 TACHOMETER GENERATOR: from these terminals it is possible to have the

voltage of the tachometer generator that is spliced to the motor shaft. It supplies

a direct voltage of 20VDC at 2800RPM that is directly proportional to motor

speed; for this reason, besides being connected to the drive for speed control,

it can be used for analog revolution counters, display counters or other

servomechanisms, provided the overall loading being not lower than 5Kohm

TACHOMETER

GENERATOR

VENTILATOR

THERMIC PROBE

(max tachometer current 5mA). It is always necessary, to avoid interferences,

to connect the tachometer with screened cable.

3-4 VENTILATOR: it is necessary to supply these terminals with 220VAC for the separated ventilation of motor; make sure

that this voltage is present also when the motor is not running, in order to guarantee the max cooling efficiency. As for the

power absorbed by cooling fans, see table on the previous page.

5-6 THERMIC PROBE: it is a N.C. contact which opens when the temperature of motor windings exceeds 150°C, safety

limit corresponding to H class (180°C). It is used as emergency for the switching off of RUN remote control switch. The

max capacity of this contact is 1A - 230VAC. (Rowan motor MEC 63 0,15 HP is not equipped with Thermic Probe; for this

reason terminals 5-6 are not present in its service terminal board).

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 8

BRAKE CONNECTION

On request, ROWAN motors can be provided with

electromagnetic brake. In this case the motor must be

constructed expressly with lengthened motor shaft and

the brake is mounted on the front part, supported by a bell

which reproduces the normal flanging conditions.

There are 2 different types of brakes:

- DIRECT BRAKE: in this case it is necessary to supply the brake to block the motor shaft. This kind of brake is suitable

for precision stops. Its efficiency can be increased by using ROWAN card cod. 210, which oversupplies it at the stop

improving its precision.

- SAFETY SPRING BRAKE: in this case it is necessary to remove supply from the brake to block the motor shaft. It is used

as safety brake in case of lack of main power supply, with suspended loads as overhead travelling cranes, cranes etc.

Both brakes operate with direct voltage 24VDC, and are supplied through the single terminal or connector placed on the

front brake bearing-bell. It is always advisable to connect a diode or a R/C in parallel with the brake, above all when near

to equipments that are particularly sensitive to disturbances. As for the power absorbed by brakes see table on page 3.

In case a transformer with secondary 24VDC is used, it is necessary to insert a levelling condenser C1 dimensioned

for the power of the brake; when the condenser is not present, a transformer with secondary 27 VAC must be used.

INSTRUCTIONS FOR CONNECTION and START-UP

Before powering, connect to the ground and set up the microswitches on the board to suit the desired type of operation:

- 2 or 3 wire speed regulation potentiometer

- inclusion of internal/external torque limitation (see microswitch description)

- 2, 4 or 6-pole motor

In case of a 6-pole single-phase motor recalibrate the maximum speed with trimmer P4 until the tachometer dynamo

generates approx. 5.7 VDC with the speed regulation potentiometer or DC signal at maximum value.

- Before powering, adjust the potentiometer or DC signal for zero speed; at power up the motor must be stationary.

Illumination of led L1 (power on) indicates that power supply is flowing through the driving circuits. Turn potentiometer or

increase DC signal: motor speed should increase or decrease according to the set acceleration/deceleration ramp, while

leds L2 (run) and L3 (tachometer gen. presence) must light up accordingly; progressive illumination of led L2 indicates

the presence of voltage in the motor windings, whereas light-up of L3 indicates that the motor is rotating.

- If the motor suddenly races to maximum speed without following potentiometer regulation, and pilot lamp L3 does not

illuminate, it means that tachometer dynamo voltage is not reaching terminals 7 and 8; when this happens reinspect the

connections.

- Check attainment of maximum speed and, if necessary, fine adjust the maximum value with trimmer P4; be sure not to

exceed the maximum speed as this would cause the motor to overheat even when loadless; when this happens regulate

P4 until motor consumption equals the value measured at an intermediate speed. In any case check that motor

consumption (measured at power supply line) conforms with the rated value. If during motor operation oscillations take

place due to a particular type of load or due to mechanical transmission, these may be suppressed by regulating trimmer

P7 clockwise; if regulation of P7 were not enough, also regulate trimmer P6 counter-clockwise. To prompt and smoothen

motor response you may close microswitch S5.

Drive 119/92 is provided with a 0,5A protection fuse only for driving circuit; provide external power protection through a

10A fuse for drive 119/92 and 20A fuse for drive 119/92-2HP. Use a shielded cable for control connections (potentiometer,

tachometer generator) especially if they are long stretches or run close to power cables; connect cable braiding to ground

and not to the circuit negative, and only at one cable terminal; the board negative must also not be connected to ground;

at any rate, do your best to avoid routing near power cables or large transformers.

Use relays with contacts for low current for the switching of DC signals on the control terminal panel, and avoid the use

of electromagnetic switch auxiliary contacts for these types of operations.

Drives 119/92 series operate efficiently with panel temperatures ranging from -5°C to +40°C; temperatures outside this

range may give rise to faulty operation, speed control drifts and, if temperatures are particularly high, breakdown. Thus place

the boards far from heat sources and provide adequate ventilation to the panel if the environment is subject to high

temperatures.

ISTRUCTIONS FOR THE CORRECT INSTALLATIONS AS PER THE ELECTRO-MAGNETIC COMPATIBILITY

STANDARDS (E.M.C.)

Drive Code 119/92 must be supplied through anti E.M.I. filter as indicated in the connection diagrams on page 11; if more

C119/92 drives are installed into the same cabinet we can use a unique filter dimensioned for the total supply currents.

In addition, it is necessary to use a shielded cable to connect the commands (potentiometer, tachometer) especially when

distances are long and we are near to power cables; the cable sleeve must be connected to ground (not to the negative

of the circuit) to one end only; do not connect the negative of the drive to ground; avoid, in any case, the proximity to power

cables or big transformers. Avoid, finally, to create ground loops.

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 9

CONNECTION DIAGRAMS

Application

MOTOR POWER TERM. BOARD

Diagram No. 1

RIGHT

ROTATION

SENSE

MOTOR POWER TERM. BOARD

LEFT ROTATION

SENSE

CODE 119/92

SPEED REG.

CODE 119/92

SPEED REG.

TACHOMETER

GENERATOR

TACHOMETER

GENERATOR

MAINS LINE

MAINS LINE

This is the basic schematic

diagram for drive 119/92

connection; the two individual

diagrams show how to manually

invert the rotation sense of the

motor by operating on power

connections (tachometer

dynamo polarity does not need

to be inverted); speed regulation

is by potentiometer connected

with 3 wires which ensures linear

regulation of speed with respect

to potentiometer rotation,

whereas torque adjustment is

excluded. In this case (if the motor

is a 4-pole one) only microswitch

S4 is to be closed.

Application

MOTOR POWER TERM. BOARD

CODE 119/92

Diagram No. 2

220 VAC

TACHOMETER

SPEED REG.

GENERATOR

In this case 119/92 drives the single-phase motor in both rotation senses; rotation sense is changed by inverting the starting

winding with respect to power winding.

Set up board 119/92 as shown in schematic diagram No. 1.

EXAMPLES OF HOW TO CONNECT THE CONTROL TERMINAL BOARD

Connection of 2-wire speed regulating potentiometer:

Should you need to use the 2-wire speed regulating potentiometer (as for instance

SPEED REG.

when replacing Rowan drives of previous manufacture such as old C119) close

TACHOMETER

GENERATOR

microswitch S1 and connect a 10 KOhm potentiometer; speed regulation with 2wire potentiometer is not very linear with respect to its rotation.

Selection of different speeds with more potentiometers in parallel:

Two or more potentiometers can be connected in parallel making sure that the

overall resistance between terminals 4 and 6 is not lower than 3 KOhm.

Motor torque limitation through external potentiometer:

MAINS LINE

TACHOMETER

GENERATOR

The potentiometer value has not to load the voltage reference of +10Vdc on terminal

4 (R= 3Kohm including the value of the potentiometer); in this case close microswitch

S2 and it is possible to limit the regulation range of the potentiometer by using

trimmer P1 (max.) and P2 (min.). If maximum torque internal limitation were enough,

the external potentiometer can be omitted: in this case close microswitch S1 and

limit torque by regulating trimmer P1.

Speed/torque control from analog signal 0/+10VDC:

In code 119/92 speed and torque regulations, in addition to the conventional

manual potentiometer, can be performed by applying a 0/+10 VDC signal; depending

on requirements, this signal can be picked up by Rowan interface boards of by other

commercial equipment as PLCs, LOGIC BOARDS, COMPUTERS, etc.; the

connection can be carried out directly because the board inputs are galvanically

insulated from high voltage. Input impedance is 100 KOhm. Close microswitch S2.

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

TORQUE

LIMITATION

TORQUE SET

0/10VDC

INPUT

SPEED

REG.

SPEED SET

0/10VDC

INPUT

TACHOMETER

GENERATOR

TACHOMETER

GENERATOR

Page 10

Static run:

When the single-phase motor is used in only one direction, and frequent run and

stop operations have to be performed, it is convenient to keep the power supply

electromagnet switch excited and to enable static motor rotation by opening contact

AR connectable to terminals 1-2.

- By opening contact AR, the motor follows the acceleration ramp up to the maximum

speed set and with a ramp time that is adjustable by trimmer P3.

- Closure of contact AR immediately removes voltage, zero-sets the ramp and

switches off RUN led L2.

If motor run/stop were necessary with acceleration and deceleration ramps without

immediately removing voltage from the motor in its stopping phase, perform the

following operations:

- disconnect terminal clamp 5 from the voltage reference to cause the motor to

decelerate to zero revs (or at a minimum speed calibrated with P5);

- connect terminal clamp 5 to the voltage reference to cause the motor to accelerate

to the maximum speed set.

Speed variations are conditioned by the acceleration/deceleration ramp set with

trimmer P3; the controlled deceleration ramp operates with motors applied to

braking loads or irreversible systems, but it is inefficient with inertial type loads.

STATIC RUN

SPEED

REG.

TACHOMETER

GENERATOR

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 11

MAINTENANCE INSTRUCTIONS FOR HIGH SLIP ROWAN MOTORS

“HIGH SLIP ROWAN” type motors are specifically designed to be controlled by tachometrically controlled

electronic circuits and their intrinsic characteristics are especially suited to support repeated start-up surges and

dynamic braking.

Since they are brushless their maintenance is reduced to a bare minimum and normally merely concerns the

bearings and changing the tachometric dynamo, which nevertheless may be necessary after a minimum of 5000

work hours.

Changing bearings or tachometric dynamo

If the motor has to be dismantled to change the bearings, proceed as follows:

1- remove the screws on the rear fan housing or scroll fan and slide it out, disconnecting the wires on the service

terminal block

2- take out the tachometric dynamo

3- slide the stays out and remove the rear housing

4- remove the front housing that comes out followed by the rotor attached to it

5- if necessary remove the front bearing, the dust guard screws and remove the snap ring (if mounted) on the shaft

6- slide the shaft out of the bearing

7- remove the snap ring (if mounted) that holds the bearing on the housing

8- slide off the bearing and replace it with an equivalent type - Z C3 version lubricated with high temperature stringy

grease

9- the rear bearing must be type 2RS C3.

If necessary, replace the tachometric dynamo while assembling the motor.

Calibration of the air gap on the spring or direct brake

If a spring brake is mounted and the air gap requires calibration, proceed as follows:

1- remove the bolts coupling the motor to the brake hub

2- slide off the hub and brake off the shaft

3- remove the screws attaching the brake to the hub,

4- disconnect the brake cable from the terminal block

5- slide the brake off the hub.

At this stage the calibration can be made by adjusting the 3 bolts until an air gap between 0.2 and 0.3mm is

obtained. If the brake mounts a dustproof filter, remove it to access the calibration bolts.

The spring brake is supplied with the maximum braking torque, which can be reduced by unscrewing the specific

crown to a maximum of 40%, always making sure not to unscrew it right out.

If the direct brake has been mounted, there is no need to dismantle it, just control the air gap (maximum 0.3 mm)

with a calliper through the side vents and if necessary correct it by slackening the grubscrew on the brake hub.

Rowan motors require continuous ventilation and therefore it is essential that all the internal and external air

passages in the motor are not blocked by foreign bodies and moreover an adequate air change must be provided.

In particularly aggressive environments Rowan motors, which are normally IP 23, can mount a dustproof filter up

to an IP 54 protection rating, and especially in this case frequent controls have to be made to ensure the filter is

clean and the fan is in perfect working order.

Greater protection ratings can be obtained, up to IP 55, providing a completely closed motor down-rated by 50%.

The motor has a heat sensor in the windings that is calibrated to trip at 150°C (Rowan motor windings are class

H with a working temperature limit of 180°C).

The sensor gives a normally closed contact that opens at 150°C and has to be used to cut of the motor power

by a suitable relay switch in the event of an overload. The sensor will take a maximum load of 1A at 230VAC.

If the overload probe trips, check:

- the fan operation

- a free air flow

- the motor absorption, if over the ID plate data, may be caused by excessive load or worn bearings.

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 12

The stator winding is for a three or single phase asynchronous motor, particularly well built in class H insulation.

If necessary it can be carried out by any coil winder so long as the winding data is respected, which is available

from our technical office.

1 > FRONT SHIELD (aluminium), which can be supplied in the following versions

- FLANGED for B5, B3/B5 motors or with auxiliary electromagnetic brake motors;

- FOOTED for B3 and B3/B5 motors.

2 > FRONT AND REAR BEARING in C3 2RS.

3 > SEEGER RING (63, 71 and 80 motors have this part only if equipped with brake).

4 > CONIC DEFLECTER (aluminium).

5 > MOTOR SHAFT (C40 Steel) normally supplied in the following versions:

- STANDARD SHAFT for B3 or B5 motors without brake; LONG SHAFT for motors equipped with brake; REDUCED SHAFT

(hardened steel) with reduced output dimensions.

6 > MASSIVE ROTOR (iron) with cavities for air cooling passage.

7 > STATOR FRAME composed by: EXTERNAL RIBBED FRAME with the housing for power terminal board (Aluminium

F91); STATOR CORE

(iron); STATORIC WINDING (copper).

8 > POWER TERMINAL BOARD for the connection of motor windings, with relative terminal board covering.

9 > FEET for B3 or B3/B5 versions

10 > THERMIC SENSOR INSIDE WINDINGS

11 > COMPENSATOR RING

12 > REAR RING for rear bearing housing.

13 > SERVICE TERMINAL BOARD for tachometer generator, ventilator and thermic sensor connection.

14 > TACHOMETER GENERATOR TYPE 24VDC/2800 rpm, IP54, with relative joints; it can be supplied in 2 versions:

- DIN55: for motors MEC 63, 71, 80, 90, 100

- DIN70: for motors from MEC 112 to MEC 200L

15 > INDEPENDENT VENTILATOR, for motor cooling, of 2 possible types: Axial and Scroll.

16 > VENTILATOR COVERING for axial fan; not present on motors with scroll fan where there is the fan support only.

17 > ELECTROMAGNETIC BRAKE which can be supplied in the following 2 types: spring/safety brake (normally closed)

and direct brake (normally open); the spring/safety brake can be equipped on request with a lever for manual

opening.

18 > FLANGED DISC of BRAKE BEARING BELL (separated from the brake bearing bell only on motors Mec 90, 100, 112

and 112L).

19 > BRAKE BEARING BELL (aluminium).

20 > REAR SPACER.

21 > TACHOMETER JOINT.

ROWAN MOTORS OPERATE CORRECTLY AT AMBIENT TEMPERATURES BETWEEN -15°C AND +40°C;

HIGHER TEMPERATURES CAN CAUSE OPERATING FAULTS AND, IF VERY HIGH, BREAKDOWNS.

THEREFORE, IT IS RECOMMENDED TO KEEP THEM AWAY FROM HEAT SOURCES AND GUARANTEE A

MINIMUM AIR CHANGE.

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 13

INSTRUCTIONS FOR THE REPLACEMENT OF PREVIOUS DRIVES WITH ACTUAL TYPE CODE 119/92

Drive code 119/92 replaces previous drives for the Rowan single phase motors type code 119 and code 120/121.

Remember that in any case code 119/92-2HP board is necessary for the single phase motor 2HP Mec 100.

Replacing drive 119 with drive 119/92:

With regard to power connections:

the wires previously connected to terminals 7 and 8 are to be shifted to terminals 11 and 12 of the code 119/92,

whereas the wires connected to terminals 5 and 6 are to be shifted to terminals 9 and 10.

With regard to control connections:

the tachometer wires that were previously connected to terminals 3 and 4 are to be connected to terminals 7 and

8 of the code 119/92, whereas potentiometer wires as follows: P- (OV) connected to terminal 2 is to be shifted to

terminal 6, and P+ connected to terminal 1 is to be shifted to terminal 5 of the code 119/92. For functioning as old

card cod. 119, microswitch S3 must be closed.

With new drive C119/92, speed regulation with 2 wire potentiometer is not linear but according to an exponential

curve which presents strong variations at slow speed and small variations at high speed. If one wishes to avoid this

behaviour and obtain a variation directly proportional to potentiometer variation, it is necessary to connect speed

potentiometer with 3 wires as indicated in connection diagram of code 119/92 and open microswitch S3.

With regard to control wires connected to the lateral terminal strip of code 119:

- the wire connected to terminal NEG is to be shifted to terminal 1 of the code 119/92

- the wire connected to terminal AR is to be shifted to terminal 2 of the code 119/92

- the wire connected to terminal INV.TACH. is to be omitted (not necessary for the C119/92)

- the resistor connected to terminal REG. COPPIA must be eliminated.

Close microswitch S1 (for the other microswitches refer to the section containing the description of the

microswitches).

If a potentiometer is connected to torque regulation terminals, reconnect it to code C119/92 with 3 wires to terminals

1 3 4 as from electrical drawing; in this case microswitch S2 must be closed.

The circled numbers in the electrical drawing designate the terminals in the code C119/92.

Reg. Coppia = Torque Regulation

Reg. Giri = Speed Regulation

Tachim.= Tachometer Generator

Linea = Mains Line

Negativo = Negative

Azz. Rampa = Ramp to zero setting

Inv. Tach. = Tachometer Inversion

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 14

Replacing drive C120/121 with drive C119/92

For the power connections proceed as follows:

the wires that were connected to the terminals 1 and 2 are to be shifted to terminals 11 and 12 of C119/92, whereas

the wires connected to terminals 3 4 5 6 7 8 related to the capacitor and power and launching windings are to be

reconnected together as shown in the schematic.

For the control connections proceed as follows:

the tachometer wires that were connected to terminals 9 and 10 are to be connected to terminals 7 and 8 of C119/92,

whereas the potentiometer wires as follows: P-(OV), connected to terminal 11, must be shifted to terminal 6,

whereas P+, connected to terminal 12, must be shifted to terminal 5 of C119/92.

For control wires connected to lateral terminal strip M2 of board C120/121 proceed as follows:

shift the wire connected to terminal NEG to terminal 1 of C119/92;

shift the wire connected to terminal AR to terminal 2 of C119/92;

exclude the wire connected to terminal INV. TACH. since it is unnecessary for C119/92;

connect wire connected to terminal DECEL to terminal 5 of C119/92.

Close microswitch S1 (for other microswitches refer to the paragraph describing the microswitches).

If a potentiometer is connected to terminal board M4 for torque limitation, you should reconnect it to terminals

1 3 4 of code 119/92 with 3 wires as illustrated in the schematic diagram; in this case close microswitch S2.

The circled numbers in the schematic refer to the terminals on C119/92.

Reg. Coppia = Torque Regulation

Reg. Giri = Speed Regulation

Tachim.= Tachometer Generator

Linea = Mains Line

Negativo = Negative

Azz. Rampa = Ramp to zero setting

Inv. Tach. = Tachometer Inversion

Decel = Deceleration

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 15

BLOCK DIAGRAM

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Page 16

CONFORMITY

EMC

ROWAN ELETTRONICA S.R.L. - Via Ugo Foscolo, 20 - 36030 CALDOGNO (VICENZA) ITALY

Motori, azionamenti, accessori e servizi per l'automazione

Via Ugo foscolo, 20 - CALDOGNO - VICENZA - ITALIA

Tel.: 0039 0444 - 905566 - Fax: 0039 0444 - 905593

E-mail: info@rowan.it - WEB-SITE: www.rowan.it

Loading...

Loading...