Page 1

/F180R series

very accurate positioning

and motion data

™

F180R series

User & Reference Guide

Copyright © 2015 Coda Octopus Products Ltd

Version: 2.0.0

Page 2

This guide describes the installation and

configuration of the F180R™ series hardware

and software developed by CodaOctopus that

allows to produce highly accurate positioning

and motion data in the most dynamic offshore

conditions.

™

F180R series

User & Reference Guide

Page 3

F180R MOTION Sensor User and Reference Guide

Copyright © 2015 Coda Octopus Products Ltd

All rights reserved. No part of this manual, including the products and software described in it, may be

stored in a retrieval system, transmitted, or reproduced by any means, including, but not limited to

photocopy, photograph, digitizing, or otherwise - without the written permission of the publisher.

Coda®, Octopus®, F180®, F180R™, F170™ and F175™ are registered trademarks (Reg. U.S Pat & TM Off) or

trademarks of Coda Octopus Group Inc.

Other products that are referred to in this document may be either trademarks and/or registered

trademarks of the respective owners. The publisher and the author make no claim to these trademarks.

Specifications and information contained in this manual are furnished for informational use only, and

are subject to change at any time without notice, and should not be construed as a commitment by Coda

Octopus Products. Coda Octopus Products assumes no responsibility or liability for any errors or

inaccuracies that may appear in this manual, including the products and software described in it.

While every precaution has been taken in the preparation of this document, the publisher and the

author assume no responsibility for errors or omissions, or for damages resulting from the use of

information contained in this document or from the use of programs and source code that may

accompany it. In no event shall the publisher and the author be liable for any loss of profit or any other

commercial damage caused or alleged to have been caused directly or indirectly by this document.

Version: 2.0.0 (16/06/2015)

Page 4

Table of Contents

Contents

4

Chapter 1 Export Policy

Chapter 2 Introduction

2.1 General Description

2.2 Warranty

2.3 Calibration

................................................................................................................................... 12

Inertial Measurement Unit 2.1.1

GNSS System 2.1.2

Software 2.1.3

................................................................................................................................... 14

................................................................................................................................... 14

......................................................................................................................................................... 13

......................................................................................................................................................... 13

......................................................................................................................................................... 13

Chapter 3 Hardware

3.1 Communication

3.2 Technical Specification

3.3 Hardware Installation

3.4 Measure Installation Parameters

................................................................................................................................... 16

Ethernet 3.1.1

Serial Outputs 3.1.2

3.1.2.1

3.1.2.2

3.1.2.3

3.1.2.4

3.1.2.5

3.1.2.6

RTK and Differential Corrections 3.1.3

PPS 3.1.4

................................................................................................................................... 30

Model Specifications 3.2.1

Interfaces 3.2.2

Reference Frames 3.2.3

................................................................................................................................... 34

Component Identification 3.3.1

Antenna Installation 3.3.2

IMU Installation 3.3.3

................................................................................................................................... 41

IMU Orientation 3.4.1

Antenna Offset 3.4.2

Antenna Separation 3.4.3

......................................................................................................................................................... 16

......................................................................................................................................................... 17

MCOM

NMEA

TSS1

TSS HHRP

EM1000 (Tate-Bryant)

EM3000 (Tate-Bryant)

.................................................................................................................................................. 18

.................................................................................................................................................. 18

GGA

GGK

GSA

GSV

GST

HDT

PASHR

PPS

PRDID

PTCF

RMC

ROT

UTC

VTG

ZDA

......................................................................................................................................................... 29

......................................................................................................................................................... 30

......................................................................................................................................................... 31

......................................................................................................................................................... 32

......................................................................................................................................................... 33

......................................................................................................................................................... 34

......................................................................................................................................................... 36

......................................................................................................................................................... 40

......................................................................................................................................................... 42

......................................................................................................................................................... 43

......................................................................................................................................................... 44

........................................................................................................................................... 18

........................................................................................................................................... 19

........................................................................................................................................... 20

........................................................................................................................................... 21

........................................................................................................................................... 21

........................................................................................................................................... 22

........................................................................................................................................... 22

........................................................................................................................................... 22

........................................................................................................................................... 23

........................................................................................................................................... 23

........................................................................................................................................... 25

........................................................................................................................................... 26

........................................................................................................................................... 26

........................................................................................................................................... 26

........................................................................................................................................... 27

.................................................................................................................................................. 27

.................................................................................................................................................. 28

.................................................................................................................................................. 28

.................................................................................................................................................. 29

9

11

16

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 5

Contents

5

Antenna Orientation 3.4.4

Remote Lever Arms 3.4.5

3.5 Communication

................................................................................................................................... 46

Ethernet 3.5.1

Serial Outputs 3.5.2

3.5.2.1

3.5.2.2

......................................................................................................................................................... 45

......................................................................................................................................................... 45

......................................................................................................................................................... 47

......................................................................................................................................................... 48

MCOM

NMEA

GGA

GGK

GSA

GSV

GST

HDT

PASHR

PPS

PRDID

PTCF

RMC

ROT

UTC

VTG

ZDA

3.5.2.3

3.5.2.4

3.5.2.5

3.5.2.6

TSS1

TSS HHRP

EM1000 (Tate-Bryant)

EM3000 (Tate-Bryant)

RTK and Differential Corrections 3.5.3

PPS 3.5.4

......................................................................................................................................................... 60

......................................................................................................................................................... 61

.................................................................................................................................................. 49

.................................................................................................................................................. 49

........................................................................................................................................... 49

........................................................................................................................................... 50

........................................................................................................................................... 51

........................................................................................................................................... 51

........................................................................................................................................... 52

........................................................................................................................................... 53

........................................................................................................................................... 53

........................................................................................................................................... 53

........................................................................................................................................... 54

........................................................................................................................................... 54

........................................................................................................................................... 55

........................................................................................................................................... 56

........................................................................................................................................... 57

........................................................................................................................................... 57

........................................................................................................................................... 57

.................................................................................................................................................. 58

.................................................................................................................................................. 59

.................................................................................................................................................. 59

.................................................................................................................................................. 60

Chapter 4 Operation

4.1 Quick Start

4.2 Power-on the System

4.3 Calibration

................................................................................................................................... 63

................................................................................................................................... 63

................................................................................................................................... 65

Pre-Calibration Checks 4.3.1

Calibration Procedure 4.3.2

Calibration Specification 4.3.3

Invalid Calibration 4.3.4

......................................................................................................................................................... 65

......................................................................................................................................................... 66

......................................................................................................................................................... 68

......................................................................................................................................................... 69

Chapter 5 Software

5.1 Installation / Uninstallation

5.2 Main Interface

................................................................................................................................... 72

Software Installation 5.1.1

Software Uninstallation 5.1.2

......................................................................................................................................................... 72

......................................................................................................................................................... 73

................................................................................................................................... 74

Ribbon Bar Tabs 5.2.1

5.2.1.1

......................................................................................................................................................... 74

Data Source - Ethernet

.................................................................................................................................................. 75

Ethernet Source - Live Tab

........................................................................................................................................... 76

RD Files

Change IP Address

Update Firmware

Rebroadcast MCOM

Calibration

........................................................................................................................................... 83

.................................................................................................................................................. 85

.................................................................................................................................................. 87

5.2.1.2

5.2.2.1

Ethernet Source - Logging Tab

Data Source - Replay

Real Time Data 5.2.2

......................................................................................................................................................... 86

Setup Real Time Data Display

System Status 5.2.3

......................................................................................................................................................... 88

63

72

...................................................................................................................................... 76

...................................................................................................................................... 77

...................................................................................................................................... 78

...................................................................................................................................... 80

...................................................................................................................................... 80

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 6

Contents

6

Message Log 5.2.4

System Indicator 5.2.5

5.3 MOTION Settings Wizard

................................................................................................................................... 96

Introduction 5.3.1

Orientation 5.3.2

Advanced Orientation 5.3.3

Primary Antenna Mounting 5.3.4

Secondary Antenna 5.3.5

Remote Lever Arms 5.3.6

Output Frame of Reference 5.3.7

Correction Type 5.3.8

Altitude 5.3.9

GNSS Environment 5.3.10

Outputs 5.3.11

Advanced Options 5.3.12

Upload Settings 5.3.13

Save Wizard Settings 5.3.14

Finish 5.3.15

5.4 Motion Data

5.5 Diagnostics

................................................................................................................................... 112

................................................................................................................................... 113

Graphical QC 5.5.1

Heading Initialisation 5.5.2

Connection Properties 5.5.3

System Properties 5.5.4

Help About 5.5.5

5.6 iHeave

................................................................................................................................... 123

Description 5.6.1

iHeave Data Files 5.6.2

iHeave Data Logging 5.6.3

iHeave Status Area 5.6.4

iHeave Alarm Setup 5.6.5

iHeave Alarm Log 5.6.6

......................................................................................................................................................... 95

......................................................................................................................................................... 96

......................................................................................................................................................... 97

......................................................................................................................................................... 98

......................................................................................................................................................... 98

......................................................................................................................................................... 100

......................................................................................................................................................... 101

......................................................................................................................................................... 102

......................................................................................................................................................... 103

......................................................................................................................................................... 103

......................................................................................................................................................... 106

......................................................................................................................................................... 107

......................................................................................................................................................... 108

......................................................................................................................................................... 109

......................................................................................................................................................... 110

......................................................................................................................................................... 111

......................................................................................................................................................... 112

......................................................................................................................................................... 114

......................................................................................................................................................... 116

......................................................................................................................................................... 119

......................................................................................................................................................... 119

......................................................................................................................................................... 122

......................................................................................................................................................... 123

......................................................................................................................................................... 124

......................................................................................................................................................... 125

......................................................................................................................................................... 127

......................................................................................................................................................... 128

......................................................................................................................................................... 129

Chapter 6 Appendices

6.1 Technical Specification

6.2 Inertial Attitude and Position System Theory

6.3 Rotation Convention

6.4 Troubleshooting

................................................................................................................................... 131

Physical 6.1.1

Electrical 6.1.2

Performance 6.1.3

Environmental 6.1.4

Data Logging Rate & Latency 6.1.5

Antenna Cable 6.1.6

......................................................................................................................................................... 131

......................................................................................................................................................... 132

......................................................................................................................................................... 132

......................................................................................................................................................... 134

......................................................................................................................................................... 134

......................................................................................................................................................... 134

................................................................................................................................... 135

Global Positioning System (GPS) 6.2.1

Inertial Navigation System (INS) 6.2.2

GPS-INS Integration 6.2.3

......................................................................................................................................................... 135

......................................................................................................................................................... 138

......................................................................................................................................................... 138

................................................................................................................................... 139

................................................................................................................................... 140

System Troubleshooting 6.4.1

6.4.1.1

6.4.1.2

6.4.1.3

6.4.1.4

Network Troubleshooting 6.4.2

6.4.2.1

6.4.2.2

6.4.2.3

......................................................................................................................................................... 140

Shock Watch

Antenna

Differential / RTK Correction Input

System Operation

Physical Connection

PC LAN Connection

Testing The Network Connection

.................................................................................................................................................. 140

.................................................................................................................................................. 140

.................................................................................................................................................. 142

.................................................................................................................................................. 142

......................................................................................................................................................... 143

.................................................................................................................................................. 144

.................................................................................................................................................. 144

.................................................................................................................................................. 146

131

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 7

Contents

7

6.4.2.4

6.4.2.5

6.5 System Dimensions

6.6 Measure Installation Worksheet

6.7 Corrosion Prevention

................................................................................................................................... 149

................................................................................................................................... 156

................................................................................................................................... 156

Changing the IP Address

Network Q & A

F180R Reference Point 6.5.1

Antenna Reference Points 6.5.2

.................................................................................................................................................. 147

.................................................................................................................................................. 148

......................................................................................................................................................... 153

......................................................................................................................................................... 153

Index

158

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 8

Chapter

1

Export Policy

Page 9

1 Export Policy

The F180R System Precision Attitude and Positioning System is subject to Export control under

the dual-use item list. Dual-use items are goods, software, technology, documents and

diagrams which can be used for both civil and military applications. It is important when

exporting a F180R System that you always keep a full record of all export destinations, dates

and export documents.

This document aims to provide basic guidance and advice for all users and includes links to

further sources of information where required.

USA

In the US, the F180R System is export controlled under ECCN: 7A103a1 of the Commerce

Control List (CCL) (Supplement No. 1 to Part 774 of the EAR). The Department of Commerce’s

Bureau of Industry and Security (BIS) is responsible for implementing and enforcing the Export

Administration Regulations (EAR).

For further information in the USA visit: http://beta-www.bis.doc.gov/index.php/licensing/

commerce-control-list-classification/export-control-classification-number-eccn

UK and European Union

The main legal basis for controls on dual-use goods is the European Union Dual-Use Regulation

(Council Regulation (EC) No 428/2009 and associated legal amendments). This legislation is

directly applicable in all EU countries, including the UK.

Export Policy

9

The F180R System is restricted under entry 7A103a1 of the EU Dual-Use List and the UK

Consolidated list.

From the UK, the F180R System may be exported:

Within the EU providing that export documents state that the items require a licence if

exported outside the EU and keep appropriate records.

To CGEA countries: Australia, Canada, Japan, New Zealand, Norway, Switzerland and USA

providing according registration has been done and records are kept

To other destinations by applying for a Standard Individual Export Licence

To other destination by using OGELs (Open General Export Licence). They remove the

need to apply for a Standard Individual Export Licence providing a registration has been

done and are subject to conditions. More information available at: https://www.gov.uk/

dual-use-open-general-export-licences-explained

There are also a number of countries where trade embargoes are imposed. These are

constantly changing. For further information on embargoes please visit: https://www.gov.uk/

current-arms-embargoes-and-other-restrictions

For further information in the UK visit: https://www.gov.uk/uk-strategic-export-control-lists-

the-consolidated-list-of-strategic-military-and-dual-use-items

The information contained herein is provided for guidance only. CodaOctopus believes this

information to be correct as of October 2012; however, it is the sole responsibility of the

exporter to ensure that they comply with Export Regulations within the country of export.

CodaOctopus accepts no responsibility for any failure to comply with regulations.

Please contact sales@codaoctopus.com for further details and assistance with export

guidelines.

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 10

Chapter

2

Introduction

Page 11

2 Introduction

WARNING: Although selected for their ruggedness, the solid–state accelerometers

and rate sensors used in the IMU are susceptible to excessive shock and vibration.

Refer to the environmental specifications for details. Treat the IMU with care when

you handle it—store it in the transit case until you are ready to install it. Never drop

the IMU or subject it to shocks. A 'Shockwatch' label attached to the IMU casing will

show a red central vial if the unit is subjected to severe shock. If this occurs, return the

unit to CodaOctopus Limited for test and repair. The solid–state inertial measurement

components are not field repairable.

The F180R System Inertial Attitude and Positioning System from CodaOctopus is an instrument

for making precision measurements of vessel attitude (including heading), dynamics and

geographical position for use in any marine hydrographic survey application. The F180R

System is light in weight, compact in size and can be installed and uninstalled easily and

quickly. The F180R System Inertial Attitude and Positioning System requires none of the

complicated post-installation setup and configuration procedures demanded by other similar

systems, yet provides all the functionality required within hydrographic survey applications.

The F180R System is a multi-sensor system consisting of an inertial measurement unit (IMU),

built up of three solid-state gyros and three inertial-grade accelerometers, and two survey

grade GPS receivers. The F180R System is delivered with the IMU components in a separate

waterproof pod (wetpod) in order to allow the IMU to be located close to a transducer head.

Introduction

11

The F180R System integrates the information provided by the attitude and position sensors

and takes advantage of their complimentary attributes in order to yield a position and attitude

solution more stable than either system in operating in isolation. This blended navigation

solution gives the F180R System several key advantages:

Measurement of position, attitude and heading that exhibit the long-term stability of a

GNSS navigation system with the short term accuracy of the inertial navigator.

Precise position and attitude information at a high 100Hz update rate ideal for highdynamic applications.

Automatic system calibration compensating for IMU bias, drift and scale factor errors.

Robust navigation output capable of maintaining a useful degree of accuracy during

GNSS signal blockage and degradation.

Recognises and ignores anomalous transient jumps in the GNSS position solution.

This guide describes the F180R System Inertial Attitude and Positioning System in detail and is

an important part of the system. You should retain the guide so that it is available to all those

who will install, operate and maintain the system.

Although installation and operation of the F180R System are not complex tasks, you should

spend time to familiarise yourself with the contents of this manual before you start to install

or use the system. The time that you spend in identifying the task sequence now will help you

to have your system operational with minimal delay.

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 12

Introduction

NOTE: Hints and tips are sparsed through the user guide to help you speed up a

process of carrying out an action, or to provide reminders. These are formatted like

this.

WARNING: It is strongly recommended that the instructions given in warnings should

be followed and important information should be heeded. These are formatted like

this.

Unless otherwise stated, all measurements throughout this manual conform to the SI system

of units.

12

2.1

General Description

The F180R System Inertial Attitude and Positioning System comprises four separate subsystems:

Figure 1: F180R System Unit, Antennas and Interfacing Cables

the Inertial Measurement Unit with the interconnection cables

two GNSS antennas and their signal cables

software supplied on a Disc with the system

IMU components mounted in a separate water-proof housing

Figure 2: F180R System IMU component (wetpod)

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 13

2.1.1 Inertial Measurement Unit

The F180R System Box unit includes:

dual GPS receiver cards that accept and process data from each GNSS antenna

the interface electronics that process signals from the IMU and communicate the

blended position, attitude and heading measurements to the receiving PC

four LEDs to indicate the system status

The F180R System IMU unit includes:

an array of accelerometers and rate sensors to measure accelerations and rotations that

affect the unit.

The standard system operates from a DC supply in the range 9 to 18V (nominally 12V DC). This

is normally supplied through a 110 – 240V mains powered supply.

2.1.2 GNSS System

Two GNSS systems supply the information required by the F180R System to produce a heading

solution. The antennas and the dual GNSS receiver cards are all designed for use in harsh

marine environments where vibration and extremes of temperature are the norm. Low–loss

antenna cables connect the antennas to their ports on the integrated electronics unit and

ensure optimal reliability of operation.

Introduction

13

Novatel OEMV cards are the standard receivers integrated in the F180R System. Included are

also a matching pair of GNSS antennas. (Novatel GPS 701 for L1 enabled receivers and Novatel

GPS 702 for receivers enabled in L1/L2 mode.

The system comes with a standard set of 15m (Novatel CO16) antenna cables with options for

5m (Novatel C006) and 30m (Novatel C031). Refer to Antenna Cable Appendix for further

technical information on antenna cables.

2.1.3 Software

The MOTION Control software supplied with the system runs on an IBM–compatible PC under

a Microsoft® Windows™ Vista, 7 and 8 both 32 bit and 64 bit environments and provides

several important and useful functions:

configuration and real–time data display

system calibration and QC diagnostics

long period heave processing (iHeave)

interface capabilities with external receiving equipment

data acquisition and playback

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 14

Introduction

NOTE: To ship the units between installation sites or to return them to CodaOctopus

for repair, package them with care. You should retain the original transit packing cases

for this purpose. The use of improper packing for shipping any part of this equipment

will invalidate the warranty.

NOTE: In no event will CodaOctopus be liable for any indirect, incidental, special or

consequential damages whether through tort, contract or otherwise. This warranty is

expressly in lieu of all other warranties, expressed or implied, including without

limitation the implied warranties of merchantability or fitness for a particular

purpose. The foregoing states the entire liability of CodaOctopus with respect to the

products described herein.

14

2.2

Warranty

Coda Octopus Products Ltd warrants the F180R System Inertial Attitude and Positioning System

to be free of defects in materials or workmanship for one year. The warranty period begins on

the date when the equipment was shipped from CodaOctopus or from their authorised

distributor.

For information concerning the proper return location and procedure, contact CodaOctopus or

their authorised distributor. The How To Get Support sections list contact details for

CodaOctopus. The responsibility of CodaOctopus in respect of this warranty is limited solely to

product replacement or product repair at an authorised location only. Determination of

replacement or repair will be made by CodaOctopus personnel or by personnel expressly

authorised by CodaOctopus for this purpose. This warranty will not extend to damage or

failure resulting from misuse, neglect, accident, alteration, abuse, improper installation, nonapproved cables or accessories, or operation in an environment other than that intended. A

'Shockwatch' label attached to the IMU casing will show a red central vial if the unit is

subjected to severe shock. If this occurs, contact CodaOctopus technical support for test

instructions.

2.3

The solid–state inertial measurement components are not field repairable.

Calibration

We recommend to factory calibrate the F180R System hardware every 2 years to ensure

maximum accuracy. The calibration can't be performed in the field so please get in touch with

the CodaOctopus Support team to arrange a hardware calibration.

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 15

Chapter

3

Hardware

Page 16

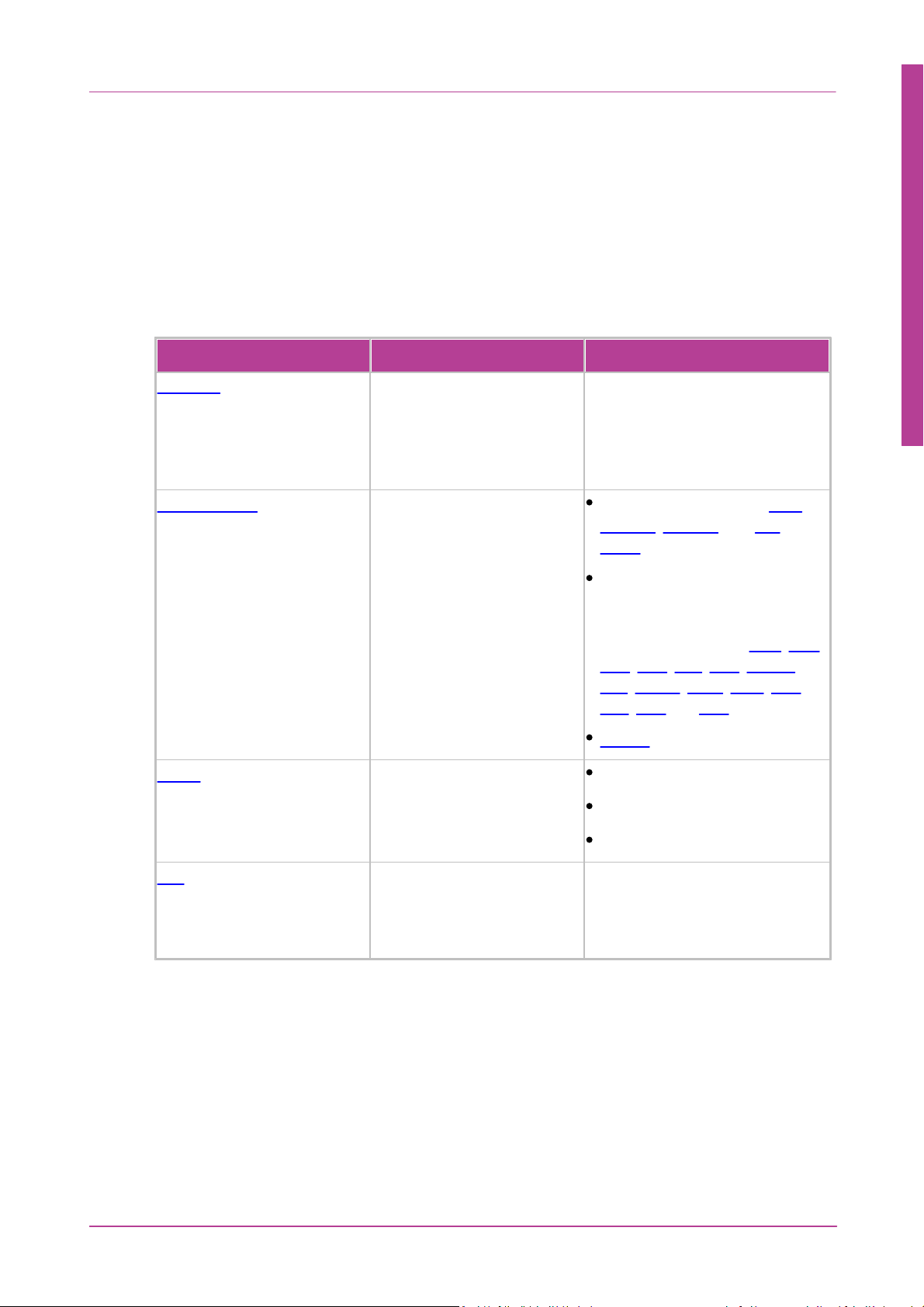

3 Hardware

Port type

Description

Available Data protocols

Ethernet

(100 Base T)

For control, configuration,

acquisition and QC of the

F180R System system using

the supplied Windows–based

application software

MCOM binary data output string

COM1 / COM2

(RS232)

Configurable ports

outputting data at rates up to

115200 baud

Attitude data using the TSS1,

EM1000, EM3000 and TSS

HHRPdata strings

NMEA data strings for reporting

of position, fix, heading,

velocity, date, time and error

statistic using NMEA GGA, GGK,

GSA, GSV, GST, HDT, PASHR,

PPS, PRDID, PTCF, RMC, ROT,

UTC, VTG and ZDA strings

MCOM binary data output string

COM3

(RS232)

Differential correction input

at rates up to 115200 baud

RTCM

RTCA

CMR

PPS

(BNC Plug)

The system also supplies a 1

pulse per second (PPS)

output synchronised with

GPS time

Hardware

16

3.1

Communication

So far you have installed and interconnected the components of the F180R System Inertial

Attitude and Positioning System so that they are ready for use. This chapter of the manual

describes the various interface options and data output formats that you may use with the

F180R System.

The F180R System system communicates with the controlling PC and with external equipment

over various protocols using five interface ports: Ethernet, COM1, COM2, COM3 and PPS:

3.1.1 Ethernet

The Ethernet connection allows you to make maximum use of the F180R System system. The

system outputs data using a UDP (User Datagram Protocol) broadcast on port 3000 that allows

all PCs connected to the network to receive the transmitted MCOM data. It provides

significantly greater data transfer capacity than a serial RS232 connection. To receive data from

the F180R System system on a PC, the PC must have an Ethernet card fitted and be connected

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 17

Hardware

WARNING: For optimal performance you should use a direct exclusive connection

between your PC and the F180R System, thus avoiding potential data latencies and

interference that would otherwise be caused by other traffic existing on the network.

WARNING: Any firewalls between the F180R System and the control computer must

be either disabled or allow all traffic to and from the MOTION Control software to

pass.

F180R System Default Network Settings

IP Address

195.0.0.180

User configurable

Subnet Mask

255.255.255.0

User configurable

NOTE: The F180R System kit contains an in-line coupler and a CAT5 Ethernet crossover

cable which can be used for direct F180R System-to-PC connection.

NOTE: Definitions of Heading, Pitch and Roll that are output by the F180R System can

be found in Rotation Convention.

to the same 100 Base T local area network (LAN) over which the system is broadcasting. The PC

must be running the supplied MOTION Control software.

You do not need to know details of the output packet format for the UDP broadcast to work

effectively. However, if you require a detailed description of the MCOM format, please

contact support@codaoctopus.com.

17

There is an RJ–45 connector, J6, on the user interface cable that allows direct connection

between the F180R System system and a network hub/switch. You may extend the cable if

necessary by using commercially available network cables connected to the system through an

RJ–45 direct in–line coupler that has a straight–through configuration. You may also connect

the F180R System system directly to an Ethernet card in a PC. To do this the Ethernet link must

be a crossover connection.

3.1.2 Serial Outputs

The F180R System sends attitude (heave, pitch and roll) information using the TSS1 data

string format through a serial RS232 link updated at 100 Hz.

The F180R System sends attitude, heave and heading information using the binary Simrad

EM3000 format through a serial RS232 link updated at up to 100 Hz.

The F180R System outputs NMEA 0183 ASCII text sentences for position (GGA), true heading

(HDT), velocity (VTG) and Date/Time (ZDA) information through a serial RS232 link updated

at up to 50 Hz.

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 18

Once you have defined the serial output settings, after power–on and initialisation, receiving

NOTE: If you have specified a Remote Lever Arm then the position, velocity, heading

and attitude data are for the remote lever arm location.

NOTE: If you have entered a IMU Alignment/Orientation but you have not set a

Remote Lever Arm, the position, velocity, attitude data are relative the IMU and the

heading data are for the vessel.

NOTE: If you have not set either a Remote Lever Arm or a IMU Alignment/Orientation,

then the position, velocity, attitude and heading data are for the IMU.

equipment connected to the serial ports will continue to receive the TSS1 or EM3000 data

packets and/or NMEA sentences even with the Ethernet port disconnected. The heave data is

processed onboard the F180R System for a 16 second period.

3.1.2.1 MCOM

Binary data output string that include position, attitude, heading, velocity, track and speed,

acceleration, status and performance and raw data.

Hardware

18

The MCOM format is a proprietary format defined by CodaOctopus. The format description is

available to third parties who wish to implement libraries for decoding the MCOM data

stream. Contact CodaOctopus Support for further information.

3.1.2.2 NMEA

3.1.2.2.1 GGA

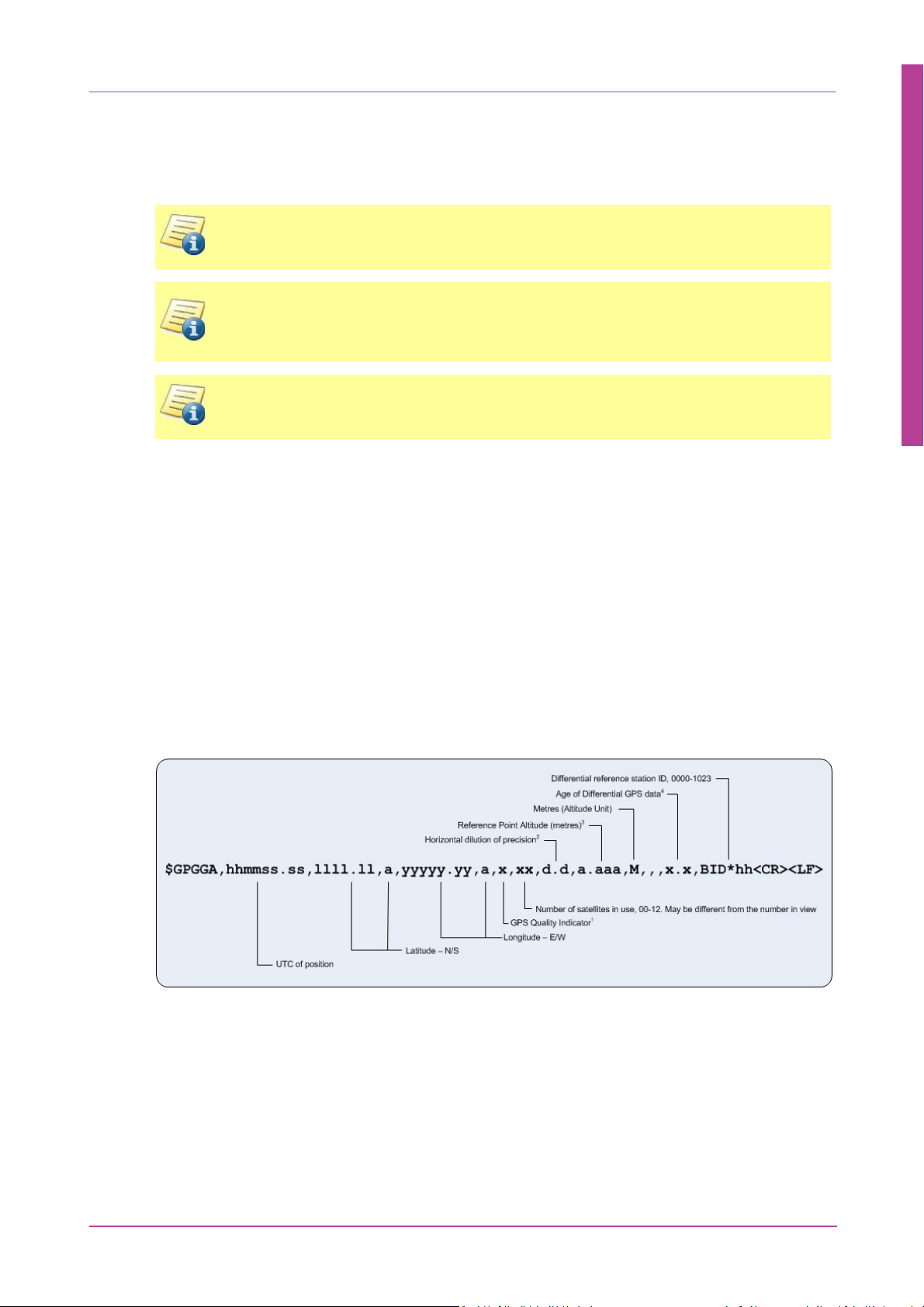

The NMEA - GGA string contains time, position and fix related data for a GPS receiver.

Figure 3: NMEA - GGA Format

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 19

Hardware

1. GPS Quality Indicator:

0 = Fix not available or invalid

1 = GPS SPS Mode, fix valid

2 = Differential GPS, SPS Mode, fix valid

3 = GPS PPS Mode, fix valid

4 = Real Time Kinematic. System used in RTK

mode with fixed integers

5 = Float RTK. Satellite system used in RTK

mode with floating integers

6 = Estimated (dead reckoning) mode

7 = Manual Input mode

8 = Simulator mode

The GPS Quality indicator shall not be a null

field.

2. Horizontal dilution of precision:

The system adds leading digits as required.

3. Reference Point Altitude:

Which will be the IMU sensing centre or a

remote position depending on how the system

has been configured. The Altitude output will

be to the datum that you have chosen in the

Settings Wizard.

4. Age of Differential GPS data:

Time in seconds since last SC104 Type 1 or 9

update, null field when DGPS is not used. The

system also adds leading digits as required

19

Also, note that commas separate all items, including null fields.

If no differential corrections are being received, the Age of Differential GPS data and Digital

reference station ID fields are also null.

3.1.2.2.2 GGK

The GGK string is a Trimble proprietary data string that provided time, position, position type,

and DOP. It is considered a "pseudo-NMEA" string, because it looks similar to a standard NMEA

string, but does not quite adhere to the NMEA specification.

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 20

Figure 4: NMEA - GGK Format

Field

Description

a

Mode

M = Manual, forced to operate in 2D or 3D mode

A = Automatic, allowed to automatically change between 2D or 3D

m

Mode

1 = Fix not available

2 = 2D

3 = 3D

ss

IDs of the satellites used in the solution. This field is repeated 12 times. (null

for unused fields)

p.p

PDOP

Hardware

20

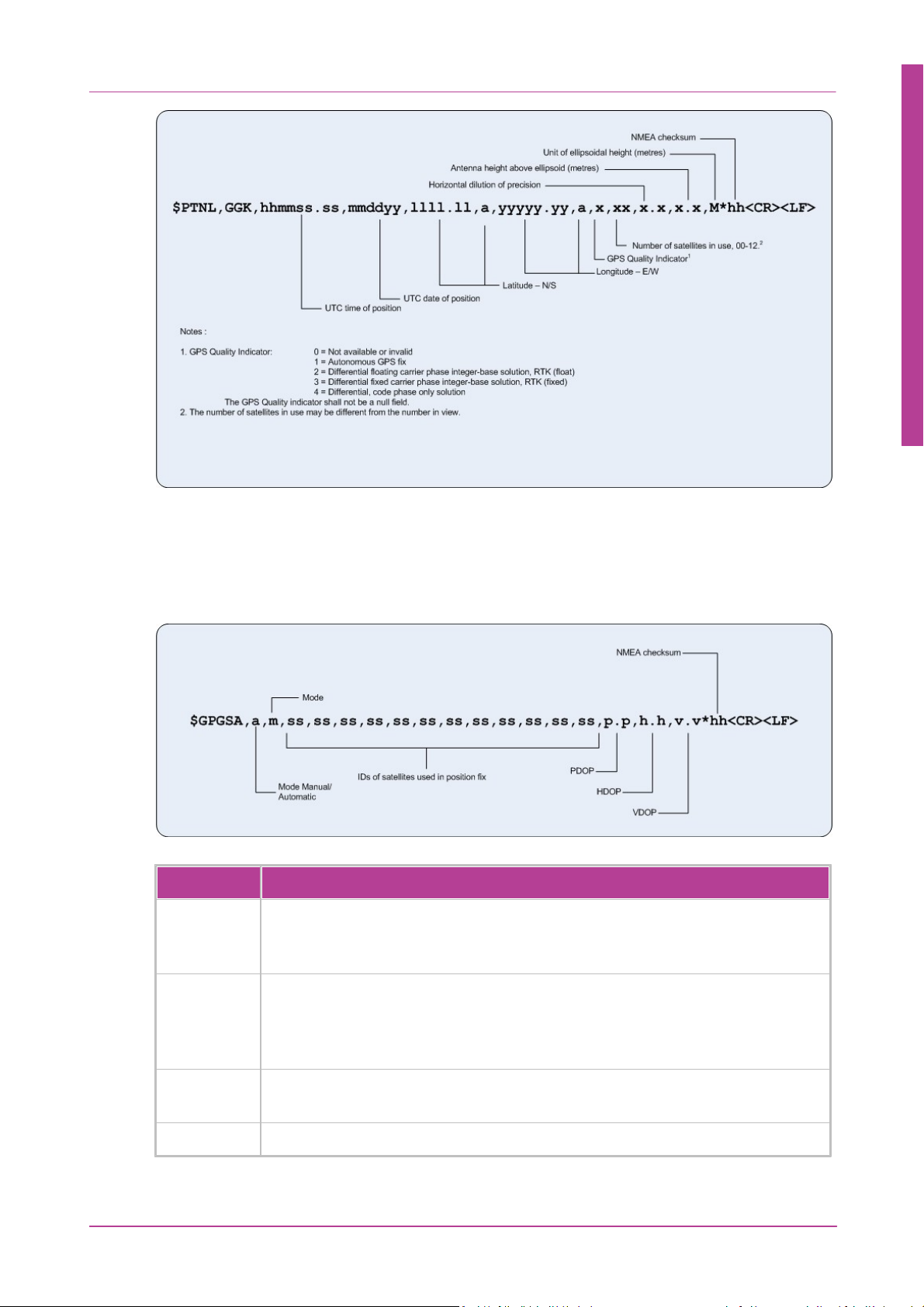

3.1.2.2.3 GSA

The NMEA - GSA string identifies the GPS position fix mode, the ID of the Satelite Vehicles

used for navigation, and the Dilution of Precision (DOP) values.

Figure 5: NMEA GSA String

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 21

Field

Description

h.h

HDOP

v.v

VDOP

*hh

Checksum

3.1.2.2.4 GSV

Field

Description

t

Total number of messages of this type in this cycle

m

Message number, 1 to 4

ss

Number of theoretically visible satellites according to the current alemanac

xx

Satellite's PRN number

ee

Elevation in degrees, 90° maximum, empty when not tracking

aaa

Azimuth, degree from true north, 000° to 359°

nn

SNR in dB, 00 to 99 dB of L1 signal, null field when not tracking

...

Repeat set of PRN, elevation, azimuth and SNR for the remaining three

satellites

*hh

Checksum

The GSV message identifies the number of satellites in view, the pseudorange noise (PRN)

numbers, elevation, azimuth, and signal-to-noise (SNR) value.

Hardware

21

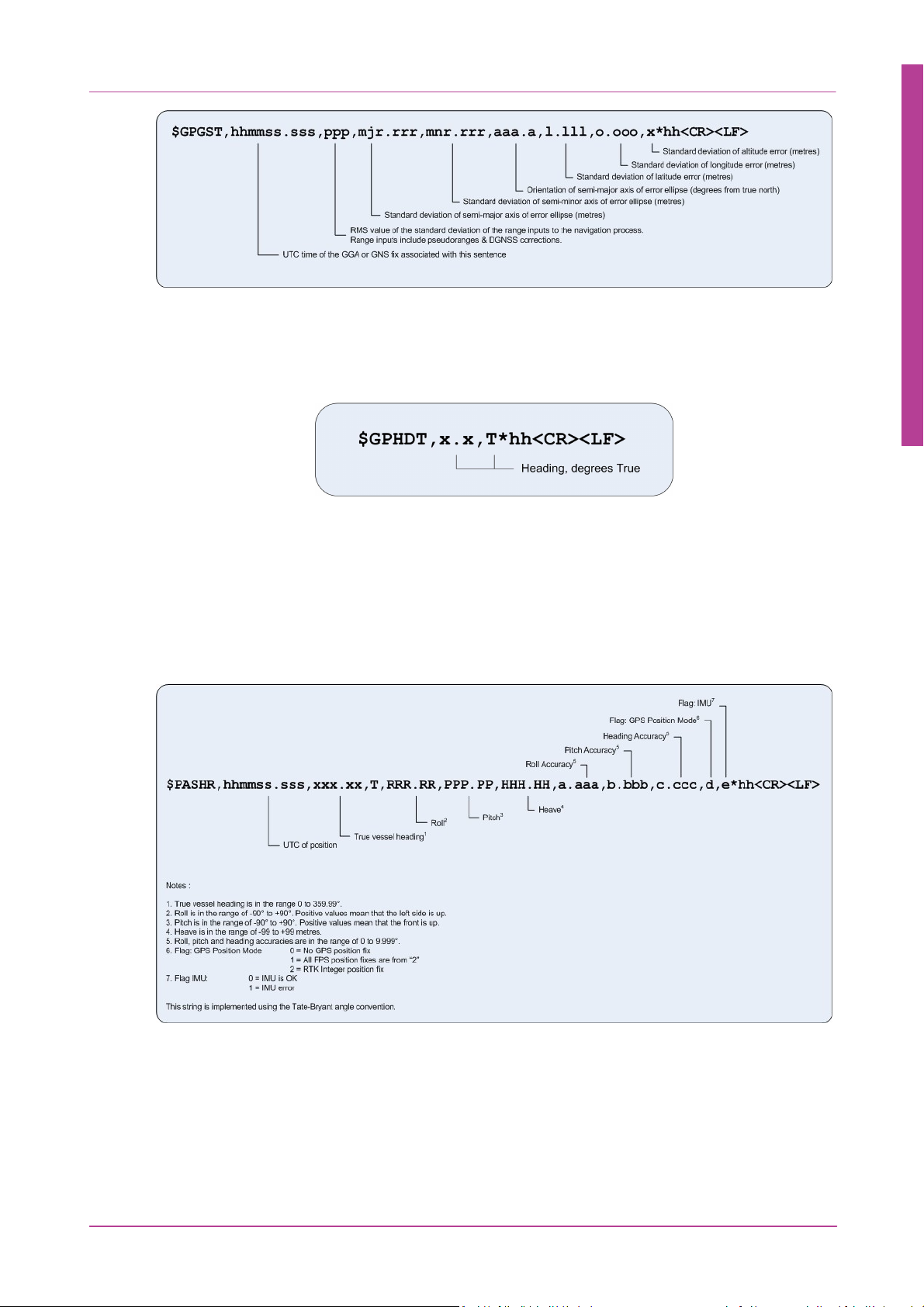

3.1.2.2.5 GST

Figure 6: NMEA GSV string

This string, GNSS Psuedorange Error Statistics, is used to support Receiver Autonomous

Integrity Monitoring (RAIM). Psuedorange measurement error statistics can be translated in

the position domain in order to give statistical measures of the quality of the position

solution.

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 22

3.1.2.2.6 HDT

The NMEA - HDT string contains true heading in degrees.

Figure 7: NMEA - GST Format

Figure 8: NMEA - HDT Format

Hardware

22

Note that, in the case of the true heading field, the system adds leading digits as required.

Also, note that commas separate all items, including null fields.

3.1.2.2.7 PASHR

The PASHR sentence contains UTC time, heading, pitch, roll and heave measurements.

Accuracy data for the measurements is also included.

3.1.2.2.8 PPS

The PPS (Pulse Per Second) is a non-standard NMEA message which is useful for integrating

the F180R System with other devices. This message contains useful information such as the

PPS count, the UTC time of the current PPS, and other time-related information.

Copyright © 2015 Coda Octopus Products Ltd

Figure 9: PASHR String

F180R MOTION Sensor User and Reference Guide

Page 23

Figure 10: NMEA PPS string

Field

Description

hhmmss.ss

UTC time of PPS in hours / minutes / seconds.decimal seconds

dddddd

Day offset in days in days

wwwwww

GPS week in weeks

fff.ff

UTC time offset in seconds

pppppp

PPS count

*hh

Checksum separator and checksum

Hardware

23

3.1.2.2.9 PRDID

The PRDID sentence contains attitude data.

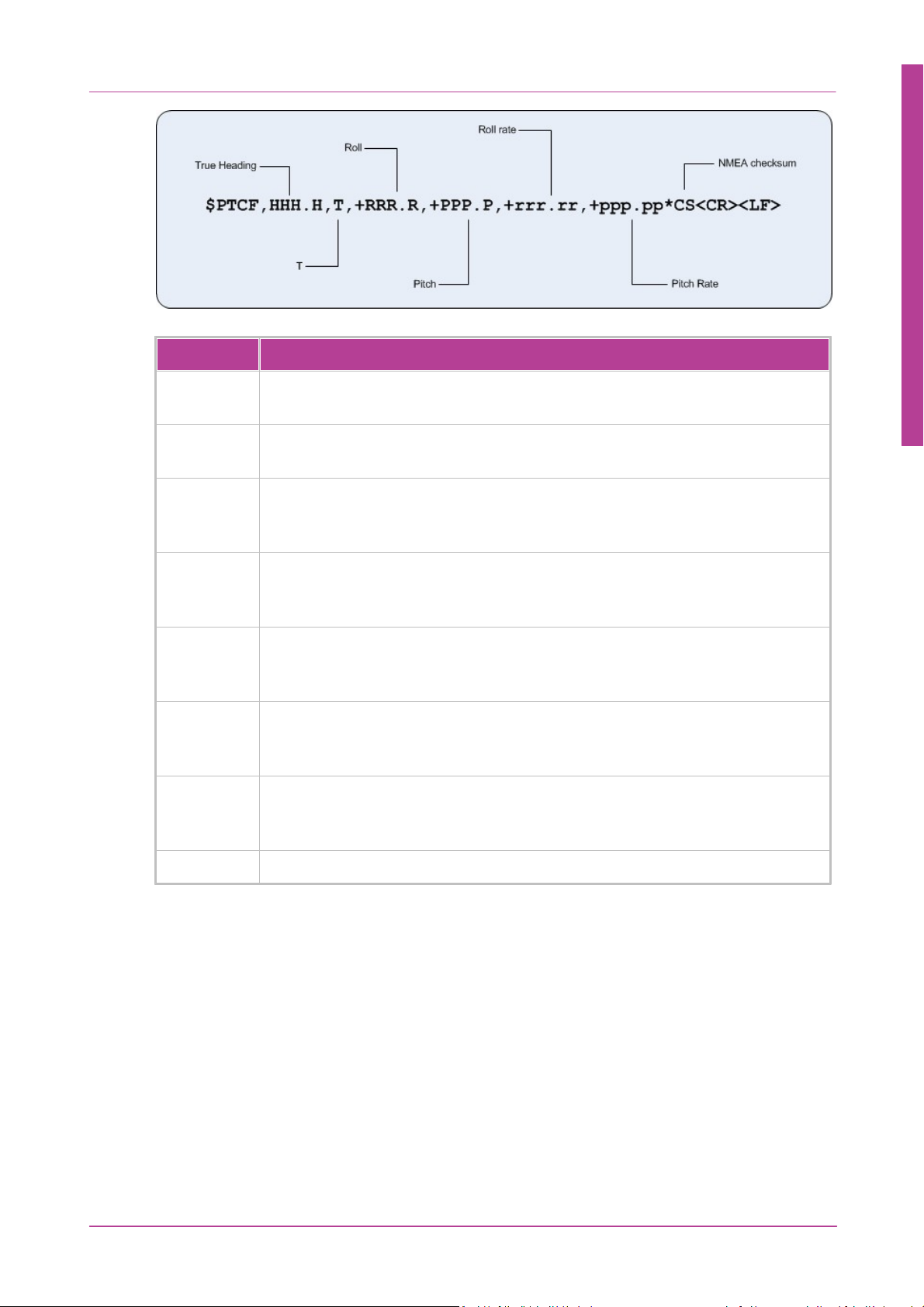

3.1.2.2.10 PTCF

The PTCF sentence contains the orientation (heading, pitch and roll Euler angles) of the

vessel. The angular rates for roll and pitch are also included. This sentence only contains the

orientation measurements accurate to 1 decimal place so it is not suitable for high accuracy

applications.

Figure 11: PRDID String

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 24

Figure 12: NMEA PTCF string

Field

Description

HHH.H

True Heading of the navigation system, from 0 to 359.99 degrees, using 1

decimal place.

T

The character ‘T’ is output by the navigation system to represent that the

heading is to true north. Grid north and magnetic north are not output.

+RRR.R

Roll of the navigation system, measured in degrees, with leading sign, leading

0’s where needed and 1 decimal place. Positive values mean that the left side

is up.

+RRR.R

Roll of the navigation system, measured in degrees, with leading sign, leading

0’s where needed and 1 decimal place. Positive values mean that the left side

is up.

+PPP.P

Pitch of the navigation system, measured in degrees, with leading sign, leading

0’s where needed and 1 decimal place. Positive values mean that the front is

up.

+rrr.rr

X-axis angular rate (roll rate) of the navigation system, measured in degrees/

second, with leading sign, leading 0’s where needed and 2 decimal places.

Positive values mean that the left side is moving up.

+ppp.pp

Lateral angular rate (pitch rate) of the navigation system, measured in degrees/

second, with leading sign, leading 0’s where needed and 2 decimal places.

Positive values mean that the front is moving up.

*CS

Checksum separator and checksum

Hardware

24

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 25

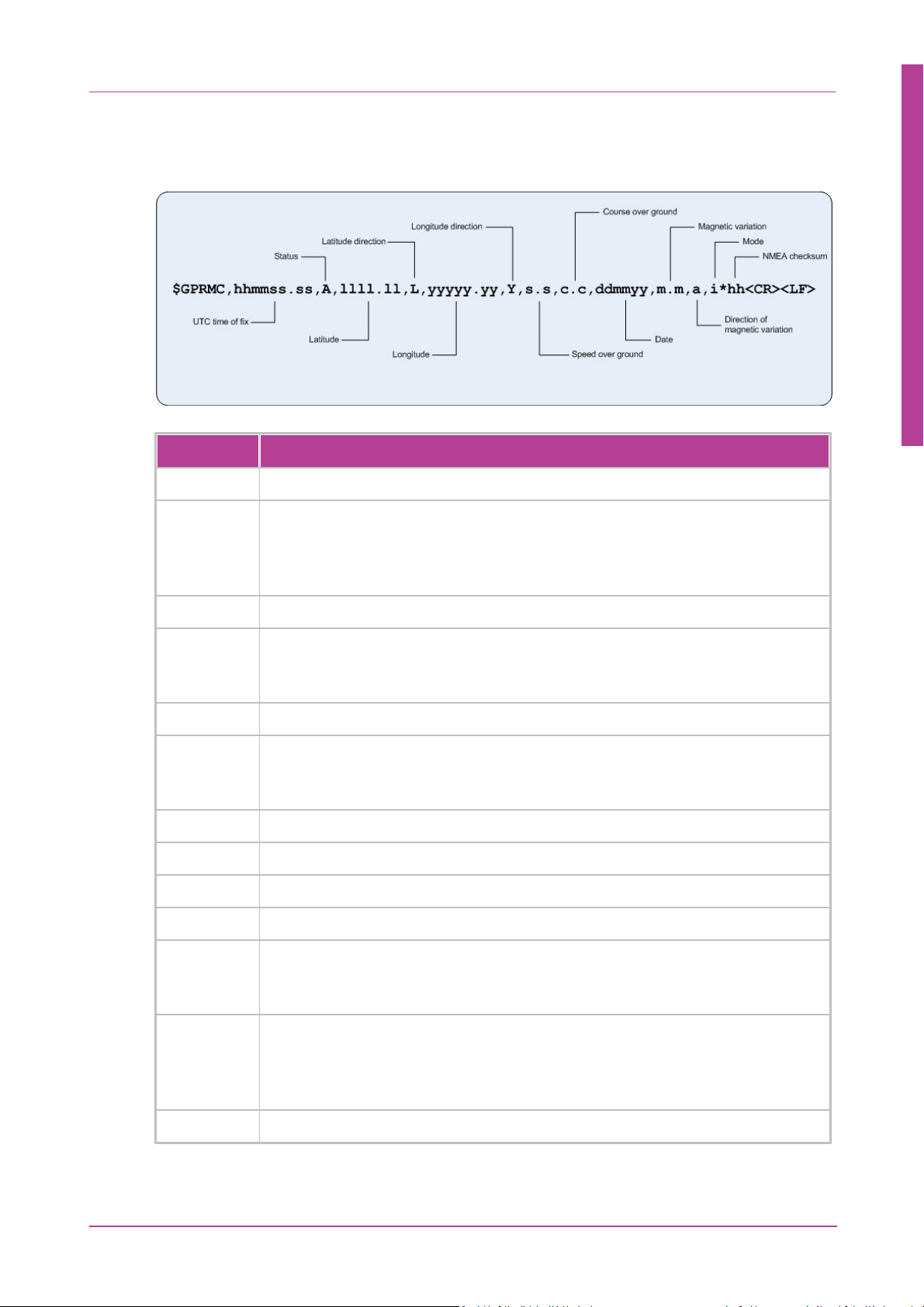

3.1.2.2.11 RMC

Field

Description

hhmmss.ss

UTC time of the position fix in hhmmss.ss format

A

Status

A = Data valid

V = Navigation receiver warning (V is output whenever the receiver indicates

that something is wrong)

llll.ll

Latitude (WGS-84)

L

Latitude direction

N = North

S = South

yyyyy.yy

Longitude (WGS-84)

Y

Longitude direction

W = West

E = East

s.s

Speed Over Ground (SOG) in knots

c.c

Course Over Ground in degree

ddmmyy

Date in ddmmyy format

m.m

Magnetic Variation in degrees

a

Direction of magnetic variation

E = Easterly variation from True course (subtracts from True course)

W = Westerly variation from True course (adds to True course)

i

Mode indicator

A = Autonomous

D = Differential

N - Data not valid

*hh

Checksum

The RMC message identifies the UTC time, status, latitude, longitude, speed over ground

(SOG), date, and magnitude variation of the position fix.

Figure 13: NMEA RMC string

Hardware

25

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 26

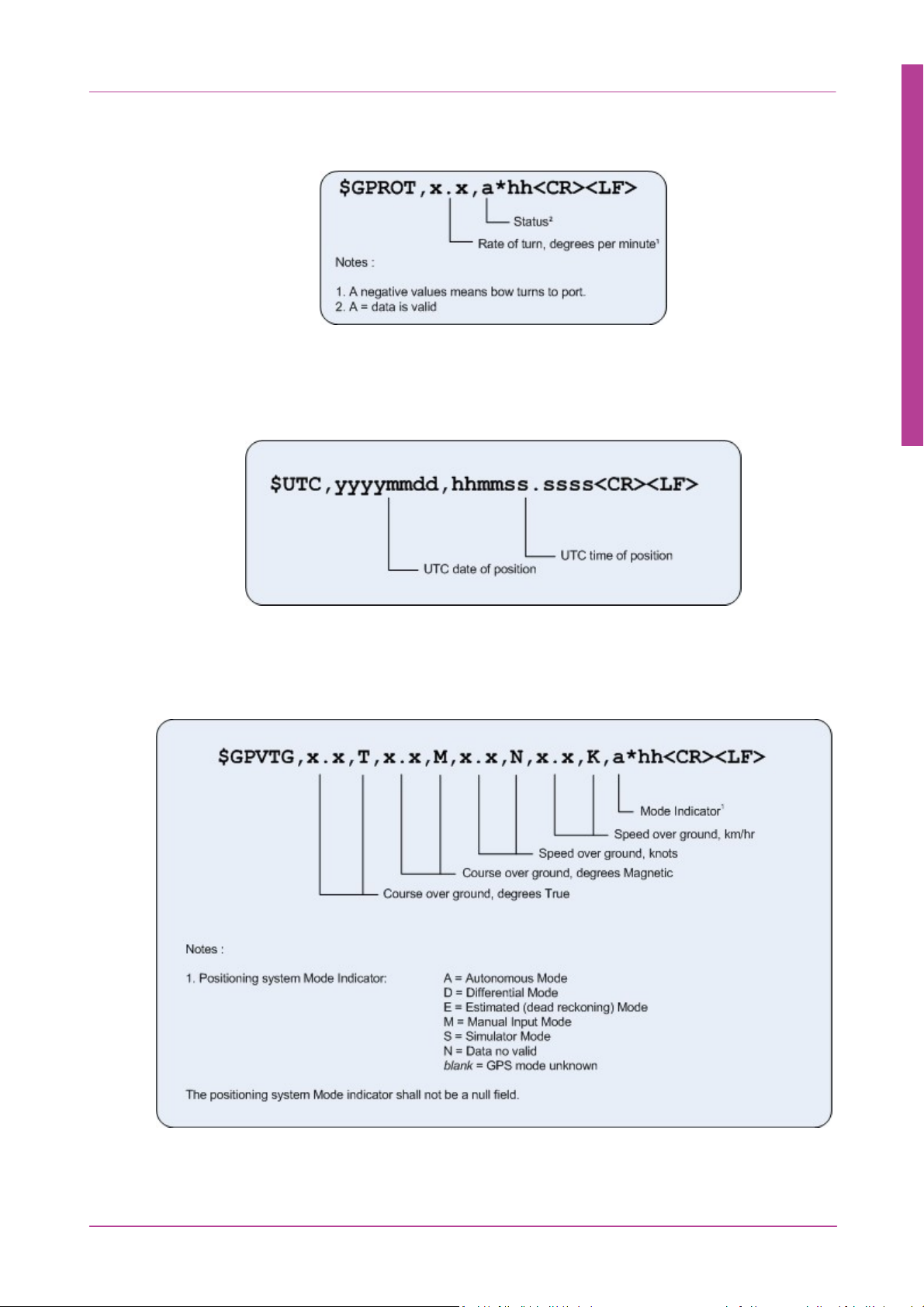

3.1.2.2.12 ROT

The ROT sentence contains Rate of Turn data.

3.1.2.2.13 UTC

The UTC sentence contains UTC date and time.

Figure 14: ROT String

Hardware

26

3.1.2.2.14 VTG

The NMEA - VTG string contains the actual course and speed relative to the ground.

Figure 15: UTC String

Copyright © 2015 Coda Octopus Products Ltd

Figure 16: NMEA - VTG Format

F180R MOTION Sensor User and Reference Guide

Page 27

3.1.2.2.15 ZDA

The NMEA - ZDA string contains UTC time, day, month, year and local time zone information.

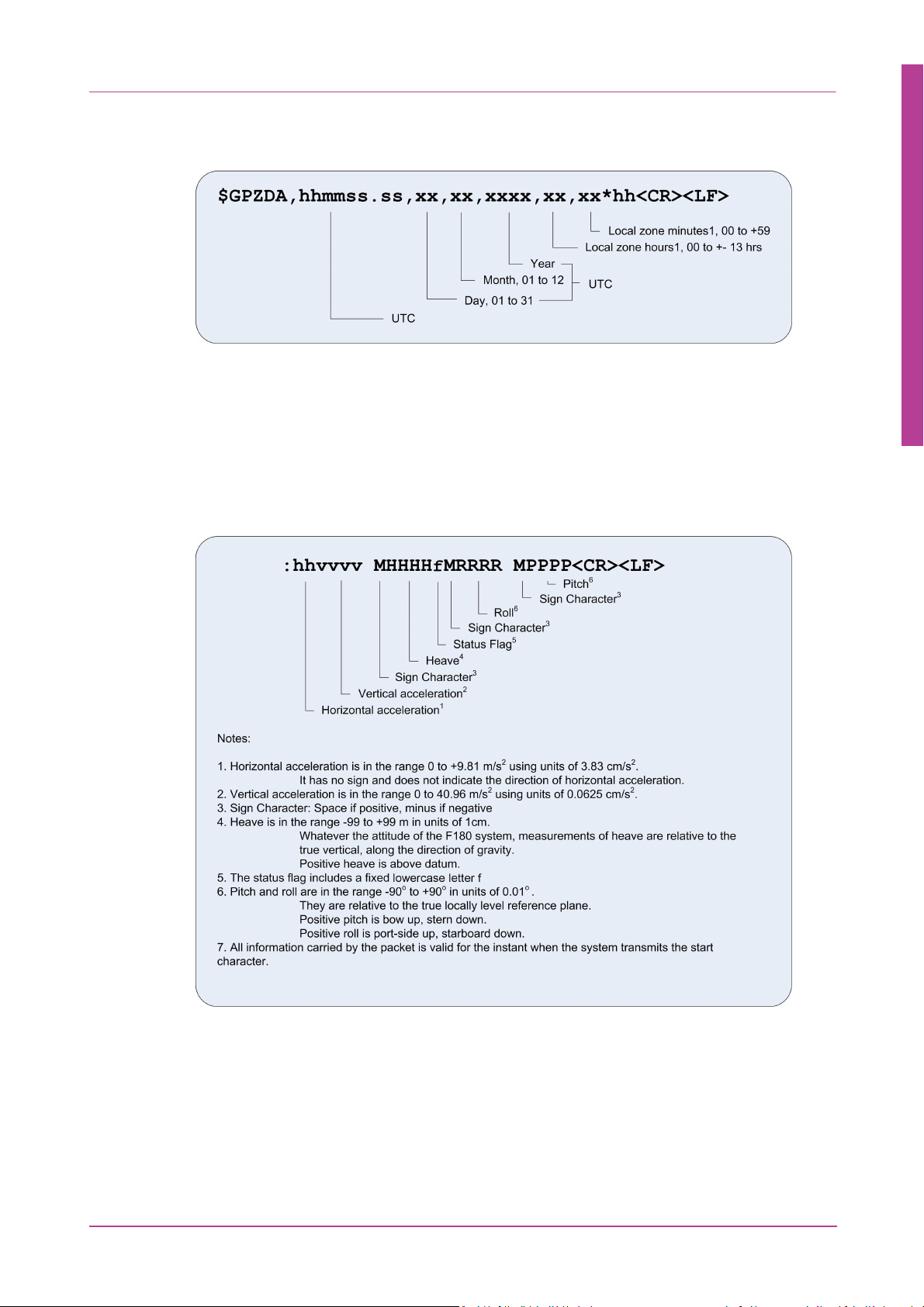

3.1.2.3 TSS1

The TSS1 data string format has five fields and contains 27 ASCII characters. Each string begins

with a start character and ends with the carriage return and line–feed characters. All fields

contain measurements in real–world units - the F180R System supplies acceleration

measurements using ASCII–coded hexadecimal values and heave, pitch and roll as ASCII–

coded decimal values.

Figure 17: NMEA - ZDA Format

Hardware

27

Example:

:053C22 0000f-0046 -0563

:043C86 0000f-0048 -0563

:053D1C 0000f-0050 -0563

:073D89 0000f-0052 -0562

:043CF7 0000f-0055 -0562

Copyright © 2015 Coda Octopus Products Ltd

Figure 18: TSS1 Data String

F180R MOTION Sensor User and Reference Guide

Page 28

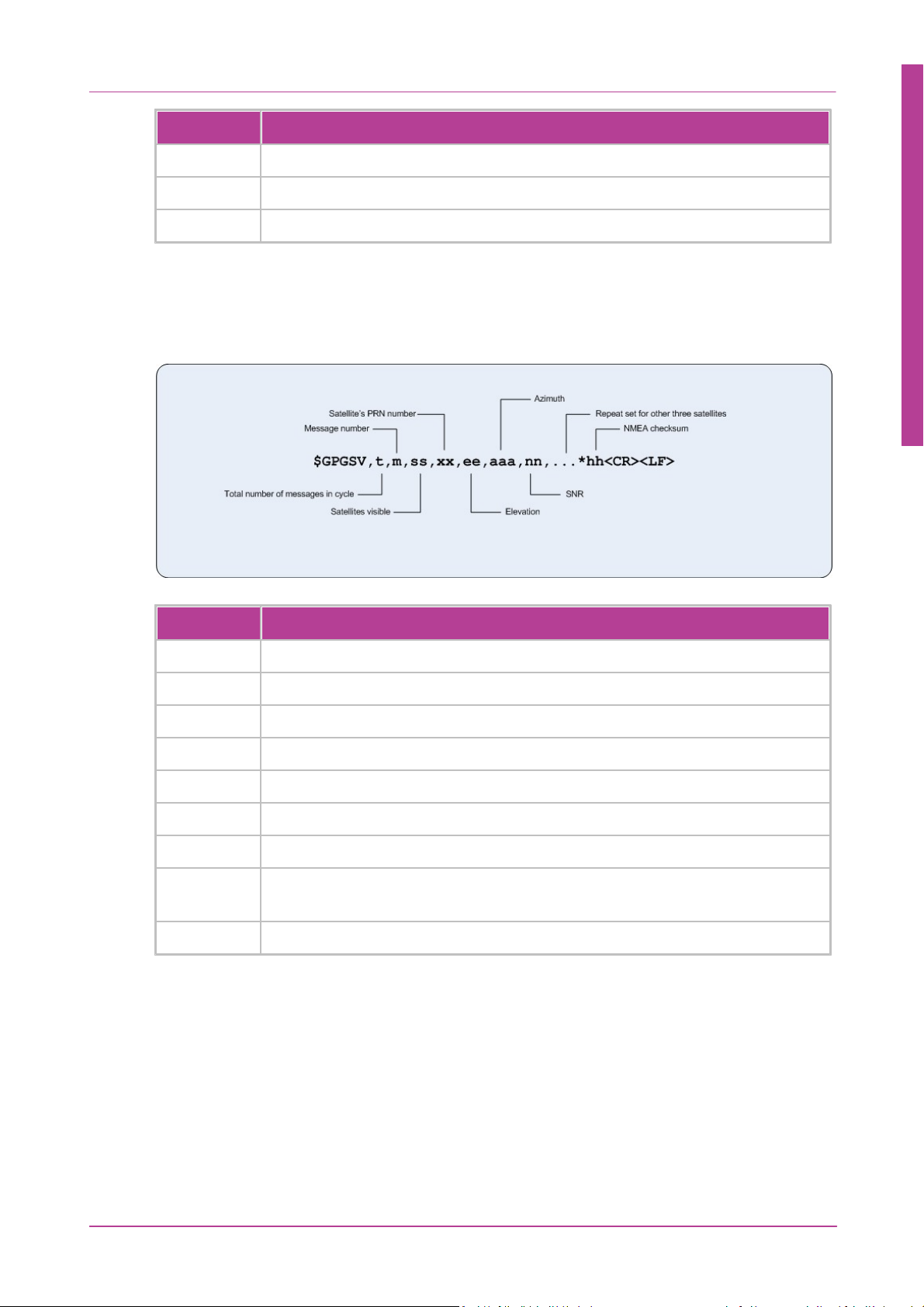

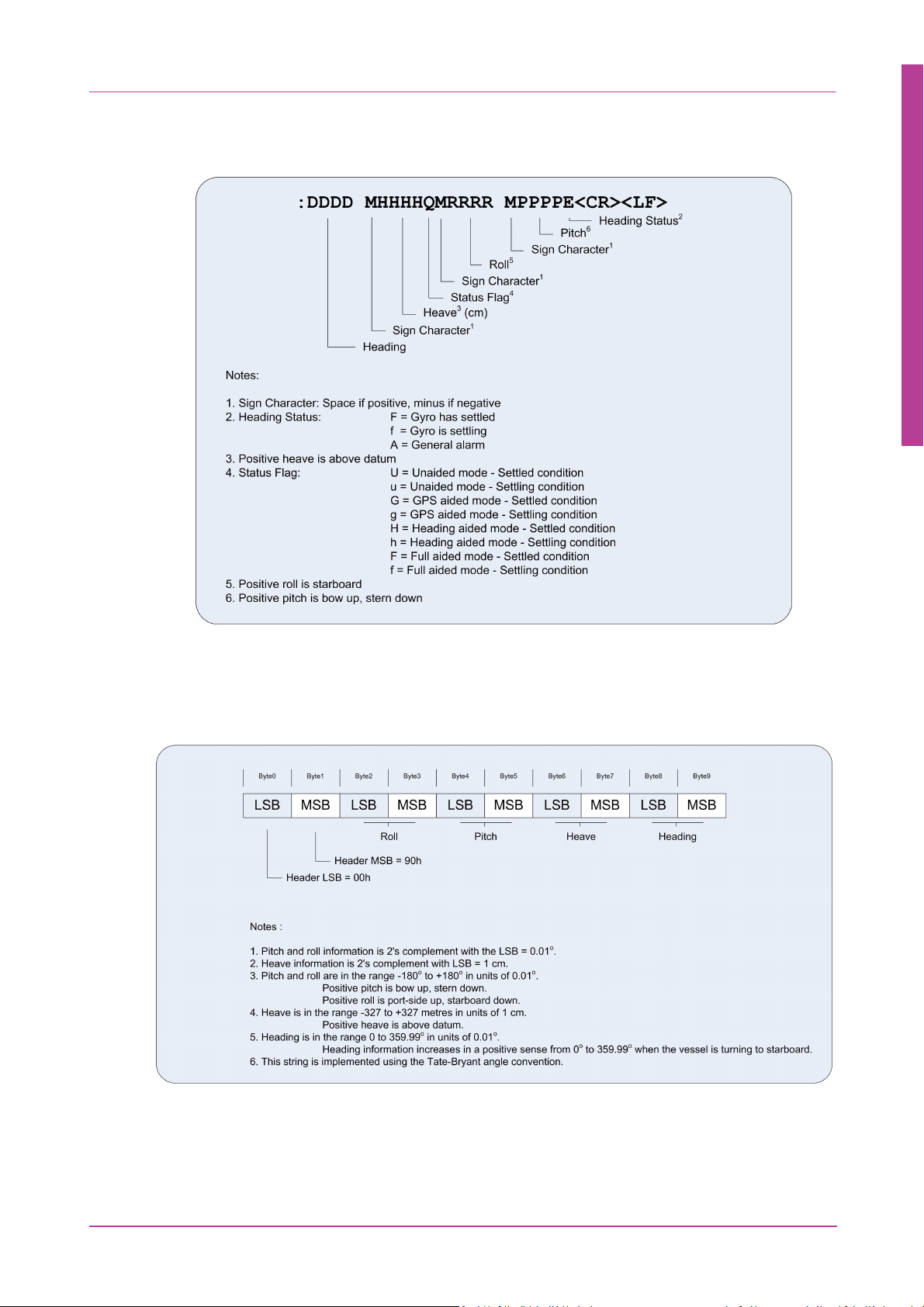

3.1.2.4 TSS HHRP

The HHRP sentence contains attitude data.

Hardware

28

3.1.2.5 EM1000 (Tate-Bryant)

This 10–byte binary format is for use with the Simrad EM1000 multibeam sounder system.

Figure 19: HHRP String

Copyright © 2015 Coda Octopus Products Ltd

Figure20: EM1000 Format

F180R MOTION Sensor User and Reference Guide

Page 29

3.1.2.6 EM3000 (Tate-Bryant)

NOTE: The F180R System can only process correction strings if they are referenced to a

single base station or differential beacon. Some differential GPS receiver units can

receive and output data from multiple differential beacons simultaneously. This type

of output is not compatible with the F180R System and a single reference source

should be used in the correction input to theF180R System. This input must arrive on

the J3 user interface cable.

Receive (Rx) pin on J3 is Pin 3 for correction input

This 10–byte binary format is for use with the Simrad EM3000 multibeam sounder system.

Figure 21: EM3000 Format

Hardware

29

3.1.3 RTK and Differential Corrections

The F180R System can decode corrections supplied in RTCM, RTCA and CMR and CMR from

external GPS receivers or standalone demodulators. The system is configured by default to

receive RTK and differential correction information, using the RTCM format with default input

port settings 9600,8,N,1,OFF. You can change the correction configuration in the Configuration

Wizard

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 30

Hardware

Format

Description

RTCM

The F180R System will accept standard RTCM-SC104

messages:

Version 1/2.2: 3,9,15,16,16t,18,19,20,21,22,59

Version 3: 1001, 1002, 1003, 1004, 1005, 1006

(Please note that only later releases of OEM4 based system

are capable of utilising the RTCM Version 3 messages. Please

contact CodaOctopus for exact information on your F180R

System model.)

RTCA

The F180R System will accept RTCA Standard Type 7

messages.

CMR/CMR+

Trimble open format and available as an output from their

instruments and some other 3rd party.

NOTE: The formats listed above are sent in binary format. Thus you may not see any

recognisable data if the data output is viewed on Hyperterminal. This is worth noting

when trying to troubleshoot F180R System input issues.

30

For further information on correction formats contact CodaOctopus.

3.1.4 PPS

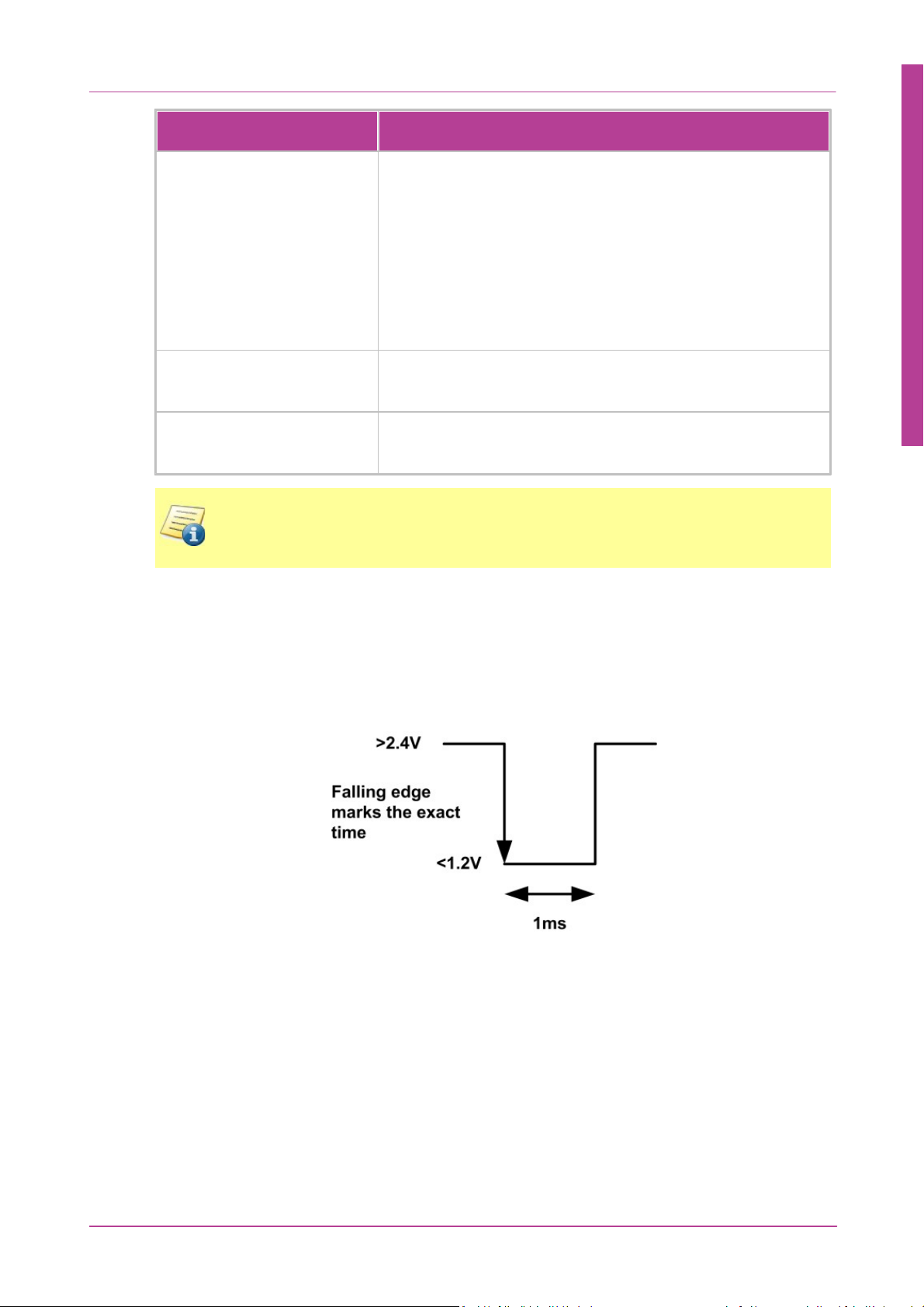

The PPS timing output pulse is a TTL–level high–to–low (>2.4V to <1.2V) transition coincident

(to within 1µs) with the PPS strobe of GPS time. The pulse width is 1ms.

In order to minimise the chance of encountering problems related to time synchronisation we

recommend that a PPS converter is interfaced to one of the onboard serial ports on the

navigation computer and not to external or USB serial ports.

Figure 22: PPS timing output pulse

3.2

Copyright © 2015 Coda Octopus Products Ltd

Technical Specification

CodaOctopus operates a policy of continual product improvement. The technical specification

listed below for the systems manufactured at the time of writing and is therefore subject to

change without notice. For details of current specifications, refer to the CodaOctopus website

F180R MOTION Sensor User and Reference Guide

Page 31

at www.codaoctopus.com or contact CodaOctopus for additional information.

Product

RT20 RTK

L1/L2 on

1st

Antenna

RT2 RTK

Satellite

GPS

L1/L2 on

2nd

Antenna

Description

F180R

Standard F180R with up

to 20 cm positional

accuracy when used with

a suitable external RTK

receiver and base-station

F185R

As standard F180R but

with improved positional

accuracy capability up to

1cm when used with

suitable external RTK

receiver and base-station

F185R+

As F185R but with L1/L2

enabled on both

receivers for rapid

heading initialisation.

F190R

As F180R but with

integrated satellitebroadcast differential

correction receiver

providing up to 20 cm

positional accuracy.

Additional subscription is

required.

F190R+

As F190R but with L1/L2

enabled on both

receivers for rapid

heading initialisation.

3.2.1 Model Specifications

Hardware

31

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 32

3.2.2 Interfaces

Ethernet 100 Base-T

Function

Control, set–up and QC monitoring of the

system using MOTION Control Windows

application software.

MCOM Format

Outputs include position, attitude, heading,

velocity, track and speed, acceleration, status

and performance and raw data.

Serial 1 and 2 Outputs

High data rate output packet (100 Hz) for

high–speed interfacing

Attitude data

TSS1, EM3000, EM1000, HHRP, PASHR and

PRDID attitude strings. RS232 (DB9) up to 115k

baud

NMEA data

GGA position, HDT heading, VTG velocity, ZDA

date/time, GST GNSS Error, etc. RS232 (DB9)

up to 115k baud

MCOM Format

Outputs include position, attitude, heading,

velocity, track and speed, acceleration, status

and performance and raw data

Serial 3 Input

RTK/Differential Correction Input

RS232 (DB9) up to 115k baud.

Receive (Rx) pin on J3 is Pin 3 for correction

input

Other

1 PPS

Hardware

32

Serial outputs 1 and 2 can be configured for any data output type, including the binary MCOM

format.

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 33

3.2.3 Reference Frames

Global Reference System

Horizontal Domain

WGS84 Latitude, Longitude

Vertical Domain

WGS84 Ellipsoidal Height

OSU89B Geoid Height

User Defined

Time Domain

Coordinated Universal Time (UTC)

Local Reference System - F180R System Standard Orientation

Figure 23: Local Reference System

NOTE: The IMU frame for the F180R System wetpod are defined with positive y-axis

through connector plate and positive x and z-axis according to marking on the unit

itself.

Lever Arm Convention

If you have specified a Remote Lever Arm then the position, velocity, heading, heave and

attitude data are for the remote lever arm location.

If you have not set a Remote Lever Arm, the position, velocity, heave, attitude data are

relative the IMU and the heading data are for the vessel.

Hardware

33

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 34

Hardware

NOTE: Running through the MOTION Settings Wizard before physically installing the

F180R System on the vessel could provide helpful as it would give a better

understanding of what is required during the hardware installation.

NOTE: It is a relatively easy operation to transfer theF180R System between different

vessels. This is of particular benefit for those who will use the system in a series of

short–term operations conducted using different vessels.

34

3.3

Hardware Installation

While designing the F180R System Inertial Attitude and Positioning System, CodaOctopus has

made it a high priority to ensure that the system is easy to install, configure and use. With a

need for only the bare minimum of installation parameters to be supplied manually, the

system intelligently evaluates the details of its own installation and uses them to deliver

navigation measurements of optimal accuracy.

These instructions explain how to install and connect the components of the F180R System.

Although it is easy to install and configure the system, you should take some time to read

these instructions and identify each of the components of the system before you begin so that

you can be sure you have everything you need readily available.

A typical installation should then be accomplished quickly so that you may have the system

running and delivering accurate measurements within less than a couple of hours. Unlike

other similar systems, the F180R System requires no complex installation measurements that

delay progress and make the system susceptible to simple errors of geometry.

The task sequence you need to follow is:

1. Identify the major components of the F180R System.

2. Select and prepare suitable locations in the vessel to install them.

3. Install the cabling and components on the vessel.

4. Configure the installation.

3.3.1 Component Identification

The major components of the F180R System Inertial Attitude and Positioning System as they

are shipped are shown below.

The shipping case includes:

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 35

the F180R System Box Unit

NOTE: For L1 deployment this is the Novatel GPS-701 antenna. For L1/L2 deployment

this is the Novatel GPS-702 antenna.

WARNING: Although selected for their ruggedness, the solid–state accelerometers

and rate sensors used in the IMU are susceptible to excessive shock and vibration.

Refer to the environmental specifications for details. Treat the IMU with care when

you handle it—store it in the transit case until you are ready to install it. Never drop

the IMU or subject it to shocks. A 'Shockwatch' label attached to the IMU casing will

show a red central vial if the unit is subjected to severe shock. If this occurs, return the

unit to CodaOctopus Limited for test and repair. The solid–state inertial measurement

components are not field repairable.

WARNING: A common point of failure is damage to the two antenna cables. Any

exterior or interior damage to the cables can deteriorate the GNSS signal strength to a

point where the system turns unreliable. Special care should therefore be considered

when installing and fixing the cables to the vessel structure. Cables should not be

subject to a short bend radius or stepped on as it can break the internal insulation

layer.

Wetpot IMU

two identical GNSS antennas

Hardware

35

antenna mounting components

two identical antenna cables with appropriate connectors at both ends

the power connection cable

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 36

3.3.2 Antenna Installation

NOTE: Do not mount the antennas on flexible masts, or on mast platforms that tend to

move significantly relative to the vessel.

NOTE: Multipath reflections of GPS signals are the dominant source of errors in

theF180R System. Typical reflectors include flat surfaces on the vessel and the surface

of the sea. Locating the antennas as high as possible will reduce the multipath

reflections from the sea surface and vessel superstructure.

NOTE: You should consult the documentation for any microwave emitters or radar

antennas mounted on the vessel close to your proposed F180R System antenna

mounting location. The F180R System antennas are sensitive to any electromagnetic

radiation that might interfere with electrical equipment.

NOTE: For L1 deployment this is the Novatel GPS-701 antenna. For L1/L2 deployment

this is the Novatel GPS-702 antenna. For mixed systems the antennas are marked as

primary and secondary in order to avoid confusion.

There are several important points that you must remember when you choose a location for

the GPS antennas. You must mount them:

outside in an elevated position on the vessel where they have a clear view of the sky in

all directions

rigidly with respect to each other and with respect to the IMU

with a known separation distance between them

in locations that are least likely to experience multipath satellite signals caused by

reflections off nearby structures or flat surfaces

Hardware

36

in locations where salt deposits are unlikely to accumulate and degrade the received

signal quality

in locations isolated from high levels of vibration, shock or electrical noise

more than 5 metres from radar, UHF, satellite communications or other communications

antennas

where they are not exposed to extremes of temperature beyond the acceptable limits

listed in the environmental specifications

where the antenna cables can run easily in one continuous length from each antenna to

the F180R System Box

To install the antennas you will need:

the supplied antennas

antenna cables

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 37

NOTE: The F180R System comes with a standard set of 15m (Novatel CO16) antenna

cables with options for 5m (Novatel C006) and 30m (Novatel C031). Refer to Appendix

- Antenna Cable for further technical information on antenna cables.

the optional antenna mounting bar (supplied on request)

NOTE: It is essential that you check and record the separation distance between

the two GPS antenna centres before you finally mount the antenna assembly,

otherwise it might be difficult to obtain an accurate measurement. It is essential

that you measure this antenna separation to an accuracy of better than 5mm. This

measurement will be used as the Antenna Separation input parameter in the

MOTION Control application. Once you have done this, the system will use

measurements delivered by the dual GPS receivers to 'aid' the independent

measurements of the IMU.

For simplicity and convenience, you may make this measurement as soon as you

have mounted the two GPS antennas on their mounting bar. For accurate

measurement make sure you measure at the Antenna Reference Points.

a kit of suitable tools

waterproof sealing tape or compound

cable clips

To install the antennas:

1. Choose a location for the antennas using the guidelines printed above.

Hardware

37

Figure 24: Antenna Installation

2. Fix the optional mounting bar or your antenna support in position using bolts at both

ends to ensure rigidity of antenna installation. The bolt dimension is 5/8 inch by 2

inches, UNC stainless steel.

3. Decide which end of the mounting bar will support the primary GPS antenna and which

end will support the secondary GPS antenna.

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 38

Hardware

NOTE: For simplicity, the standard recommended configurations are either:

(a) with the antenna mounting bar level and at right–angles to the ship's

heading, and the primary antenna located on the port side of the vessel with

the secondary antenna mounted on the starboard side; or

(b) with the antenna mounting bar level and parallel to the ship's heading,

with the primary antenna located on the forward end of the mounting bar and

the secondary antenna on the aft end of the bar.

However, you may mount the antennas at other orientations if you need to. You

must set the antenna orientation chosen in Secondary Antenna Configuration of

the Configuration Wizard.

NOTE: The phase centres of the GPS antennas might move by several millimetres

as the vessel turns or as satellites move across the sky. When both antennas have

the same orientation, their phase centres will move approximately together. This

will help to maintain optimal measurement accuracy under all conditions.

4. Fit the primary GPS antenna to the mounting bar at its chosen location by passing the

central support stud through the hole and fitting the securing washer and nut.

5. Run one of the supplied cables from the F180R System Box to the primary GPS antenna

location. Use clips or adhesive tape to secure the cable at regular spacings. Do not

subject the cable to sharp bends, stresses or points where extended vibration might

cause wear to the cable.

38

6. Connect the cable to the primary GPS antenna and apply waterproof sealing tape to seal

the connection against water ingress. Do not over–tighten the connector.

7. The primary antenna cable in F180R System kit is normally marked with a red sleeve.

Alternatively attach a label to identify this as the primary antenna cable.

8. Fit the secondary GPS antenna to the mounting bar, following the same procedure that

you used for the primary antenna.

9. Before you tighten the fixings on the secondary antenna, turn it so that the connector

port faces in approximately the same direction as that on the primary GPS. This gives

both antennas the same orientation with respect to the vessel.

10.Run the secondary antenna cable from the F180R System Box to the secondary GPS

antenna location.

11.Connect the second supplied cable to the secondary GPS antenna and seal it against

water ingress, following the same precautions and instructions used for the primary

antenna cable.

12.Attach a label at the bottom end to identify this as the secondary antenna cable.

13.Connect both antenna cables to the F180R System Box through their appropriate

connection ports. Upper BNC port is primary antenna connection. Lower BNC port is

secondary antenna connection.

14.Connect the user interface cable to the 22–way port on the F180R System Box.

Copyright © 2015 Coda Octopus Products Ltd

F180R MOTION Sensor User and Reference Guide

Page 39

Hardware

Port