Coda Cold-Mount Laminator User Manual

Coda Cold

-

Mount

®

Laminator

Operation Guide

Coda, Inc. • 30 Industrial Avenue • Mahwah, NJ 07430 Phone: 201-825-7400 Fax: 201-825-8133

Cold-Mount® Laminator Operation Manual January 2006

Email: sales@codamount.com www.codamount.com

Cold-Mount ® is a registered trademark of Coda Inc.

Cold-Mount® Laminator Operation Guide

Index

INSTRUCTIONS

• Laminator Set-Up

• Location and Function of Controls

• Setting the Roller Pressure, Alignment and Gap

• Mounting a Print (Basic Cold-Mount® Procedure)

• Laminating a Print with a Sheeted Laminate

• Heavy Duty Roll Feed Option

• Coating Boards with Roll Adhesive

• Laminating with Roll Laminate

PRODUCTS

• Cold-Mount® System

• Cold-Mount® Adhesive Coated Boards

• Cold-Mount® Adhesives

• Cold-Mount® Laminates

• Accessories

Coda, Inc. • 30 Industrial Avenue • Mahwah, NJ 07430 Phone: 201-825-7400 Fax: 201-825-8133

Email: sales@codamount.com www.codamount.com

Cold-Mount ® is a registered trademark of Coda Inc.

Cold-Mount® Laminator Operation Manual January 2006

Laminator Set

-

Up

When the crated machine is delivered be sure to inspect for any shipping damage

that may have occurred. If there is any damage notify the carrier and Coda, Inc.

immediately. Remove the cardboard carton and unbolt the machine from the

wooden base. Locate the laminator on a flat surface with enough space to work

with your materials. It is important to use the laminator in a clean room as dirt and

dust will stick to exposed adhesive. Adhesives and laminates perform best in a

room with a temperature of 70 degrees F or higher.

In the crate is a cardboard box

containing the footswitch and

pressure adjustment tool (shown in

section labeled Setting the Spring

Pressure). Place the footswitch on

the floor near the in-feed of the

laminator. You will find a

convenient location for the foot

switch once you begin working with

the laminator.

Coda, Inc. • 30 Industrial Avenue • Mahwah, NJ 07430 Phone: 201-825-7400 Fax: 201-825-8133

Email: sales@codamount.com www.codamount.com

Cold-Mount ® is a registered trademark of Coda Inc.

Cold-Mount® Laminator Operation Manual January 2006

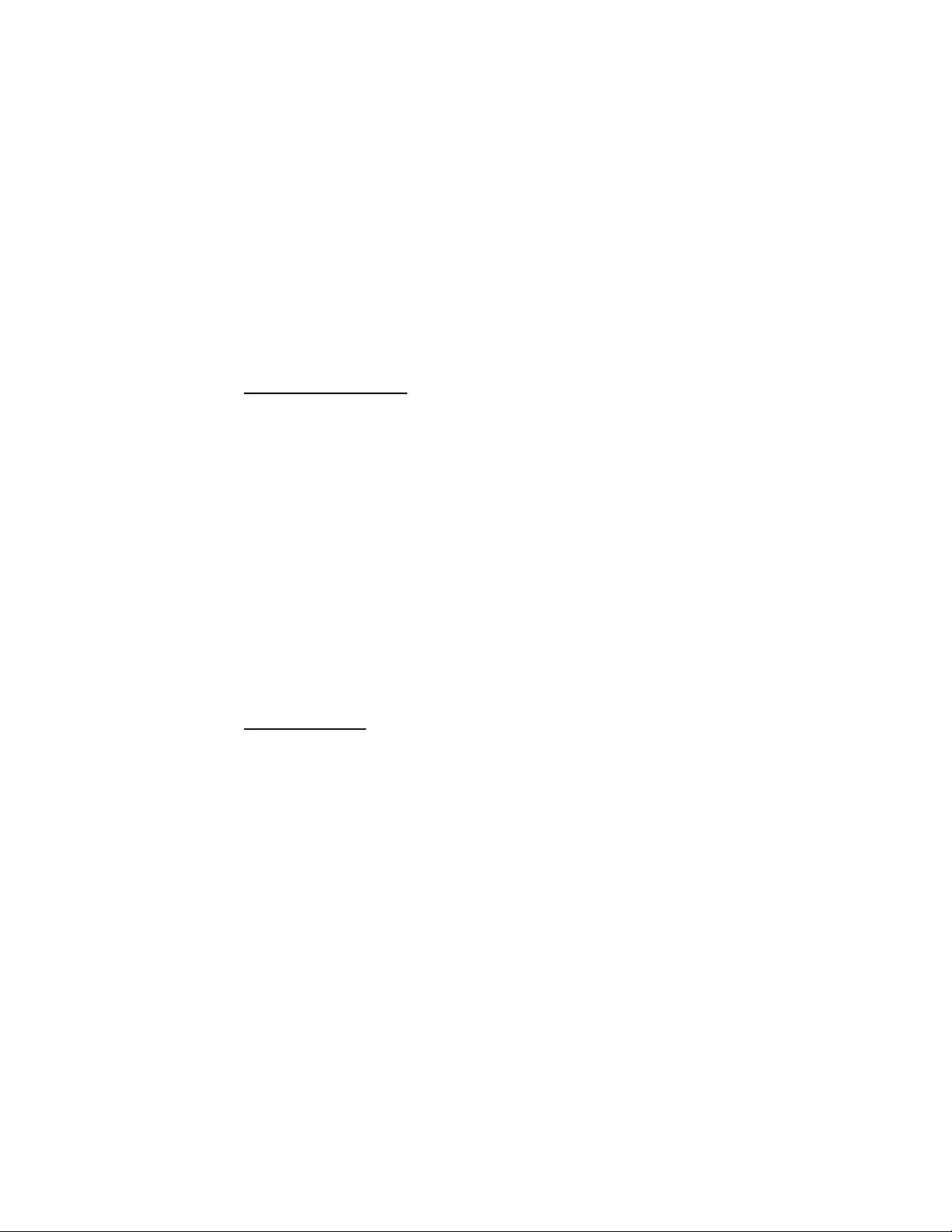

Figure 1

Connect the footswitch cord to the

Laminator Set

-

Up

(continued)

connector on the side of the

operator’s control box as shown.

Figure 2

Plug the main power cord into a

110-115 VAC outlet.

Coda, Inc. • 30 Industrial Avenue • Mahwah, NJ 07430 Phone: 201-825-7400 Fax: 201-825-8133

Cold-Mount® Laminator Operation Manual January 2006

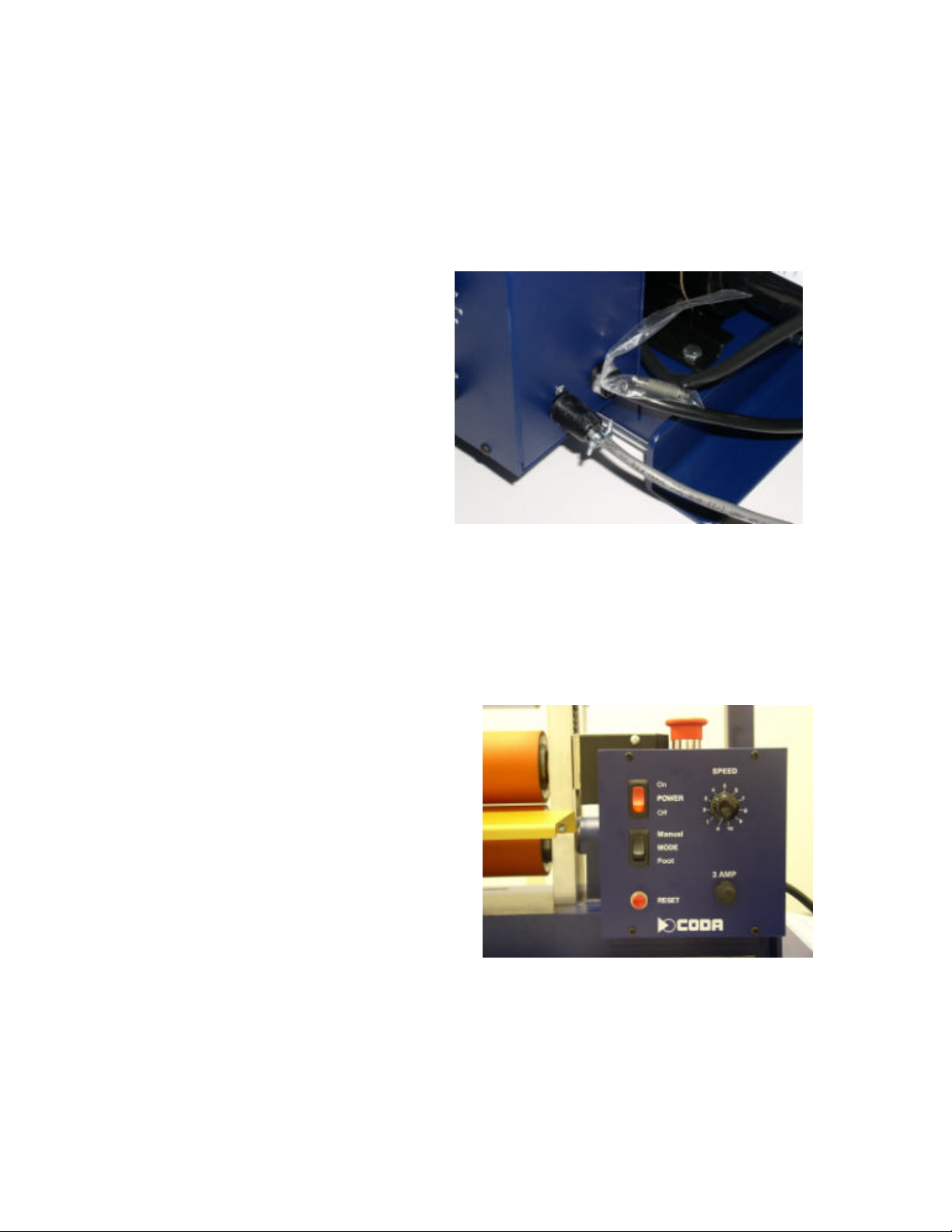

Figure 3

Email: sales@codamount.com www.codamount.com

Cold-Mount ® is a registered trademark of Coda Inc.

Location and Function of Controls

Figure 4

eset has

? Power ON-OFF

? Manual Mode – When power is applied and R

been pressed the machine will run at the speed set by

the Speed Dial.

? Foot Mode - When power is applied and Reset has

been pressed the machine will run at the speed set by

the Speed Dial whenever the footswitch is depressed.

? Reset – Machine will stop when the electric eye is

interrupted. The Reset must be pressed to re-activate

the machine.

? Emergency Stop – This button is located on top of the

control box. Rotate and pull up to allow the machine

to run. Push down for emergency STOP.

? SPEED – Controls the speed of the machine and has

an integrated ON-OFF position. Note: The motor

starts running when the speed is at about 2 on the

Speed Dial.

Coda, Inc. • 30 Industrial Avenue • Mahwah, NJ 07430 Phone: 201-825-7400 Fax: 201-825-8133

Email: sales@codamount.com www.codamount.com

Cold-Mount ® is a registered trademark of Coda Inc.

Cold-Mount® Laminator Operation Manual January 2006

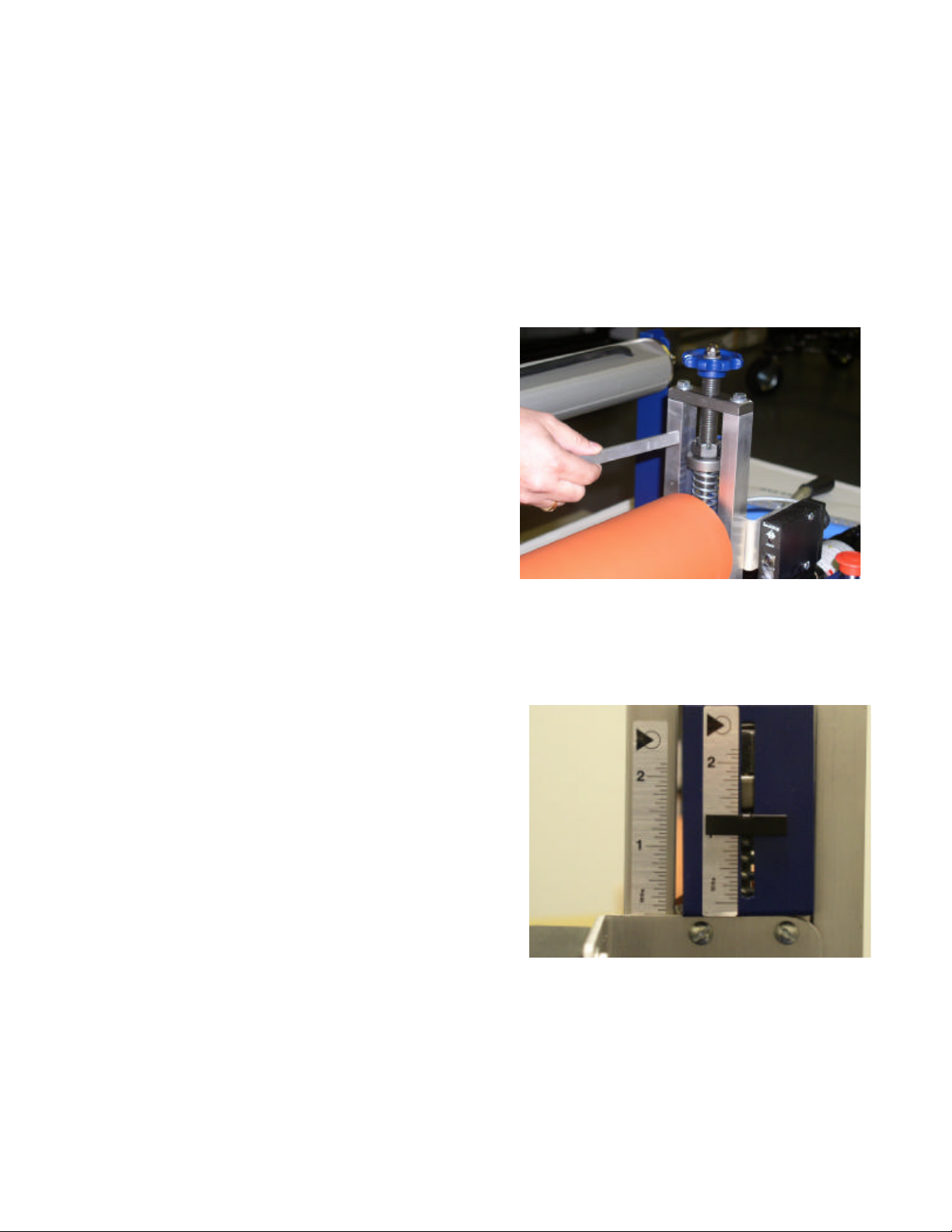

Setting the Spring Pressure

starting pressure applied

nt of force being applied to the material by the

load on the pressure springs and/or

by the amount of gap. Place the pressure adjustment tool into the slots and turn to adjust the

The roller pressure is a measure of the amou

rollers. It can be adjusted in two ways, by the amount of pre-

pressure spring.

To adjust the amount of

by the pressure springs, insert the adjusting tool

that came with your press into the slots in the

castle nut. To increase the amount of pressure,

rotate the nut clockwise so the spring

compresses. To decrease the amount of

pressure, rotate the nut counter-clockwise so the

spring decompresses.

The pressure indicator is located on the side

post assembly and is provided as a visual

indication of the amount of pressure. The

typical setting is 1-1/8” aligned with the top

edge of the indicator. Be sure to set both

sides to the same setting.

Figure 5

Figure 6

Coda, Inc. • 30 Industrial Avenue • Mahwah, NJ 07430 Phone: 201-825-7400 Fax: 201-825-8133

Email: sales@codamount.com www.codamount.com

Cold-Mount ® is a registered trademark of Coda Inc.

Cold-Mount® Laminator Operation Manual January 2006

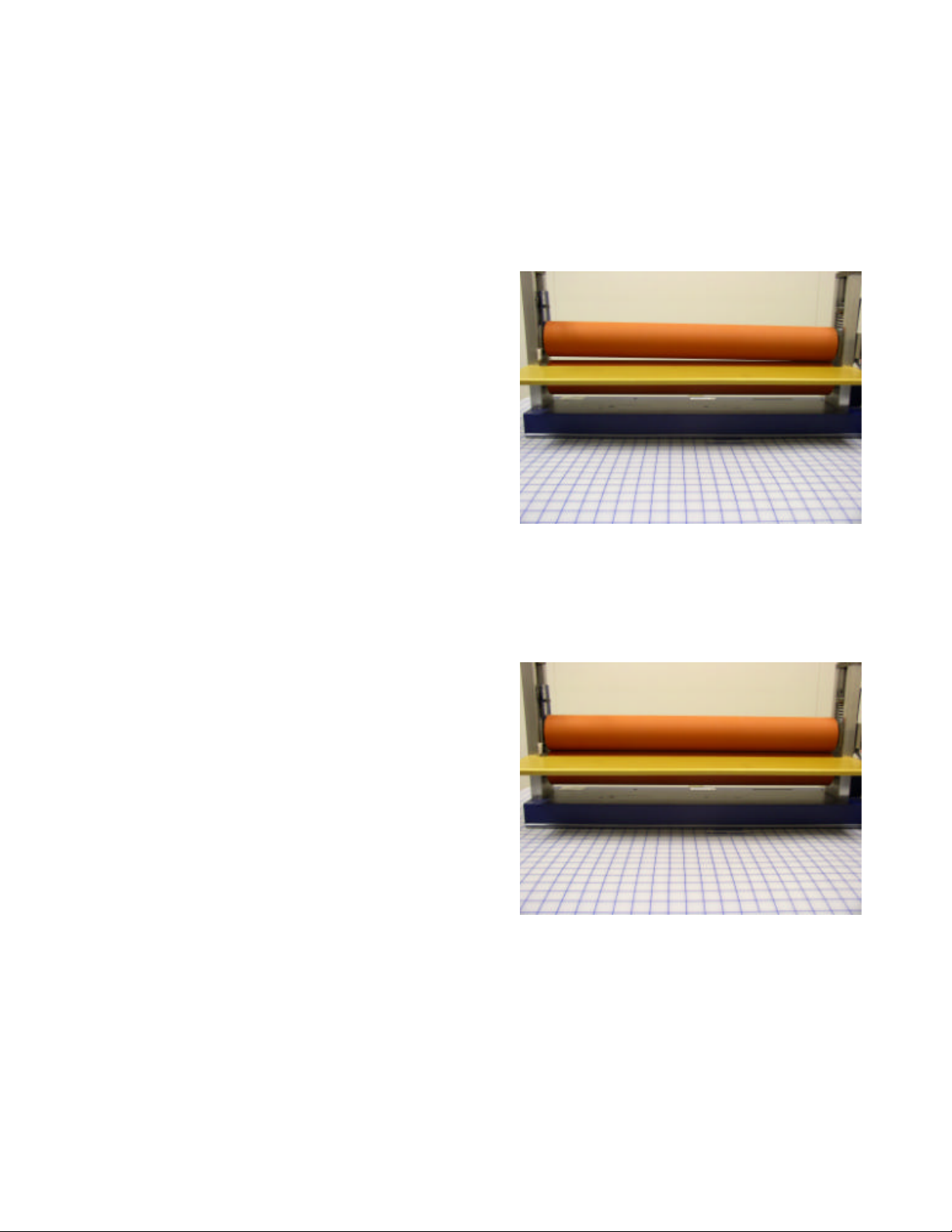

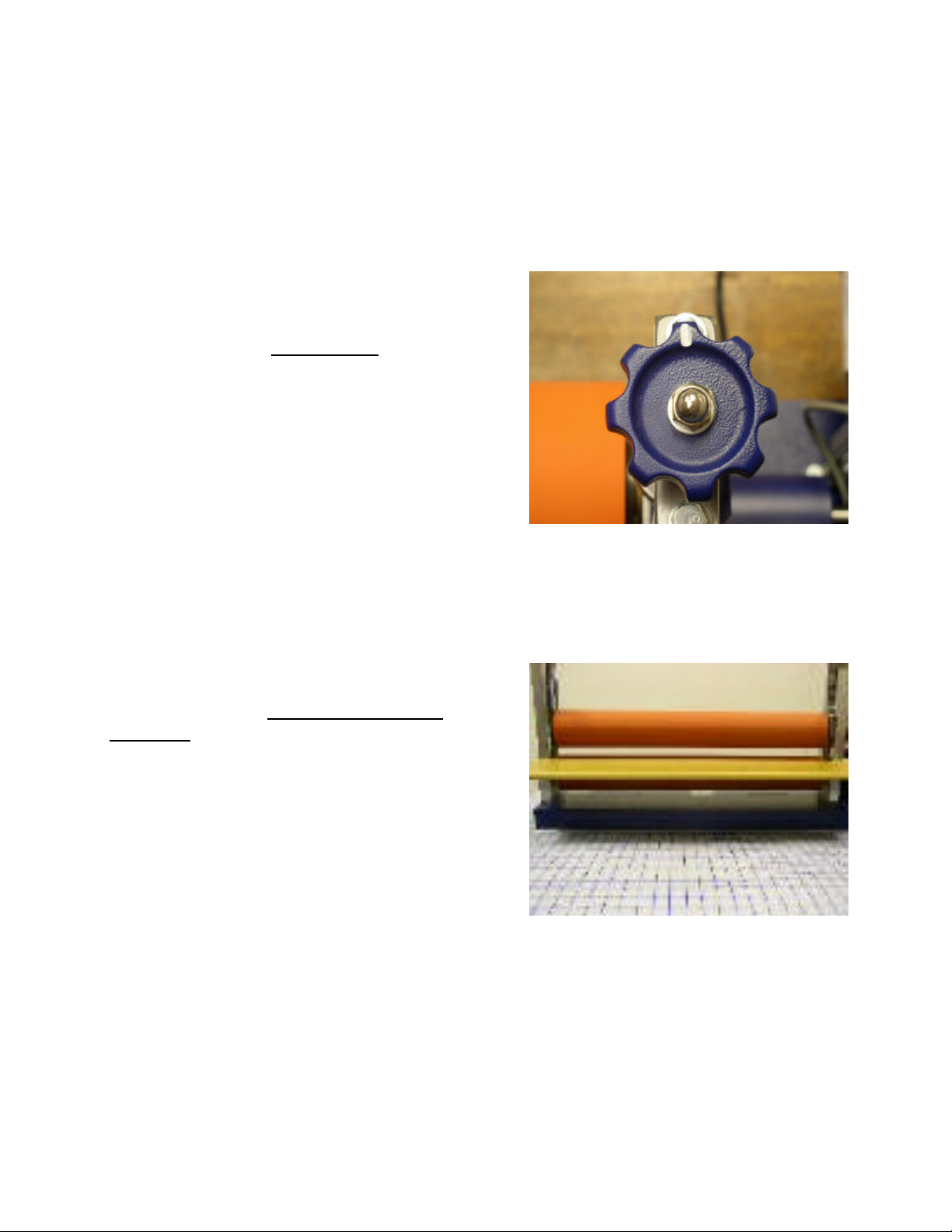

Adjusting the Rollers for Even Pressure

the right side of the top roller so that it

Using the gap adjusting knobs, lower

almost touches the bottom roller.

Then do the same on the left side.

Figure 7

Next make the fine adjustment on the

right by turning the gap adjusting

knob clockwise until the rollers just

touch. Then do the same on the left

side until the rollers are parallel.

Figure 8

Coda, Inc. • 30 Industrial Avenue • Mahwah, NJ 07430 Phone: 201-825-7400 Fax: 201-825-8133

Email: sales@codamount.com www.codamount.com

Cold-Mount ® is a registered trademark of Coda Inc.

Cold-Mount® Laminator Operation Manual January 2006

Roller Alignment Procedure

Look at the top of the laminator and notice

on top of the

the position of the WHITE LINE

gap adjusting knobs. At this point they

should be very close to pointing in the same

direction. Now adjust them so they are

completely aligned (pointing in the same

direction).

Any time you raise and lower the top roller

you must have the lines facing the same

direction. Example- When you turn the knob

on the right 3 times you must also turn the

knob on the left 3 times so the lines point in

the same direction.

This procedure will assure even application

of pressure by the top roller.

Figure 9

Coda, Inc. • 30 Industrial Avenue • Mahwah, NJ 07430 Phone: 201-825-7400 Fax: 201-825-8133

Email: sales@codamount.com www.codamount.com

Cold-Mount ® is a registered trademark of Coda Inc.

Cold-Mount® Laminator Operation Manual January 2006

Figure 10

Setting the Roller Gap

thumb is that the roller gap should be about

Now that the rollers are properly aligned

you are ready to set the gap for the work

you are running.

Raise the top roller evenly as described in

the previous section and place the

substrate between the rollers.

Now lower the top roller evenly until the

roller just touches the substrate. Then

rotate each knob an additional three

quarters of a revolution. This will allow for

about 1/16” spring compression when the

material is fed thru the laminator. (Rule of

1/16” less than the thickness of the

substrate.)

Figure 11

With the proper gap it will not be possible

to pull the board and slide it between the

rollers.

Once the gap is set feed a test board

through the laminator. If the rollers crush

the board, the roller gap is set too close.

Figure 12

Coda, Inc. • 30 Industrial Avenue • Mahwah, NJ 07430 Phone: 201-825-7400 Fax: 201-825-8133

Email: sales@codamount.com www.codamount.com

Cold-Mount ® is a registered trademark of Coda Inc.

Cold-Mount® Laminator Operation Manual January 2006

Loading...

Loading...