Page 1

2003 PW3

Owners / Service Manual

“CHAMPIONS START HERE”

Page 2

For parts orders contact your local dealer

To locate your closest Cobra dealer

log on to

www.cobramotorcycle.com

or call

(330) 549-9600

If you need technical assistance

contact your local dealer or call

the Cobra Technical Support Hotline at

(330) 549-9603

1

Cobra Motorcycle MFG., Inc.

11511 Springfield Road

North Lima, Ohio 44452

MCPW2003.4

Page 3

DISCLAIMER OF WARRANTY

This motorcycle is sold “as is” with all faults, obvious or not. There are no warranties

expressed or implied, including any warranty of merchantability and warranty of fitness

for any particular purpose.

“WARNING”

THE COBRA PW3 IS A COMPETITION MODEL ONLY AND IS NOT

MANUFACTURED FOR, NOR SHOULD IT BE USED ON PUBLIC STREETS, ROADS

OR HIGHWAYS.

THE USE OF THIS BIKE SHOULD BE LIMITED TO PARTICIPATION IN

SANCTIONED COMPETITION EVENTS UPON A CLOSED COURSE BY A

SUFFICIENTLY SKILLED RIDER AND SHOULD NOT BE USED FOR GENERAL

OFF-ROAD RECREATIONAL RIDING.

IMPROPER USE OF THIS MOTORCYCLE CAN CAUSE INJURY OR DEATH.

THIS BIKE IS INTENDED FOR EXPERIENCED RACERS ONLY AND NOT FOR

BEGINNERS.

IT IS YOUR RESPONSIBILITY AS THE OWNER OF THIS COBRA MOTORCYCLE

OR AS THE PARENT, OR LEGAL GUARDIAN OF THE OPERATOR, TO KEEP THIS

COBRA MOTORCYCLE IN PROPER OPERATING CONDITION.

THIS BIKE WAS DESIGNED FOR RIDERS THAT WEIGH LESS THAN 80 LBS WITH

FULL RIDING GEAR AND SHOULD NOT BE OPERATED BY RIDERS THAT WEIGH

MORE THAT.

BE SURE THAT THE RIDER ALWAYS WEARS ADEQUATE SAFETY GEAR

EVERYTIME HE OR SHE RIDES THEIR COBRA MOTORCYCLE.

IMPORTANT SAFETY NOTICE

Failure to follow WARNING instructions could result in severe injury or death to

the machine operator, a bystander, or a person inspecting or repairing the

machine.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to

the machine.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

2

Page 4

Table Of Contents

General Information.........................................................................................................4

Specifications - General..............................................................................................4

Specifications - Torque Values ..................................................................................5

Optional Components..................................................................................................6

Break-In Procedure......................................................................................................7

Starting Procedure.......................................................................................................8

General Tips ..................................................................................................................9

Maintenance....................................................................................................................10

Schedule & Tips .........................................................................................................10

M1: Replacing Transmission / Clutch Lubricant....................................................11

M2: Chain adjustment................................................................................................12

M3: Front brake adjustment......................................................................................13

M4: Rear brake adjustment ......................................................................................14

M5: Air Filter Cleaning ...............................................................................................14

M6: Fork Oil Replacement........................................................................................15

M7: Clutch Adjustment ..............................................................................................16

Engine Service / Parts...................................................................................................17

ES1: Top End Parts ...................................................................................................18

ES2: Bottom end & transmission.............................................................................19

ES3: Clutch.................................................................................................................22

ES4: Igni tion................................................................................................................23

ES5: Cooling System.................................................................................................24

ES6: Fuel & Air System.............................................................................................25

ES7: Exhaust ..............................................................................................................30

Chassis Service / Parts .................................................................................................30

CS1: Wheels & Tires .................................................................................................30

CS2: Suspension ........................................................................................................32

Troubleshooting..............................................................................................................36

3

Page 5

General Information

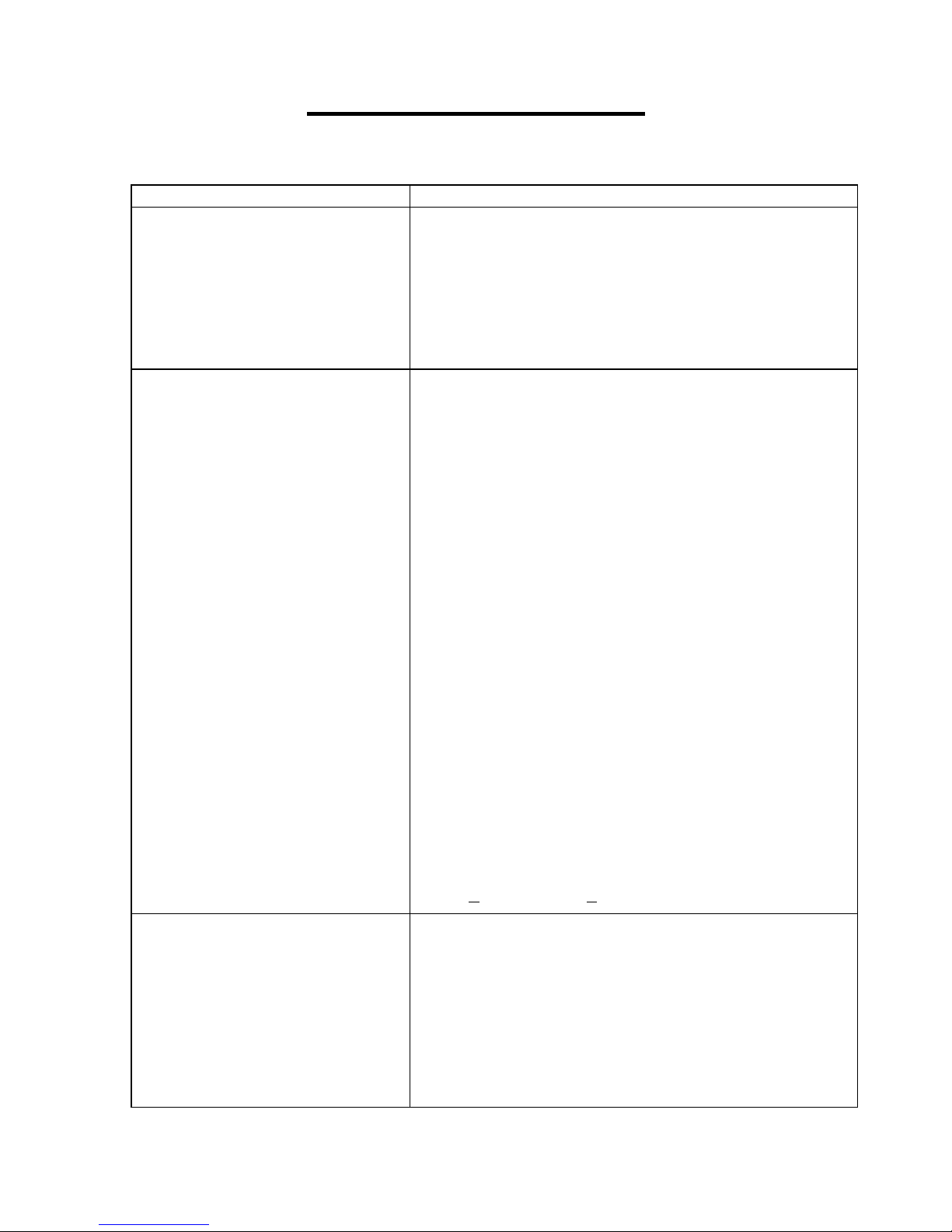

Specifications - General

Items PW3

Dimensions

Wheelbase 35.75” (908mm)

Wheel size 10” (254mm)

Seat height 22” (559 mm) Stock #TCHO0001

23.9” (607 mm) Optional #TCHJ0001

Engine

Type 2-stroke, single cylinder, reed valve

Cooling system Liquid-cooled

Displacement 49.8 cc

Bore and stroke 39 mm x 41.7 mm

Ignition system Digital Electronic

Spark plug Champion C53, NGK B11EGV

Gap 0.023” – 0.025” (0.58 – 0.64 mm)

Fuel type Sunoco MO2X or 93 octane pump gasoline

Injector oil type Cobra Venom 2-cycle Race Oil

Fuel / oil mix ratios Fill oil reservoir as required

Ignition timing Fixed

Carburetion 12 mm Dell’Orto PHVA - PS

Main jet 82

OTHER RACE FUELS ARE NOT RECOMMENDED

Slow (Pilot) jet 42

Float height 5 mm + 0.3mm (0.2” + 0.012”)

Transmission

Speed Single

Clutch 3 shoe centrifugal

Final drive ratio 10/46 T

Transmission / clutch oil type Cobra Venom 3 Shoe Clutch Milk, or Dexron III

4

Quantity 250 ml (8.5oz)

Page 6

Chassis

Front tire 2.50 - 10

Pressure 15 psi minimum

Rear tire 2.75 - 10

Pressure 15 psi min. (20 psi for hard pack or rocky conditions)

Front fork Marzocchi 32mm

Fork oil type SAE 20 weight

Fork oil amount 200 ml (6.8 oz) oil change, 220 ml (7.4 oz) rebuild

Fork oil height 70 mm (2.75”) collapsed from top with spring (no

spacer)

Specifications - Torque Values

Torque Value Fastener

Size &

ft-lb in-lb Nm

Front engine mount bolts 22 264 30 8 x 1.25

Rear engine mount bolts 22 264 30 8 x 1.25

Swingarm pivot bolt 21 250 28 14 x 2

Rear sprocket bolts 18 216 24 7 x 1

Rear axle bolts 25 300 34 12 x 1.25

Rear shock mounts 40 480 54 10 x 1.5

Clutch adjust access plug 10 124 14 12 x 1.25

Units of mm unless otherwise specified

Remarks

5

Page 7

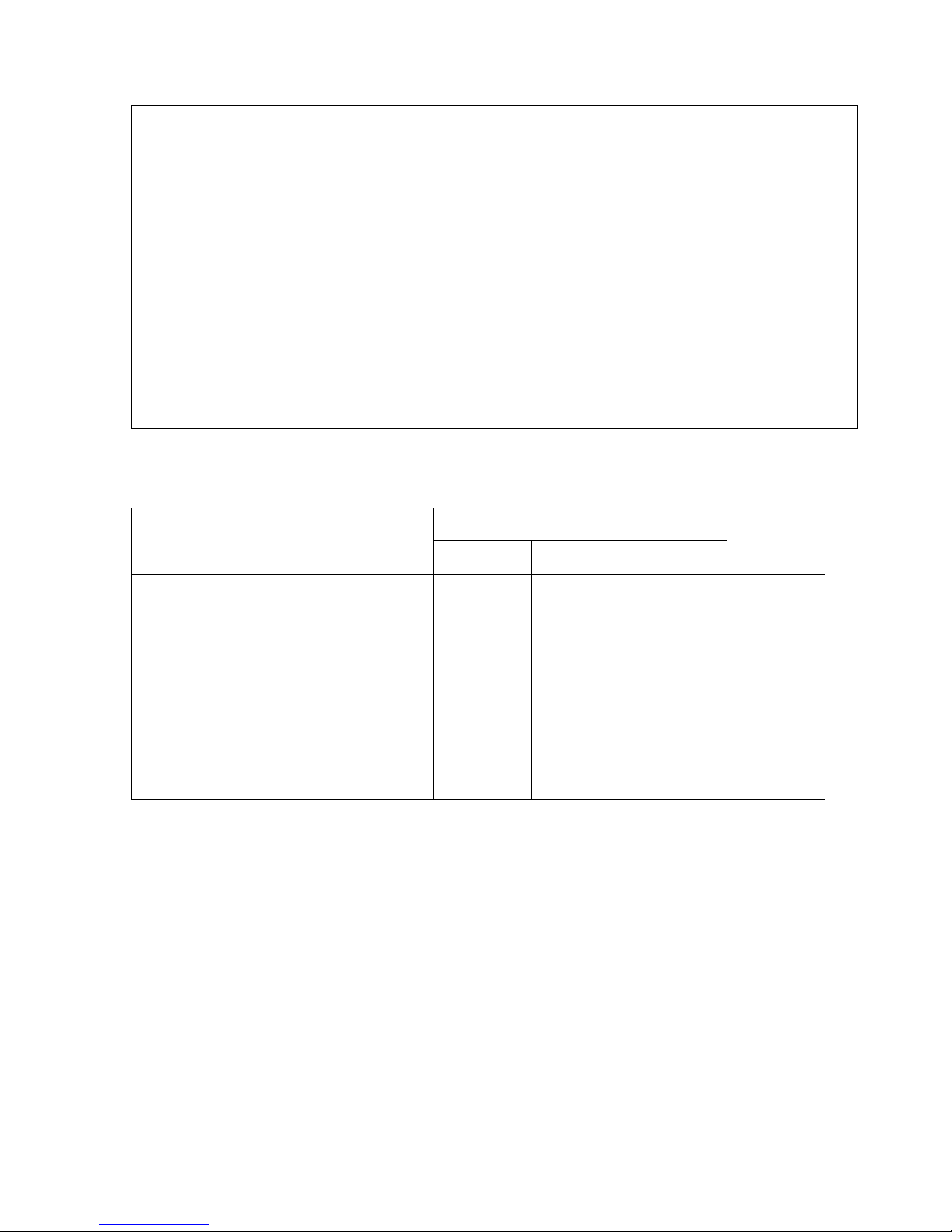

Optional Components

• Carburetor jets

o Main jets #’s 74, 76, 78, 80, 84, 86, 88

o Slow jets #’s 38, 40, 45,

• Sprockets

o Front sprocket, 11T

o Rear sprocket, 39 T – 45 T

• Seat – higher seat height 23.9” (607 mm) part # TCHJ0001

• Suspension Springs

Weight of Rider (lb) Fork Spring Shock Spring

Less than 38 (light) KCMZ0012A SCMU0321 (yellow, 320 lb/in)

38 – 45 (std) KCMZ0012 SCMU1360 (red, 260 lb/in)

46 to 55 (stiff) KCMZ0012B SCMU1380 (white, 380 lb/in)

Extra stiff SCMU1400 (silver, 400 lb/in)

• Suspension Valving

Damping Rate Fork Valving

Soft (fast) KCMZ0033A KCMZ0032A SCMU0318A

Standard KCMZ0033 KCMZ0032 SCMU0318

Hard (slow) KCMZ0033B KCMZ0032B SCMU0318B

Compression

(right)

Fork Valving

Rebound

(left)

Shock Valving

(kit)

6

Page 8

Break-In Procedure

Your Cobra PW3 is a close-tolerance high performance machine and break-in

time is very important for maximum life and performance. The PW3 can be

ridden hard after the first ½ hour break-in time but it is recommended that no

adjustments are made to the carburetion or suspension until the full 8 hours of

bike break-in has elapsed. Also, after the engine, transmission, and drive train

have been broken -in for the full 8 hours, the bike will be faster!

Fill the fuel tank with 93 octane pump gas, or Sunoco MO2X without oil. Also, fill

the oil injection reservoir with Cobra’s specially formulated Cobra Venom 2-cycle

Race Oil. (Part # MCMUOL02)

CAUTION:

Failure to use proper fuel or oil may result in premature engine wear, or damage

to the machine.

Adhering to the following break-in schedule will result in long lasting high

performance machine.

• First ½ hour of operation

o Follow the starting procedure listed in this manual.

o Avoid prolonged operation at Wide Open Throttle.

• After 1 hour of operation

o Check for loose bolts and nuts on the bike and retighten as

necessary (proper toque values are listed under Specifications).

o Clean the carburetor bowl.

o Change the transmission / clutch lubricant.

• After 8 hours of operation

o Change the fork oil.

o Have a Certified Cobra Mechanic change the shock oil.

• Your bike is now ready for the highest level of competition!

7

Page 9

Starting Procedure

Before starting the machine inspect the following:

• Fill the 2-stroke injector oil reservoir with Cobra’s specially formulated Cobra

Venom 2-cycle Race Oil.

• Insure that the fuel tank contains an adequate volume of fuel to complete

the distance required. (Sunoco MO2X or 93 octane pump gas).

• Check for proper tire pressure in both tires.

• Observe the chain tension and adjust if necessary.

• Observe the coolant level and fill if necessary.

• Verify that the chain rollers do not have improper wear.

• Inspect the frame for;

o Cracks in the metal.

o Cracking paint which might indicate overly stressed material.

• Verify that the handlebars are tight.

• Check the throttle for;

o Smooth operation and sound closing.

o Frayed strands of the cable inside the throttle housing.

• Check for loose bolts and nuts, and re-torque as necessary.

• Verify that the air filter is clean and properly saturated with oil.

• Turn the fuel on by rotating the fuel petcock knob to the vertically downward

position (reserve posit ion is horizontally forward).

CAUTION:

For best results from your Cobra Motorcycle use only the recommended fuels.

Testing has shown that most ‘race’ fuels actually degrade performance.

When your pre-ride inspection is complete the bike may be started. For a cold

engine follow this procedure.

1. Place the motorcycle on a stand of sufficient strength that positions the

motorcycle in a level upright position with the rear wheel off the ground.

2. On the carburetor, flip the black choke knob upward from the right side of

the bike.

3. Kick start the engine by kicking the lever forward.

4. Rev the engine in short spurts, turning the throttle no more than 1/4 open

until the engine will run without the choke.

5. Verify a functional engine shut-off switch by shutting off the engine.

6. Restart the engine and proceed with riding when the engine is sufficiently

warm (i.e. the side of the cylinder is warm to touch).

CAUTION:

Never rev an engine full throttle when it's cold or slightly warmed up. Cobra

recommends that you tell you r child to take it easy the first couple of minutes in

practice until the engine comes up to full operating temperature. Make sure your

engine is properly warmed up before racing.

8

Page 10

General Tips

1. Always wear a helmet and other protective riding gear.

2. Cobra recommends that you tell your child to take it easy the first couple of

minutes in practice until the engine comes up to full operating temperature.

3. Make sure your riders’ foot is not resting on the foot brake while they are

riding.

4. Evaluate the bikes jetting only after it has been warmed up to race

temperatures.

5. A properly maintained machine is safer, faster, and more fun to ride.

6. When washing the bike, be careful to not directly aim the hose at the

bottom edge of the seat, or water is apt to enter the airbox.

7. Your Cobra Motorcycle has a 10 digit VIN (Vehicle Identification Number).

The first two digits indicate the model and the seventh indicates the model

year (MY).

a. Example, OIxxxx3xxx is a 2003 MY PW3.

9

Page 11

Maintenance

Schedule & Tips

It is important that you adhere to this maintenance schedule so as to promote the

longevity of your Cobra Motorcycle.

• Between each ride

o Fill the 2-stroke injector oil reservoir.

o Check the air filter (clean and re-oil as necessary).

o Insure the smooth operation of the throttle cable (throttle soundly

‘clacks’ shut).

o Check for frayed strands of the throttle cable inside the throttle housing

and replace if necessary.

o Check for adequate tire pressures and adjust if necessary.

o Check all nuts and bolts for proper torque and re-torque if necessary.

o Spray all moving parts with WD40 or other light oil.

o Check drive chain for

§ Proper tension and adjust if necessary.

§ Adequate lubrication and lubricate if necessary.

o Insure that the ignition stator and rotor are clean and dry.

o Check the frame for cracks in the metal or cracks in the paint that

might indicate that the metal has been stressed beyond it’s safe limits.

Replace or get properly rewelded as necessary.

o Fill the 2-stroke injector oil reservoir with Cobra’s specially formulated

Cobra Venom 2-cycle Race Oil.

• Every 2 hours of operation

o Replace the transmission oil.

• Every 10 hours of operation

o Replace the fork oil.

o Have the shock oil replaced by a Certified Cobra Mechanic.

CAUTION:

1. If you ever need to weld anything on the bike, disconnect the spark plug

cap, unplug the ignition, disconnect the kill switch, scrape the paint bare

near the area to be welded and put the ground clamp as close to the area

to be welded as possible.

10

Page 12

Be sure the fuel tank and carburetor have been removed and safely located

away from the welding process.

2. The frame is 4130 Chrome Moly and it is important to weld it with the proper

rod and heat settings set as light as possible. Cobra recommends replacing

the frame with a new one if the old one becomes damaged.

M1: Replacing Transmission / Clutch

Lubricant

Tools needed:

• 250 ml (8.5oz) Cobra Venom 3 Shoe Clutch Milk (Part # MCMUGF01) or

Dexron III Automatic Transmission Fluid

• #3 Phillips screwdriver

• large flat blade screwdriver or coin

Procedure:

1. Begin this procedure with a bike that has been ridden more than 5 minutes

but less than 10 minutes. It is desired to have the engine warm enough so

that the oil ‘runny’ but not so hot that there is risk of being burned by the

engine or the oil.

Hot oil and hot components on the motorcycle may cause burns.

2. Lean bike against somethin g or set on stand with oil drain hole.

3. Using Phillips screwdriver, remove the oil drain bolt located on the right side

of the engine (figure 1).

Figure 1

11

Page 13

NOTE: You may need to adjust the brake pedal (up or down) to gain access to

the drain bolt.

4. After it has drained, reinstall the drain screw with gasket.

5. Refill oil from oil fill plug 250 ml (8.5oz) Cobra Venom 3 Shoe Clutch Milk

(Part # MCMUGF01), or Dexron III Automatic Transmission Fluid, thru the fill

plug.

NOTE: Leaning the bike over onto it’s lef t hand side will facilitate the oil filling

procedure.

6. Reapply the oil fill screw, securely, being sure the gasket is in place.

CAUTION:

Cobra has spent considerable time and money developing the proper lubrication

to handle the harsh environment of the automatic clutch and transmission of this

motorcycle. Cobra was forced to put forth this effort because the other available

options and not adequate. Cobra’s specially developed Cobra Venom 3 Shoe

Clutch Milk (Part # MCMUGF01) is the recommended lubricant for your PW3

motorcycle.

M2: Chain adjustment

Tools required for chain adjustment

• Two 19 mm wrenches or sockets

• 13 mm wrench or socket

1. Make sure that the rear

wheel is aligned

properly.

2. For proper adjustment,

the chain should have 35

mm (1 3/8”) free

movement just behind

the chain block with no

load on the bike (figure

2)

Figure 2

CAUTION:

Verify that the chain has a minimum of 6mm (1/4”) free movement when the

suspension is collapsed.

12

Page 14

3. If the chain requires adjusting, loosen the axel

with a pair of 19 mm wrenches and tighten the

chain by rotating the adjuster bolts clockwise

(CW) or loosen the chain by rotating the adjuster

bolts (CCW).

4. Retighten the axel bolt to 25 ft-lb (34 Nm).

Figure 3

M3: Front brake adjustment

Tools recommended for front brake maintenance:

• 10mm open end wrench

Figure 4, from the brake lever Figure 5, from the brake hub

From the brake lever:

1. Loosen the locking nut on the brake lever.

2. Adjust the bolt to desirable position.

3. Tighten the locking nut.

From the brake hub:

1. Loosen the 10mm nut on the hub.

2. Adjust the brake cable to desirable position

3. Tighten the 10mm nut.

CAUTION:

If you tighten the front brake up too much, the brakes may hang up causing the

brake pads to wear incorrectly and prematurely.

13

Page 15

M4: Rear brake adjustment

Tools recommended for rear brake maintenance:

• 10mm open end wrench

There are 2 adjustments on the brake.

Figure 6, adjust brake lever free height Figure 7, adjust lever ‘free play’

From the brake lever:

4. Loosen the 10mm nut on the back of the brake pedal.

5. Adjust the bolt to desirable position

6. Tighten the 10mm nut.

From the brake hub:

1. Adjust the wing nut up to desirabl e position.

CAUTION:

If you tighten the wing nut up too much, the brakes may remain engaged. If so,

the brake pads will burn up, and need replaced.

M5: Air Filter Cleaning

Tools recommended for air filter maintenance:

• #2 Phillips head screwdriver

• 4 mm hex key (Allen)

• Foam filter oil

Procedure

1. Removed the seat with the 4 mm hex key

2. Remove the two Phillips head screws holding the filter to the entrance of the

airbox.

3. Clean the filter in a nonflammable solvent to remove the filter oil.

4. Clean the filter in hot soapy water to remove all dirt particles.

5. Allow to dry thoroughly.

6. Saturate with filter oil and remove excess.

14

Page 16

Do not clean the air filter with gasoline or other highly volatile petroleum product.

Diesel fuel or kerosene would be preferred but caution should still be taken. Hot

soapy water works well.

NOTE:

The Cobra is equipped with a special designed Air box. It is very important to

keep the air filter clean and properly oiled with high quality water-resistant fo am

filter oil. It’s very important to oil your filter consistently each time because varied

amounts of oil will change your carburetor jetting.

NOTE:

Make sure you change or clean your filter after each moto. We recommend

carrying three or more filters in your toolbox.

• 1 for practice

• 1 for each moto

M6: Fork Oil Replacement

Tools required

• 5 & 6 mm Allen wrench

• 19 mm wrench or socket (two required)

• Spring clip remover

Disassembly

1. Remove the front wheel.

2. Remove the fork legs from the triple clamps.

3. Perform the following on one leg at a time.

4. Using your hands, remove the black rubber plug from the top of the fork leg

exposing the white plastic cap.

5. Secure the fork leg assembly in a vice by gripping the leg across the flats

through which the axle bolt goes through.

6. Depress the white plastic cap inwards (down) and remove the wire spring clip

from its groove.

7. Remove the white cap, the fork spring preload sleeve, and the fork spring.

NOTE: Depressing the fork leg will facil itate removing the white cap.

8. The fork can now be turned upside down and drained.

Assembly

1. Fill the leg with 200 cc (6.8 oz) 20 wt fork oil.

2. Standard fork oil level is 70 mm (2.75”) from the top edge with the fork

collapsed.

15

Page 17

NOTE: Remove the preload sleeve but leave the spring in for the measurement.

3. Install the preload sleeve.

4. Install and depress the white cap while installing the spring clip.

5. Fork may be reinstalled.

M7: Clutch Adjustment

Tools required

6 mm hex key (Allen wrench)

large flat blade screw driver

Process

1. Remove the clutch adjustment access plug (6mm hex key).

2. Using the kick lever, turn the engine over (rotate the crank) until one of the

large flat head screws is visible through the access hole (this flat head screw

is one of the three adjusters).

NOTE: Turning the adjusting screw Counter Clock Wise (CCW) will allow the

shoe to engage at a lower RPM, this is the direction you should adjust to

compensate for shoe wear. Alternatively, a Clock Wise (CW) adjustment of the

screw will allow the clutch to engage at a higher RPM.

3. Subsequently use the kick lever to rotate the crank and expose the other two

clutch shoe adjusters and adjust them by the same amount.

CAUTION:

Be sure to adjust each of the three shoe adjustors by the same amount.

4. Reinstall the clutch adjust access plug (10 ft-lb, 14 Nm).

16

Figure 8

Page 18

Engine Service / Parts

Factory trained technicians with precision gauging and proper assembly fixtures

carefully assemble all Cobra engines to specific cl earances. If you feel you have

the skills, and the appropriate tools, to perform the following service tasks please

follow the instructions closely. The part numbers are listed throughout to help you

when ordering parts from your local Cobra dealer.

If you don’t feel comfortable with the service work, simply take your engine out of

the frame and sent it to:

Cobra Precision Engines

11511 Springfield Road

North Lima, Ohio 44452

Cobra’s technicians will go through the entire engine, replacing gaskets, bolts,

any old part that is worn. The engine will be rebuilt using the same precision

gauging and assembly fixtures as when it was assembled new. Before leaving,

the engines performance will be measured on a dynamometer to ensure that

your engine is operating at its highest potential. All this for one low nominal fee,

plus cost of parts. Call (330) 549-9603 for details.

17

Page 19

ES1: Top End Parts

Figure 9, Top End Components

REF NO PART NO DESCRIPTION

1 ECMOTE01 CYLINDER - CHROME

2 ECMOTE02 PISTON KIT - SINGLE RING

3 HCBC0603 6X30 CAP SCREW

4 HCNF0601 FLANGED NUT 6MM

5 ECMOTE05 CYLINDER HEAD

6 ZCMOTE06 CYLINDER HEAD O-RING

7 ECMU0026 6MM DOWEL

9 ECMOTE09 CYLINDER HEAD STUD BOLT 6MM

10 ZCMOTE10 BASE GASKET

11 ZCMOTE11 O-RING - EXHAUST FLANGE

12 ECMU0056 PISTON RING - CAST

13 ECMU0076 WRIST PIN

14 ECMUSR04 SNAP RING-FRANCO PISTON

18

Page 20

ES2: Bottom end & transmission

Figure 10, bottom end components

REF NO PART NO DESCRIPTION

1 ECMOBE01 CASES - COMPLETE SET

2 ECMOBE02 OUTPUT BEARING

3 ECMOBE03 OUTPUT BEARING - SNAP RING

4 ECMOBE04 PRECISION BEARING

5 ECMOBE05 CRANK SEAL

6 ECMU0016 CRANK BEARING

7 ECMOBE07 CRANKSHAFT COMPLETE

8 ECMOBE08 FLYWHEEL KEY

9 ECMU0077 WRIST PIN BEARING

10 HCBC0660 6X60 CAP SCREW

11 HCBC0607 6X50 CAP SCREW

12 ZCMOBE12 CRANKCASE GASKET

13 ECMOBE13 OUTPUT SEAL

14 ECMOBE14 ROD WITH WRIST PIN AND BEARING

15 S6 V/EC.+COM. SET OF SEAL

16 ZKMOBE16 GASKET KIT

17 ECMOBE17 DOWEL PIN - CASE

18 ECMOBE18 CASE VENT PIPE

19

Page 21

CAUTION:

Take caution when handling the crankshaft. It is the main power transfer to the

rest of the engine. If it is out of alignment, it will cause premature failure of your

bearings which can lead to serious damage to the cylinder and the rest of the

engine. Do not try to true the crank yourself. Truing the crank should be done

professionally.

Cobra trues every crank before it leaves the factory, and also welds the pin to

keep it true. If there are any problems send the engine in, or call tech support

(330) 549-9603 to determine what the problem is.

CAUTION:

• If you split the cases, check the gear tooth faces for chapping & signs of

fatigue.

• Check the small needle bearings for fatigue. If the bearings are damaged,

the engine cases should be checked to make sure the needle -bearing casing

didn’t oblong the bearing hole in the case.

• Needle bearings should be replaced every racing season.

20

Page 22

Kick lever mechanism

Figure 11, kick mechanism

REF NO PART NO DESCRIPTION

1 ECMOKS01 CLUTCH COVER

2 ECMOKS02 CRUSH WASHER - WATER DRAIN PLUG

3 ECMOKS03 WATER DRAIN PLUG - 6X8

4 ZCMU0001 OIL FILL PLUG GASKET

5 ECMU0037 OIL FILL PLUG

6 ECMOKS06 RETAINER CLIP - THRUST WASHER

8 HCBC0625 6X25 CAP SCREW

9 ECMPKS09 KICK START LEVER

11 HCBC0603 6X30 CAP SCREW

12 ZCMOKS12 CLUTCH COVER GASKET

13 ECMOKS13 THRUST WASHER

14 ECMOKS14 SEAL - KICK START SHAFT

15 ECMOKS15 KICK START SHAFT WITH GEAR

16 ECMOKS16 KICK START SPRING

17 ECMOKS17 WASHER - RETURN SPRING RETAINER

18 ECMOKS18 RETAINER CLIP - RETURN SPRING

19 ECMOKS19 J-SPRING KICK START

20 ECMOKS20 DOG GEAR

21 ECMOKS21 GASKET - ADJUSTING PLUG

22 ECMOKS22 ADJUSTING PLUG

21

Page 23

ES3: Clutch

Figure 12 Clutch components

REF NO PART NO DESCRIPTION

1 ECMOCL01 GEAR - DRIVE

3 ECMOCL03 CLUTCH START NUT - LH THREAD

4 ECMOCL04 WASHER - CLUTCH NUT BACK UP

5 ECMOCL05 CLUTCH COMPLETE

6 ECMOCL06 SPACER - CLUTCH TO HUB

7 ECMOCL07 BUSHING - CLUTCH HUB

9 ECMOCL09 WASHER - CLUTCH BASKET BACK UP

10 PCMOCL10 SPROCKET - 10 TOOTH

11 ECMOCL11 SNAP RING - OUTPUT SHAFT

12 ECMOCL12 CLUTCH BASKET WITH GEAR

13 ECMOCL13 S6 TCBEI M5X14 SCREW FOR MASS.

14 ECMOCL14 ADJUSTING SPRING

15 ECMOCL15 S6 D.2,5 BALL

16 ECMOCL16 S6 SPECIAL-SCREW

17 ECMOCL17 FEDER ATAZZA 6.2X12X0.6 DIN 2093

18 ECMOCL18 CLUTH WASHER

19 ECMOCL19 CLUTCH SHOE

21 ECMOCL21 S6 CLUTCH PAWL

22 ECMOCL22 CLUTCH SCREW COUPLING

23 ECMOCL23 S6 CLUTCH SPRIG

24 ECMOCL24 BUSH

22

Page 24

ES4: Ignition

CAUTION:

• Make sure ground wires are secure. If the bike is not grounded it will not run.

• Make sure connections are free of dirt.

Figure 13, ignition components

REF NO PART NO DESCRIPTION

1 ECMOIG01 FLYWHEEL

2 HCWF0801 8MM WASHER

3 HCNS0801 8MM NUT

4 HCBC0401 4X10 CAP SCREW

5 ECMOIG05 COIL WITHOUT SPARK PLUG CAP

6 ECMOIG06 CDI BO X

7 ECMOIG07 SPARK PLUG

8 ECMOIG08 SPARK PLUG CAP

9 ECMOIG09 RUBBER FOR CONTROL UNIT

11 HCBC0502 5X20 CAP SCREW

12 HCBC0550 5X50 CAP SCREW

13 ECMOIG13 7MM DOWEL

14 ECMOIG14 IGNITION COVER GROMMET - OPEN

15 ECMOIG15 IGNITION COVER GROMMET - CLOSED

16 ECMOIG16 SPACER - FLYWHEEL

18 ECMOIG18 IGNITION COVER

20 ECMOIG20 FLYWHEEL GROMMET

21 HCWF0501 5MM WASHER

23 ECMOIG23 SPARK PLUG RUBBER

24 ECMOIG24 SPARK PLUG BOOT

23

Page 25

ES5: Cooling System

Water pump

Figure 14 water pump

REF NO PART NO DESCRIPTION

1 ECMOWP01 WATER PUMP SHAFT

2 ECMOWP02 RETAINER CLIP - WATER PUMP BEARING

3 ECMOWP03 BEARING WATER PUMP

4 ECMOWP04 SPACER - WATER PUMP BEARING

5 ECMOWP05 CRANK PULLEY

6 ECMOWP06 WATER PUMP BELT

7 ECMPWP07 CLAMP FOR OIL TUBE

8 HCBC0501 5X12 CAP SCREW

9 ECMPWP09 OIL INJECTOR MOUNT PLATE

10 ECMPWP10 OIL PUMP WITH TUBE

11 ECMOWP11 WATER PUMP IMPELLER

12 ECMOWP12 SNAP RING - TOOTHED

13 ECMOWP13 WATER PUMP SEAL

14 ECMOWP14 WASHER - BEARING RETAINER

15 ECMPWP15 DOWEL PIN

16 HCWF0501 5MM WASHER

24

Page 26

ES6: Fuel & Air System

Intake system

Figure 15, Intake components

REF NO PART NO DESCRIPTION

1 ECMPIN01 12MM CARBURETOR

2 ECMOIN02 CLAMP

3 HCBC0625 6X25 CAP SCREW

4 ECMOIN04 REED SPACER PLATE

5 ZCMOIN05 REED VALVE GASKET

6 ECMOIN06 REED VALVE ASSEMBLY

8 ECMOIN08 SCREW - REED CAGE TO SPACER PLATE

9 ECMOIN09 RUBBER INTAKE BOOT

10 ECMOIN10 INTAKE RETAINING PLATE

25

Page 27

Reeds

• The reeds must lay flat on the reed cage.

• If the reed tips aren’t lying flat, replace them immediately.

• The reeds must have a tight seal on the reed cage.

• If the reed is damaged in any way, replace it. This means cracks, chips,

and ruptures. Anything abnormal, replace the reeds.

Take the reed cage out and hold it up to the light and look in through the cage. If

you see light between the reed pedals and the frame, then replace the reeds. If

you do not see light, then the reeds should be ok. (See figure 25)

Figure 16

The presence of light indicates that the reeds should be replaced, or possibly

turned over.

26

Page 28

Carburetor

REF

DESCRIPTION

PART #

Figure 17, carburetor

1 SLIDE - 40 - STOCK RCOI 0001

1 SLIDE - 30 RCOI 0030

1 SLIDE - 50 RCOI 0050

2 NEEDLE FOR SLIDE RCOI 0002

3 ATOMIZER RCOI 0003

4 MAIN JET-82 STOCK RCOI 0004

5 PILOT JET-42 STOCK RCOI 0005

6 CHOKE JET RCOI 0006

7 TOP CARB SCREW RCOI 0007

8 ORING FOR CARB TOP RCOI 0008

9 CARB TOP W/ ORING RCOI 0009

10 SLIDE SPRING RCOI 0010

11 NEEDLE RETAINER PLATE RCOI 0011

12 NEEDLE CLIP RCOI 0012

13 IDLE ADJUSTMENT SCREW RCOI 0013

14 IDLE ADJUSTMENT SPRING RCOI 0014

16 FUEL MIXTURE SCREW KIT-4 PIECE RCOI 0016

17 FLOAT KIT – 3 PIECES RCOI 0017

19 FLOAT BOWL WITH ORING – 2 PC RCOI 0019

20 BOTTOM CARB SCREW RCOI 0020

22 CHOKE ASSEMBLY – 4 PIECES RCOI 0022

23 REBUILD KIT RCOI 0023

27

Page 29

Your Cobra is equipped with an adjustable carburetor. Some fine -tuning may be

needed according to weather condition and altitude. Proper jetting is very

important for engine performance and engine life. Serious damage to the engine

can occur if not properly adjusted.

IDLE ADJUSTMENT:

On the left side of the carburetor, there are 2 adjustment screws. The larger

screw with the knurled head is the idle adjustment screw. To raise the idle, turn

the screw in clockwise (in 1/4 turn increments) and rev the engine after each

adjustment. To lower the idle, turn the screw counter-clockwise.

TOP END JETTING:

Indications that the engine is running too rich (too much fuel for the air) are:

• Engine not revving out or blubbering at high RPMs.

• Engine will not ‘clean out’

• Wet or black spark plug

NOTE: Before changing jetting be sure that the air filter is properly cleaned and

has the usual amount of air filter oil. An overly dirty air filter can cause the engine

to run rich.

NOTE: Also before changing jetting, insure that your carburetor has a proper

float height of 5

If the engine is running rich on the top end it should be leaned out. Leaning it out

can be done by:

1. Changing the main jet to a smaller number.

2. Raising the needle clip (this lowers the jet needle) one notch at a time on the

slide.

Indications that the engine is running too lean are:

• Engine cutting out on top end.

• Engine overheating and ultimately seizure.

• White spark plug

CAUTION:

It is much safer to operate the engine slightly rich as opposed to slightly lean.

This is because an overly rich engine will just run poorly while an overly lean

engine will seize, potentially causing an expensive top end rebuild and a DNF.

To richen the carburetor:

1. Change the main jet one number at a time (larger).

2. Lower the needle clip (raising the jet needle) one notch at a time until the

engine starts to blubber on the top end, then move the clip back up one notch

or until you get the blubber out.

FUEL MIXTURE SCREW

The smaller brass screw that is towards the front of the engine is a fuel mixture

28

Page 30

screw. This screw will also richen and lean your engine more on the bottom and

mid-range. In warmer conditions, turn the screw in. In colder conditions, turn the

screw out. Be sure to keep the carburetor very clean and make sure you don't

have water or dirt in the carburetor bowl. Use automotive carburetor cleaner or

WD-40 to clean the carburetor in side and out.

STOCK CARBURETOR SETTINGS

The 2003 PW3 stock carburetor settings from the factory are:

• 42 pilot jet

• 82 main jet

Cleaning the carburetor:

Clean the carburetor in a well-ventilated area, and take care that there is no

spark or flame anywhere near the working area; this includes any appliance with

a pilot light. Because of the danger of highly flammable liquids, do not use

gasoline or low flash -point solvent to clean the carburetor.

1. Make sure the fuel is shut off.

2. Remove the carburetor.

3. Drain the fuel in the carburetor.

4. Disassemble the carburetor.

CAUTION:

Do not use compressed air on an assembled carburetor. Or the pressure may

deform the float. Do not use a strong carburetor cleaning solution, which could

attack the parts of the carburetor; instead, use a mild high cleaning solution safe

for plastic parts.

5. Immerse all the metal parts in a carburetor cleaning solution.

6. Rinse the parts in water.

7. After the parts are cleaned, dry them with compressed air.

8. Blow out the fuel passages with compressed air.

9. Assemble the carburetor

10. Install the carburetor onto the motorcycle.

NOTE:

The three most common problems with this

carburetor are (figure 18):

1. Installing the carburetor top backwards.

2. The carburetor slide indexing pin falling

out.

3. Either side vent elbow falling out .

Figure 18 Proper carburetor top

installation and location of rectangular

slide indexing pin and one of the elbows

that has been known to fall out.

29

Page 31

ES7: Exhaust

The pipe is a crucial element to a motorcycle. Any kinks, dents, or damage done

to the pipe will result in a major performance loss.

NOTE:

Be sure to take the pipe off, and any carbon that may be built up. Carbon build

up is created from exhaust. Exhaust has oils in it, and the oils cling to the wa lls

of the inside of the pipe. Over a long period of time, the diameter of the pipe will

decrease, due to carbon build up. So it is essential to clear the residue.

CAUTION:

It is important to repack the silencer. Signs of your silencer needing to be

repacked are:

• The bike is louder than normal.

• A loss of power.

Chassis Service / Parts

CS1: Wheels & Tires

Rear wheel pullers

Disassembly:

Figure 19

Rear wheel alignment:

1. Remove axle, and

back wheel assembly.

2. Pull the rear wheel

pullers out of the back

of the swing arm.

30

Page 32

Figure 20

1. Measure from the side of

the swing arm to the outer

edge of the rim and make

sure both sides are equal.

2. Adjust the wheel pull bolt

on the rear wheel puller to

get the distance from the

swing arm to the rim

about the same.

31

Page 33

CS2: Suspension

VALVE STEM

Rear shock

REF # PART # DESCRIPTION

1 SCMU0304 PRELOAD NUT

2 SCMU0114

3 SCMU0004 CAP

4 SCMU0300 BODY

5 HCNJ1001 LOCKNUT

6 SCMU0311 BUSHING

7 ZCMU0023 ENERGIZER

8 SCMU0305 PISTON

9 SCMU0322 STOP DISK

10 SCMU0301 SHAFT

11 SCMU0320 PISTON BUMPER

12 SCMU0312 BUFFER DISK

13 SCMU0310 BUFFER SEAL

14 ZCMU0114 LOADER

15 SCMU0314 BUSHING RETAINER

16 SCMU0306 BUSHING

17 ZCMU0216 O-RING

18 SCMU0308 SEAL HEAD

19 SCMU0309 ROD WIPER

20 SCMU0316 BUMPER

21 SCMU0317 BUMPER SPACER

22 HCNJ0716 JAMNUT

23 SCMU0303 SPRING STOP

24 SCMU0307 ROD END

25 SCMU0200 MNTG SPACER (4x)

26 SCMU0313 BUSHING (2x)

27 SCMU0321 SPRING

Figure 21

Because of different rider weights, sizes

and riding styles, we offer various

suspension options:

See Optional Components section of

this manual for details on these and

other optional components for your

Cobra Motorcycle.

32

Page 34

Rear Shock Disassembly

1. Bleed the gas pressure from the shock.

Hold a rag over the bleed (Schrader) valve during this operation as the contents

are at extremely high pressure.

2. Remove the spring by removing the lock nut and other nut with a large

spanner.

NOTE:

Measure the distance from the top of the spring to a feature on the top of the

shock for repeatable reassembly.

3. Using a ‘Pin’ type spanner, separate the top portion of the shock from the

bottom.

NOTE:

Holding the shock in a vertical manner with the bleed valve ‘down’ during

separation will minimize the amount of oil that is spilled.

4. Drain the oil into a suitable container for proper recycling

5. Clean the components of old oil and contaminates.

6. Look for signs of wear and replace if necessary.

Assembly

1. If the bleed valve was removed, clean the threads of both components, apply

some Teflon pipe sealant to the threads of the bleed valve, and install (torque

to 10 ft-lb (14 Nm)).

2. With the bottom shock portion situated vertically, fill with 2.5 wt (often called 3

wt) shock oil until 37 – 38 mm from the top edge.

3. Install damper unit, into the bottom portion of the shock taking care to not

‘splash’ out shock oil in the process (tighten securely).

4. Holding the shock vertical, with the bleed valve upward, stroke the piston

through its complete travel several times, slowly, and then bleed off any

excess air.

5. Charge the shock with 230 psig nitrogen.

6. Reinstall the spring, to the previously measured compressed length and

secure with the lock nut.

33

Page 35

Front Forks

Figure 22

Because of different rider weights, sizes and riding styles, we offer various

suspension options:

See Optional Components section of this manual for details on these and other

optional components for your Cobra Motorcycle.

34

Page 36

2003 PW3 FRONT FORK PARTS LIST

REF # PART # DESCRIPTION

1 KCMZ0001 8 X 50 CS

2 KCMZ0002 TOP HANDLE BAR CLAMP

3 KCMZ0003 LOWER HANDLE BAR CLAMP

4 KCMZ0004 FORK PLUG – BLACK

5 KCMZ0005 TRIPLE CLAMP UPPER

6 HCBC0806 8 X 30 CS PINCH BOLT FOR TOP

TRIPLE CLAMP

7 KCMZ0007 SNAP RING FOR FORK CAP

8 KCMZ0008 INNER FORK CAP - WHITE

9 KCMZ0009 O-RING UNDER FORK CAP

11 KCMZ0011 PRELOAD SLEEVE

12 KCMZ0012 FORK SPRING

13 KCMZ0013 SWIPER

14 KCMZ0014 SNAP RING

15 KCMZ0015 FORK SEAL

16 KCMZ0016 WASHER

17 KCMZ0017 SNAP RING FOR PISTON

18 KCMZ0018 PISTON ROD - REBOUND

18A KCMZ0018A PISTON ROD - COMPRESSION

19 KCMZ0019 REBOUND SPRING

20 KCMZ0020 FORK LEG OUTER LEFT

21 KCMZ0021 FORK LEG – 5 PIECE UNIT – LEFT

22 HCWC0000 WASHER

23 HCBC0806 8 X 30 CS

25 KCMZ0025 TRIPLE CLAMP BOTTOM W/STEM

26 KCMZ0026 FORK TUBE – INNER RIGHT

27 KCMZ0027 FORK TUBE – INNER LEFT

28 KCMZ0028 TOP OUT BUMPER

29 KCMZ0029 FORK LEG – OUTER RIGHT

31 KCMZ0031 FORK LEG – 5 PIECE UNIT – RIGHT

32 HCBC0609 6 X 20 CS

33 HCBC0525 6 X 25 CS

35

Page 37

Troubleshooting

1) Engine not behaving properly

a) Carburetor top is installed backwards (happens a lot)

b) The carburetor slide indexing pin is missing

2) Engine is down on power

a) Clutch engagement is not set properly

b) Jetting is incorrect

c) Silencer needs repacked

d) Exhaust pipe

i) Has excess carbon buildup

ii) Has large dent in it

e) Compression is low

i) Piston

ii) Rings

f) Reeds are damaged

g) Ignition timing is incorrect

3) Engine is excessively loud

a) Silencer needs repacking

4) Engine ‘blubbers’ at high RPMs

a) Jetting too rich

5) Engine won’t start

a) Fuel

i) None in tank

ii) Is sour or bad

b) Carburetor is dirty

c) Ignition

i) Spark plug fouled

ii) Spark plug cap off

iii) Engine Shut-off ‘kill’ switch is shorted

iv) Bad electrical ground

v) Stator winding damaged

d) Exhaust is plugged

6) Engine won’t idle

a) Idle knob needs adjusted

b) Carburetor jets are dirty

36

Page 38

Index

Air Filter

Maintenance..................................14

Bottom End

Service...........................................19

Break-In................................................7

Carburetion

Specifications..................................4

Chain

Adjustment..............................12, 13

Chassis

Specification....................................4

Clutch

Parts...............................................22

Service...........................................22

Clutch Lubricant

Replacing.......................................11

Cooling System.................................24

Engine

Parts List........................................17

Specifications..................................4

Exhaust..............................................30

Fork Oil

Replacement.................................15

Front Brake

Adjustment.....................................13

Front Forks

Service...........................................34

Front Forks:.......................................34

Fuel

Petcock............................................8

Fuel System

Parts list .........................................25

Service...........................................25

General Tips ........................................9

Ignition

Parts...............................................23

Service...........................................23

Jetting

How To...........................................28

Stock.................................................4

Kick Lever..........................................21

Lubrication

Recommended ...............................4

Maintenance

Schedule........................................10

Tips.................................................10

Oil

Recommended ...............................4

Optional Components........................6

Parts

Bottom end ....................................19

Clutch.............................................22

Ignition............................................23

Inlet.................................................25

Kick mechanism ...........................21

Rear shock ....................................32

Reeds.............................................25

Top end..........................................18

Water pump...................................24

Parts List

Front Forks....................................34

Rear Shock....................................32

Petcock................................................8

Pullers ................................................30

Rear Brake

Adjustment.....................................14

Rear Shock

Service...........................................33

Rear Wheel

Pullers ............................................30

Reeds..........................................25, 26

Shock..................................................32

Service...........................................33

Spark Plug

Recommended ...............................4

Specifications......................................4

Torque Values.................................5

Starting.................................................8

TIps.......................................................9

Top End

Service...........................................18

Transmission

Service...........................................19

Specifications..................................4

Transmission Lubricant

Replacing.......................................11

Troubleshooting................................36

VIN reading .........................................9

WARNING ...........................................2

Water pump.......................................24

37

Loading...

Loading...