Page 1

Nucleus® CP900 Series

Sound Processors

User Guide

Page 2

Cochlear Li mited 20112 323649 Iss 3 C P900 Series S ound Processo rs | User guides CP900 S eries Sound Proc essors | User gui des 3Cochlear Limit ed 2011

Symbols

Contents

About ...............................................................................................................................4

Turn on.............................................................................................................................6

Wear ...............................................................................................................................10

Store ...............................................................................................................................31

Charge ............................................................................................................................32

Care ................................................................................................................................39

Lights, beeps and buttons ........................................................................................ 54

General warnings and cautions .............................................................................. 58

Other information ...................................................................................................... 60

Note

Important information or advice. Can save

inconvenience.

Tip

Time saving hint or saves inconvenience.

Caution (no harm)

Special care to be taken to ensure safety and

effectiveness.

Could cause damage to equipment.

Warning (harmful)

Potential safety hazards and serious adverse

reactions.

Could cause harm to person.

Page 3

Cochlear Li mited 20114 323649 Iss 3 C P900 Series S ound Processo rs | User guides

CP900 S eries Sound Proc essors | User gui des 5Cochlear Limit ed 2011

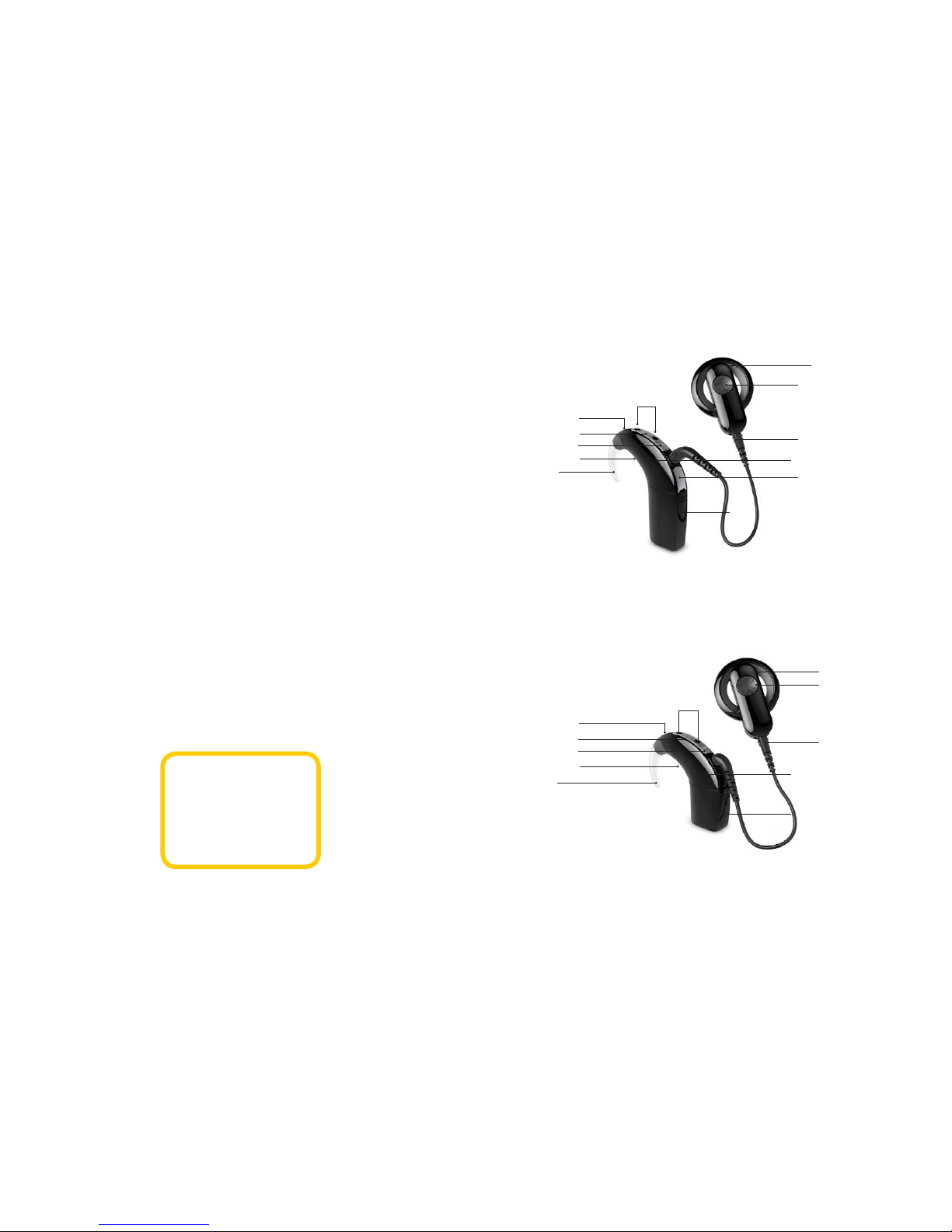

About

The Cochlear Nucleus CP900 Series Sound Processors works with your Cochlear

Implant to transfer sound to the ear. Your processor is made up of a processing

unit, earhook, coil, coil cable and a battery module.

You can choose either the CP910 or the CP920 processing unit. The CP920

processing unit is smaller than the CP910 and has no accessory port.

You can power your processing unit with a range of battery modules. The range

includes a tamper resistant battery module that uses disposable batteries, a

standard rechargeable and compact rechargeable battery module, and a LiteWear

cable that allows the battery to be worn on the body.

You can control your sound processor as a stand-alone device by pressing the

buttons on the processor. All stand-alone functions are covered in this guide.

You can also choose a Cochlear Nucleus CR210 Remote Control or CR230 Remote

Assistant to control your processor. The remotes let you control one or two

bilateral processors at a time and can provide extra troubleshooting functions. All

remote functions are covered in separate user guides.

People with certain types of hearing loss can wear the processor in Hybrid mode

by adding an accessory called the acoustic component. The acoustic component

sends extra acoustic sound into the ear canal. Hybrid mode must be set up by

your clinician.

A number of tools and accessories are supplied with your sound processor. The

most important of these are your drying pack, screwdriver, and microphone

protector applicator with removal tool.

Warning

Do not allow children under

three to play with the system.

Removable parts of the system

can be lost or may be a choking

hazard.

Coil magnet

Coil cable

Coil

CP910 processing unit

Processing unit

Standard rechargeable battery module

Lower button

Earhook

Upper button

Accessory port

Microphones and protectors

Microphones and protectors

Serial number

Earhook

Upper button

Lower button

Coil magnet

Coil

Coil cable

Compact rechargeable

battery module

Behind the Ear (BTE) parts (standard)

BTE parts (mini)

Serial number

Indicator light

Indicator light

CP920 processing unit

Page 4

Cochlear Li mited 2011

6 323649 Iss 3 C P900 Series S ound Processo rs | User guides

Tur n On

CP900 S eries Sound Proc essors | User gui des 7Cochlear Limit ed 2011

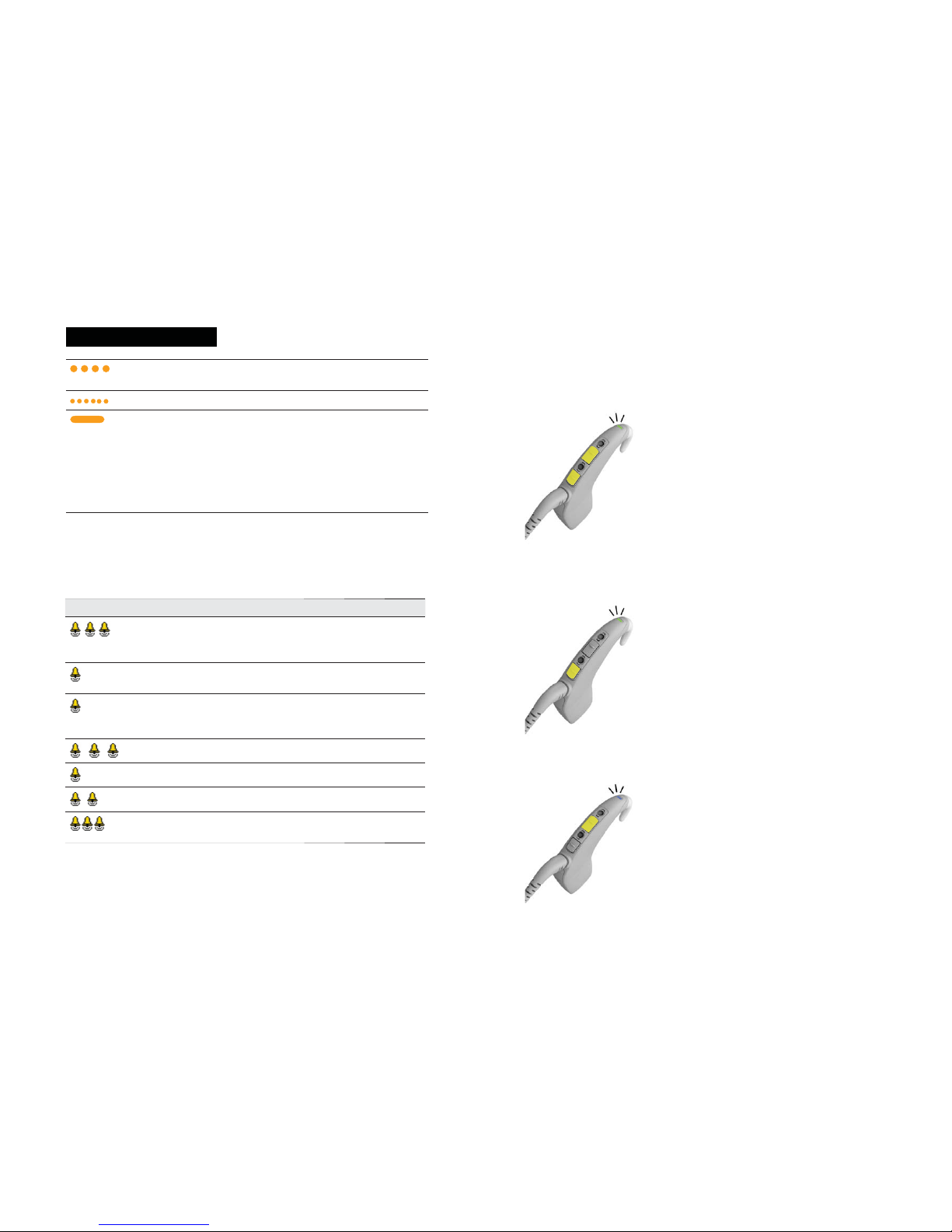

Turn on and off

Indicator light What it means

Green fl ashes

Turning on processor. The number of

fl ashes indicates the number of the

current program.

Steady orange while

pressing the lower button

Turning off processor.

Quick green fl ashes

Microphones are receiving sound

Press and hold the lower button for two

seconds to turn on or off.

Turn on

Turn on and off ............................................................................................................. 7

Change programs ..........................................................................................................8

Lock and unlock buttons ............................................................................................. 9

Note

Your clinician may set up your processor to turn

off automatically when it has not been used or

worn for more than two minutes. If this happens,

simply turn your processor back on.

Page 5

Cochlear Li mited 2011

8 323649 Iss 3 C P900 Series S ound Processo rs | User guides

Tur n On

CP900 S eries Sound Proc essors | User gui des 9Cochlear Limit ed 2011

Change programs

You can choose between programs to change the way your sound processor deals

with sound e.g. in windy, noisy or quiet places. Usually two programs are all you

need, but your clinician can give you up to four programs.

Indicator light What it means

Green fl ashes

Changing the program. The number of

fl ashes indicates the number of the selected

program.

Quick-press and release the lower button to

switch between programs.

Ask your clinician to write your programs below

Lock and unlock buttons

Quick-press and release both buttons at the

same time to lock and unlock the processor.

Indicator lights What it means

Green fl ash followed by orange Locking processor buttons.

Orange fl ash followed by green Unlocking processor buttons.

Orange fl ash when pressing buttons Processor buttons are locked.

Page 6

Cochlear Li mited 2011

10 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Wear

CP900 Se ries Sound Proc essors | User guid es 11Cochlear Limite d 2011

Wear

Attach to your head ....................................................................................................11

Talk on the phone ........................................................................................................12

Water, sand and dirt ...................................................................................................14

Sport and exercise ....................................................................................................... 16

Wear LiteWear .............................................................................................................22

Travel ..............................................................................................................................23

Audio accessories ........................................................................................................24

Turn audio accessories on and off ...........................................................................26

Personalise your processor ........................................................................................27

Wear an acoustic component ...................................................................................28

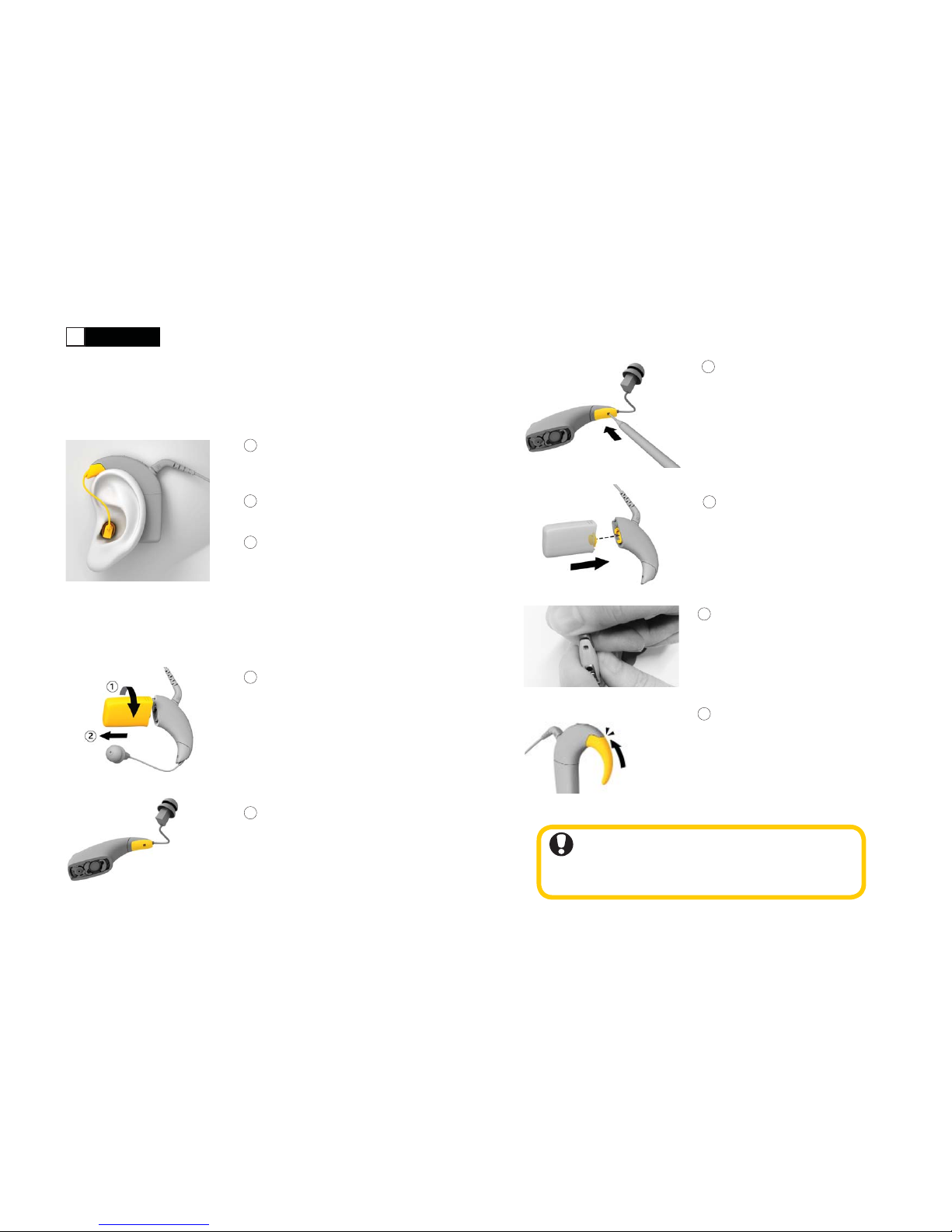

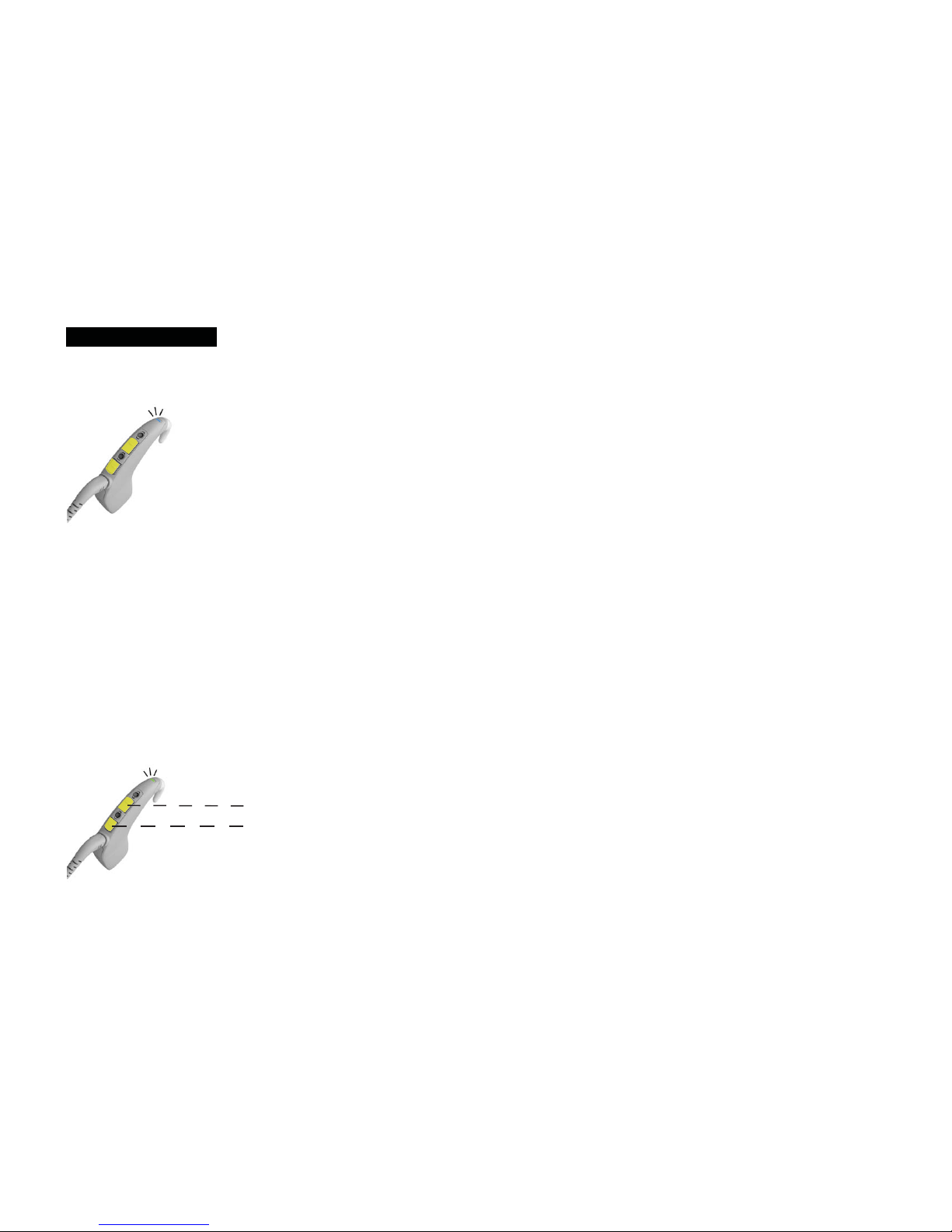

Attach to your head

Indicator light What it means

Flash of orange every

second

Coil is off, or processor is not connected to

the correct implant.

Place the BTE on your ear, letting

the coil dangle.

Move the coil sideways and onto

your implant.

1

2

Tip

Twist the coil clockwise (right BTE) or

counter clockwise (left BTE) once ONLY

before placing it on the head. The twist

will help the coil stay in place.

Page 7

Cochlear Li mited 2011

12 323649 Iss 3 C P900 Series S ound Processo rs | User guides

Wear

CP900 Se ries Sound Proc essors | User guid es 13Cochlear Limite d 2011

Indicator light What it means

Long fl ash of blue Changing between microphones and

the telecoil or audio accessory.

Long fl ash of green Changing between the telecoil or audio

accessory and the microphones.

Constant quick blue fl ashes Processor is receiving sound

Talk on the phone

Listen to hearing loops and hear voices on the telephone more clearly with the

telecoil (t-switch). Your processor can be set up with either manual or auto telecoil.

Auto telecoil turns the telecoil on and off whenever you use a phone or move in

and out of range of a hearing loop.

Whether you choose auto or manual telecoil, you can control the telecoil with

your remote or just turn it on and off with your processor.

Quick-press the top button to turn telecoil on

and off.

Note

Certain electronic devices or machiner y may

automatically turn on Auto Telecoil. If this

happens, move away from the device or machinery

and wait a few seconds for Auto Telecoil to turn

itself off, or turn it off manually.

Tip

Slowly move the phone's sound

outlet over the microphones

on your processor to fi nd your

best position for talking on the

phone.

Phone being held over

microphones

Page 8

Cochlear Li mited 2011

14 323649 Iss 3 C P900 Serie s Sound Processo rs | User guides

Wear

CP900 Se ries Sound Proc essors | User guid es 15Cochlear Limite d 2011

Water, sand and dirt

Your processor is water resistant

with rechargeable batteries

attached. But do not wear it while

bathing or swimming.

Your processor is dust resistant

with rechargeable batteries

attached. But do not get sand or

dirt into any part of your sound

processor.

Your sound processor is resistant to water, sand and dust. However, it is still a

precision electronic device so the following precautions should be taken.

If your processor ever does get wet,

dry it with a soft cloth, change the

microphone protectors and place it

in a drying kit for 12 hours.

If sand or dirt ever do enter the

system, shake the components

carefully to remove it and change

the microphone protectors.

Your processor is protected against

failure from dust and temporary

immersion in water (IP57) when

you wear it with:

• a rechargeable battery module

• a coil and coil cable

• a closed accessory port

• no acoustic component

Fully assembled

as described

Your processor is protected against

failure from splashing water or

access of foreign objects 1.0 mm in

diameter or larger (IP44) when you

wear it with:

• a tamper resistant battery cover

• a coil and coil cable

• a closed accessory port

• an acoustic component worn in

the ear.

Fully assembled

as described

Aqua Accessory TBA

Page 9

Cochlear Li mited 2011

16 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Wear

CP900 S eries Sound Proc essors | User gui des 17Cochlear Limi ted 2011

Sport and exercise

Then check your microphone

protectors.

Change them whenever you notice

signs of sweat or grime, or any

change in performance.

After exercise, wipe your processor

with a soft cloth to remove sweat or

grime.

Use Cochlear CP900 series

accessories such as the Snugfi t or

Mic Lock to help hold your processor

in place when you play sport or

exercise.

Accessories like the Snugfi t or Mic Lock can help hold a processor on

a child's ear. Children under three years of age should only use tamper

resistant accessories such as the tamper resistant earhooks, tamper

resistant battery cover and tamper resistant Snugfi t. Always ensure these

are properly locked together before use.

Childproofing Tip

A thin sweatband or skullcap worn

over the sound processor can make

wearing a helmet easier.

Rechargeable batteries give you

the maximum water and sweat

resistance.

TBA

Aqua Accessory TBA

TBA

Page 10

Cochlear Li mited 2011

18 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Wear

CP900 S eries Sound Proc essors | User gui des 19Cochlear Limi ted 2011

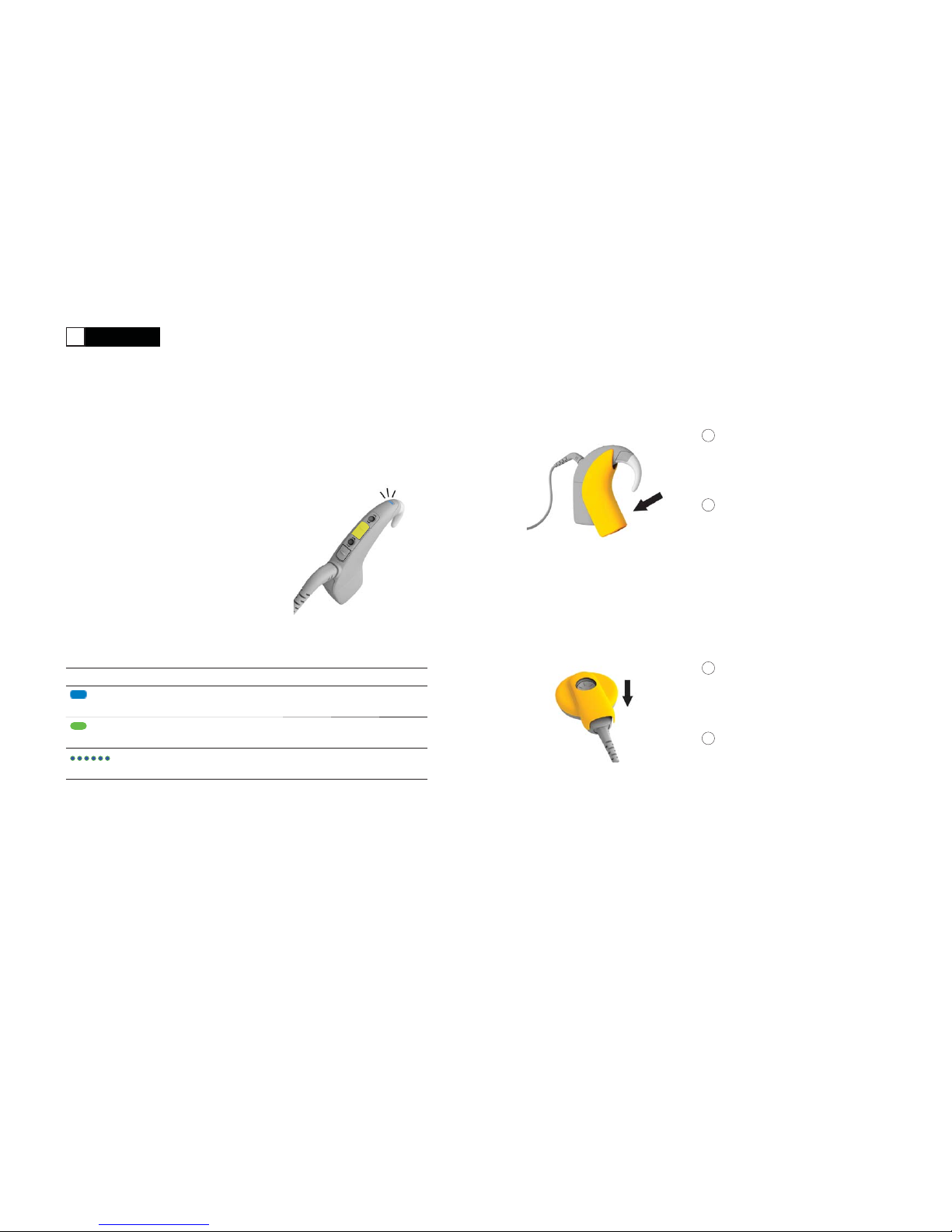

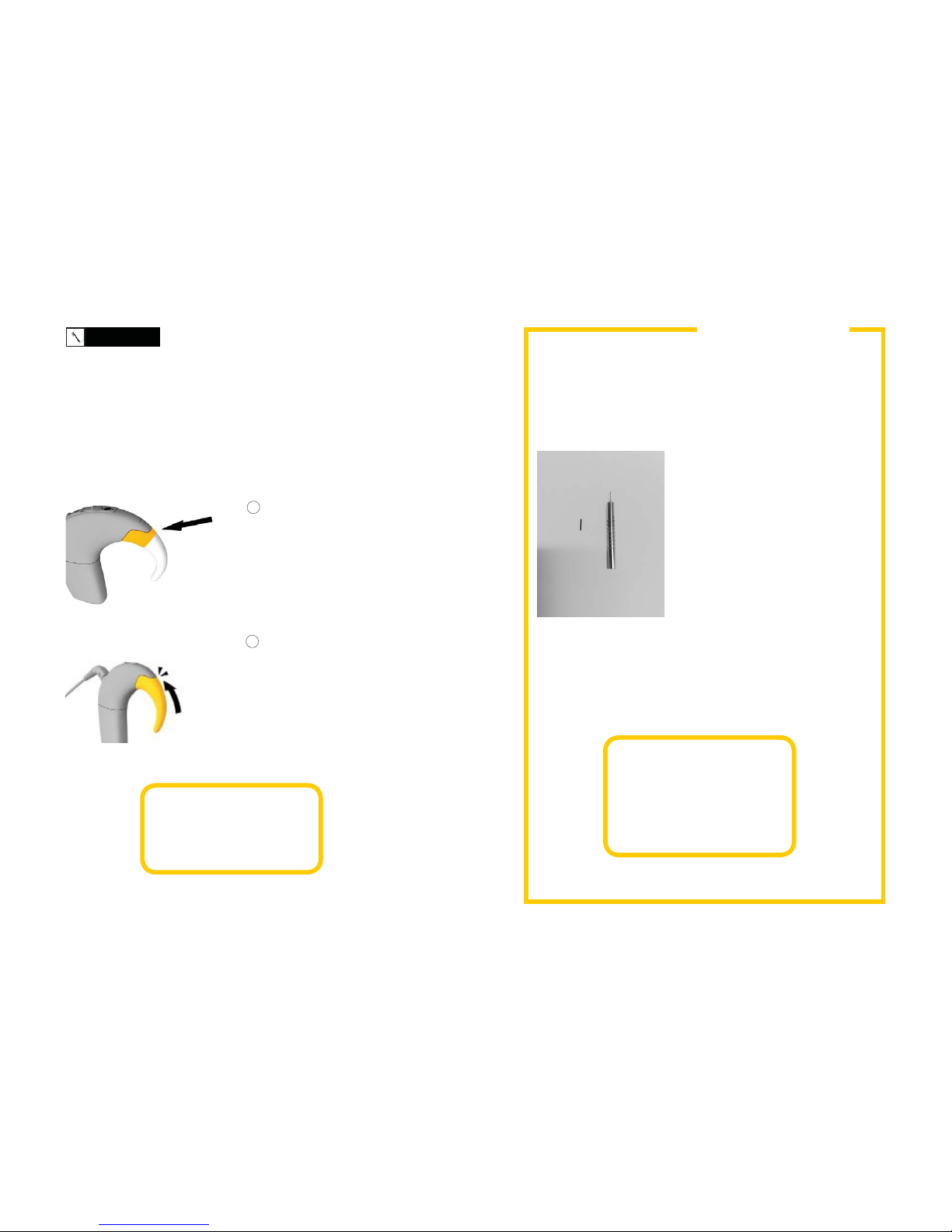

Wear a Snugfi t

The Cochlear Nucleus CP900 Series Snugfi t holds your sound processor more

securely in place than an earhook alone. It gives parents and carers easy access to

controls and accessories and is available in large, medium and tamper resistant

(small).

To attach a Snugfi t:

Click your Snugfi t into place.

2

Press fi rmly on the top of the

earhook with your thumb to click it

off the sound processor.

1

Carefully bend the lower part into

shape to suit your ear.

3

To remove a Snugfi t:

Remove your Snugfi t by clicking it

off the processor.

1

Page 11

Cochlear Li mited 2011

20 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Wear

CP900 S eries Sound Proc essors | User gui des 21Cochlear Lim ited 2011

Wear a Mic Lock

The Cochlear Nucleus Mic Lock helps hold the processor securely on the ear.

Push the Mic Lock band onto the

processor with the tubing facing

forward.

Place the processor on your ear and

bring the tubing up to the earhook.

Soften the end of the tubing in

warm water and push it onto your

earhook.

1

2

3

Trim the tubing to a length that will

hold the processor fi rmly in place

without discomfort. Do not cut it

too short.

Let the tubing cool before wearing.

5

4

To attach the Mic Lock the fi rst time:

To attach the Tamper Resistant Snugfi t:

Childproofing Tip

Thread the Snugfi t band onto the

Snugfi t as shown.

Click the Snugfi t into place on the

processor and push the Snugfi t

band onto the battery module.

Push the band securely onto the

battery module.

2

3

4

The smallest Snugfi t comes with

a Snugfi t band to fi x it more

securely to the processor.

1

Page 12

Cochlear Li mited 2011

22 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Wear

CP900 S eries Sound Proc essors | User gui des 23Cochlear Lim ited 2011

Wear LiteWear

The Cochlear Nucleus CP900 Series LiteWear Cable allows any standard (not

compact) battery module to be worn on the body - so only the processing unit is

worn on the ear. You can order LiteWear at <TBA> or talk to your clinician.

LiteWear is made up of a LiteWear cable,

case and a choice of fi xing aids.

Note

You can wear a Snugfi t with

LiteWear to hold the processing

unit more securely on the ear.

IMAGE SHOWING

LITEWEAR BEING WORN

BY A CHILD

Childproofing Tip

Attach the LiteWear case between the shoulder blades of very young children

to help prevent tampering.

Travel

You can travel with your sound processor with confi dence because Cochlear is

supported by clinics all over the world.

Take a printout of your most recent program in case you need help with your

processor.

If you have a back-up sound processor, check that it is programmed correctly

and take it with you.

It's okay to move through metal detectors and full body scanners with your

sound processor on. To avoid any possible buzzing sounds in your ear, turn

off the telecoil.

Ask your clinician for a Nucleus 6 ID card. In the unlikely event that your

implant sets off a metal detector the ID card will help you explain that you

have an implanted medical device.

Do not place sound processors directly onto conveyor belts as you move

through airports. Place them in a bag or plastic tray.

Your sound processor will not interfere with a plane's navigation system so

you won't need to turn it off during takeoff and landing.

Note

Visit www.cochlear.com/clinicfi nder to fi nd the nearest clinic in

the places you are travelling

Page 13

Cochlear Li mited 2011

24 323649 Iss 3 CP 900 Series So und Processor s | User guides

Wear

CP900 S eries Sound Proc essors | User gui des 25Cochlear Lim ited 2011

Audio accessories

The accessory port on the CP910

processing unit lets you connect a

wide range of audio accessories.

The Cochlear Nucleus Lapel

Microphone can make conversation

easier in noisy environments.

Parents and carers can use

the Cochlear Nucleus Monitor

Earphones to check the processor

and audio accessories are working.

For example, a Cochlear Nucleus

personal audio cable let you listen

to iphones, computers, TV sets

etc. Bilateral recipients can listen in

stereo.

TBA

You can order audio accessories at <TBA> or talk to your clinician.

Note

The CP910 processing unit is compatible with the CP800 range of audio

accessories. You can order adaptors to make your CP910 processor

compatible with Freedom and Euro accessories. Your CP910 processor is

NOT compatible with the BAHA range of audio accessories.

Warning

Always use the Mains Isolation Cable when connecting any Personal Audio

Cable (including Bilateral) to:

• a mains powered device e.g. TV.

• a battery powered device that is connected to mains power (e.g. a

laptop connected to an electric outlet for charging).

Do not use excessive force, twist or pull on accessories when connecting

them to the processor or at any time while they are connected.

When you connect an audio

accessory, your processor

automatically detects it.

If applicable, insert the other end of

the audio accessory cable into the

compatible device e.g. Ipod.

3

4

Hold the side grips on the

accessory connector and carefully

push it into the accessory port until

it clicks into place.

1

Carefully lift open the accessor y

cover with the screwdriver. Do not

twist the cover.

2

Connect audio accessories

To connect an audio accessory to the processor:

Page 14

Cochlear Li mited 2011

26 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Wear

CP900 S eries Sound Proc essors | User gui des 27Cochlear Lim ited 2011

Indicator light What it means

Long fl ash of blue Changing between microphones and the

telecoil or audio accessory.

Long fl ash of green Changing between the telecoil or audio

accessory and the microphones.

Constant quick blue fl ashes Processor is receiving sound from audio

accessory

Turn audio accessories on and off

Audio accessories turn on automatically when you plug them into your processor.

You can turn them off and back on again as follows.

Quick-press the top button to switch between

microphones and the audio accessory.

Personalise your processor

You can order Cochlear Nucleus Sound Processor Covers and Coil Covers to

personalise your processor and protect it from scratches.

Attaching and removing processor covers:

Attaching and removing coil covers:

To attach, slide the cover onto the

processor.

To remove, pull the cover away

from the processor.

1

2

To attach, discard the clear plastic

protector on the cover and click the

cover into place on the coil.

To remove, lift the cover off the

coil.

1

2

Bilateral stickers

If you have two Cochlear implants, you must match the correct processor to the

correct implant. Ask your clinician to give you bilateral stickers (red for right, blue

for left) to make identifying left and right processors easier.

Page 15

Cochlear Li mited 2011

28 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Wear

CP900 S eries Sound Proc essors | User gui des 29Cochlear Lim ited 2011

Wear an acoustic component

If your sound processor is set up for use in Hybrid mode, you can wear it with an

acoustic component.

Remove your acoustic component

Wear your processor without the acoustic component by replacing it with a

standard earhook:

Hold the coil in one hand and place

the processor on your ear with the

other.

Insert your Cochlear screwdriver

into the opening under the earhook

to unlatch the receiver cable.

Place the coil on your head.

1

2

2

Place your dome or earmould in

your ear as instructed by your

clinician.

3

Remove the battery module from

the processing unit by twisting the

two parts as shown.

1

Press fi rmly on top of the earhook

with your thumb to click it off the

sound processor.

Click the standard earhook into

place.

5

6

Carefully push and twist the

screwdriver until the receiver cable

disconnects.

3

Re-attach the battery module.

4

Caution

Use only the Hybrid screwdriver – not the CP800 screwdriver – to

remove the acoustic component.

Page 16

Cochlear Li mited 2011

30 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Wear

CP900 S eries Sound Proc essors | User gui des 31

Cochlear Li mited 2011

Attach your acoustic component

Press fi rmly on the top of the

standard earhook with your thumb

to click it off the processor.

Click the Hybrid earhook into place.

Carefully slide the receiver cable

plug into the sound processor.

It should click securely into place.

If necessary, carefully twist it until

you feel the click.

1

2

3

4

Store

Warning

All drying chemicals must be

kept away from young children.

Swallowing this material can

cause serious internal injuries.

For long term storage, remove the

batteries and store them separately

from each other to prevent shorting.

Storage cases are available from

Cochlear.

Store your processor at night in a UV

protected dry aid kit or drying pack.

You can store the processor fully

assembled for short periods.

Storage cases are available from

Cochlear. Buy dry aid kits and drying

packs from Cochlear or pharmacies

and read the instructions for use.

Page 17

Cochlear Li mited 201132 323649 Is s 3 CP900 Serie s Sound Processo rs | User guides

Charge

CP900 Se ries Sound Proc essors | User guid es 33Cochlear Limite d 2011

Charge

Batteries ........................................................................................................................33

Battery life expectancy ..............................................................................................33

Replace the battery.................................................................................................... 34

Lock the battery to the processing unit .................................................................35

Lock and unlock the tamper resistant battery cover .......................................... 36

The standard battery has a tamper resistant lock

to help prevent children opening the battery cover. ......................................... 36

Charge rechargeable battery modules....................................................................37

Change disposable batteries ....................................................................................38

Batteries

You have a choice of three battery types with the CP900 series system:

Battery life expectancy

Battery life varies according to the programs used each day, the thickness of skin

covering your implant, and the type of battery. Use 675 zinc/air batteries in the

standard battery module for longest battery life. To get the longest life from the

rechargeable batteries, always recharge before use. Rechargeable batteries may

take longer to fully recharge with age and should be replaced as needed.

The Cochlear Nucleus CP900 Series

Standard Rechargeable Battery

module.

The Cochlear Nucleus CP900 Series

Standard Battery module, which uses

disposable batteries and has a tamper

resistant lock.

The Cochlear Nucleus CP900 Series

Compact Rechargeable Battery

module.

Page 18

Cochlear Li mited 201134 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Charge

CP900 S eries Sound Proc essors | User gui des 35Cochlear Limit ed 2011

Replace the battery

To remove the battery:

Twist the battery module as shown

to remove it from the processing

unit.

1

Touch the battery module and

processing unit at an angle so their

parts fi t together.

1

To attach the battery:

Twist the battery module as shown

to attach the two parts.

2

Lock the battery to the processing unit

Lock the CP910 Processing Unit:

1

Carefully lift open the accessor y

port cover with your Cochlear

screwdriver. Do not twist the

cover.

Childproofing Tip

Carefully close the cover by

pushing in the top hinge fi rst.

4

Push the lock to the far left to

lock the battery module.

2

Push the lock to the far right with

your Cochlear screwdriver to

unlock the battery module.

Caution

Always check this lock is unlocked before attaching or removing the

battery module.

3

Page 19

Cochlear Li mited 201136 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Charge

CP900 Se ries Sound Proc essors | User guid es 37Cochlear Limite d 2011

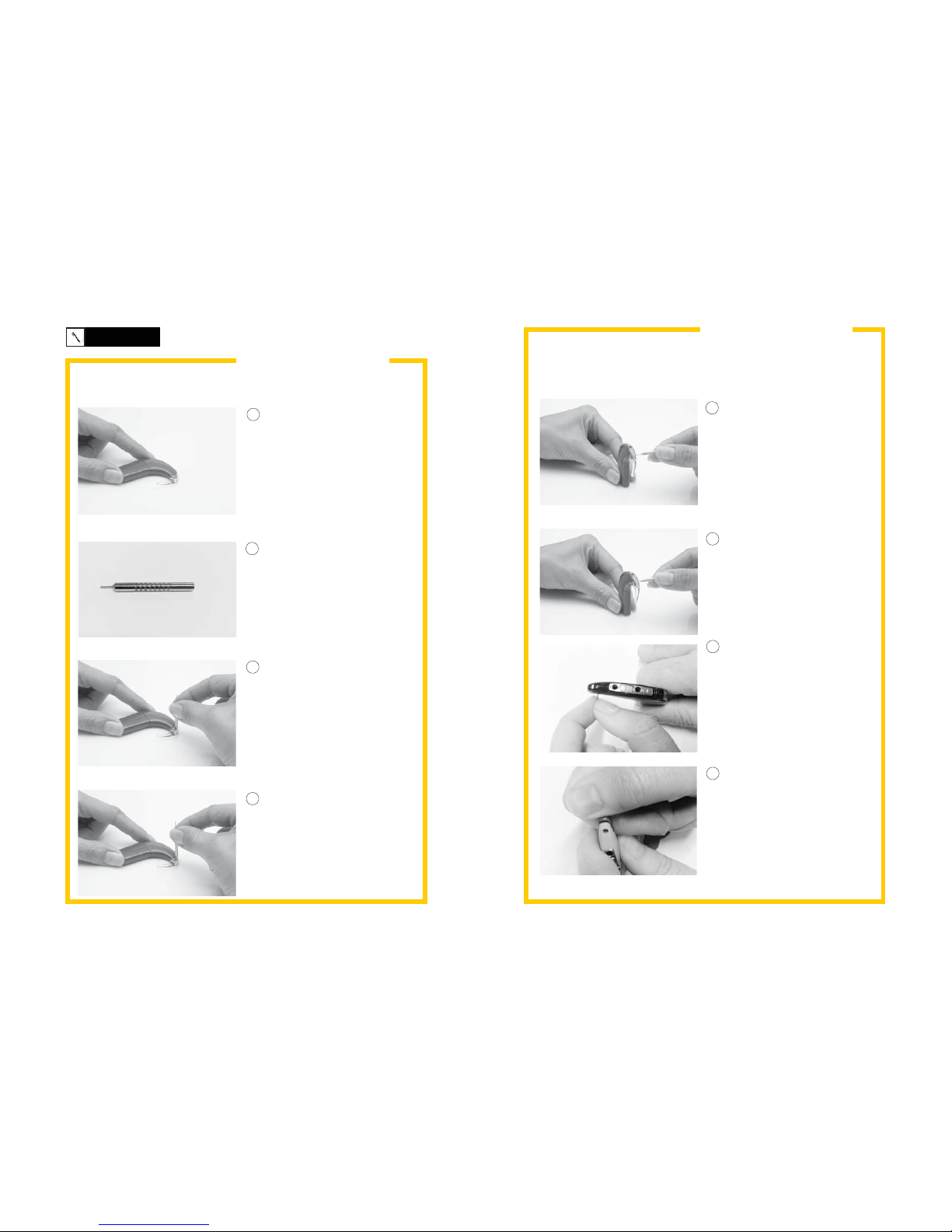

Lock the CP920 processing unit

To lock, turn the locking screw

clockwise with the CP800

screwdriver until it is in a horizontal

position.

To unlock, turn the locking screw

anticlockwise until it is in a

vertical position.

1

2

Lock and unlock the tamper resistant

battery cover

The standard battery has a tamper resistant lock to help prevent children

opening the battery cover.

Push the lock to the far left with

your Cochlear screwdriver to

lock the battery module.

Childproofing Tip

Push the lock to the far right to

unlock the battery module.

1

2

Angle and fi t the rechargeable

battery into a socket on the

Cochlear Nucleus Battery Charger.

Twist clockwise to connect.

Connect the battery charger to the

power adaptor, plug it into mains

power and switch on.

1

2

3

Charge rechargeable battery modules

Battery wall power light What it means

Steady green

Battery charger power is on

Does not light up Power is not plugged in or turned on at the

power socket, or there is no power.

Battery module light What it means

Steady orange

Battery module is recharging.

Steady green

Battery module is fully recharged.

Flashing orange

There is a problem with the battery module.

Does not light up Battery module is not properly placed, or

there is no power.

This image will show lights.

Page 20

Cochlear Li mited 201138 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Charge

CP900 S eries Sound Proc essors | User gui des 39Cochlear Limi ted 2011

Pull the battery cover away from

the battery holder.

Remove the batteries from the

battery holder.

Insert the batteries into the holder

with the fl at side (positive terminal)

facing up.

Replace the battery cover by sliding

it up towards the processing unit.

Remove the new batteries from the

packet and let them stand for a few

seconds.

1

2

3

4

5

Change disposable batteries

The Cochlear Nucleus CP900 Series Tamper Resistant Battery Cover uses two

high power zinc/air disposable batteries. Cochlear recommends Power One p675

Implant plus zinc/air batteries. Do not use silver oxide or alkaline batteries.

Care

Care for your sound processor ................................................................................ 40

Replace microphone protectors ...............................................................................41

Care for your battery charger ...................................................................................43

Change earhooks ........................................................................................................ 44

Change the coil cable ................................................................................................48

Change the coil magnet ............................................................................................ 49

Care for your acoustic component ......................................................................... 50

Page 21

Cochlear Li mited 201140 323649 I ss 3 CP900 Seri es Sound Process ors | User guides

Care

CP900 S eries Sound Proc essors | User gui des 41Cochlear Limit ed 2011

Care for your sound processor

Every day

Check all parts for dirt and moisture. Wipe the processor, coil cable, earhook,

covers, Snugfi ts and Mic Lock cables with a soft dry cloth. (You can leave the

earhooks, Snugfi ts, Mic Locks or coil cables on the processor while cleaning.)

Keep your processor free from moisture by drying it every night in your

drying pack.

Remove the battery and make sure all the contacts are clean. Carefully tap

or blow on them to remove any dirt.

Make sure the accessory port and audio accessories are clean. Blow on the

accessory port to remove any dust and clean accessories with a soft dry

cloth.

Check the microphone protectors for signs of dirt or grime and replace if

needed.

Every month

Replace the dry brick in your drying pack.

Check if earhooks or Snugfi ts are becoming loose or showing signs of wear.

Replace as needed.

Every three months

Replace the microphone protectors.

Note

If your sound processor is subject

to extreme conditions, you should

clean and replace parts more often

to keep it working at its best.

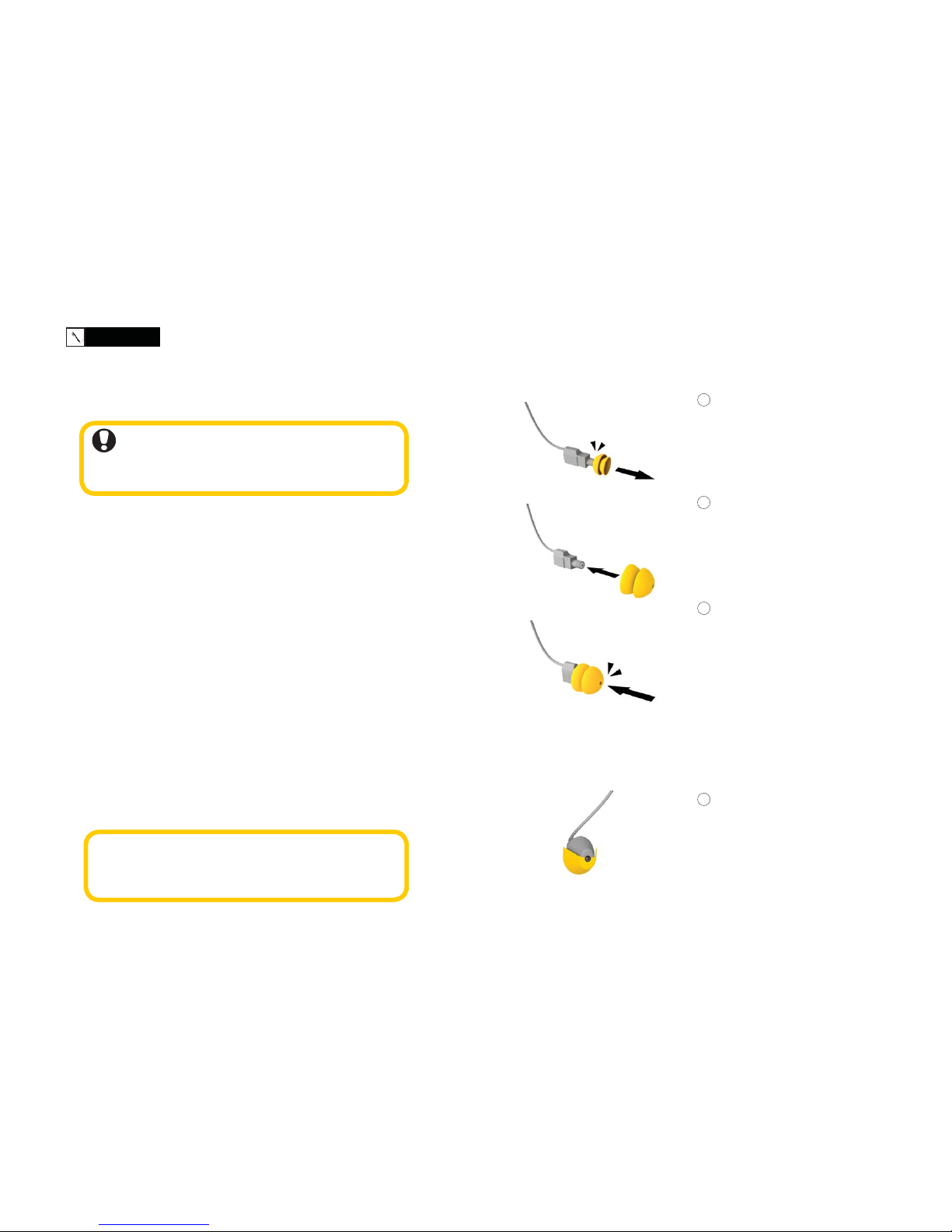

Replace microphone protectors

Replace your microphone protectors every three months, whenever they look dirty

or whenever you notice any loss in sound quality. Always replace both protectors

at the same time.

To remove microphone protectors:

Remove the protective cap from

the Cochlear Nucleus Microphone

Protector Removal Tool.

Push the tip of the removal tool

under the edge of the microphone

protector. Do not push the tool into

the middle of the protector as you

might damage the microphone.

Carefully lift out the microphone

protector and discard.

1

2

3

Warning

The removal tool is a sharp

object. It is not recommended

for use by children under the age

of 12 years.

Page 22

Cochlear Li mited 201142 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Care

CP900 S eries Sound Proc essors | User gui des 43Cochlear Limit ed 2011

Pull the Cochlear Nucleus

Microphone Protector Applicator

out of its sleeve.

1

The top end of the applicator is

marked with an arrow. Hook the

top end onto the earhook.

2

Hook the bottom end onto the coil

cable.

3

Align the microphone protectors

with the microphones.

4

Press the microphone protectors

into the microphone holes one at

a time.

5

Remove the applicator by carefully

peeling it upwards from the coil

cable end.

6

To insert new microphone protectors:

Care for your battery charger

Every day:

Check your battery charger is clean. If you notice any dust or dirt:

1. Unplug the power adaptor and remove any battery modules.

2. Hold the charger upside down and tap it to remove any dirt from the

battery charger sockets. Carefully blowing on the batter y charger sockets

may also help remove dirt.

3. Wipe the battery charger sockets with a soft dry cloth.

Cycle batteries in different sockets when recharging for a more even wear of

the sockets.

If it gets wet:

If the battery charger ever gets splashed with liquid, carefully shake out the

liquid and dry the charger for 24 hours. Do not use the charger until it is dry.

Page 23

Cochlear Li mited 201144 323649 I ss 3 CP900 Seri es Sound Proces sors | User guides

Care

CP900 Se ries Sound Proc essors | User guid es 45Cochlear Limite d 2011

Change earhooks

Cochlear Nucleus CP900 Series Standard Earhooks come in large, medium

and small sizes. The smallest earhook can be made tamper resistant and is

recommended for children under three. The acoustic component is worn with a

Cochlear Hybrid Earhook. (To change the hybrid earhook, see "Wearing/Removing

your acoustic component".)

To change a standard earhook:

Press fi rmly on the top of the

earhook with your thumb and click

it off the sound processor.

Click the standard earhook in place.

1

2

Note

Remove your earhook only when

necessary - it may become loose

if it is removed too often.

About the tamper resistant earhook:

The tamper resistant earhook can be locked to the processor with a pin to

reduce the risk of the earhook becoming a choking hazard for young children.

Older children and adults can wear it without the pin.

The tamper resistant earhook comes with a locking tool and fi tting pins.

Warning

The locking tool and pin is not

recommended for use by children

under 12. Do not let children attach

or remove the tamper resistant

earhook without adult supervision.

Childproofing Tip

Page 24

Cochlear Li mited 201146 323649 I ss 3 CP900 Seri es Sound Proces sors | User guides

Care

CP900 Se ries Sound Proce ssors | User guide s 47Cochlear Limited 2 011

Flip the tool and use the pointed

end to push the pin fully into

the earhook. The pin should not

protrude from either side of

the earhook.

Partly insert the fi tting pin into

the hole on the earhook.

3

4

Attach the tamper resistant earhook

Click the tamper resistant

earhook onto the processor.

Make sure the hole on the

earhook is aligned with the hole

on the processing unit.

Insert a fi tting pin into the hole

on the blunt end of the locking

tool.

1

2

Childproofing Tip

Remove the tamper resistant earhook

Hold the processor as shown

and insert the pointed end of

the locking tool into the hole

on the earhook.

Push the tool into the hole to

partly remove the fi tting pin. Be

gentle as too much force may

damage the tool.

Press fi rmly on the top of the

earhook with your thumb and

click it off the sound processor

1

2

4

Lift out the earhook fi tting pin

with tweezers.

3

Childproofing Tip

Page 25

Cochlear Li mited 201148 323649 I ss 3 CP900 Seri es Sound Proces sors | User guides

Care

CP900 S eries Sound Proc essors | User gui des 49Cochlear Limi ted 2011

Change the coil cable

The Cochlear Nucleus CP900 Series Coil Cable come in four lengths so you

can choose the most comfortable fi t. Only remove the coil cable when you are

changing it.

Hold the cable grip as shown

and fi rmly pull it straight out of

the processor. Do not tug on the

fl exible part of the cable.

Use your fi ngernails to hold the

cable grip as shown and pull the

cable fi rmly off the coil. Do not tug

on the fl exible part of the cable.

Push the new coil cable into the

processor until it clicks into place.

1

2

3

Push the new coil cable into the coil

until it clicks into place.

4

Change the coil magnet

The strength of the Cochlear Nucleus CP900 Series Coil Magnet can be adjusted

by changing the magnet depth or by replacing with a magnet of a different

strength. If the magnet is too weak or strong the coil may fall off or cause

discomfort.

To change the strength of the magnet:

To change the coil magnet:

With fi nger grips facing up, unscrew

the magnet anticlockwise and

remove.

With fi nger grips facing up, turn the

magnet clockwise to increase the

magnet's strength.

Insert the new magnet into the coil

hole and turn it clockwise until it is

at a comfortable depth.

Turn the magnet anticlockwise to

reduce its strength.

1

1

2

2

Page 26

Cochlear Li mited 201150 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Care

CP900 S eries Sound Proc essors | User gui des 51Cochlear Limi ted 2011

Care for your acoustic component

The acoustic component accessory is used only by people who are set up to use

their processor in Hybrid mode.

If you use Power or Plus domes:

Every day:

Check the wax fi lter in the receiver and change it whenever it is clogged with

wax or the system does not sound normal.

Domes have an additional inbuilt fi lter. Check the inbuilt fi lter and change

the dome whenever it is clogged with wax, or whenever the dome is dirty,

discoloured or losing shape.

If you use Power or Micro moulds:

Every day:

Clean the earmould and receiver cable with the supplied brush, a soft dry

cloth or our recommended cleaning fl uids, Hadeo™ and Cedis® ONLY. Wipe

any traces of wax away from the opening of the vent.

Check if the vent is clogged, and use the supplied vent cleaner to remove

wax as needed. Do NOT use the vent cleaner to clean any other part of the

system.

Check the wax fi lter and change whenever it is clogged with wax or the

system does not sound normal.

Caution

Handle your sound processor and acoustic component with care

above fl at surfaces. Never drop them or twist the receiver cable.

Note

Micro moulds can use WaxStop fi lters ONLY. Power moulds can use

either NoWax or WaxStop fi lters.

Pull the dome off using your

fi ngernails if necessary and discard.

Push the new dome directly onto

the receiver.

Click it securely into place.

1

2

3

Replace Power domes

4

When fi tting a Plus dome, the outer

sleeve should face down.

Replace Plus domes

Follow the directions for replacing Power domes and add the following step:

Page 27

Cochlear Li mited 201152 323649 Is s 3 CP900 Serie s Sound Processo rs | User guides

Care

CP900 S eries Sound Proc essors | User gui des 53Cochlear Limi ted 2011

Change wax fi lters

Caution

Wax fi lters must ALWAYS be used with the acoustic component

and replaced regularly.

Replace a NoWax fi lter

Power moulds (only) can use a NoWax fi lter in the sound outlet. Change the fi lter

whenever it is clogged with wax or whenever the system does not sound normal.

Remove a new NoWax tool from

its shell. One point on the tool has

a removal tool and the other point

has the new fi lter.

Insert the removal tool into the

existing wax fi lter and work it out

of the Power mould.

1

2

Push the new fi lter into the sound

outlet on the mould and dispose of

the tool and used fi lter.

3

Remove a WaxStop tool from

its shell. One end of the tool has

a new fi lter and the other has a

removal tool.

Insert the removal tool into the

existing wax fi lter.

1

2

Pull the used fi lter out slowly,

keeping the tool straight.

3

Flip the tool and push the new fi lter

into the sound outlet. Carefully pull

the tool free and dispose of the

used tool and fi lter.

4

Replace a WaxStop fi lter

Micro moulds use a WaxStop fi lter in the sound outlet. Power moulds use either

a WaxStop fi lter or a NoWax fi lter. Power and Plus domes must be worn with a

WaxStop fi lter in the receiver.

Page 28

Lights, beeps and buttons

Cochlear Li mited 201154 323649 Is s 3 CP900 Serie s Sound Process ors | User guides Cochlear Li mited 2011 CP900 Se ries Sound Proc essors | User guid es 55

Light What it means

Short green fl ashes

Turning on processor. The number of

fl ashes indicates the number of the

selected program.

Steady orange while

lower button is pressed

Turning off processor.

Short green fl ashes

Changing the program. The number

of fl ashes indicates the number of the

selected program e.g. 2 fl ashes for

program 2.

Single green fl ash

Changing volume or sensitivity level.

Green followed by orange fl ash Locking processor buttons.

Orange followed by green fl ash Unlocking processor buttons.

Orange fl ash when pressing buttons Processor buttons are locked.

Long fl ash of blue Changing between microphones to

the telecoil or audio accessory

Long fl ash of green Changing between the telecoil or

audio accessory to the microphones.

Constant quick green fl ashes Processor is receiving sound from the

microphones

Constant quick blue fl ashes

Processor is receiving sound from

telecoil or audio accessory

Lights, beeps and buttons

Lights

Your clinician can set up your processor to show some or all of the following light

indications.

Lights ..............................................................................................................................55

Beeps ..............................................................................................................................56

Button controls in advanced mode .........................................................................57

Page 29

Lights, beeps and buttons

Cochlear Li mited 201156 323649 Is s 3 CP900 Serie s Sound Process ors | User guides Cochlear L imited 2011 CP900 S eries Sound Pro cessors | User gui des 57

Beep What it means

Short high beeps

Changing the program. The

number of beeps indicates the

number of the selected program.

High beep

Changing volume or sensitivity

level.

... Long high beep

Switching between using the

microphones and the telecoil or

audio accessory.

... ... Long low beeps

General fault.

Short low beep when you press a button

Processor buttons are locked.

Short low beeps

Processor battery is low.

Short low beeps

Battery is empty and processor

is turning off.

Beeps

Your clinician can set up your processor so you can hear the following beeps.

Flash of orange every second Coil is off, or processor is not

connected to the correct implant.

Quick fl ashes of orange

Processor battery is empty.

Steady orange General fault:

• Fault with processor

• Corrupt program

• Fault and coil off error at the same

time

• Fault with acoustic component

while in Hybrid mode.

Button controls in advanced mode

Sound processors can be set up in Advanced mode by your clinician to give you

extra control over the volume and sensitivity of the sound you hear.

Turn processor on and off

Press and hold upper and lower buttons

at the same time. Pressing and holding

the lower button will only turn on the

processor.

Press and hold the lower button.

Press and hold the upper button to

switch between microphones and

telecoil/audio accessor y.

Change program

Turn telecoil/audio accessory on and off.

Page 30

Lights, beeps and buttons

Cochlear Li mited 201158 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

CP900 S eries Sound Pro cessors | User gu ides 59

Cochlear Li mited 2011

In Advanced mode, you can choose to control volume and sensitivity with your

remote and the buttons on your processor. See the user guides for the CR210 and

CR230 remotes for more information.

Select "Volume" via your remote and use the buttons below to control the

loudness of sound.

Select "Sensitivity" via your remote and use the buttons below to control the

range of sounds picked up by the processor e.g. soft, background, close or far

away.

Press the upper button to

increase volume or sensitivity.

Press the lower button to

decrease volume or sensitivity.

Quick-press both the upper and lower

buttons at the same time.

Lock/unlock processor buttons

Change volume or sensitivity

General warnings and cautions

Processor and parts

• Do not push the master volume too high for comfort in case a loud noise occurs nearby.

• Do not place your processor or parts in nose or mouth or other body openings.

• Do not use your processor or parts in a way that will restrict your air ways (e.g. when

using LiteWear or long coil cable).

• Do not let your processor or parts entangle with any jewellery (e.g. earhook and

earrings) or machinery.

• Do not apply continued pressure to the coil when in contact with the skin (e.g. sleeping

while lying on coil, or using tight-fi tting headwear).

• Remove the processor and coil immediately if there is any discomfort or pain (e.g. if

device becomes hot, or sound is uncomfortably loud) and inform clinician.

• Do not attach or wear a body-worn battery confi guration beneath layers of clothing in

direct contact with the skin (e.g. in pocket or under child's vest).

• Make sure all cables used by a child are securely attached to their clothing.

• Do not place processor or parts in any household devices (e.g. microwave oven, dr yer).

• Do not modif y your processor. Warranty will be void if modifi ed.

• Do not use a dr ying aid that has an Ultra Violet C (UVC) lamp (e.g. do not use the

Freedom Dry and Store).

• Store spare magnets safely and away from cards that may have a magnetic strip (e.g.

credit cards, bus tickets, etc).

Page 31

Cochlear Li mited 201160 323649 Is s 3 CP900 Seri es Sound Process ors | User guides

General Warnings

CP900 S eries Sound Proc essors | User gui des 61

Cochlear Li mited 2011

Batteries

• Dispose of used batteries promptly and carefully, in accordance with local regulations.

Keep away from children.

• Wash hands after handling disposable batteries.

• Do not recharge disposable batteries.

• Do not disassemble, deform, immerse in water or dispose of batteries in fi re.

• Do not mix old and new batteries or batteries of different types or brands.

• Replace disposable batteries with high power Cochlear supplied or recommended zinc

air batteries only. We recommend Power One p675 Implant Plus zinc/air batteries. We

do not recommend using silver oxide or alkaline batteries.

• Only use rechargeable batteries and battery chargers supplied or recommended by

Cochlear. Use of other batteries or battery chargers may result in harm or injury.

• Do not allow children to replace batteries without adult supervision.

• Do not touch the battery charger contacts or allow children to use the battery charger

without adult supervision.

• Do not shor t-circuit batteries (e.g. do not let terminals of batteries contact each other,

do not place batteries loose in pockets, etc.).

• Store unused batteries in original packaging, in a cool dry place. When processor is not

in use, remove the disposable or rechargeable batteries and store separately in a cool

dry place.

• Do not expose batteries to heat (e.g. never leave batteries in sunlight, behind a window

or in a car).

• Do not use damaged or deformed batteries. If skin or eyes come into contact with

battery fl uid or liquid, wash out with water and seek medical attention immediately.

• Never put batteries in mouth. If swallowed, contact your physician or local Poison

Information Centre.

• Please contact your clinician for battery service.

Acoustic Component

• Refi t and replace hard earmoulds regularly. Hard earmoulds can cause deformation

of the ear canal. Have them refi tted every two years for adults and more regularly for

children.

Product component dimensions (Typical values)

Component Length Width Depth External diameter

CP910 processing

unit

51.3 mm 47.7 mm 9.0 mm NA

CP920 processing

unit

39.1 mm 47.7 mm 9.0 mm NA

Standard battery

module

28.0 mm 9.0 mm 19.0 mm

NA

Compact

rechargeable

battery module

19.0 mm 9.0 mm 19.0 mm

NA

Standard

rechargeable

battery module

28.0 mm 9.0 mm 19.0 mm

NA

Coil 8.0 mm 32.0 mm

Weight (Typical values. All weights are measured with medium earhook)

Component Weight

CP910 processor (no battery) 5.7 g

CP920 processing unit (no battery) 5.0 g

CP910 processor with compact rechargeable battery 10.5 g

CP910 processor with standard

rechargeable

battery 13.0 g

CP910 processor with Zinc/Air batteries 12.8 g

CP920 processor with compact rechargeable battery 9.8 g

CP920 processor with standard rechargeable battery

12.4 g

CP920 processor with Zinc/Air batteries

12.1 g

Coil (without coil magnet) 5.0 g

Other information

Page 32

Cochlear Li mited 2011

62 323649 Is s 3 CP900 Serie s Sound Process ors | User guides

Other information

CP900 S eries Sound Proc essors | User gui des 63

Cochlear Li mited 2011

Operating characteristics

Processing unit

Characteristic Value/range

Sound input frequency range 100 Hz to 8 kHz

Operating voltage 2.00 V to 4.25 V

Power consumption 20 mW to 100 mW

Push-button functions Turn processor on and off, turn

telecoil/audio accessory on and off,

change program, lock/unlock buttons,

change sensitivity or volume level.

Battery module

Type Capacity/voltage range

Standard battery module Two PR44 (Zinc/Air) button cell

batteries. 1.45 V (nominal) each.

Cochlear recommends Power One

p675 Implant Plus zinc/air batteries.

Compact rechargeable battery module 120 mAh / 3.0 V to 4.2 V

Standard rechargeable battery module 205 mAH / 3.0 V to 4.2 V

Coil

Characteristic Value/range

Operating voltage 2.0 V to 2.6 V

Operating frequency 5 MHz

Environmental conditions

Processing unit, coil, coil cable and accessories

Condition Minimum Maximum

Storage temperature -40 ºC +50 ºC

Storage relative humidity 0% RH 90% RH

Operating pressure 700 hPa 1030 hPA

Operating temperature +5 ºC +50 ºC

Operating relative humidity 0% RH 90% RH

The processing unit comprises:

• Two omni-directional microphones for receiving sound.

• An internal telecoil for receiving magnetic fi elds radiated by phones, neckloops

and roomloops.

• Custom analogue and digital integrated circuits with digital signal processing

(DSP) and bi-directional wireless communication capabilities.

• A tri-colour visual indication of processor function or problem.

• Two push-buttons to allow user control of key features.

• CP910 only – Custom 4-pin accessory connector for connection of audio

accessories.

• Custom 4-pin coil connector for connection of the coil cable.

• A range of earhooks.

The batteries provide power to the processor.

The coil acts as a transformer coupling that transfers energy and data to the

implant.

Materials

• Processing unit: copolyester

• Battery modules (all types) are made of copolyester

• Coil is made of polypropylene (PP), thermoplastic elastomer (TPE)

• Magnet casing is made of acrylonitrile butadiene styrene (ABS)

• Coil cable sheath is made of polyvinyl chloride (PVC)

• Coil cable plugs are made of PP & TPE

• LiteWear cable is of polyester, TPE & PVC (same construction as the coil cable)

sheath is PVC; plugs/strain relief are PP and TPE

• LiteWear connection boots are made of copolyester

• LiteWear retention case is made of polyamide

Standard battery module

Check the battery manufacturer’s recommended operating conditions for

disposable batteries used in your processor.

Page 33

Cochlear Li mited 2011

64 323649 I ss 3 CP900 Seri es Sound Process ors | User guides

Other information

CP900 S eries Sound Proc essors | User gui des 65

Cochlear Li mited 2011

Certifi cation and applied standards

The CP900 series sound processors fulfi l the essential requirements listed in

Annex 1 of the EC directive 90/385/EEC on Active Implantable Medical Devices as

last amended by EC Directive 2007/47/EEC.

Equipment classifi cation

Your processor is internally powered equipment Type B as described in the

international standard IEC 60601-1:2005, Medical Electrical Equipment - Part 1:

Basic Safety and Essential Performance.

• LiteWear Fixing Aids are made of polycarbonate

• Processor covers are made of polystyrene and polycarbonate

• Coil covers are made of polycarbonate

• Hybrid materials for outer sheathing of the housing adaptor and the outer cable

sheathing is made of polyamide

• Custom moulds are made of Stereo Lithography Acrylic covered with a UVcured lacquer

• Plus Domes are made of elastosil silicone polymer

• Power Domes are made of TPE

FCC (Federal Communications Commission) and

Canadian IC compliance

This device complies with part 15 of the FCC Rules and with RSS-210 of Industr y

Canada. Operation is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including interference that

may cause undesired operation.

Changes or modifi cations made to this equipment not expressly approved by

Cochlear Limited may void the FCC authorization to operate this equipment.

This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Consult the dealer or an experienced radio/TV technician for help.

FCC ID: WTOP900

IC ID: 8039A-P900

Page 34

Cochlear Li mited 2011

66 323649 Is s 3 CP900 Seri es Sound Process ors | User guides

Other information

CP900 S eries Sound Proc essors | User gui des 67

Cochlear Li mited 2011

Labelling symbols

The symbols below are found on your processor components and

packaging:

Consult instructions for use

Catalogue number

Batch code

Serial number

Temperature limitations

Relative humidity limitations

By prescription

Certifi cation Japan

Certifi cation Australia

Certifi cation New Zealand

Type B applied part

Recyclable material

Segregate electronic waste

Do not dispose in fi re

CE Registration Mark

%

0

90

Legal statement

The statements made in this guide are believed to be true and correct as of the

date of publication. However, specifi cations are subject to change without notice.

Nucleus® Cochlear

™

implant systems are covered by one or more international

patents.

© Cochlear Limited 2012

Page 35

Printed in Australia

323649 ISS3 APR12

Nucleus is a re gistered trad emark of Cochlea r Limited.

Cochlear a nd the elliptica l logo, Snugfi t, Mic Loc k and Freedom are t rademarks o f Cochlear Limite d.

Dry and Sto re is a registered tr ademark of Ear Tech nology Corpo ration.

The state ments made in thi s guide are believe d to be true and cor rect in every d etail as of the date of pu blication. Ho wever,

specifi cations are subjec t to change witho ut notice.

Cochlear Ltd (ABN 96 002 618 073) 14 Mars Road, Lane Cove NSW 2066, Australia Tel: 61 2 9428 6555 Fax: 61 2 9428 6352

Cochlear Americas 13059 E Peakview Avenue, Centennial, CO 80111, USA Tel: 1 303 790 9010 Fax: 1 303 792 9025

Cochlear AG European Headquarters, Peter Merian-Weg 4, CH - 4052 Basel, Switzerland Tel: 41 61 205 0404 Fax: 41 61 205 0405

Cochlear Deutschland GmbH & Co. KG Karl-Wiechert-Allee 76A, D-30625 Hannover

Germany Tel: 49 511 542 770 Fax: 49 511 542 7770

Cochlear Europe Ltd

6 Dashwood Lang Road, Bourne Business Park, Addlestone, Surrey KT15 2HJ, United Kingdom Tel: 44 1932 87 1500 Fax: 44 1932 87 152

6

Nihon Cochlear Co Ltd

Ochanomizu-Motomachi Bldg, 2-3-7 Hongo, Bunkyo-Ku, Tokyo 113-0033, Japan Tel: 81 3 3817 0241 Fax: 81 3 3817 024

Cochlear (HK) Ltd

Unit 1810, Hopewell Centre, 183 Queens Road East, Wan Chai, Hong Kong SAR Tel: 852 2530 5773 Fax: 852 2530 518

3

Cochlear Medical Device (Beijing) Co Ltd Unit 2208 Gemdale Tower B, 91 Jianguo Road, Chaoyang District, Beijing 100022

P.R. China Tel: 86 10 5909 7800 Fax: 86 10 5909 7900

Cochlear Ltd (Singapore Branch) 6 Sin Ming Road, #01-16 Sin Ming Plaza Tower 2, Singapore 575585 Tel: 65 6553 3814 Fax: 65 6451 4

Cochlear Korea Ltd 1st floor, Cheongwon building, 828-5, Yuksam dong, Kangnam gu, Seoul, Korea Tel: 82 2 533 4663 Fax: 82 2 533 8

Cochlear Benelux NV Schaliënhoevedreef 20i, B - 2800 Mechelen, Belgium Tel: 32 1579 5511 Fax: 32 1579 5500

Cochlear Italia S.r.l. Via Larga 33, 40138 Bologna, Italia Tel: 39 051 601 53 11 Fax: 39 051 39 20 62

Cochlear France S.A.S.

Route de l’Orme aux Merisiers, Z.I. Les Algorithmes - Bât. Homère, 91190 Saint Aubin, France Tel: 33 811 111 993 Fax: 33 160 19

6

Cochlear Nordic AB Konstruktionsvägen 14, SE - 435 33 Mölnlycke, Sweden Tel: 46 31 335 14 61 Fax: 46 31 335 14 60

Cochlear Tıbbi Cihazlar ve Sağlık Hizmetleri Ltd. Sti. Cubuklu Mah. Bogazici Cad., Bogazici Plaza No: 6/1, Kavacik

TR - 34805 Beykoz-Istanbul, Turkey Tel: 90 216 538 5900 Fax: 90 216 538 5919

Cochlear Canada Inc 2500-120 Adelaide Street West, Toronto, ON M5H 1T1 Canada Tel: 1 416 972 5082 Fax: 1 416 972 5083

Cochlear Medical Device Company India Pvt Ltd Ground floor Platina Bldg, Plot no C 59, G Block, Bandra Kurla Complex,

Bandra East, Mumbai 400051, India Tel: 91 22 61121111 Fax: 91 22 61121100

Loading...

Loading...